Production method of L-erythrulose and erythritol

A technology of erythrulose and erythritol, which is applied in the production field of L-erythrulose and erythritol, and can solve the problems of long fermentation cycle, high cost of raw materials, and difficulty in increasing product scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] Embodiment 1, preparation and functional detection of enzymes used in the production of L-erythrulose and erythritol

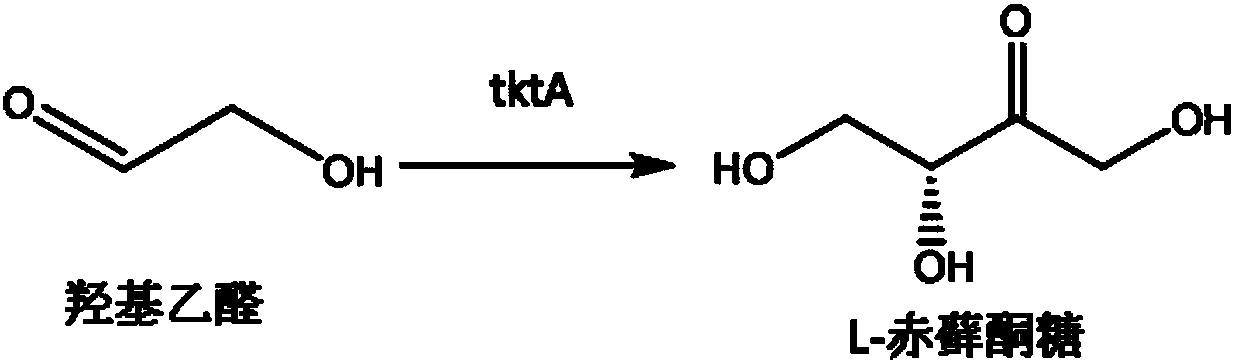

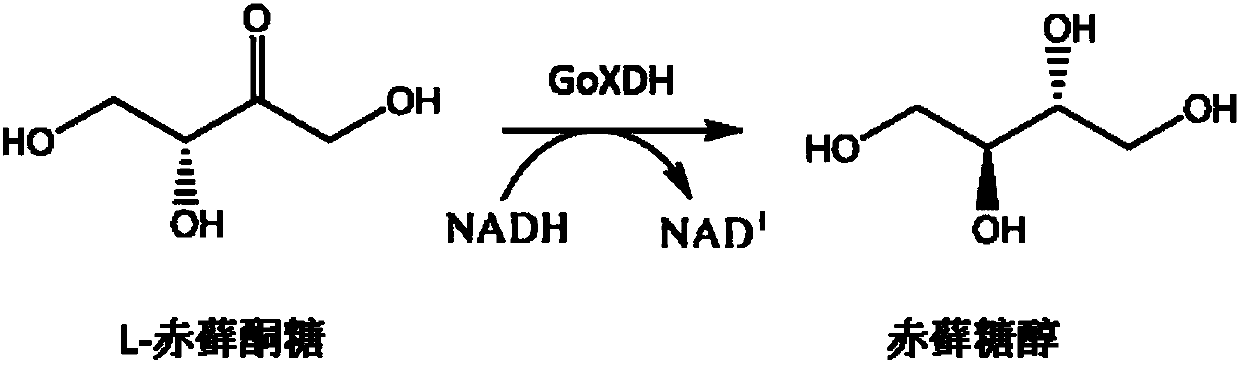

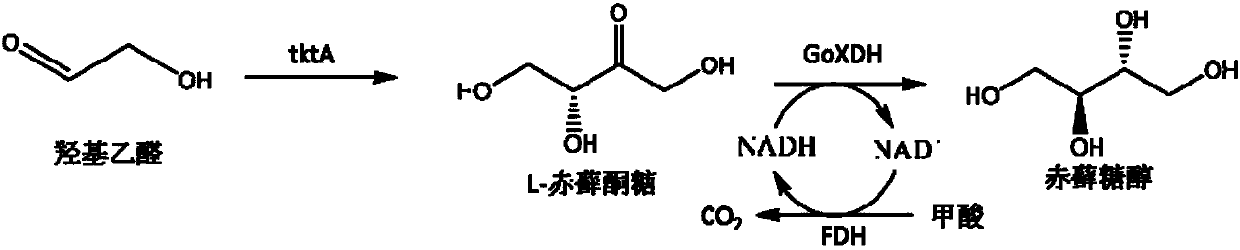

[0145] figure 1 Schematic diagram of the new reaction catalyzed by tktA. figure 2 Schematic diagram of the new reaction catalyzed by GoXDH. image 3 Schematic diagram of the reaction for the new method of producing erythritol using glycolaldehyde. Figure 4 It is a schematic diagram of the reaction of the new method for producing L-erythrulose by utilizing ethylene glycol.

[0146] 1. Preparation of enzymes tktA, GoXDH, EgDH, NOX2 and FDH required for the production of L-erythrulose and erythritol 1. Acquisition of DNA encoding enzymes

[0147] tktA, the amino acid sequence is sequence 1, from Escherichia coli (Escherichia coli) K12, the nucleotide sequence of the DNA molecule encoding the protein is sequence 6;

[0148] GoXDH, the amino acid sequence is sequence 2, from Gluconobacter oxydans; under the premise of not changing the amino acid sequen...

Embodiment 2

[0196] The production method of embodiment 2, L-erythrulose and erythritol

[0197] 1. Production of L-erythrulose with glycolaldehyde as raw material

[0198] A. tktA enzyme catalyzes the production of L-erythrulose from glycolaldehyde

[0199] 1. Prepare 50mM potassium phosphate buffer (adjust pH to 6.5, 7.0, 7.5, 8.0 respectively), add 1mM TPP and 5mM magnesium sulfate, add 0.5mg / mL tktA enzyme, preheat at 37°C for 5min, add raw material 200mM hydroxyethyl Aldehydes start to react. React at 37°C for 30 minutes. 100 μL of the reaction product was added to 100 μL of acetonitrile, mixed thoroughly, and then centrifuged at 12,000 rpm for 30 minutes, and 100 μL of the supernatant was taken for HPLC analysis. The result is as Figure 21 As shown, the yield of L-erythrulose was the highest when the pH of the buffer solution was 7.

[0200]2. Prepare 50mM potassium phosphate buffer (pH=7.0), add 1mM TPP and different concentrations of magnesium sulfate (0, 0.01, 0.1, 1, 5, 10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com