Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Aldehyde synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stephen aldehyde synthesis, a named reaction in chemistry, was invented by Henry Stephen (OBE/MBE). This reaction involves the preparation of aldehydes (R-CHO) from nitriles (R-CN) using tin(II) chloride (SnCl 2), hydrochloric acid (HCl) and quenching the resulting iminium salt ([R-CH=NH 2] + Cl ...

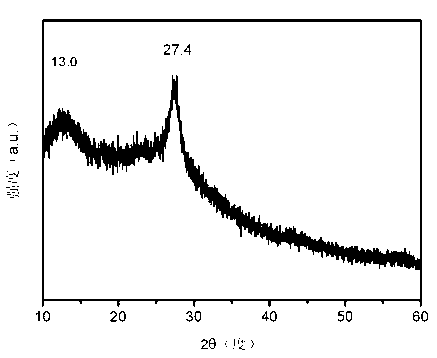

Polymer photocatalyst, and method of water-phase photo-catalytic selective alcohol oxidation

InactiveCN103127948AImprove conversion rateGood choicePhysical/chemical process catalystsOrganic compound preparationPtru catalystUltraviolet

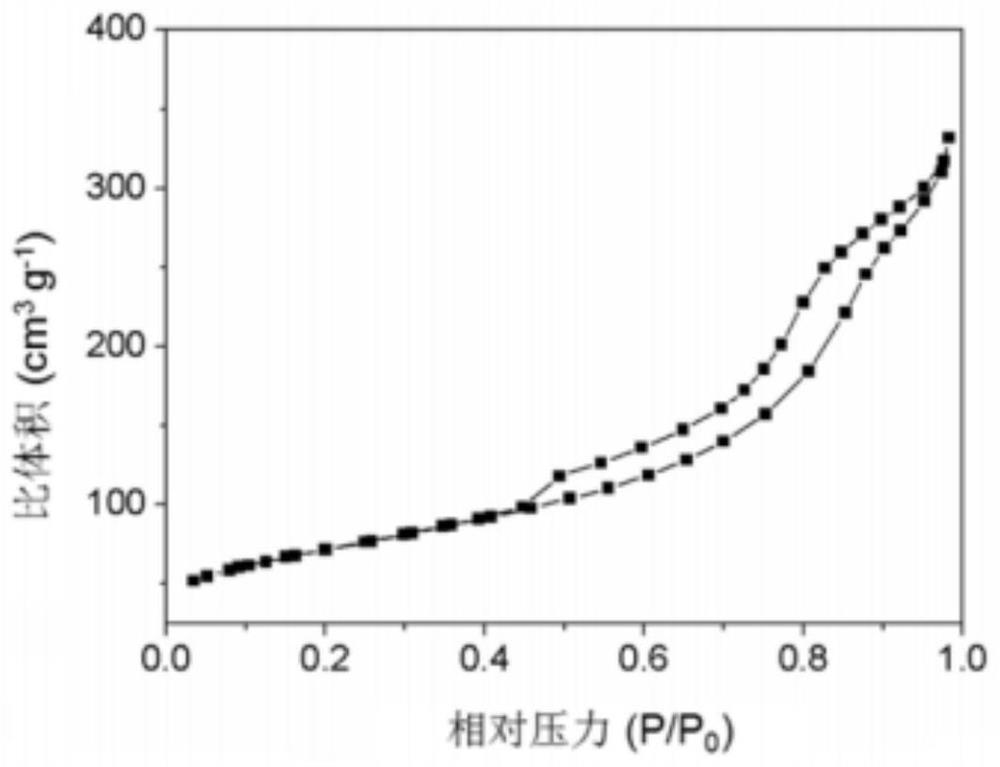

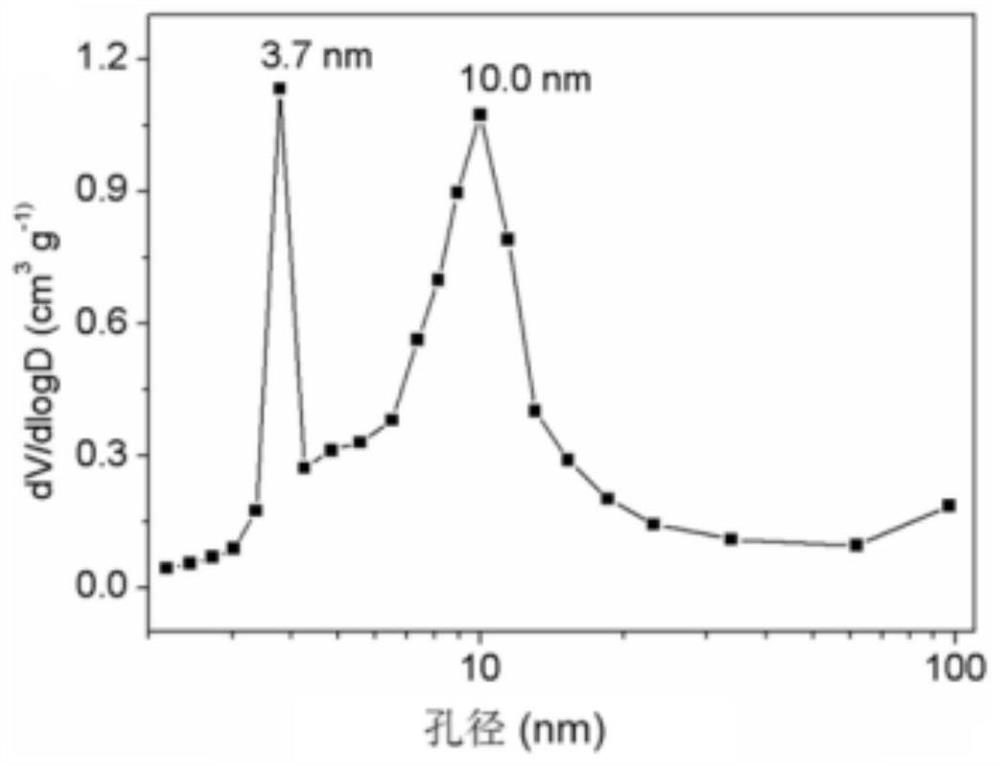

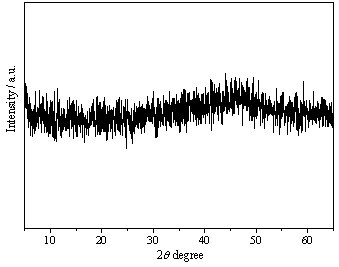

The invention discloses a polymer photocatalyst and a method of water-phase photo-catalytic selective alcohol oxidation. According to the invention, an organic polymer carbon nitride catalyst is prepared, and is applied in a water-phase photo-catalytic selective alcohol oxidation system. Compared with common ultraviolet catalyst TiO2, visible light catalyst TiO2-xNx, metal sulfide, metal nitride, metal nitrogen oxides, and the like, when alcohol is oxidized in water phase with a green oxidant air / oxygen under mild conditions, the carbon nitride catalyst is more stable and shows higher efficiency. The preparation method of the carbon nitride catalyst is simple and feasible, and the catalyst comprises no metal element, such that the catalyst is cheap. With the catalyst, alcohol oxidation aldehyde synthesis or ketone synthesis processes are simple and feasible, such that industrialized large-batch productions of aldehyde and ketone compounds can be facilitated.

Owner:FUZHOU UNIV

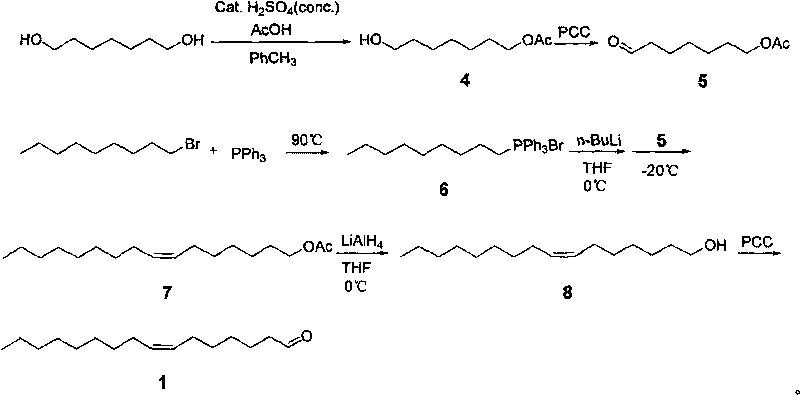

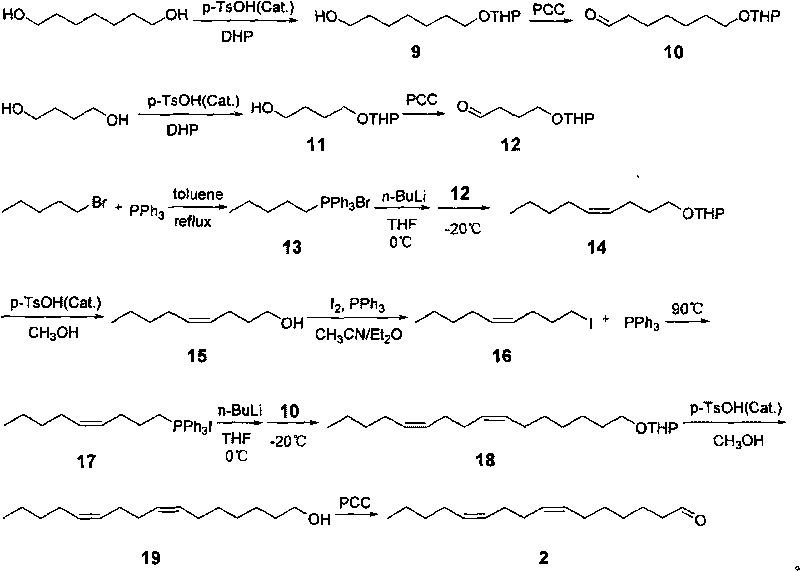

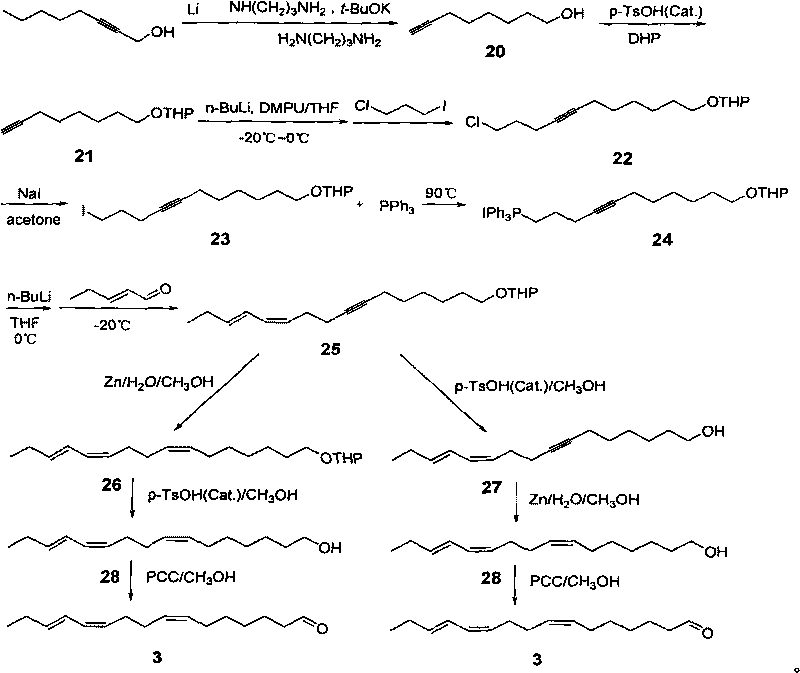

Method for synthesizing phyllocnistis citrella stainton pheromone compound

InactiveCN101712601AIncrease profitSimple and safe operationCarbonyl compound preparation by oxidationAlcoholButanediol

The invention relates to a method for synthesizing a phyllocnistis citrella stainton pheromone compound. (Z)-7-hexadecene aldehyde is synthesized by using 1,7-heptandiol and bromo-n-nonane as starting materials and through six steps of reactions (comprising a Witting reaction); (Z,Z)-7,11-hexadecadienoic aldehyde is synthesized by using the 1,7-heptandiol, 1,4-butanediol and bromo-n-pentane as starting materials and through multi-step of reactions (comprising two Witting reactions); and (Z,Z,E)-7,11,13-hexadecatrienoic aldehyde is synthesized by using 2-octyne-1-alcohol, 1-iodine-3-chloropropane and trans-2-amylene aldehyde as starting materials and through multi-step of reactions (comprising a coupling reaction and a Witting reaction). The invention has the advantages of low price and easy obtaining of raw materials, simple and reasonable synthesizing route, convenient and safe operation and high utilization rate of the raw materials.

Owner:WENZHOU MEDICAL UNIV +1

Technology for synthesizing isoprene with olefine aldehyde

InactiveCN103467234AImprove applicabilityPromote the development of deep processingHydrocarbon from oxygen organic compoundsAir compressionWastewater

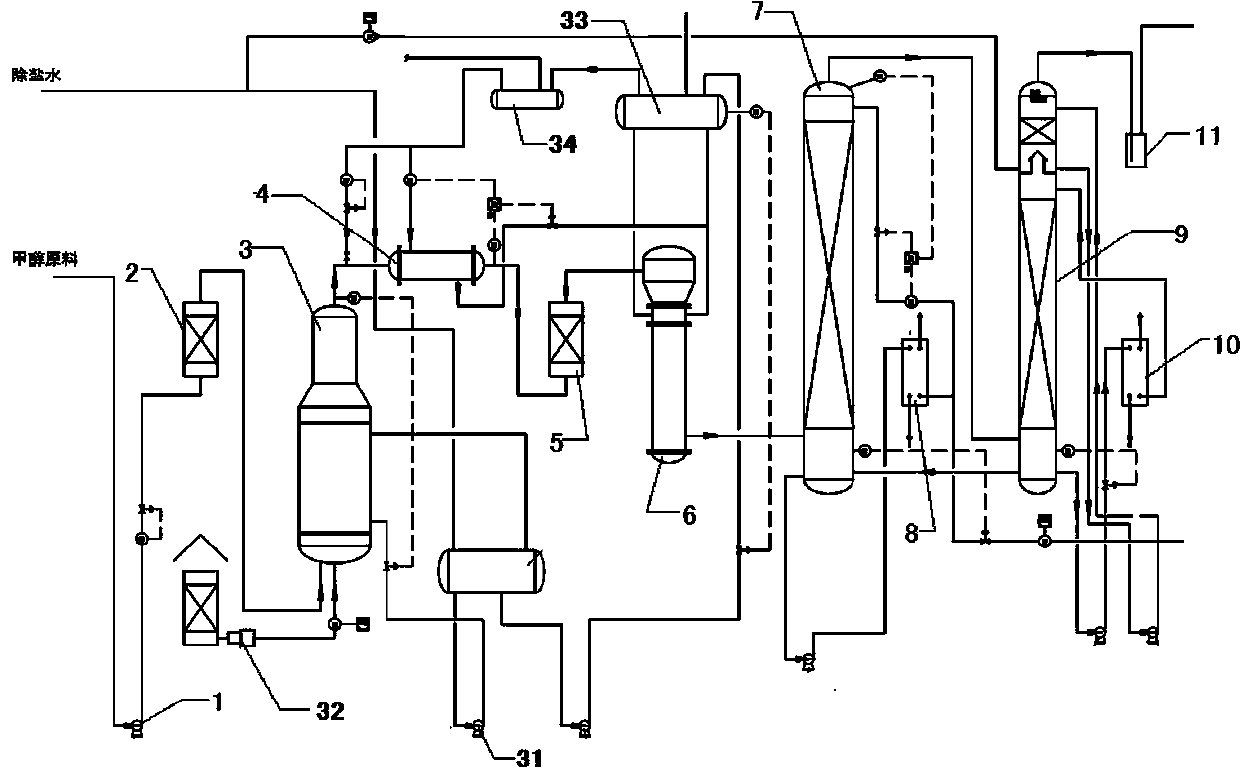

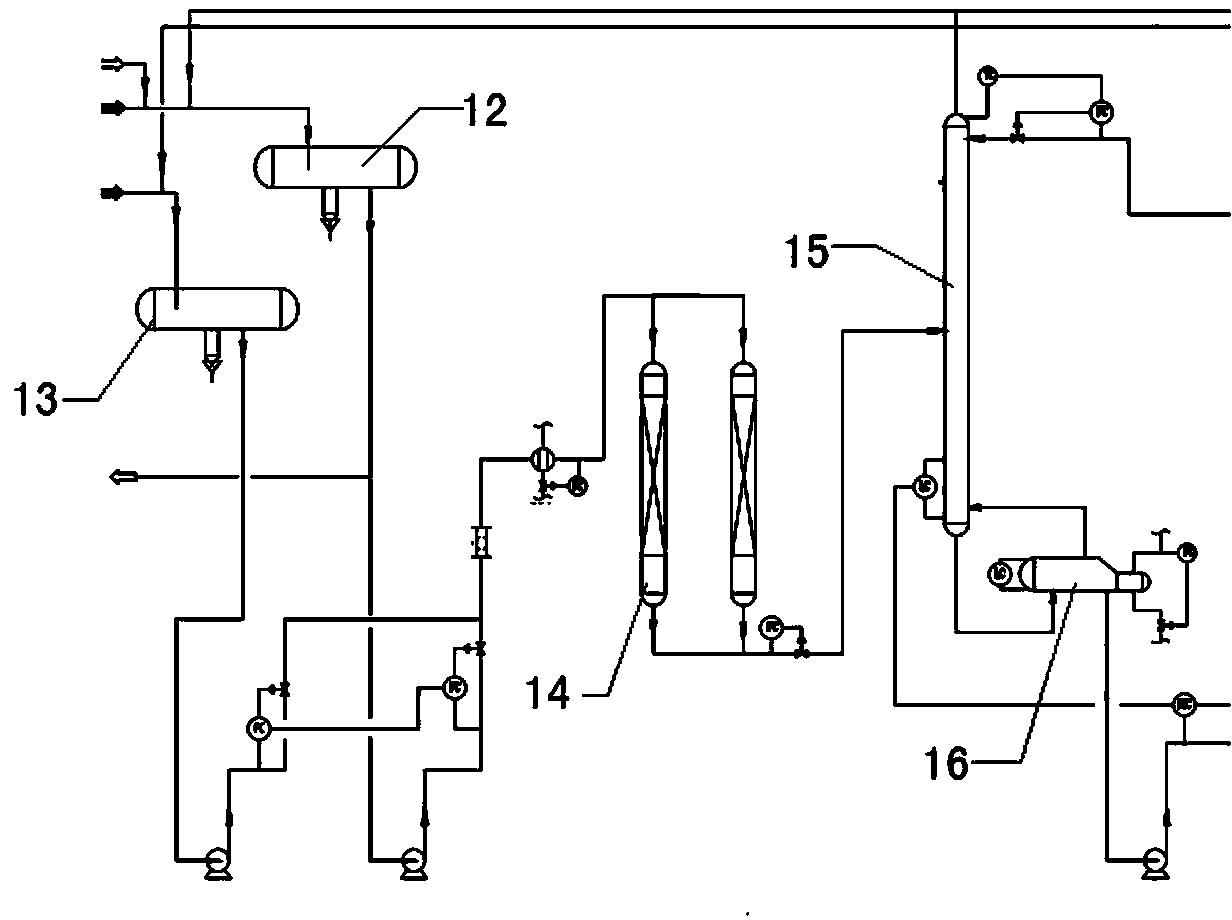

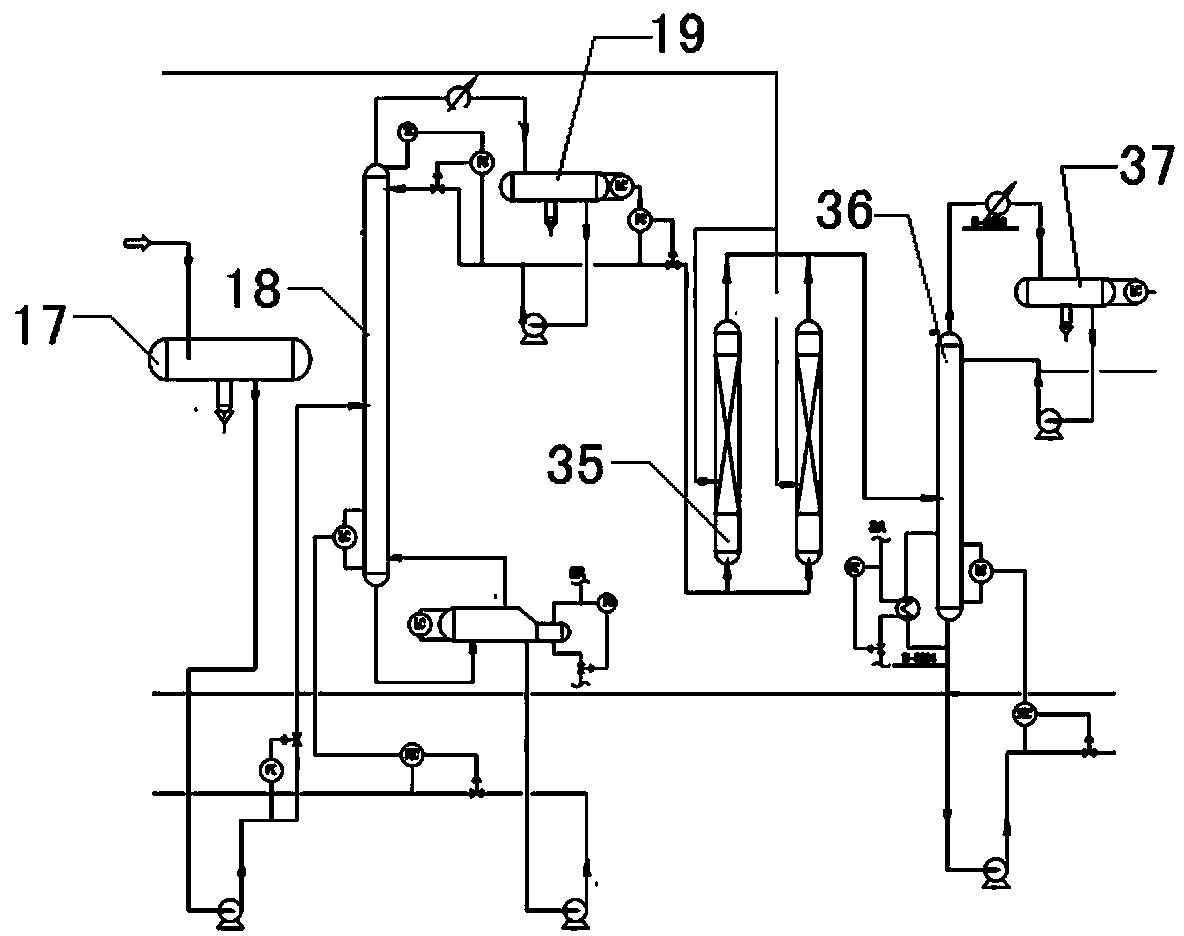

The invention relates to a technology for synthesizing isoprene with olefine aldehyde. The technology adopts a unit for preparing formaldehyde from methanol and a liquid phase olefine aldehyde synthesis unit, wherein 1) the unit for preparing formaldehyde from methanol comprises an air compression process, a reaction process, a formaldehyde absorption process and a steam generation process; 2) the liquid phase olefine aldehyde synthesis unit: TMC from a TMC preparation unit and dioxane fractions from a dioxane preparation unit enter isoprene reactors together, the materials after reaction enter a precipitation tank to be precipitated, the materials at the bottom of the tank are pumped out by a pump and are sent to a dehydrating tower of the dioxane preparation unit to be circulated, the materials at the bottom of the tower enter a fractionating tower and an isoprene monomer is obtained on the top of the fractionating tower and then enters a synthetic rubber unit. The technology has the beneficial effects of reducing the isoprene production cost, improving the purity of isoprene and reducing the wastewater and waste gas emission in the technology.

Owner:SHANDONG KENLI PETROCHEM GRP

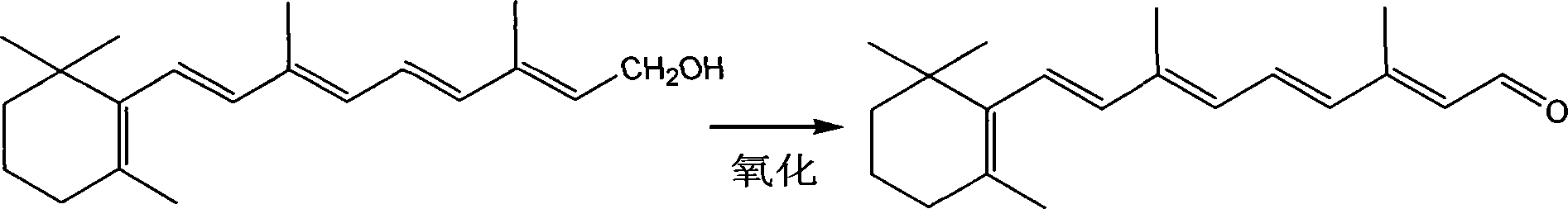

Technique for synthesizing vitamin A aldehyde

InactiveCN101168521AHigh catalytic activityHigh yieldOrganic chemistryOrganic solventVitamin A Alcohol

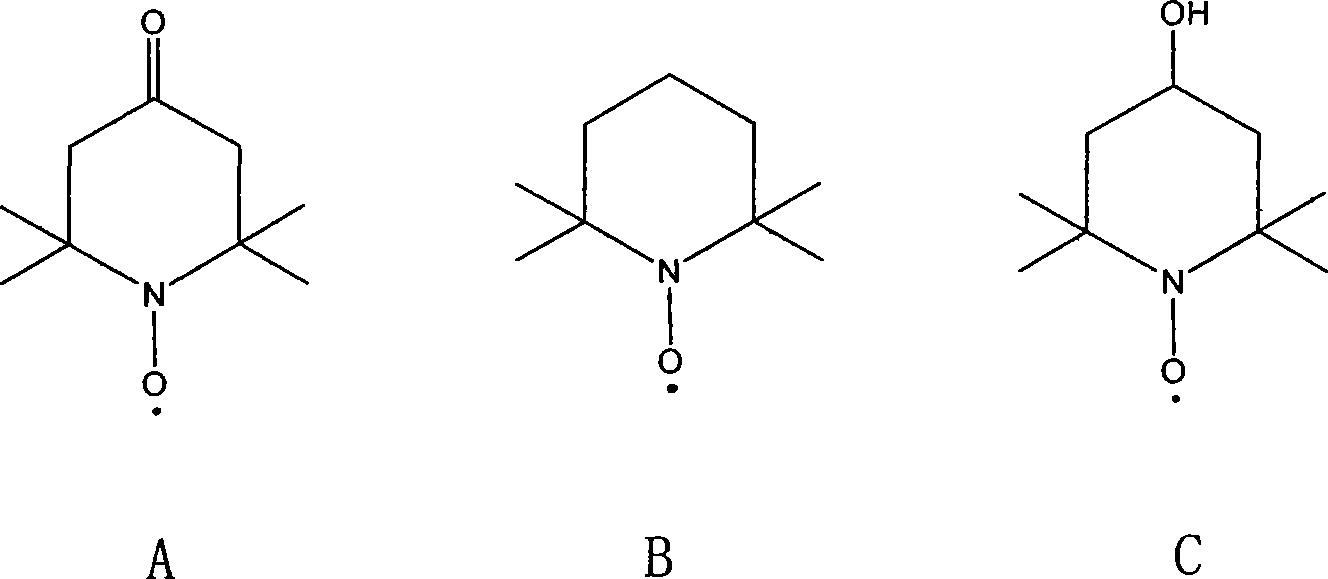

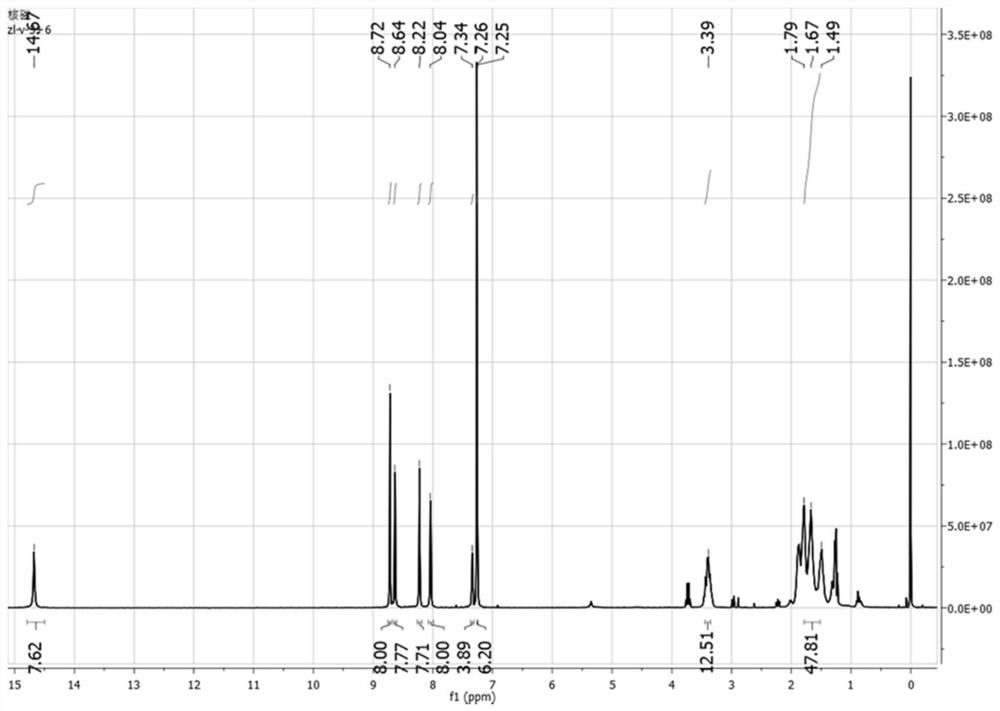

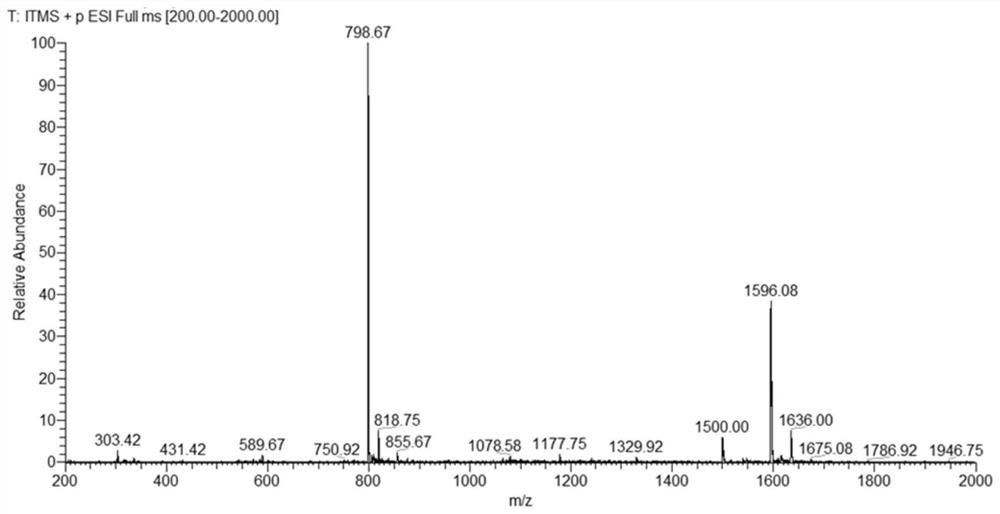

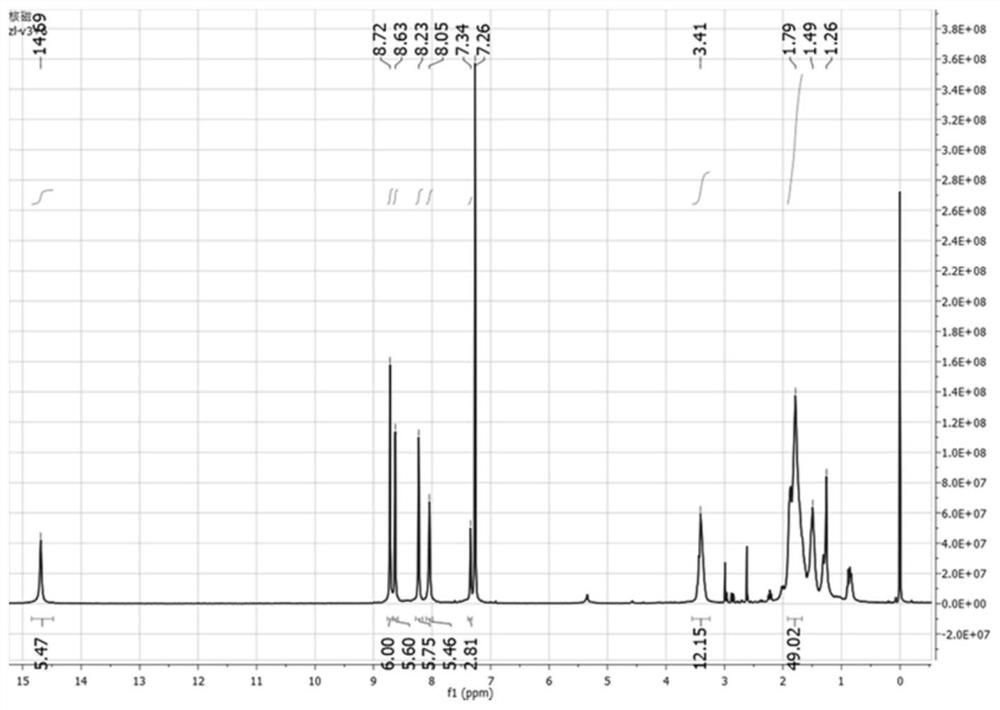

The invention discloses a vitamin A aldehyde synthesis process. The invention has the process steps that vitamin A alcohol is taken as the raw material, which is performed with oxidation reaction under a certain reaction temperature and a certain reaction time, and under the existence of catalytic agent and organic solvent, so as to prepare vitamin A aldehyde, the catalytic agent is formed by a catalyzing system composed of main catalytic agent and auxiliary catalytic agent, and the main catalytic agent adopts one of 4-methoxy-1-oxo-2, 2, 6, 6-tetramethyl-piperidine, and 4-ethoxy-1-oxo-2, 2, 6, 6-tetramethyl-piperidine. The invention has the advantages that the stability of the catalytic agent is high, the catalytic activity is high, the utilization quantity is small, the reaction speed is quick, and the yield rate is high.

Owner:SHAOXING UNIVERSITY

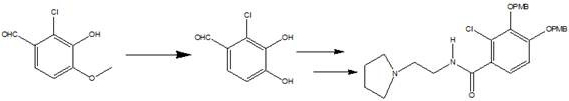

Universal method for constructing chiral organic molecular cage

The invention discloses a universal method for constructing a chiral organic molecular cage, which comprises the following steps: with a 2,6-dicarbonyl-4-substituted phenol structure as a parent nucleus, carrying out aldehyde ligand synthesis by coupling reaction, methoxy protection and deprotection reaction, Duff reaction and the like; and then introducing polyaldehyde synthons with different structures and functions are constructed by introducing rigid functional groups such as various benzene rings, naphthalene and anthracene, and then efficiently constructing the chiral porous molecular cage by the polyaldehyde synthons and chiral cyclohexanediamine under organic / water / acid conditions. The method has the advantages of simple and efficient ligand design, rich chiral molecular cage configuration, easiness in purification, wide ligand application range, easiness in reaction expansion and the like. By utilizing the modular synthesis method, a series of chiral molecular cages with richand adjustable structures can be prepared on a large scale for the fields of adsorption, separation, catalysis, energy and the like.

Owner:YANCHENG INST OF TECH

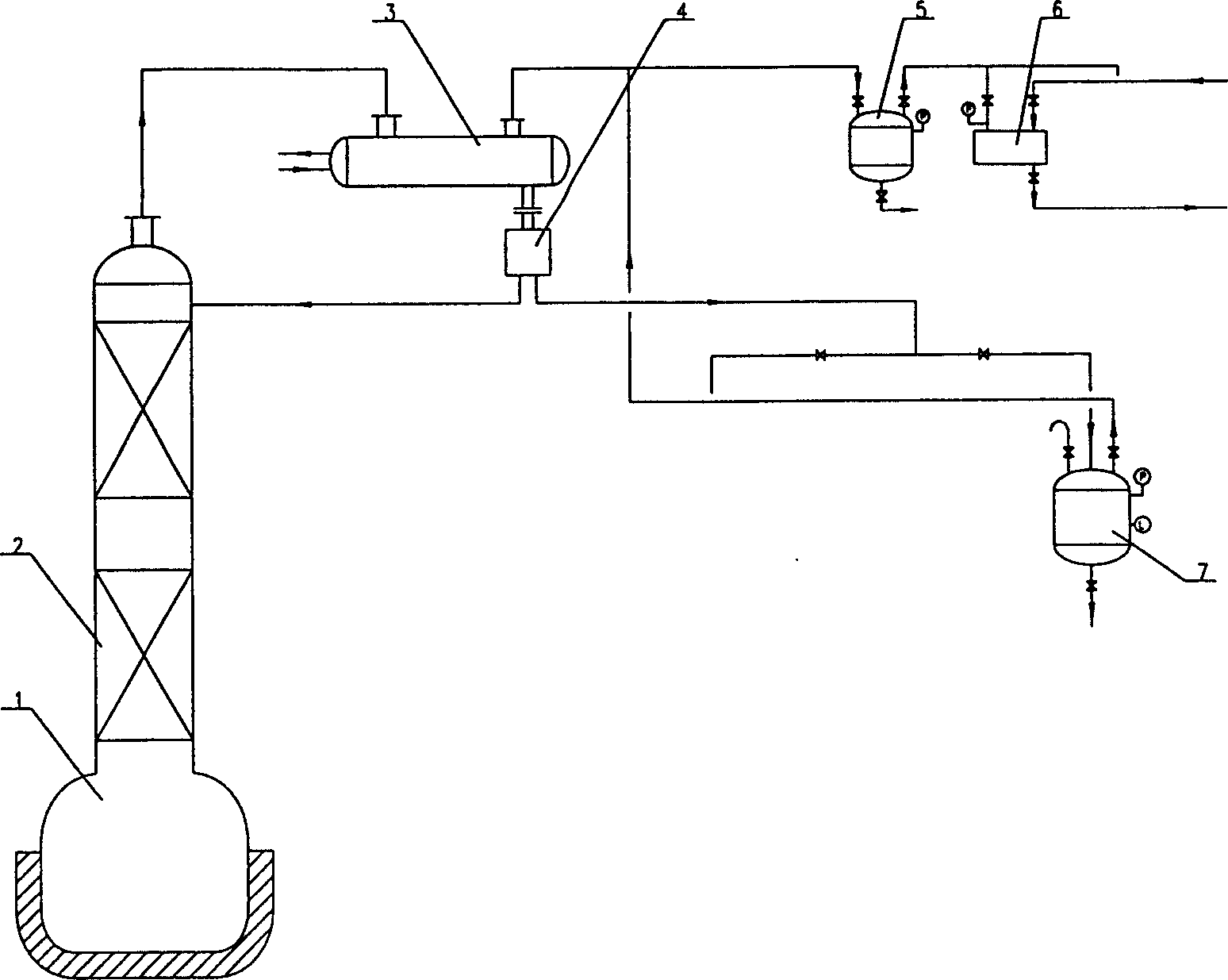

Apparatus and process for purifying peach aldehyde by decompressing batch rectifying

InactiveCN1255395CSimple operation processReduce thicknessOrganic chemistryEssential-oils/perfumesRefluxSurge tank

The invention discloses a device and process for purifying peach aldehyde by intermittent rectification under reduced pressure, which belongs to the separation and purification technology for synthesizing peach aldehyde. The device consists of a rectification tower, a condenser, a reflux tank, a surge tank, a vacuum pump, and a storage tank. The tower is equipped with high-efficiency packing. It is characterized in that the still of the rectification tower is a jacket column with a height-to-diameter ratio of 0.6 to 0.3. tube heater. The device is used to carry out the process of purifying peach aldehyde by intermittent distillation under reduced pressure. The pressure at the top of the tower is 133.3Pa ~ 1333Pa, and the temperature of the bottom of the tower is 150 ~ 180°C. Peach aldehyde with light components and qualified purity. The invention has the advantages that the tower kettle has the characteristics of small liquid film thickness, high evaporation efficiency, large heat transfer coefficient and short material residence time, the operation process of the tower is simple, and the product purity can reach more than 99 wt%.

Owner:TIANJIN UNIV

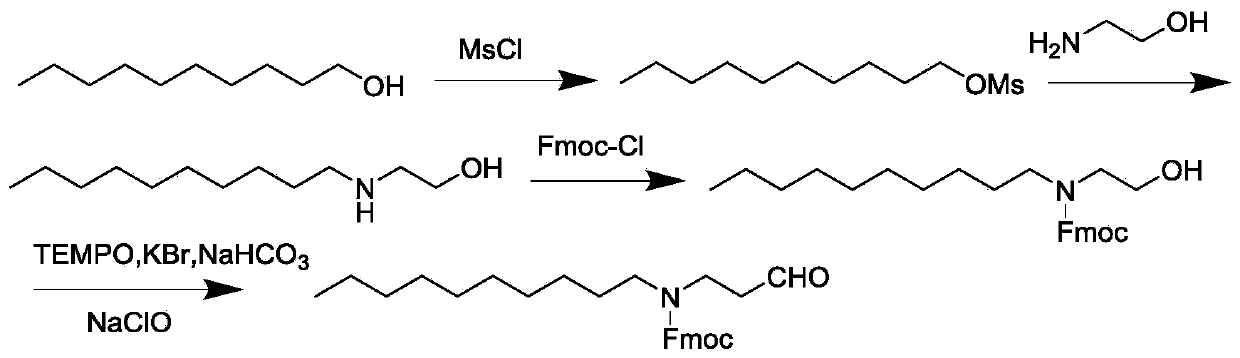

Method for synthesizing Vibativ intermediate

InactiveCN111233713ALow priceSimple oxidation conditionsCarbamic acid derivatives preparationOrganic compound preparationReaction temperatureSide reaction

The invention discloses a method for synthesizing a Vibativ intermediate. The method comprises the following steps: taking n-decanol and aminoethanol as starting materials, carrying out condensation and Fmoc-Cl amino protection, and performing oxidation to obtain N-(9-fluorenylmethoxycarbonyl)decylaminoacetaldehyde. 2, 2, 6, 6-tetramethylpiperidine oxide (TEMPO) is used as an oxidizing agent, a reaction temperature is below 0 DEG C, dichloromethane is used as a solvent, the primary alcohol is selectively controlled to be oxidized into aldehyde, materials involved in synthesis are low in price,the synthesis cost is greatly reduced, the synthesis yield is high, side reactions are few, all synthesis steps are easy to operate, follow-up treatment is simple and environmentally friendly, TEMPOoxidation conditions are mild, the pH value and the reaction temperature of a reaction liquid are controlled, aldehyde is obtained by selective oxidation, the reaction conditions are easy to control,and follow-up treatment is simple.

Owner:福建康鸿生物科技有限公司

Method for treating high-concentration wastewater in citral synthesis process

ActiveCN110937745AMild treatment conditionsReduce processing costsOrganic compound preparationWater contaminantsButeneAlcohol

The invention provides a method for treating high-concentration wastewater in a citral synthesis process. In the method, high-concentration wastewater of 3-methyl-3-butene-1-aldehyde prepared by oxidizing 3-methyl-3-butene-1-alcohol is taken as a raw material, and the method comprises the following steps of: performing stripping to separate alcohol compounds and aldehyde compounds contained in thehigh-concentration wastewater, and converting the high-concentration wastewater into low-concentration wastewater containing acetal compounds; converting the acetal compounds in the low-concentrationwastewater into 3-methyl-3-butene-1 alcohol and 3-methyl-3-butene-1-aldehyde by adopting an acidic hydrolysis reaction, so as to obtain low-concentration wastewater containing hydrolysate; and separating 3-methyl-3-butene-1-alcohol and 3-methyl-3-butene-1-aldehyde from the low-concentration wastewater containing the hydrolysate through stripping, so that the COD of the treated wastewater is reduced to 200 ppm or below. The method is economical and high in treatment efficiency, heavy component impurities are converted into process raw materials and products, and the separation yield is increased.

Owner:WANHUA CHEM GRP CO LTD

Synthesis method of Z9,11-dodecadienol acetate

InactiveCN105061205AImprove protectionGood dispersionOrganic compound preparationCarboxylic acid esters preparationPtru catalystSilica gel

The invention discloses a synthesis method of Z9,11-dodecadienol acetate. The synthesis method comprises the following steps: (1) by taking 1,9-nonanediol as a raw material, performing unilateral oxidation to synthesize 9-hydroxyl-1-nonanal; (2) synthesizing an intermediate Z9,11-dodecadienol; (3) synthesizing the Z9,11-dodecadienol acetate. The synthesis method has the advantages of mild synthesis conditions, short reaction time, easy operation, wide application range, high yield, low cost and easy industrialization, the process flow is shortened, and three wastes are few. In a synthesis reaction of the 9-hydroxyl-1-nonanal, silica gel is added, the dispersion of PCC (Pyridinium Chlorochromate) is facilitated, the opportunity of oxidation of two hydroxyls is reduced by adding the PCC in batches, the reaction is performed at room temperature, and energy is saved; after the reaction is completed, ethyl ether and water are added for extraction, and the yield of reactants is improved. In the synthesis process of the Z9,11-dodecadienol, a phase transfer catalyst 18-crown ether-6 and non-polar solvent benzene are adopted to react so as to obtain a cis-product; meanwhile, weak alkali potassium carbonate is adopted, so that the protection of the hydroxyls of the 9-hydroxyl-1-nonanal is avoided, and a reaction synthesis route is shortened.

Owner:SHANXI AGRI UNIV

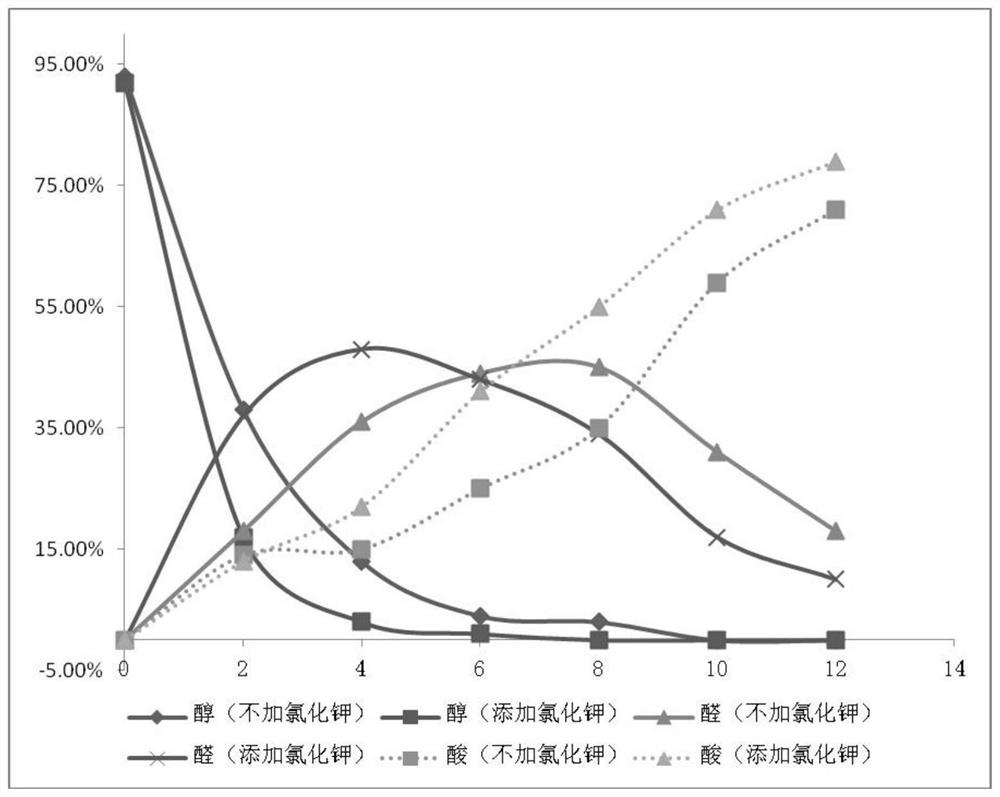

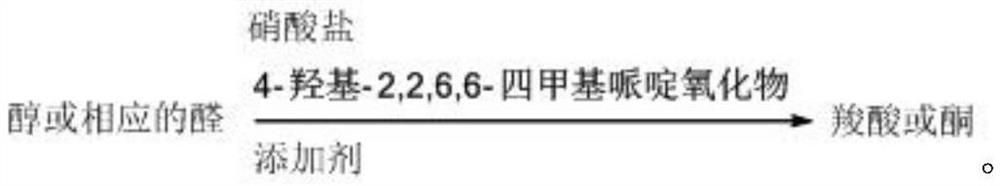

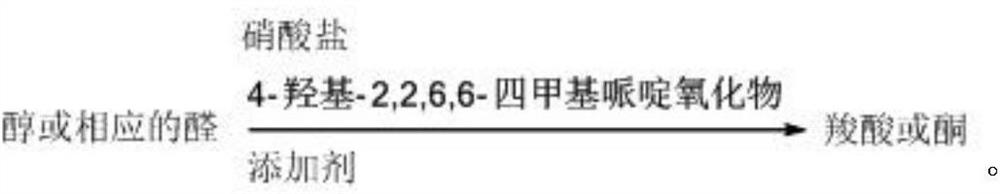

Method for synthesizing carboxylic acid or ketone compounds from alcohol or aldehyde by taking oxygen or oxygen in air as oxidant

ActiveCN112409144ARich diversityLow priceOrganic compound preparationCarbonyl group formation/introductionPtru catalystCarboxylic acid

The invention discloses a novel method for synthesizing a carboxylic acid or ketone compound from alcohol or corresponding aldehyde by taking oxygen or oxygen in air as an oxidant, which comprises thefollowing step of: oxidizing the alcohol or the corresponding aldehyde into the corresponding carboxylic acid or ketone compound under the catalysis of nitrate / 4hydroxy 2, 2, 6, 6-tetramethylpiperidine oxide and the action of an additive. When an inorganic chloride is additionally added, the reaction is accelerated. The method has the advantages that the catalyst is low in price, easy to operate,high in yield, rich in substrate diversity, mild in reaction condition, environmentally friendly and the like. The method is not only suitable for laboratory synthesis, but also suitable for industrial synthesis of carboxylic acid or ketone compounds.

Owner:ZHEJIANG UNIV

Simple high-carbon aldehyde synthesis catalyst

ActiveCN110694657AReduced internal ene yieldLow costPhysical/chemical process catalystsOrganic compound preparationPtru catalystEngineering

The invention relates to the field of high-carbon aldehyde synthesis, and provides a high-activity high-carbon aldehyde synthesis catalyst which is capable of realizing conversion of high-carbon alpha-olefin into high-carbon aldehyde, wherein the alpha-olefin conversion rate is close to 100%, and the product aldehyde yield is 96%. The catalyst comprises metal cobalt Co, nickel Ni, non-metal phosphorus P and boron B, and a Ni-Co-P-B amorphous alloy is formed. Compared with a traditional metal catalyst, the advantages are that the catalyst is at a non-equilibrium metastable state in thermodynamics, has unique coordination unsaturation and electron interaction, is adjustable in composition, and shows excellent catalytic performance. According to the scheme, the catalyst has the characteristics of simple preparation process, low cost, high activity and adjustable product proportion.

Owner:NINGXIA UNIVERSITY

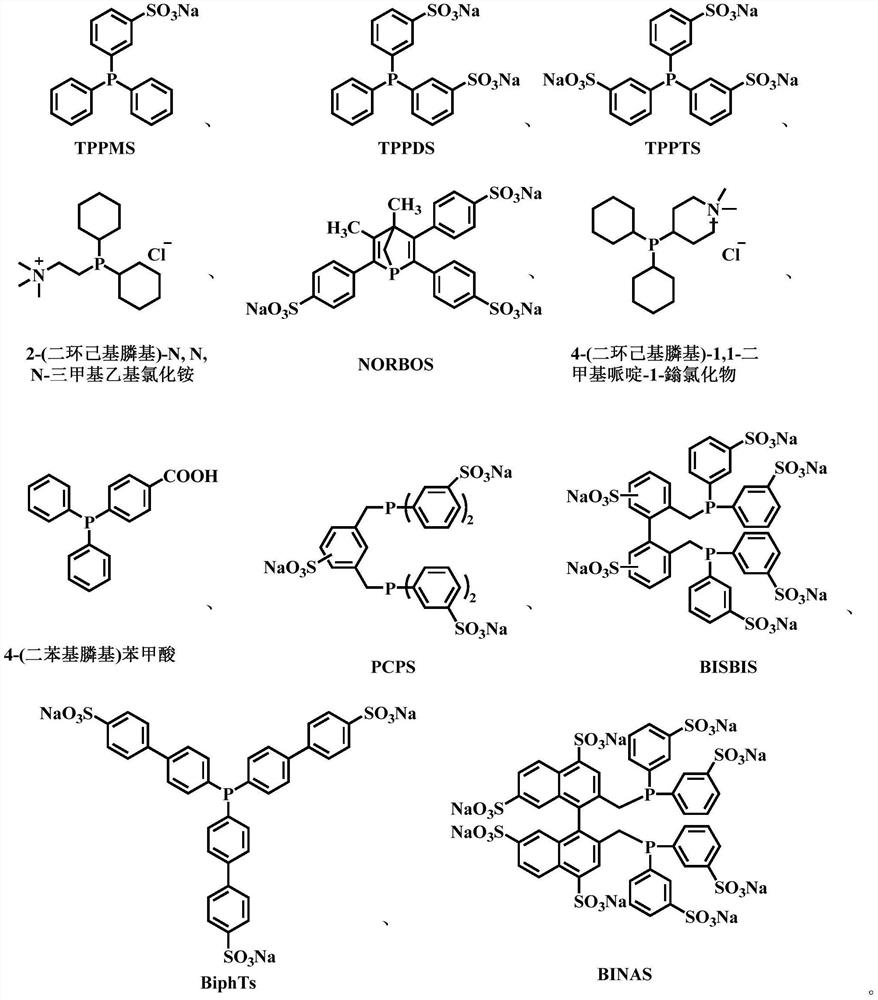

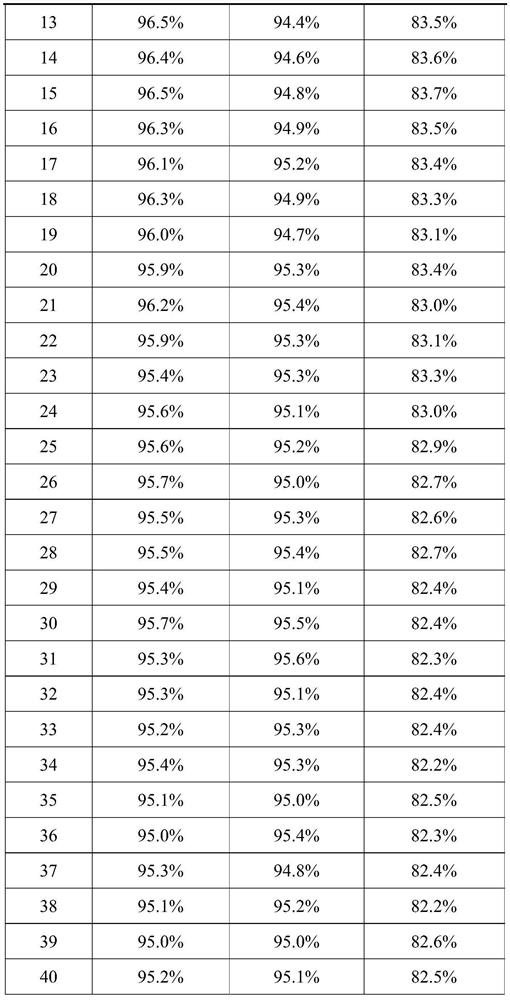

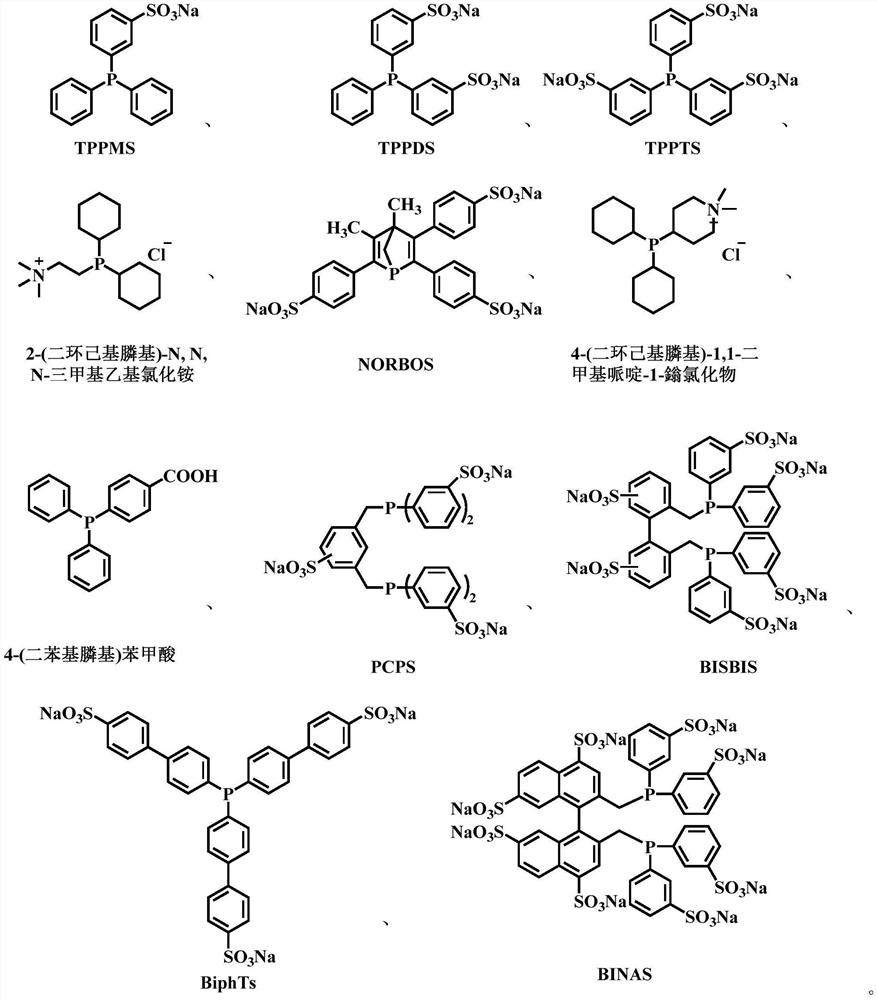

A kind of method for preparing aldehyde compounds by two-phase hydroformylation of olefins

ActiveCN112679327BRealize multiple recyclingHigh reactivityPreparation by carbon monoxide reactionChemical recyclingPtru catalystFormylation reaction

The invention discloses a method for preparing aldehyde compounds by two-phase hydroformylation of olefins, and belongs to the technical field of aldehyde synthesis. Formamide, N-methylformamide, N,N-dimethylformamide, etc. are used as solvents to make alkenes and H 2 / CO synthesis gas hydroformylation reaction to generate aldehydes, because the solubility of olefins in large polar organic solvents is much greater than its solubility in water, the reactivity is greatly improved compared with water-oil two-phase hydroformylation; reaction After the end, the system automatically separates phases, the upper layer is the product aldehyde with low polarity, and the lower layer is the high polarity solvent phase, and the water-soluble catalyst is dissolved in the high polarity solvent phase, and the multiple cycles of the catalyst can be realized through the liquid separation operation Utilization; the invention has the characteristics of mild reaction conditions, high selectivity and high conversion rate, and the catalyst can be circulated for a long time, and has excellent industrial application prospects.

Owner:SICHUAN UNIV +1

Preparation method for synthesizing carboxylic acid by oxidizing aldehyde through using bimetallic catalyst

ActiveCN111116348AHigh yieldMild reaction conditionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMetal catalyst

The invention discloses a preparation method for synthesizing carboxylic acid by oxidizing aldehyde through using a bimetallic catalyst. The method comprises the following steps: an aldehyde compoundtaken as a substrate is reacted for 1-12 h in a reaction solvent under a normal-pressure oxygen condition at the temperature of 10-90 DEG C under the action of the bimetallic catalyst under a stirringcondition, the reaction system is cooled to room temperature after the reaction conversion is completed, and the obtained reaction solution is centrifuged, filtered and dried to constant weight to obtain the carboxylic acid compound, wherein the aldehyde compound is aromatic aldehyde, fatty aldehyde or alicyclic aldehyde. The method has the advantages of mild reaction conditions and simplicity inoperation; and Cu(OAc)2. H2O and Co(OAc)2. 4H2O in a molar ratio of 1:1 are used as the bimetallic catalyst, high-yield carboxylic acid products can be obtained by adjusting the reaction temperature,the solvent and the catalyst dosage aiming at different types of raw material aldehydes, and the highest yield can reach 98%.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing aldehyde compounds through olefin two-phase hydroformylation

ActiveCN112679327ARealize multiple recyclingHigh reactivityPreparation by carbon monoxide reactionChemical recyclingPolymer sciencePtru catalyst

The invention discloses a method for preparing an aldehyde compound by olefin two-phase hydroformylation, and belongs to the technical field of aldehyde synthesis. The method comprises the following steps: forming a catalytic system by using a water-soluble phosphine ligand and a rhodium catalyst, and synthesizing the aldehyde compound by using cheap and accessible high-polarity formamide, N-methylformamide, N, N-dimethylformamide and the like as solvents; enabling olefin and H2 / CO synthesis gas to be subjected to hydroformylation reaction to generate aldehyde. Due to the fact that the solubility of olefin in a high-polarity organic solvent is much higher than that of olefin in water, the reaction activity is greatly improved compared with that of water-oil two-phase hydroformylation; after the reaction is finished, the system is subjected to automatic phase splitting, the upper layer is a small-polarity product aldehyde, the lower layer is a large-polarity solvent phase, a water-soluble catalyst is dissolved in the large-polarity solvent phase, and repeated cyclic utilization of the catalyst can be realized through liquid splitting operation; the method has the characteristics of mild reaction conditions, high selectivity and high conversion rate, and the catalyst can be recycled for a long time and has an excellent industrial application prospect.

Owner:SICHUAN UNIV +1

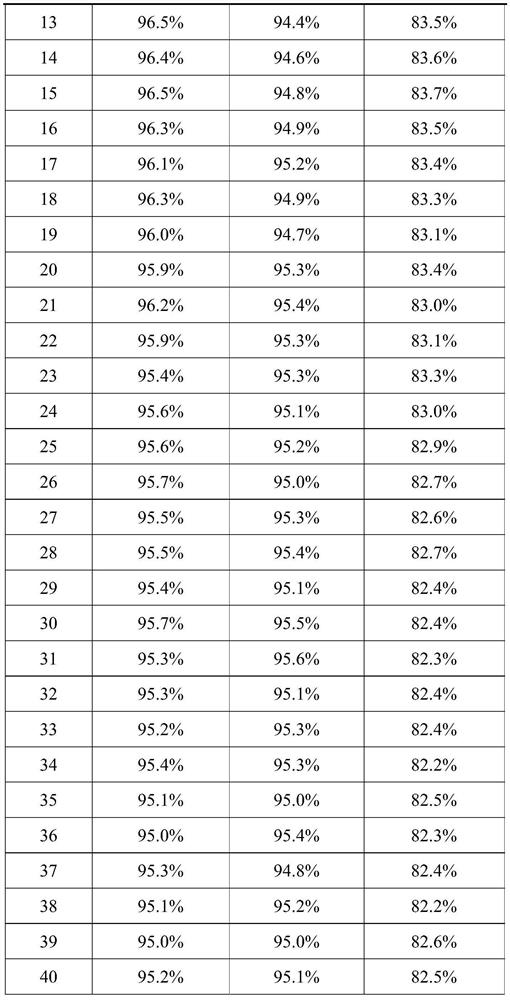

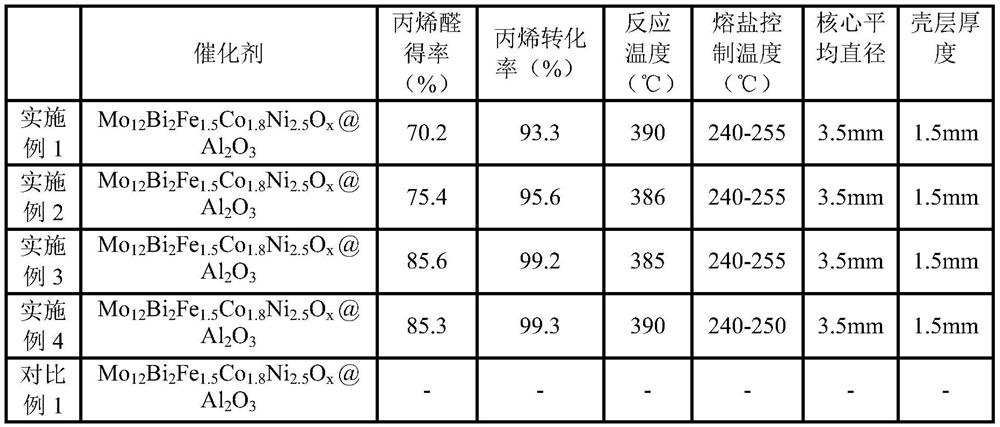

Composite catalyst for acraldehyde synthesis as well as preparation method and application thereof

ActiveCN112691680ALower catalytic temperatureHigh yieldOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystAcrolein

The invention discloses a composite catalyst for acraldehyde synthesis as well as a preparation method and application of the composite catalyst. The composite catalyst comprises an inner core composed of active components and a shell which covers the surface of the inner core and is made of an inert porous material. When the catalyst is applied to the process of synthesizing acraldehyde through propylene oxidation, the temperature runaway phenomenon can be effectively inhibited, side reactions are reduced, and the product yield is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

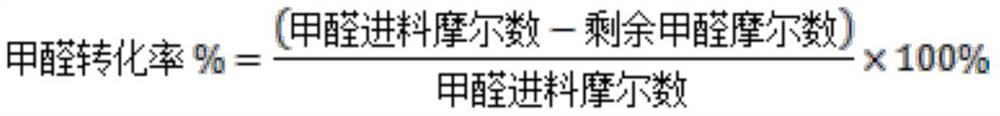

Rhodium-based catalyst for glycollic aldehyde synthesis and preparation method thereof

InactiveCN112337508AIncrease loadIncrease contactMolecular sieve catalystsOrganic compound preparationPtru catalystFormylation reaction

The invention provides a rhodium-based catalyst for glycollic aldehyde synthesis and a preparation method of the rhodium-based catalyst. The method adopted by the invention comprises the steps of firstly, carrying out organic functional group modification on the surface of a carrier, then dipping and adsorbing in a rhodium precursor solution, washing and drying to obtain the high-dispersion and high-load rhodium-based immobilized catalyst. Compared with a solid catalyst prepared by a common impregnation method, the catalyst provided by the invention is higher in conversion rate and selectivitywhen being used for hydroformylation reaction of formaldehyde, and compared with a traditional homogeneous formaldehyde hydroformylation method, the yield of the glycolaldehyde product generated integrally is basically the same, so that the problems that the homogeneous catalyst is difficult to separate from the product and precious metal is difficult to recover are solved, and the problems of low formaldehyde conversion rate and low yield of a common supported rhodium catalyst are also solved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

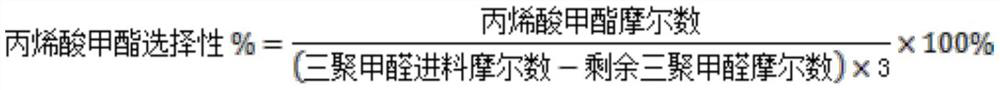

Methyl acrylate synthesis method, catalyst and application

PendingCN114478244AAvoid generatingHigh selectivityCatalyst carriersOrganic compound preparationPolymer sciencePtru catalyst

The methyl acrylate synthesis method comprises the steps that under the action of a catalyst, methyl acetate and an aldehyde source are subjected to an aldol synthesis reaction to obtain methyl acrylate, and the aldehyde source is fed in a segmented mode. The invention also provides a preparation method of the solid base catalyst for synthesis of methyl acrylate. The preparation method comprises the following steps: mixing a catalytic amount of alkali metal element precursor salt water solution with the carrier; and roasting to obtain the solid base catalyst. Wherein the alkali metal comprises a Group IA alkali metal element, preferably selected from K, Rb, Cs or a combination thereof; the carrier has an average pore size of 2-50nm by a BET method and a pore volume of 0.2-2ml / g by the BET method. The method is simple, easy to implement and suitable for large-scale production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

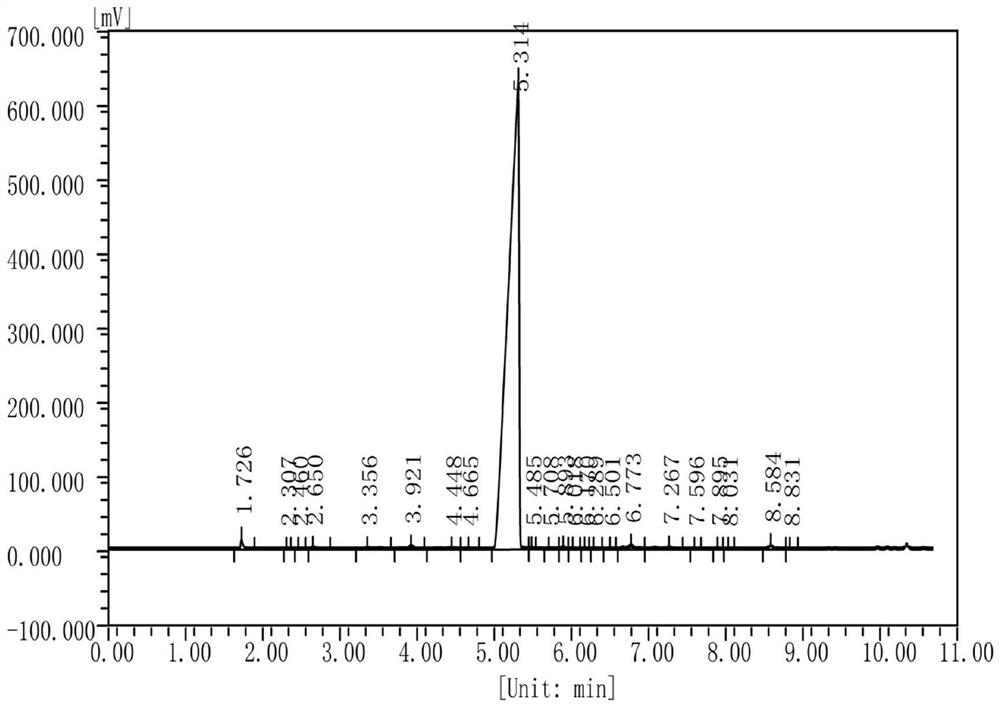

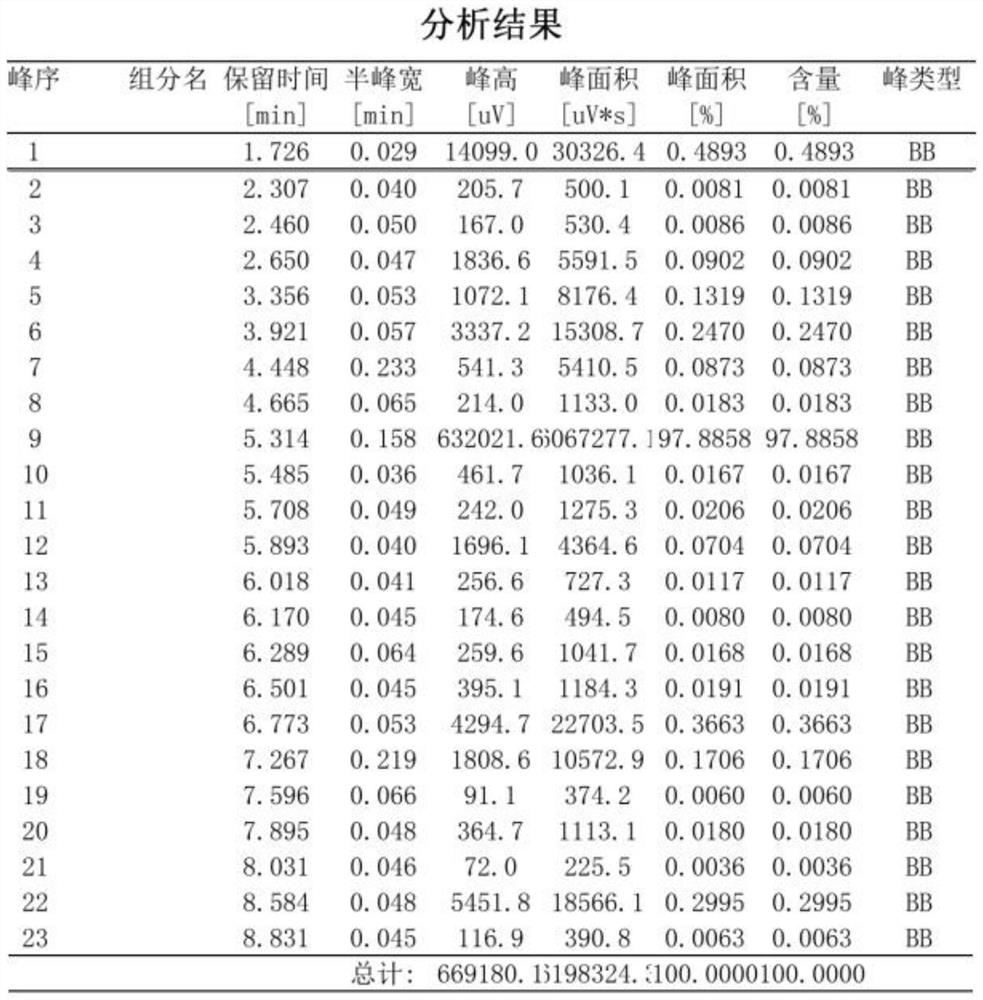

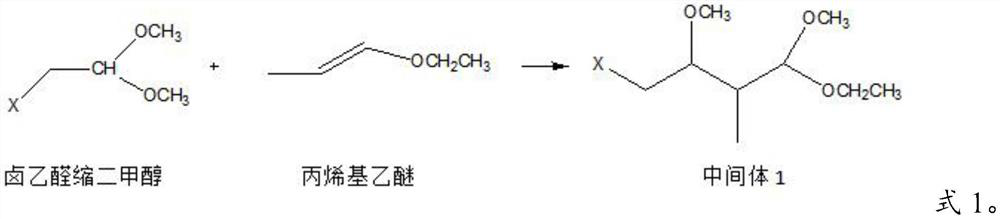

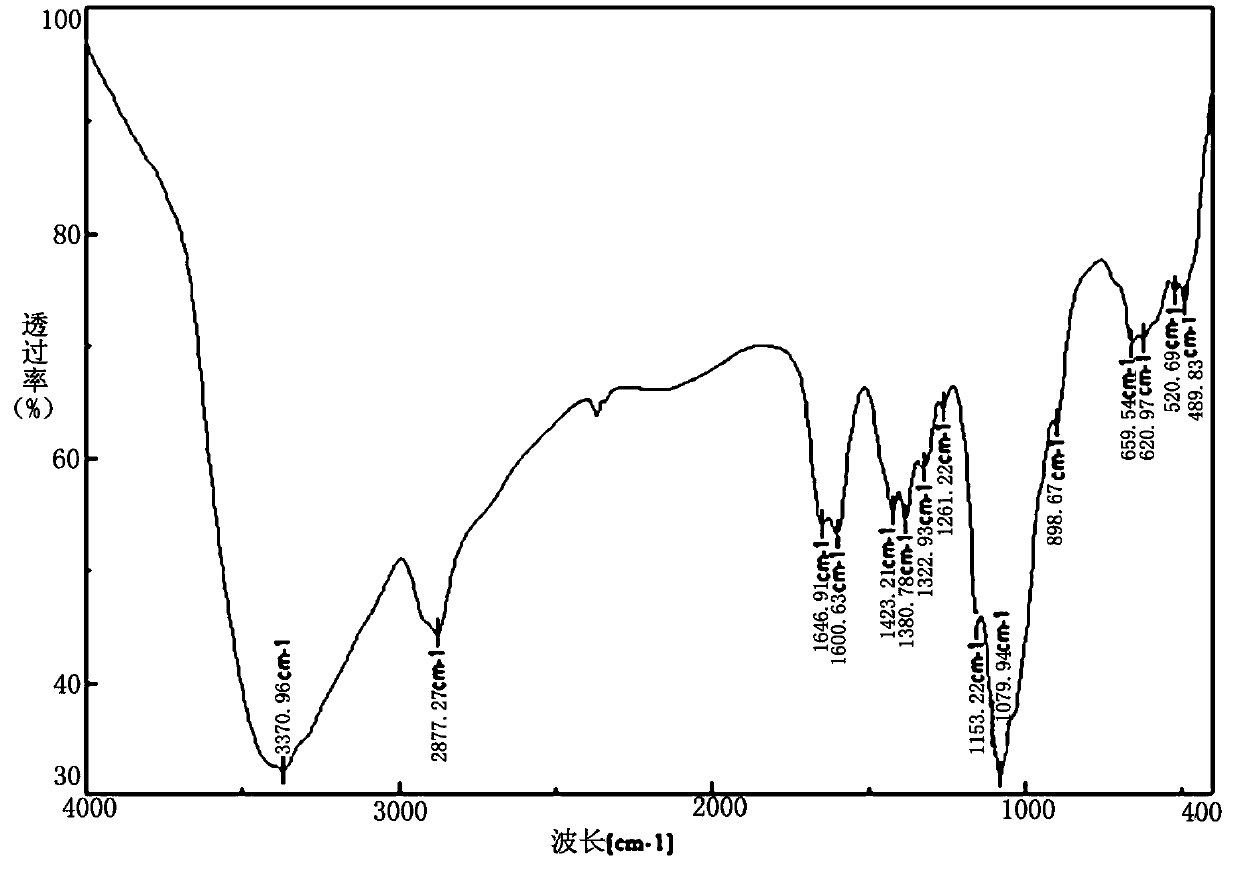

Aldehyde synthesis method

PendingCN114835577AThree wastes lessReduced risk of reactionOrganic compound preparationCarboxylic acid esters preparationButeneBiochemical engineering

The invention discloses a synthesis method of aldehyde. The synthesis method comprises the following steps: step 1, synthesis of an intermediate 1, step 2, synthesis of an intermediate 2, and step 3, synthesis of 4-acetoxy-2-methyl-2-butene-1-aldehyde. According to the synthesis method, the problems of high production cost, more three wastes and difficulty in treatment after the 4-acetoxy-2-methyl-2-butene-1-aldehyde is synthesized by the existing technical route are solved, a large amount of three wastes are reduced, the synthesis method is more environment-friendly, and meanwhile, the reaction risk is reduced.

Owner:安徽智新生化有限公司

A kind of chitosan bispyridine quaternary ammonium salt and its preparation method and application

The invention relates to the field of daily chemicals and the pharmaceutical industry, in particular to a preparation method and application of a chitosan diquaternary ammonium salt derivative. Chitosan diquaternary ammonium derivatives are qcts2Py, qcts3Py or qcts4Py shown in formula (1), (2) or (3); with chitosan as raw material, the corresponding pyridine aldehydes are synthesized to generate corresponding Schiff base, and then reduced by sodium borohydride to obtain N-substituted chitosan, and then reacted with methyl iodide to obtain biquaternary ammonium chitosan derivatives. Compared with the chitosan raw material, the shown biquaternary ammonium salt derivative has good antioxidant activity. The present invention has synthesized chitosan diquaternary ammonium salt derivatives through effective synthetic means, and water solubility is better, and antioxidant activity is significantly improved, has strengthened the biological activity of chitosan, expanded the application scope of chitosan, can Used in daily chemical and pharmaceutical industries and other fields.

Owner:烟台美嘉全生物科技有限公司

A kind of treatment method of high concentration wastewater in citral synthesis process

ActiveCN110937745BMild treatment conditionsReduce processing costsOrganic compound preparationWater contaminantsMeth-Hydrolysate

The invention provides a method for treating high-concentration wastewater in a citral synthesis process. Using high-concentration wastewater obtained by oxidizing 3-methyl-3-butene-1-alcohol to prepare 3-methyl-3-butene-1-aldehyde as a raw material, the steps include: stripping and separating alcohols contained in the high-concentration wastewater compound and aldehyde compounds, converting high-concentration wastewater into low-concentration wastewater containing acetal compounds; converting the acetal compounds in the low-concentration wastewater into 3-methyl-3-butene-1 alcohol and 3-methyl-3-butene-1-aldehyde, to obtain low-concentration waste water containing hydrolyzate; Separating the low-concentration waste water containing hydrolyzate by stripping 3-methyl-3-butene-1 alcohol and 3-methyl base-3-butene-1-aldehyde, reducing the COD of the treated wastewater to below 200ppm. The method is economical, has high processing efficiency, and converts heavy component impurities into process raw materials and products, thereby improving the separation yield.

Owner:WANHUA CHEM GRP CO LTD

Preparation and application of titanium dioxide loaded molybdenum trioxide and vanadium pentoxide catalyst

PendingCN114308010AHigh selectivityImprove performanceOrganic compound preparationCarboxylic acid esters preparationPtru catalystHeteropoly acid

The invention relates to preparation and application of a titanium dioxide loaded molybdenum trioxide and vanadium pentoxide catalyst, and belongs to the technical field of catalyst preparation. The active component of the catalyst is a compound composed of molybdenum oxide and vanadium oxide, the catalytic activity of the compound can be adjusted through the ratio of molybdenum oxide to vanadium oxide so as to improve the selectivity of a target product, and the catalyst mainly comprises a molecular sieve, heteropoly acid and the like and is excellent in aldehyde synthesis performance through alcohol oxidation. However, the defects of high preparation cost, high wastewater and the like exist. In the catalyst preparation process, only the ammonium sulfate aqueous solution is generated and can be used as a nitrogen fertilizer, no three wastes are generated, the preparation cost is low, and the performance is excellent.

Owner:JIANGSU JINJU ALLOY MATERIAL

O-nitrotoluene aldehyde synthesis method

InactiveCN107488122AHigh yieldNo pollution in the processOrganic chemistryOrganic compound preparationOrtho aminobenzaldehydeO-nitrobenzaldehyde

The present application discloses an o-nitrotoluene aldehyde synthesis method, wherein o-nitrobenzaldehyde is subjected to a reducing reaction by using o-nitrobenzaldehyde as a starting raw material and using FeSO4.7H2O as a reducing agent to prepare o-aminobenzaldehyde. According to the present invention, the o-aminobenzaldehyde is synthesized by using FeSO4.7H2O as the reducing agent, such that the yield is high, and the method is pollution-free.

Owner:ZHANGJIAGANG JINFENG RUNERFA HARDWARE PLASTIC FACTORY

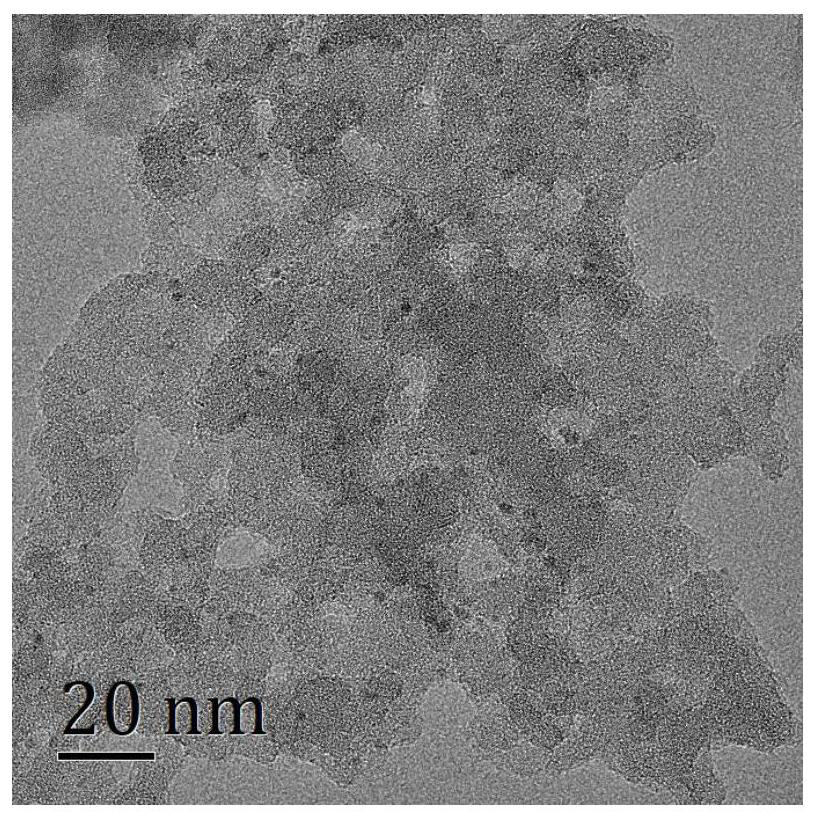

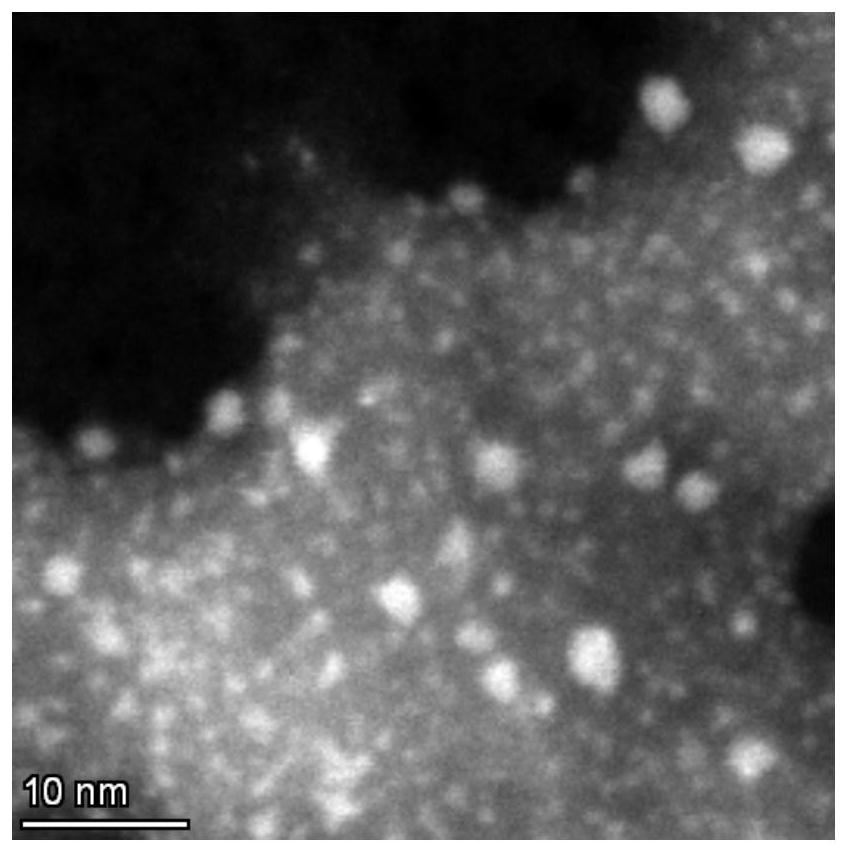

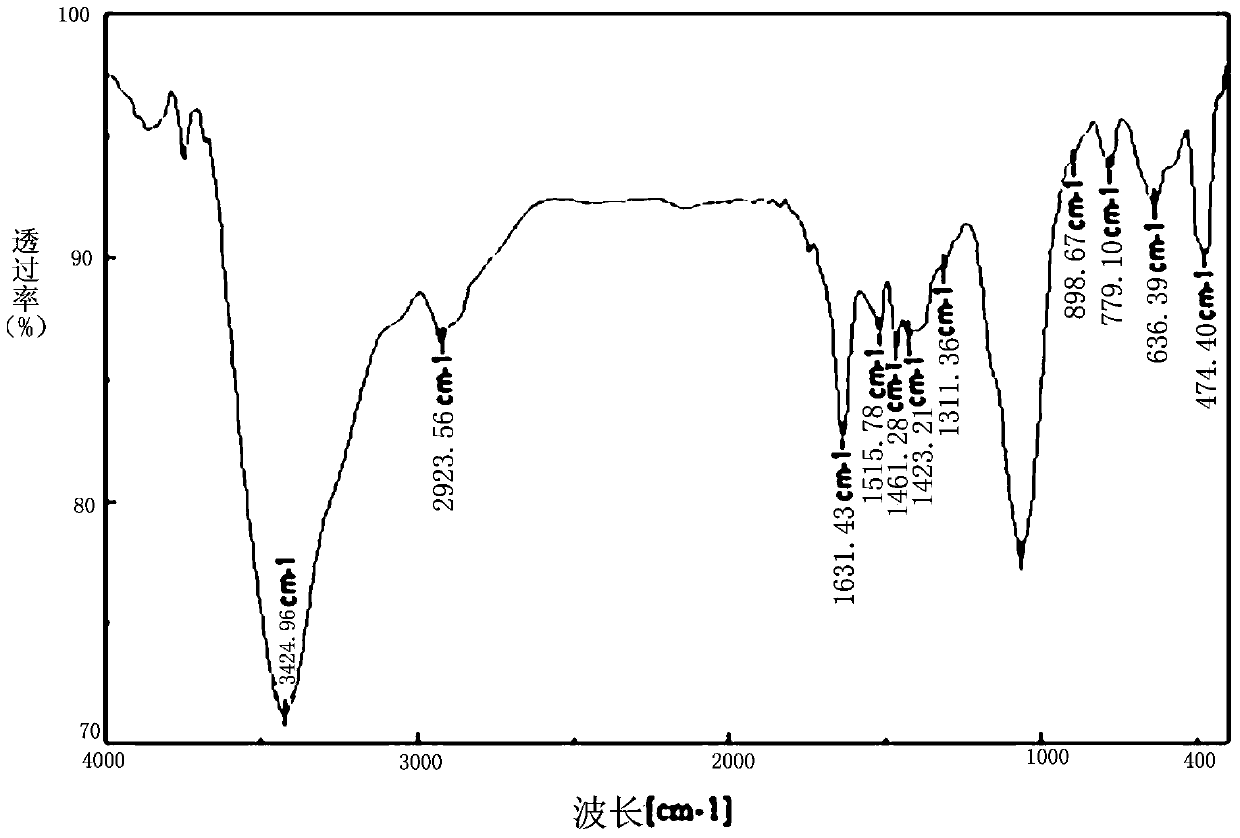

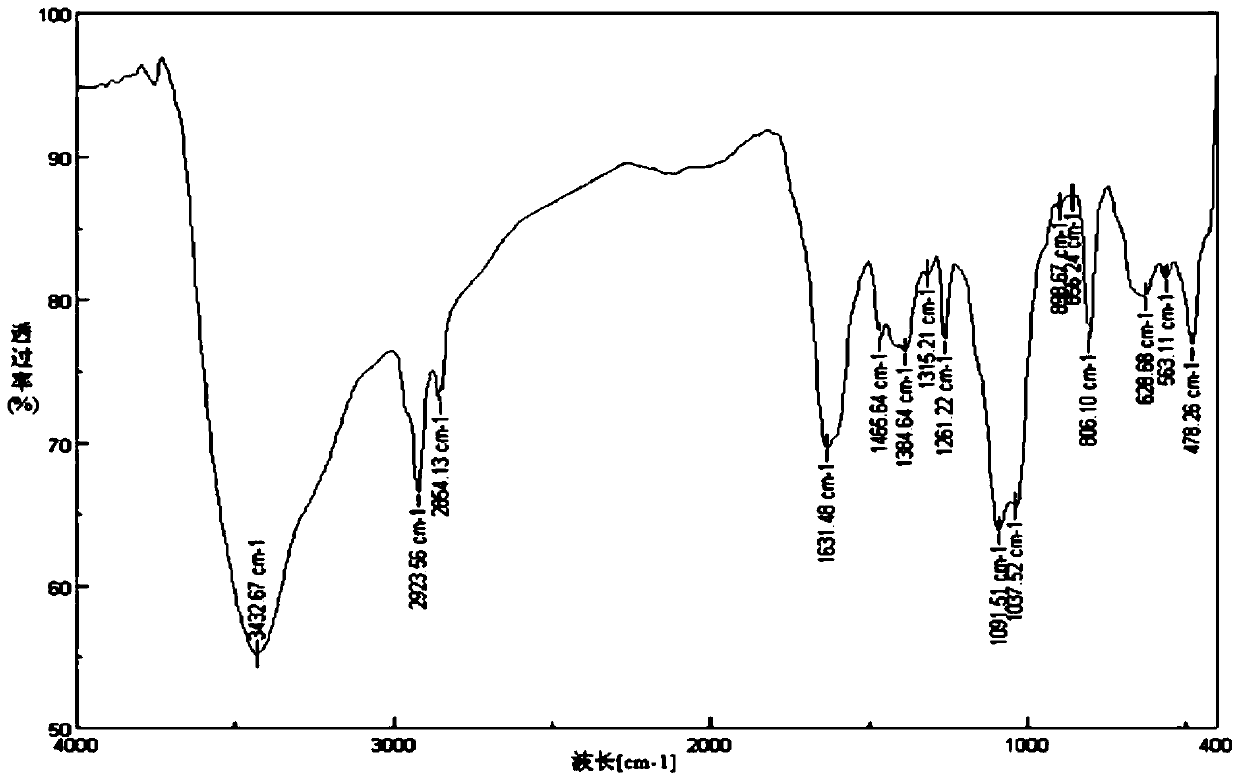

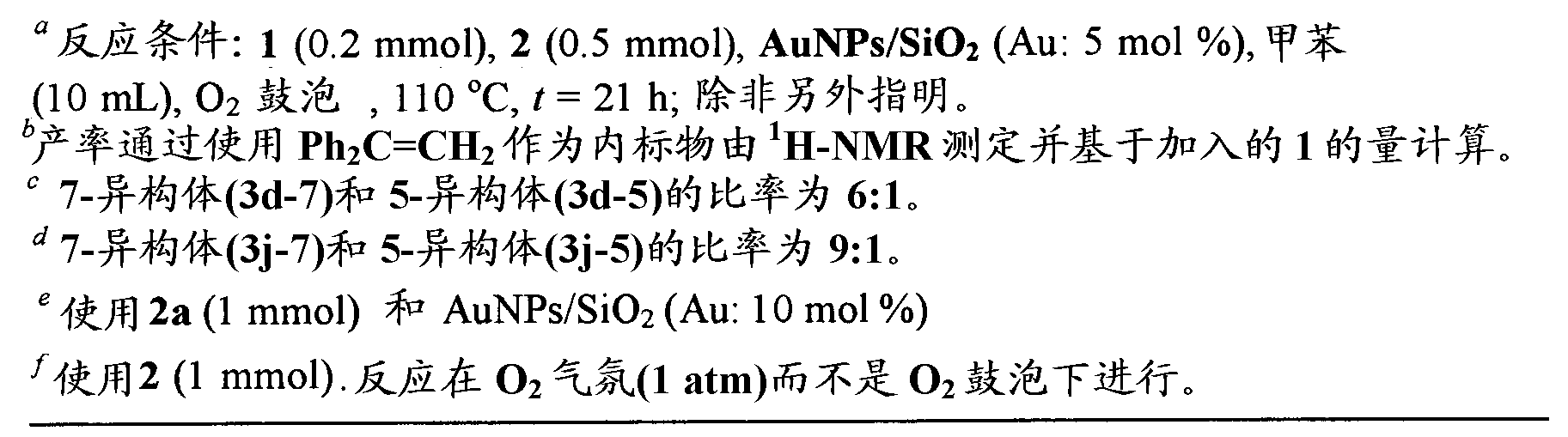

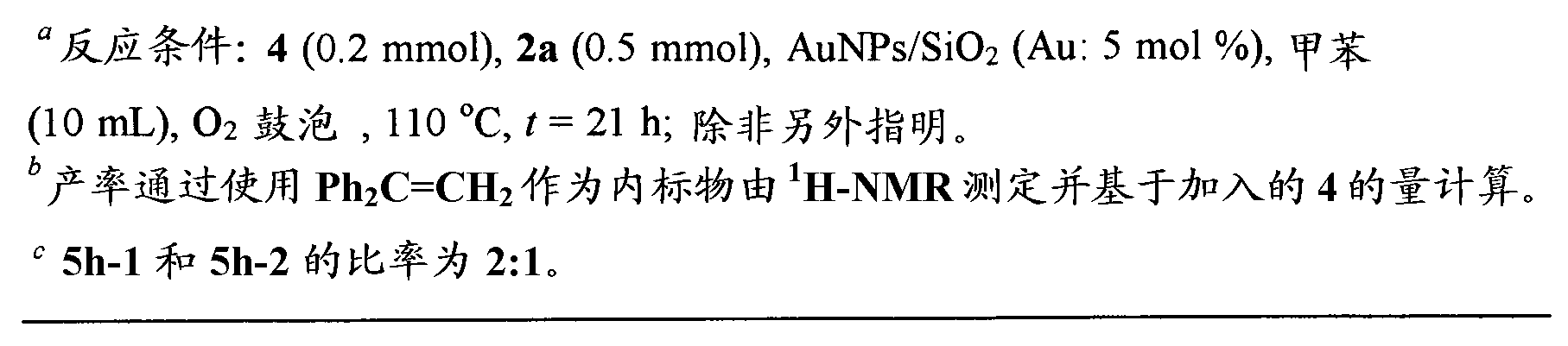

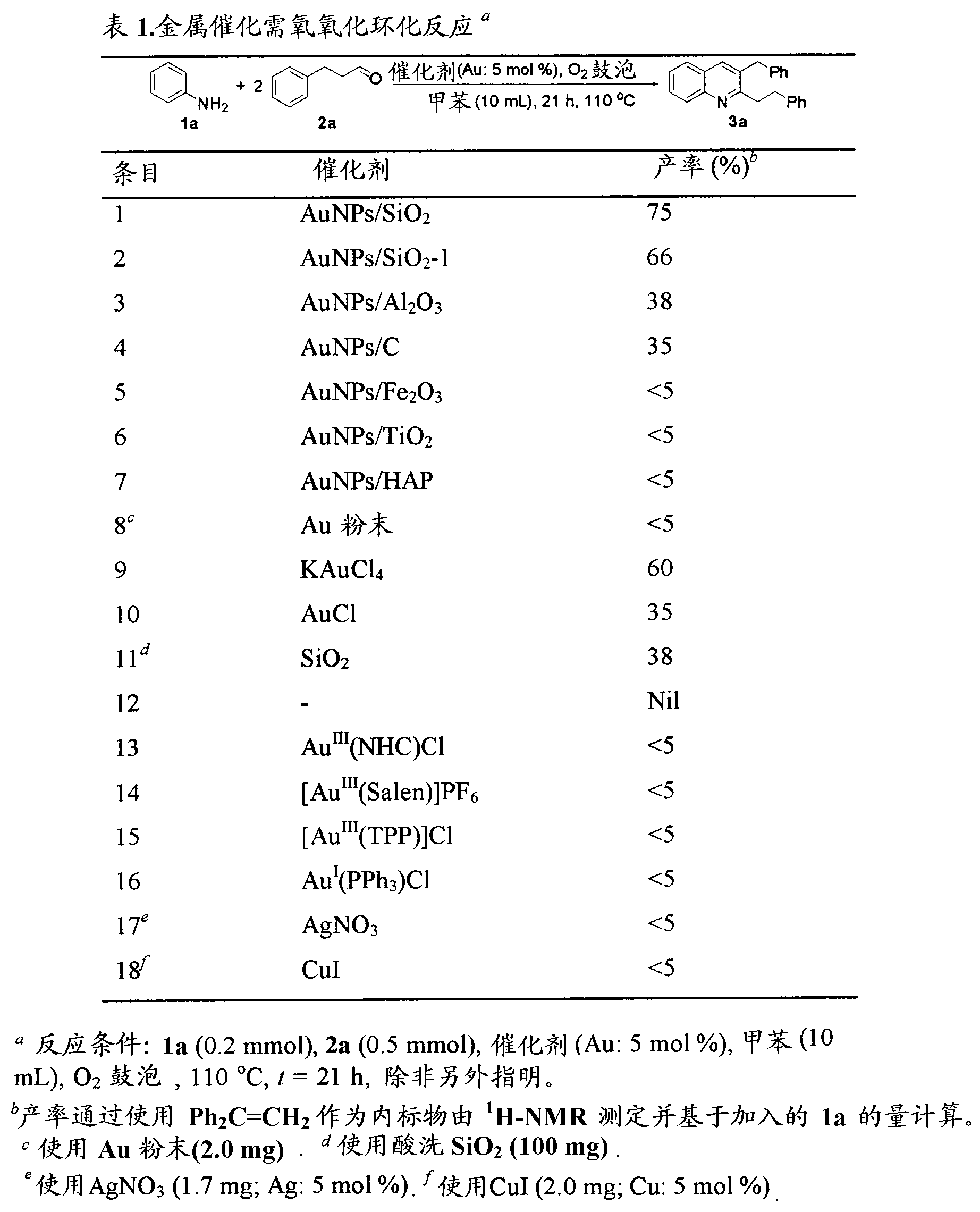

Solid supported gold nanoparticles, methods of use thereof, and methods for making same

Solid-supported gold nanoparticles for use as a catalyst for the synthesis of quinolines from anilines and aldehydes using oxygen as an oxidant are provided. Also provided are a method for the preparation of Si02-supported gold nanoparticles by in situ deposition of gold nanoparticles to silica gel and a method for synthesizing quinolines from anilines and aldehydes using oxygen as an oxidant.

Owner:THE UNIVERSITY OF HONG KONG

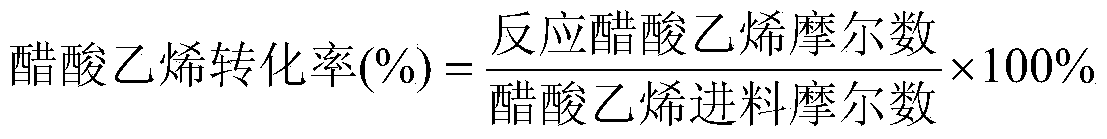

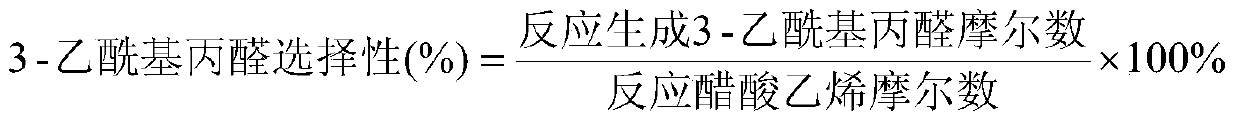

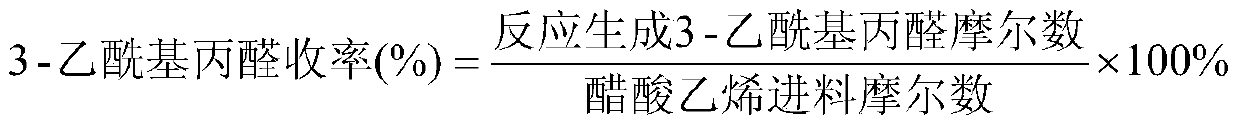

Catalyst for synthesis of 3-acetoxy propionaldehyde

ActiveCN105498785AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionLow activityActive component

The invention relates to a catalyst for synthesis of 3-acetoxy propionaldehyde, and mainly solves the problems of low activity and selectivity of 3-acetoxy propionaldehyde catalyst in the prior art. According to a technical scheme, the 3-acetoxy propionaldehyde catalyst adopts SiO2, Al2O3 or a mixture thereof as the carrier, the active component includes at least one of iron series elements, an alkali metal element and at least one metal element selected from VA and IB, thus welling solving the problems. The 3-acetoxy propionaldehyde catalyst can be used for the industrial production of 1.3-propanediol.

Owner:CHINA PETROLEUM & CHEM CORP +1

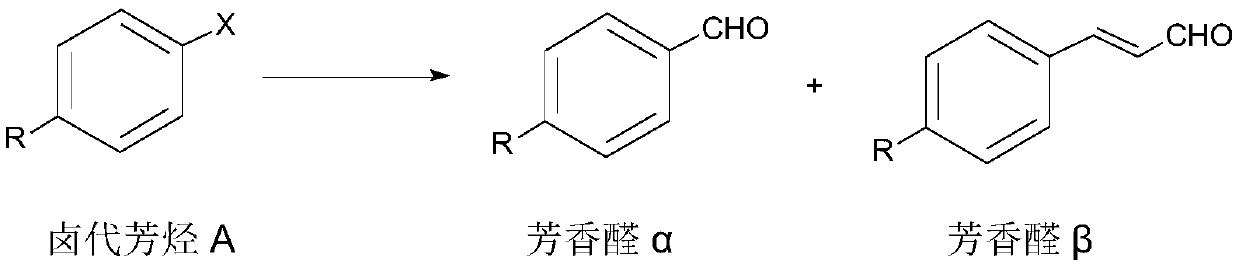

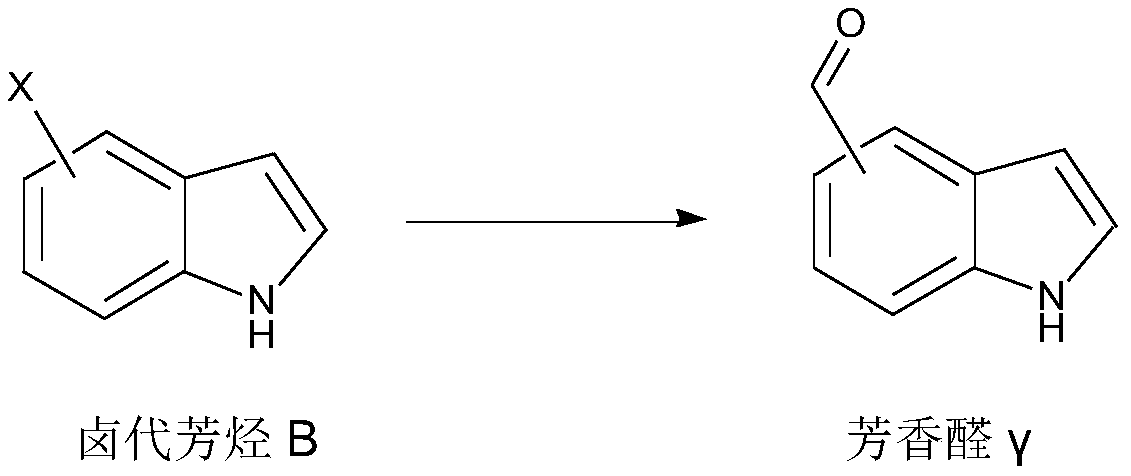

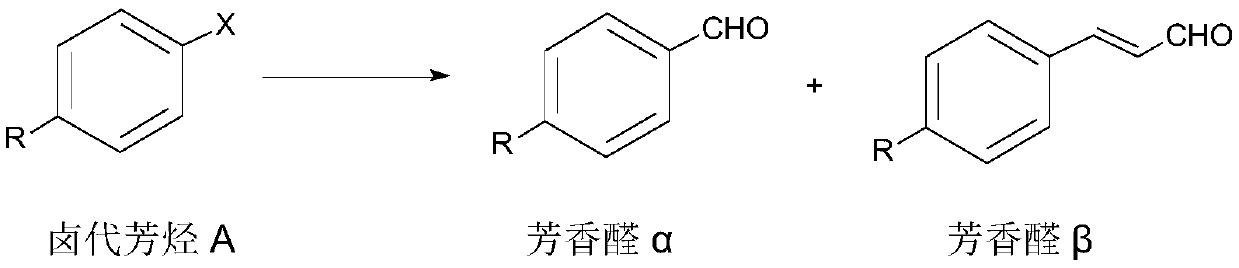

Aromatic aldehyde synthesis method

ActiveCN109824567AConducive to large-scale industrial productionEasy to separateOrganic compound preparationCarboxylic acid esters preparationGlyoxylic acidReaction rate

The invention provides an aromatic aldehyde synthesis method. Aryl halide serves as a starting material, glyoxylic acid serves as a carbonyl source, proper palladium catalysts and phosphine-containingorganic ligands are used, and aromatic aldehyde serving as a target product is prepared by heating and sealing reaction. Raw materials of the synthesis method are easily obtained, operation is simple, the product is easily separated, total reaction rate is high, process cost is low, and the yield of the target product is easily adjusted. Therefore, the aromatic aldehyde synthesis method is beneficial to large-scale industrial production of the aromatic aldehyde.

Owner:SHANGHAI BILOR NEW MATERIALS TECH

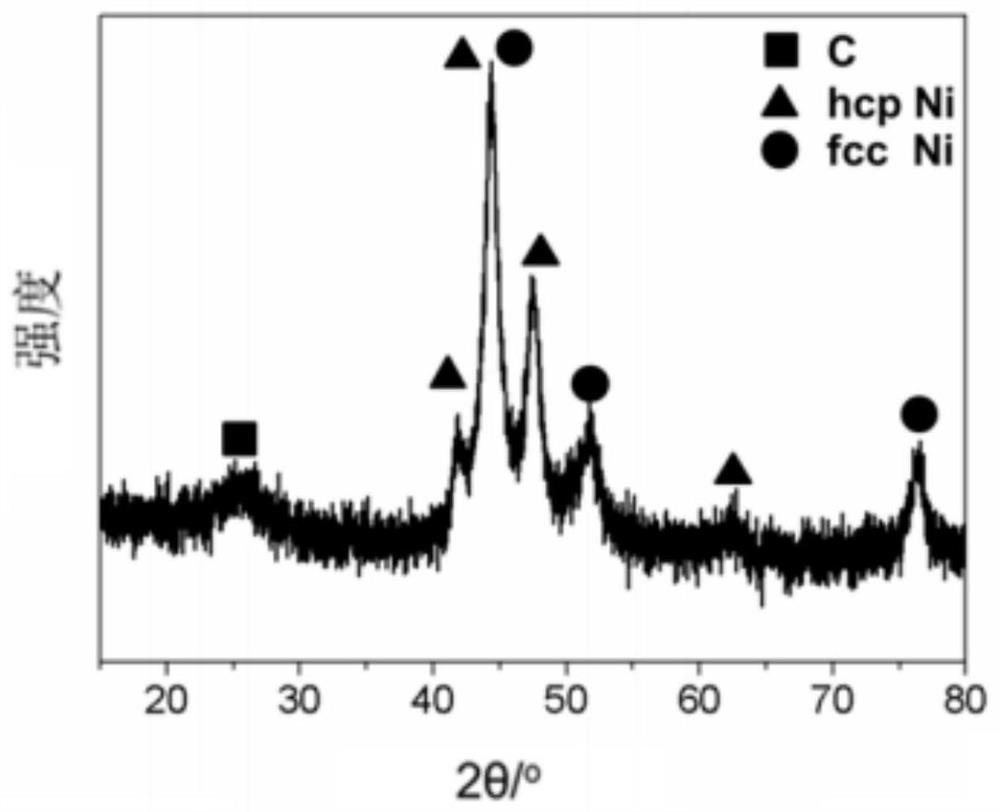

Synthesis method of saturated aldehyde

PendingCN112707802AEnsure safetyReduce riskOrganic compound preparationCarbonyl compound preparationCarbon layerPtru catalyst

The present invention provides a synthesis method of saturated aldehyde, which comprises that a carbon-coated nickel nanometer composite material is adopted as a catalyst, and alpha, beta-unsaturated aldehyde is catalyzed under a hydrogen atmosphere to carry out a hydrogenation reduction reaction so as to obtain saturated aldehyde, wherein the nano composite material contains a core-shell structure with a shell layer and an inner core, the shell layer is a graphitized carbon layer, the inner core is nickel nano particles, and the inner core of the nickel nano particles comprises a face-centered cubic lattice structure and / or a hexagonal compact lattice structure. The carbon-coated nickel nano composite material is used as the catalyst, C=C bonds can be selectively hydrogenated to synthesize corresponding saturated aldehyde from alpha, beta-unsaturated aldehyde, the reaction selectivity is high, the condition is mild, the product is conveniently separated from the catalyst, and compared with an industrial traditional Raney nickel catalyst, the catalytic system has better safety and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Simple Synthesis of High-Carbon Aldehyde Catalyst

ActiveCN110694657BReduced internal ene yieldLow costPhysical/chemical process catalystsOrganic compound preparationPtru catalystMetal catalyst

The invention relates to high-carbon aldehyde synthesis, and provides a high-activity high-carbon aldehyde synthesis catalyst, which realizes the conversion of high-carbon α-olefin into high-carbon aldehyde, the conversion rate of α-olefin is close to 100%, and the yield of product aldehyde is 96%. The catalyst of the invention comprises metallic cobalt Co and nickel Ni, non-metallic phosphorus P and boron B to form a Ni-Co-P-B amorphous alloy. Compared with traditional metal catalysts, this catalyst belongs to non-equilibrium metastable state in thermodynamics, and has unique coordination unsaturation, electronic interaction, and adjustable composition, showing superior catalytic performance. The catalyst according to the invention has the advantages of simple preparation process, low cost, high activity and adjustable product ratio.

Owner:NINGXIA UNIVERSITY

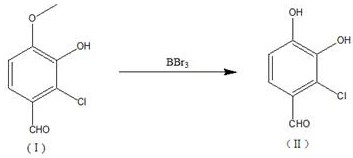

Preparation method for removing aromatic methyl ether and methyl

InactiveCN112390711ASimple and fast operationPreparation method greenOrganic compound preparationCarbonyl compound preparationBenzaldehydeSide reaction

The invention discloses a method for removing aromatic methyl ether and methyl in synthesis of a key intermediate 2-chloro-3, 4-dihydroxybenzaldehyde of cefdinir, and belongs to the field of synthesisof medical intermediates. The method comprises the following steps: dissolving 2-chloro-4-methoxy-3-hydroxy benzaldehyde serving as a raw material, putting the dissolved 2-chloro-4-methoxy-3-hydroxybenzaldehyde into a low-temperature reactor, dropwise adding a boron tribromide solution, reacting for a certain time, quenching BBr3 by using methanol after the reaction is finished, adding hydrochloric acid to adjust the pH value, heating and refluxing, reducing the temperature of a reaction solution, cooling to obtain the aromatic methyl ether, separating out solid, filtering and collecting thesolid, namely the 2-chloro-3, 4-dihydroxybenzaldehyde. Compared with other methyl removal methods, the method has the advantages of mild reaction conditions, simpler operation, more efficient and faster reaction, and fewer impurities, byproducts and side reactions.

Owner:UNIV OF JINAN

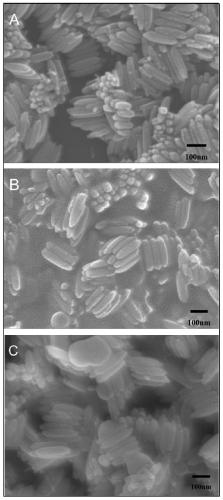

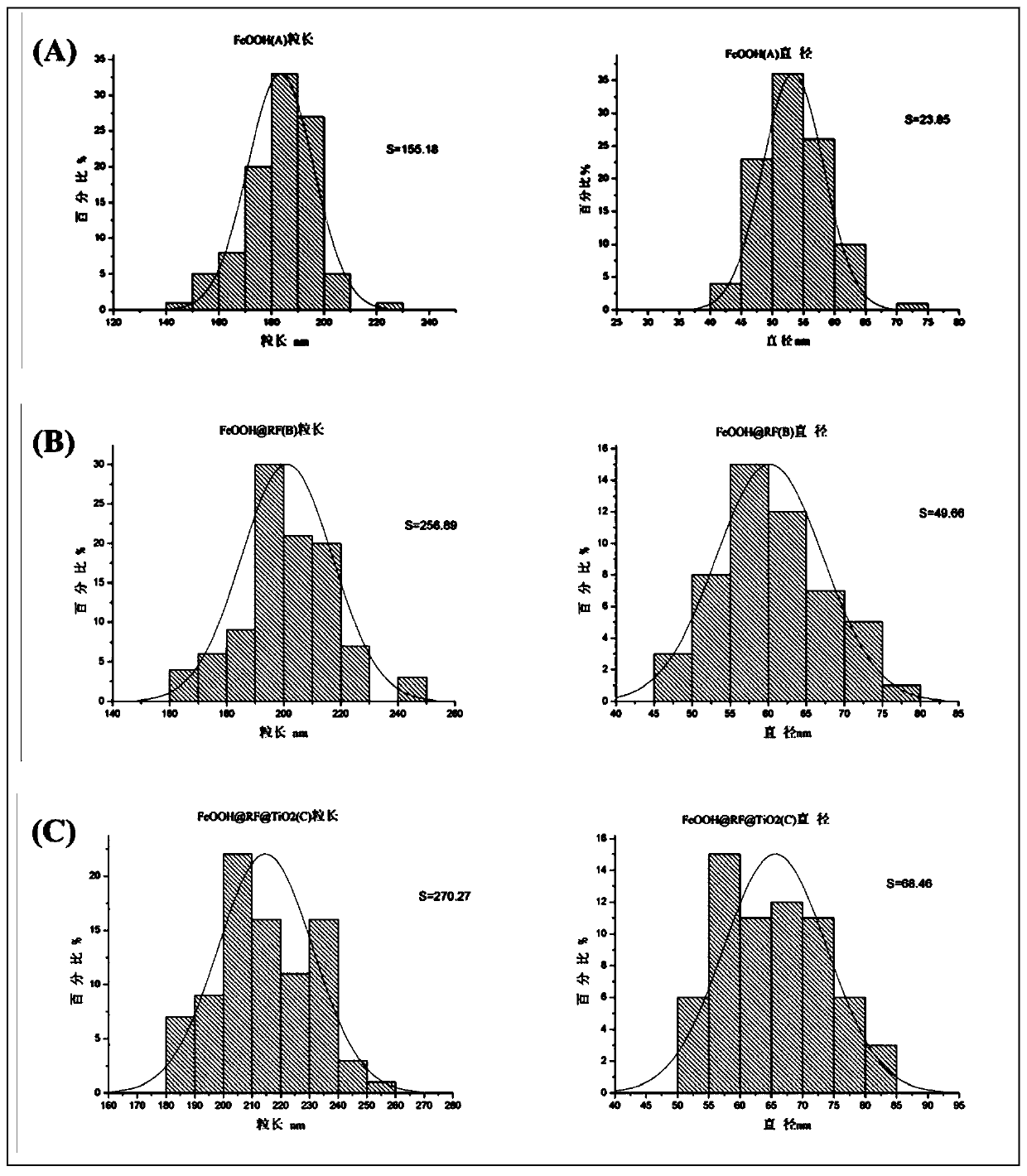

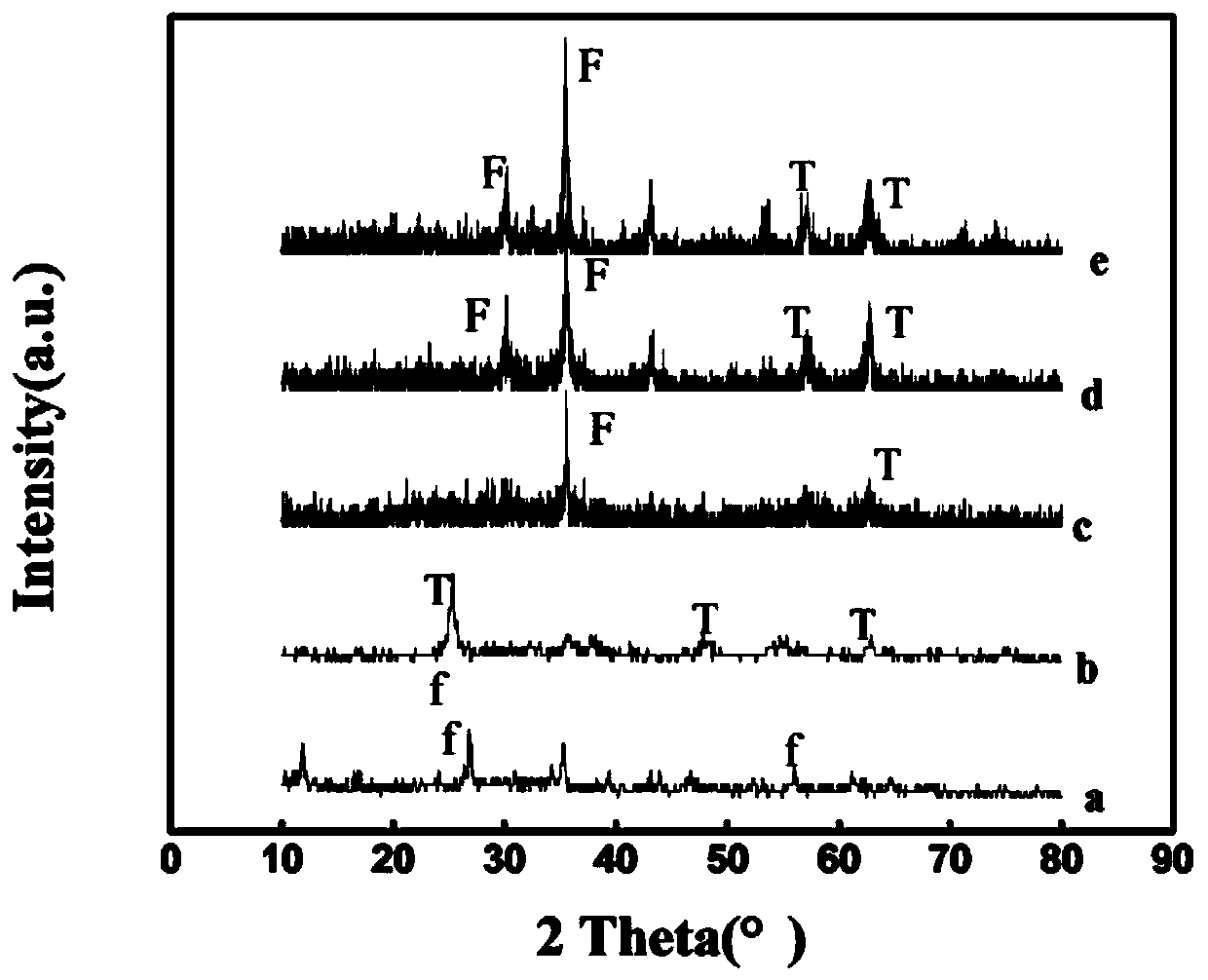

a fe 3 o 4 @c@tio 2 A Simple Preparation Method of Magnetic Separation Photocatalyst

InactiveCN106964350BOvercoming the shortcomings of photocatalytic instabilityEasy to separate and recycleMaterial nanotechnologyWater/sewage treatment by irradiationDispersityMagnetic response

The invention relates to a Fe 3 O 4 @C@TiO 2 A simple preparation method for magnetic separation photocatalysts includes the following steps: 1) Take β-FeOOH nanorods and disperse them in water to form a dispersion; 2) Synthesize FeOOH@RF core-shell nanorods with resorcinol and formaldehyde and disperse them in ethanol Form a dispersion in; 3) Add ethanol and CH 3 Stir CN and ammonia water to form liquid A; separately take ethanol and CH 3 Mix CN and add TBOT to form liquid B, mix and react at room temperature for a certain time to synthesize nanorods; 4) Calculate at high temperature to obtain. The beneficial effects of the present invention are: using a simple and mild method to prepare magnetically responsive recyclable Fe 3 O 4 @C@TiO 2 Visible light nanophotocatalyst. This synthesis method is simple to operate and has low equipment requirements. The prepared Fe 3 O 4 @C@TiO 2 The core-shell structure of nanorods has better dispersion and the nanoparticle size is relatively uniform.

Owner:WUHAN UNIV OF TECH

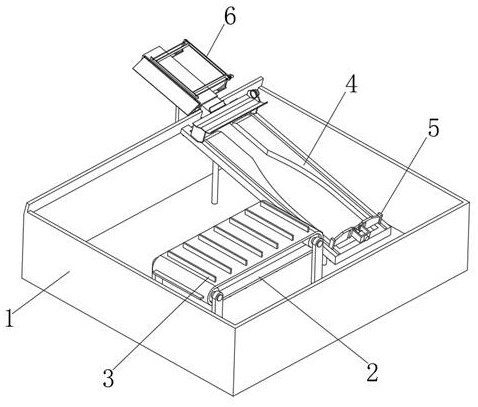

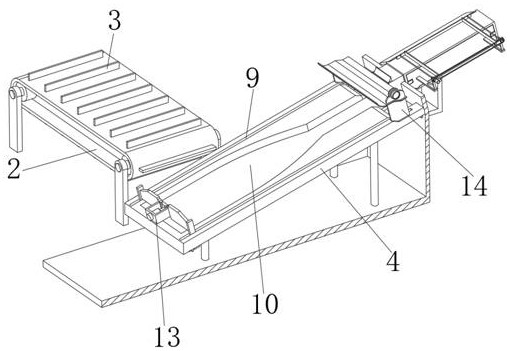

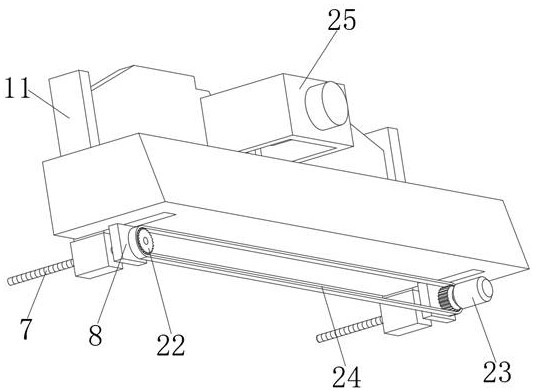

Adjusting device for propionaldehyde synthesis reactor

ActiveCN111715151APrevent oxidation reactionsAdequate responseCarbonyl compound preparation by hydrolysisFeed devicesPhysical chemistryAldehyde synthesis

The invention discloses an adjusting device for a propionaldehyde synthesis reactor. The adjusting device comprises a mounting shell, a belt conveyor is mounted in the mounting shell; a plurality of baffles are fixed to the surface of a conveying belt of the belt conveyor. An inclined table is mounted in the mounting shell; a conveying device used for pushing metallic sodium and capable of removing surface sodium oxide impurities is mounted on the inclined table; a slitting device convenient for reaction of metal sodium is mounted on the side wall of the mounting shell; quantitative kerosene is poured into the mounting shell; oxidation reaction between metal sodium in the mounting shell and air is prevented; the belt conveyor and the conveying device are matched with each other, the metalsodium strip is conveyed out of kerosene, the negative influence of sodium oxide on the reaction is avoided, meanwhile, the metal sodium strip is divided into a plurality of sodium sheets through theslitting device, the mass of the fed metal sodium can be calculated, the reaction is more sufficient, faster and more thorough after the metal sodium is fed, and the reaction efficiency is improved.

Owner:NINGBO JUHUA CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com