Nickel-based high dispersion emulsion catalyst, preparation method and application thereof

A catalyst and high-dispersion technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve the problems of unsuitability for large-scale industrial production, large amount of acid catalyst addition, poor catalyst dispersion performance, etc. problem, to achieve the effect of simplifying the multi-stage emulsification and dispersion process, good coke suppression effect and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A nickel-based high-dispersion emulsion catalyst, the catalyst active component is nickel, the weight content of nickel in the catalyst is 5.01%, and its preparation method is as follows:

[0029] (1) Take 13.84g Ni(NO 3 ) 2 ·6H 2 O, 0.40g sodium lauryl sulfonate, add 4.27g deionized water;

[0030] (2) Take another 0.80g Span-80, add 30g 400N base oil, heat to 70°C and stir at a shear speed of 2000r / min; 150N base oil, 400N base oil, clay refined wax oil

[0031] (3) Slowly add the water phase into the container containing the oil phase, shear and disperse at 70°C for 10 minutes, the dispersion speed is 2000r / min, cool to room temperature after the dispersion is completed, and it is a nickel-based high-dispersion emulsion catalyst.

Embodiment 2

[0033] A nickel-based high-dispersion emulsion catalyst, the catalyst active component is nickel, the weight content of nickel in the catalyst is 5.01%, and its preparation method is as follows:

[0034] (1) Get 13.84g nickel carbonate, 0.60g sodium dodecylbenzenesulfonate, add 43.3g deionized water;

[0035] (2) Take another 0.60g of Span-85, add 30g of 150N base oil, heat to 50°C and stir at a shear speed of 4000r / min;

[0036] (3) Slowly add the water phase into the container containing the oil phase, shear and disperse at 50°C for 15 minutes, and disperse at a speed of 1000r / min. After the dispersion is completed, cool to room temperature, which is a nickel-based high-dispersion emulsion catalyst.

Embodiment 3

[0038] A nickel-based highly dispersed emulsion catalyst, the catalyst active component is nickel, and the weight content of nickel in the catalyst is 6.04%. Its preparation method is as follows:

[0039] (1) Get 17.63g nickel chloride, 0.24g cetyltrimethylammonium bromide and 0.24g Tween-80, add 10g deionized water;

[0040] (2) Take another 0.72g of oleic acid, add 30g of clay refined wax oil, heat to 80°C and stir at a shear speed of 1000r / min;

[0041] (3) Slowly add the water phase into the container containing the oil phase, shear and disperse at 80°C for 5 minutes at a dispersing speed of 4000r / min, cool to room temperature after dispersing, and it becomes a nickel-based high-dispersion emulsion catalyst.

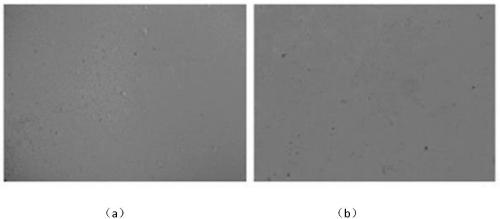

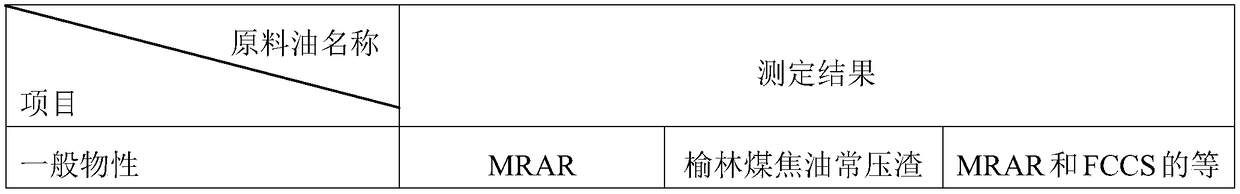

[0042] The stability parameters of the prepared catalysts are shown in Table 1.

[0043] Table 1 catalyst stability data

[0044] Catalyst name

Stable parameter / % after standing for 5 days

Stable parameter / % after standing for 15 days

Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com