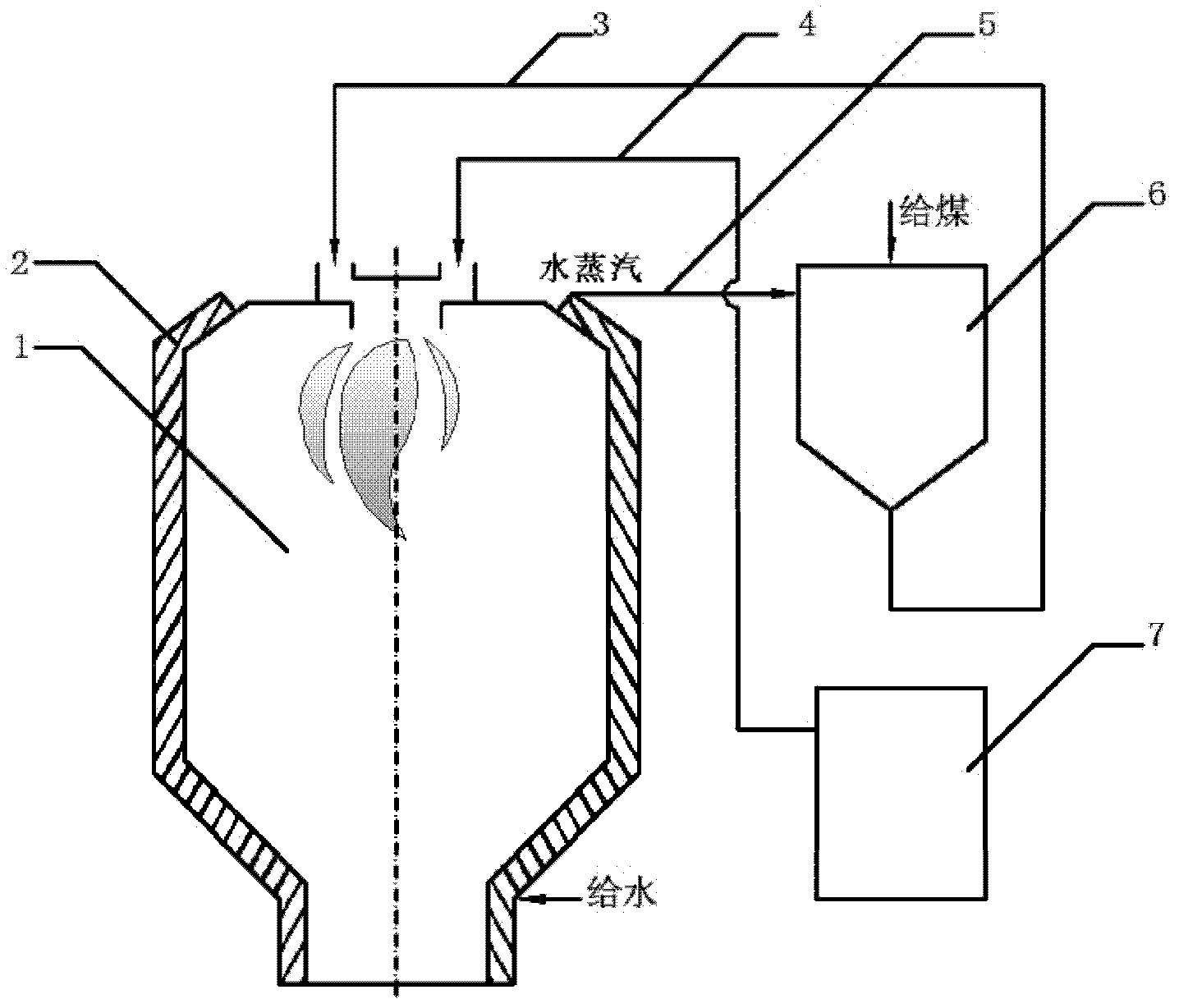

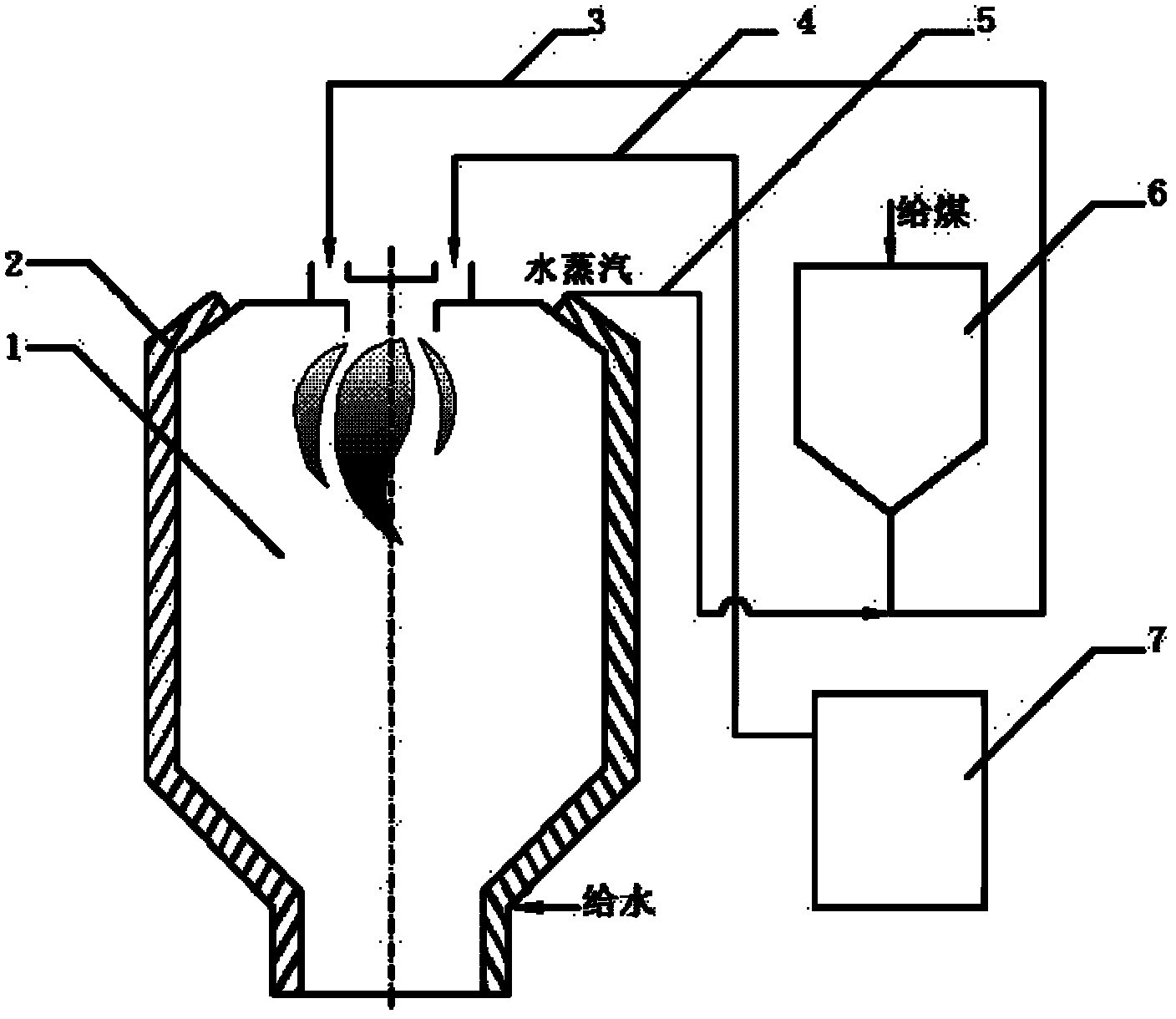

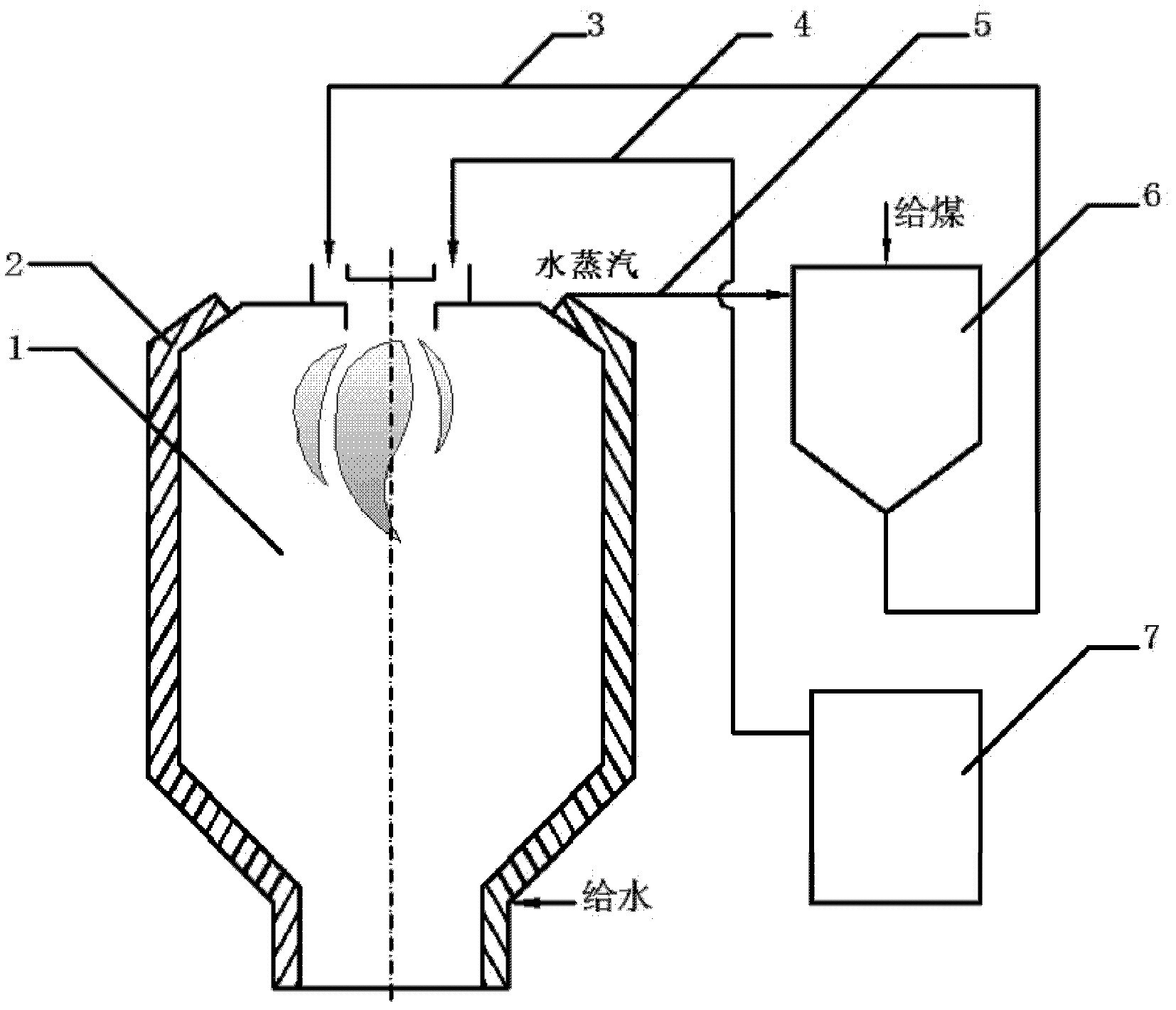

Entrained-flow bed gasification system and method for vapour conveyed pulverized coal

An entrained flow and water vapor technology is applied in the field of coal gasification system, which can solve the problems such as restricting the improvement of the thermal efficiency of the gasifier to improve the purity of the synthesis gas, affecting the safe operation of the gasifier, reducing the purity of the synthesis gas, etc., so as to reduce the sensible heat. loss, avoidance of heat loss, effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Set the calorific value of coal for gasification to 29MJ / kg, the coal feed rate is 1kg / s, the mass flow rate of the high-temperature superheated steam generated by the water wall is 25% of the coal feed rate, that is, 0.25 kg / s, then the water wall absorbs 2% of the heat generated by coal can heat the unsaturated water with an initial temperature of 67°C into high-temperature superheated steam with a temperature of 480°C and a pressure of 5.5MPa. The high-temperature superheated steam is used to heat pulverized coal with an initial temperature of 187°C with a supply amount of 1 kg / s, and finally a mixture of steam and pulverized coal at 270°C is formed. Under the above-mentioned mass ratio, the concentration of pulverized coal in the mixture of steam and pulverized coal is much lower than that of conventional nitrogen conveying pulverized coal, which fundamentally alleviates the accident of pulverized coal. The high-temperature superheated steam is used as the carrier ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com