Composite catalyst for acraldehyde synthesis as well as preparation method and application thereof

A technology of composite catalyst and acrolein, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems of poor heat dissipation, exacerbated risk of overheating, and large heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

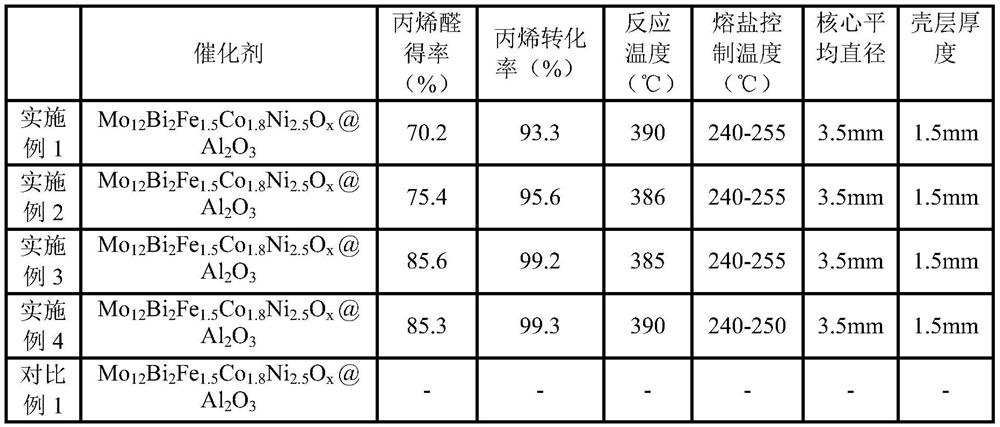

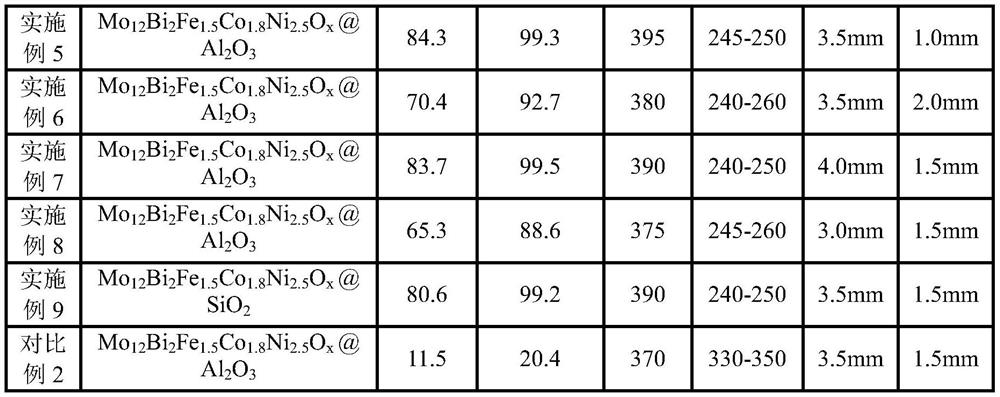

Embodiment 1

[0047] 200 grams of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 (2), 91.6 gram of bismuth nitrate, 57.8 gram of iron nitrate, 49.5 gram of cobalt nitrate, 69.3 gram of nickel nitrate, be dissolved in 500ml deionized water, obtain active component compound aqueous dispersion, dry under the condition of 80-180 degree, will The resulting block was pulverized to a mesh size of 100 or less to obtain active ingredient powder.

[0048]Using silica sol (ammonia type, 40wt%) as a binding agent, the active component powder is granulated in a rolling ball machine to obtain particles with an average diameter of 3.5mm, and then use graphite and γ-Al 2 o 3 The mixture (mass ratio 30:70) was coated on the surface of the active component particles, and the ball was rolled to obtain a spherical catalyst with an average diameter of 5.0mm. Finally, it was calcined and activated at 550°C for 6 hours to obtain the final catalyst product.

[0049] The comparison catalysts were evaluated...

Embodiment 2

[0051] 200 grams of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 (2), 91.6 gram of bismuth nitrate, 57.8 gram of iron nitrate, 49.5 gram of cobalt nitrate, 69.3 gram of nickel nitrate, be dissolved in 500ml deionized water, obtain active component compound aqueous dispersion, dry under the condition of 80-180 degree, will The resulting block was pulverized to a mesh size of 100 or less to obtain active ingredient powder.

[0052] Using silica sol (ammonia type, 40wt%) as a binding agent, the active component powder is granulated in a rolling ball machine to obtain particles with an average diameter of 3.5mm, and then use graphite and γ-Al 2 o 3 The mixture (mass ratio 40:60) was coated on the surface of the active component particles, and the ball was rolled to obtain a spherical catalyst with an average diameter of 5.0mm. Finally, it was activated by calcination at 550°C for 6 hours to obtain the final catalyst product.

[0053] The comparison catalysts were evalua...

Embodiment 3

[0055] 200 grams of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 (2), 91.6 gram of bismuth nitrate, 57.8 gram of iron nitrate, 49.5 gram of cobalt nitrate, 69.3 gram of nickel nitrate, be dissolved in 500ml deionized water, obtain active component compound aqueous dispersion, dry under the condition of 80-180 degree, will The resulting block was pulverized to a mesh size of 100 or less to obtain active ingredient powder.

[0056] Using silica sol (ammonia type, 40wt%) as a binding agent, the active component powder is granulated in a rolling ball machine to obtain particles with an average diameter of 3.5mm, and then use graphite and γ-Al 2 o 3 The mixture (mass ratio 50:50) was coated on the surface of the active component particles, and the ball was rolled to obtain a spherical catalyst with an average diameter of 5.0mm. Finally, it was calcined and activated at 550°C for 6 hours to obtain the final catalyst product.

[0057] The comparison catalysts were evaluate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com