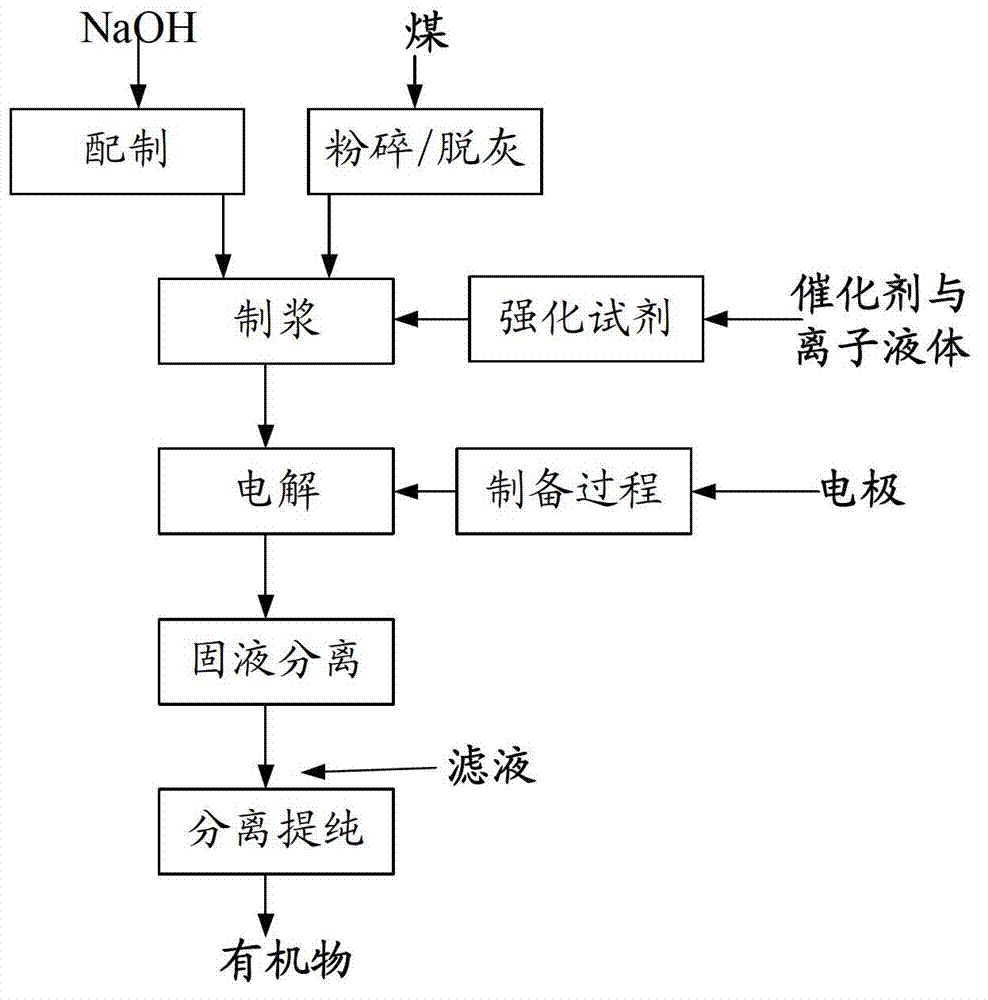

Method for preparing organics by strengthening electrolysis of coal slurry under alkaline system

A technology of organic matter and coal slurry, applied in the direction of electrolytic organic production, electrolytic process, electrolytic components, etc., can solve the problem of low organic matter output, achieve the effect of small investment, strong controllability, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

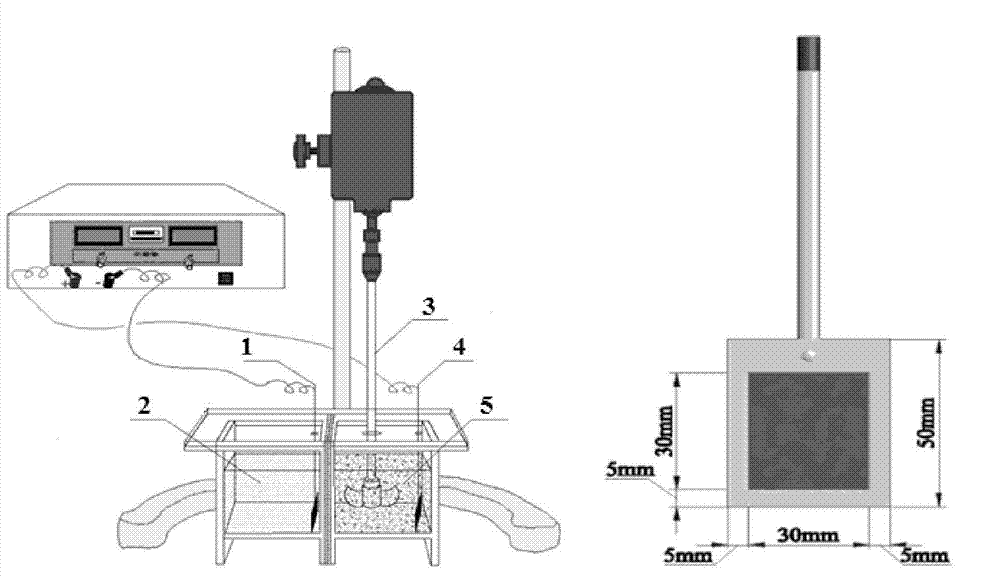

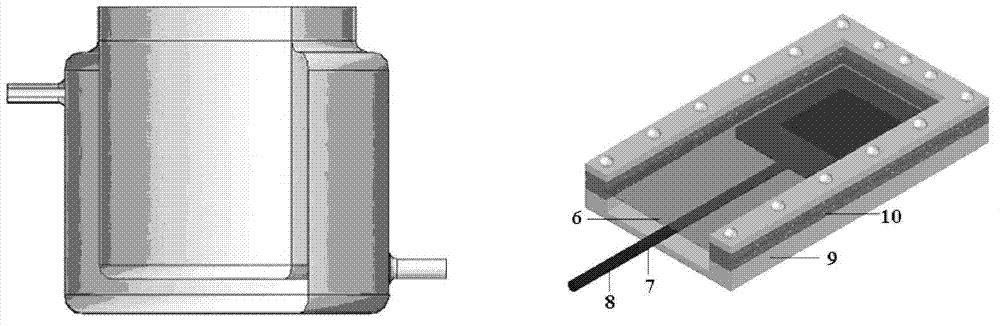

Embodiment 1

[0054] The coal quality analysis of the coal sample is shown in Table 1. The coal was crushed to below 74 microns and dried. Prepare an effective area of 9cm with an iron plate 2 The square is coated with silica gel to ensure the insulation of other parts; and NaOH solution is prepared, and [BP y ] Br. Place the iron electrodes in the anode / cathode compartments of the square electrolytic cell respectively, add electrolyte, and add coal powder into the anode compartment to ensure that the concentration of coal slurry is 50g / L, [BP y ] The concentration of Br is 0.1mol / L, and the concentration of NaOH is 1mol / L. Use a constant voltage and constant current power supply to control the current at 1A, and conduct constant current electrolysis at 30°C for 6 hours. After the reaction, the total organic carbon concentration value of the primary filtrate is 1128mg / L.

Embodiment 2

[0056] The coal quality analysis of the coal sample is shown in Table 1. The coal was crushed to below 74 microns and dried. Draw the iron plate with an effective area of 9cm 2 The other parts were coated with silica gel, dried for later use, and NaOH solution was prepared, and then [OMim]Br was added. Place the iron electrodes in the cathode / anode compartments of the square electrolytic cell respectively, add electrolyte, and add coal powder into the anode compartment to ensure that the concentration of coal slurry is 40g / L, the concentration of [OMim]Br is 0.2mol / L, NaOH The concentration is 2mol / L, and the current is controlled by a constant voltage and constant current power supply at 1A, and the constant current is electrolyzed at 30°C for 6h. After the reaction, the total organic carbon concentration of the primary filtrate is 1210mg / L.

Embodiment 3

[0058] The coal quality analysis of the coal sample is shown in Table 1. The coal was crushed to below 74 microns and dried. Draw the iron plate with an effective area of 9cm 2 The other parts were coated with silica gel, dried for later use, and NaOH solution was prepared, and [BMim]Cl was added. Place the iron electrodes in the cathode / anode chambers of the square electrolytic cell respectively, add electrolyte, and add coal powder into the anode chamber to ensure that the concentration of coal slurry is 20g / L, the concentration of [BMim]Cl is 0.1mol / L, NaOH The concentration is 1mol / L, and the constant current is electrolyzed at 1A at 85°C for 6 hours with a constant voltage and constant current power supply. After the reaction, the total organic carbon concentration value of the primary filtrate is 1717mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com