Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Glycolaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycolaldehyde is the organic compound with the formula HOCH₂-CHO. It is the smallest possible molecule that contains both an aldehyde group and a hydroxyl group. It is a highly reactive molecule that occurs both in the biosphere and in the interstellar medium. It is normally supplied as a white solid. Although it conforms to the general formula for carbohydrates, Cₙ(H₂O)ₙ, it is not generally considered to be a saccharide.

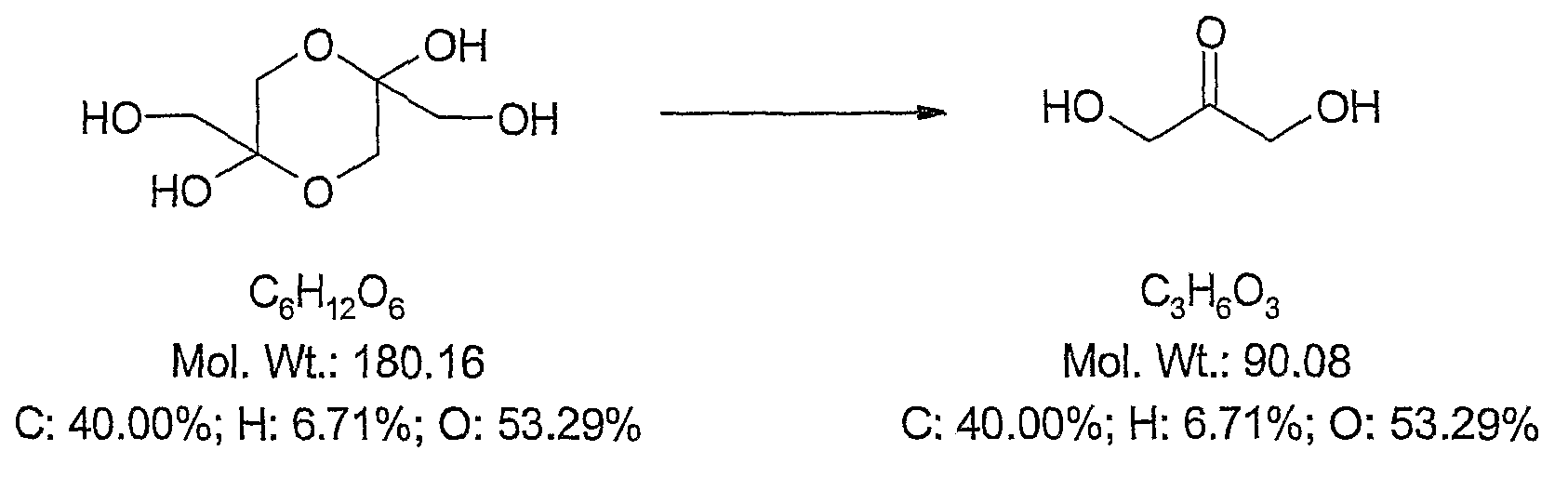

Production of glycolaldehyde by hydrous thermolysis of sugars

ActiveUS7094932B2Increase productionMinimize formationOrganic compound preparationConfectioneryGlucose polymersD-Glucose

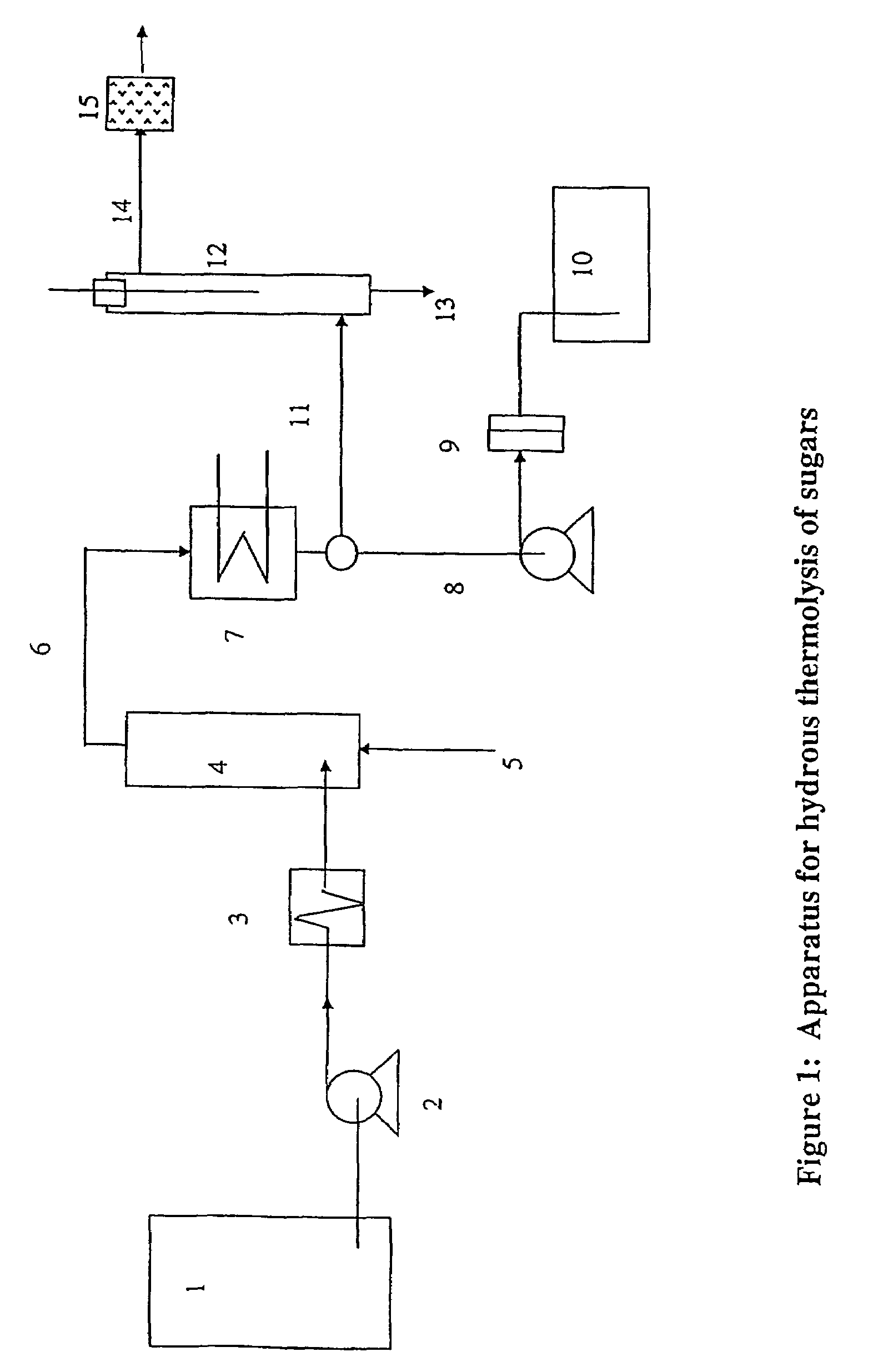

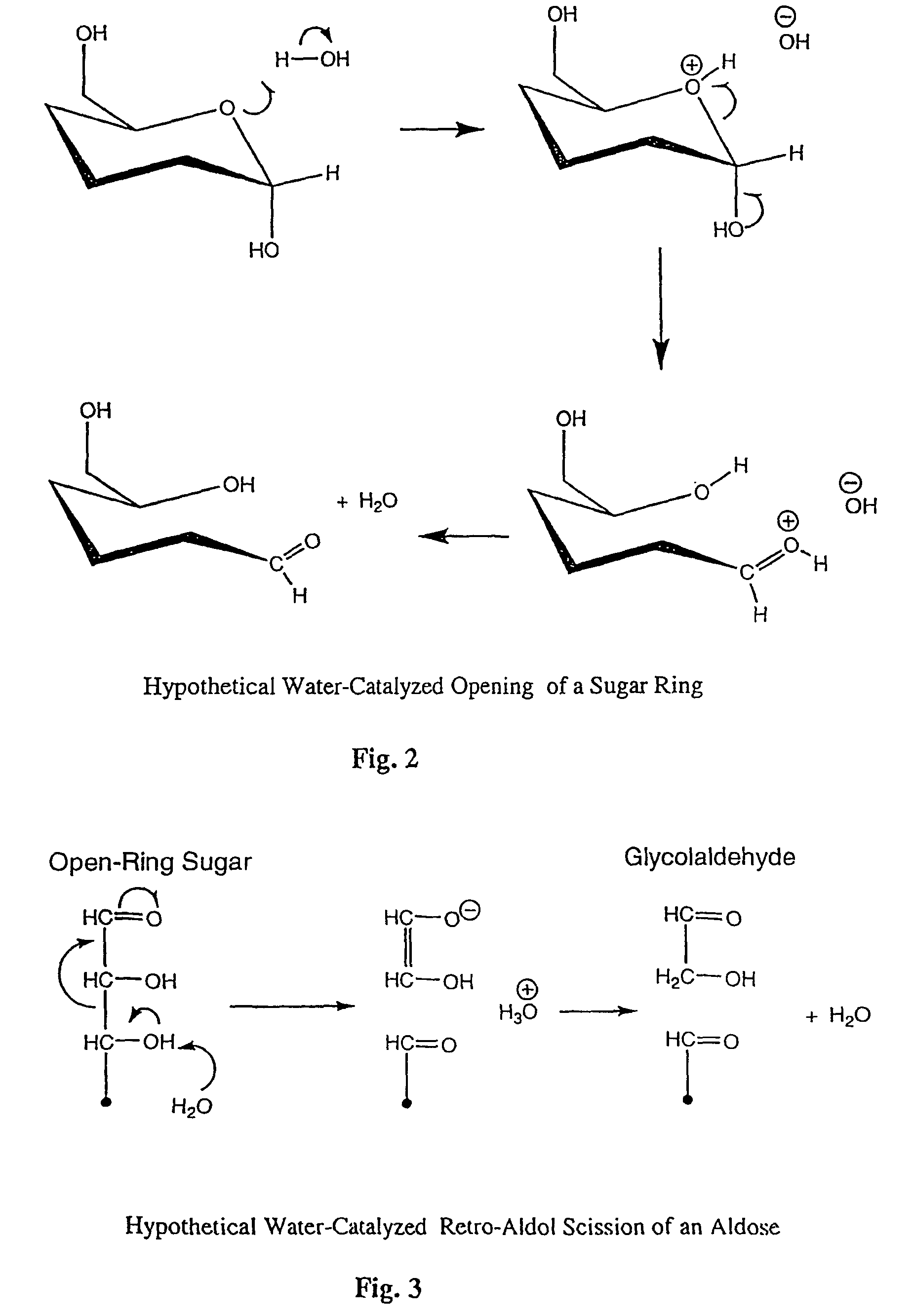

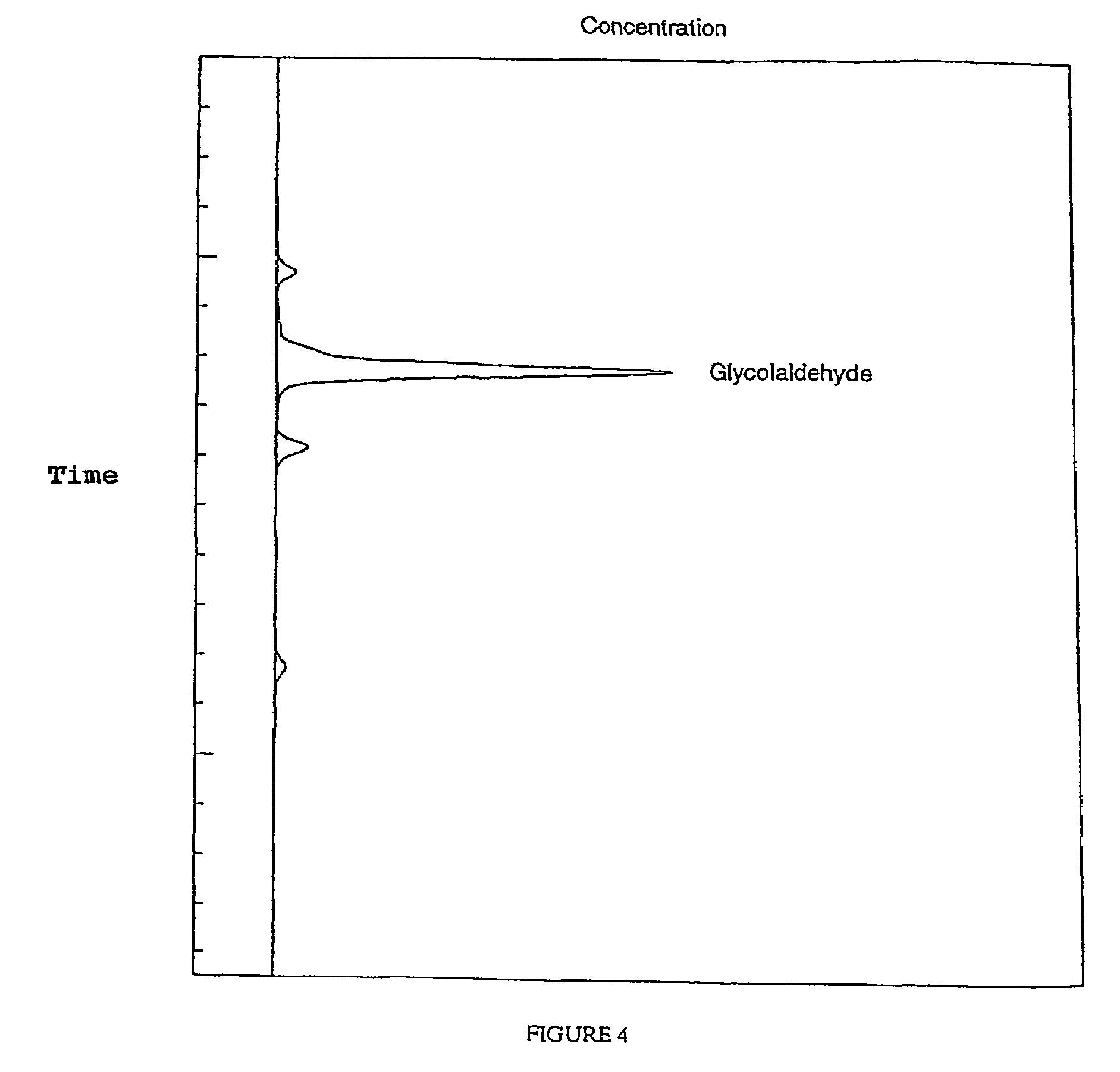

The present invention provides a method for the production of glycolaldehyde with high specificity. The hydrous thermolysis consists of the spraying of aqueous sugar solutions containing from 25 to 80% of water but preferably 30 to 60% water, as a fine mist into a reactor held at the between 500 and 600° C., but preferably between 520 and 560° C. and the condensation of the resulting vaporous product in a surface condenser with optional heat recovery. The residence time of the vaporous product in the reactor should be in the range 0.1–5 seconds, but preferably in the range 0.5 to 2 seconds. Aldose monomeric sugars, preferably glucose (also known as dextrose), are preferred for use in the aqueous solution. The yield of glycolaldehyde in the condensed liquid is minimum 50% by weight of the sugar fed for glucose solutions.

Owner:KERRY GRP SERVICES INT

Process for the continuous production of ethylene glycol from carbohydrates

ActiveUS20150329449A1Organic compound preparationOxygen compounds preparation by reductionHydrogenPropylene glycol

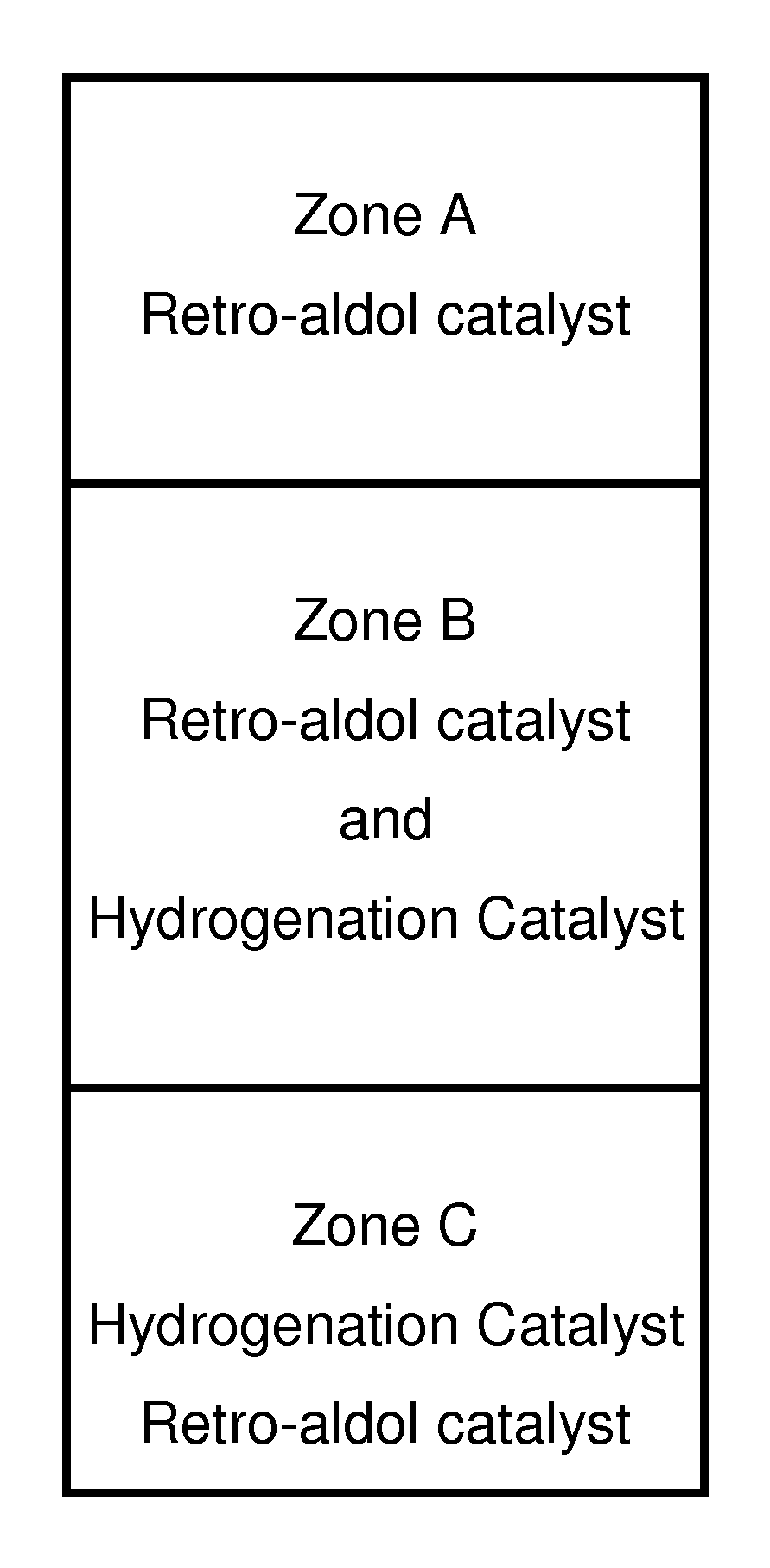

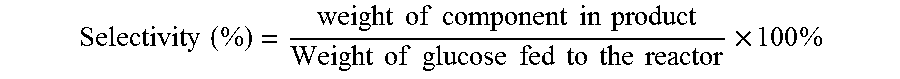

A continuous process for converting carbohydrates to ethylene and propylene glycol. The carbohydrates are mixed with water and passed through a reactor at a temperature that hydrolyzes the carbohydrate mixture at least partially to monosaccharides. The reactor has a first zone comprising a retro-aldol catalyst and a second zone comprising a reducing catalyst. The aldose is converted in the first zone into glycolaldehyde by the retro-aldol catalyst and the glycolaldehyde, in the presence of hydrogen, is converted to ethylene glycol in the second zone of the reactor. The reaction products are removed from the reactor and the ethylene glycol is recovered. The selectivity to propylene glycol can be enhanced via feeding ketose as the carbohydrate.

Owner:TECH PRECESS TECH INC

Zeolite-catalyzed preparation of alpha-hydroxy carboxylic acid compounds and esters thereof

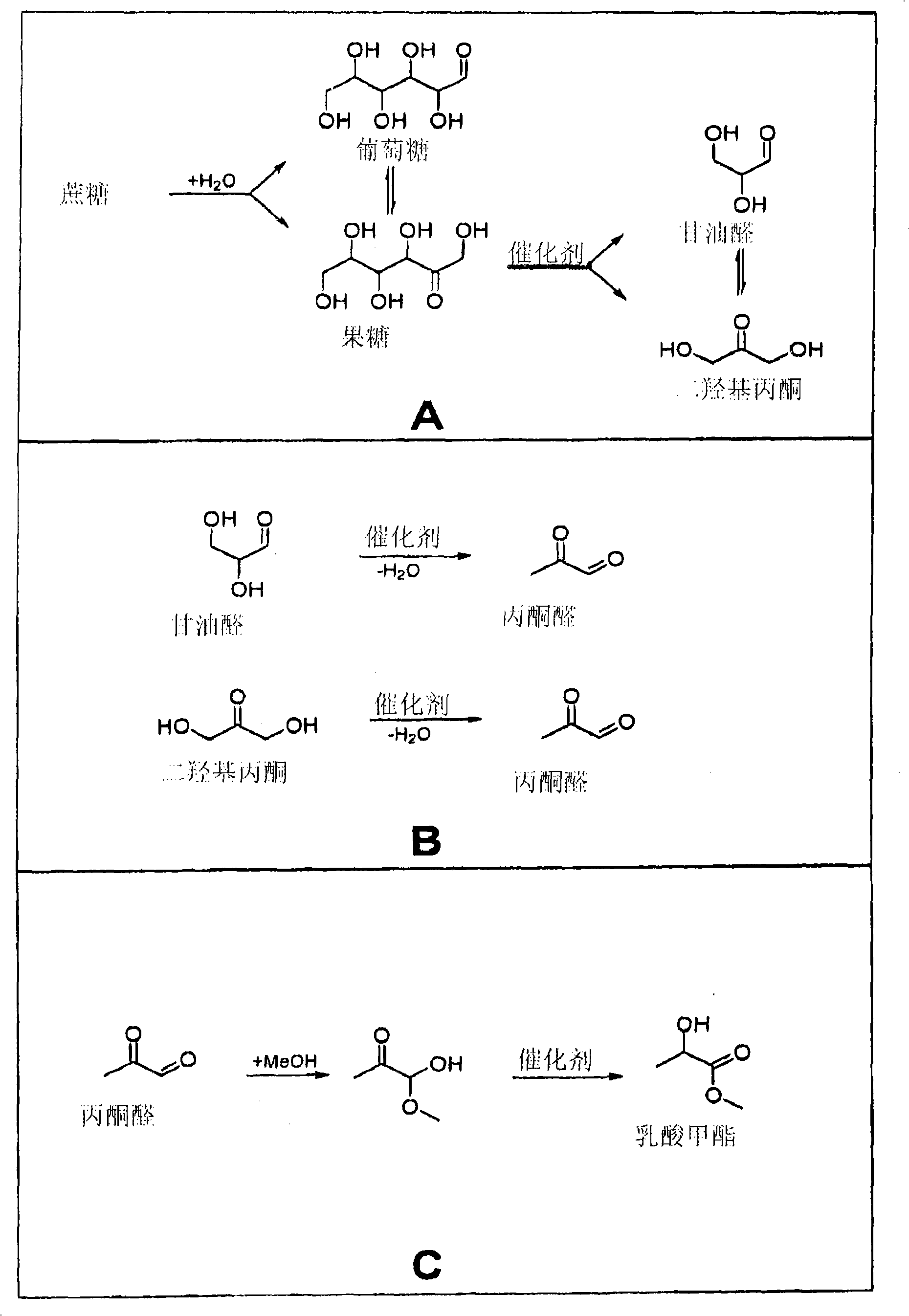

A process for the production of lactic acid and 2-hydroxy-3-butenoic acid or esters thereof by conversion of glucose, fructose, sucrose, xylose and glycolaldehyde dissolved in a solvent in presence of a solid Lewis acidic catalyst.

Owner:HALDOR TOPSOE AS

Novel method for the conversion of cellulose and related carbohydrate materials to low-molecular-weight compounds

ActiveUS20110137085A1Eliminate needOrganic compound preparationPreparation by OH group eliminationCelluloseChemical compound

Methods of converting cellulose or related biorenewable carbohydrate materials into high-value chemical compounds. The methods provide a means of converting low-cost materials such as cellulose and biomass into high yields of compounds such as ethylene glycol, propylene glycol, glycerin, methanol, hydroxyacetone, glycolaldehyde and dihydroxyacetone.

Owner:IOWA STATE UNIV RES FOUND

Process for removing formaldehyde from a composition comprising glycolaldehyde

ActiveUS20160002137A1Reducing percentage by weightLower the volumeFruit and vegetables preservationSugar derivativesAlcoholReactive distillation

A process for reducing the percentage by weight of formaldehyde present in a composition comprising glycolaldehyde, wherein formaldehyde is transformed into one or more formaldehyde acetal(s) and removed from the reactive distillation reaction solution by reactive distillation in the presence of at least one alcohol and a catalyst.

Owner:HALDOR TOPSOE AS

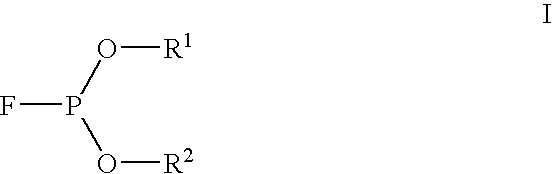

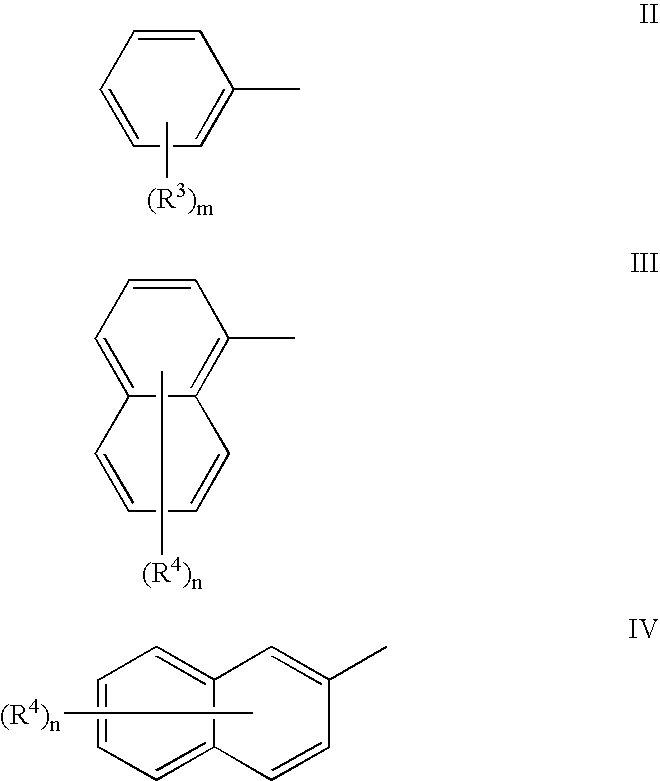

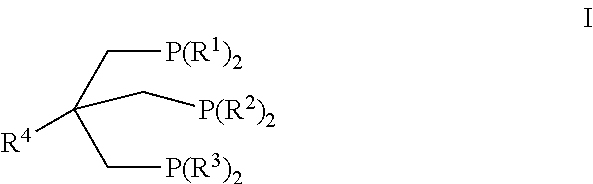

Process of Preparing Glycolaldehyde

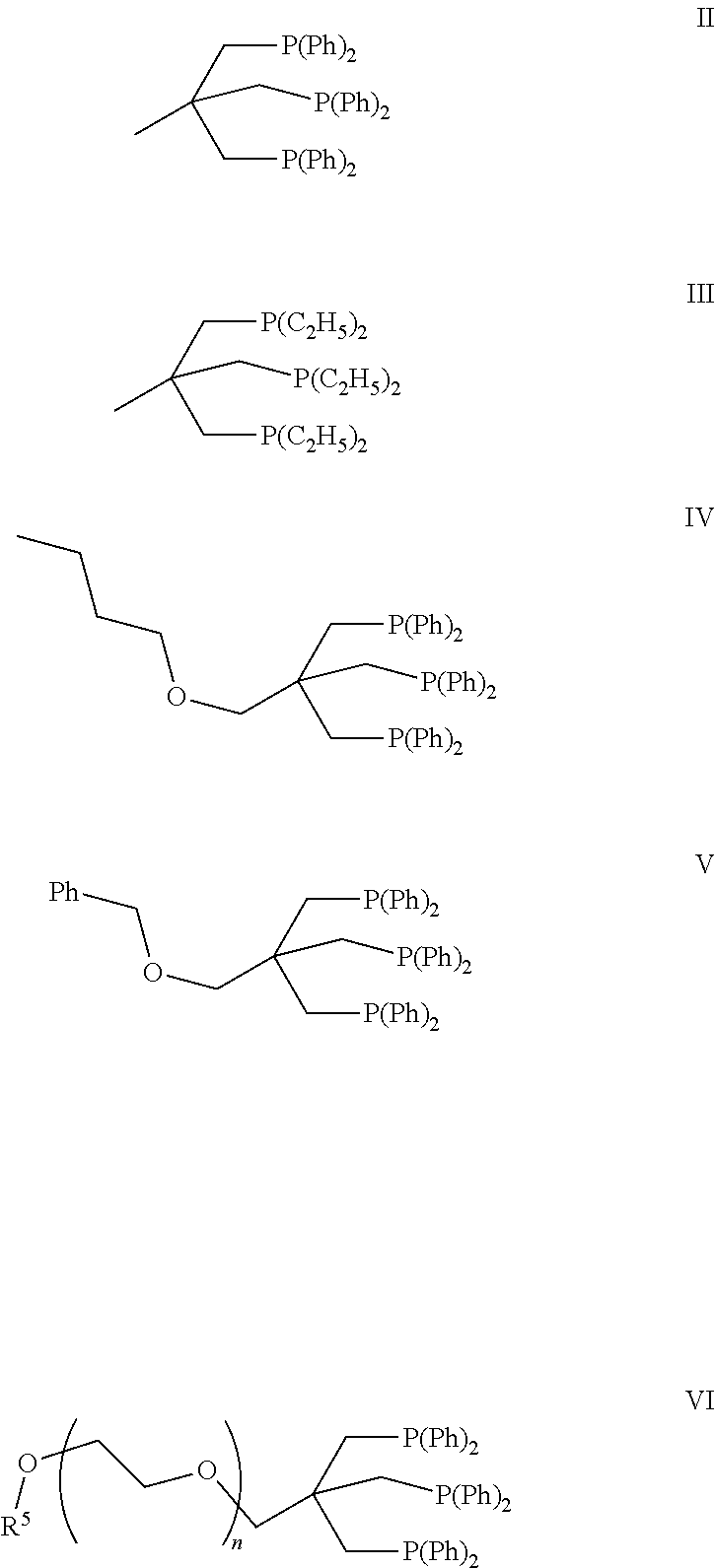

InactiveUS20090012333A1Organic compound preparationGroup 5/15 element organic compoundsPolymer scienceAldehyde

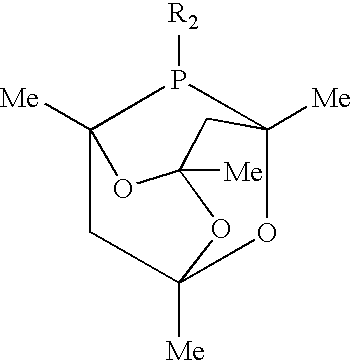

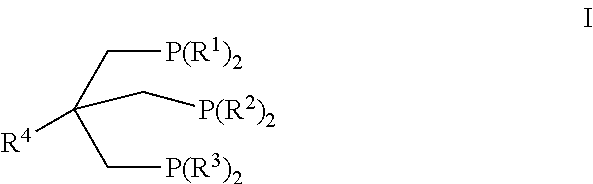

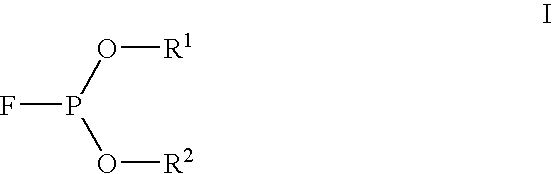

The invention provides a process of preparing glycolaldehyde by reacting formaldehyde with hydrogen and carbon monoxide in the presence of a catalyst composition which is based on, a) a source of rhodium, and b) a ligand of general formula R1P—R2(I), wherein R1 is a bivalent radical that together with the phosphorous atom to which it is attached is an optionally substituted 2-phospha-tricyclo[3.3.1.1{3,7}]-decyl group, wherein from 1 to 5 of the carbon atoms has been replaced by a heteroatom, and wherein R2 is a monovalent radical which is an optionally substituted hydrocarbyl group having from 1 to 40 carbon atoms; a catalyst composition of use in said process; and a process of preparing ethylene glycol from the glycolaldehyde thus prepared.

Owner:SHELL OIL CO

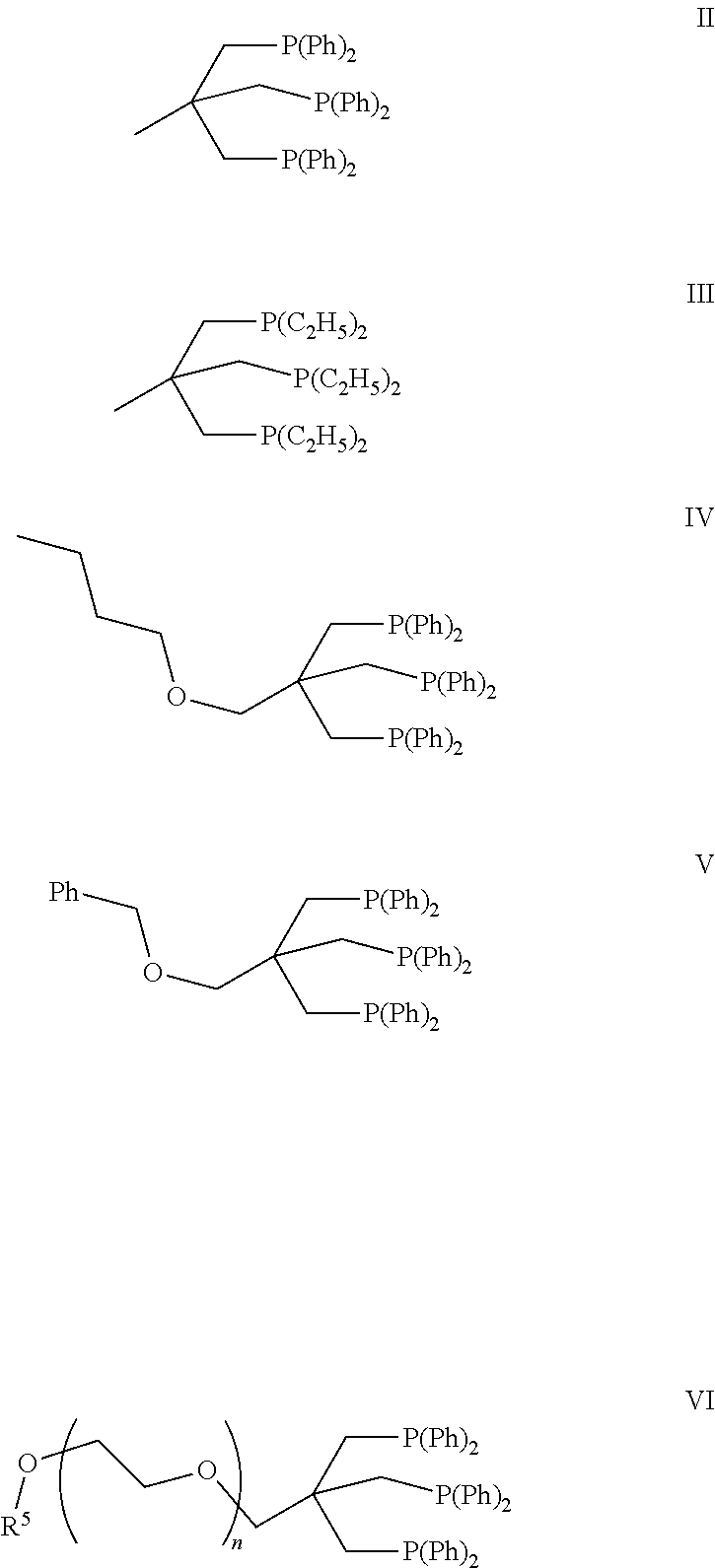

Process for the preparation of glycolaldehyde

ActiveUS20080081931A1High selectivityPromote conversionOrganic compound preparationPreparation by carbon monoxide reactionHydrogenSolvent

Disclosed are processes for the preparation of glycolaldehyde in which formaldehyde is contacted with carbon monoxide and hydrogen in the presence of a rhodium catalyst and a solvent containing at least one N,N-dihexylbutyramide. The glycolaldehyde product is recovered by extraction with water. The process provides high selectivity to glycolaldehyde and efficient separation of hydroformylation products from the solvent and rhodium catalyst.

Owner:EASTMAN CHEM CO

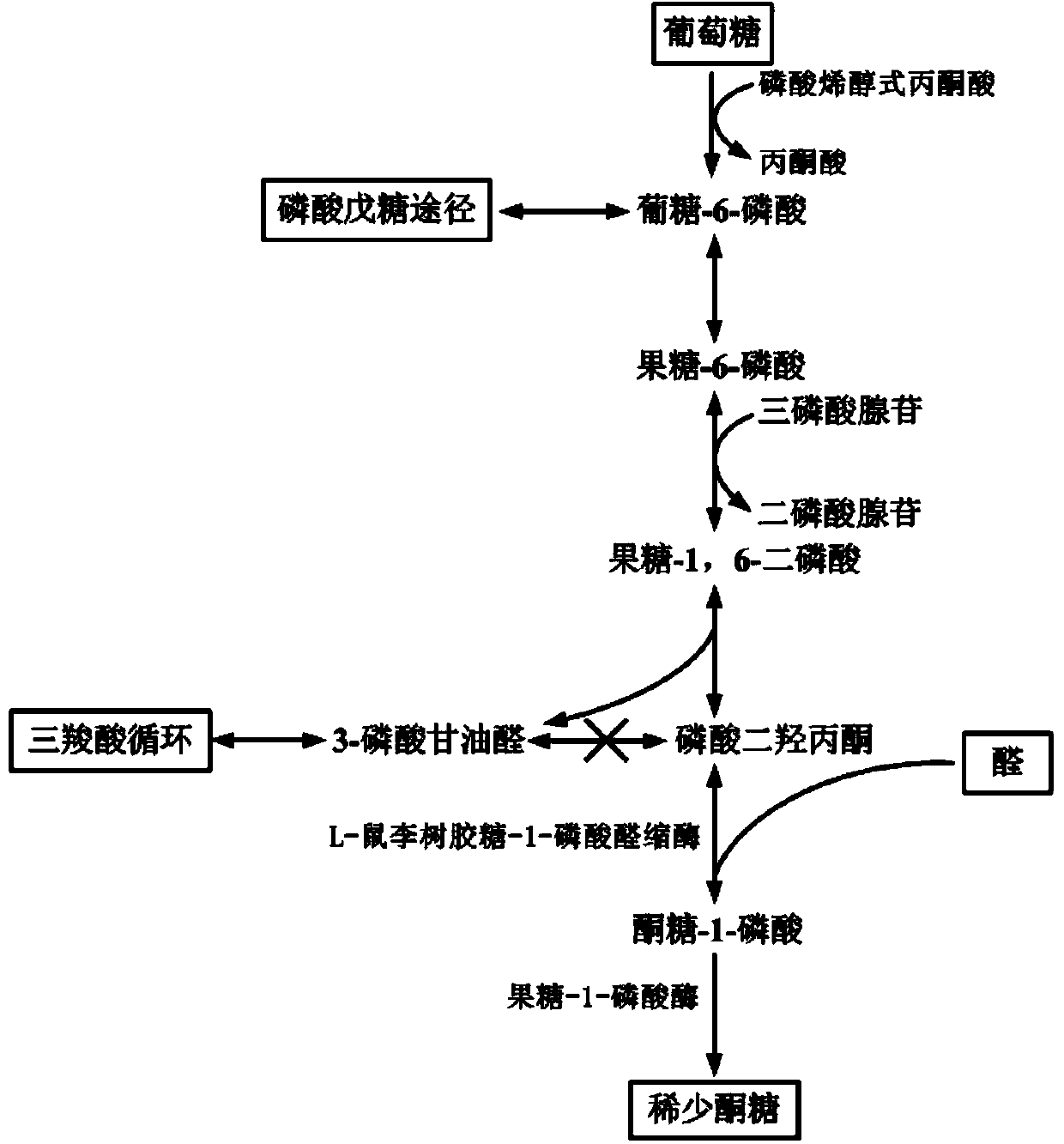

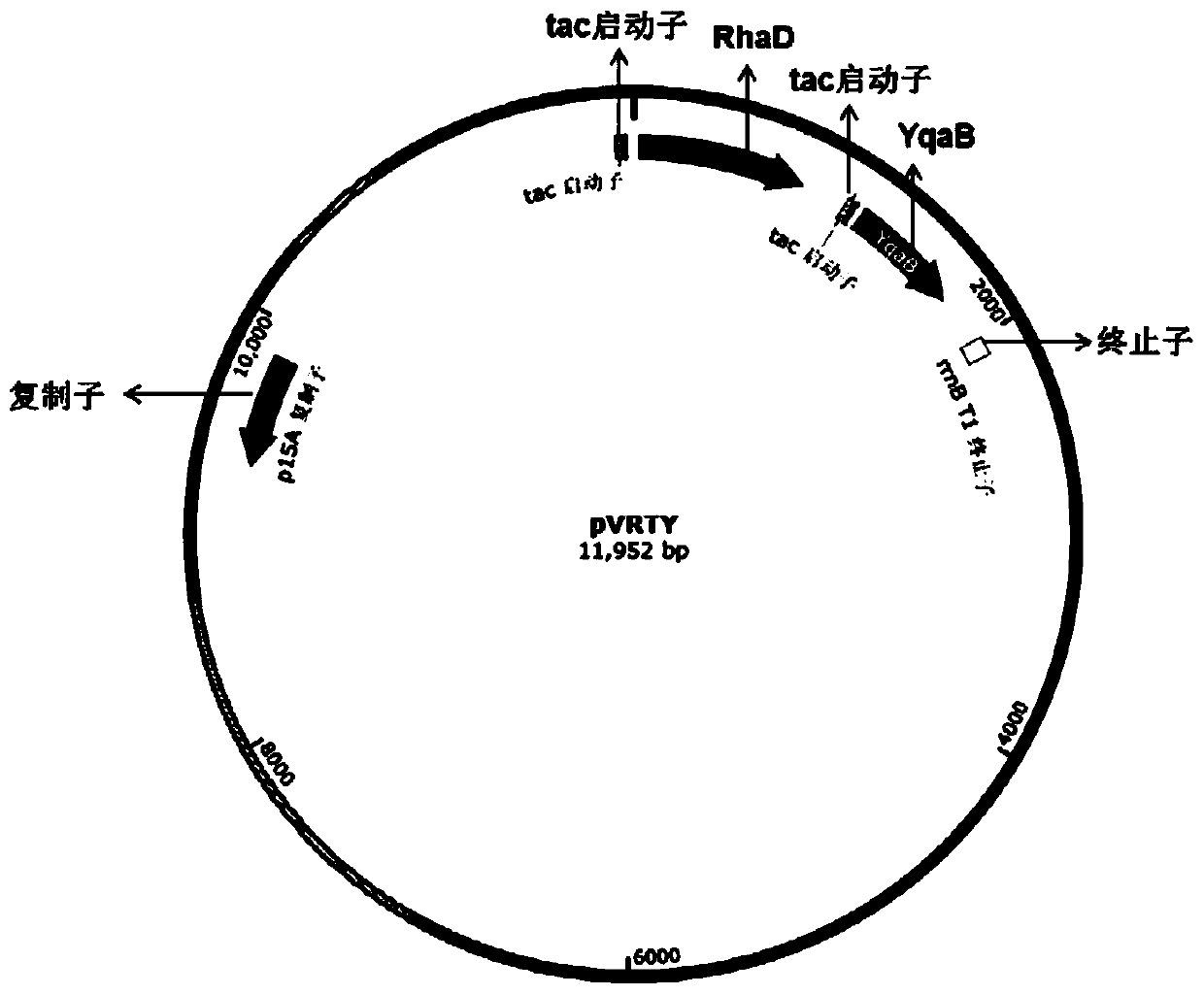

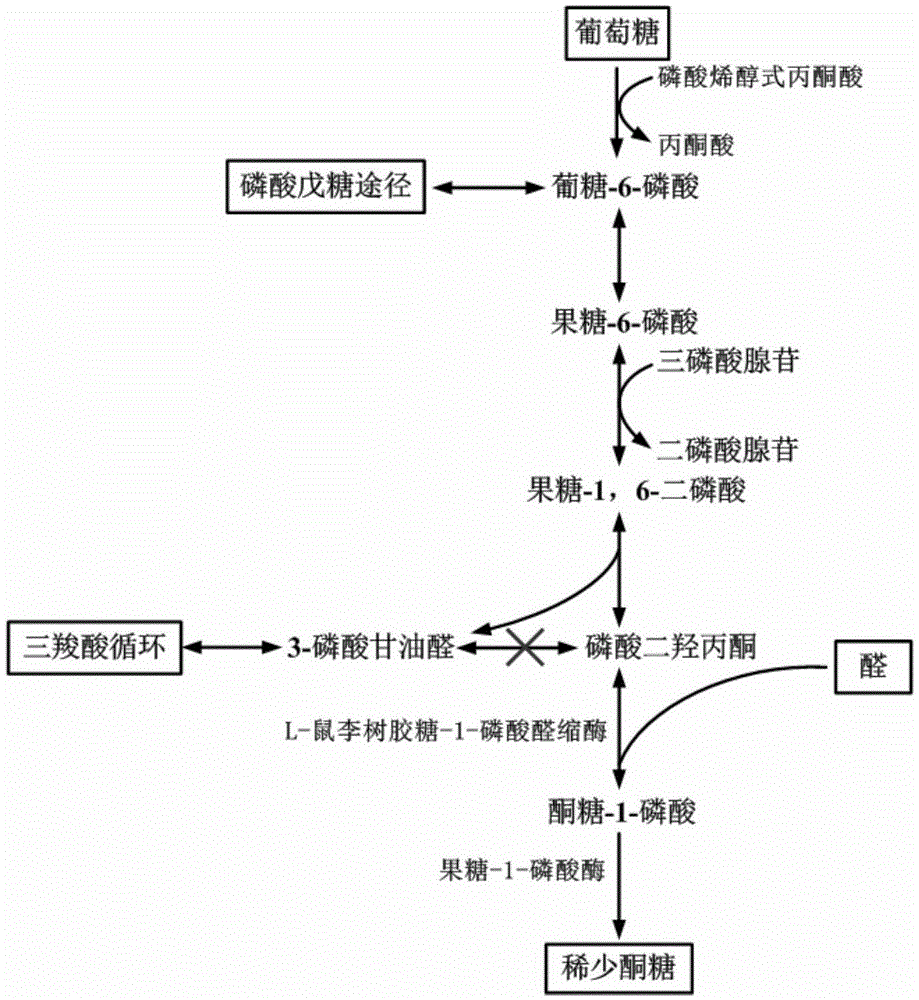

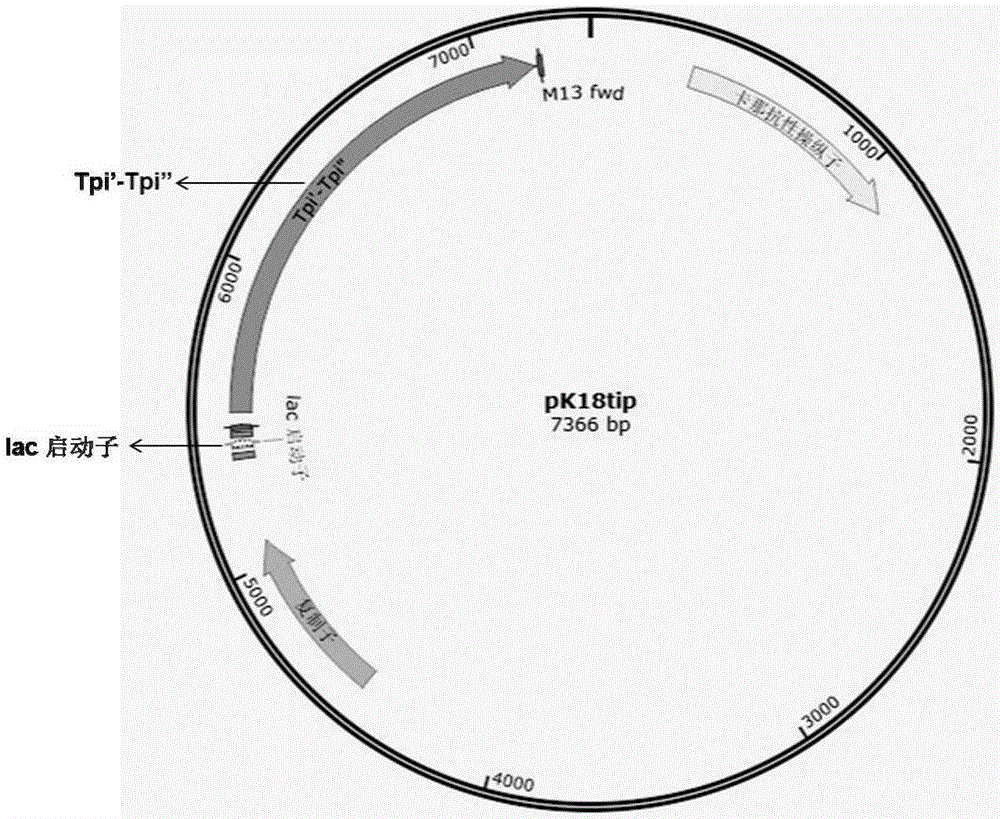

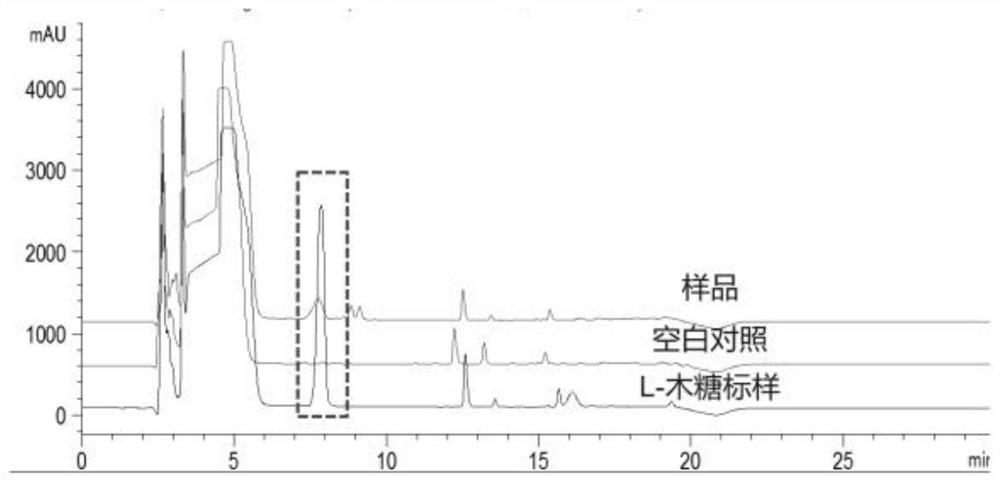

Corynebacterium glutamicum engineering strain for biosynthesis of rare sugar, and building method and application thereof

The invention discloses a corynebacterium glutamicum engineering strain for biosynthesis of rare sugar, and a building method and application thereof, and discloses a corynebacterium glutamicum recombination strain SY10. An experiment proves that rare ketose and deoxidized ketose can be synthesized by adopting a plurality of hydroxyaldehydes and glucoses as substrates by the strain in a fermentation manner, for example, D-erythrulose can be synthesized by adopting formaldehyde and glucose as substrates, L-xylulose can be synthesized by adopting glycolaldehyde and glucose as substrates, D-sorbose and D-psicose can be synthesized by adopting D-glyceraldehyde and glucose as substrates, L-fructose can be synthesized by adopting L-glyceraldehyde and glucose as substrates, and 3R, 4S, 5R, 6R-heptose and 3R, 4R, 5R, 6R-heptose can be synthesized by adopting D-erythrose and glucose as substrates. Therefore, the corynebacterium glutamicum recombination strain SY10 disclosed by the invention can be applied to the field of production of the rare ketose and the deoxidized ketose by whole-cell fermentation; the produced rare ketose and deoxidized ketose have broad application prospects in the industries such as a food, a medicine and the like.

Owner:天工生物科技(天津)有限公司

Process of preparing ethylene glycol

InactiveUS7511178B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceAldehyde

Owner:SHELL OIL CO

Process for the continuous production of ethylene glycol from carbohydrates

Owner:TECH PRECESS TECH INC

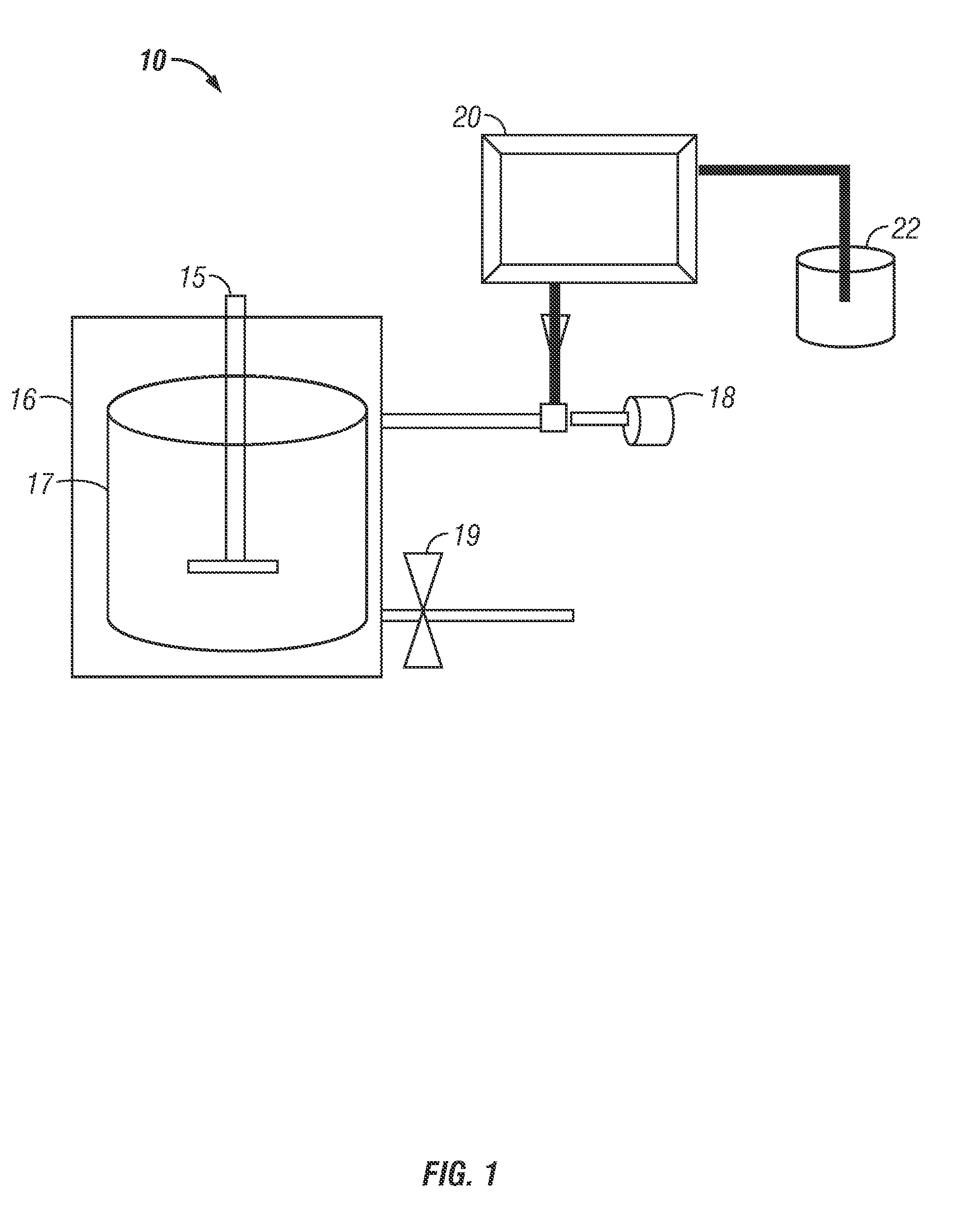

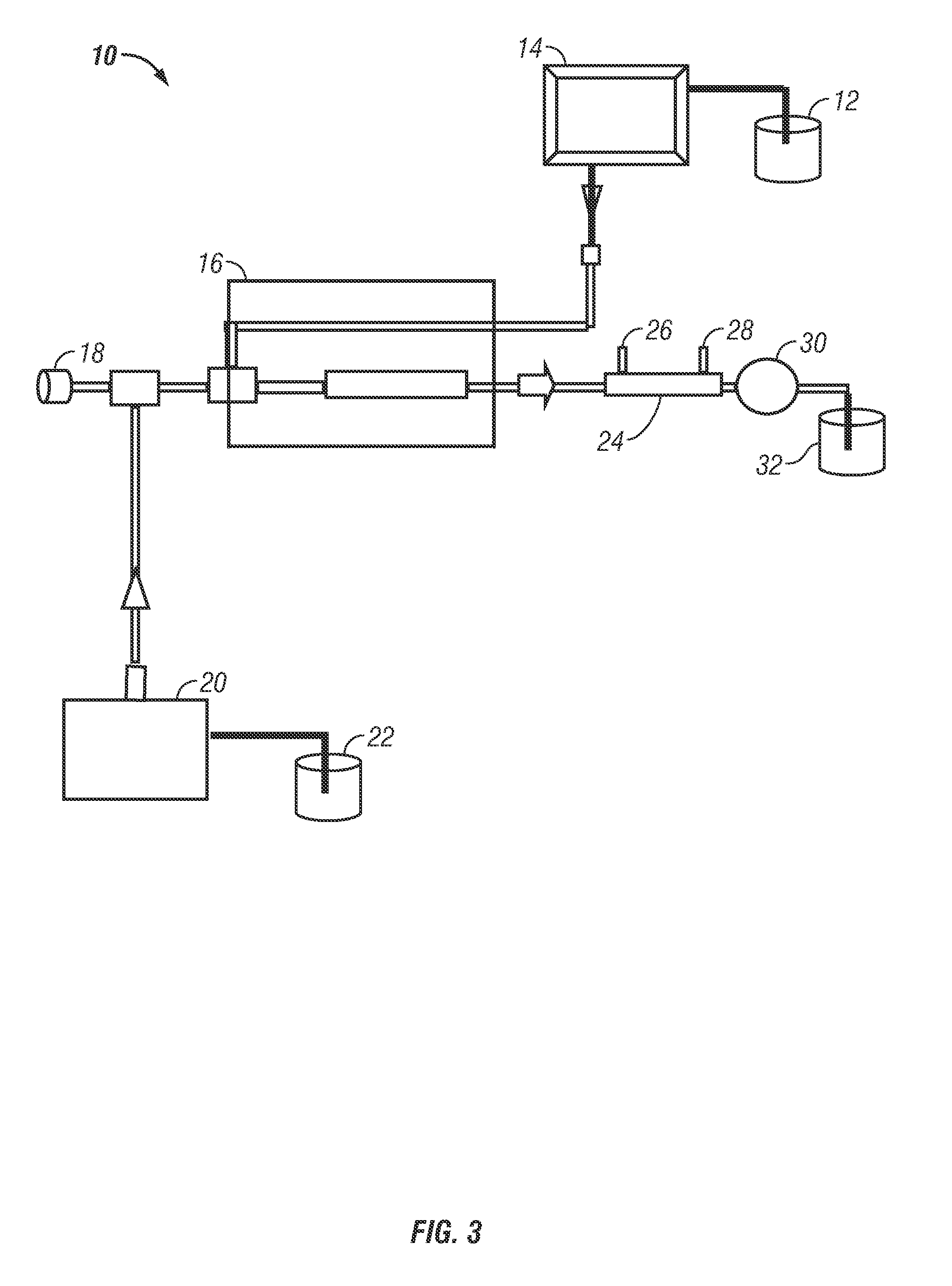

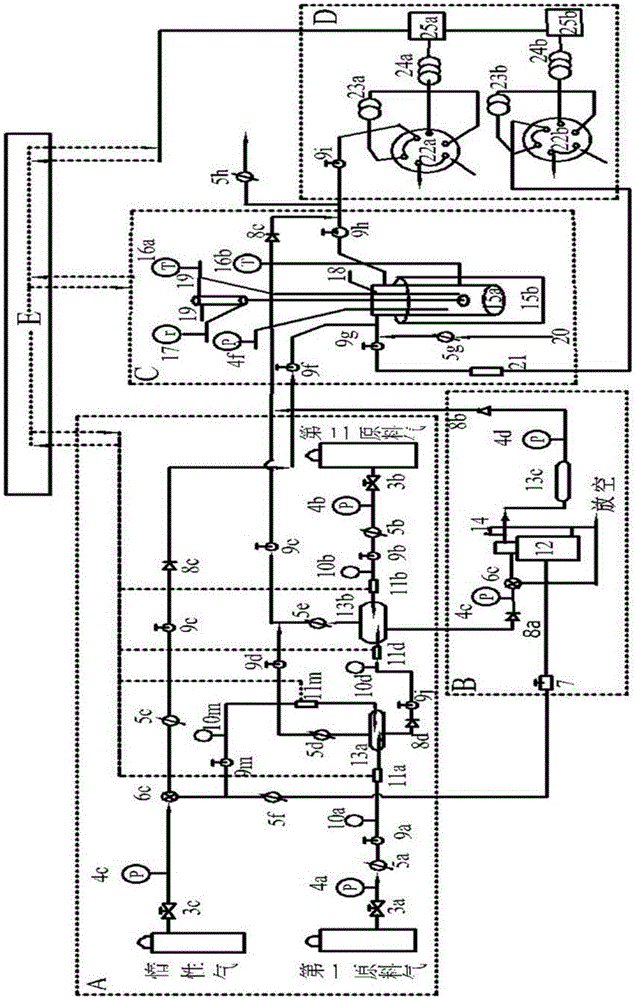

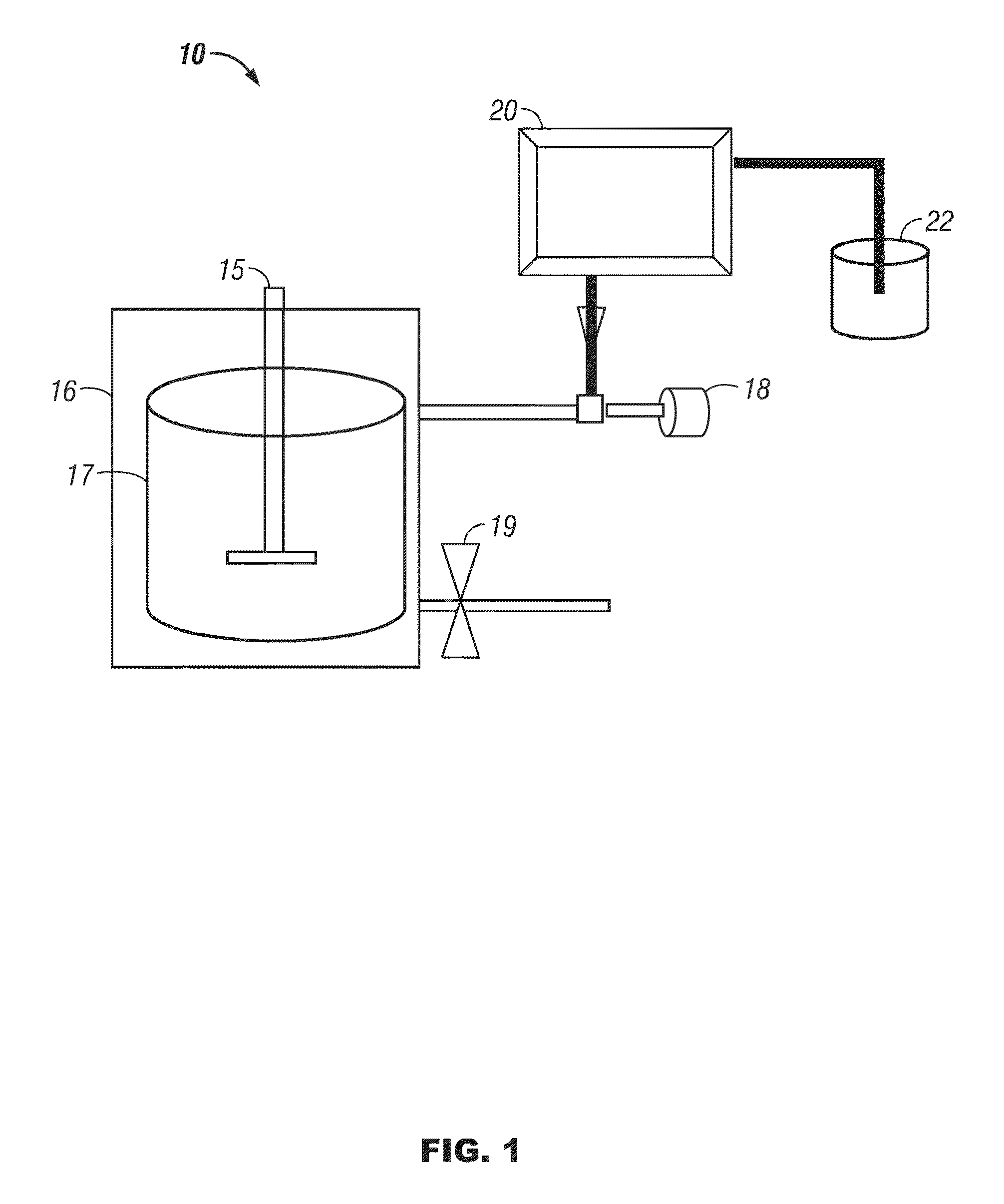

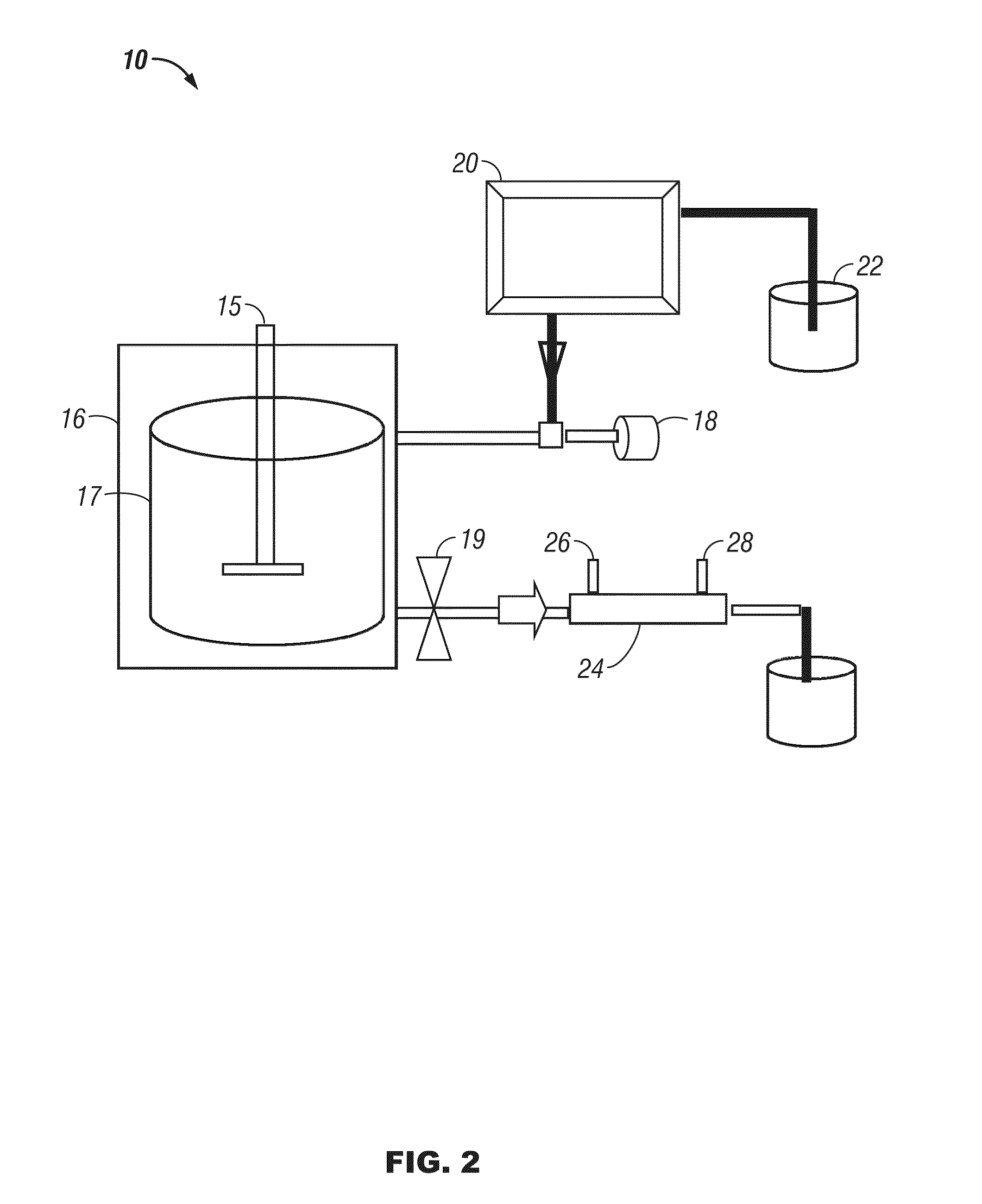

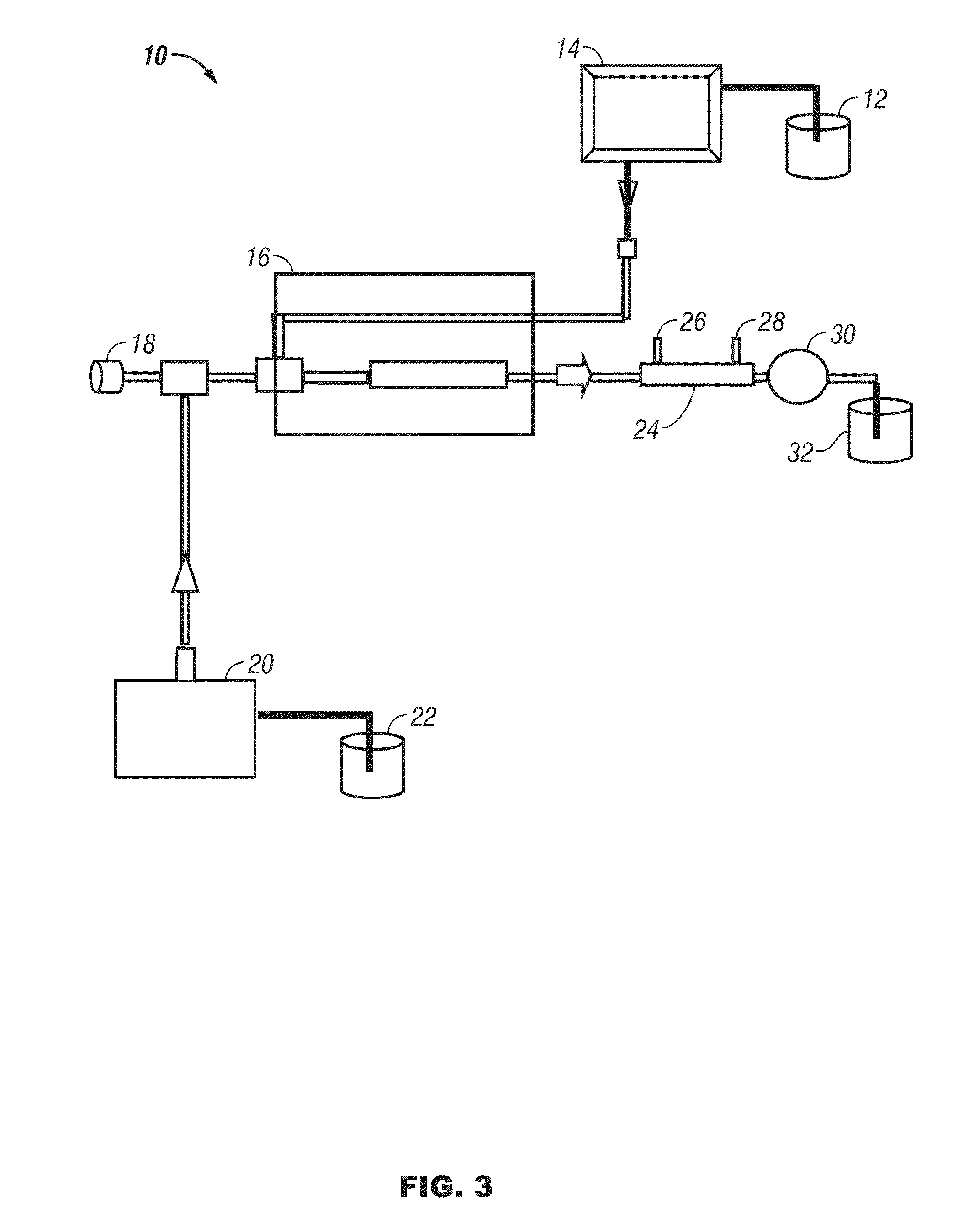

Online-controllable-atmosphere feedback device for preparing glycolaldehyde by using synthesis gas and application thereof

ActiveCN105566084APrecisely adjust the ratioAdjust the ratioOrganic compound preparationCarbonyl compound preparationControl systemProcess engineering

The invention discloses an online-controllable-atmosphere feedback device for preparing glycolaldehyde by using synthesis gas and an application thereof, and belongs to the technical field of glycolaldehyde production. The device comprises a gas control system A, a pressurization system B, a reaction kettle system C, an analysis system D and a central processing system E. The device solves the technical problems of a conventional high pressure reaction device for preparing glycolaldehyde by using synthesis gas: 1, the raw material gas proportion is relatively fixed, the change period is long, and the raw material gas proportion cannot be adjusted targetedly according to a rhodium precursor component; 2, the reaction evaluation data analysis period is long, and adjustment and change of the raw material gas proportion of the reaction process cannot be timely fed back and guided; and 3, gas ways are frequently dismantled, potential safety hazards are increased, and the work is tedious.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for synthesizing low-impurity content glyoxal through gas phase oxidation

ActiveCN103772169AFast nucleationImprove bindingOrganic compound preparationCatalyst activation/preparationGas phaseCatalytic oxidation

The invention belongs to the technical fields of chemistry and chemical engineering and in particular relates to a method for synthesizing low-impurity content glyoxal through gas phase catalytic oxidation. The method comprises the following steps: taking crystallized silver prepared by an electrolytic process as a carrier; performing high-temperature treatment, performing metal deposition, drying and roasting to obtain crystallized silver containing copper-silver alloy particles; taking the crystallized silver loaded with the copper-silver alloy particles as a catalyst, carrying out an oxidizing reaction among ethylene glycol, oxygen, water and inert gases to generate glyoxal in the presence of a catalyst. The 40 percent of glyoxal aqueous liquid in which the formaldehyde content is less than 500ppm and the glycolaldehyde content is less than 0.5 percent is directly obtained by performing air oxidation on ethylene glycol. The catalyst is easily regenerated and can be regenerated with a similar electrolytic silver method, and the prepared glyoxal is high in product quality.

Owner:FUDAN UNIV +1

Passivation of a homogeneous hydrogenation catalyst for the production of ethylene glycol

ActiveUS8969632B2Rate of forming at leastReduce probabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenDiol

A process for making ethylene glycol by feeding reactants including 1,2-dioxygenated organic compounds, an organometallic homogeneous catalyst, and hydrogen to a hydrogenation reactor, reacting at least a portion of the reactants with hydrogen in the presence of the organometallic homogeneous catalyst to produce a reaction product mixture containing ethylene glycol, and passivating the catalyst by contacting the catalyst with a carbon monoxide to thereby suppress the formation of by-product diols other that the ethylene glycol primary product, and suppress the formation of by-product tetrols and by-product glycolaldehyde acetals; and separating at least a portion of the ethylene glycol from the reaction product mixture.

Owner:EASTMAN CHEM CO

Novel method for the conversion of cellulose and related carbohydrate materials to low-molecular-weight compounds

ActiveUS20130060067A1Eliminate needOrganic compound preparationOxygen compounds preparation by reductionCelluloseChemical compound

Methods of converting cellulose or related biorenewable carbohydrate materials into high-value chemical compounds. The methods provide a means of converting low-cost materials such as cellulose and biomass into high yields of compounds such as ethylene glycol, propylene glycol, glycerin, methanol, hydroxyacetone, glycolaldehyde and dihydroxyacetone.

Owner:IOWA STATE UNIV RES FOUND

Process for the preparation of glycolaldehyde

ActiveUS7420093B2High selectivityPromote conversionOrganic compound preparationPreparation by carbon monoxide reactionHydrogenSolvent

Disclosed are processes for the preparation of glycolaldehyde in which formaldehyde is contacted with carbon monoxide and hydrogen in the presence of a rhodium catalyst and a solvent containing at least one N,N-dihexylbutyramide. The glycolaldehyde product is recovered by extraction with water. The process provides high selectivity to glycolaldehyde and efficient separation of hydroformylation products from the solvent and rhodium catalyst.

Owner:EASTMAN CHEM CO

Exterior wall emulsion paint and preparation method thereof

InactiveCN104263103AGood weather resistanceImprove water resistanceEmulsion paintsDefoaming AgentsStain

The invention discloses exterior wall emulsion paint and a preparation method thereof. The exterior wall emulsion paint is composed of the following raw materials by weight: 100-150 parts of styrene-acrylic emulsion, 120-160 parts of hydrated magnesium silicate superfine powder, 180-240 parts of sienna stone powder, 40-60 parts of titanium dioxide, 80-120 parts of composite nano powder, 3-6 parts of ethanediol, 1-3 parts of glycolaldehyde, 0.5-1.5 parts of dodecyl dimethyl benzyl ammonium chloride, 2-4 parts of sodium hydroxypropyl oxidized starch succinate, 3-5 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 0.5-1.5 parts of a multi-functional additive AMP-95, 4-6 parts of a dispersant HT-5000, 1-2 parts of a moistening agent SF-2, 2-3 parts of a thickening agent MS-1, 1-2 parts of a polyurethane rheological agent HT-860, 0.5-1 part of a defoaming agent HT-6520 and 250-350 parts of water. The exterior wall emulsion paint has excellent weather resistance, water resistance, stain resistance and adhesion resistance, does not crack, peel off, shell or change color by being exposed to air for a long time, is durable in use, is safe and non-toxic, has no pollution, and is suitable for decoration of building exterior walls.

Owner:SUZHOU ZHONGLI HEAT PRESERVATION & ENERGY SAVING MATERIAL CO LTD

Use of alpha-hydroxy carbonyl compounds as reducing agents

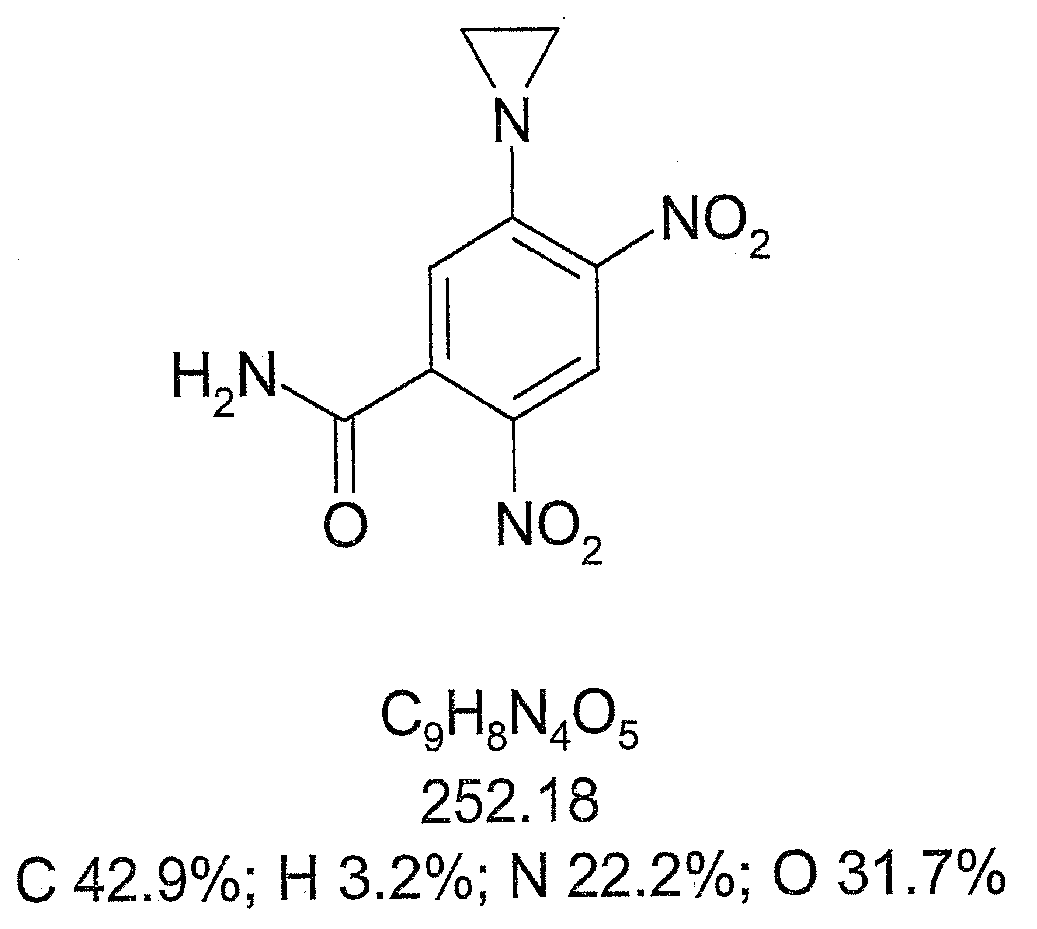

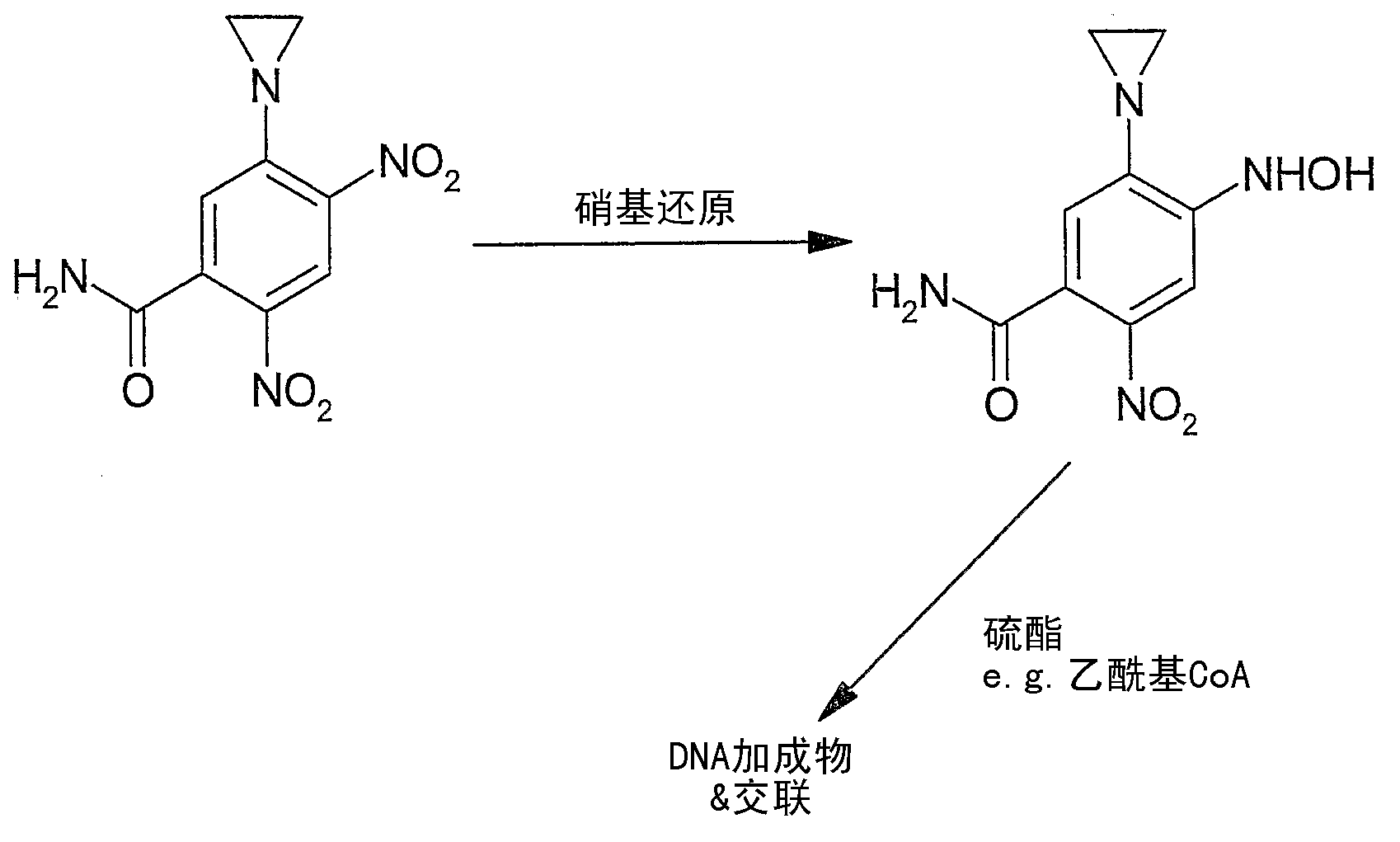

There is provided the use as reducing agents of alpha-hydroxycarbonyl compounds capable of forming cyclic dimers. There is also provided corresponding methods of reducing reducible compounds, particularly reduction-activated prodrugs . Examples of the alpha-hydroxycarbonyl compounds used are dihydroxyacetone, glycolaldehyde , glyceraldehyde, erythrose, xylulose, erythrulose or 3-hydroxy-2-butanone.

Owner:GORDIAN PHARMA LIMITED

Passivation of a homogeneous hydrogenation catalyst for the production of ethylene glycol

ActiveUS20130253230A1Reduce probabilityMinimize formationOxygen-containing compound preparationOrganic compound preparationHydrogenDiol

A process for making ethylene glycol by feeding reactants including 1,2-dioxygenated organic compounds, an organometallic homogeneous catalyst, and hydrogen to a hydrogenation reactor, reacting at least a portion of the reactants with hydrogen in the presence of the organometallic homogeneous catalyst to produce a reaction product mixture containing ethylene glycol, and passivating the catalyst by contacting the catalyst with a carbon monoxide to thereby suppress the formation of by-product diols other thatn the ethylene glycol primary product, and suppress the formation of by-product tetrols and by-product glycolaldehyde acetals; and separating at least a portion of the ethylene glycol from the reaction product mixture.

Owner:EASTMAN CHEM CO

Methods and compositions of enzymatic cycling based assays for myeloperoxidase

The present invention provides a method for assaying myeloperoxidase activity. In the assay, a sample containing myeloperoxidase or suspected of containing myeloperoxidase is contacted with substrate including serine, hydrogen peroxide, and a halide. If myeloperoxidase is present in the sample, serine is converted into glycolaldehyde, which is further converted into glycolate by a glycoaldehyde converting enzyme. The method then utilizes a cycling reaction system between glycolate and glyoxylate to generate a detectable signal that corresponds to the myeloperoxidase activity. Kits for assaying myeloperoxidases based on the same principle are also provided.

Owner:GENERAL ATOMICS

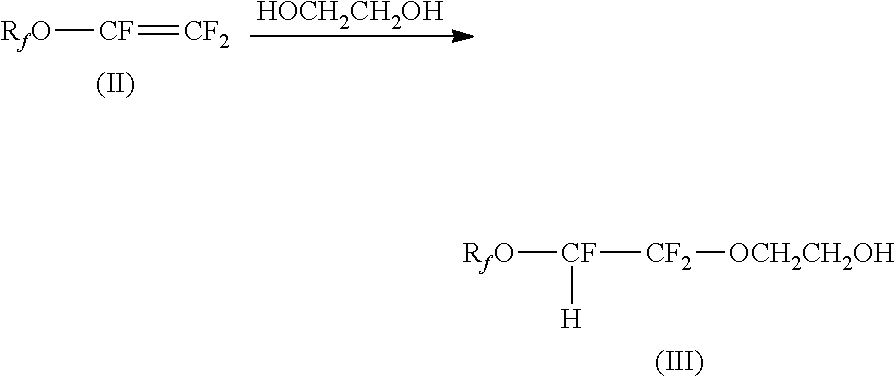

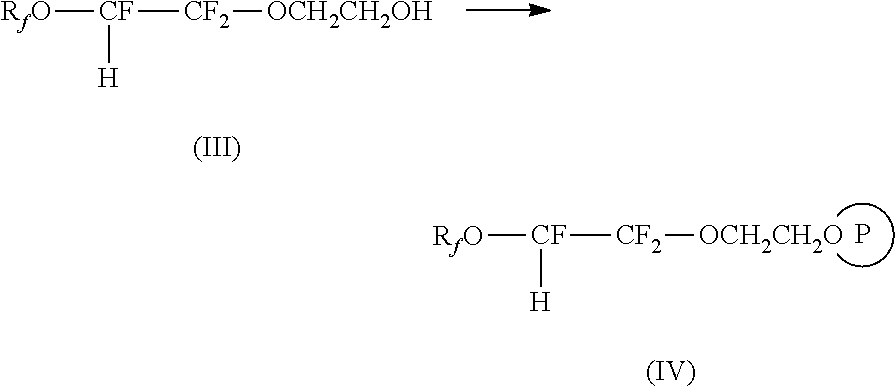

Process for the manufacture of fluorosurfactants

ActiveUS9416085B2Preparation from carboxylic acid halideOrganic compound preparationGlycollic acidFluoride

A process for the manufacture of a perfluorooxycarboxylate of formula (I): RfO—CF2CF2—O—CF2—COOXa (I), wherein Rf is a perfluoro(oxy)alkyl group, and Xa is H, a monovalent metal or an ammonium group of formula NRN4, with RN, equal or different at each occurrence, being H or a C1-6 hydrocarbon group, said process comprising: (A) reacting a perfluorovinylether of formula Rf—O—CF═CF2 with an ethylene glycol derivative selected among ethylene glycol (HO—CH2CH2—OH), glycolic acid (HO—CH2—COOH), glycolaldehyde (HO—CH2—CHO) and protected derivatives thereof, so as to yield the corresponding addition product of formula Rf—O—CFH—CF2—O—CH2-E, and E being selected among —CH2OH, —COOH and —CHO; (B) optionally protecting functional group E with suitable chemistry; (C) fluorinating the (protected) addition product to yield the corresponding perfluorinated addition product; (D) optionally deprotecting the perfluorinated addition product to yield corresponding acyl fluoride of formula Rf—O—CF2—CF2—O—CF2—C(O)F; and (E) hydrolyzing and, optionally, neutralizing, the acyl fluoride for yielding the perfluorooxycarboxylate of formula (I).

Owner:SOLVAY SOLEXIS

Methods and compositions of enzymatic cycling based assays for myeloperoxidase

Owner:GENERAL ATOMICS

Process for removing formaldehyde from a composition comprising glycolaldehyde

ActiveUS9796649B2Reducing percentage by weightLower the volumeOrganic compound preparationCarboxylic acid esters preparationAlcoholReactive distillation

A process for reducing the percentage by weight of formaldehyde present in a composition comprising glycolaldehyde, wherein formaldehyde is transformed into one or more formaldehyde acetal(s) and removed from the reactive distillation reaction solution by reactive distillation in the presence of at least one alcohol and a catalyst.

Owner:TOPSOE AS

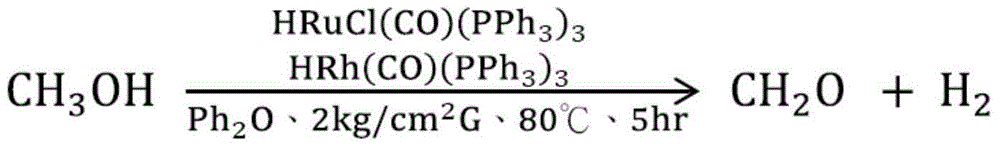

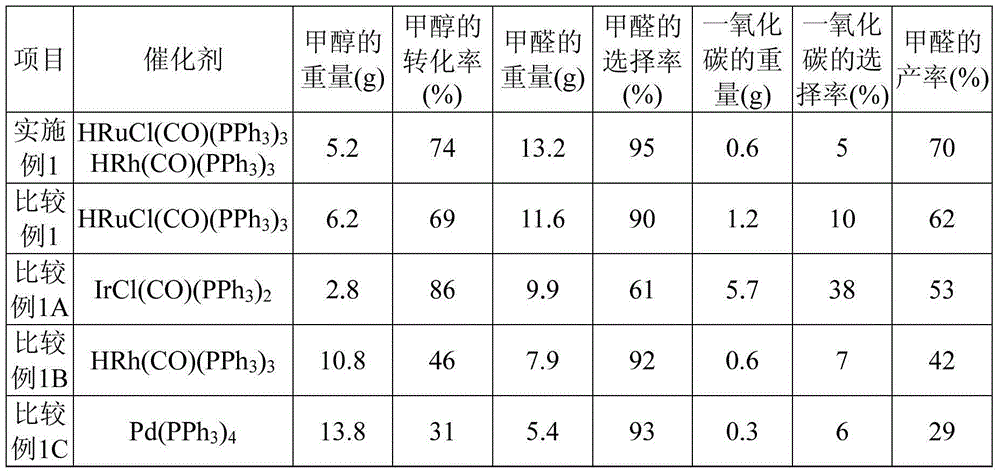

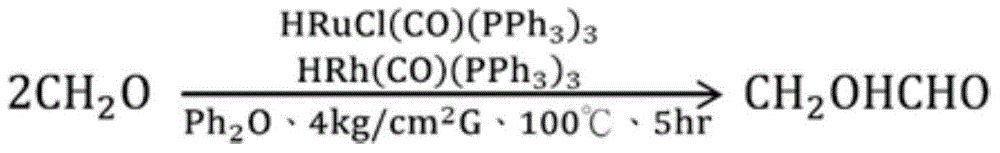

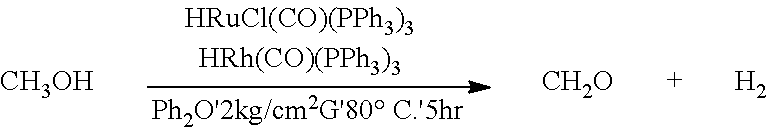

Manufacturing method of formaldehyde, glycolaldehyde and glycol

InactiveCN105085211AReduce manufacturing costSimplify manufacturing stepsOrganic compound preparationOxygen compounds preparation by reductionHigh pressureGlycolaldehyde

The invention provides a manufacturing method of formaldehyde, glycolaldehyde and glycol. According to the manufacturing method of formaldehyde and glycolaldehyde, methanol is subjected to a reaction in the presence of a catalyst composition, so as to form formaldehyde and glycolaldehyde; and formaldehyde and glycolaldehyde are used as intermediate products to synthesize glycol. The catalyst composition contains a rhodium catalyst and a ruthenium catalyst, and the process of forming glycol by the reaction of methanol is carried out at the temperature of 50-150 DEG C and at the pressure of 0-40 kg / cm<2>G. The same catalyst composition is used by the manufacturing method of formaldehyde, glycolaldehyde and glycol. After the end of a reaction in the last manufacturing process, a reaction in the next manufacturing process can be carried out in a same high-pressure reactor. According to the manufacturing method of glycol, manufacturing processes can be simplified, manufacturing time can be minimized, and manufacturing costs of glycol can be reduced more sharply.

Owner:陈建安 +1

A Corynebacterium glutamicum engineering strain that biosynthesizes rare sugars and its construction method and application

The invention discloses a corynebacterium glutamicum engineering strain for biosynthesis of rare sugar, and a building method and application thereof, and discloses a corynebacterium glutamicum recombination strain SY10. An experiment proves that rare ketose and deoxidized ketose can be synthesized by adopting a plurality of hydroxyaldehydes and glucoses as substrates by the strain in a fermentation manner, for example, D-erythrulose can be synthesized by adopting formaldehyde and glucose as substrates, L-xylulose can be synthesized by adopting glycolaldehyde and glucose as substrates, D-sorbose and D-psicose can be synthesized by adopting D-glyceraldehyde and glucose as substrates, L-fructose can be synthesized by adopting L-glyceraldehyde and glucose as substrates, and 3R, 4S, 5R, 6R-heptose and 3R, 4R, 5R, 6R-heptose can be synthesized by adopting D-erythrose and glucose as substrates. Therefore, the corynebacterium glutamicum recombination strain SY10 disclosed by the invention can be applied to the field of production of the rare ketose and the deoxidized ketose by whole-cell fermentation; the produced rare ketose and deoxidized ketose have broad application prospects in the industries such as a food, a medicine and the like.

Owner:天津怡和生物科技有限责任公司

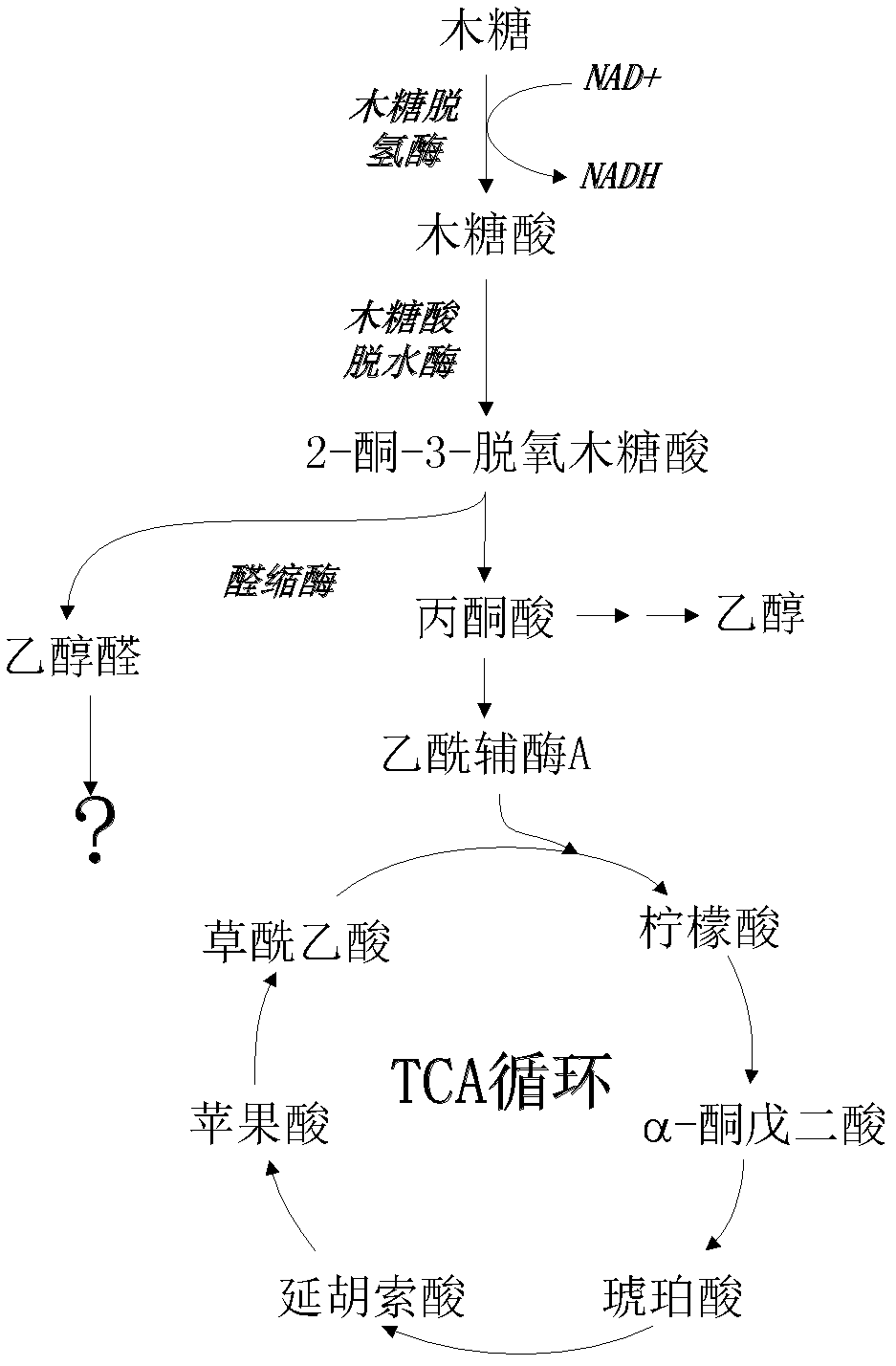

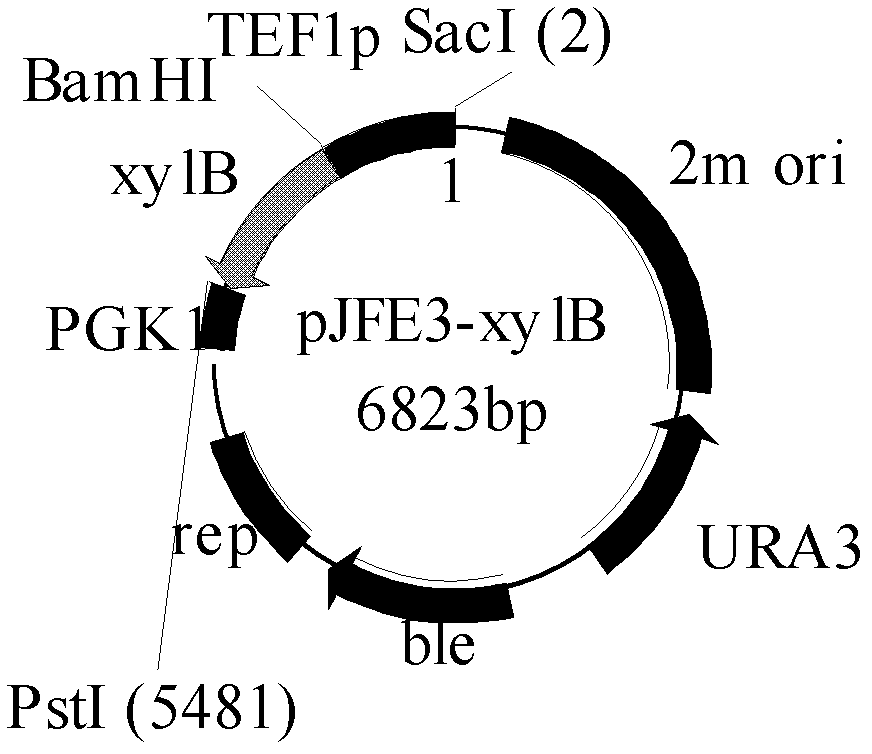

Brewing yeast strain capable of metabolizing xylose

InactiveCN102604850AGrow fastShort metabolic pathwayFungiMicroorganism based processesGlycerolCarboxylic acid

The invention discloses a brewing yeast strain capable of metabolizing xylose. The strain is a brewing yeast (Saccharomyces cerevisiae) BSHH02B, and is preserved in the China General Microbiological Culture Collection Center (CGMCC) on Feb. 8th, 2012, wherein the preservation number is CGMCC No. 5747. The strain carries a unique xylose metabolizing way, i.e. a molecular xylose generates a molecular pyruvic acid and a molecular glycolaldehyde through two mesostate, i.e. xylonic acid and 3-deoxyl-D-glycerol-ketopentose acid. By the xylose metabolizing way, the brewing yeast BSHH02B can quickly grow by using the xylose under an aerobic condition, and can be applied to the production of chemical products by using xylose-containing raw materials, wherein the chemical products include ethanol, glycol, carboxylic acid and the like.

Owner:SHANDONG UNIV

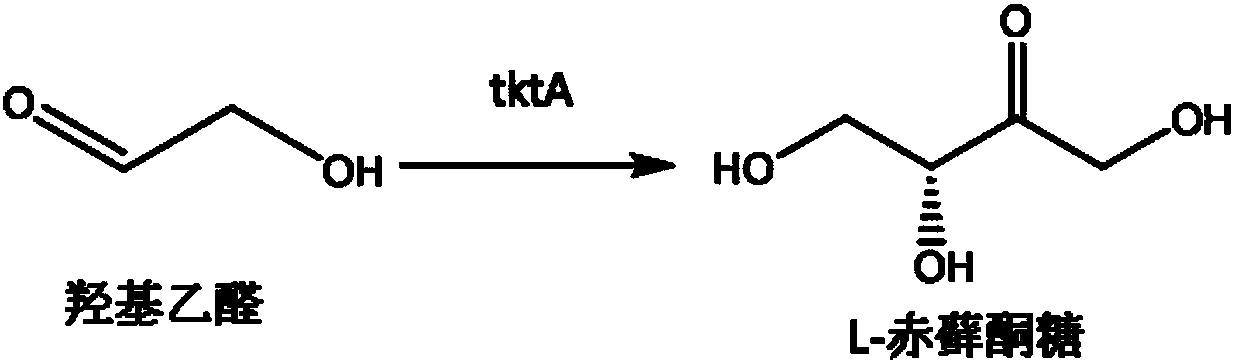

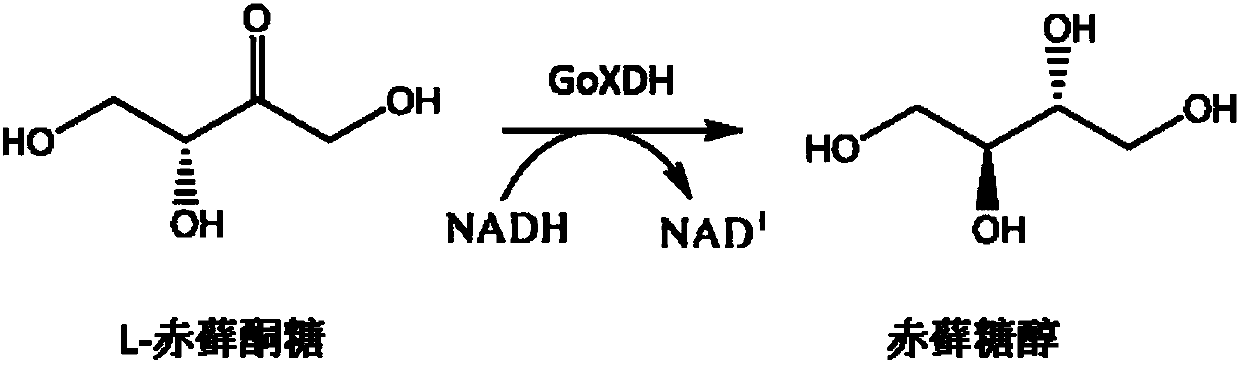

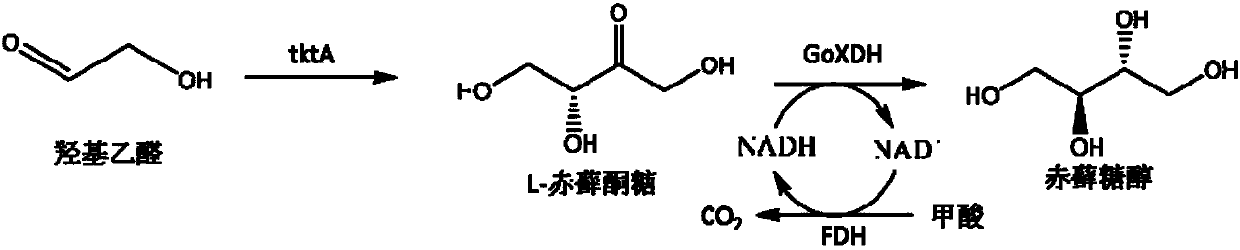

Production method of L-erythrulose and erythritol

The invention discloses a production method of L-erythrulose and erythritol. The invention provides any one of 1) to 3) applications: 1) an application of tktA enzyme or related biological materials thereof in the production of L-erythrulose, wherein the substrate of the application does not contain hydroxypyruvic acid; 2) an application of GoXDH enzyme or related biological materials thereof in the production of erythritol; and 3) an application of the tktA enzyme or related biological materials thereof and the GoXDH enzyme or related biological materials thereof in the production of erythritol, wherein the substrate of the application does not contain hydroxypyruvic acid. In summary, the present invention provides a new approach for converting glycolaldehyde to L-erythrulose or L-erythritol.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Processes for preparing formaldehyde, glycolaldehyde and ethylene glycol

InactiveUS9126912B1Simple stepsShorten production timeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolyethylene glycolGlycol synthesis

A process for preparing ethylene glycol comprising: forming intermediums of formaldehyde and glycolaldehyde to synthetize ethylene glycol by reacting methanol with methanol in the presence of a catalyst composition comprising rhodium catalysts and ruthenium catalysts at a temperature between 50-150° C. and a pressure between 0-40 kg / cm2G.

Owner:CHEN CHIEN AN +1

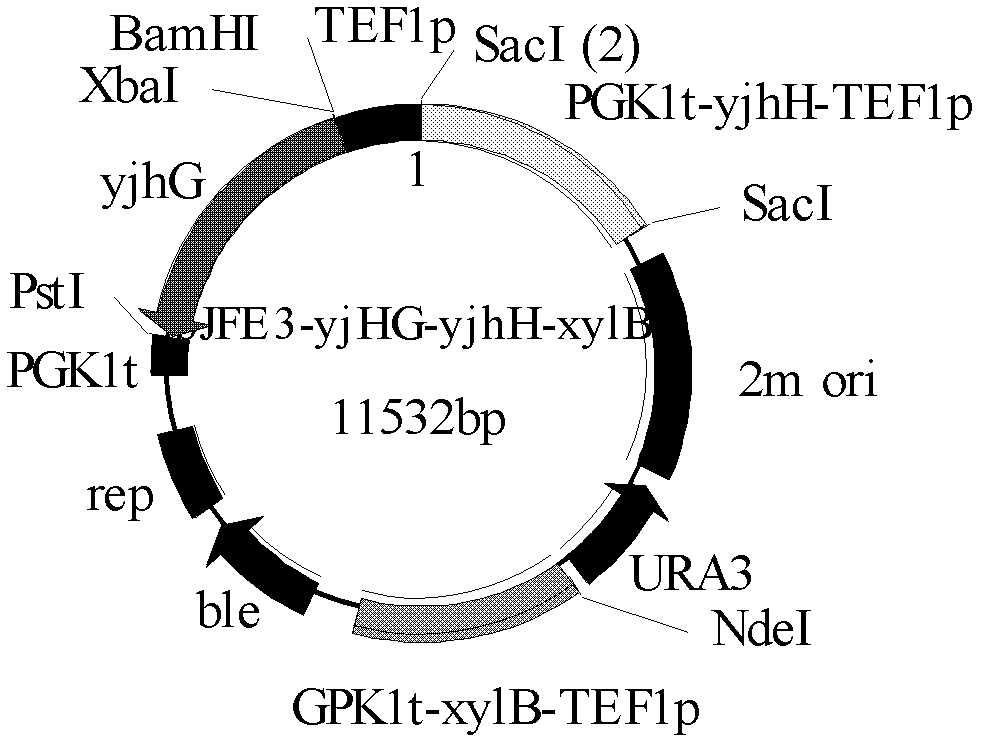

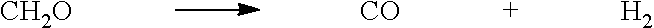

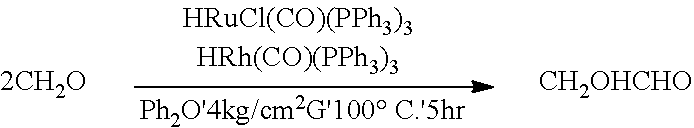

Process for producing at least one metabolite of interest by conversion of a pentose in a microorganism

ActiveUS20190010523A1Simple and cost-efficientHigh value-added compoundsFermentationMicroorganismMetabolite

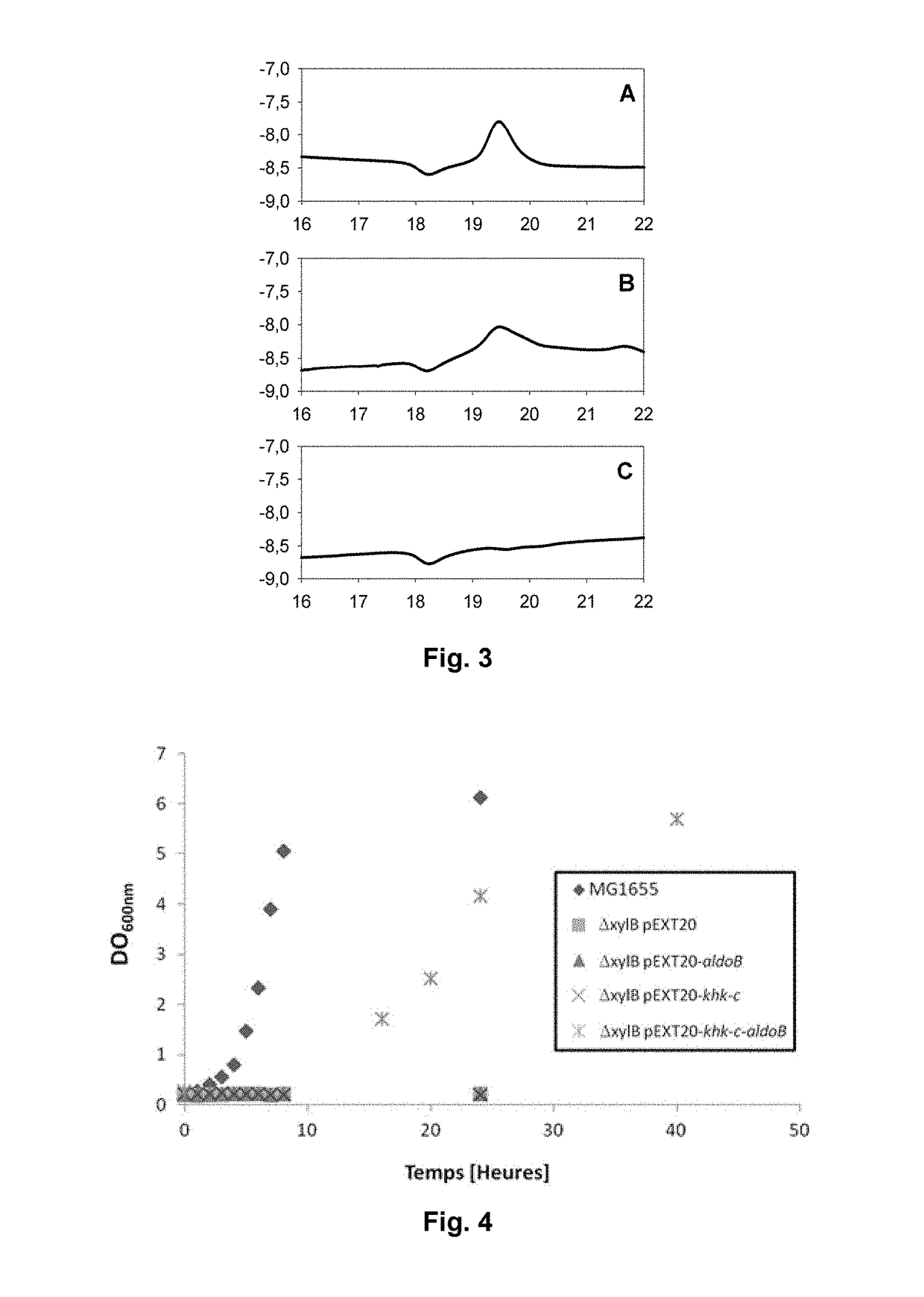

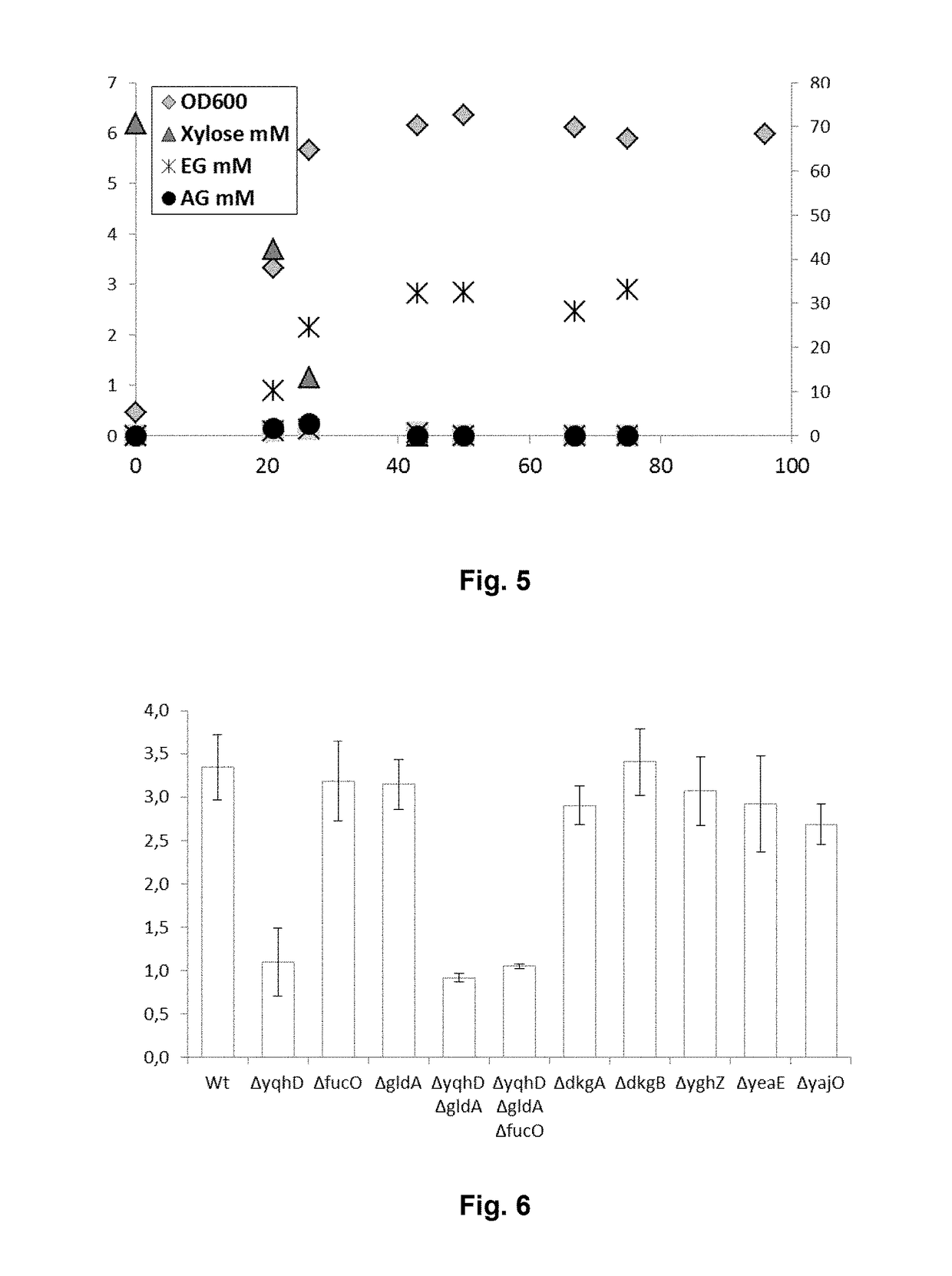

Disclosed is a process for producing at least one metabolite of interest by conversion of a pentose in a microorganism. The process includes at least: (i) an operation of culturing a recombinant microorganism expressing a synthetic pathway for pentose assimilation which includes at least the following steps: a) phosphorylation in position 1 of a pentose chosen from (D)-xylulose and / or (L)-ribulose, b) cleavage of the pentose-1-phosphate obtained at the end of step a), in order to obtain glycolaldehyde and dihydroxyacetone phosphate (DHAP), and (ii) an operation of recovering the at least one metabolite of interest obtained at the end of the culturing operation (i). Also disclosed is an associated microorganism.

Owner:INSTITUT NAT DES SCI APPLIQUEES INSA +2

Method for preparing glycolaldehyde through hydroformylation of formaldehyde

PendingCN114751813AHigh catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystReaction rate

The invention relates to a method for preparing glycolaldehyde through hydroformylation of formaldehyde. The method comprises the following steps: mixing a substrate, a rhodium source and a metal additive, adding the mixture and a solvent into a high-pressure kettle to obtain a reaction solution, then introducing synthesis gas, reacting for 0.5-12 hours at 60-150 DEG C, and cooling to obtain glycolaldehyde, the substrate is formaldehyde or paraformaldehyde; the synthesis gas is composed of hydrogen and carbon monoxide. According to the invention, through the synergistic effect of two metals in the bimetallic catalyst, high glycolaldehyde yield, fast reaction rate and reaction cost reduction are realized; the reaction system is simple, the reaction activity is obviously improved, and the precious metal consumption is greatly reduced.

Owner:TIANJIN UNIV

Method for biosynthesizing xylose

PendingCN113699195ARich sourcesImprove conversion rateFermentationCarbon-carbon lyasesFormateAldehyde formation

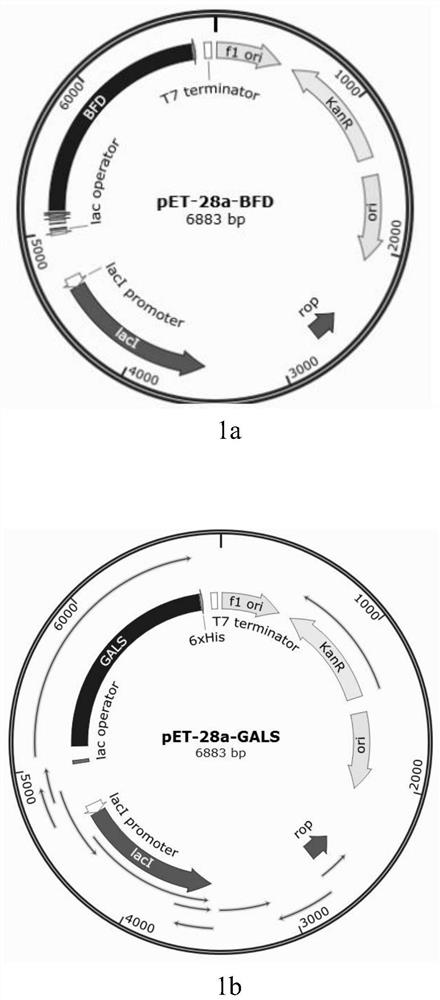

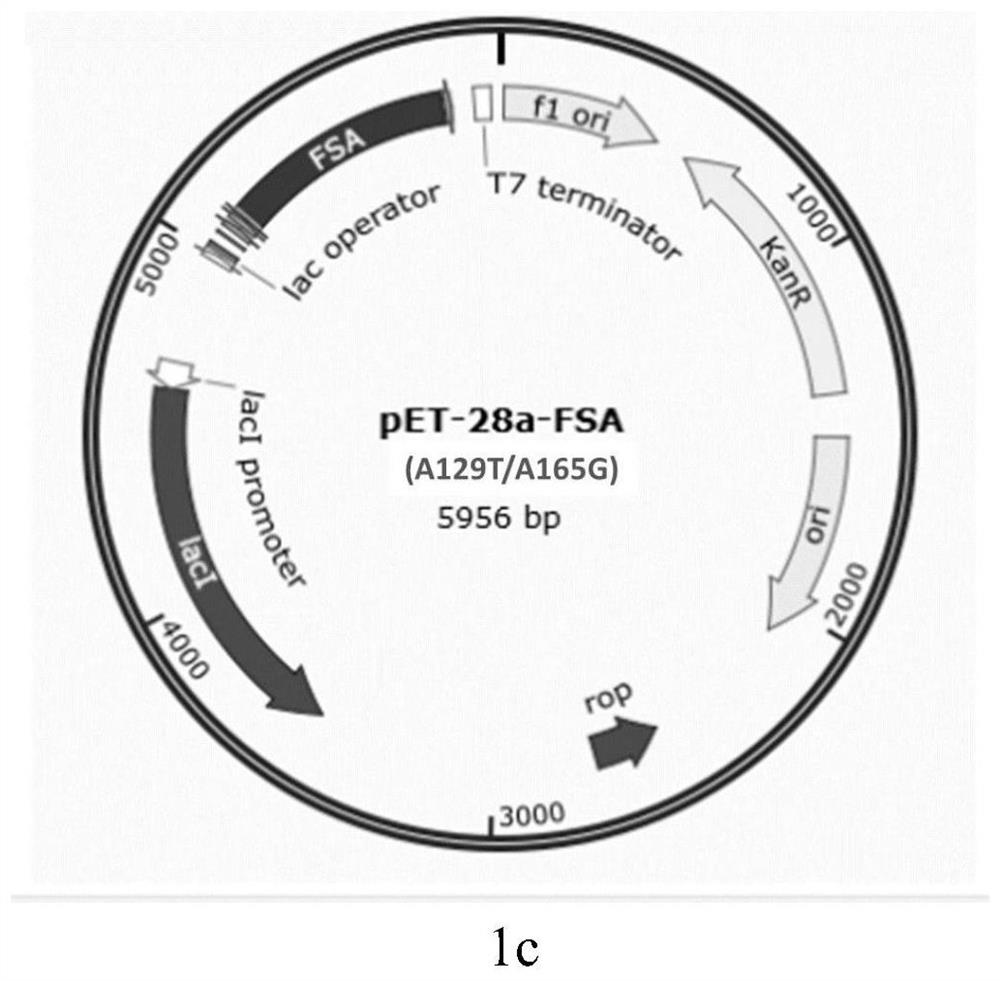

The invention provides a method for biosynthesizing L-xylose. The method is characterized in that aldolase, such as D-fructose-6-phosphate aldolase (FSA), is used for converting substrates formaldehyde and glycolaldehyde into the L-xylose; or a combination of glycolaldehyde condensing enzyme (GALS), a mutant thereof or an enzyme with a function of catalyzing formaldehyde to synthesize glycolaldehyde, such as benzoyl formate decarboxylase (BFD), and aldolase, such as D-fructose-6-phosphate aldolase (FSA), can be utilized to convert the substrate formaldehyde into L-xylose by a one-pot method. The biosynthesis method disclosed by the invention has the advantages of high conversion rate, simple production process, greenness, friendliness, easiness in large-scale production and the like.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com