Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133 results about "Coal conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

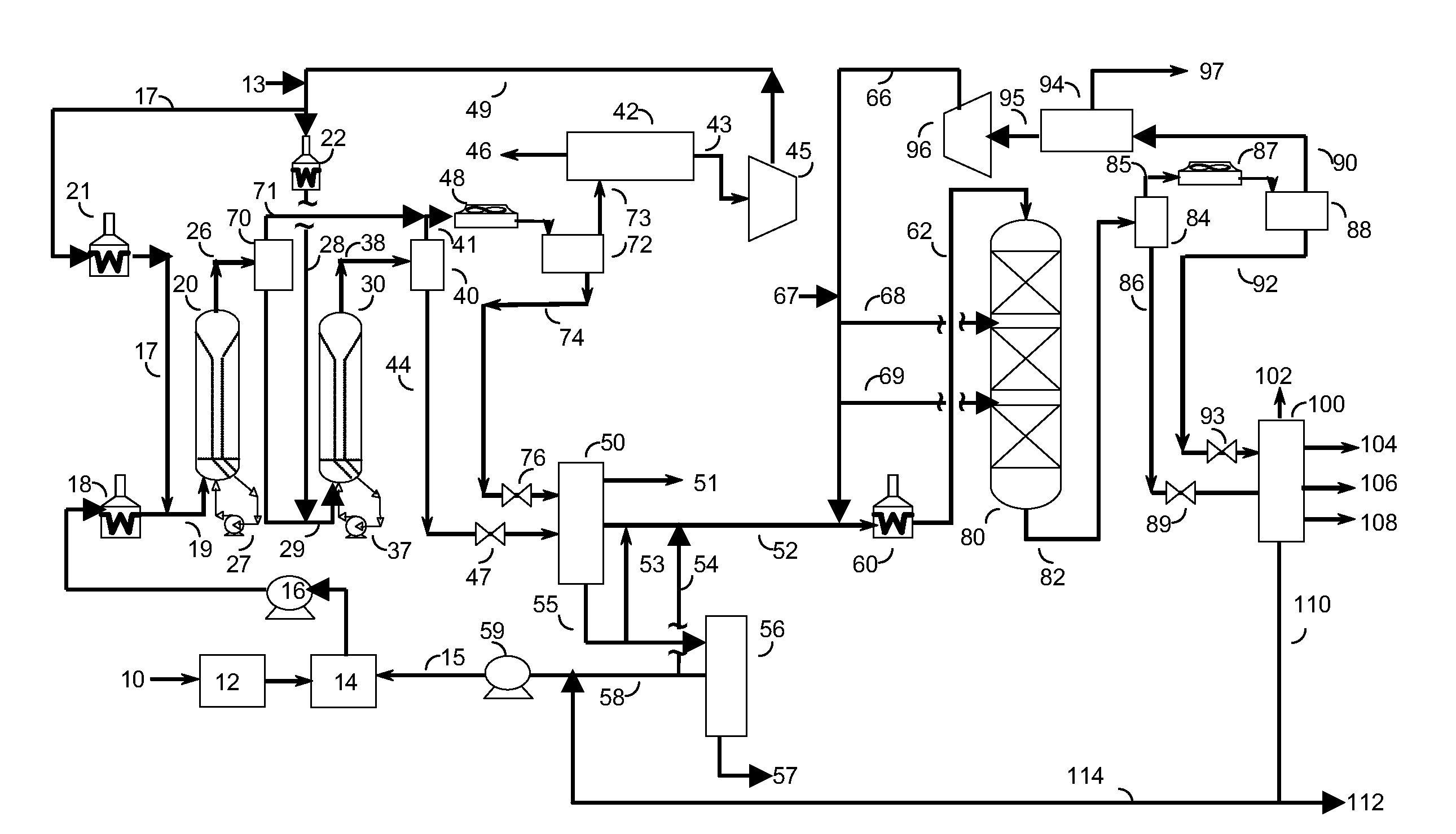

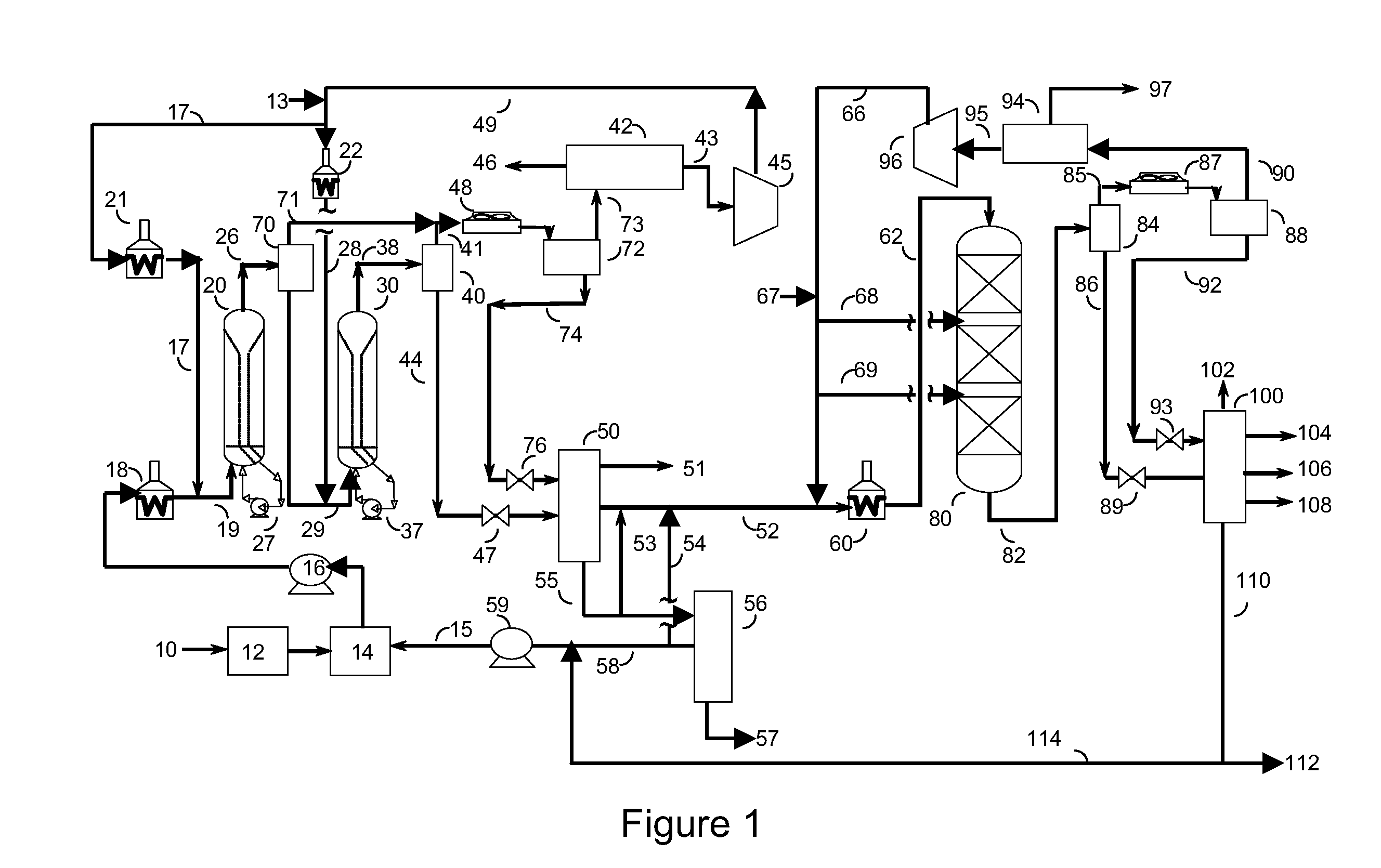

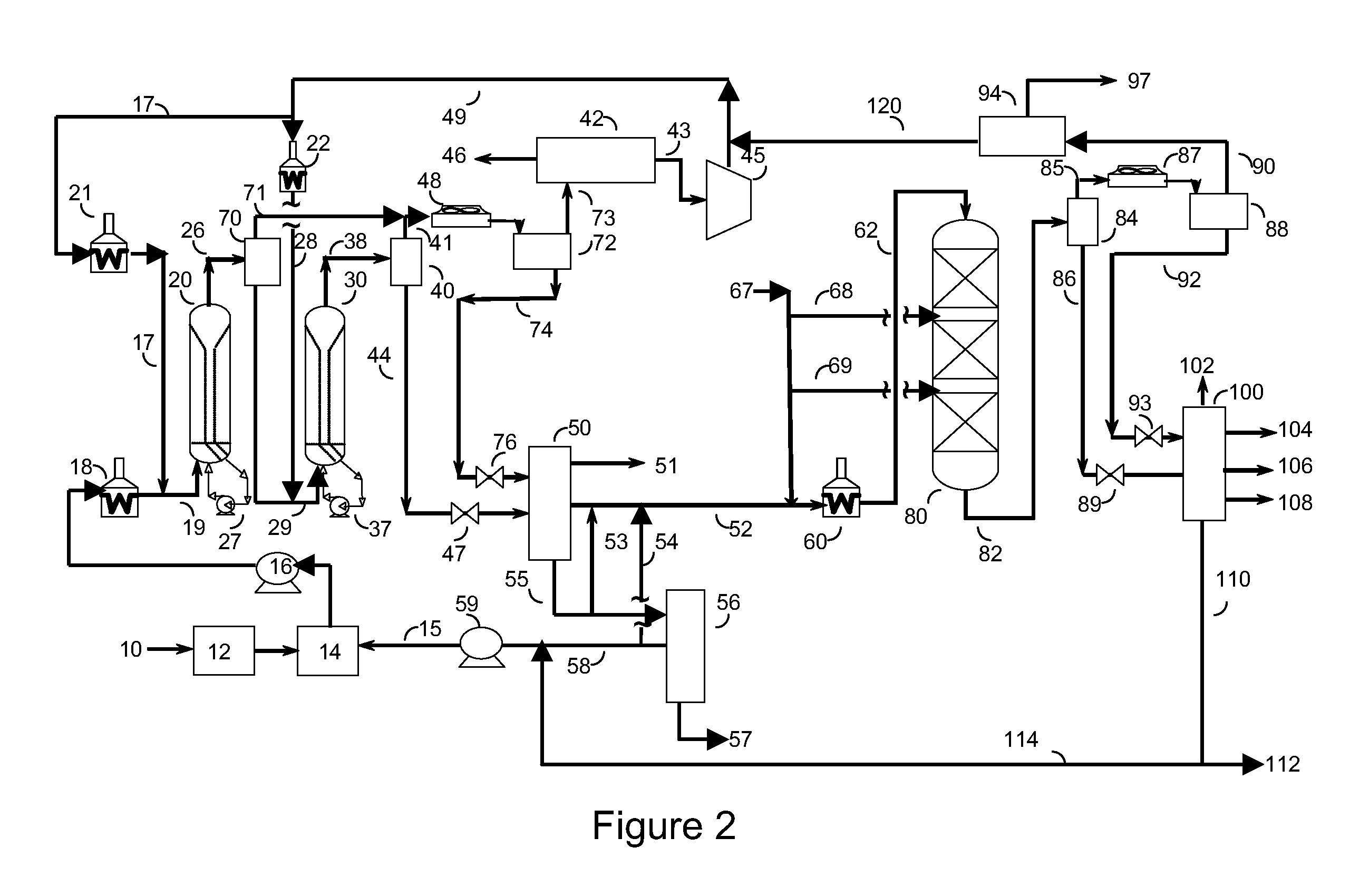

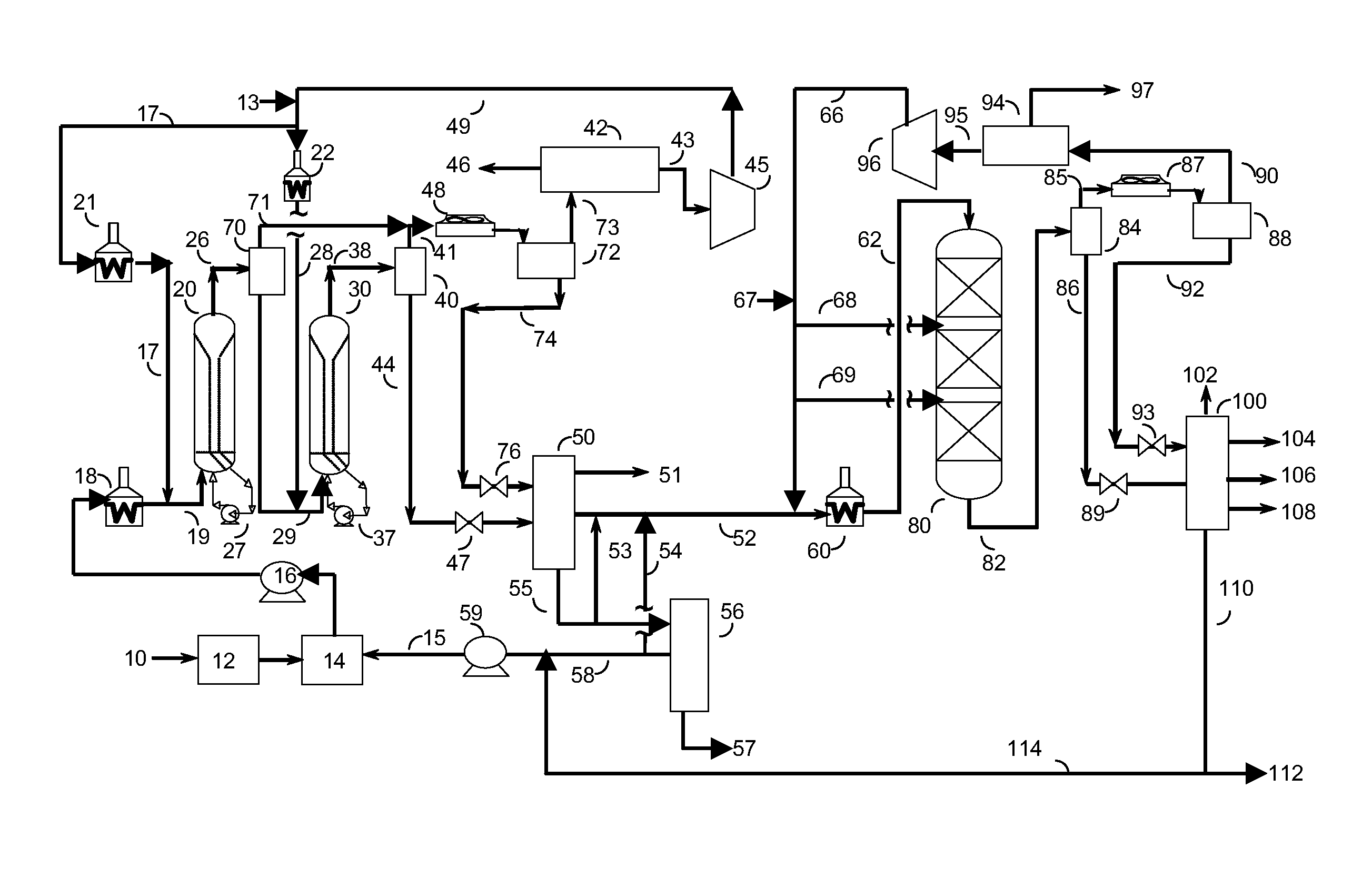

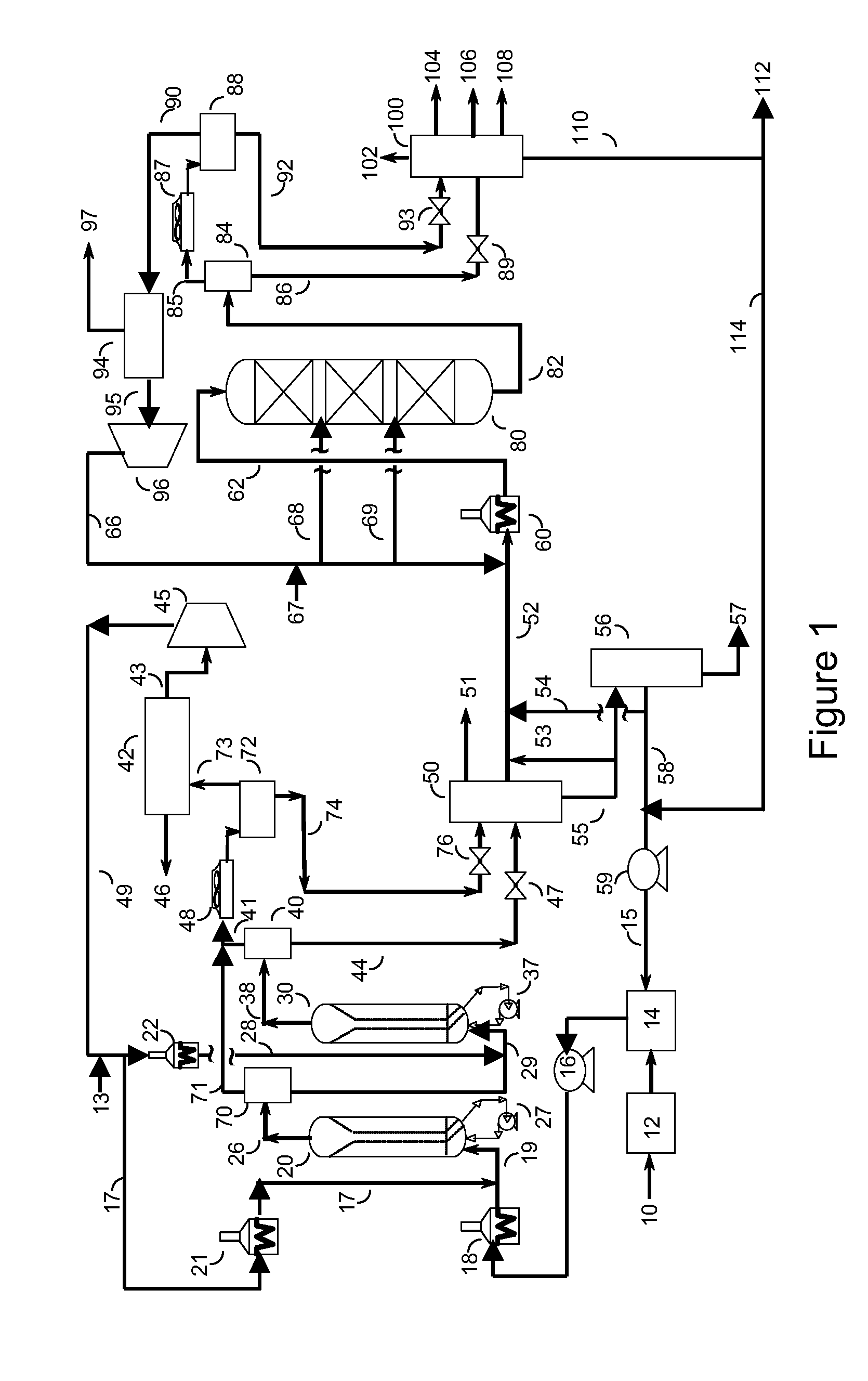

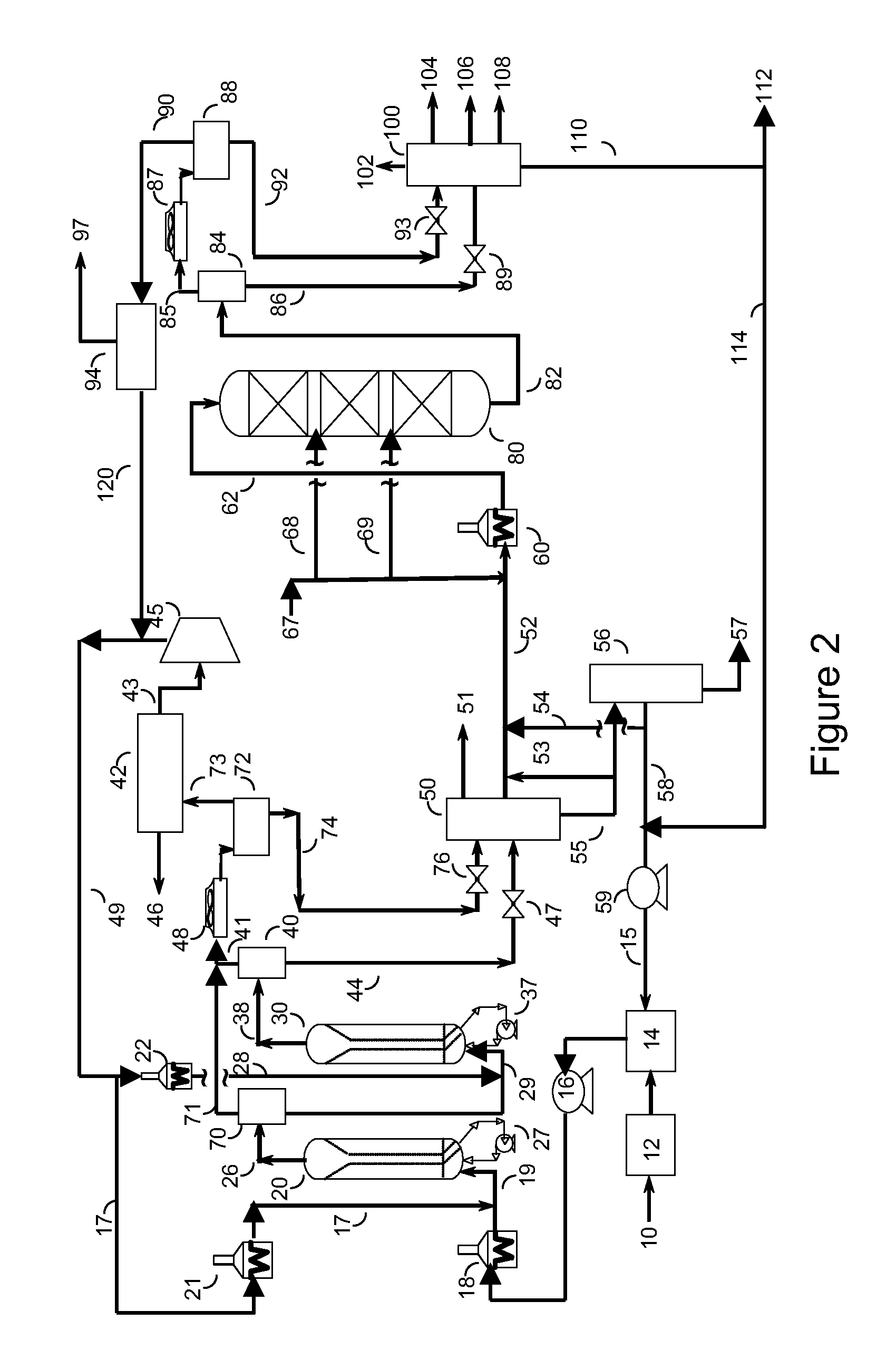

Coal conversion process and products, comprising two direct ebullated bed liquefaction stages and a fixed bed hydrocracking stage

ActiveUS20110230688A1High yieldEasy to transportWaste based fuelLiquid carbonaceous fuelsKeroseneFixed bed

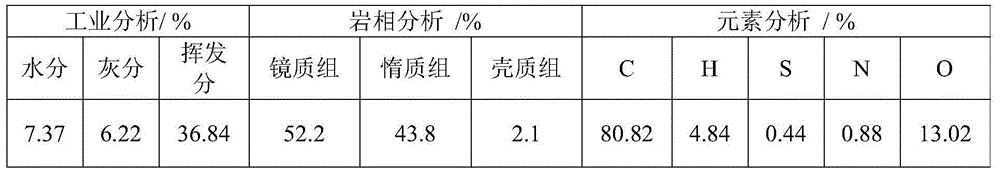

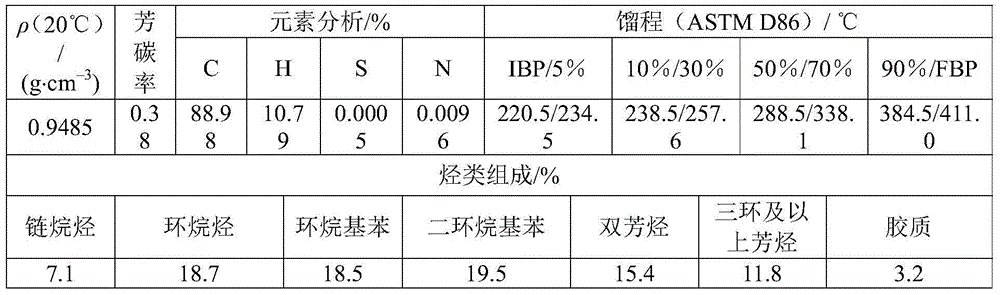

A process for the conversion of coal into fuel bases comprises two successive direct liquefaction stages in ebullated bed reactors followed by a fixed bed hydrocracking stage. This process can produce excellent quality fuel bases (kerosene and diesel).

Owner:INST FR DU PETROLE

Direct liquefaction process of coal by replacing circling solvent with petroleum or petroleum refining byproduct

ActiveCN101333448AWide range of sources and cheapLow use valueLiquid hydrocarbon mixture productionCoal conversionSolvent

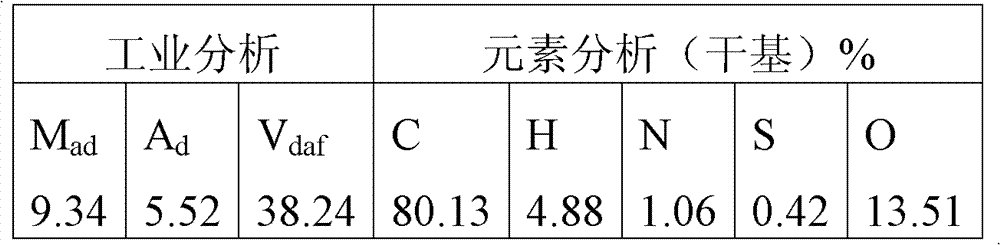

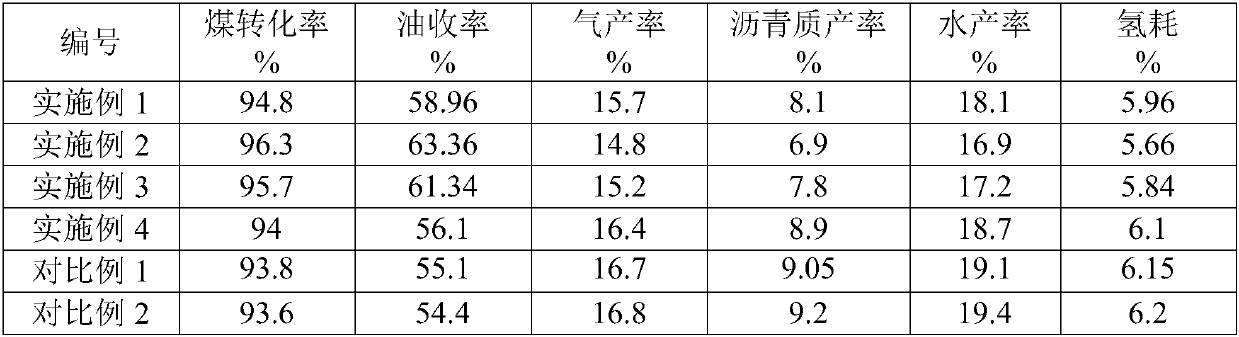

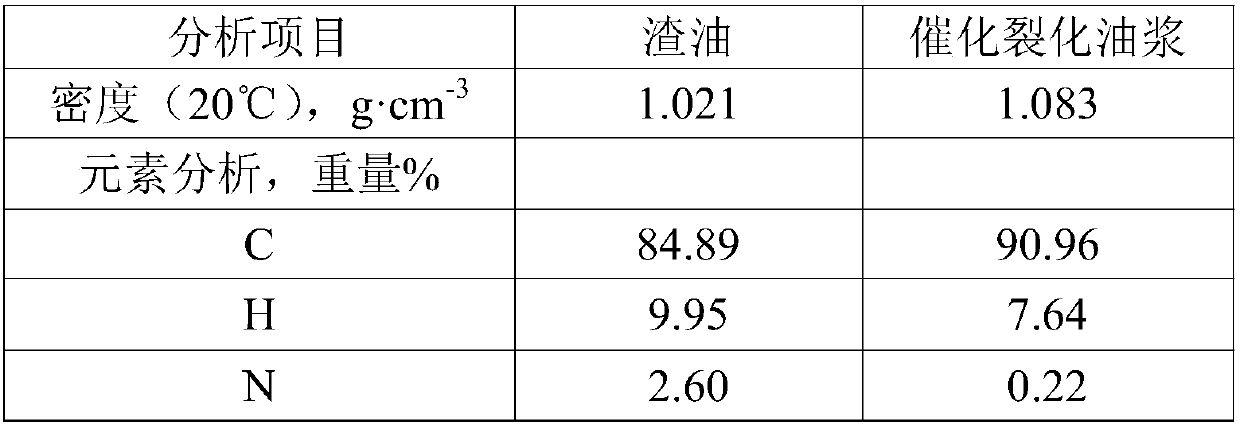

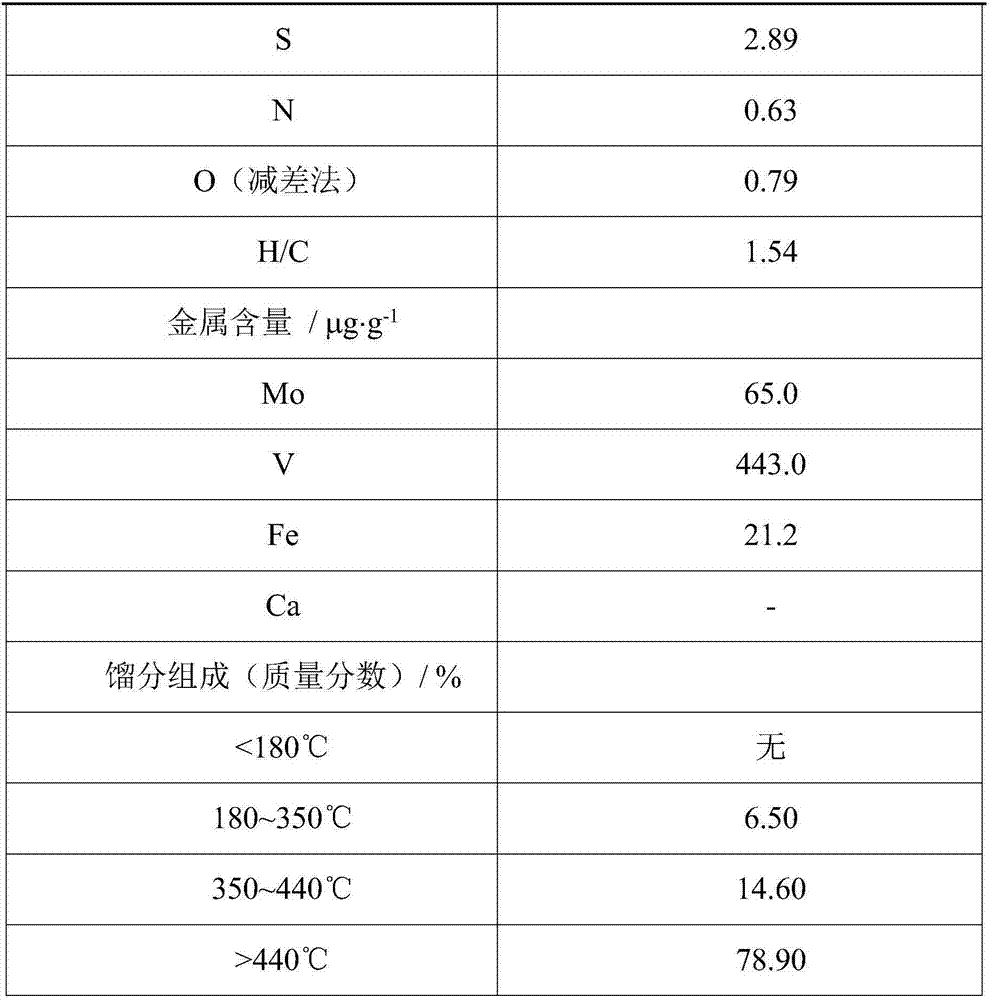

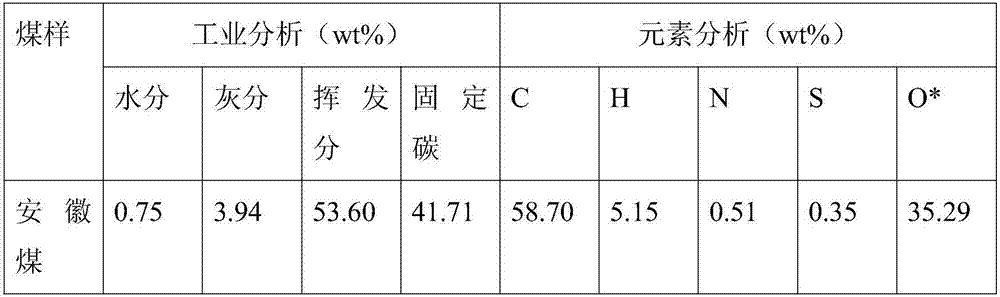

The invention relates to a coal direct liquefaction method using petroleum or petroleum refining byproducts to replace a cycling solvent, which comprises processes of: replacing or partially replacing the traditional coal liquefied cycling solvent by low quality petroleum with high metal and asphaltene content and heavy oil, as well as petroleum refining byproducts such as catalytic cracking heavy recycle stock, clarified oil and outside throwing slurry oil, preparing coal slurry by co-catalyst sulfur and high-activity Gamma-hydrated iron oxide type liquefaction catalyst, then implementing the coal direct liquefaction and hydrogenation, finally obtaining light and medium distillate oil, the coal conversion is increased by 1 percent to 5 percent, the yield of generated oil products is increased by 5 percent to 40 percent, the sedimentation and coking in a reactor are reduced, also the utilization value of low value-added petroleum and petroleum refining byproducts is greatly increased, and economic benefits of coal direct liquefaction are increased. The method can be widely used for coal direct liquefaction.

Owner:CCTEG CHINA COAL RES INST

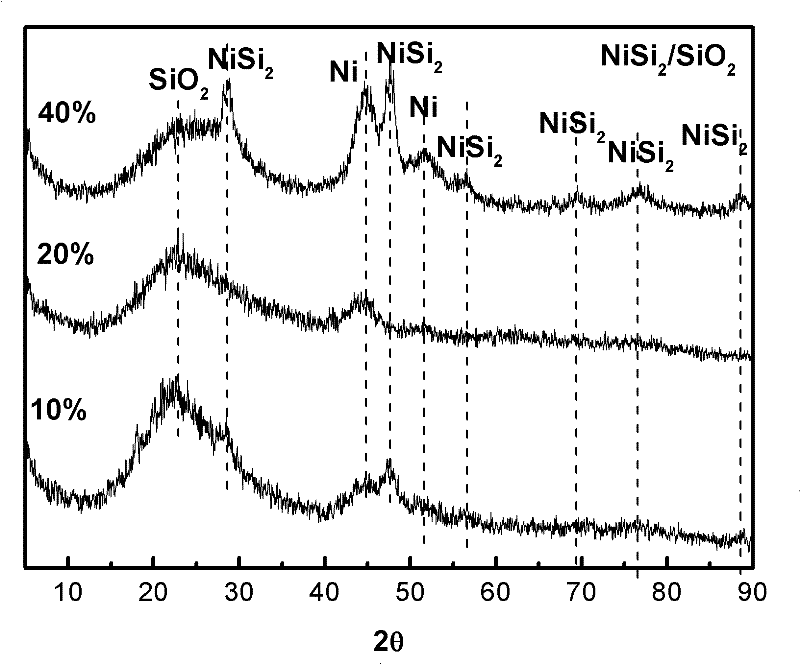

Methanation catalyst and application thereof

InactiveCN102327769AImprove thermal stabilityImprove anti-sinteringPhysical/chemical process catalystsHydrocarbon from carbon oxidesForming gasMethanation

The invention which belongs to the technical field of coal processing utilization and coal conversion relates to a highly efficient and stable metal silicide catalyst of for the preparation of methane through carrying out coal-formed gas methanation. The stable metal silicide catalyst is formed through reducing a uniformly dispersed supported metal which is adopted as a precursor in hydrogen, siliconizing a mixed gas SiH4 / H2 at a low temperature and normal pressure. The preparative metal silicide catalyst has a high activity and a methane selectivity to CO methanation; and in addition, compared with traditional metal catalysts, the metal silicide catalyst of the invention has the advantages of high thermostability, high anti-sintering, high carbon deposition resistance, difficult loss of carbonyl compounds formed from active components, strong sulfur resistance and the like.

Owner:DALIAN UNIV OF TECH

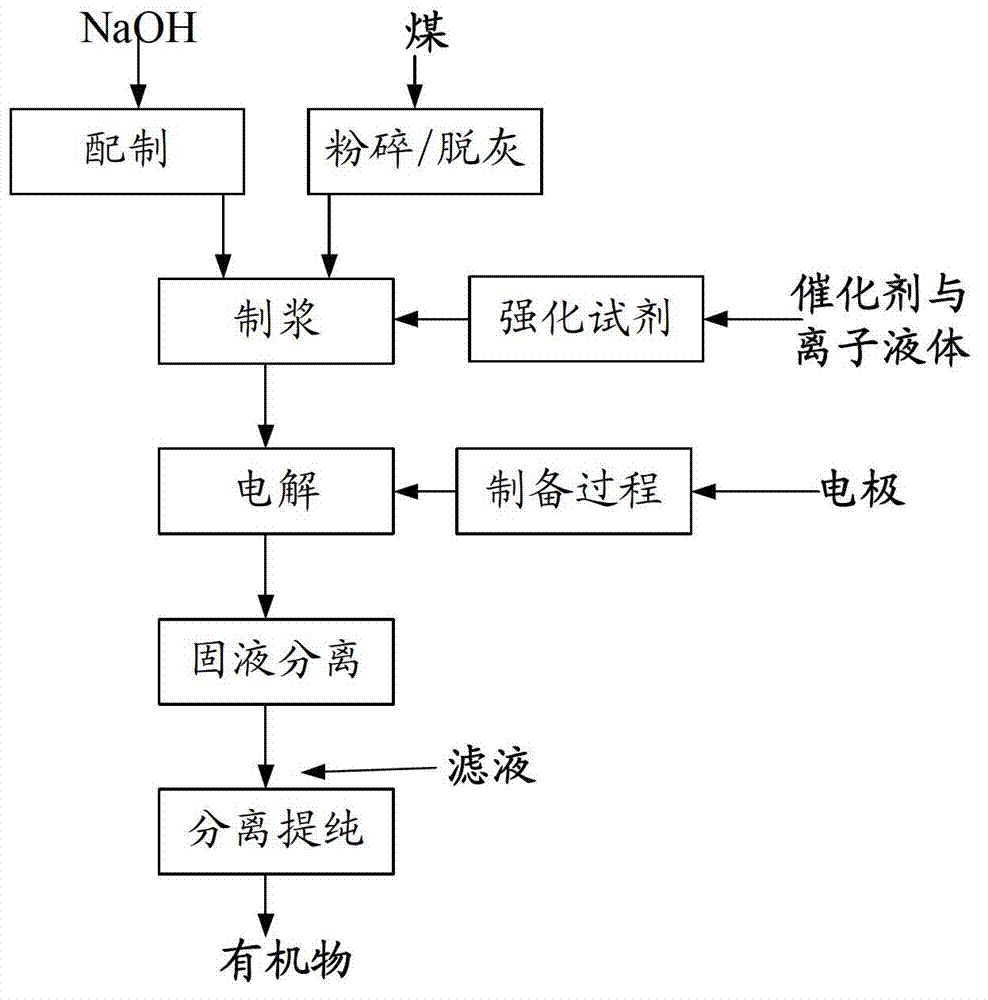

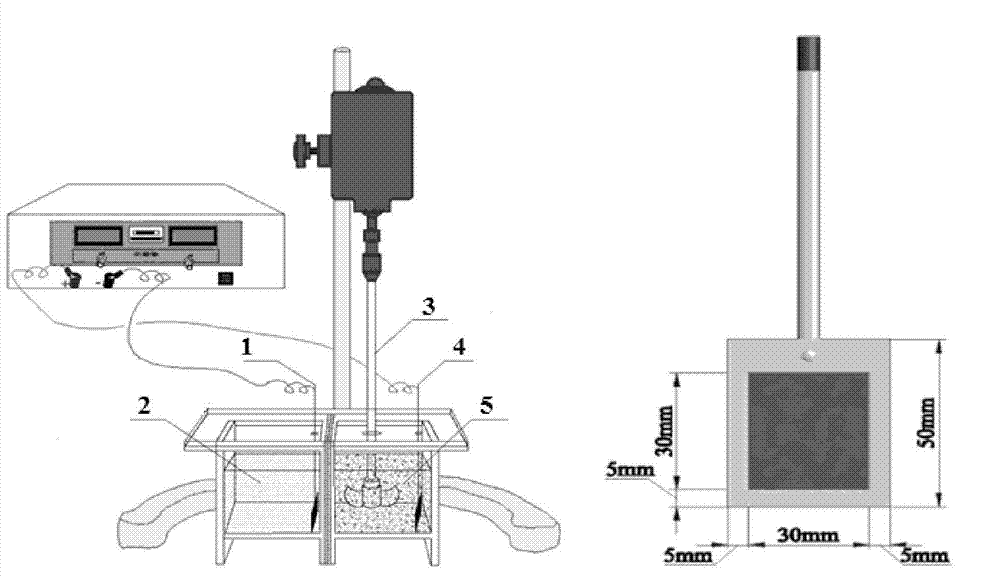

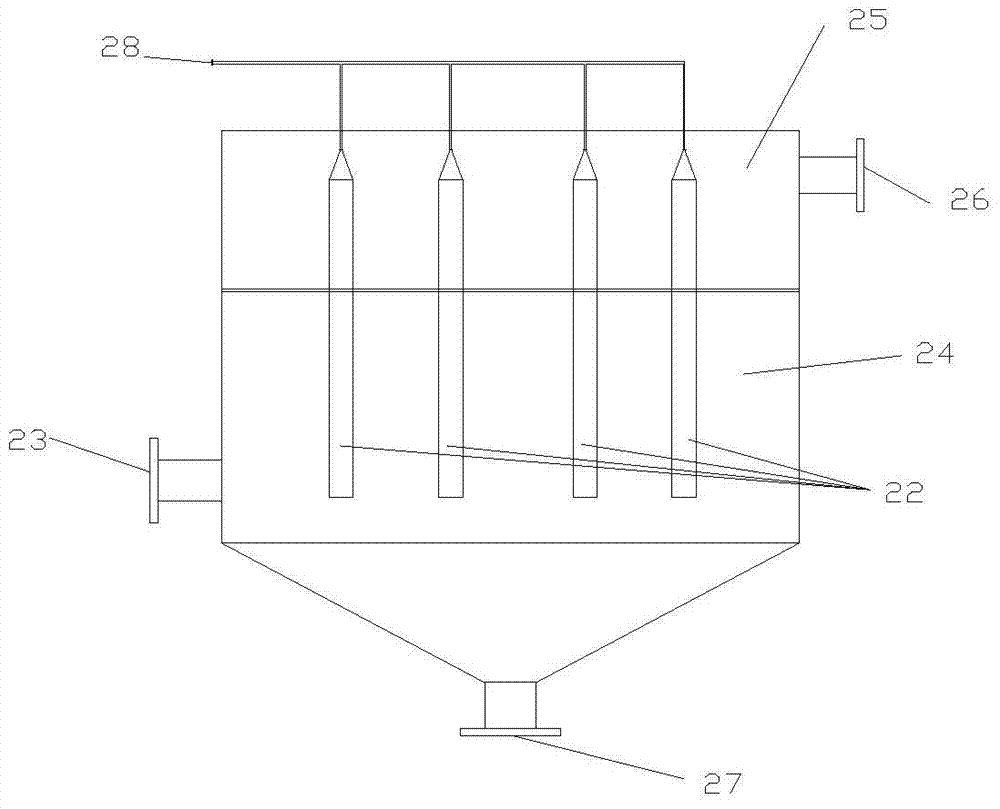

Method for preparing organics by strengthening electrolysis of coal slurry under alkaline system

InactiveCN102732910AIncrease productionLess investmentElectrolysis componentsElectrolytic organic productionElectrolysisCoal conversion

The invention relates to a method for preparing organics by strengthening electrolysis, oxidation and degradation of coal slurry with strong oxidizing mediums generated by an anode in a water-electrolyzed hydrogen production process under an alkaline system, belonging to the field of high-value coal conversion technology. The method comprises the following steps: preparing the coal slurry with coals and alkaline liquid, and strengthening oxidation and degradation process of the coal slurry by adding catalysts and / or applying to external field to realize anode electrolysis and oxidation process of the coal slurry, and significantly increase electrolysis and oxidation efficiency of the coal slurry. The method has the advantages of high yield of organics, simple processes and controllable operation conditions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

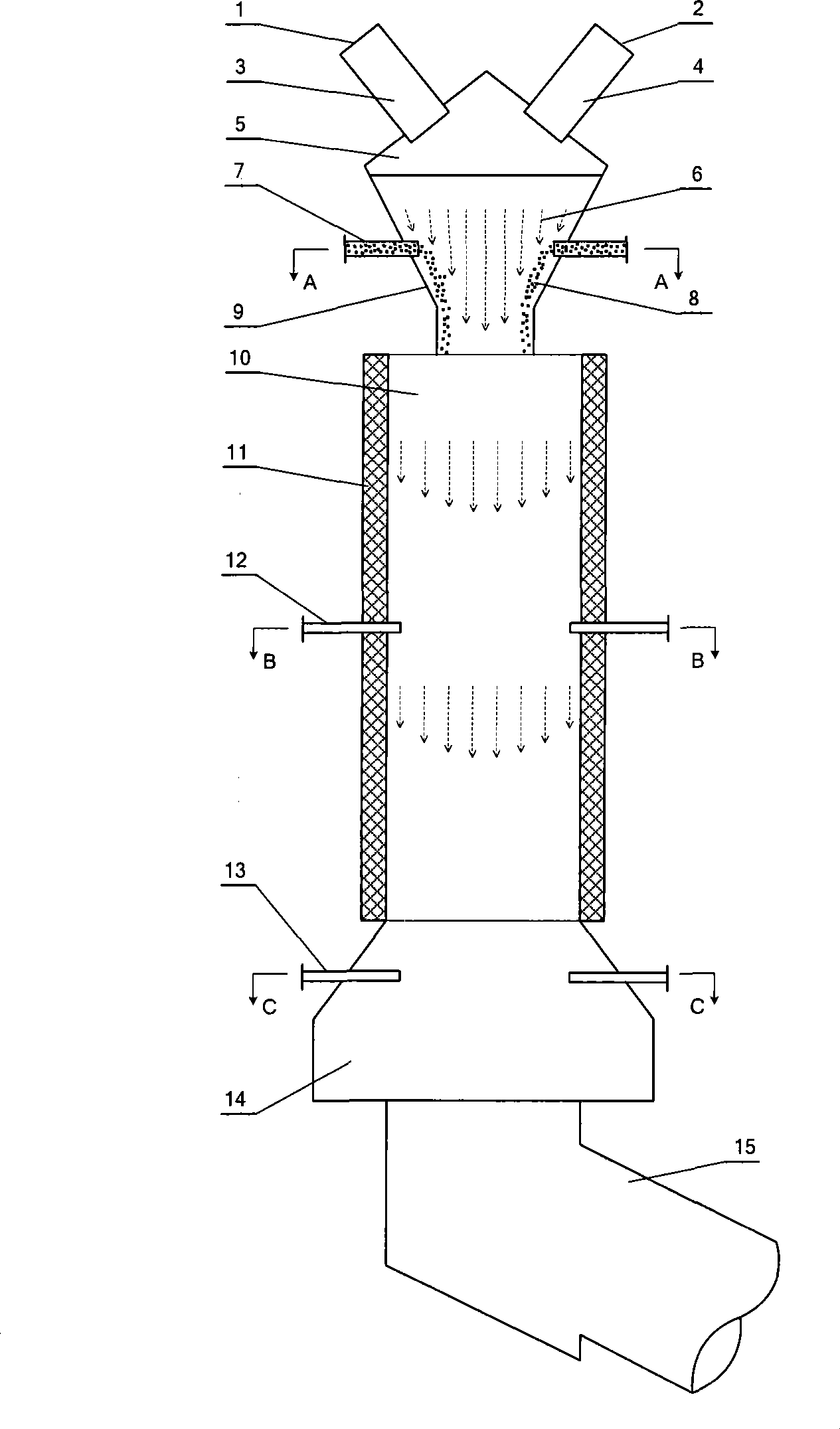

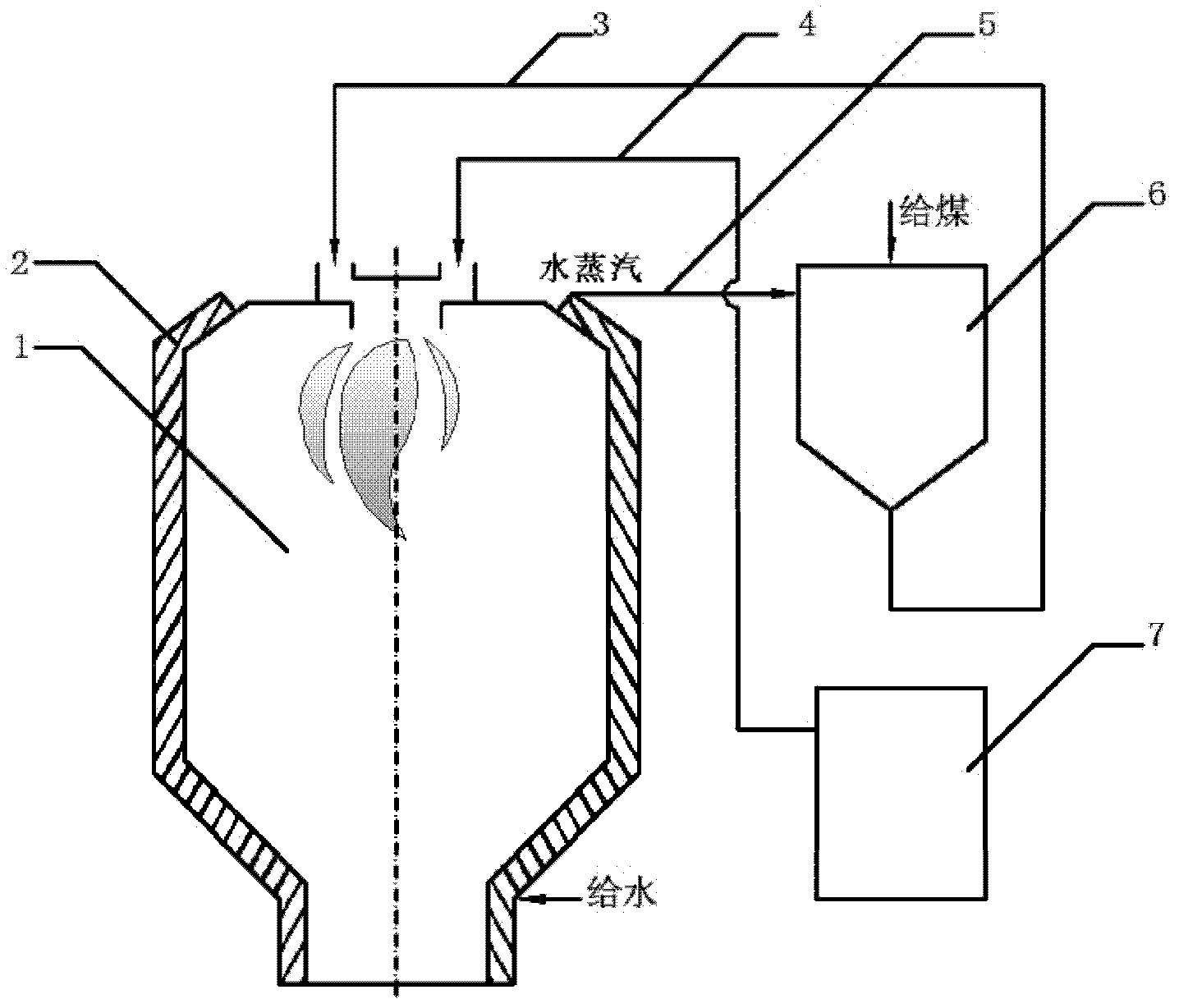

Method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal

ActiveCN103497784AReliable waySafe wayLiquid hydrocarbon mixture productionSpecial form destructive distillationCoal conversionPollution

The invention relates to a method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal. The method comprises the steps of low-degree of coalification powdered coal pre-drying, dry powdered coal separation, low-degree of coalification powdered coal conversion, light gaseous product dedusting, light gaseous product separation and collection, pyrolysis product semi-coke recovery and the like. The method provided by the invention provides a safe and reliable way for realizing efficient utilization of the powdered coal. The method provided by the invention is high in throughput and high in heat exchange efficiency, and can automatically sieve raw material grains, so that load on a coal preparation system is reduced, and yield of a light product is increased. Compared with the prior art, the method provided by the invention has the advantages that inert component content and tar dustiness in the synthetic fuel gas are effectively reduced, heat transfer efficiency and conversion reaction speed are effectively improved, and yield of tar and synthetic fuel gas products is increased, wherein the tar dustiness is less than 0.1mg / kg. The method has the characteristics of low energy consumption and low environment pollution, thereby having very important economic significance and social significance and having a great application prospect.

Owner:THE NORTHWEST RES INST OF CHEM IND

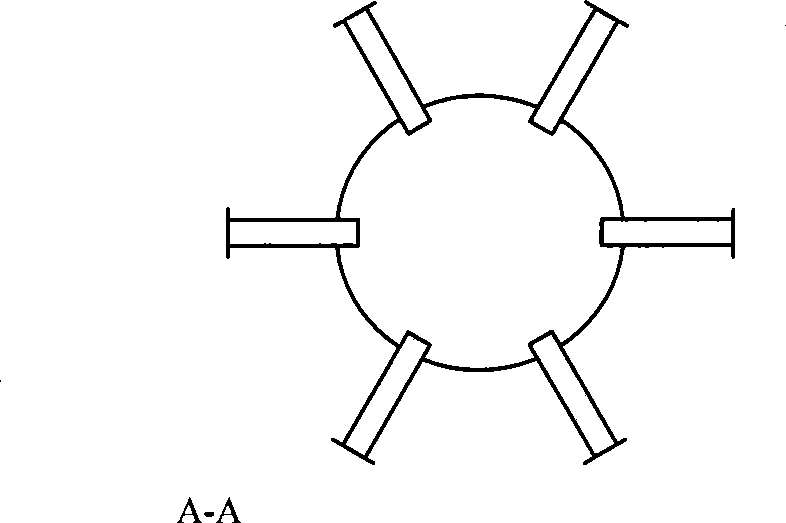

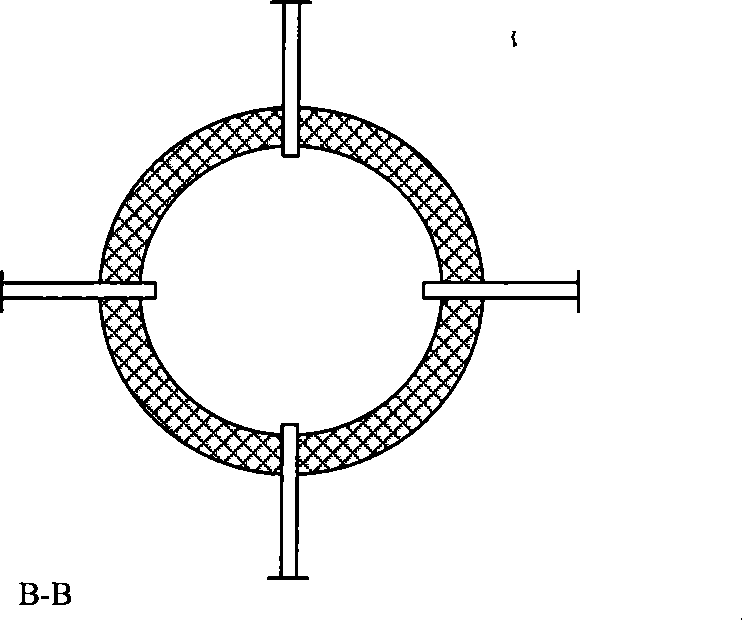

Plasma coal cracking reaction apparatus relating to flow screening component

InactiveCN101508623AIncrease the depth of incidenceImprove contact efficiencyOrganic chemistryInjected materialCoal dust

The invention belongs to a plasma coal pyrolysis reactor involving cover flow components in the field of chemical equipment. The reactor comprises a plasma torch anode, a plasma torch cathode, a crossing area of the plasma torch anode and the plasma torch cathode, a working gas inlet of the plasma torch anode, a working gas inlet of the plasma torch cathode, a mixing area and a coal dust spraying tube, a reaction area, a reaction area wall surface, a reaction area feed gas injection pipe, a sharp quenching area, a sharp quenching medium injection pipe, a sharp quenching outlet and cover flow components arranged in the mixing area, the reaction area or the sharp quenching area. Cover flow components are arranged in the high temperature and high flow rate reactor, space distribution of fluid is changed, injection depth of injected material is increased, and contact and mixing efficiency between reactants is enhanced so as to realize the purpose of improving coal conversion and heat conversion capability of the reactor.

Owner:TSINGHUA UNIV +1

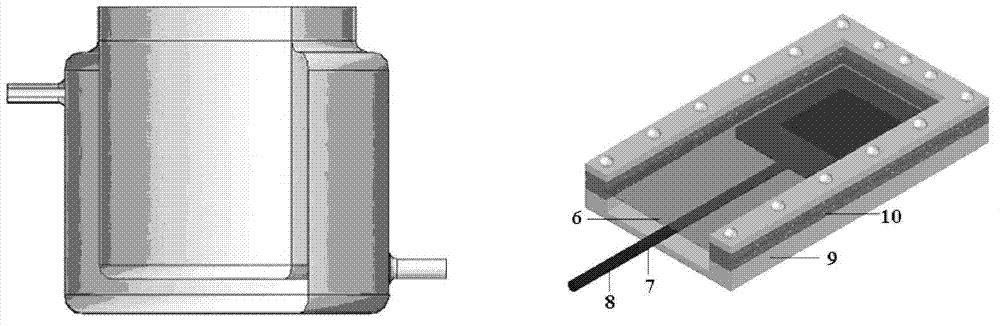

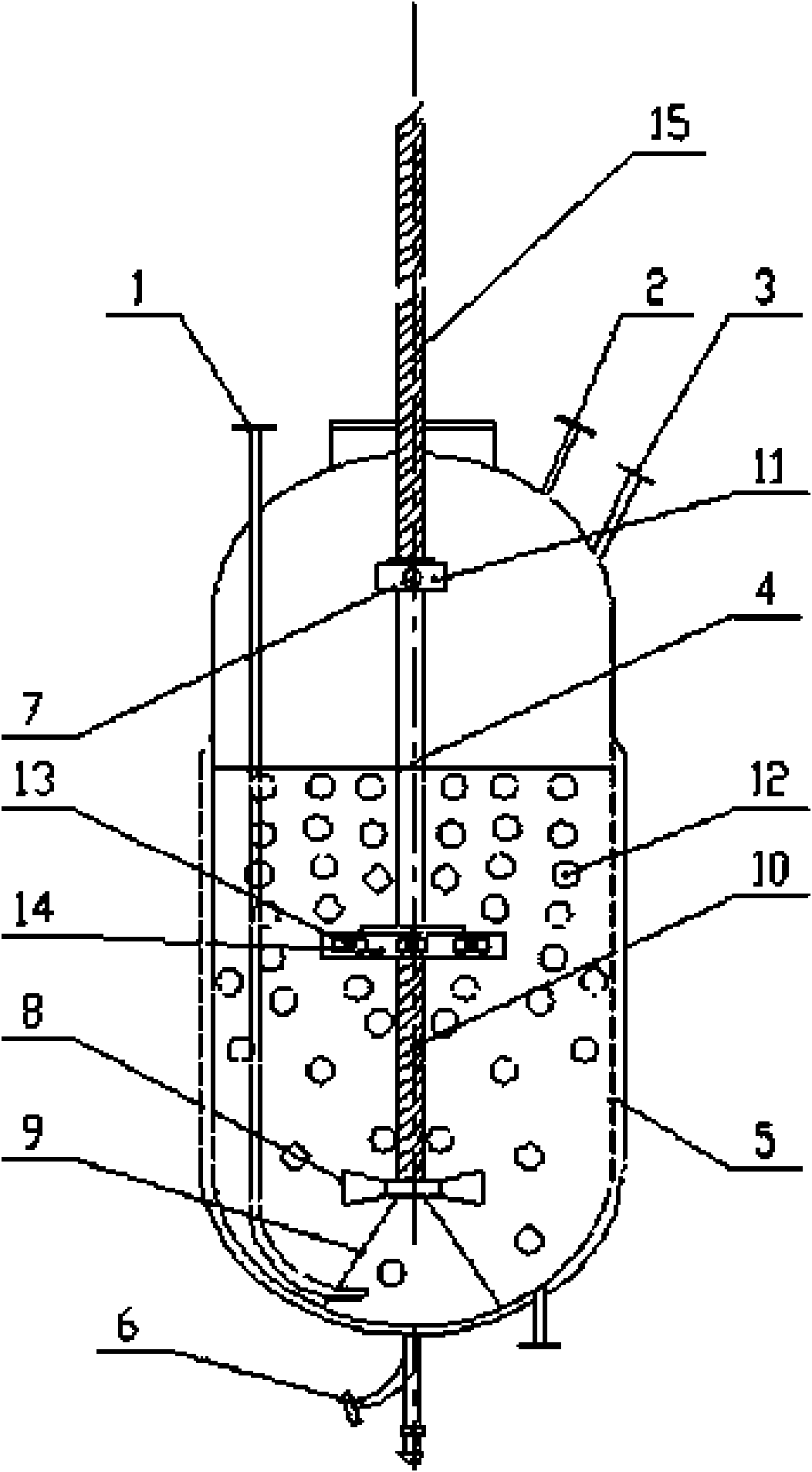

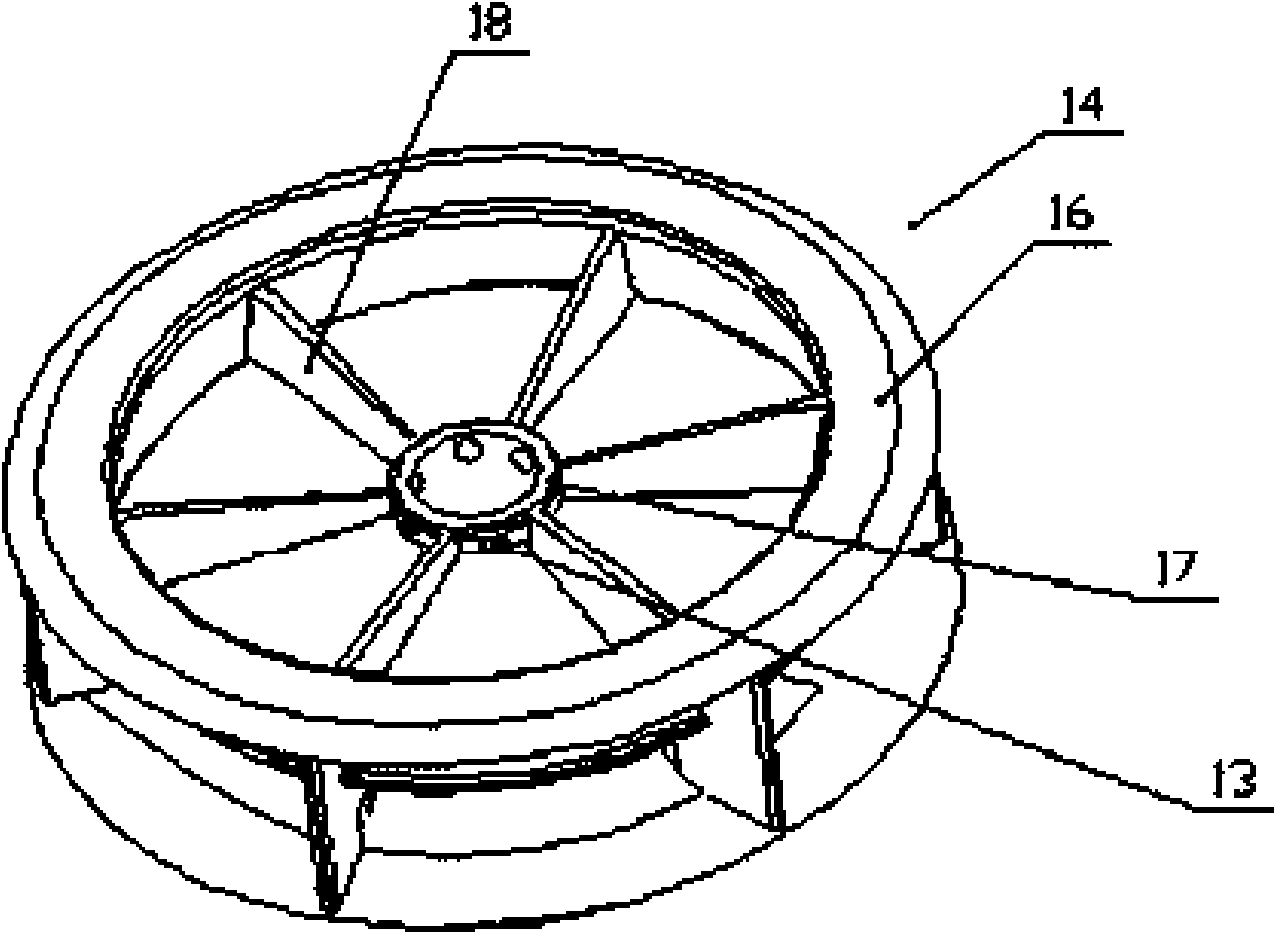

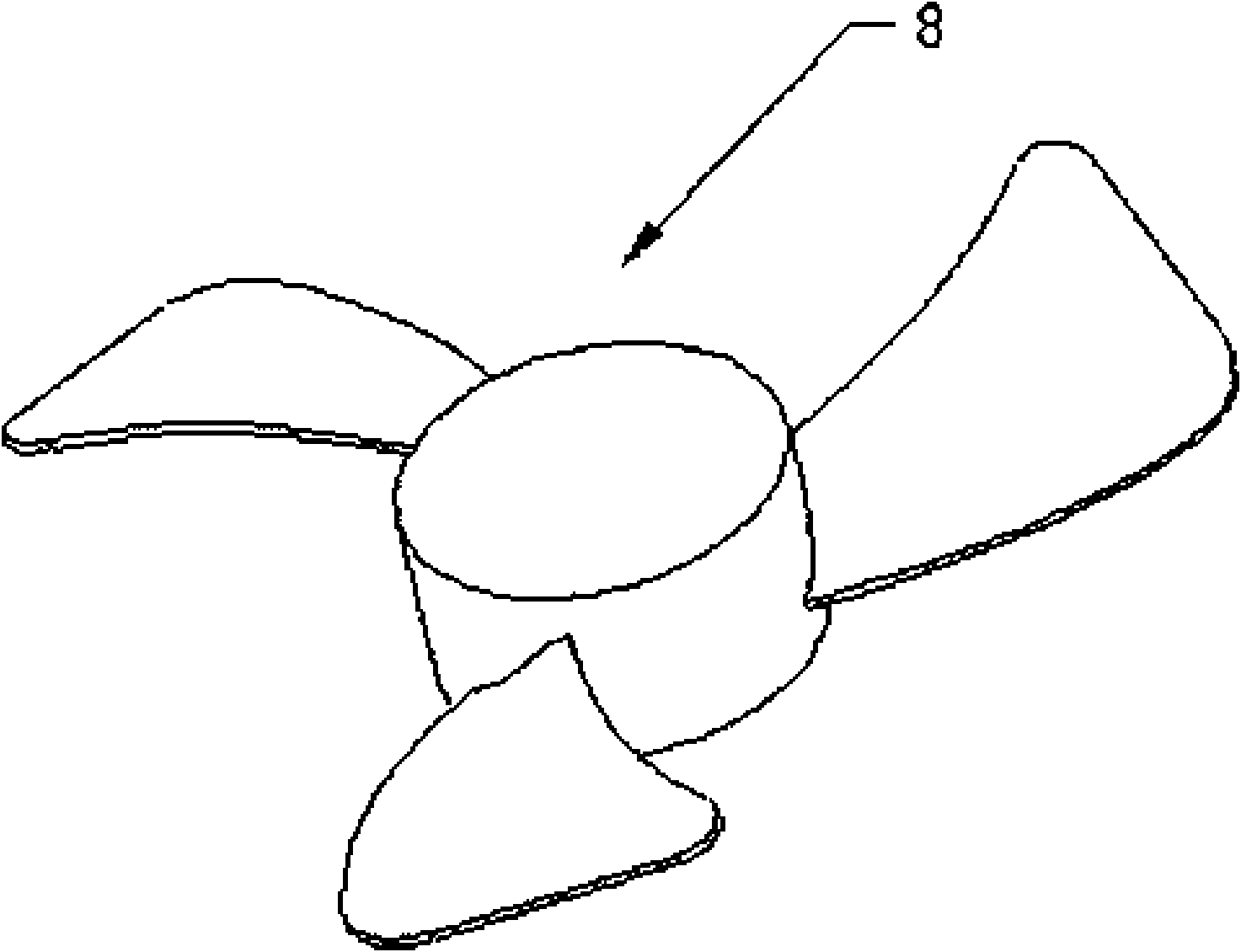

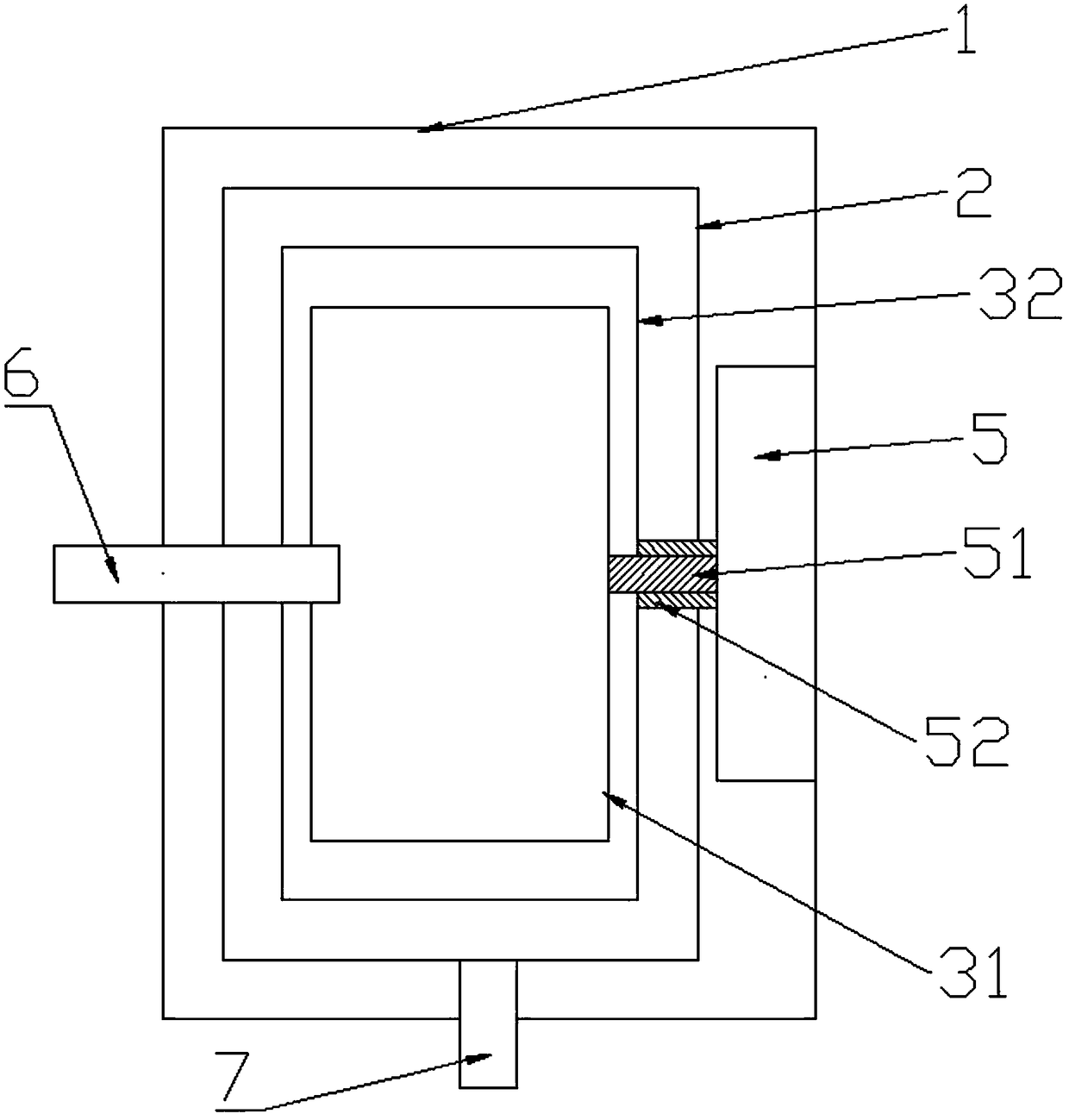

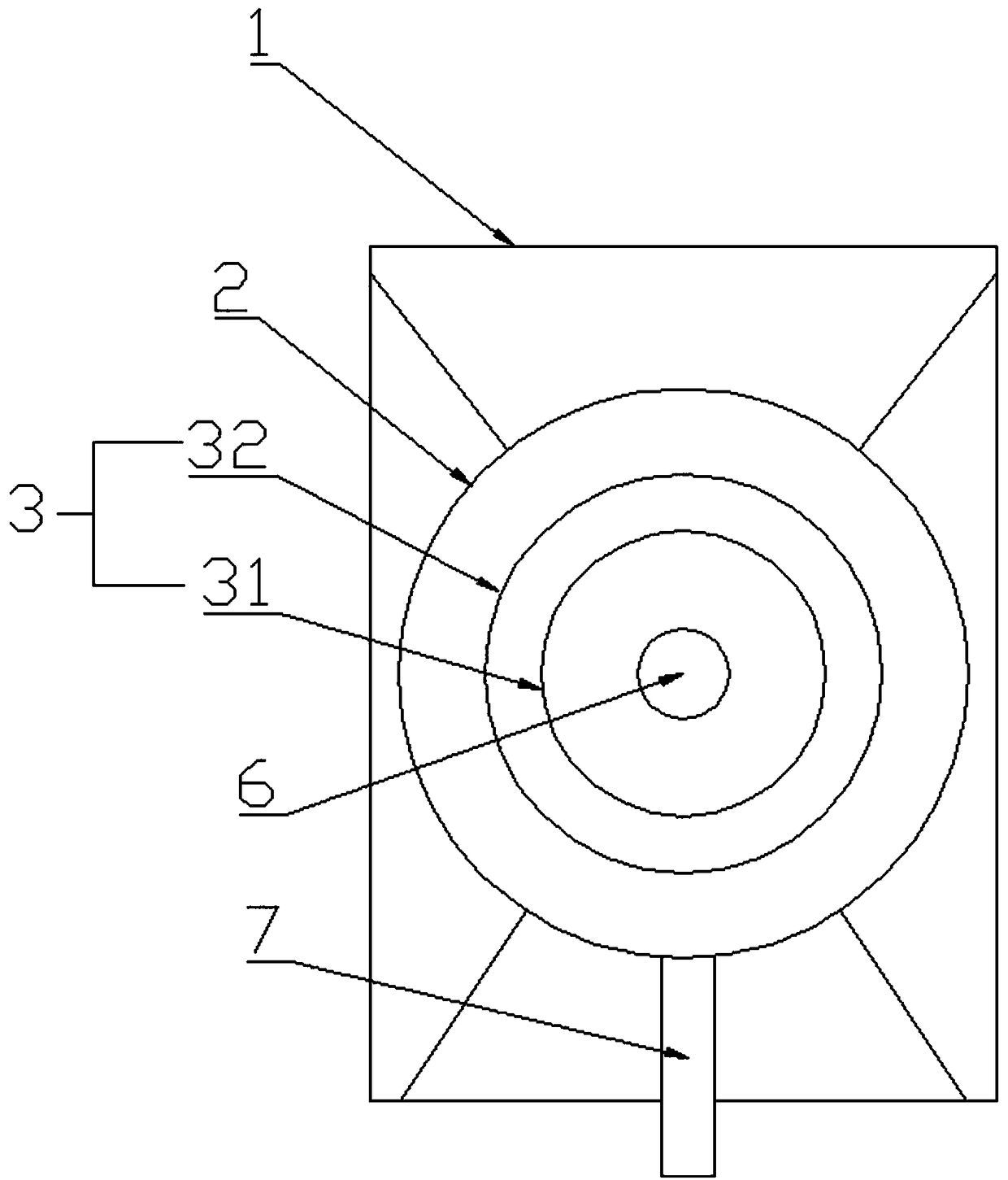

Reaction kettle for direct coal liquefaction and application thereof

InactiveCN101619225ATo avoidLittle turbulenceLiquid hydrocarbon mixture productionEngineeringCoal conversion

The invention discloses a reaction kettle used for direct coal liquefaction and applications thereof. The reaction kettle comprises a reaction kettle body, an agitating shaft and an agitating blade arranged in the reaction kettle body and an air suction pipe which is arranged in the reaction kettle body and communicated with exterior; wherein the agitating blade is arranged at the free end of the agitating shaft, the agitating shaft is additionally provided with a self priming agitating blade which is arranged above the agitating blade; air suction holes communicated with the reaction kettle are arranged at the upper part of the agitating shaft; the self priming agitating blade is provided with air outlet holes communicated with the air suction holes at the self priming agitating blade. The invention further discloses a method for direct coal liquefaction in the reaction kettle; when the direct coal liquefaction is carried out in the reaction kettle of the invention, compared with the direct coal liquefaction by the ordinary reaction kettle, the coal conversion rate and yield of components soluble in normal hexane can be improved by 7% and sometimes by as high as 15%, as a result, conversion rate of coal is greatly improved.

Owner:HANERGY TECH

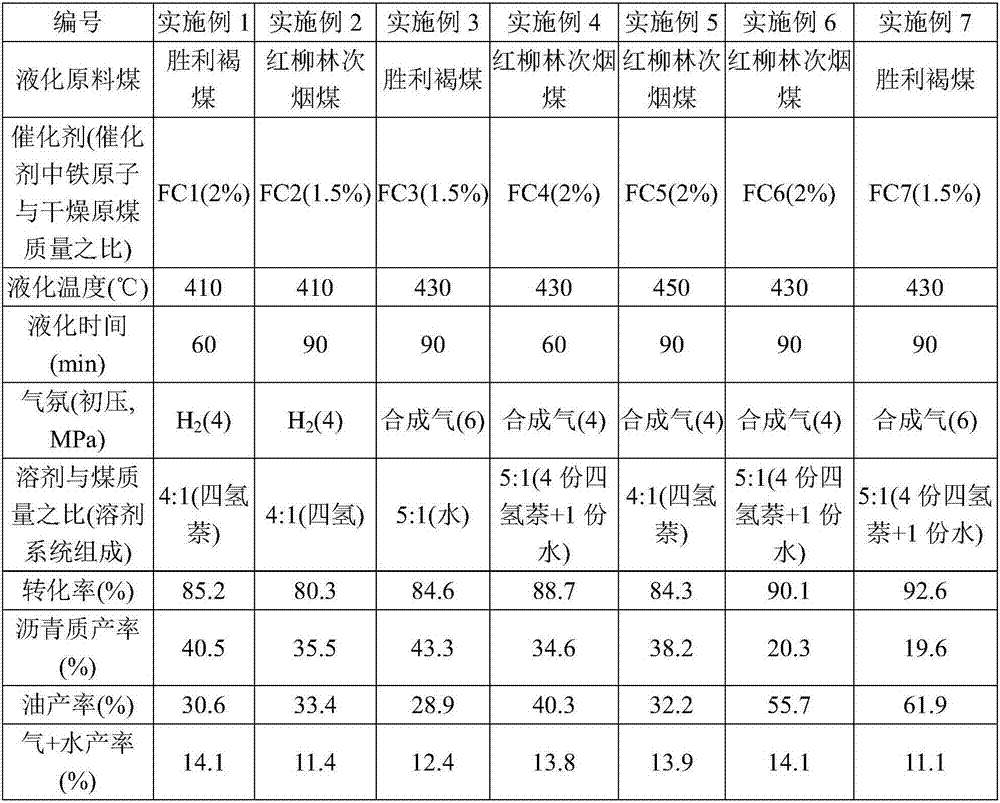

Complex catalyst for direct liquefaction of coal, and preparation method thereof

ActiveCN102895973AOvercoming the defect of too high costLow costLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSoutheast asiaIronstone

The invention relates to a complex catalyst for direct liquefaction of coal, and a preparation method thereof. The preparation method comprises the steps of simple-processing outdoor natural laterite-nickel ore which includes iron and nickel or more active metal components and is mainly produced in countries of Southeast Asia and the like near the equator, and grinding the laterite-nickel ore into fine powder to obtain the catalyst for direct liquefaction of the coal; or employing the natural laterite-nickel ore or other iron-containing ores as raw materials, loading chemicals or the ores comprising active components of transition metal elements of nickel, molybdenum, cobalt and the like on the iron ores via a manual method to form the complex catalyst for direct liquefaction of the coal. The preparation method by using the natural laterite-nickel ore as the catalyst or by using the laterite-nickel ore or other iron ores as raw materials and manually loading active metal components of cobalt, molybdenum and nickel to prepare the catalyst is simple and mature. By using the prepared complex catalyst for direct liquefaction of the coal to catalyze a direct liquefaction reaction of the coal, the catalyst has the characteristics of low catalyst consumption, high coal conversion rate, high product oil yield, etc.

Owner:CCTEG CHINA COAL RES INST

Slurry bed hydrogenation catalyst, and preparation, design method and use thereof

ActiveCN104907078AHigh catalytic activityGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonRed mud

The invention discloses a slurry bed hydrogenation catalyst, and preparation, a design method and a use thereof; the catalyst includes the following components: a catalyst main body, molybdenum-containing red mud or hematite powder, a carrier and activated carbon; the molar ratio of a metal center Fe to the other metal center Mo in the red mud or hematite is 1:150 to 1:200, the mass ratio of the catalyst main body to activated carbon is 0.2:1 to 1.1:1, and the activated carbon has the pore size of 1-100 nm. The preparation method includes the following steps: firstly, preparing the molybdenum-containing red mud or hematite powder, then adding activated carbon with the particle size of 50-150 [mu]m into the molybdenum-containing red mud or hematite powder, mixing evenly, and thus obtaining the slurry bed hydrogenation catalyst. The slurry bed hydrogenation catalyst has the advantages of low cost, simple preparation method, and easy storage and transportation, can be discarded and has no need of recycling, is applied to heavy oil slurry bed hydrogenation, coal direct liquefaction and oil coal mixing, and achieves quite high residual oil / oil coal conversion rate and liquid yield.

Owner:CATECH TECH

A post treatment process containing a fast gas-solid separation structure after plasma coal cracking

ActiveCN101550055AAvoid simultaneous coolingImprove cooling efficiencyOrganic chemistryChemical industryThermal energyGas phase

The present invention discloses a post treatment process containing a fast gas-solid separation structure after plasma coal cracking, which pertains to the technical field of coal chemical industry. This process includes: a) through a fast gas-solid separation device, gas-phase intermediate and solid-phase intermediate are obtained from the reaction products of plasma coal cracking; b) the gas-phase intermediate enters a quenching unit to obtain acetylene-containing cracking gas; c) the solid-phase intermediate enters another reactor to further react with water or hydrogen; d) the heat obtained from the reaction of the solid-phase intermediate provides partial electricity for plasma generator. The present invention may raise the acetylene content of cracking gas product, the overall coal conversion rate and the comprehensive value of the process and is applicable to the post treatment of high-temperature, high-flowrate gas-solid mixture.

Owner:TSINGHUA UNIV

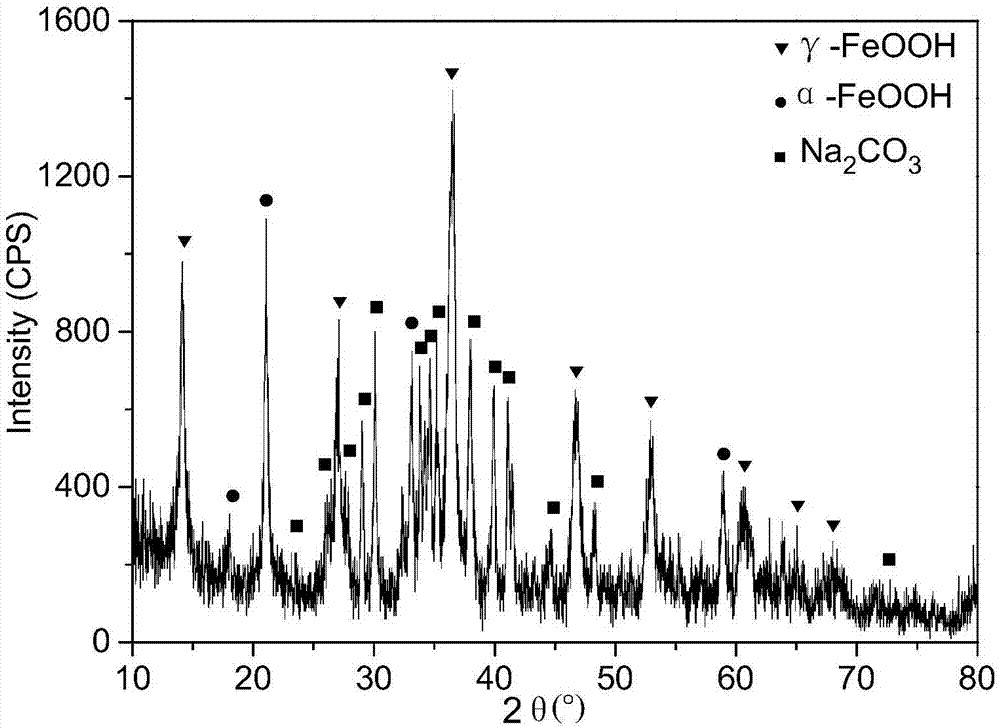

Iron-based catalyst and preparation method thereof

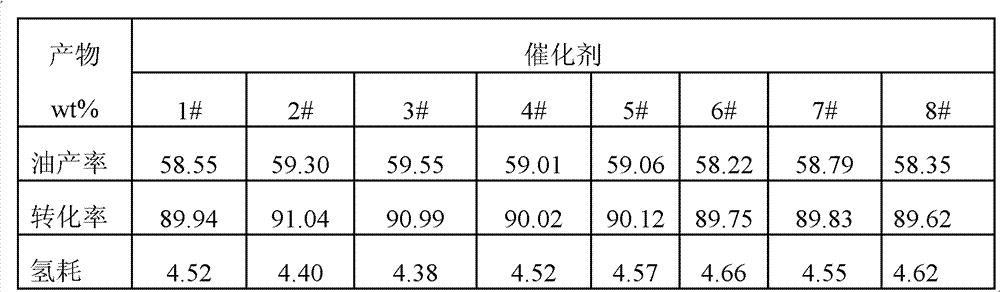

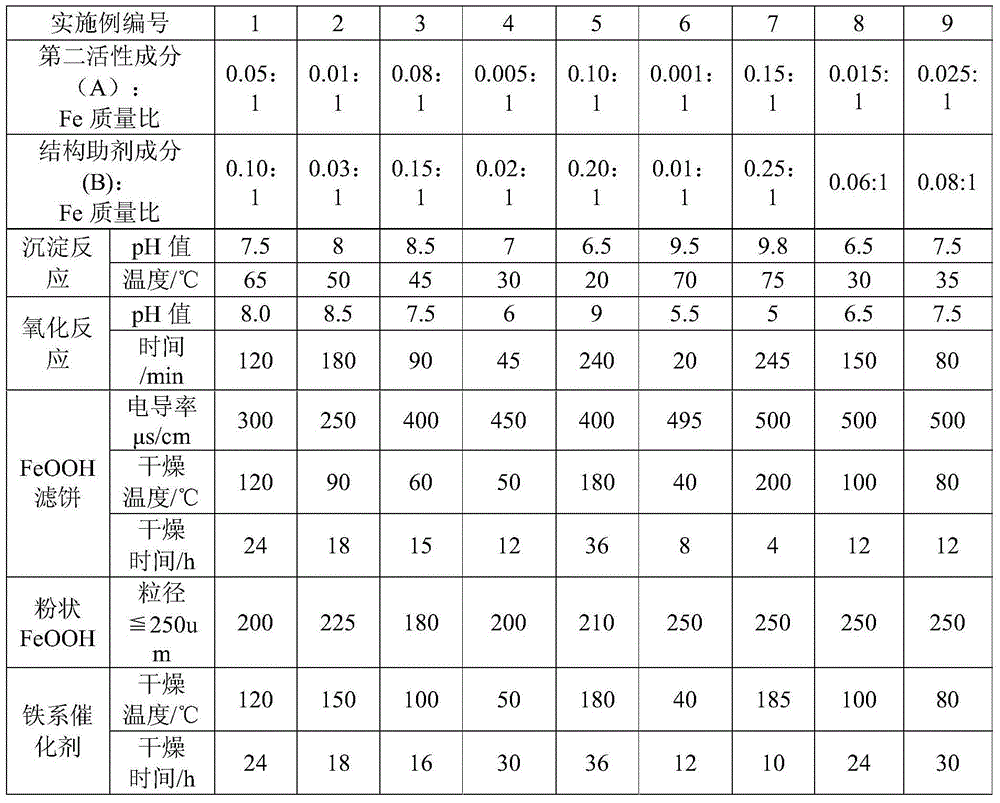

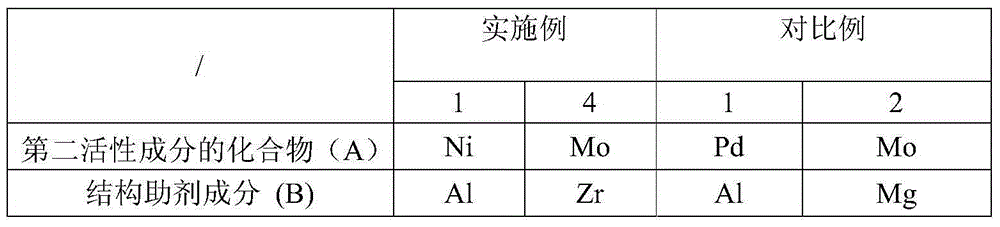

InactiveCN104888797AHigh catalytic activityAvoid reunionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsCoal conversionOil production

The invention discloses an iron-based catalyst and a preparation method thereof. The iron-based catalyst comprises a compound FeOOH containing a first active ingredient Fe, a compound containing a second active ingredient, and a compound containing a structure promoter ingredient, wherein the second active ingredient comprises one or more elements selected from nickel, molybdenum, cobalt and tungsten; the structure promoter ingredient comprises one or more elements selected from silicon, aluminum and zirconium. Based on the compound FeOOH containing the first active ingredient Fe, the compound containing a second active ingredient comprising one or more elements selected from nickel, molybdenum, cobalt and tungsten and the compound containing the structure promoter ingredient comprising one or more elements selected from silicon, aluminum and zirconium are added to compound Fe, the second active ingredient and the structure promoter so as to achieve the synergistic effect, so that the catalytic activity of the iron-based catalyst is improved, the agglomeration phenomenon of catalysts is overcome, the catalyst dose during the coal liquefaction process is reduced, and the coal conversion rate and the oil production rate are increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Treatment method of sewage containing coal tar

InactiveCN102198991ARealize rational utilizationHigh recovery rateHydrogenMultistage water/sewage treatmentBriquetteCoal conversion

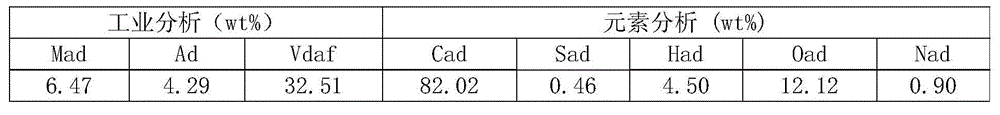

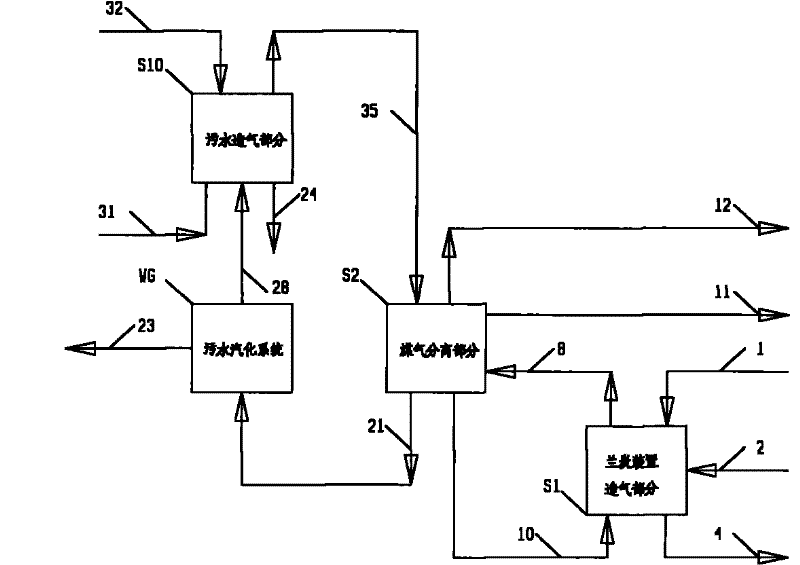

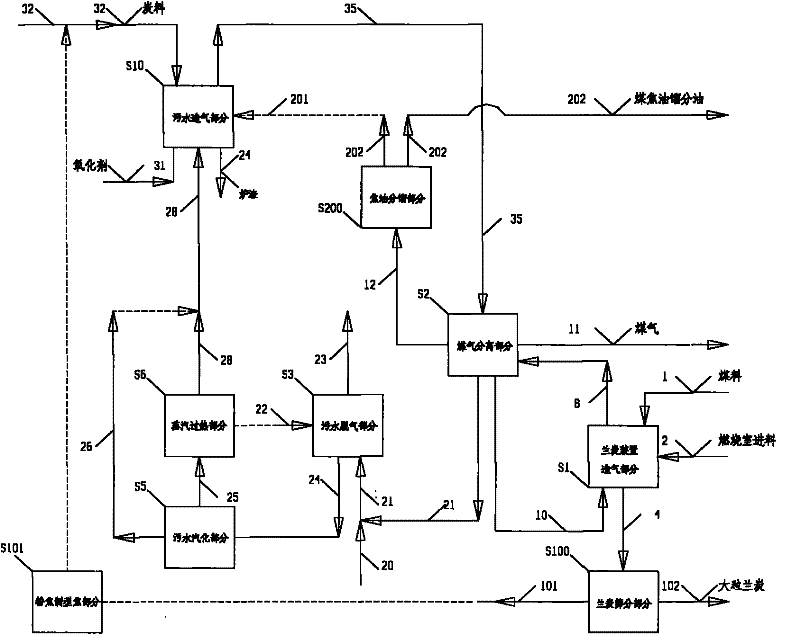

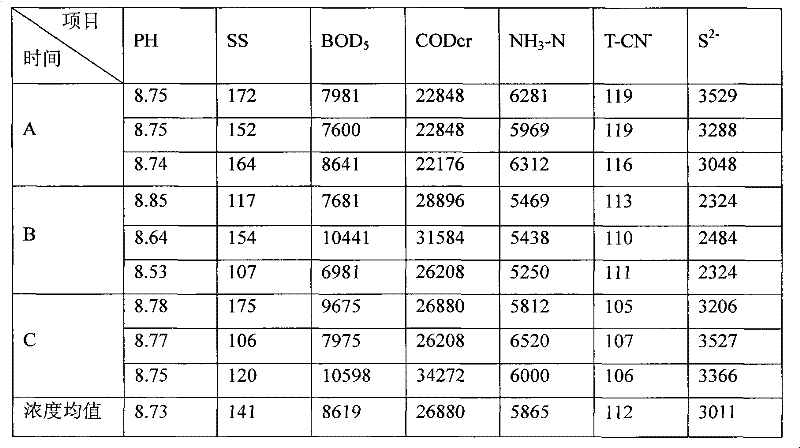

The invention relates to a treatment method of sewage containing coal tar, which is particularly suitable for a process for preparing Lan carbon. Raw material water passes through a sewage vaporization system WG to obtain steam which then enters a sewage gas generating part S10; and coal gas 2G is produced in a condition that an oxidant and a carbon raw material exist, and the coal gas enters a separation part S2 of the coal gas produced in the Lan carbon preparation process. The carbon raw material of the sewage gas generating part S10 can be either formed coke prepared from powered Lan carbon or a coal tar separator, i.e., coal pitch. The treatment method is integrated with a Lan carbon preparation process to form an environment-friendly, large-scale, chemical-engineering-oriented and circular-economy-type coal conversion process route with low investment, high utilization rate of raw materials and high product value. Because the coal and the oxidant are used as raw materials, three products, i.e. coal gas, coal tar and Lan carbon, are obtained.

Owner:何巨堂

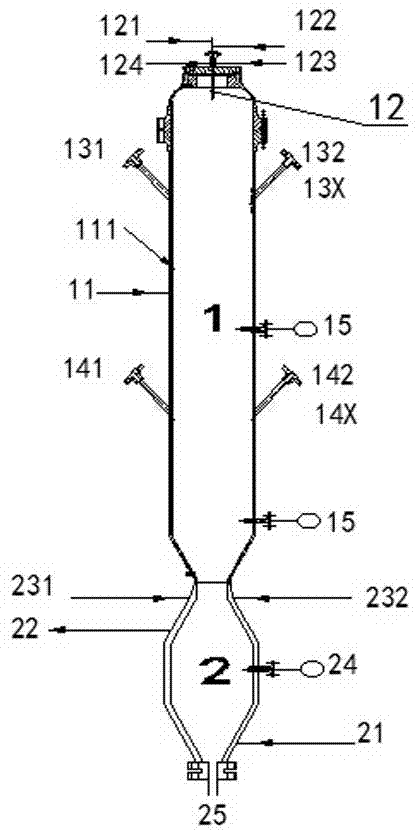

Quick hydropyrolysis reactor and process thereof

ActiveCN104498075APromote formationReduce processLiquid hydrocarbon mixture productionChemical/physical processesHydrogen atmosphereCoal conversion

The invention discloses a quick hydropyrolysis reactor and a process thereof and relates to pyrolysis of coal, solving the problems that the exiting pyrolysis process is high in energy consumption and low in oil extraction rate. A reactor is provided with a synthesis gas nozzle, a hydrogen nozzle and a coal ash nozzle as well as temperature measuring points of the reactor, wherein the synthesis gas nozzle is communicated with a natural gas and oxygen inlet pipe and is further communicated with a cooling water inlet / outlet; a chilling tank is communicated with the bottom of the reactor, the chilling tank is connected with a water inlet and a water outlet, and the chilling tank is provided with a cooling water nozzle, temperature measuring points of the chilling tank and an outlet of a chilling room. The process comprises the following steps: firstly, feeding the synthesis gas into the reactor; conveying coal ash for quick pyrolysis reaction in a hydrogen atmosphere; and then quickly decreasing the temperature to terminate reaction. The reactor and process disclosed by the invention are used for the coal-to-oil field and have the advantages of simple structure, low energy consumption, high coal conversion rate and high oil product yield.

Owner:中美新能源技术研发(山西)有限公司

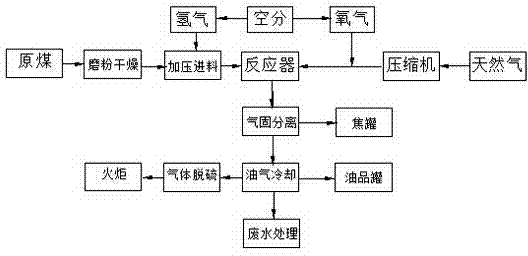

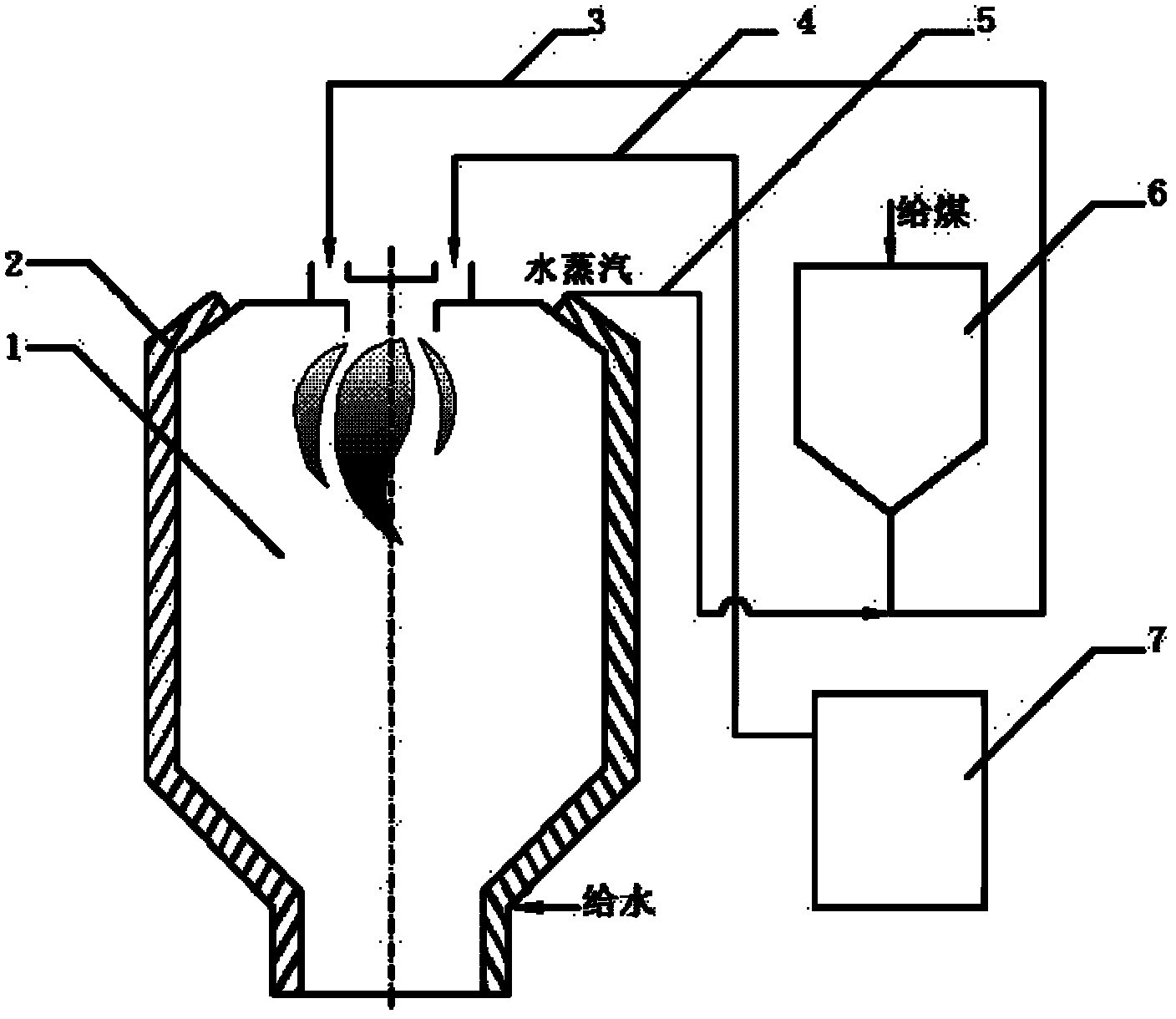

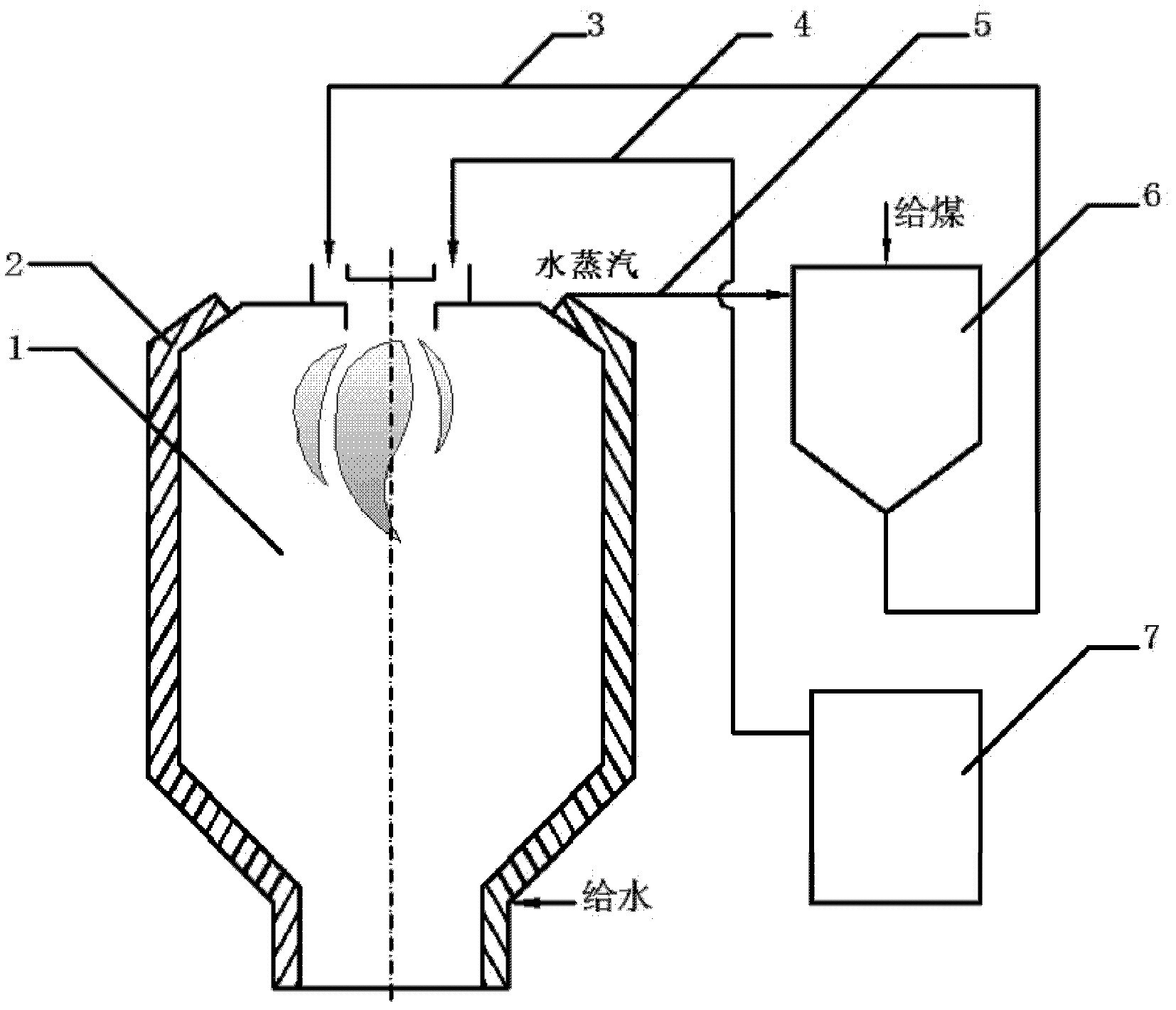

Entrained-flow bed gasification system and method for vapour conveyed pulverized coal

InactiveCN102433164AReduce sensible heat lossIncrease temperatureEnergy inputGranular/pulverulent flues gasificationCoal conversionAir separation

Entrained-flow bed gasification system and method for a vapour conveyed pulverized coal are disclosed, which belong to the technical field of coal gasification and coal conversion. The gasification system disclosed by the invention is composed of an entrained-flow bed gasification furnace with a water-cooling wall, a pulverized coal issuance tank, an air separation plant, a vapour convey tube and a concentrated-phase pulverized coal convey tube. An entrained-flow bed gasification process of conveying a pulverized coal via the vapour of the system comprises the following steps that: a high-temperature superheat vapour at the outlet of the water-cooling wall is conveyed to the body or the outlet of the pulverized coal issuance tank to heat the pulverized coal, and is used as a carrier gas for carrying the pulverized coal and conveying the pulverized coal into the entrained-flow bed gasification furnace via the concentrated-phase pulverized coal convey tube; the air separation plant provides pure oxygen into the entrained-flow bed gasification furnace; and the pure oxygen, the vapour and the pulverized coal perform a gasification reaction in the entrained-flow bed gasification furnace. In the invention, the waste heat of a gasification reaction is used for generating a high-temperature superheat vapour to realize a preheating for coal and a conveying for a concentrated-phase pulverized coal, so that the oxygen consumption of the present entrained-flow bed gasification furnace can be reduced, and the overall coal gasification efficiency can be increased.

Owner:TSINGHUA UNIV +1

Coal conversion process and products, comprising two direct ebullated bed liquefaction stages and a fixed bed hydrocracking stage

ActiveUS8916043B2Easy to transportSmooth connectionWaste based fuelLiquid carbonaceous fuelsKeroseneFixed bed

A process for the conversion of coal into fuel bases comprises two successive direct liquefaction stages in ebullated bed reactors followed by a fixed bed hydrocracking stage. This process can produce excellent quality fuel bases (kerosene and diesel).

Owner:INST FR DU PETROLE

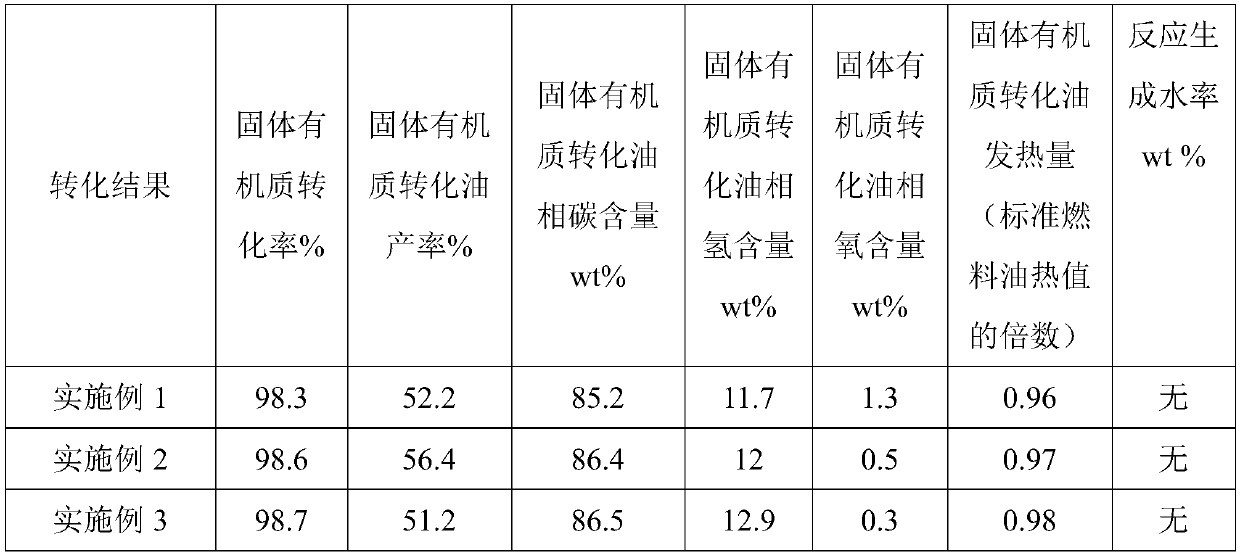

Biomass and coal conversion technology

ActiveCN109536195AHigh calorific valueRealize conversion active hydrogen hydrogenationLiquid hydrocarbon mixture productionChemical industryCoal conversion

The invention belongs to the technical fields of biomass utilization, energy and chemical industry, and concretely relates to a biomass and coal conversion technology. The conversion technology uses at least one of iron oxide, a desulfurization waste agent of the iron oxide or a regenerated material of the desulfurization waste agent of the iron oxide as a catalyst, uses a water-containing slurry,and controls a molar ratio of the iron element to the sulfur element in a reaction system. It is found that in carbonylation can be effectively utilized to block the free radical polycondensation ofbiomass in the cracking process in the presence of CO and realize active hydrogen transformation and hydrogenation of CO and water; and the biomass solid can directly undergo a conversion reaction without being hydrated in the conversion reaction, so the liquefaction yield is increased, the calorific value of an obtained oil product is improved, and a large amount of waste water is not generated after the conversion reaction is completed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

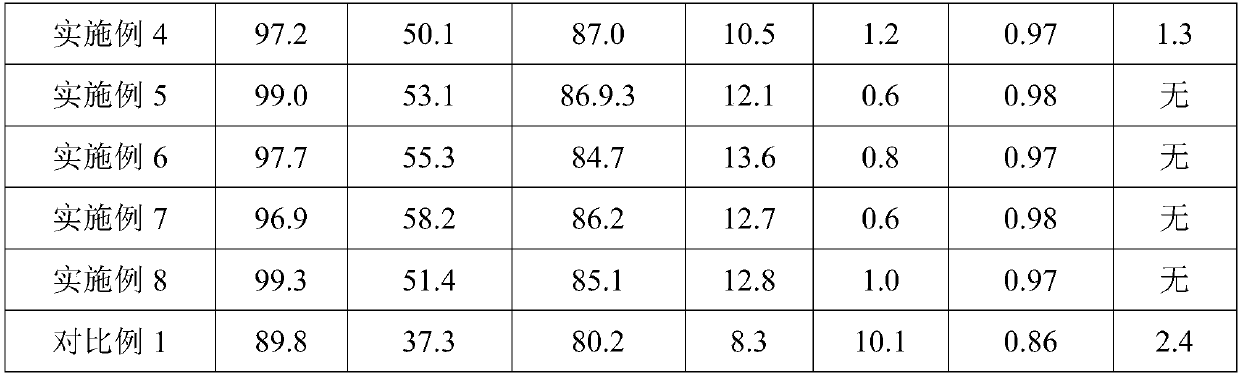

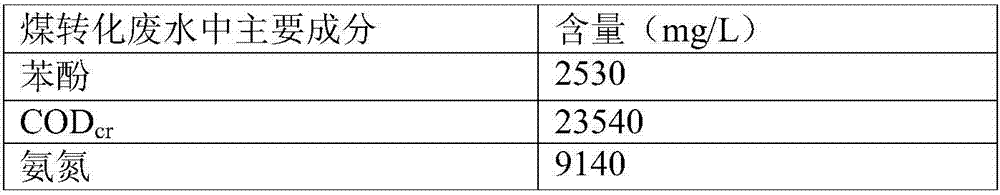

Method for preparing slurry fuel by coal conversion wastewater gradient utilization

The invention relates to a technique for coal conversion wastewater treatment and recycling, and aims at providing a method for preparing a slurry fuel by coal conversion wastewater gradient utilization. The method comprises the following steps of coagulating the coal conversion wastewater, so as to separate three phases of water-containing tar, wastewater and sludge, wherein the tar separated from the water-containing tar is used for preparing emulsifying oil with fluidity, the sludge is filtered and treated to obtain filter residues and sludge slurry with fluidity, and the sludge slurry is used for gasifying or incinerating; blending and mixing the wastewater, pulverized coal, a coal water slurry additive, and the wastewater and residues obtained by separating, so as to prepare the coal water slurry; after the gasified wastewater produced by a gasifying furnace or a boiler is congealed, mixing into the coal conversion wastewater to coagulate, so as to realize the recycling function. The method has the advantages that the three phases of waste tar, waste liquid and sludge in the coal conversion wastewater are utilized in a gradient way, the pollution to the environment by the coal conversion wastewater is decreased, the caloric value of the wastewater is fully utilized, a large amount of slurry preparation water is saved, and the combustion and gasifying property of the coal water slurry is promoted.

Owner:ZHEJIANG UNIV

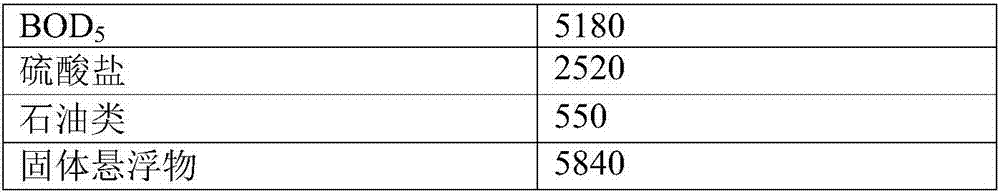

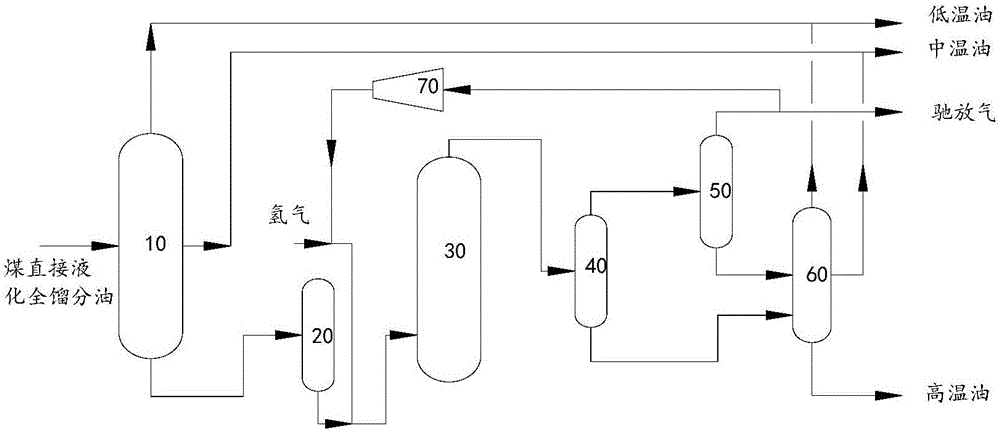

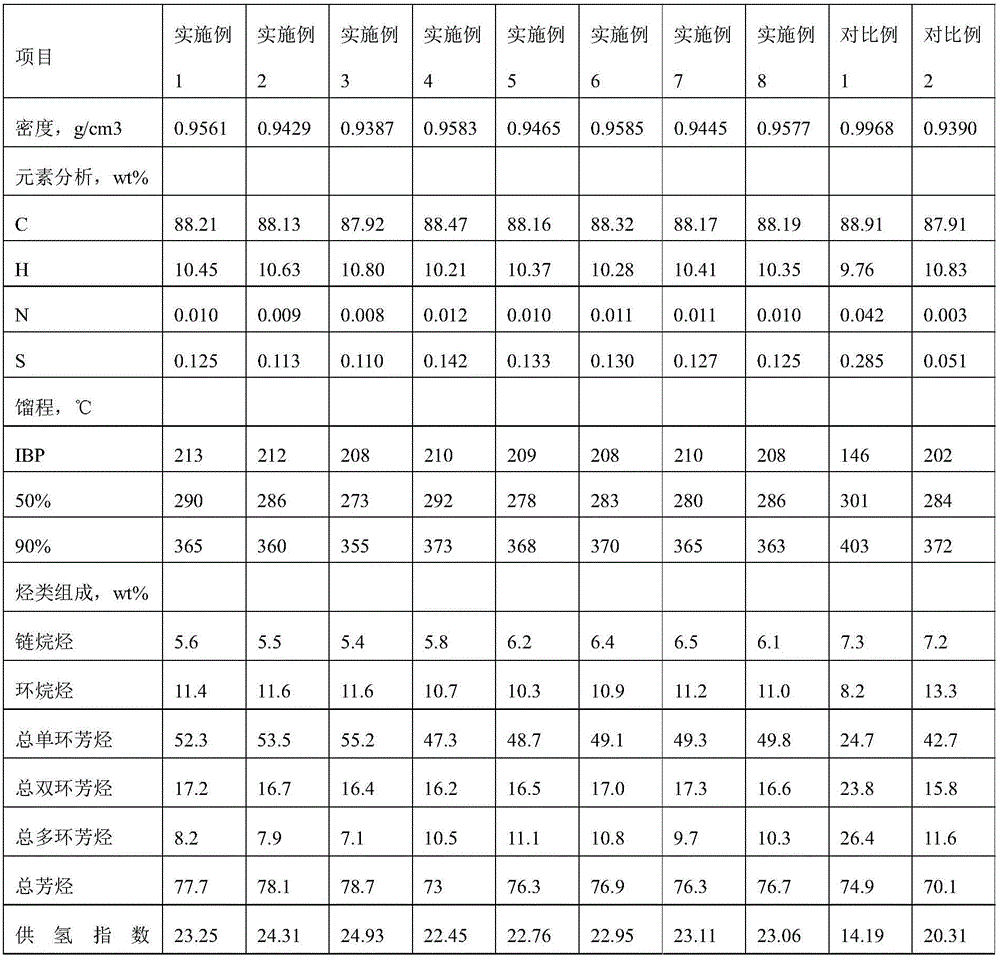

Coal direct liquefying and circulating solvent and preparation method thereof

ActiveCN105925304AReduce volumeReduce the amount addedLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesSlagFractionation

The invention discloses a coal direct liquefying and circulating solvent and a preparation method thereof. The preparation method comprises the following steps: step one, subjecting oil obtained by directly liquefying coal to fractionation under a pressure of 0.02 to 0.2 MPa to obtain primary low temperature oil, primary middle temperature oil, and primary high temperature oil; step two, subjecting primary high temperature oil to hydrogenation and fractionation to obtain secondary low temperature oil, secondary middle temperature oil, and secondary high temperature oil; step three, mixing all secondary high temperature oil, part of primary middle temperature oil, and part of secondary middle temperature oil according to a certain ratio to obtain the coal direct liquefying and circulating solvent; wherein the boiling ranges of the primary low temperature oil and secondary low temperature oil are under 200 DEG C; the boiling ranges of primary middle temperature oil and secondary middle temperature oil are in a range of 200 to 320 DEG C, and the boiling ranges of primary high temperature oil and secondary high temperature oil are above 320 DEG C. The provided preparation method has the advantages that the coal conversion rate and oil yield of coal direct liquefying technology can be improved, the loss of light oil products is reduced at the same time, and moreover, the discharge of slag is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method of the utilization of waste heat of low-concentration combustibles

InactiveCN101608794AConducive to emission concentration complianceStable temperature fieldIncinerator apparatusCombustible gasExhaust fumes

A method of the utilization of waste heat of low-concentration combustibles is disclosed, belonging to the field of the treatment of industry low-concentration combustible waste gas; the purpose of the invention is to provide a method for reasonable burning of and reutilization of low-concentration combustible waste gas, in order to solve the problem the invention uses a technical proposal as follows: the low-concentration combustible gas is discharged out and fed into a settling chamber, tail gas is subjected to inertial separation at first and then fed into a chamber for secondary combustion, after the temperature of the secondary combustion reaches 900-1100 DEG C, the secondary combustion device is stopped, the tail gas is subsequently fed into a burning chamber for burning, and the waste heat is utilized through a waste heat boiler; the invention method for the utilization of waste heat of low-concentration combustibles is adapted to the recovery and the reutilization of tail gas in coal conversion industries such as coking as well as gasification and liquefaction of active carbon, carbon and coal and also in steel-making industry.

Owner:TAIYUAN E POWER TECH

Nickel-based high dispersion emulsion catalyst, preparation method and application thereof

PendingCN109289932AAvoid the problem of high energy consumption for water removalImprove operational efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingNickel saltPolymer science

The invention discloses a nickel-based high dispersion emulsion catalyst, a preparation method and application thereof. The preparation method comprises the steps of: (1) heating and dissolving a hydrophilic surfactant and a nickel salt in a 0.3-3 times mass of deionized water; (2) putting an oleophylic surfactant and wax oil into a condenser, performing heating to 50-80DEG C, and conducting stirring under a rotating speed of 1000-4000r / min; and (3) when the oil phase reaches a required temperature, adding the water phase slowly into the container, performing shearing dispersion under a constant temperature condition for 5~15min, and then conducting cooling to room temperature, thus obtaining the nickel-based high dispersion emulsion catalyst. The deionized water introduced into the catalyst prepared by the invention has no need for removal, the problem of large water removal energy consumption in a slurry bed hydrogenation process of the previous water-soluble catalysts can be avoided, the operation efficiency is improved, and the catalyst also has the advantages of good dispersion effect in raw materials, high hydrogenation activity, good coke suppression effect and high coal conversion rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

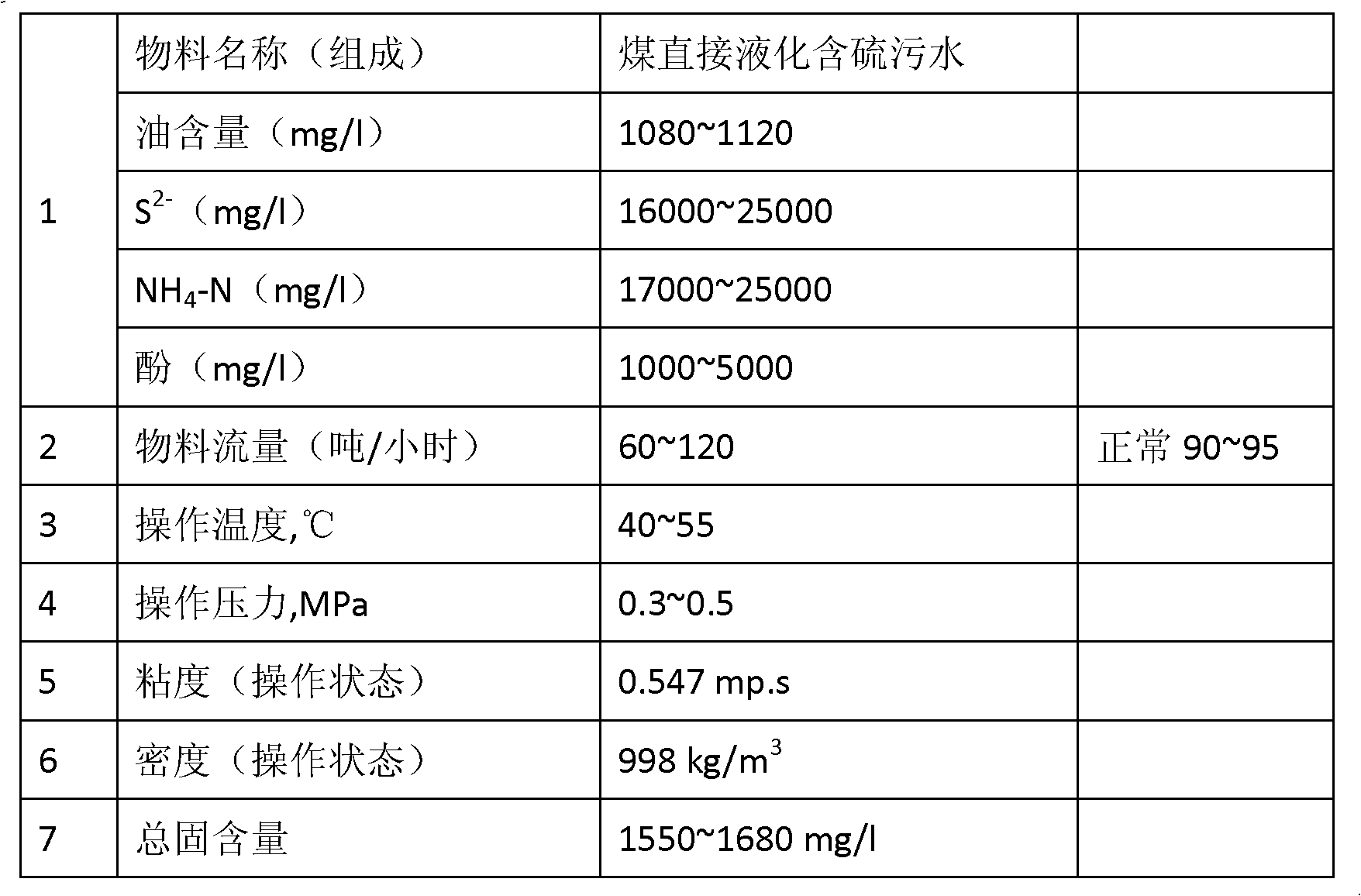

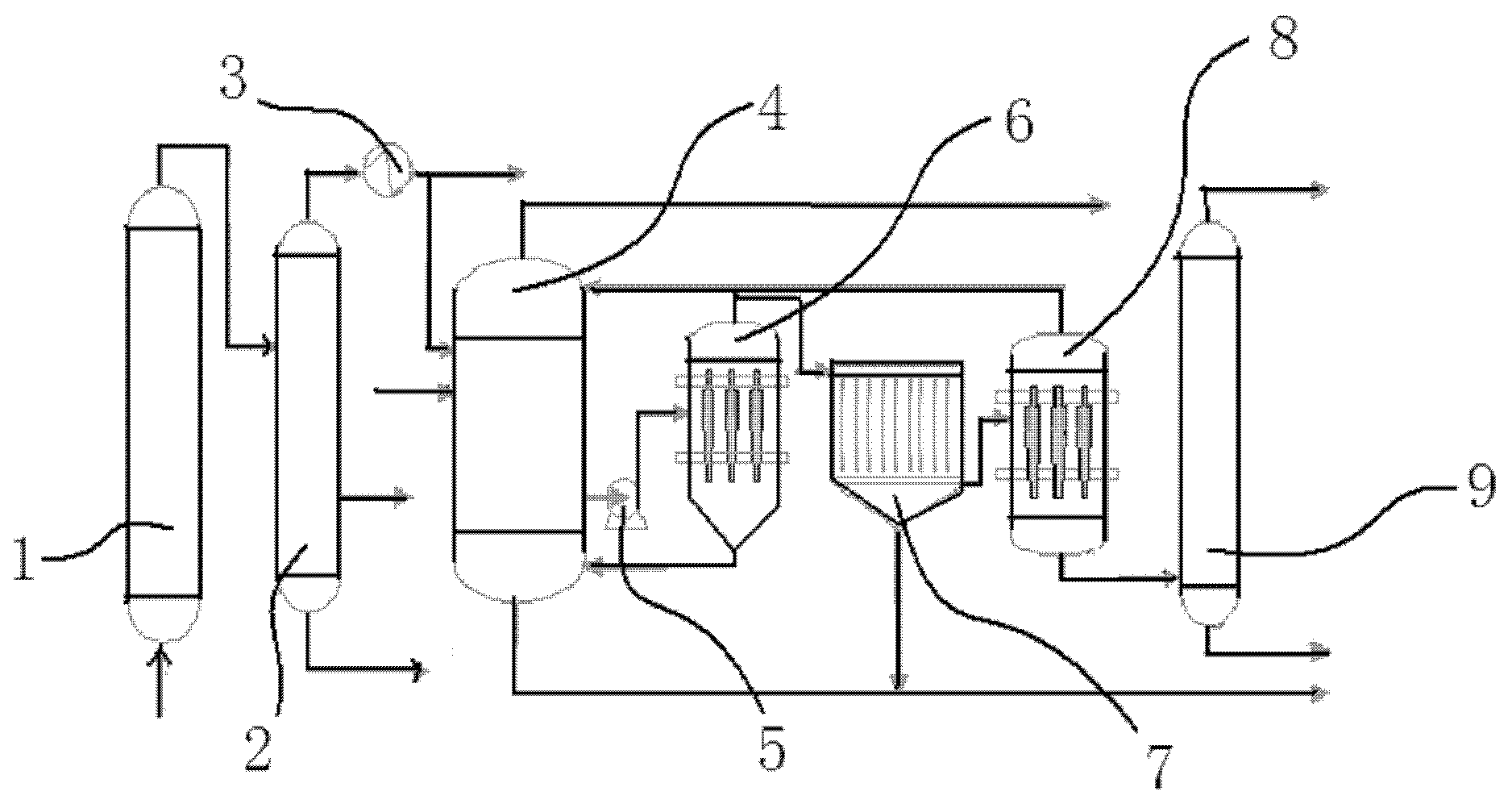

Method and device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water

ActiveCN102583821APrevent sediment cloggingReduce loadWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesCycloneCoal dust

The invention discloses a method and a device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water in the technical field of coal conversion. The method and the device can avoid deposition blocking of the coal dust in a stripping tower, reduce loads of a steam stripping device and improve steam stripping effect, the running cycle of the device is prolonged, simultaneously recycling of dirty oil is facilitated, the processing loss of the device is reduced, and the economic benefit of the device is improved. Besides, a micro cyclone separator and a cyclone deoiler which are adopted in the device are high in separating efficiency, long in continuous running cycle, small in occupied area, high in impact resistance and simple to operate and maintain. The method and the device are characterized in that the device for removing the coal dust and the oil by enabling the coal to be directly liquefied and generate the sulphur-bearing waste water comprises an adjusting tank, a sewage pump, the micro cyclone separator, a precision filter, the cyclone deoiler and the stripping tower; and sewage finally enters into the stripping tower to be treated after the sewage is treated by the adjusting tank, the sewage pump, the micro cyclone separator, the precision filter and the cyclone deoiler.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

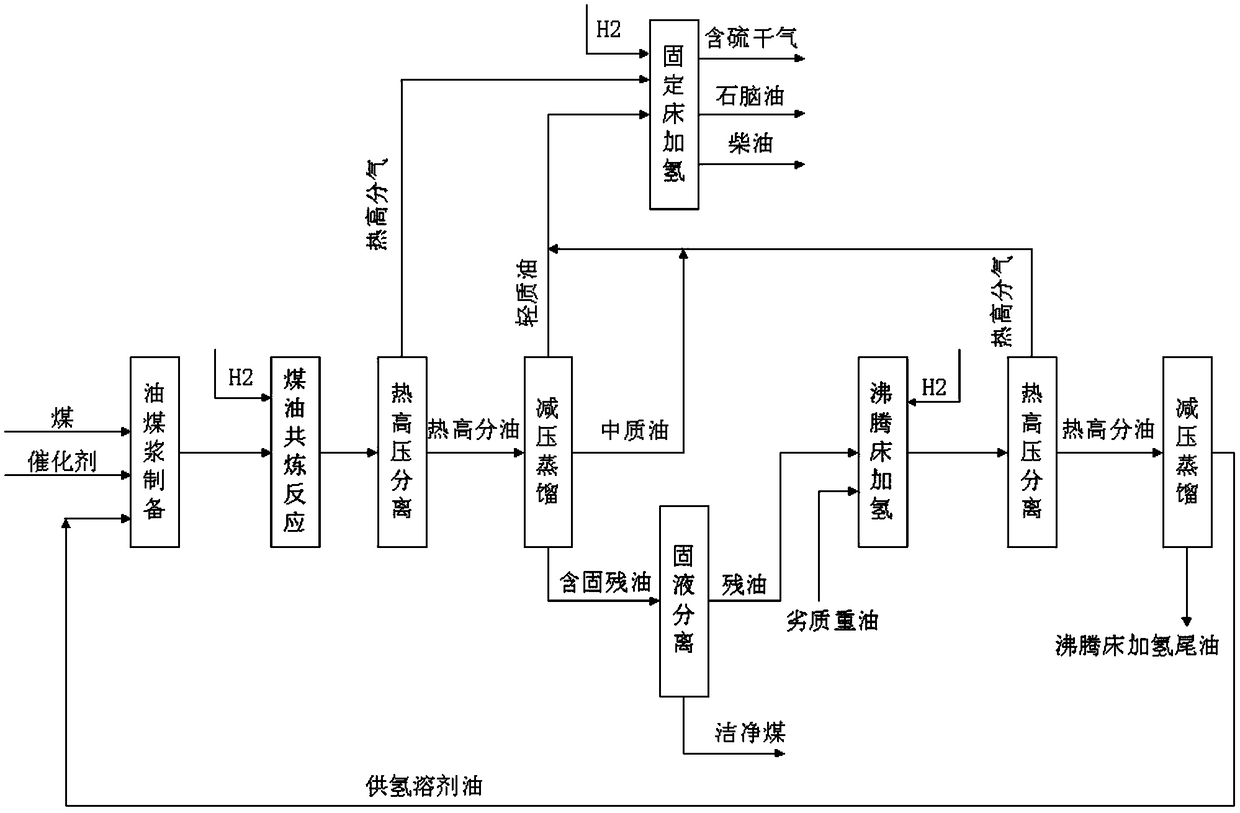

Method for producing oils and chemicals by co-refining inferior heavy oils and coals

ActiveCN109181770AImprove conversion rateHigh yieldTreatment with hydrotreatment processesKeroseneCoal conversion

The invention provides a method for producing oils and chemicals by co-refining inferior heavy oils and coals. The method comprises the following steps: preparing a coal oil mixture by mixing coal dust, hydrogen-supplying solvent oil and a catalyst; splitting in a coal oil co-refining reactor; separating the split products, thereby acquiring high-heat oil O1; decompressing and fractionally distilling the high-heat oil O1, thereby acquiring a solid-containing residual oil; performing solid-liquid separation on the solid-containing residual oil, thereby acquiring residual oil; mixing inferior heavy oils with the residual oil and hydrocracking in a boiling-bed reactor; separating the split products, thereby acquiring high-heat oil O2; decompressing and fractionally distilling the high-heat oil O2; side-drawing vacuum gas oil from a fractionating tower; and taking the vacuum gas oil as the hydrogen-supplying solvent oil and reusing in the preparation of the coal oil mixture. According to the method for producing oils and chemicals by co-refining inferior heavy oils and coals provided by the invention, the coal conversion rate and the yield of oils are increased, the coking problem of the system is relieved, the catalyst deactivation is delayed, the prolonging of running period of production equipment is benefited and the production cost is lowered.

Owner:上海竣铭化工工程设计有限公司

Iron alkali composite catalyst for direct liquefaction of coal

InactiveCN107349948ARaw materials are cheap and easy to getEasy to makePhysical/chemical process catalystsLiquid hydrocarbon mixture productionChemical reactionPrill

The invention relates to an iron alkali composite catalyst for direct liquefaction of coal. The catalyst can be a loaded type or a mixed type. The loaded catalyst is prepared by loading an iron active component and an alkali active component on the surface of coal particles through chemical reactions. The mass ratio of water to dry coal powder is (0.5-5):1. The mass ratio of iron atoms in the iron salt solution to dry coal powder is (0.1-0.5):1. The mole ratio of additive to iron atoms in the iron salt solution is (0-0.1):1. The mole ration of alkaline metal atoms in the alkali solution to iron atoms in the iron salt solution is (0.001-5):1. The mixed type catalyst is prepared by directly mixing iron containing substances and alkali containing substances, wherein the mole ratio of alkaline metal atoms to iron atoms is (0.001-5):1. The catalyst is suitable for direct liquefaction of coals in different systems and is capable of prominently improving the coal conversion rate and yield of oil. Moreover, the raw materials are cheap and easily available. The preparation is simple. The catalyst has a very good application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH +1

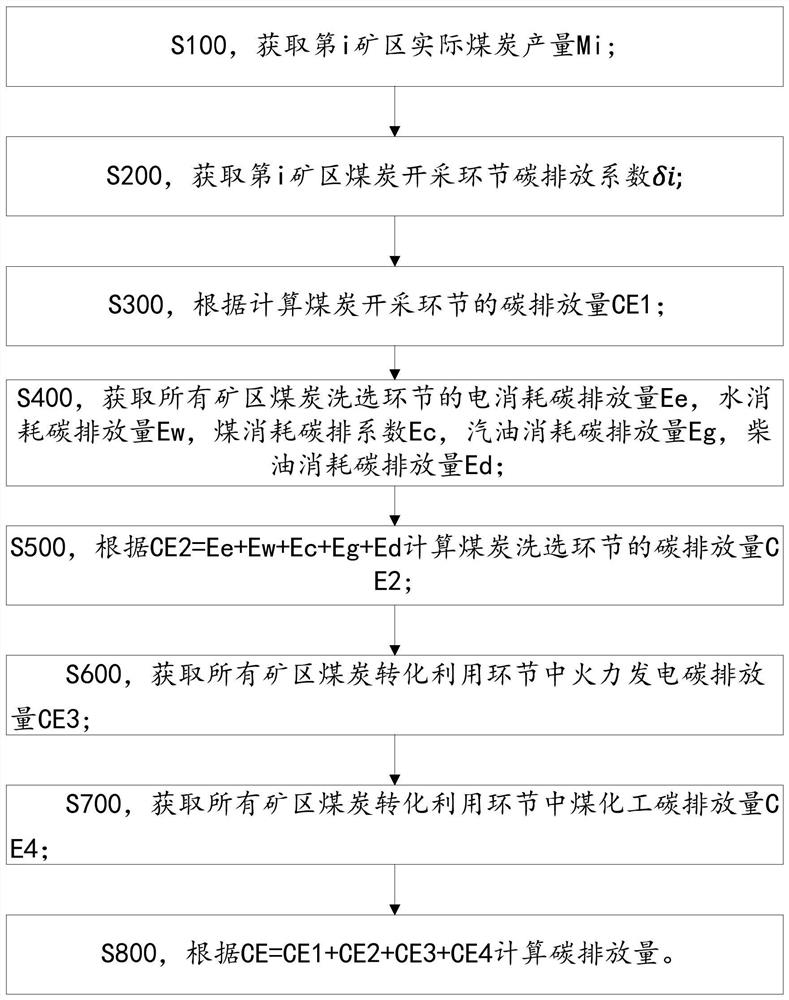

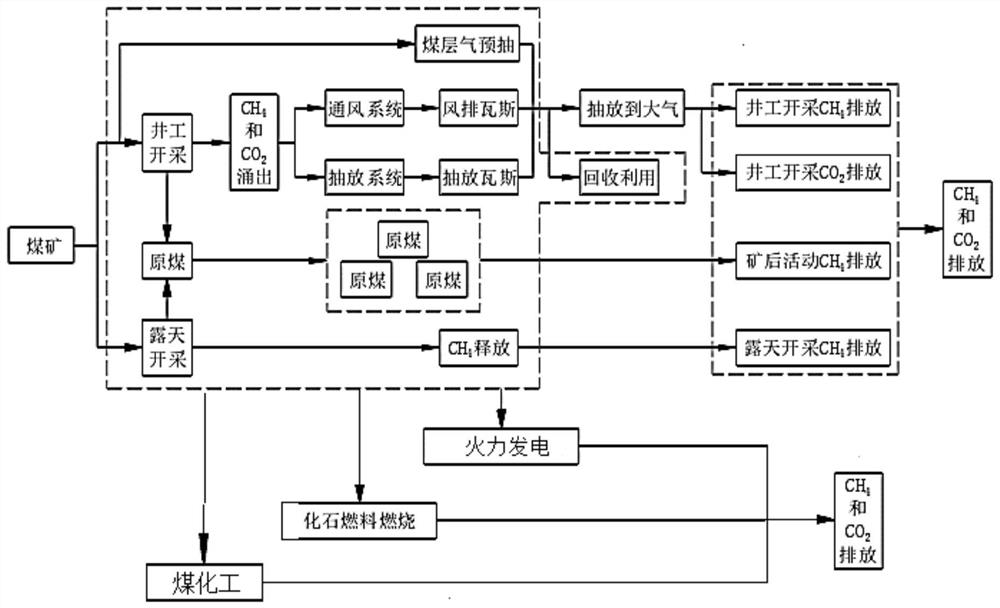

Carbon emission accounting method, storage medium and electronic equipment

PendingCN111784531AImprove accuracyAccounting realizationData processing applicationsTechnology managementGasolineCoal conversion

The invention discloses a carbon emission accounting method, a storage medium and electronic equipment. The method comprises the steps of acquiring the actual coal yield Mi of an ith mining area and the carbon emission coefficient delta i of a coal mining link ; calculating carbon emission CE1 of the coal mining link; obtaining the electricity consumption carbon emission Ee, the water consumptioncarbon emission Ew, the coal consumption carbon emission Ec, the gasoline consumption carbon emission Eg and the diesel consumption carbon emission Ed of a coal washing link; calculating the carbon emission CE2 according to CE2 = Ee + Ew + Ec + Eg + Ed; obtaining thermal power generation carbon emission CE3 and coal chemical industry carbon emission CE4 in all mining area coal conversion and utilization links; and calculating the carbon emission CE according to CE = CE1 + CE2 + CE3 + CE4. According to the invention, the accounting of the carbon emission of the whole industrial chain of a coalmine is realized to the greatest extent, and the accuracy of the carbon emission can be improved.

Owner:SHENHUA SHENDONG COAL GRP +1

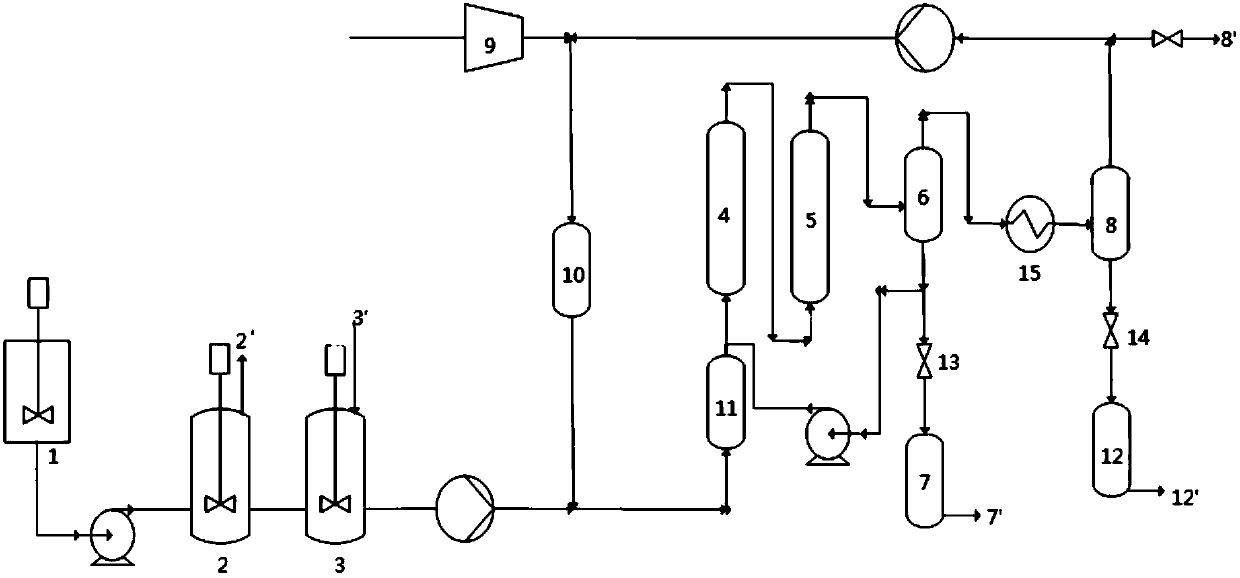

Coal liquefaction method and system thereof

ActiveCN107794073ARealize direct liquefactionImprove conversion rateLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsCoal conversionSolvent

The invention relates to the field of coal chemical processing, specifically to a coal liquefaction method and a system thereof. The coal liquefaction method comprises the following steps: mixing coalwith a hydrogen donor solvent so as to prepare a coal slurry; subjecting the coal slurry to pyrolysis so as to obtain a pyrolysis gaseous product and pyrolysis residues; mixing the pyrolysis residueswith a liquefaction catalyst, and transferring an obtained mixture and hot hydrogen to preheating treatment so as to obtain a hot liquefaction raw material; successively subjecting the hot liquefaction raw material to first liquefaction treatment and second liquefaction treatment; subjecting a product obtained by second liquefaction treatment to high-temperature gas-liquid separation so as to obtain a heavy oil component and a light component; and optionally, circularly transferring a part of the heavy oil component to first liquefaction treatment. The coal liquefaction method provided by theinvention can realize direct liquefaction treatment of coal, and achieves high coal conversion rate, low hydrogen consumption, low gas yield and water yield and high oil yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

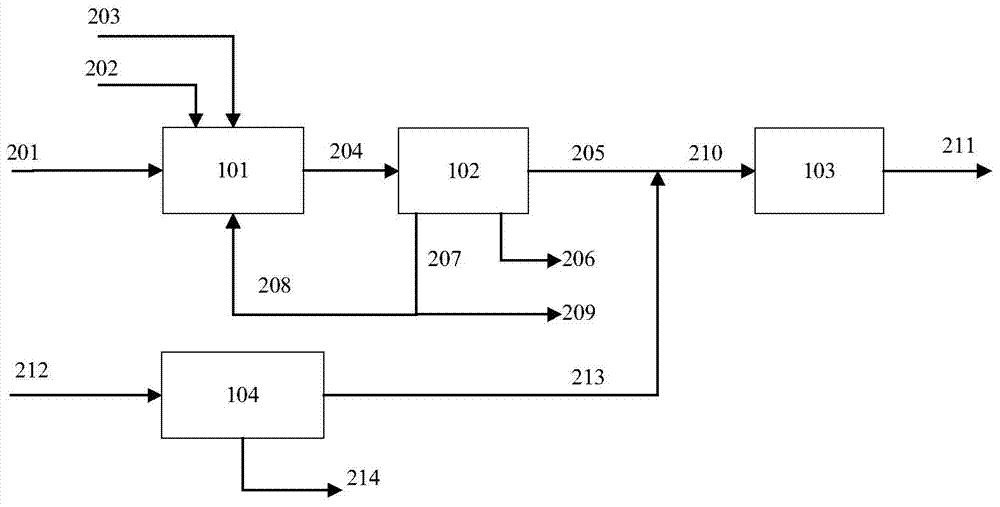

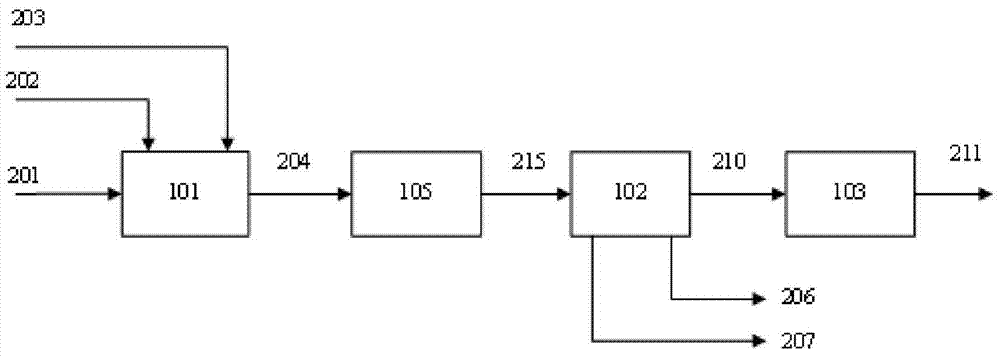

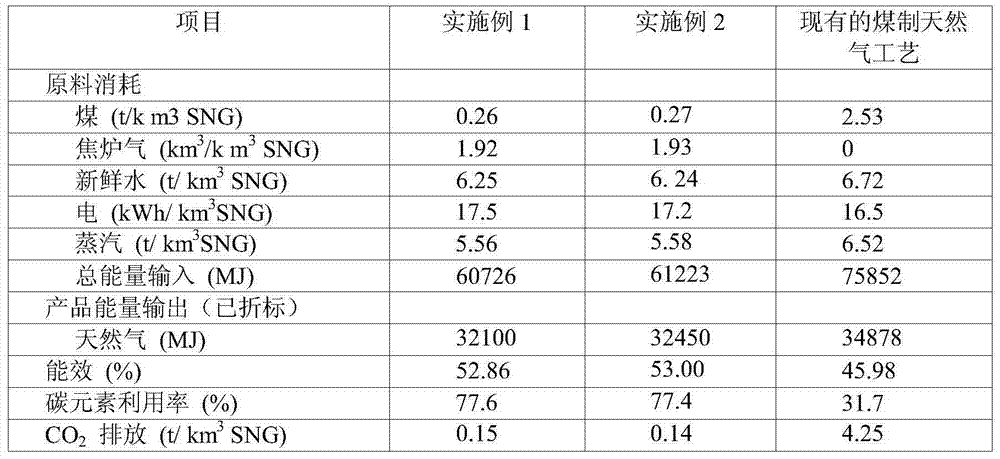

System and process for producing natural gas through combined supply of coal and coke-oven gas

The invention belongs to the technical field of energy and chemical engineering, and discloses a system and a process for producing natural gas through combined supply of coal and coke-oven gas. The system comprises a gasifying unit, an acidic gas removing unit, a methanation unit and a coke-oven gas purifying unit, wherein the gasifying unit is sequentially connected with the acidic gas removing unit; the coke-oven gas purifying unit is connected in parallel with the acidic gas removing unit and then is connected to the methanation unit. According to the process, raw coal is treated by the gasifying unit to generate rough synthesis gas; the rough synthesis gas is purified to remove sulfide and CO2 and generate clean synthesis gas; rough coke-oven gas is separated through the coke-oven gas purifying unit to obtain clean coke-oven gas; the coke-oven gas and the clean synthesis gas are mixed in ratio; the mixed gas is subjected to methanation by the methanation unit to generate natural gas. According to the system and the process, a water-coal conversion unit is saved; CO2 is recycled into the gasifying furnace to react again; meanwhile, the coke-oven gas replaces part of coal, so that the emission of CO2 and sewage in the gasifying process can be reduced, and the energy efficiency in the process is increased by not less than 8%.

Owner:SOUTH CHINA UNIV OF TECH

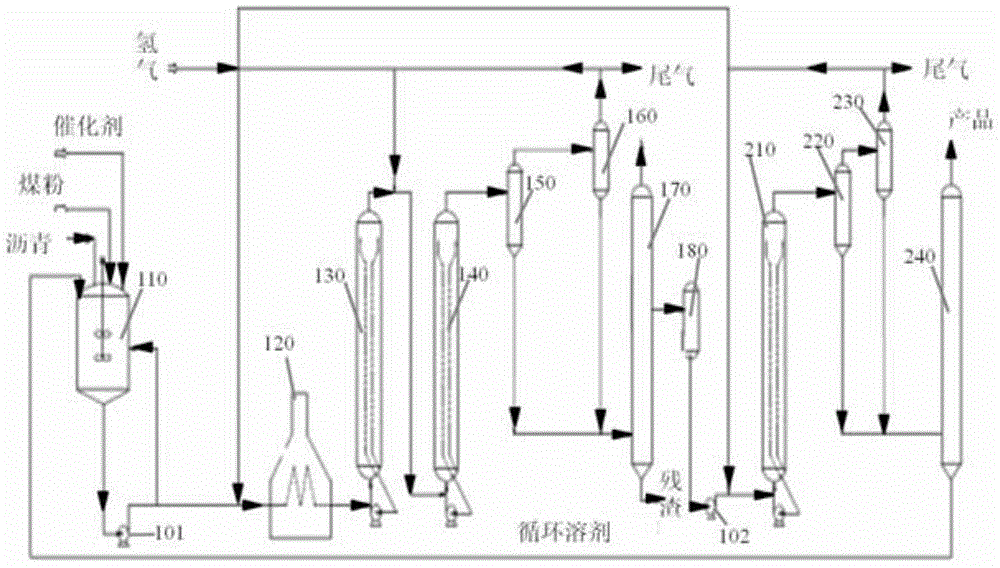

Preparation method of liquid fuel

ActiveCN104531197AHigh yieldMature technologyLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesCoal conversionLiquid fuel

The invention discloses a preparation method of a liquid fuel. The preparation method comprises the following steps: S1, mixing feed coal, asphalt and liquefaction cycle solvent to obtain oil-coal slurry; S2, carrying out a liquidation reaction on the oil-coal slurry in the presence of a catalyst, and carrying out gas-liquid separation on the product of the liquidation reaction to obtain coal liquefaction oil; and S3, carrying out a catalytic hydrogenation reaction on the coal liquefaction oil, and fractionating the liquid-phase product of catalytic hydrogenation to obtain the liquid fuel and the liquefaction cycle solvent. With the adoption of the preparation method provided by the invention, coal conversion rate and oil yield can both be increased; meanwhile, hydrogen consumption is reduced, and gas yield and water yield are reduced; the purpose of co-converting coal and asphalt into the automotive liquid fuel is realized, the problem of processing and utilization of asphalt substances is solved, the utilization value of asphalt is increased, and a new way is provided for the comprehensive utilization of the asphalt substances.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

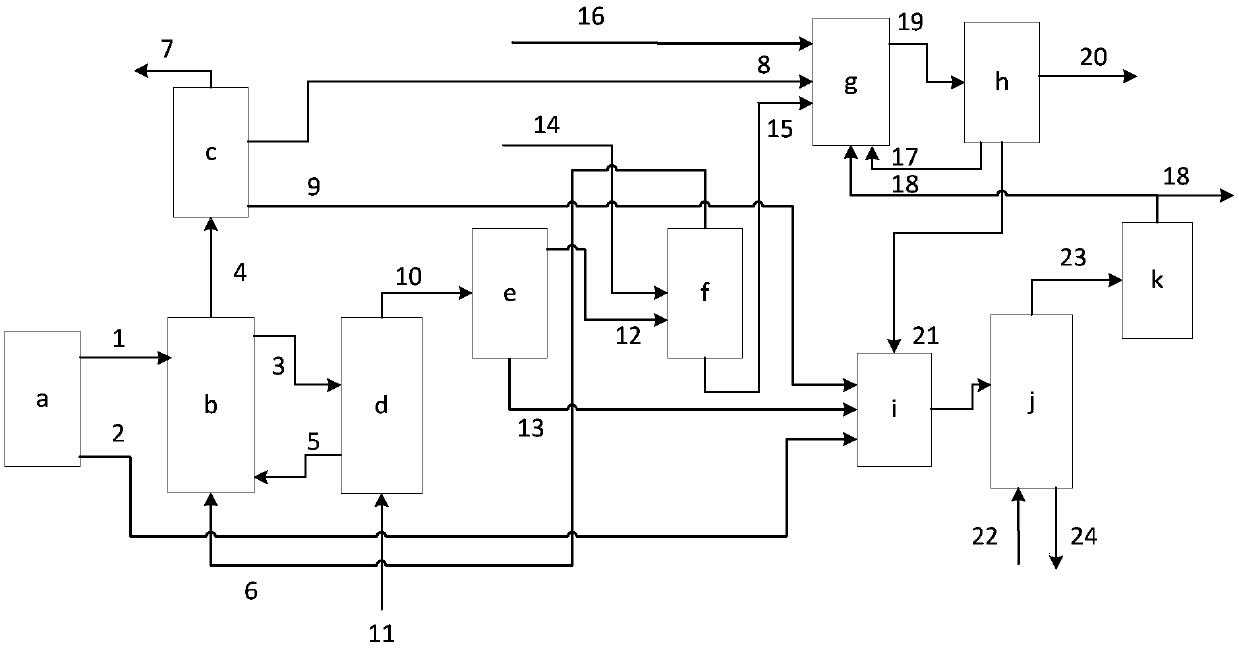

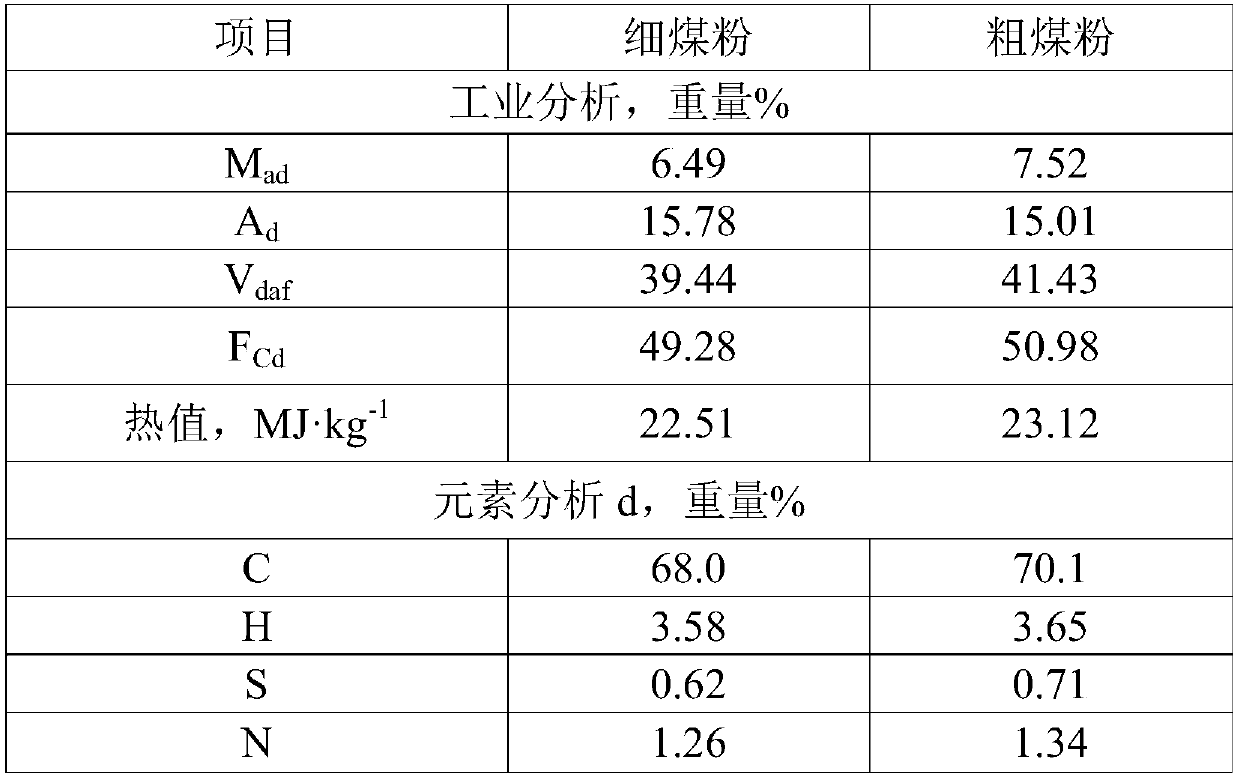

Method for graded conversion of low-rank coal and system for graded conversion of low-rank coal

ActiveCN110819390ARealize hierarchical, efficient and full conversionEfficient extractionGasification processes detailsTreatment with hydrotreatment processesSyngasPtru catalyst

The invention relates to the technical field of graded conversion of low-rank coal, and discloses a method for graded conversion of low-rank coal and a system for graded conversion of low-rank coal. The method comprises the following steps: (1) pretreating low-rank coal to obtain fine coal powder and coarse coal powder; (2) pyrolyzing the coarse coal powder to obtain coal tar, phenol-containing wastewater and the like; (3) carrying out a first gasification reaction on pyrolysis coke to obtain first coarse synthetic gas and hot semicoke; (4) separating the first coarse synthetic gas to obtain first fine coke powder and second coarse synthetic gas; (5) preparing a hydrogenation catalyst from the second coarse synthetic gas and an active metal element salt; (6) carrying out a hydrocracking reaction on the coal tar; and (7) preparing coke coal slurry from the fine coal powder, the phenol-containing wastewater and the like, and carrying out a second gasification reaction. According to the invention, deep coupling of the coal pyrolysis gasification technology and the clean fuel preparation technology is realized, and the difficult problems of graded high-efficiency utilization and cleanconversion of low-rank coal resources are solved. The method has the characteristics of high coal conversion rate, good integration, low catalyst cost, no discharge of dangerous solid waste and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal-oil hydroprocessing coal-loaded catalyst, preparation method and application thereof

InactiveCN107159271AImprove hydrogenation activityGood focus reduction effectPhysical/chemical process catalystsHydrocarbon oil crackingIron saltsCoal conversion

The invention provides a coal-oil hydroprocessing coal-loaded catalyst, a preparation method and application thereof. The catalyst contains an active ingredient, a co-active ingredient and a carrier, wherein the active ingredient is iron and molybdenum in a molar mass ratio of 35:1-1:1, the iron is water-soluble iron salt, and molybdenum is water-soluble molybdenum salt; the co-active ingredient is sulfide having a molar mass ratio to the active ingredient of 1:3-1:5; and the carrier is pulverized coal. The preparation method comprises the following steps: (1) weighing iron salt and molybdenum salt, adding into water to prepare a salt mixed solution; (2) adding sulfide and a proper amount of alcohol into the salt mixed solution, uniformly stirring and mixing, heating while stirring to a proper temperature, and adding pulverized coal to react; and (3) cooling to room temperature after the reaction in the step (2) is completed, and drying. The catalyst has the advantages of high hydrogenation activity, good coke inhibiting effect, high coal conversion rate and the like, is simple in preparation, and is suitable for large-scale industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

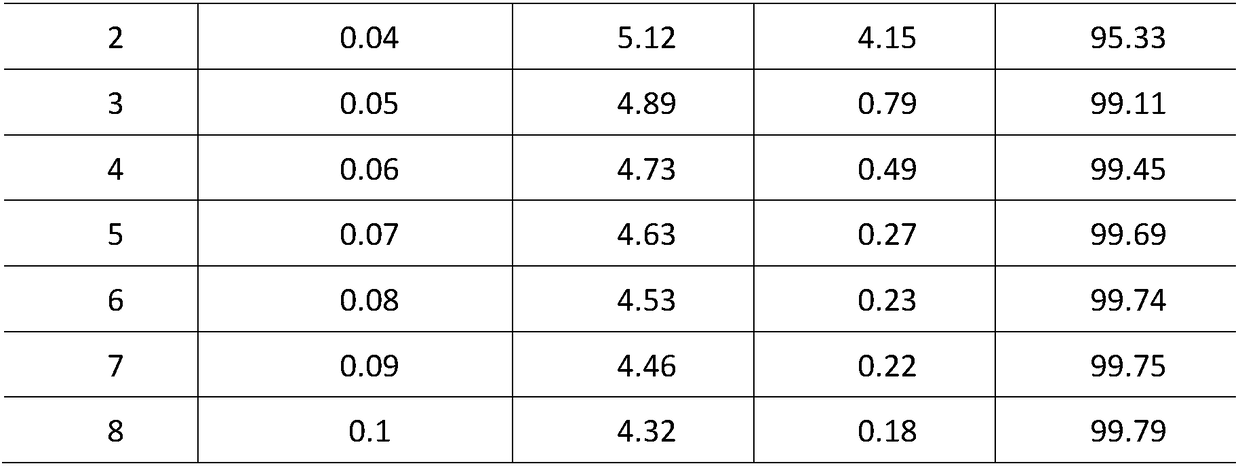

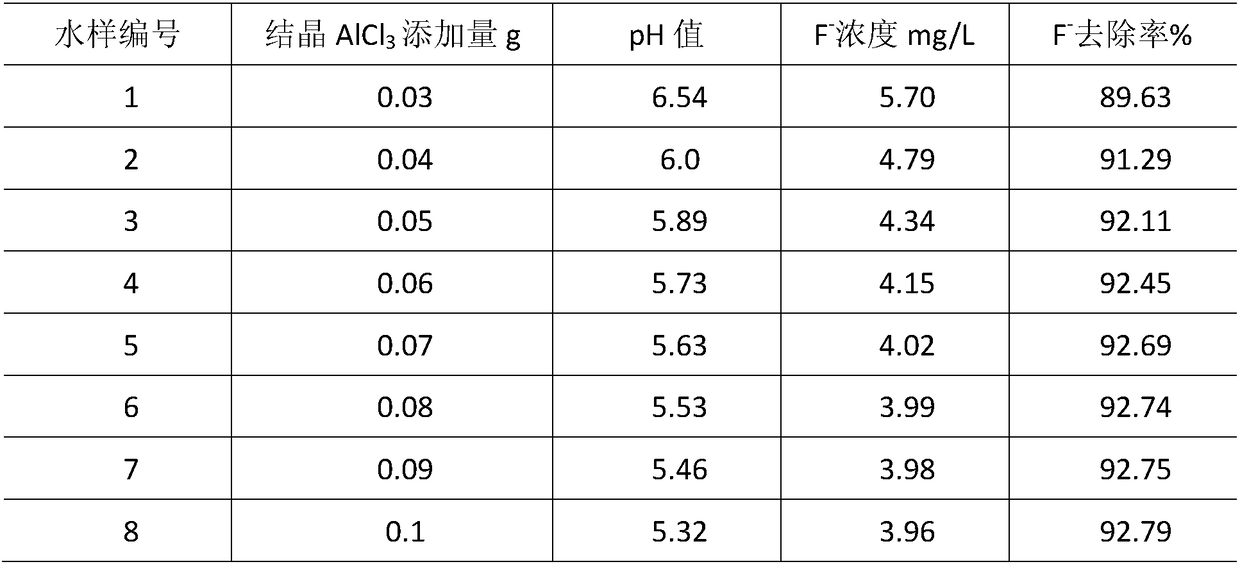

Method for removing fluorides from coal conversion wastewater

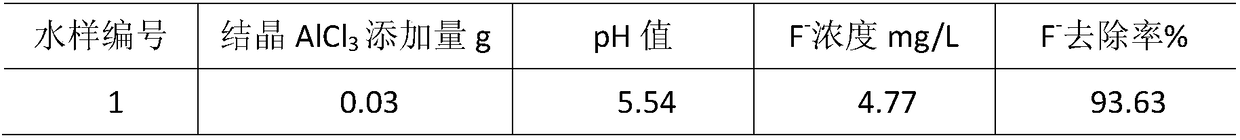

InactiveCN108585157ABest fluoride removal rateLower pHWater treatment parameter controlWater contaminantsHigh concentrationUltrafiltration

The invention discloses a method for removing fluorides from coal conversion wastewater, particularly fluorides in high-concentration brine of the coal conversion wastewater. The method comprises thespecific steps: draining the wastewater into a treatment tank, then, adding crystals AlCl3, and lowering the fluoride ion concentration of the coal conversion wastewater by adopting a coagulation settling method, wherein the mass / volume ratio of the crystals AlCl3 to the wastewater is 0.3g / L to 0.5g / L, and the fluoride ion content of treated wastewater is lower than 6mg / L. The coal conversion wastewater is complicated in water mass, is subjected to pretreatment and biochemical treatment, then, is subjected to ultrafiltration and reverse-osmosis membrane treatment and is subjected to advanced wastewater treatment and recycling. If the fluorides in the coal conversion wastewater enter a reverse osmosis membrane system for circulating concentration and produce calcium fluoride scales, flux and service lives of reverse osmosis membranes are seriously affected. According to the method disclosed by the invention, for complicated coal conversion wastewater, the crystals AlCl3 are selected asa coagulant, the coal conversion wastewater prior to entering the membrane system and the high-concentration brine subjected to membrane treatment are subjected to fluorine removing treatment, thus, the wastewater can meet the requirements of reverse osmosis concentrating, and the calcium fluoride scales are not produced.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com