Plasma coal cracking reaction apparatus relating to flow screening component

A plasma and reaction device technology, which is applied in the field of plasma coal cracking reaction device, can solve the problems of easily damaged electrodes, low energy utilization efficiency, and the difficulty of increasing the mixing effect of coal powder and plasma jet, so as to achieve coal conversion and Improved heat conversion capacity, enhanced contact and mixing efficiency, and facilitated engineering scale-up design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

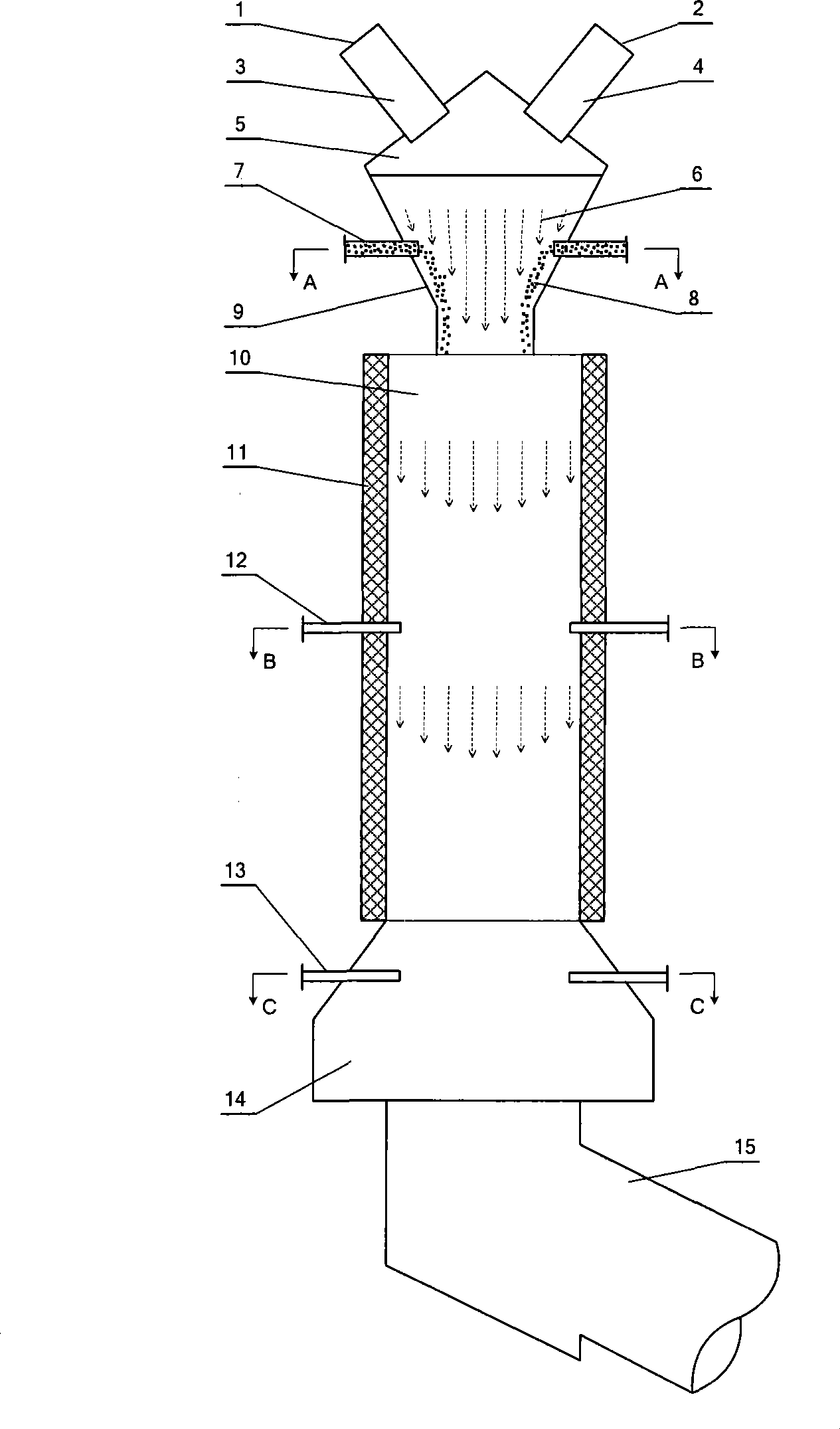

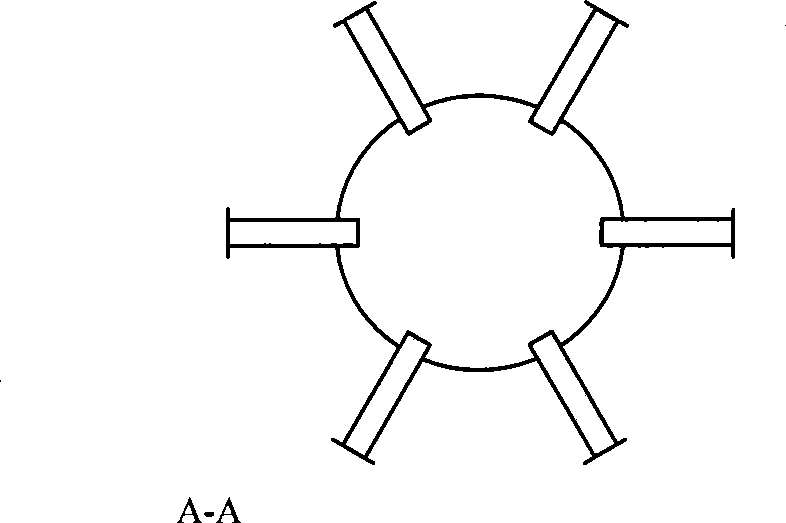

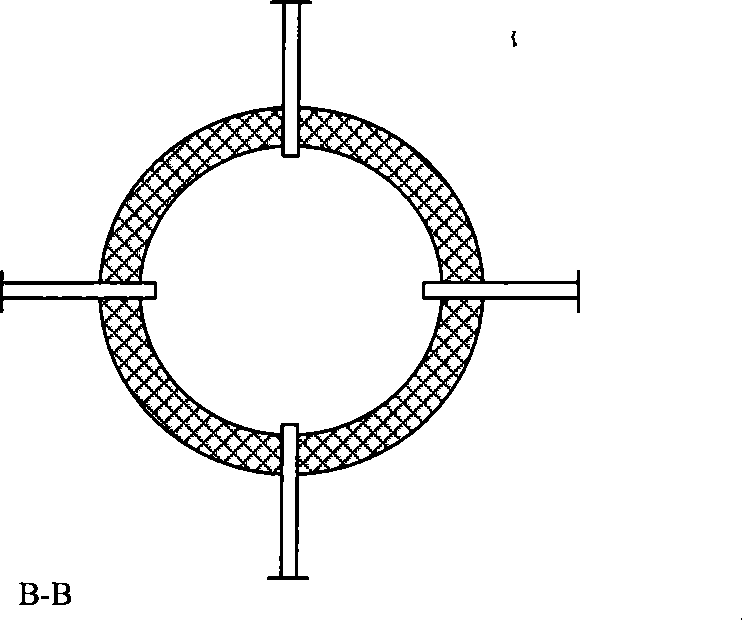

[0036] Figure 1a It is a schematic diagram of a plasma coal cracking reaction device without a shielding member, Figure 1b for Figure 1a A-A cross-sectional view of the mixing zone of the reaction device, Figure 1c for Figure 1a The B-B sectional view of the reaction zone of the middle reaction device, Figure 1d for Figure 1a C-C sectional view of the quenching zone of the medium reaction device. Such as Figure 1aAs shown, the plasma coal cracking reaction device without a shielding member includes: plasma torch anode working gas inlet 1, plasma torch cathode working gas inlet 2, plasma torch anode 3, plasma torch cathode 4 and plasma torch cathode and anode Convergence zone 5; mixing zone 9 and pulverized coal injection pipe 7; reaction zone 10, reaction zone wall surface 11 and reaction zone feed gas injection tube 12; quenching zone 14, quenching medium injection tube 13 and quenching zone outlet 15.

[0037] The plasma torch uses hydrogen as the working gas, the ...

Embodiment 2

[0043] This example is based on the improved plasma coal cracking reaction device in Example 1, and the reaction area shielding member is added.

[0044] Under the process conditions described in Example 1, the average temperature of the reaction zone is 1800-2500K, which is higher than the lowest temperature of 1400K for the formation and stable existence of acetylene. 12 The mixed gas of light aromatic fractions in coal tar and propane supplementary raw materials enters the reaction zone to participate in the cracking reaction, making full use of the heat in the reaction zone. The volume concentration of acetylene in the gas.

[0045] When no flow-shielding member is installed, the velocity of the reactant flow in the reaction zone 10 is 200-400m / s, and the velocity of the jet flow formed after the supplementary raw material mixture is sprayed through the raw material gas injection pipe 12 in the reaction zone is 40-80m / s, and its incident depth Not ideal enough, the contac...

Embodiment 3

[0050] This example is based on the improved plasma coal cracking reaction device in Example 2, and the quenching zone shielding member is added. Under the process conditions described in Example 2, the inlet temperature of the quenching zone is 1400-1800K, and water is used as the quenching medium to instantly cool the reactant flow to 600-800K. The cooling rate of 107-108K / s is the first necessary condition to ensure the acetylene yield in the process of plasma coal cracking to acetylene; the sufficient contact between the quenching medium and the reactant stream is the second necessary condition to ensure the acetylene yield.

[0051] When no blocking member is installed, the velocity of the reactant flow in the quenching zone 14 is 150-300m / s, and the velocity of the jet formed after the water is sprayed by eight quenching medium injection pipes 13 with an outer diameter of 5mm and an inner diameter of 4mm is 60-100m / s , The contact ratio with the reactant stream is 60-70%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com