Coal liquefaction method and system thereof

A technology for liquefaction treatment and coal slurry is applied in the field of coal liquefaction method and system, which can solve the problems of high liquefaction cost, low light oil yield and high hydrogen consumption, and achieve low gas and water yield and high conversion. efficiency, low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] This embodiment is used to illustrate the coal liquefaction method and system of the present invention.

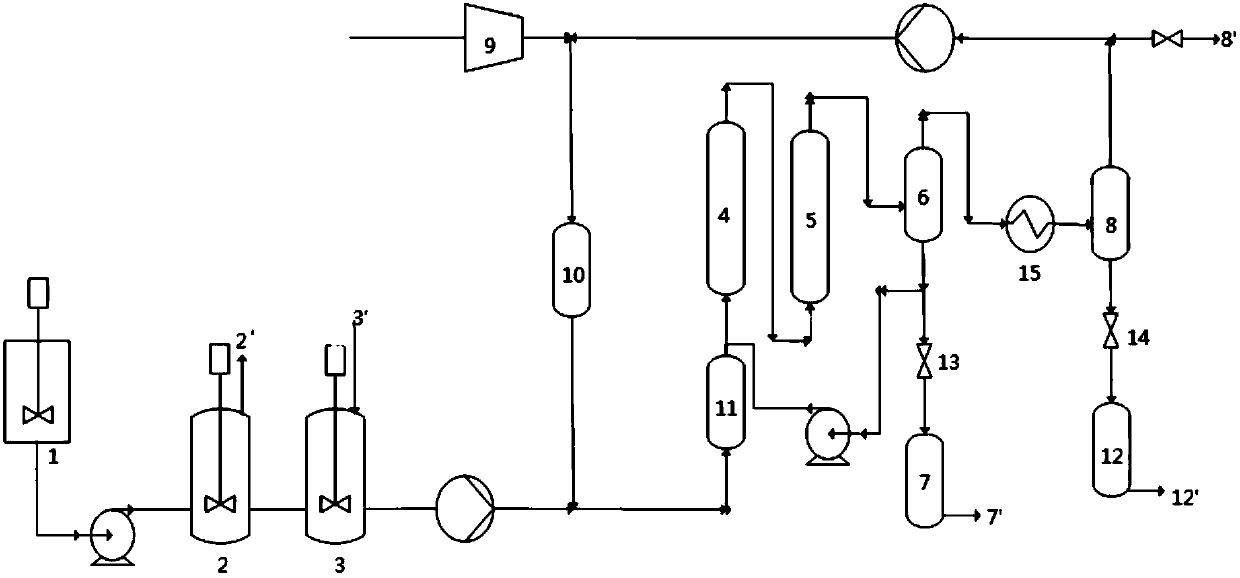

[0100] use figure 1 In the system shown, the above-mentioned coal powder and the hydrogen-donating solvent are mixed in the coal slurry preparation device 1 according to the mass ratio of 40:60, and the mixed coal slurry is pumped to the pyrolyzer 2 for pyrolysis, and the heat is collected The decomposed gaseous material is separated and analyzed, and the pyrolysis residue is sent to the mixing device 3 to mix with the main catalyst and the co-catalyst entering by the catalyst feeding port (wherein, relative to the consumption of dry coal powder, the consumption of the main catalyst is 3 wt. %, the amount of co-catalyst is 2.4% by weight); the material obtained by mixing is merged with hot hydrogen (the temperature of the hot hydrogen is 200° C.) and sent to the liquefied material preheater for preheating; then the preheated The material is sent to the first liquef...

Embodiment 2

[0107] This embodiment is used to illustrate the coal liquefaction method and system of the present invention.

[0108] Carry out the liquefaction of coal according to the method described in embodiment 1, difference is, wherein:

[0109] The pyrolysis conditions include: temperature is 400°C, residence time is 45min, gauge pressure is 0.8MPa;

[0110] The conditions of the first liquefaction treatment include: the temperature is 445°C, the residence time is 90min, and the gauge pressure is 19MPa;

[0111] The conditions of the second liquefaction treatment include: the temperature is 450°C, the residence time is 90min, and the gauge pressure is 19MPa;

[0112] The conditions for high-temperature gas-liquid separation include: the temperature is 430°C, the residence time is 20min, and the gauge pressure is 19MPa;

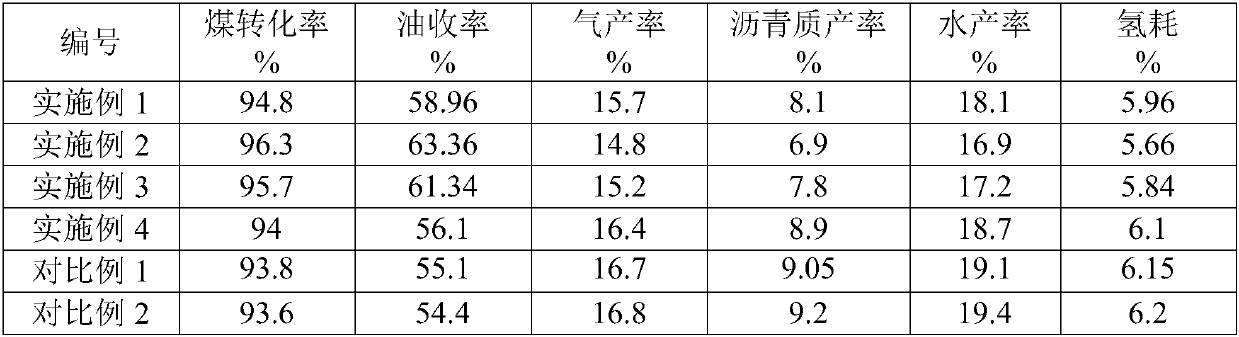

[0113] The analysis results are shown in Table 1.

Embodiment 3

[0115] This embodiment is used to illustrate the coal liquefaction method and system of the present invention.

[0116] Carry out the liquefaction of coal according to the method described in embodiment 1, difference is, wherein:

[0117] The pyrolysis conditions include: temperature 350°C, residence time 37min, gauge pressure 0.65MPa;

[0118] The conditions of the first liquefaction treatment include: the temperature is 437°C, the residence time is 50min, and the gauge pressure is 18MPa;

[0119] The conditions of the second liquefaction treatment include: the temperature is 455°C, the residence time is 50min, and the gauge pressure is 18MPa;

[0120] The conditions for high-temperature gas-liquid separation include: the temperature is 415°C, the residence time is 13min, and the gauge pressure is 18MPa;

[0121] The analysis results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com