Methanation catalyst and application thereof

A methanation catalyst and silicification technology, applied in the field of metal silicide catalysts, can solve the problems of Fe-based catalyst deactivation, poor methane selectivity, loss of active components, etc., and achieve high methane selectivity, strong sulfur resistance, and synthesis cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

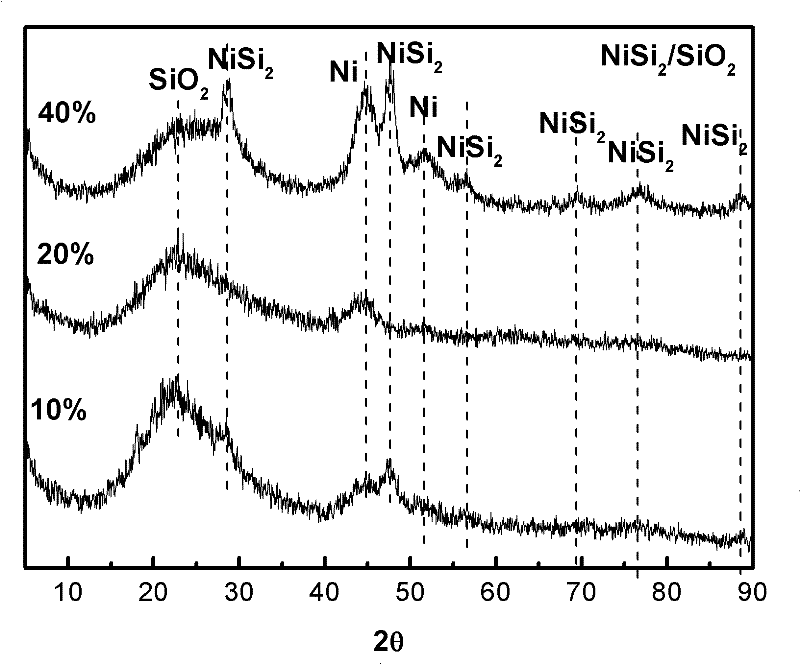

[0018] Example 1: 40% NiSi 2 / SiO 2 Catalyst preparation

[0019] Take 0.3g 40%NiO / SiO 2 placed in a quartz reactor. First pass Ar into it for purging, then switch to H 2 (30sccm), it is reduced at 450°C for 4h, and the resulting reduction product is in the same H 2 Cool to silicide temperature (250-450°C) under atmosphere to silicide it, and pass 10vol.% SiH into it 4 / H 2 Mixed gas for 15min, the total gas velocity is 100sccm, after the reaction is over, close the SiH 4 , at H 2 Cool to room temperature under the atmosphere, passivate it under the Ar atmosphere, that is, get 40% NiSi 2 / SiO 2 catalyst.

Embodiment 2

[0020] Example 2: 40% CoSi 2 / SiO 2 Catalyst preparation

[0021] Take 0.3g 40% Co 3 o 4 / SiO 2 placed in a quartz reactor. First pass Ar into it for purging, then switch to H 2 (30sccm), it is reduced at 450°C for 4h, and the resulting reduction product is in the same H 2 Cool to silicide temperature (250-450°C) under atmosphere to silicide it, and pass 10vol.% SiH into it 4 / H 2 Mixed gas for 15min, the total gas velocity is 100sccm, after the reaction is over, close the SiH 4 , at H 2 Cool to room temperature under the atmosphere, passivate it under the Ar atmosphere, that is, get 40% CoSi 2 / SiO 2 catalyst.

Embodiment 3

[0022] Example 3: 20% FeSi 2 / SiO 2 Catalyst preparation

[0023] Take 0.3g 20% Fe 2 o 3 / SiO 2 placed in a quartz reactor. First pass Ar into it for purging, then switch to H 2 (30sccm), it was reduced at 500°C for 4h, and the resulting reduction product was 2 Cool to silicide temperature (350-550°C) under atmosphere to silicide it, and pass 10vol.% SiH into it 4 / H 2 Mixed gas for 15min, the total gas velocity is 100sccm, after the reaction is finished, close the SiH4 , at H 2 Cool to room temperature under the atmosphere, passivate it under the Ar atmosphere, that is, get 20% FeSi 2 / SiO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com