Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244 results about "Afm indentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

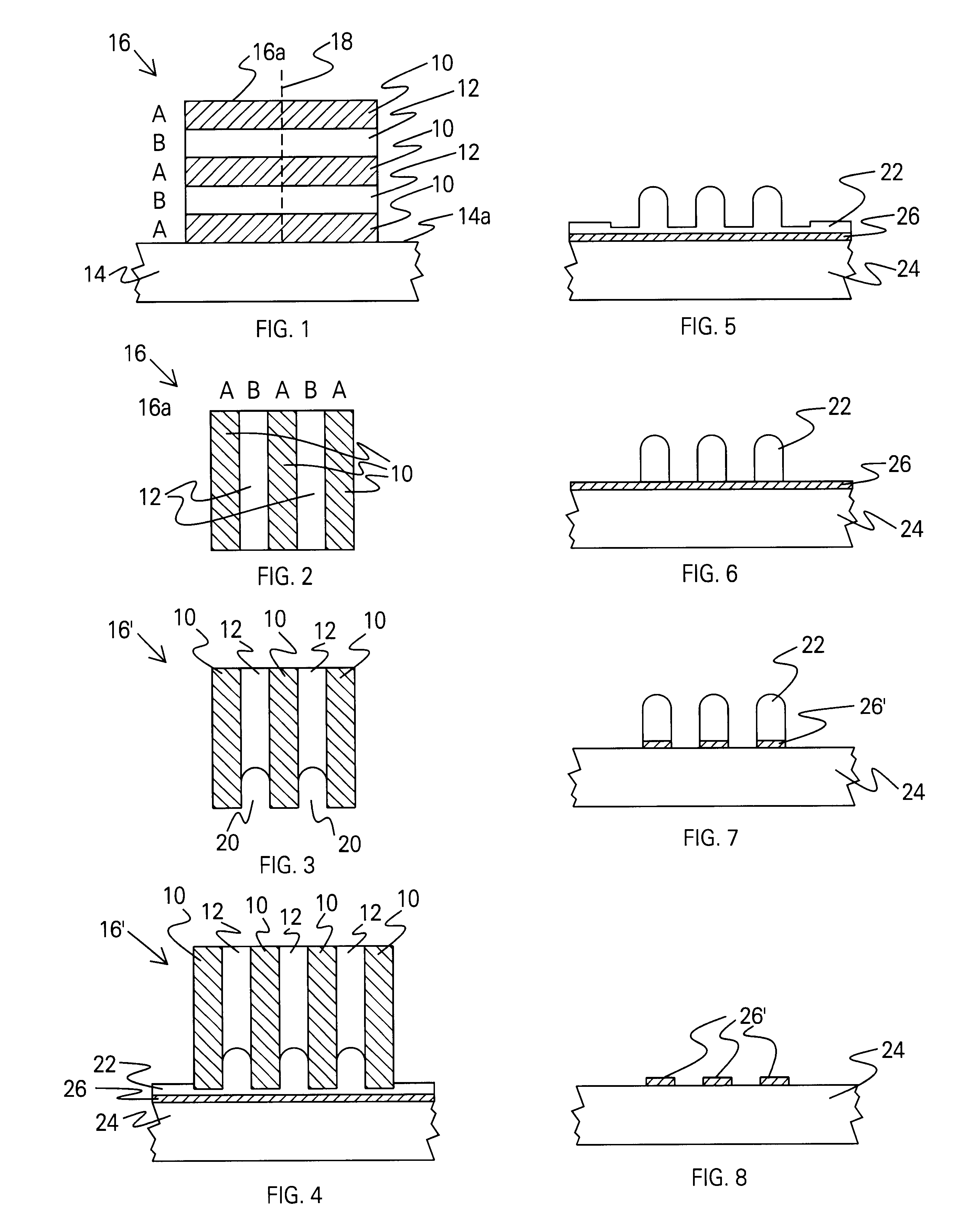

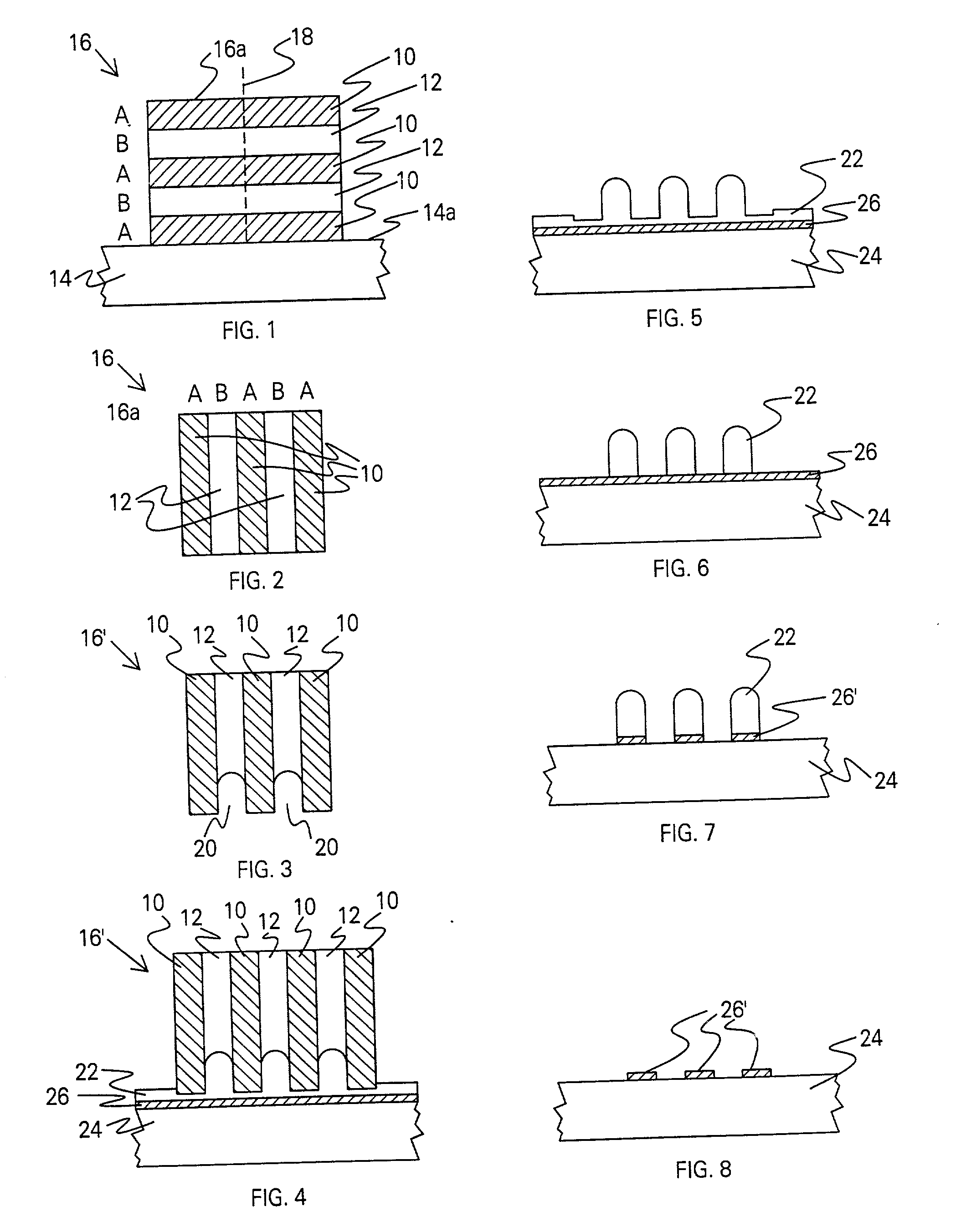

Nanoscale patterning for the formation of extensive wires

A method for forming a platen useful for forming nanoscale wires for device applications comprises: (a) providing a substrate having a major surface; (b) forming a plurality of alternating layers of two dissimilar materials on the substrate to form a stack having a major surface parallel to that of the substrate; (c) cleaving the stack normal to its major surface to expose the plurality of alternating layers; and (d) etching the exposed plurality of alternating layers to a chosen depth using an etchant that etches one material at a different rate than the other material to thereby provide the surface with extensive strips of indentations and form the platen useful for molding masters for nano-imprinting technology. The pattern of the platen is then imprinted into a substrate comprising a softer material to form a negative of the pattern, which is then used in further processing to form nanowires. The nanoscale platen thus comprises a plurality of alternating layers of the two dissimilar materials, with the layers of one material etched relative the layers of the other material to form indentations of the one material. The platen is then oriented such that the indentations are parallel to a surface to be imprinted.

Owner:SAMSUNG ELECTRONICS CO LTD

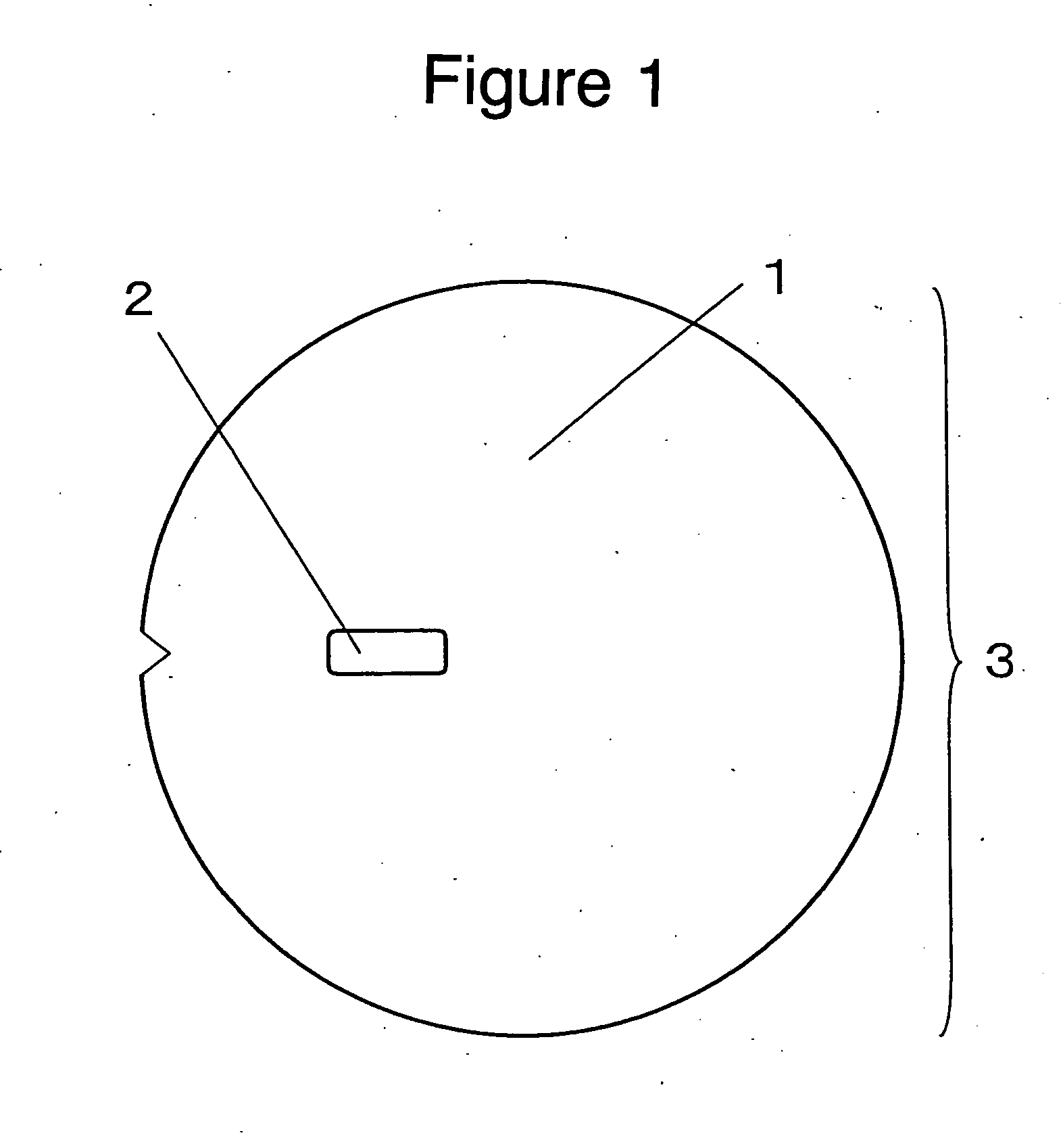

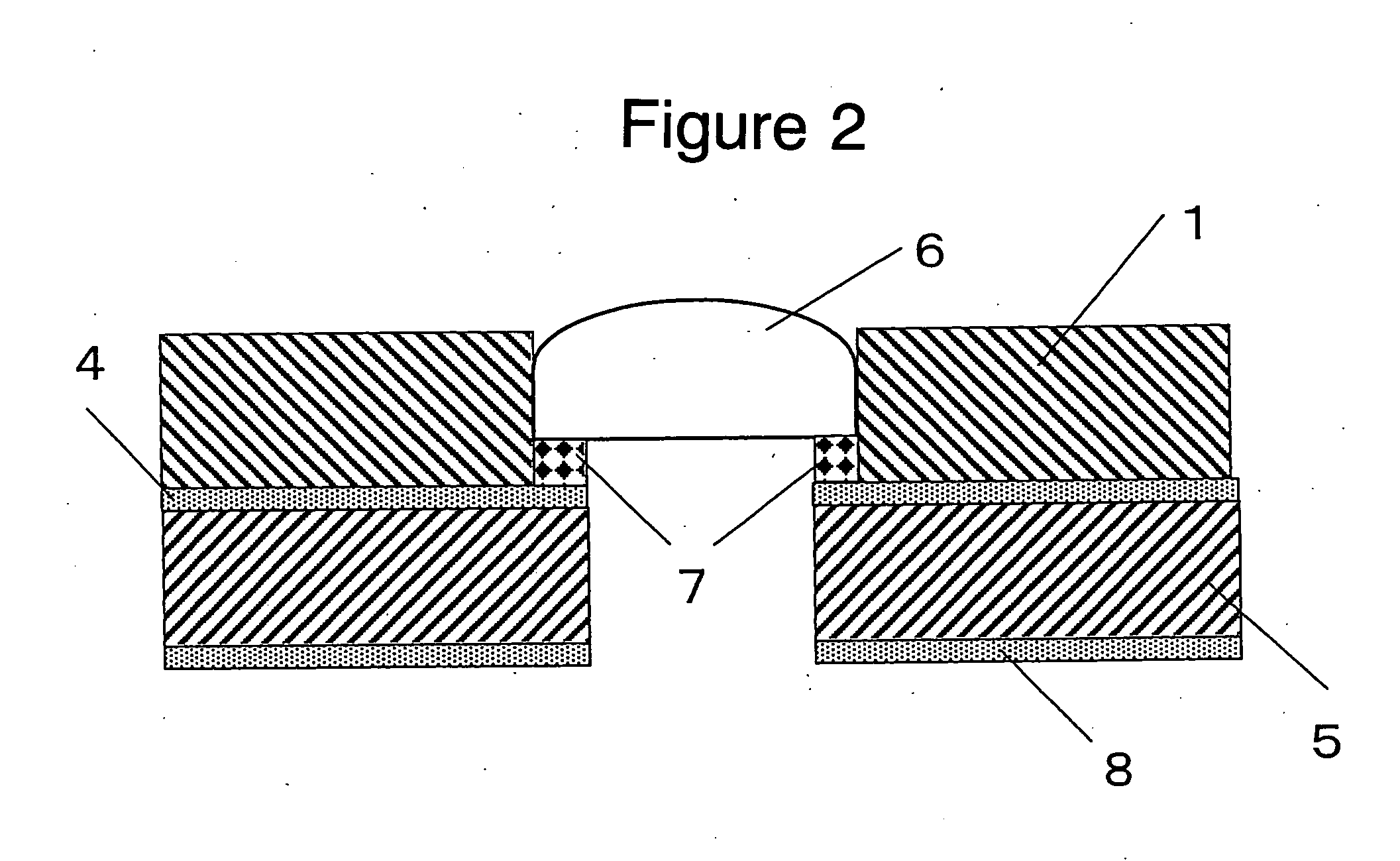

Polishing pad, platen hole cover, polishing apparatus, polishing method, and method for fabricating semiconductor device

InactiveUS20050148183A1Reduce the numberMeasured satisfactorilyEdge grinding machinesSemiconductor/solid-state device manufacturingDevice materialEngineering

It is an object of the present invention to provide a windowed polishing pad or a platen hole cover which is used to form planar surfaces in glass, semiconductors, dielectric / metal composites, integrated circuits, etc.; a polishing apparatus including the windowed polishing pad or the platen hole cover; a method for fabricating a semiconductor device using the polishing apparatus; and a polishing method, in which the number of scratches occurring on the surface of the substrate is small, and the polished state can be optically measured satisfactorily during polishing. In order to achieve the above object, a polishing pad is constructed in such a manner that the polishing pad includes a polishing layer and a light-transmissive window member disposed in an opening formed in a part of the polishing layer, wherein the amount of indentation strain measured when a constant load is applied to substantially the entire upper surface of the light-transmissive window member is larger than the amount of indentation strain measured when the same constant load is applied to a region having the same area on the upper surface of the polishing layer.

Owner:TORAY IND INC

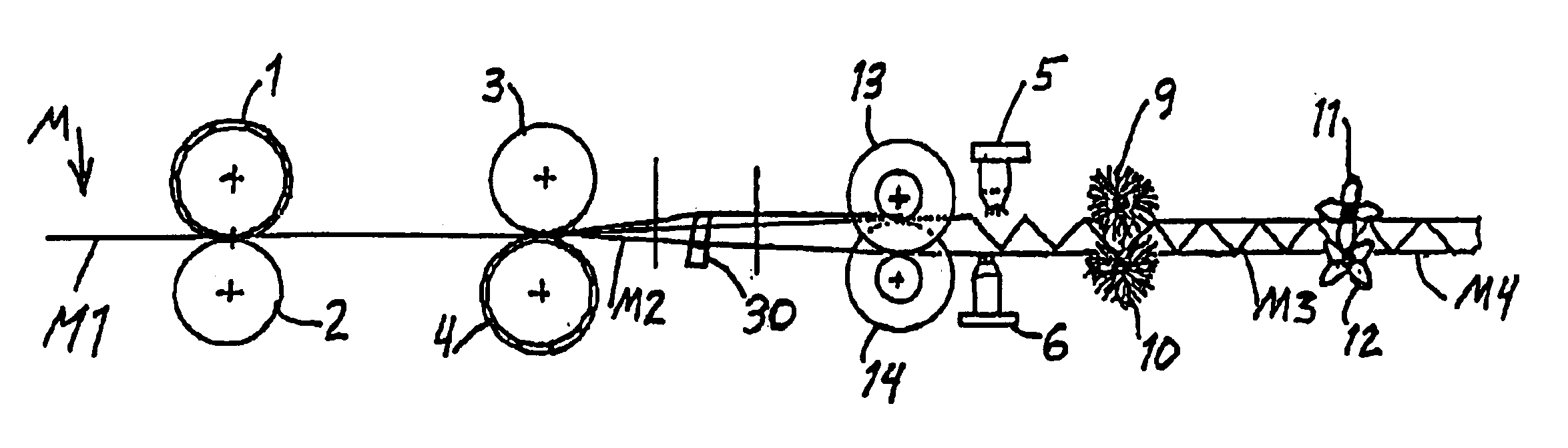

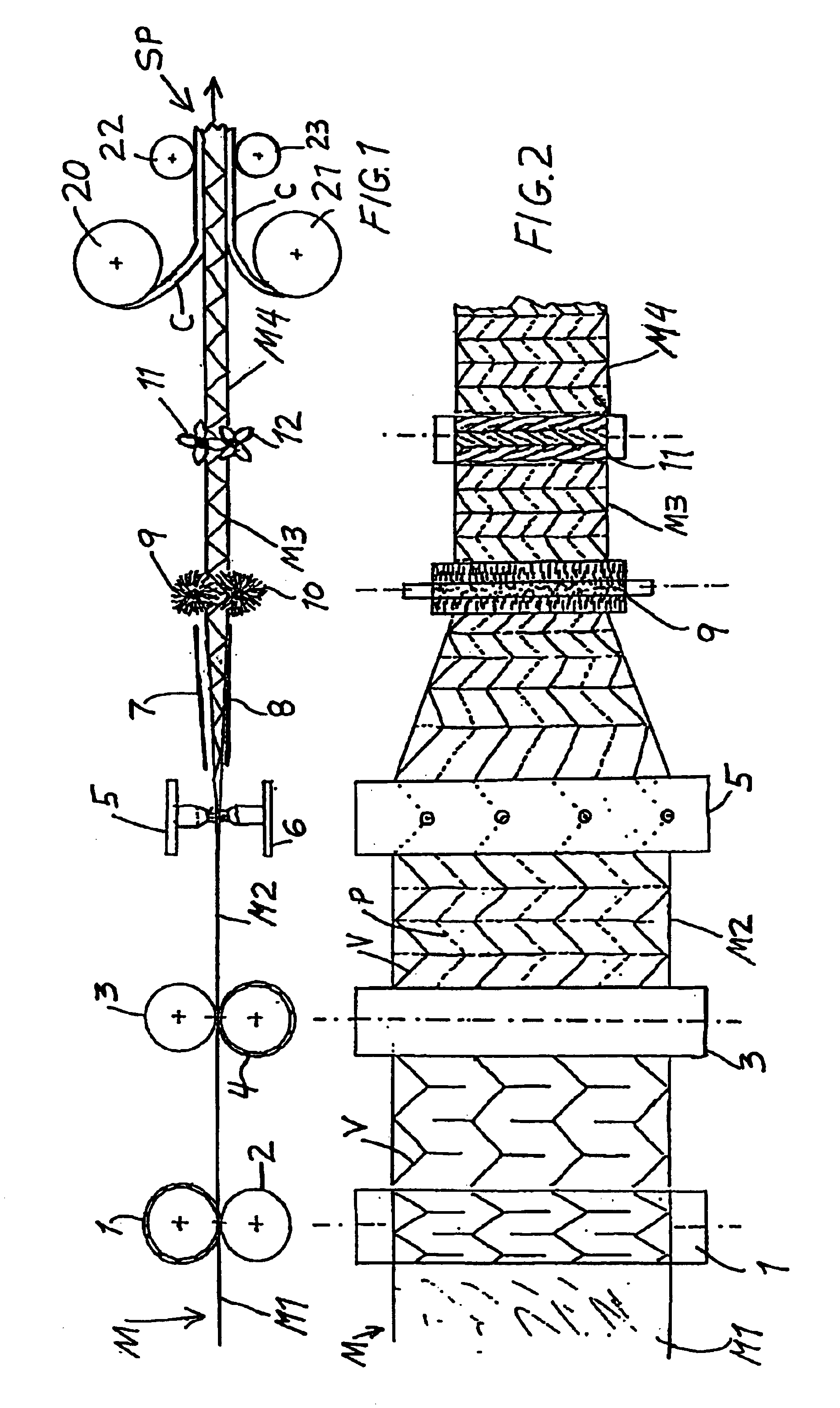

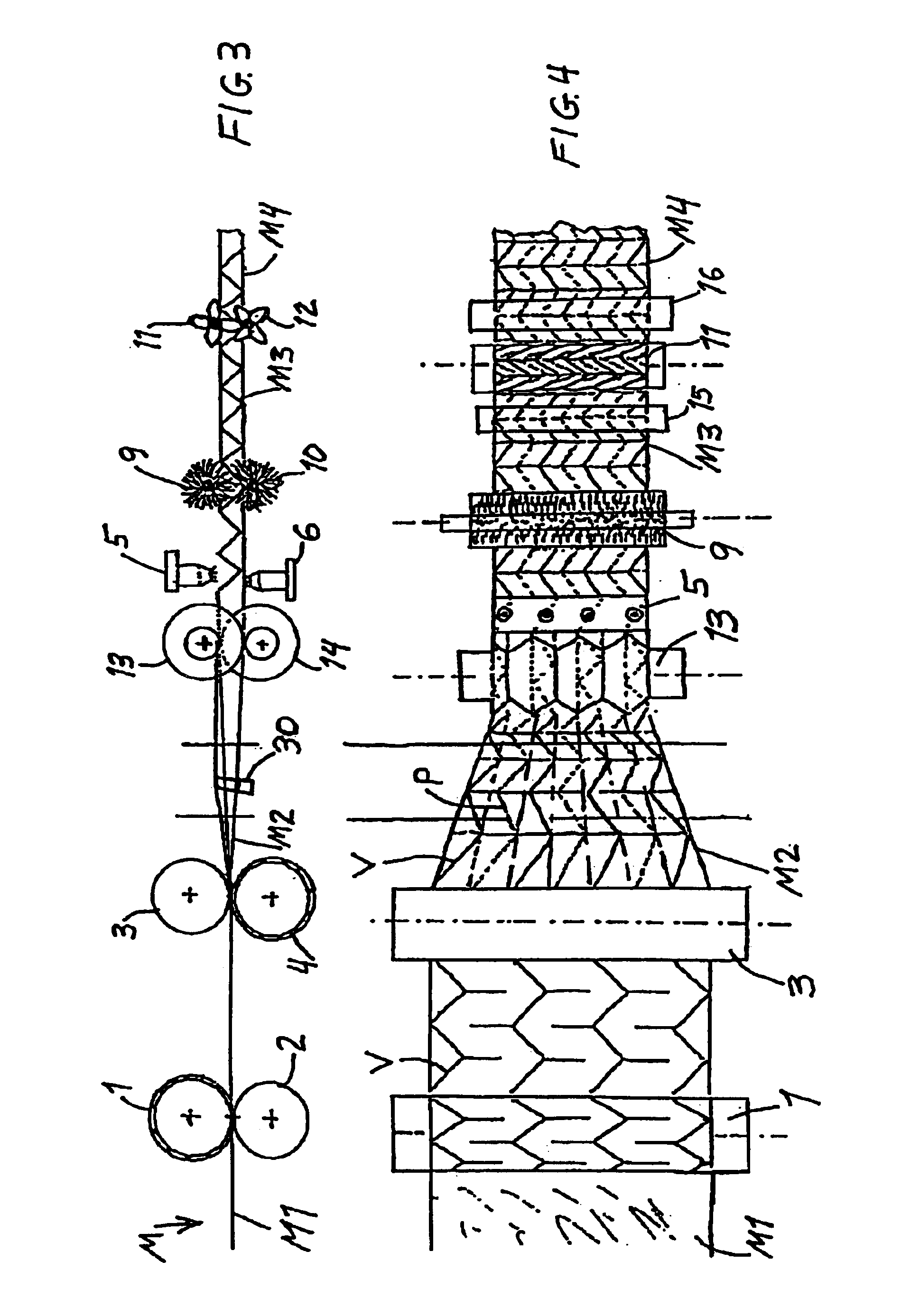

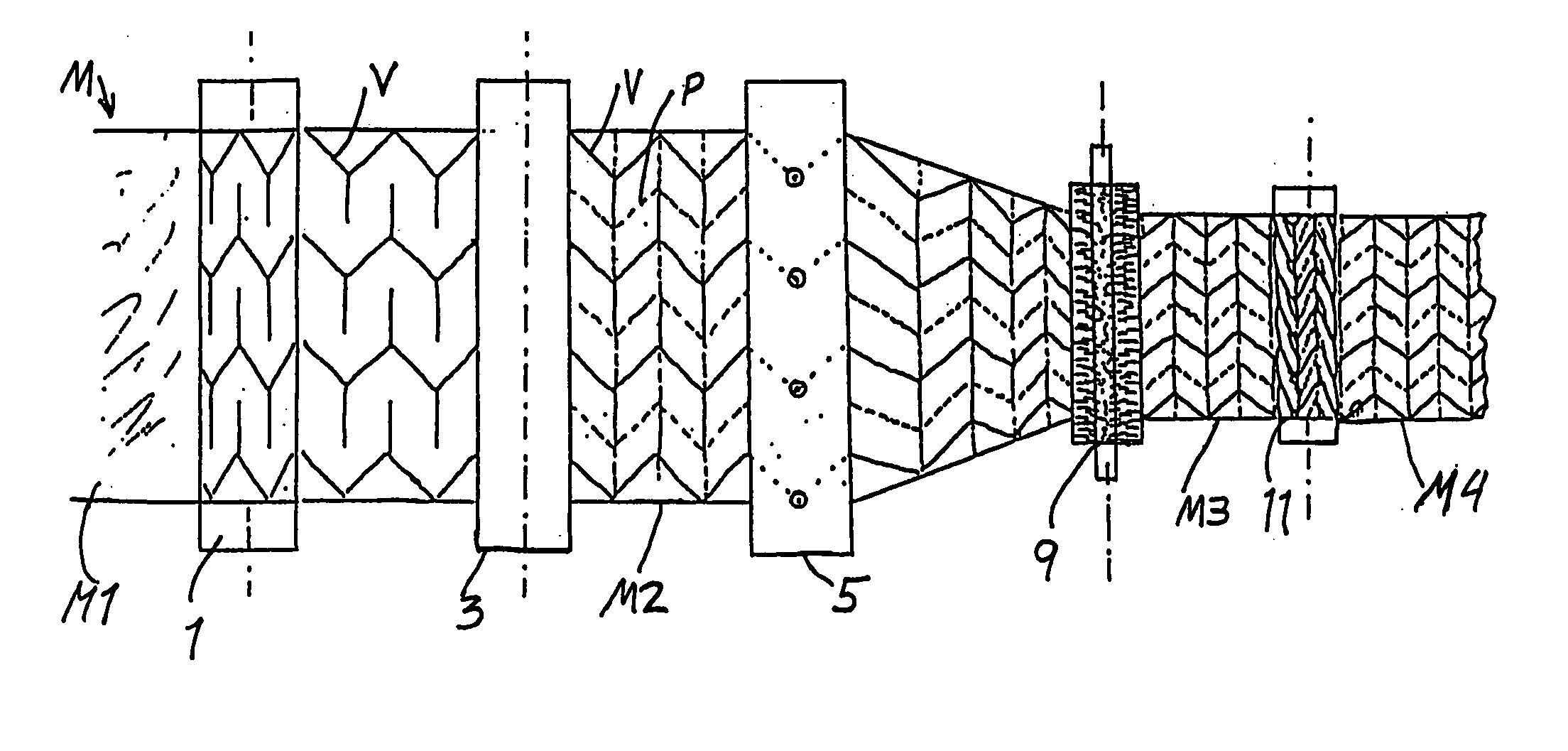

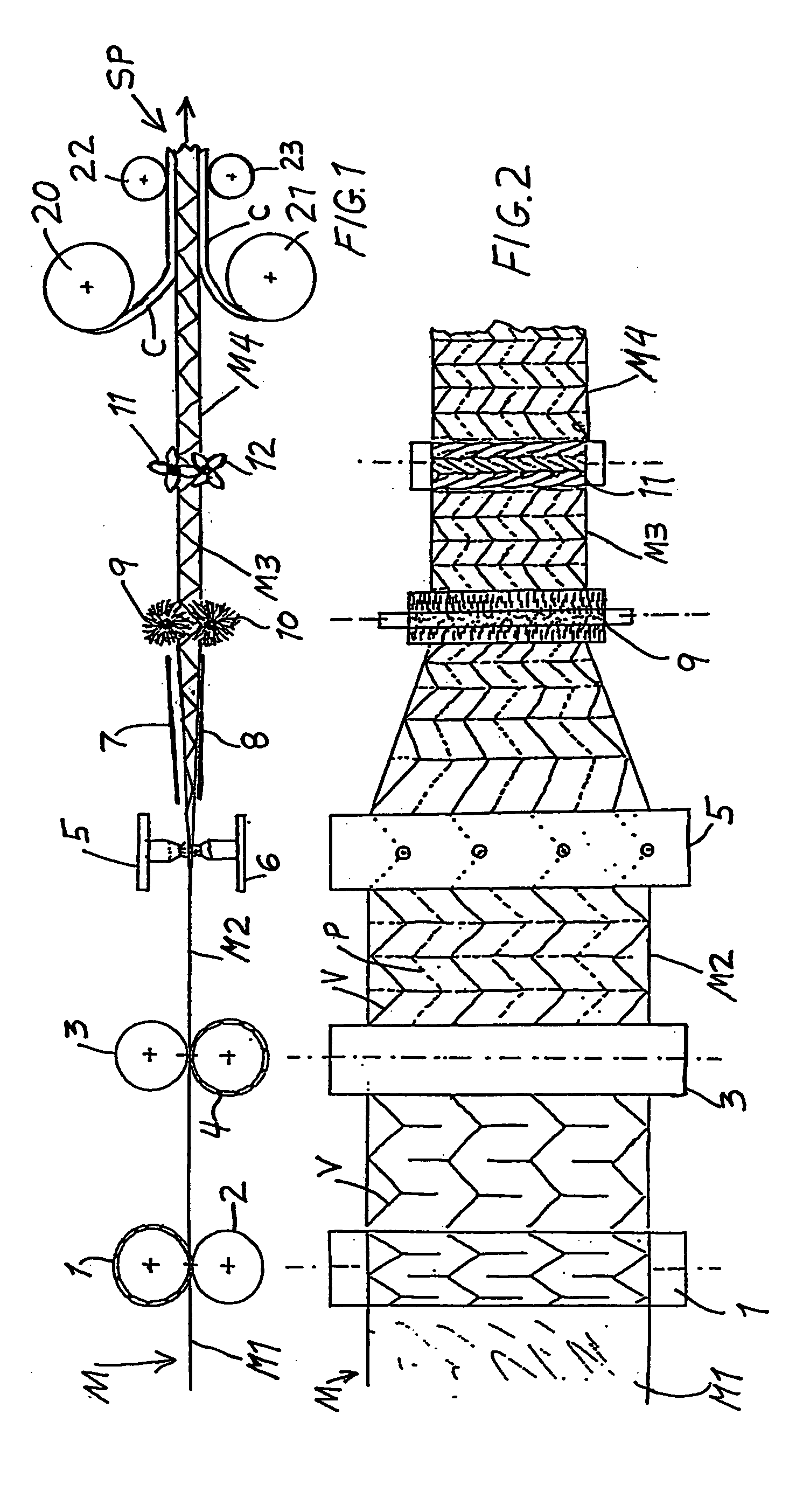

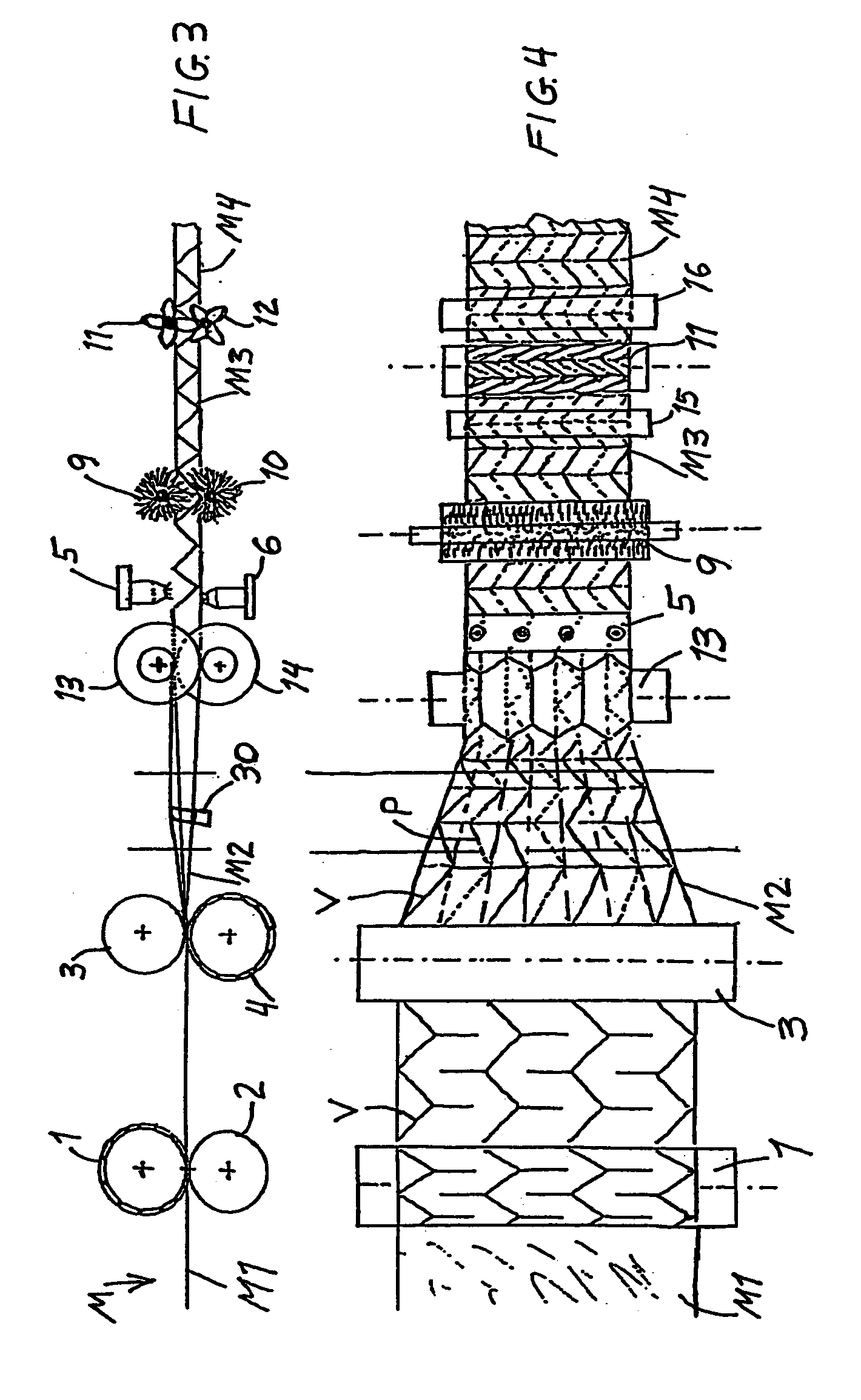

Method and apparatus for producing a composite structural panel with a folded material core

InactiveUS6913570B2Low densityIncrease stiffnessMechanical working/deformationPaper/cardboard articlesBristleEngineering

A folded core structure is produced by embossing fold lines into a flat planar material web, initiating folds along the fold lines on the upper and lower surfaces of the material web, proceeding with the formation of the folds along the fold lines to deform the material web from its two-dimensional starting configuration to a three-dimensional folded configuration, and post-processing the folded material web to stabilize or fix the folded configuration thereof. A composite structural panel is produced by bonding a cover layer onto at least one surface of the folded core structure. An apparatus preferably includes embossing or creasing rolls to form the fold lines in the material web, air nozzles or folding rolls to initiate the folding process, bristle brush rolls to complete the folding process, and further folding rolls to enhance and fix the folded configuration, optionally in connection with heating, cooling, applying a coating onto, or impregnating a resin or binder into the material web.

Owner:AIRBUS OPERATIONS GMBH

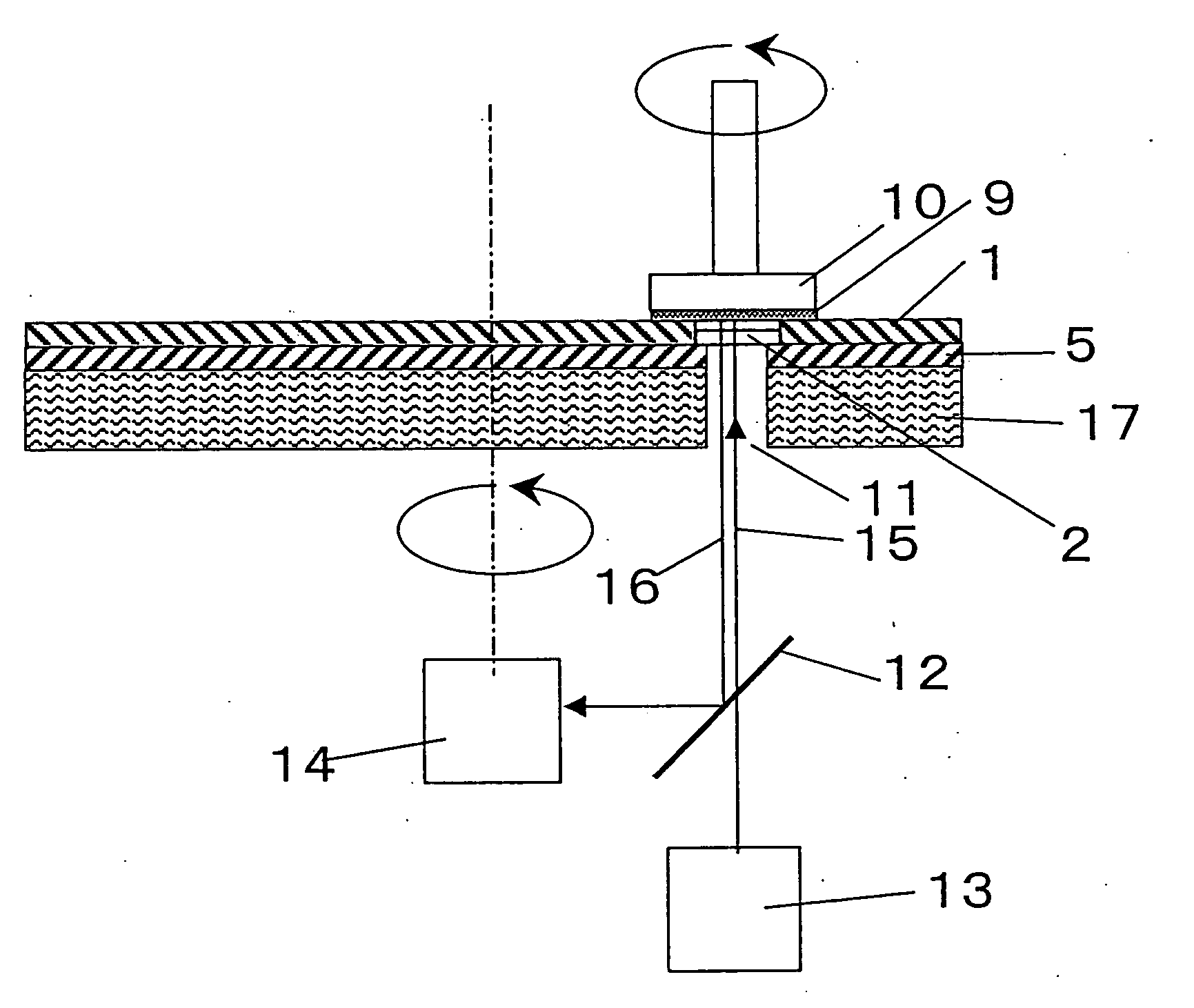

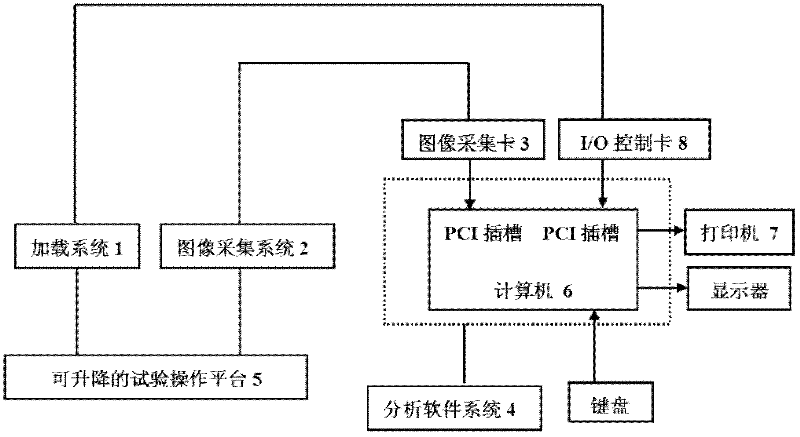

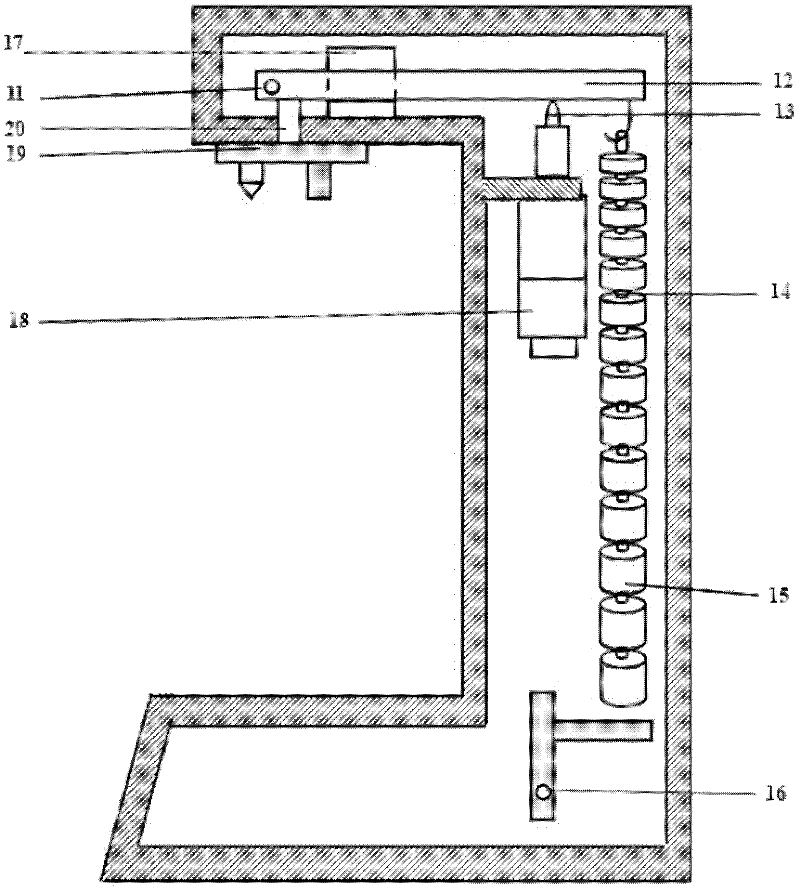

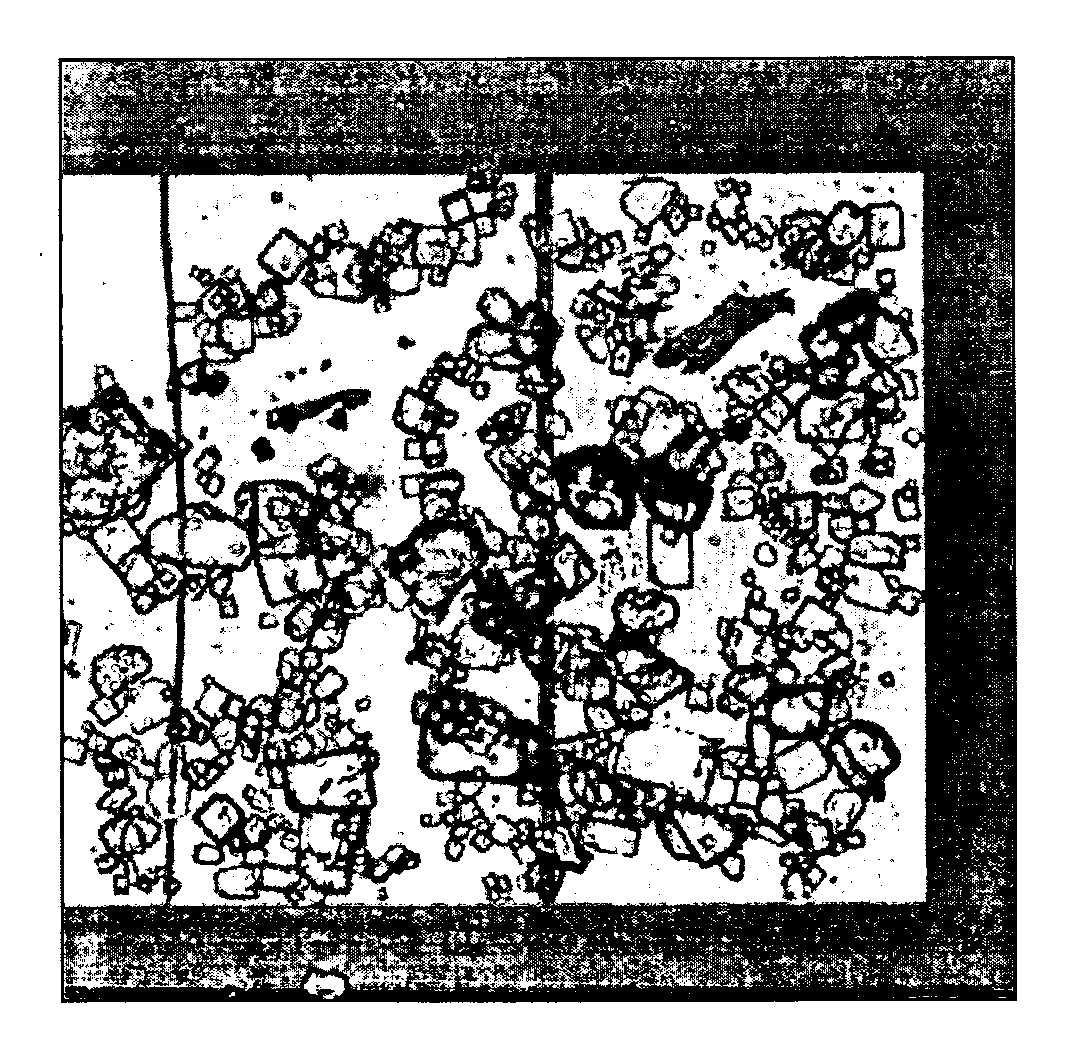

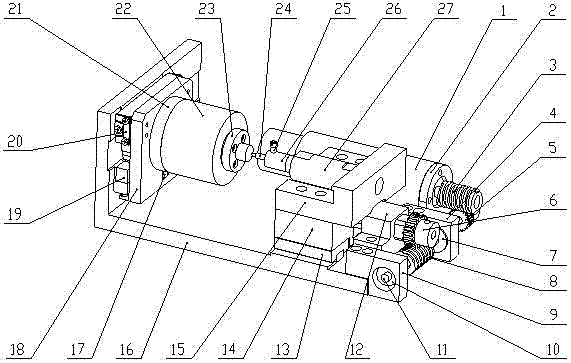

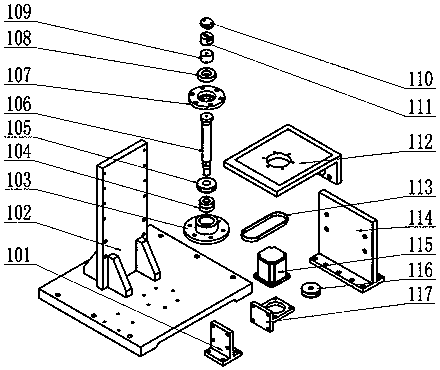

Device for testing hardness, fracture toughness and residual stress of brittle material with indentation method

ActiveCN102393341AAutomate analysisLower acquisition costsInvestigating material hardnessElectric machineryFilm material

The invention discloses a device for testing the hardness, fracture toughness and residual stress of a brittle material with an indentation method, belonging to the technical field of material property representation. The device comprises a frame and an image acquiring system, wherein the frame is provided with an eye lens, a height-adjustable testing operation platform and an adjusting rotating wheel; a loading system is arranged in the frame, and comprises a fixing support base, a lever, a mandrel, a hanging rod, a middle main shaft and a second motor; and a first motor and the second motor of the loading system are connected with a computer through an I / O (Input / Output) control card. In the invention, the conventional digital image low-load Vickers hardness meter is improved, so that the micro-hardness of a material can be directly tested, and the fracture toughness and residual stress of an interface system of the brittle material and a brittle coating film material can be directly tested; and the device can be widely applied to departments such as industrial enterprises, universities, academies and the like for rapidly detecting relevant indexes.

Owner:XIANGTAN UNIV

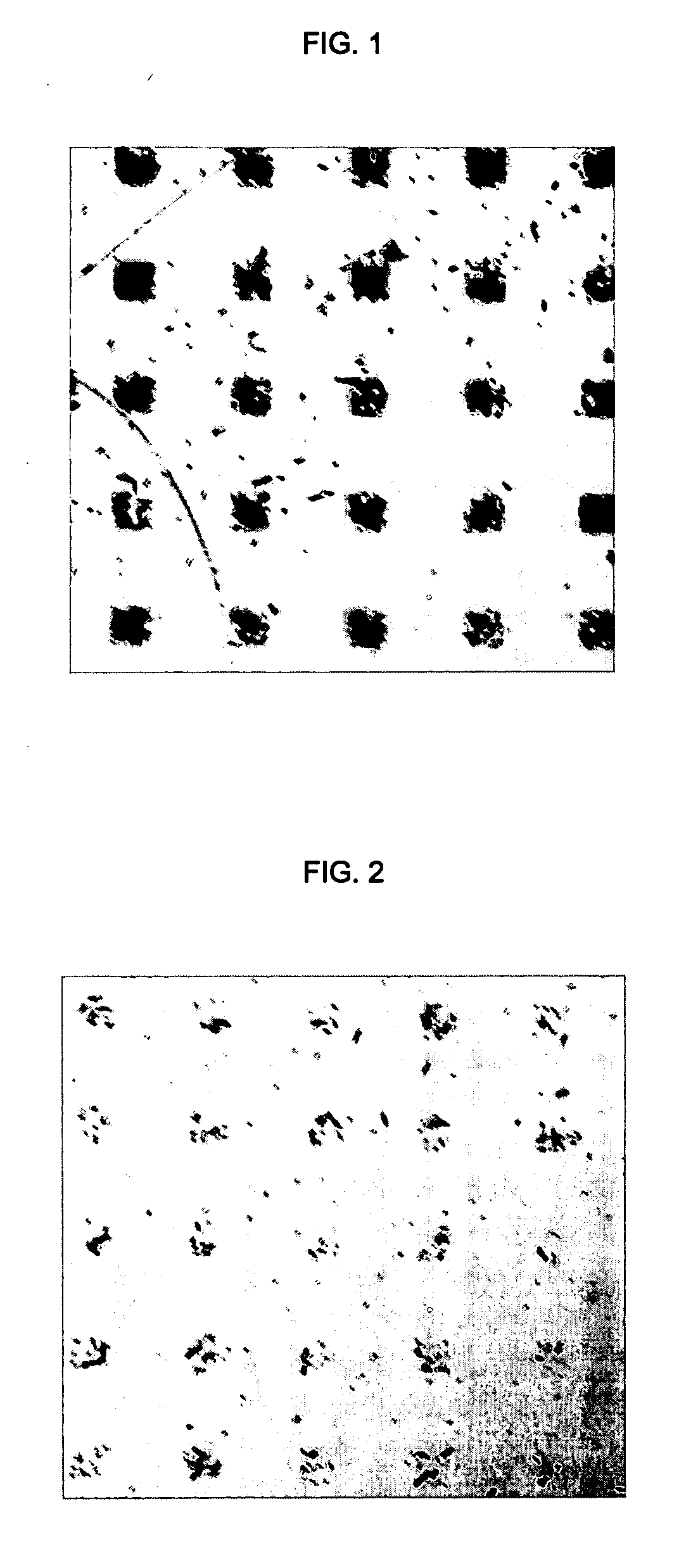

Patterning crystalline compounds on surfaces

InactiveUS20070190783A1Block compoundImprove throughputMaterial nanotechnologyNanoinformaticsCompound (substance)Organic semiconductor

A method of patterning the surface of a substrate with at least one organic semiconducting compound, comprising the steps of: (a) providing a stamp having a surface including a plurality of indentations formed therein defining an indentation pattern, said indentations being contiguous with a stamping surface and defining a stamping pattern, (b) coating said stamping surface with at least one compound (C1) capable of binding to the surface of the substrate and of binding at least one organic semiconducting compound (S), (c) contacting at least a portion of the surface of a substrate with said stamping surface to allow deposition of said compound (C1) on the substrate, (d) removing said stamping surface to provide a pattern of binding sites on the surface of the substrate, (e) applying a plurality of crystallites of the organic semiconducting compound (S) to the surface of the substrate to enable at least a portion of the applied crystallites to bind to at least a portion of the binding sites on the surface of the substrate.

Owner:BASF AG +1

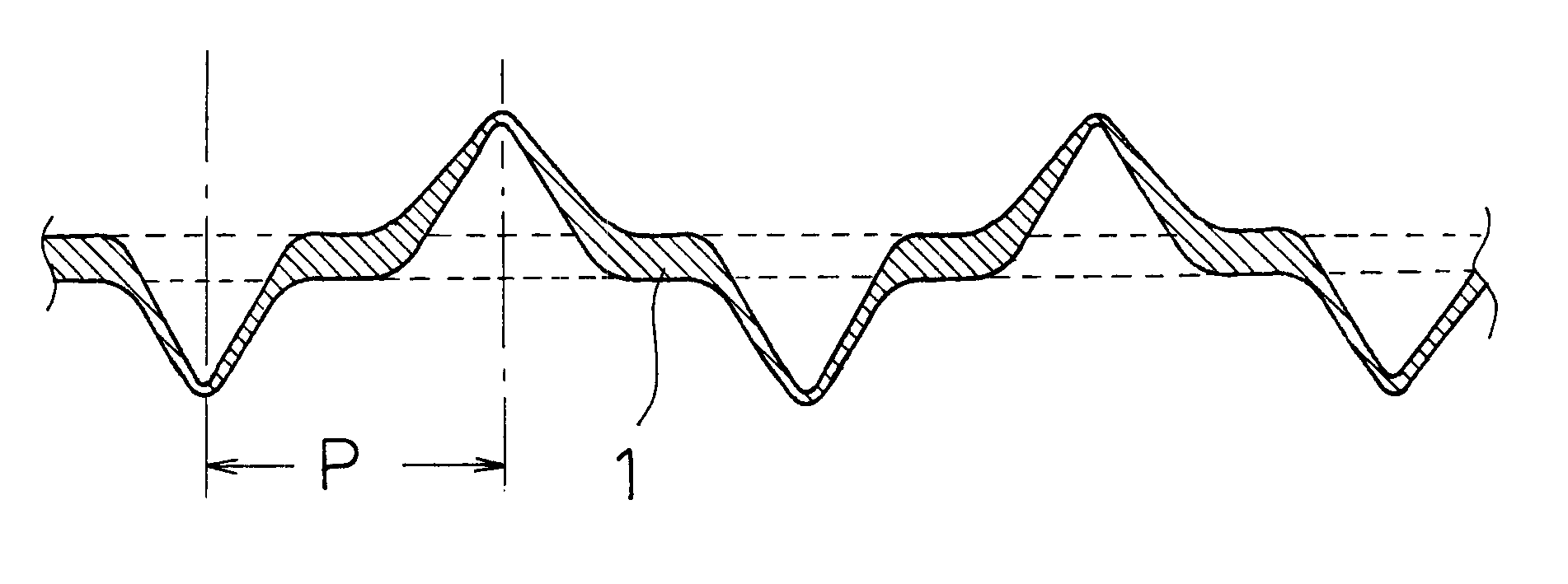

Non-sintered electrode and method of manufacturing same

InactiveUS6444366B1Improve overall utilizationQuality improvementPrimary cellsElectrode carriers/collectorsMaterials scienceMetal sheet

A metal sheet (1) which constitutes a non-sintered type electrode support is processed to have minute irregularities on its surface. The irregularities are formed by a mechanical method such that protrusions (9) and indentations (8) are configured with a center-to-center pitch (P) in the range of from 50 to 300 mum and such that the apparent thickness after processing is at least three times as large as the unprocessed material thickness.

Owner:PANASONIC CORP

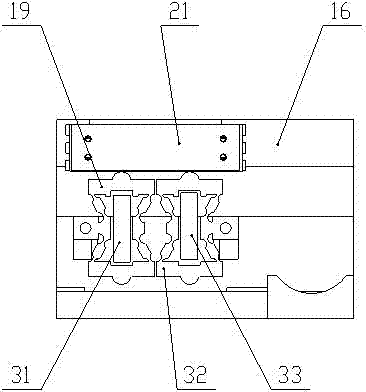

In-situ micro-nano indentation/scratch test platform and test method

ActiveCN104729911AOvercoming detectionOvercoming the lack of tangential forceInvestigating material hardnessMicro nanoScientific instrument

The invention relates to an in-situ micro-nano indentation / scratch test platform and a test method, and belongs to the field of electromechanical integrated precision scientific instruments. An X axis precision scratch unit and a Y axis large-stroke stick-slip drive scratch assembly are assembled at the tail of a base, a Z axis macro-movement adjusting mechanism is assembled at the middle of the base, a motor driving unit is assembled at the head of the base, a precision pressing driving and displacement signal detecting unit is installed on the Z axis macro-movement adjusting mechanism, and a precision three-axis force sensor used for detecting an indentation pressing force and a normal force and a tangential force of a scratch is installed on the X axis precision scratch unit. The in-situ micro-nano indentation / scratch test platform has the advantages of compact structure, miniaturization, integration, and capability of better ensuring the assembly precision, effectively improving the overall rigidity and dynamic properties and improving the overall test precision while overcoming the defect that an existing test platform cannot be used for quantitatively detecting the normal force and the tangential force in a scratch process.

Owner:JILIN UNIV

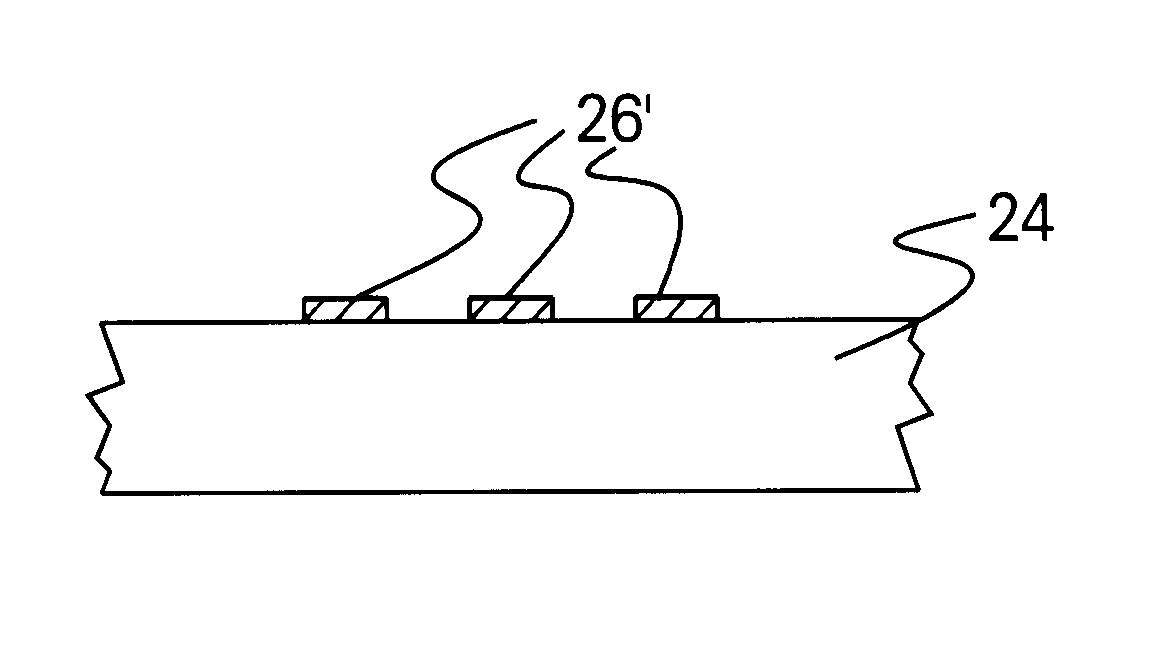

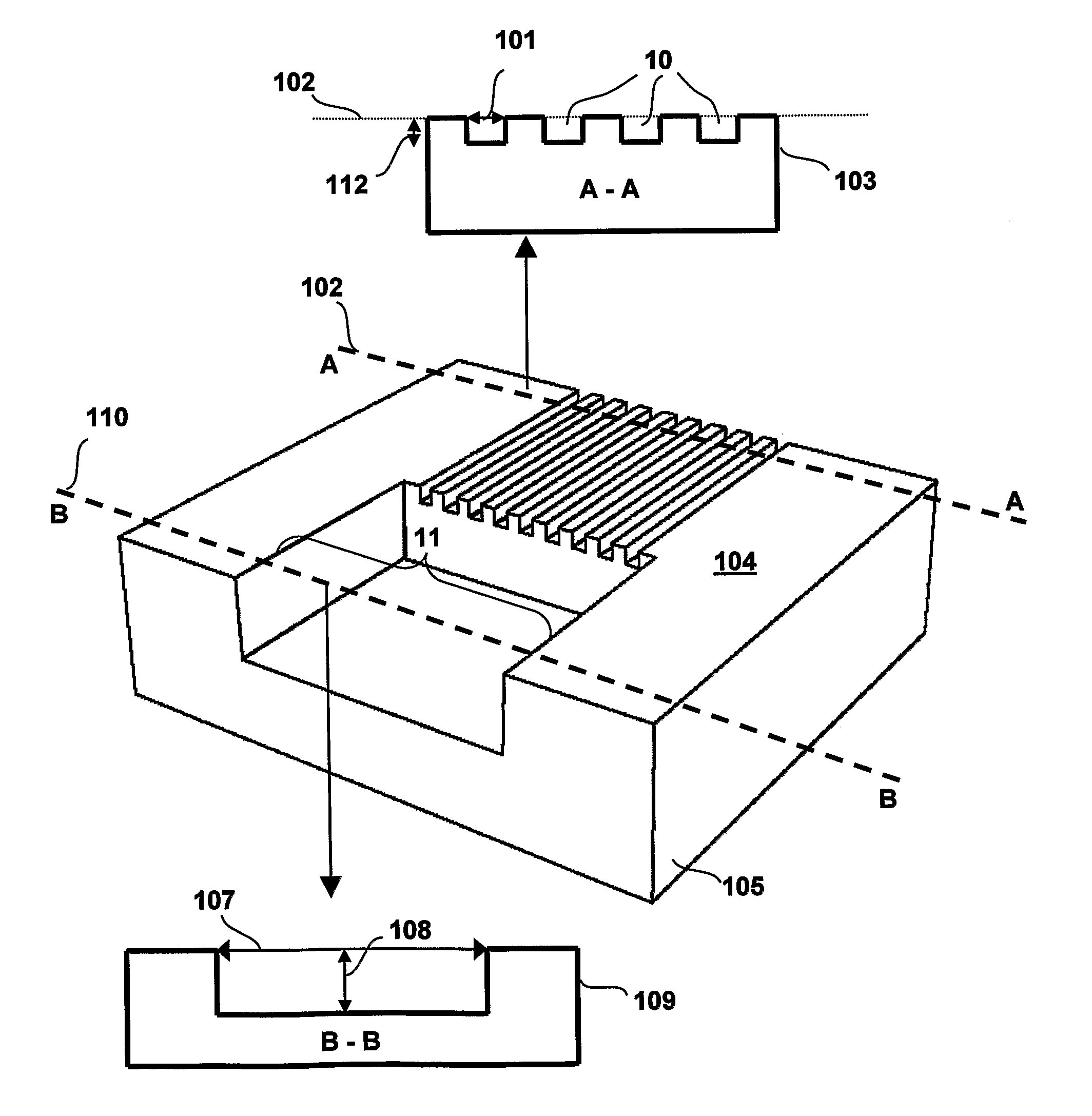

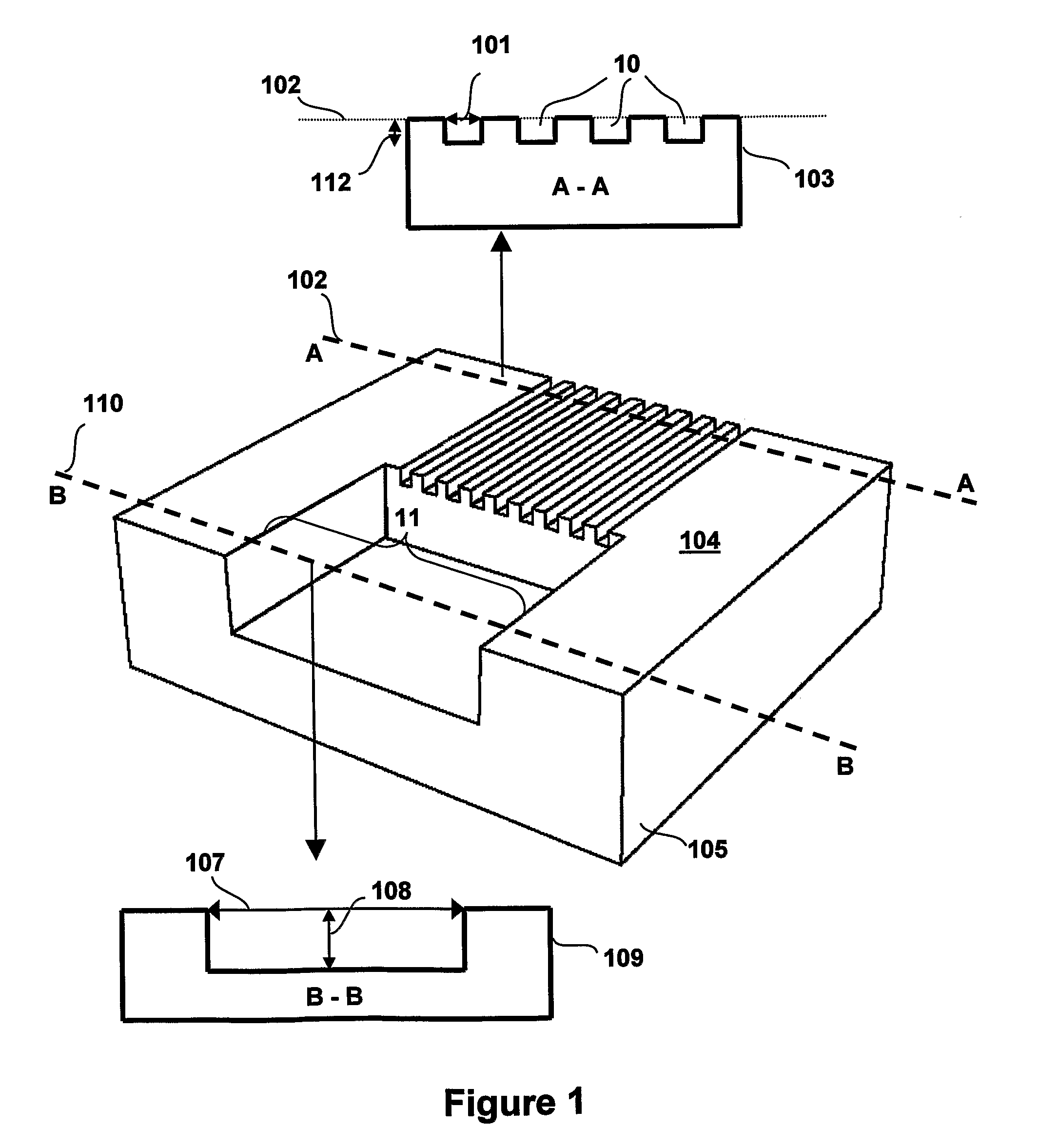

Nanoscale patterning for the formation of extensive wires

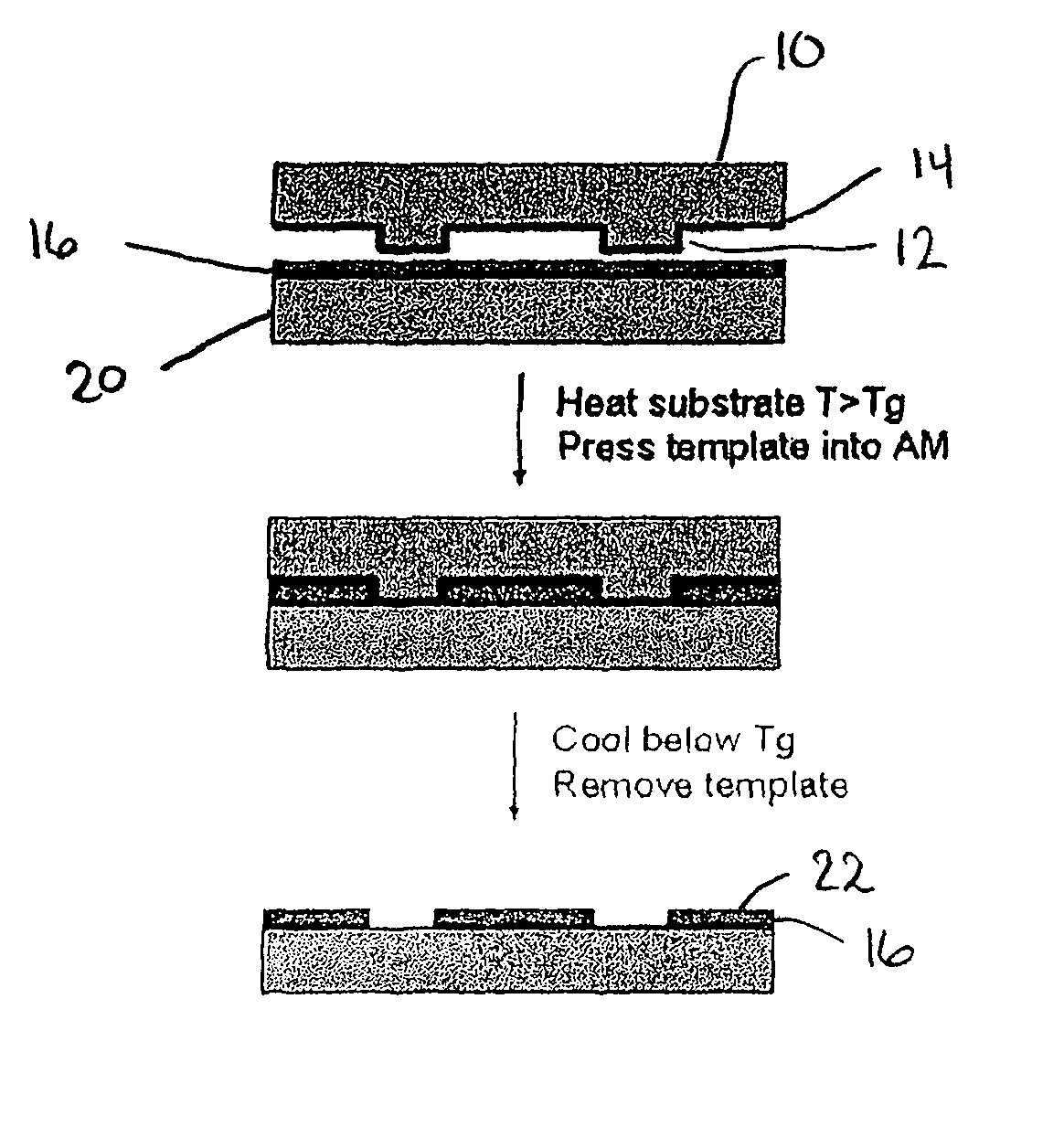

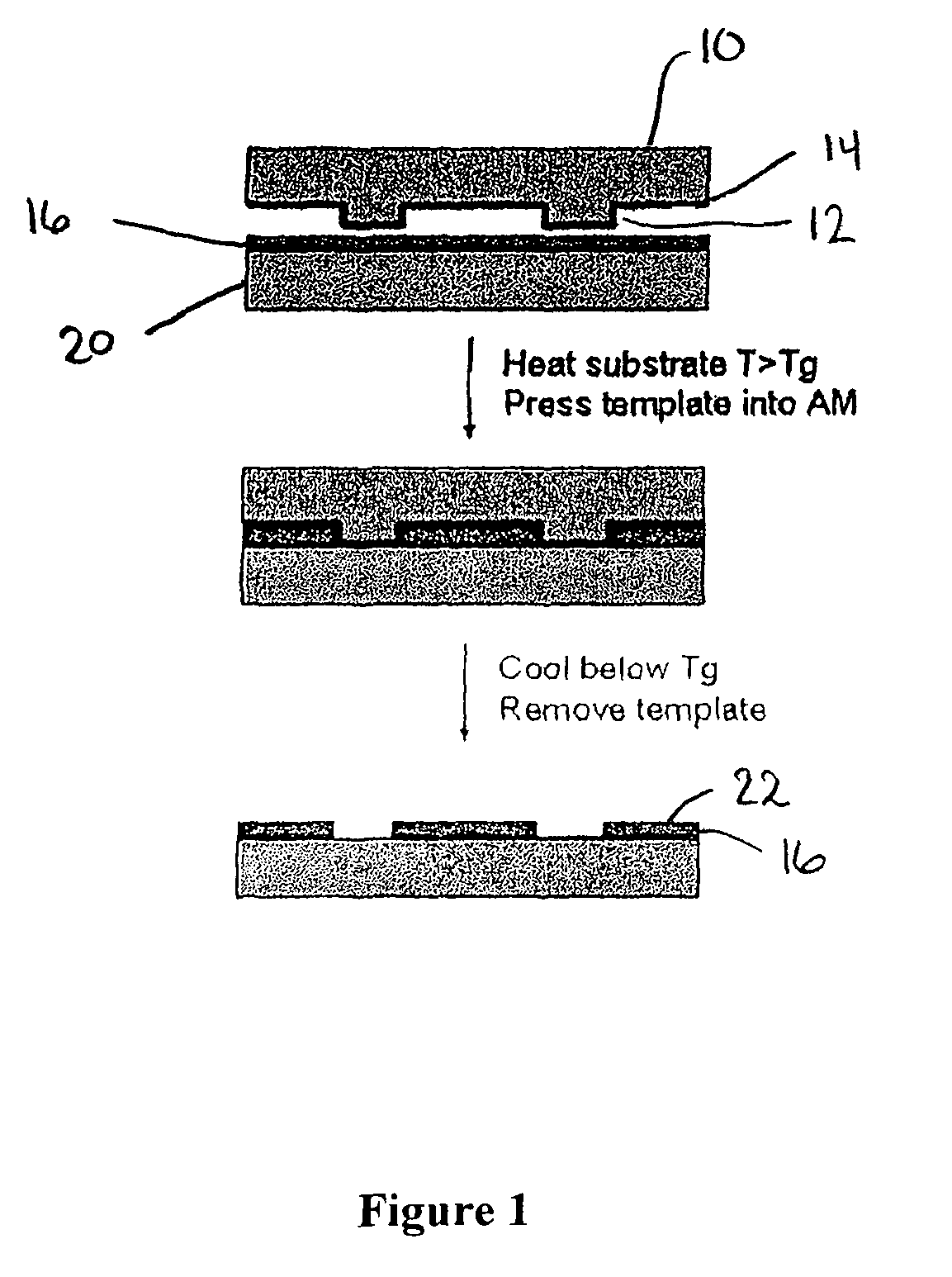

InactiveUS20010044200A1Nanostructure manufactureSemiconductor/solid-state device detailsNanowireSoft materials

A method for forming a platen useful for forming nanoscale wires for device applications comprises: (a) providing a substrate having a major surface; (b) forming a plurality of alternating layers of two dissimilar materials on the substrate to form a stack having a major surface parallel to that of the substrate; (c) cleaving the stack normal to its major surface to expose the plurality of alternating layers; and (d) etching the exposed plurality of alternating layers to a chosen depth using an etchant that etches one material at a different rate than the other material to thereby provide the surface with extensive strips of indentations and form the platen useful for molding masters for nano-imprinting technology. The pattern of the platen is then imprinted into a substrate comprising a softer material to form a negative of the pattern, which is then used in further processing to form nanowires. The nanoscale platen thus comprises a plurality of alternating layers of the two dissimilar materials, with the layers of one material etched relative the layers of the other material to form indentations of the one material. The platen is then oriented such that the indentations are parallel to a surface to be imprinted.

Owner:SAMSUNG ELECTRONICS CO LTD

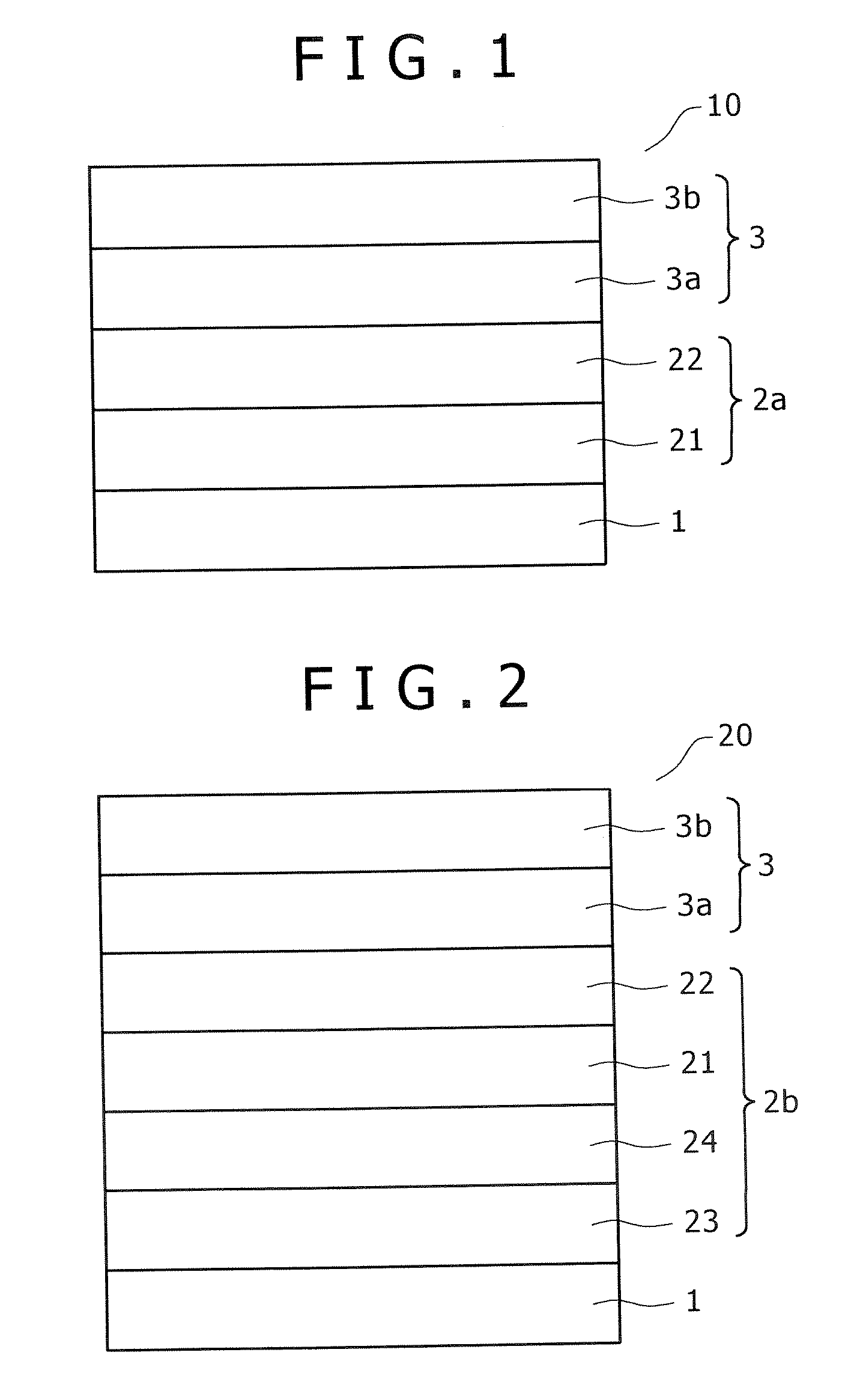

Diamondlike carbon hard multilayer film formed body and method for producing the same

InactiveUS20070054125A1Improve adhesionImprove wear resistanceLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

A diamondlike carbon hard multilayer formed film body comprises a substrate, a diamondlike carbon film mainly composed of diamondlike carbon, and an intermediate layer between the substrate and the diamondlike carbon film. The diamondlike carbon film is composed of, in order from the substrate side, a first diamondlike carbon film and a second diamondlike carbon film. The surface hardness of the first diamondlike carbon film is within the range from not less than 10 GPa to not more than 40 GPa based on nanoindentation test, and the surface hardness of the second diamondlike carbon film is within the range from more than 40 GPa to not more than 90 GPa based on nanoindentation test. According to such a structure, even if a DLC multilayer containing high-hardness DLC film on the outermost surface side is formed in a thickness of not less than about 3 μm on a substrate of a wide range extending from a material with high hardness such as cemented carbide to an iron-based material with low hardness, excellent adhesion to both the substrate and the DLC film can be ensured in addition to excellent wear resistance.

Owner:KOBE STEEL LTD

Method for producing large high-purity molybdenum planar target material for flat panel displays

ActiveCN102392222AQuality improvementImprove reliabilityVacuum evaporation coatingSputtering coatingWire cuttingDisplay device

The invention relates to a production technology of a planar high-purity molybdenum target material and discloses a method for producing a large high-purity molybdenum planar target material for flat panel displays, comprising the steps of: molybdenum powder analysis, powder selection, powder blending, die filling, pressing, sintering, rolling, annealing, width milling, wire cutting of end faces,chamfering and grinder machining. The planar high-purity molybdenum target material machined by the method has the following beneficial effects that: the length of the molybdenum target material can be up to 2700mm; the molybdenum content is greater than or equal to 99.95%; the relative density is greater than or equal to 99%; the grain structure is uniform; the flatness is less than 0.05; the surface roughness is Ra0.2; the surface is free of the defects such as flaws, peeling, folding, dents, metal or nonmetal pressed articles and the like; the lengths of internal flaws in the target material are not greater than 0.04mm; and no air bubbles and large crystals are generated.

Owner:丰联科光电(洛阳)股份有限公司

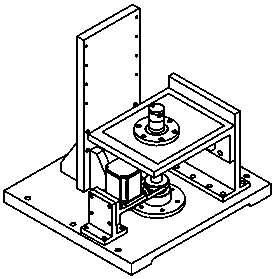

Temperature-variable indexable micro-nano indention testing device

PendingCN107703012AAccurate measurementExpand the scope of testingInvestigating material hardnessMicro nanoContinuous measurement

The invention relates to a temperature-variable indexable micro-nano indention testing device and belongs to the field of precise instruments. The device comprises a workbench indexing base, a high-and-low-temperature working cavity and an indenter driving / feeding mechanism, the high-and-low-temperature working cavity is mounted on an L-shaped mounting plate of the workbench indexing base, and theindenter driving / feeding mechanism is mounted on an equipment base of the workbench indexing base. The workbench indexing base is mainly used for indexing a workbench and supporting the whole device,the high-and-low-temperature working cavity can provide an environment atmosphere with temperature continuously changing for the process of test piece measuring and can isolate outside interference,and the indenter driving / feeding mechanism is mainly used for feeding an indenter in the vertical direction and acquiring measurement data through a pressure sensor and a displacement sensor. the device has the advantages that the device is accurate in measurement result, wide in measurement range and compact in structure, and the technical field of mechanical performance testing of materials anddevelopment of equipment for mechanical performance testing of the materials are promoted greatly.

Owner:JILIN UNIV

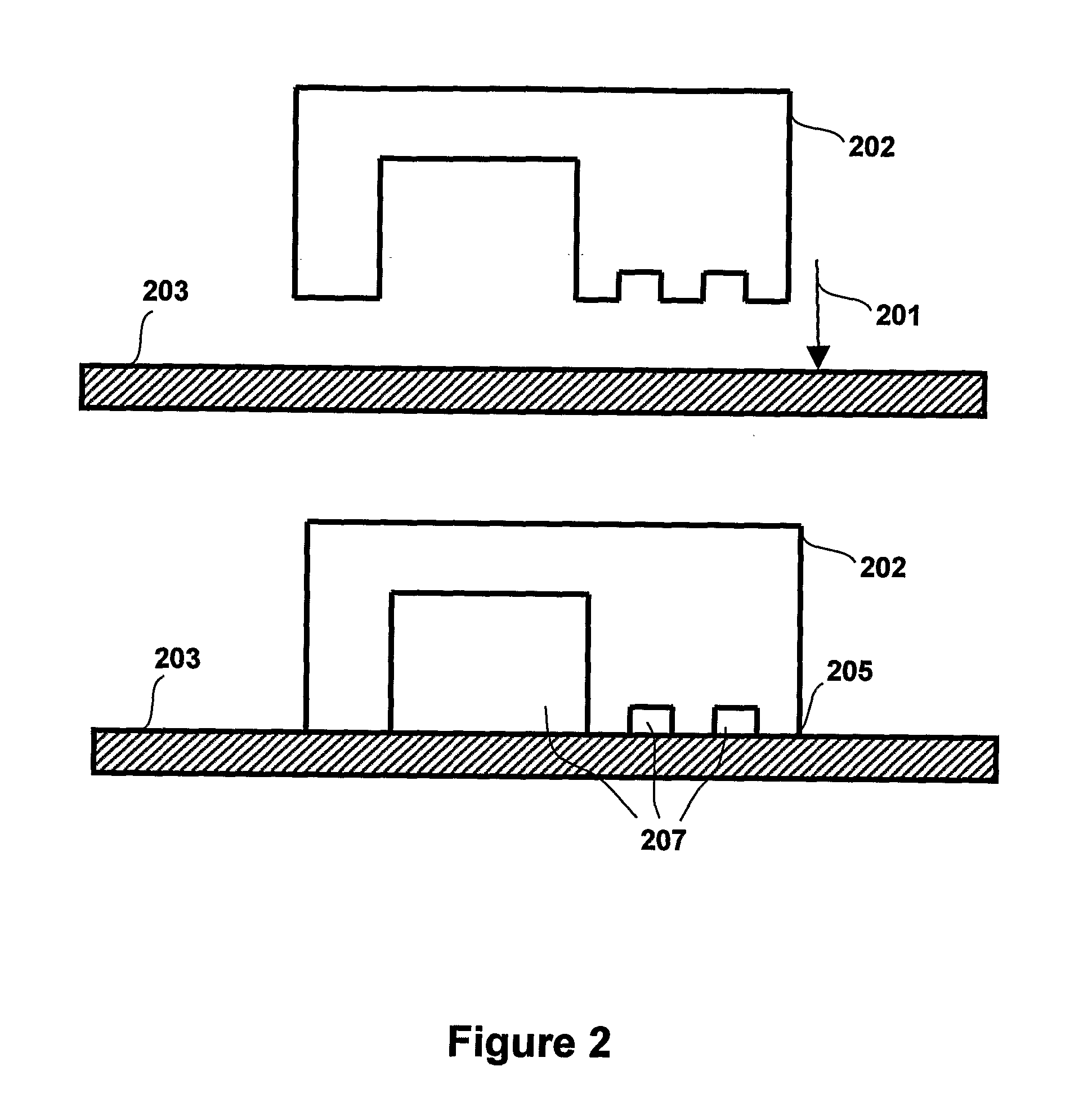

Micro and NANO structures in an elastomeric material

InactiveUS20090053471A1Low costHighly time-consumeMaterial nanotechnologyMechanical working/deformationElastomerLab-on-a-chip

The invention relates to an elastomeric device (105), wherein the elastomeric device contains a relief structure with indentations with respect to the base (110), (102) and wherein selected ones of said indentations comprise at least two indentation depths (112), (108) and indentation widths (101), (107). It also relates to a method of making a master for construction of said elastomeric device comprising a procedure to provide a pattern on a substrate of a suitable material. One step in. the construction of said elastomeric device comprises a molding procedure of an elastomer. Methods of using the elastomeric device in printing, fluidic control, sorting, lab-on-a-chip devices are also disclosed.

Owner:FORSKARPATENT I LINKOPING

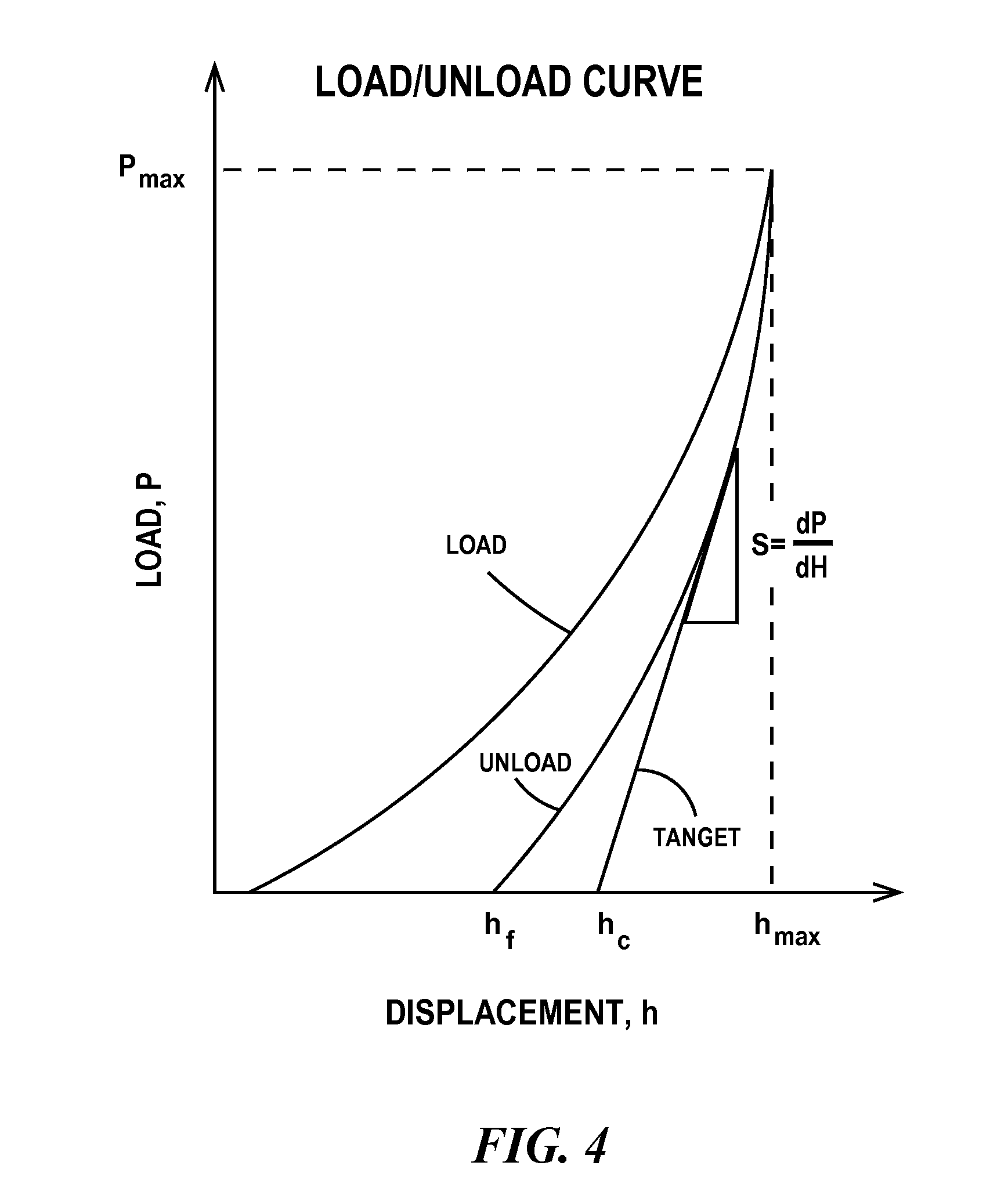

Determination of young's modulus of porous thin films using ultra-low load nano-indentation

InactiveUS20160216184A1Modulus is reducedLittle strengthInvestigating material hardnessLow loadYoung's modulus

A method and computer product program for determining Young's modulus. The method includes placing a probe in contact with a surface of a material on a substrate and, with an initial force of 800 nano newtons or less; determining the location of the surface relative to an initial indentation depth for the initial force; increasing the force on the probe from the initial force to a maximum force greater than the initial force to generate a load curve; decreasing the force on the probe from the maximum force to the initial force to generate an unload curve, the maximum force selected such that the unload curve is independent of the presence of the substrate; and using the unload curve, determining a relationship between (i) the reduced modulus of the sample material and (ii) the ratio of probe penetration depth and the thickness of the layer.

Owner:IBM CORP

Metal-based composite material shearing strength testing method and sample preparation method

InactiveCN106033040APrevent hardeningAvoid distortionPreparing sample for investigationMaterial strength using steady shearing forcesMicro nanoIon beam

The invention relates to a metal-based composite material shearing strength testing method and a preparation method of a sample applied in the testing method. According to the principle, a micro-nano size cylinder containing a separate reinforcement-substrate interface is etched by means of focused ion beams, the reinforcement-substrate interface of the micro-nano size cylinder and the axial direction of the cylinder form a 45-degree angle, pressure is exerted on the top surface of the micro-nano size cylinder in the axial direction by using a nanoindentor, and the micro-nano size cylinder is compacted and deformed; in the process, the direction, forming 45 degrees with the compaction direction, of the reinforcement-substrate interface will bear the maximum shearing strength till the shear behavior occurs on the reinforcement-substrate interface, and the shearing strength of the reinforcement-substrate interface is calculated according to a stress-strain curve, recorded through the nanoindentor, of the micro-nano size cylinder.

Owner:江苏省(丹阳)高性能合金材料研究院

Toner

ActiveUS20190041763A1Improve mechanical stabilityHeavy loadDevelopersDynamic viscoelasticityHorizontal axis

A toner comprising a toner particle that contains a binder resin and a colorant, wherein (1) an average circularity of the toner is at least 0.960, (2) an onset temperature Tε (° C.) of a storage elastic modulus E′ of the toner, as determined by a powder dynamic viscoelastic measurement, is from 50° C. to 70° C., and (3) in a differential curve obtained by differentiation, by load, of a load-displacement curve provided by measurement of the strength of the toner by a nanoindentation procedure, with the horizontal axis being load (mN) and the vertical axis being displacement (μm), the load X that provides the maximum value in the differential curve in the load region from 0.20 mN to 2.30 mN is from 1.00 mN to 1.50 mN.

Owner:CANON KK

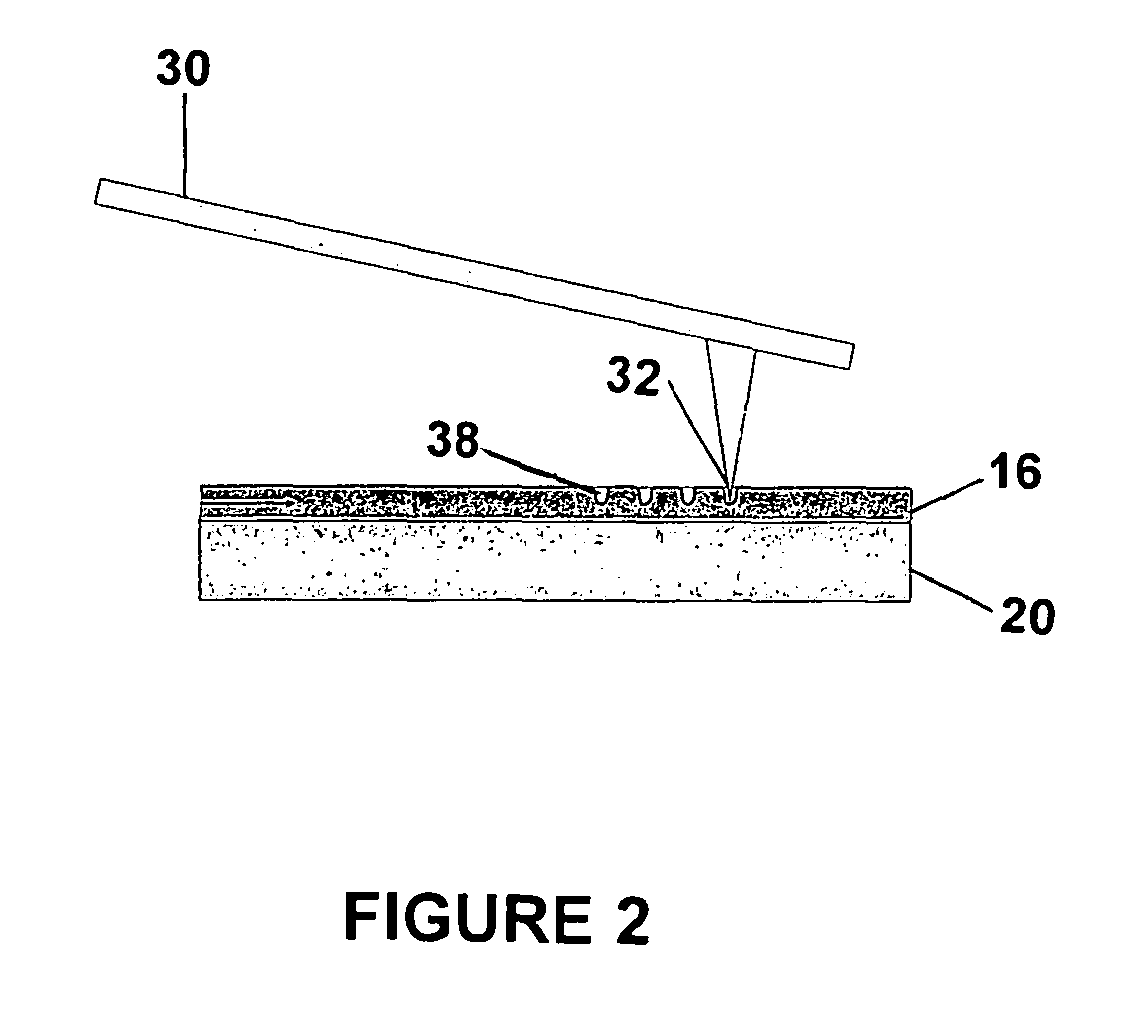

Method and apparatus for producing a composite structural panel with a folded material core

ActiveUS20040102303A1Low densityIncrease stiffnessMechanical working/deformationPaper/cardboard articlesBristleEngineering

A folded core structure is produced by embossing fold lines into a flat planar material web, initiating folds along the fold lines on the upper and lower surfaces of the material web, proceeding with the formation of the folds along the fold lines to deform the material web from its two-dimensional starting configuration to a three-dimensional folded configuration, and post-processing the folded material web to stabilize or fix the folded configuration thereof. A composite structural panel is produced by bonding a cover layer onto at least one surface of the folded core structure. An apparatus preferably includes embossing or creasing rolls to form the fold lines in the material web, air nozzles or folding rolls to initiate the folding process, bristle brush rolls to complete the folding process, and further folding rolls to enhance and fix the folded configuration, optionally in connection with heating, cooling, applying a coating onto, or impregnating a resin or binder into the material web.

Owner:AIRBUS OPERATIONS GMBH

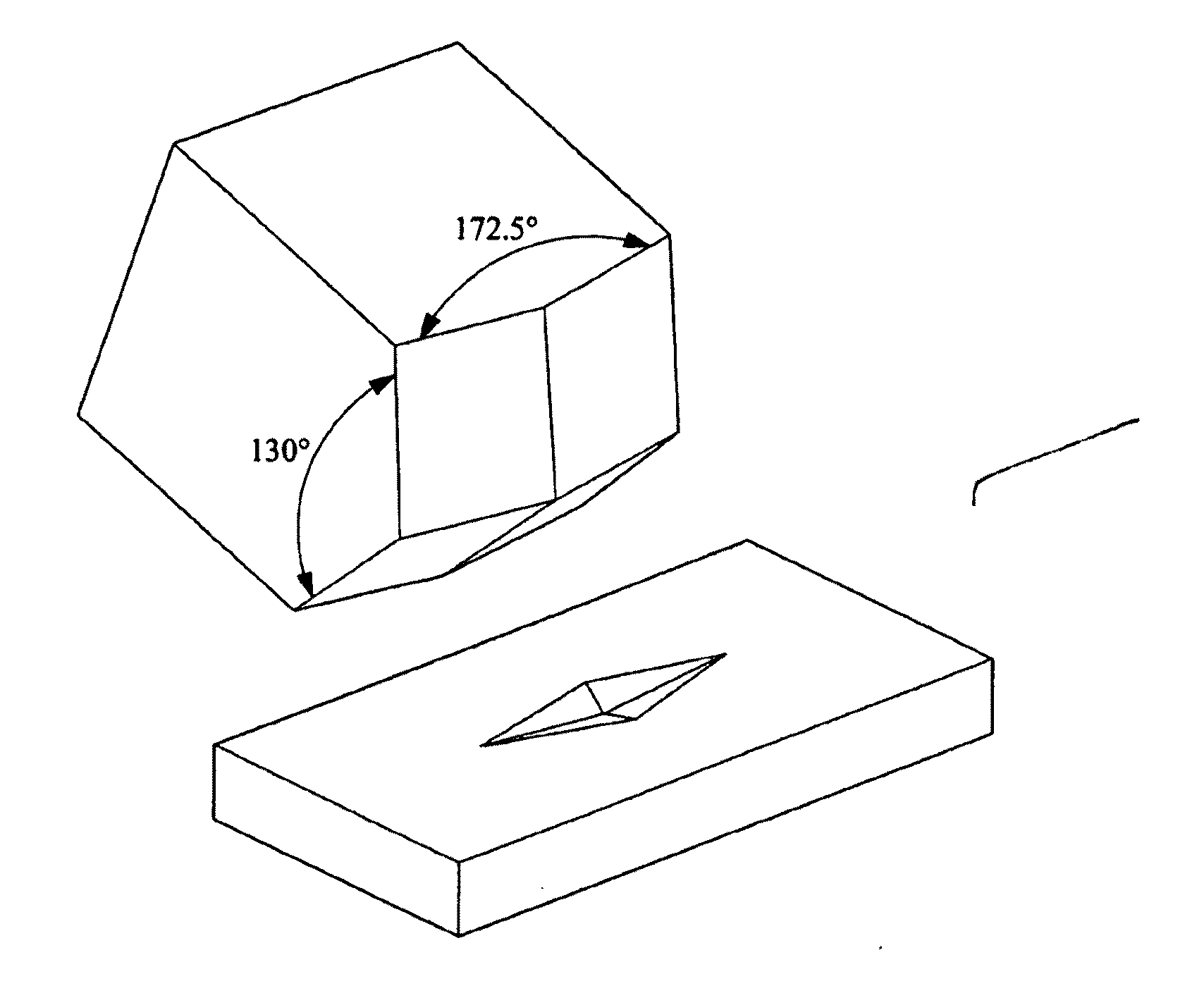

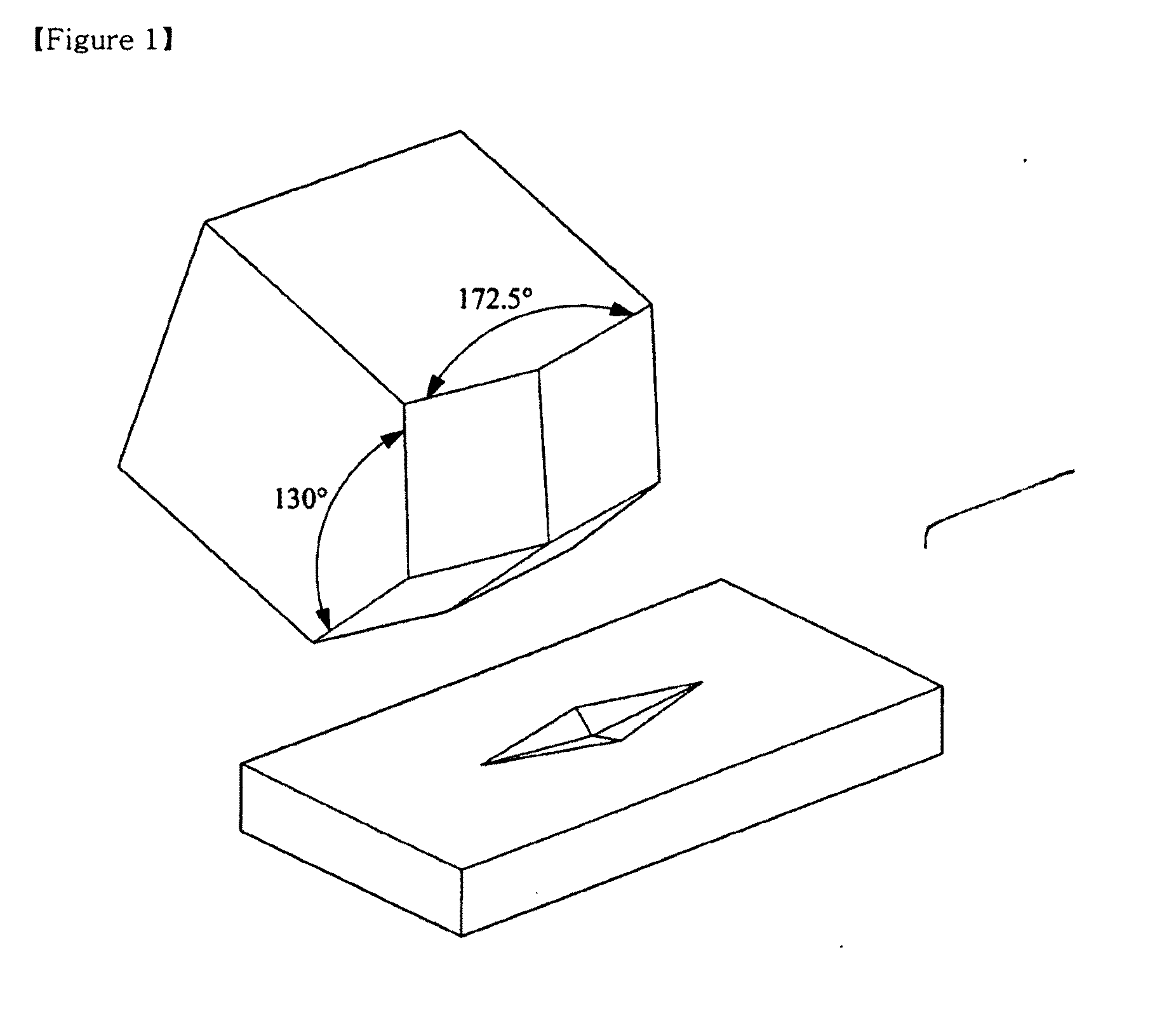

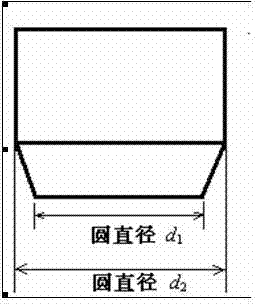

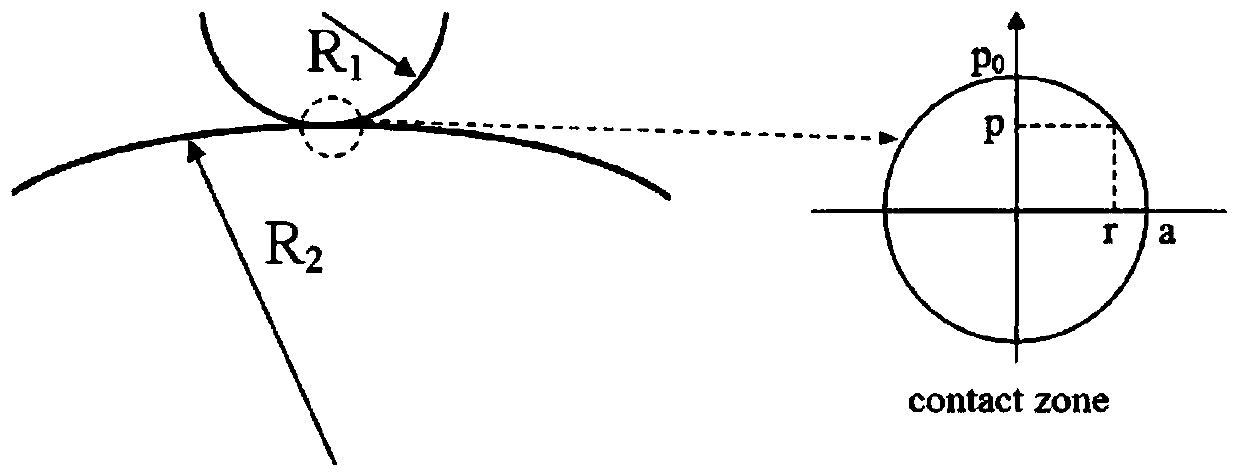

Estimation of non-equibiaxial stress using instrumented indentation technique

ActiveUS20100198530A1Analysing solids using sonic/ultrasonic/infrasonic wavesFlow propertiesDiagonalIndentation testing

Method for evaluating an asymmetric residual stress for a material by the indentation test comprises applying the residual stresses with an uniaxial and an symmetrical biaxial tensions on the material and then performing an instrumented indentation test indenting an asymmetric indenter on the material; and comparing a slope of indentation load-depth curve when the long diagonal direction of the asymmetric indenter is perpendicular to the direction of the largest residual stress with that in stress-free state, and then a slope of indentation load-depth curve when the long diagonal direction of the asymmetric indenter is parallel to the direction of the largest residual stress with that in stress-free state, so as to evaluate the asymmetric residual stress for the material.

Owner:FRONTICS

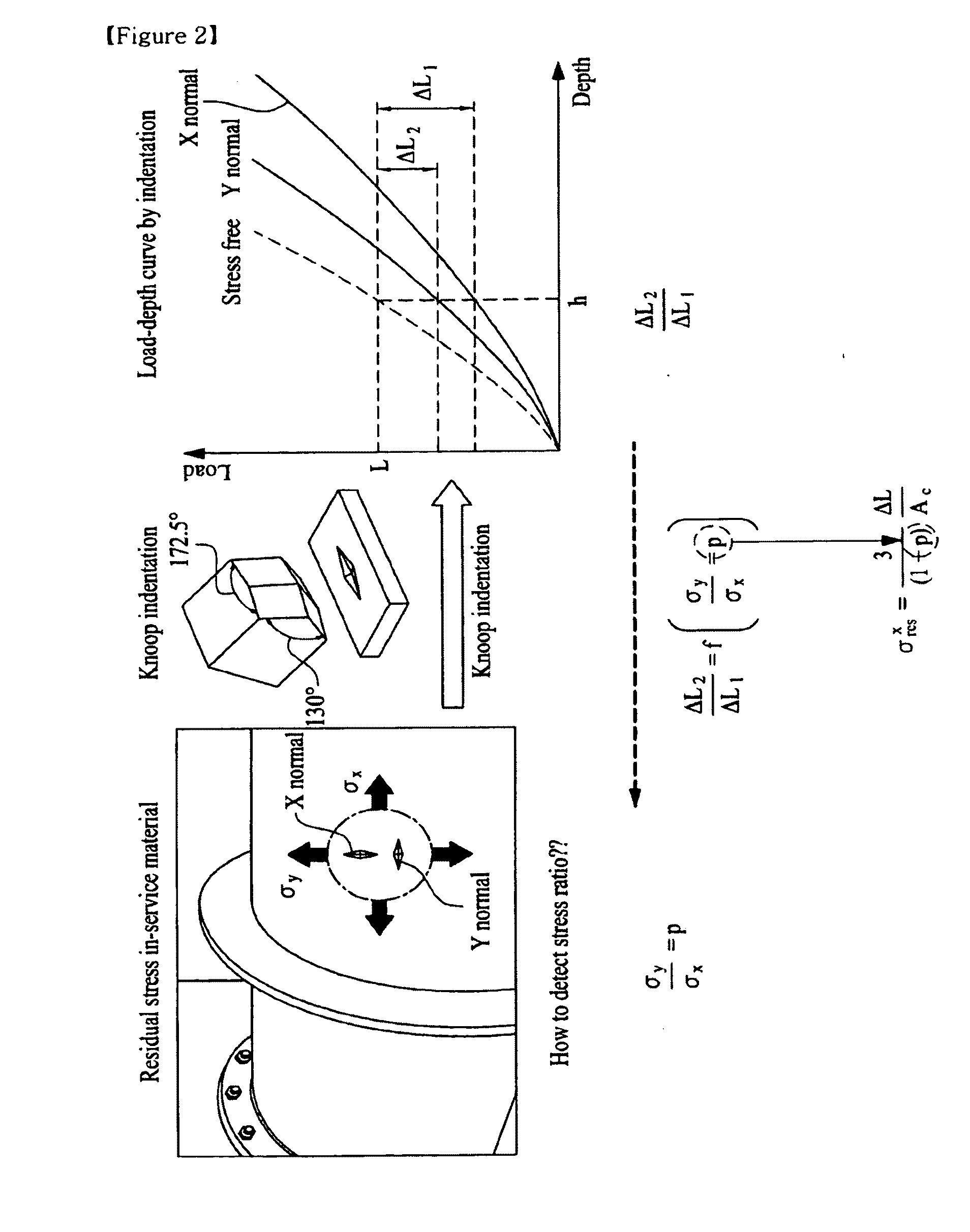

High resolution, high speed multi-frequency dynamic study of visco-elastic properites

The present invention provides an apparatus and method including hardware and software, which allows collecting and analyzing of data to obtain information about mechanical properties of soft materials. This allows surface mapping of viscoelastic properties in a high-resolution and fast manner. It also allows finding the degree of nonlinearity of the material response of the sample during the measurements. The apparatus can be used as a stand-alone device, or an add-on to either the existing atomic force microscope or nanoindenter device.

Owner:CLARKSON UNIVERSITY

Method for imprinting and erasing amorphous metal alloys

ActiveUS8641839B2Surface roughnessLayered productsMechanical recordingMicron scaleTransfer procedure

The present invention relates to materials, methods and apparatuses for performing imprint lithography using amorphous metallic materials. The amorphous metallic materials can be employed as imprint media and thermoplastic forming processes are applied during the pattern transfer procedure to produce micron scale and nanoscale patterns in the amorphous metallic layer. The pattern transfer is in the form of direct mask embossing or through a serial nano-indentation process. A rewriting process is also disclosed, which involves an erasing mechanism that is accomplished by means of a second thermoplastic forming process. The amorphous metallic materials may also be used directly as an embossing mold in imprint lithography to allow high volume imprint nano-manufacturing. This invention also comprises of a method of smoothening surfaces under the action of the surface tension alone.

Owner:YALE UNIV

Toner

A toner comprising: a toner particle that contains a binder resin and a colorant: and an external additive, wherein (1) the average circularity of the toner is at least 0.960; (2) the fixing ratio of the external additive on the toner particle is from 75% to 100%; and (3) in a differential curve obtained by the differentiation, by load, of a load-displacement curve where the horizontal axis is load (mN) and the vertical axis is displacement (μm), the load-displacement curve being provided by measurement of the strength of the toner by a nanoindentation procedure, a load A that provides a maximum value in the differential curve in a load region from 0.20 mN to 2.30 mN is from 1.15 mN to 1.50 mN.

Owner:CANON KK

Hardness testing method and usage thereof

InactiveCN102478474AHard and softDifferent hardness valuesInvestigating material hardnessEngineeringStructural engineering

A hardness testing method is characterized in that during hardness testing, a special testing pressure head with a plane end is used for applying load to an object to be tested, corresponding indentation is formed on the testing surface of the object to be tested, and the indentation and the added load are used as basis for hardness testing. The technical problem of hardness testing for representative multiple composites is solved creatively, and accordingly, different indentation area calculation modes and methods are developed by using a hardness testing system. The testing method is compatible and complementary with a traditional hardness testing method, so that testing (hardness) values obtained by using the methods can be compared, and a testing reference system is provided for hardness ratio of the composites to homogenous materials.

Owner:王严岩

Toner

ActiveUS10578990B2Improve mechanical stabilityHeavy loadDevelopersPolymer scienceUltimate tensile strength

A toner comprising a toner particle that contains a binder resin and a colorant, wherein (1) an average circularity of the toner is at least 0.960, (2) an onset temperature Tε (° C.) of a storage elastic modulus E′ of the toner, as determined by a powder dynamic viscoelastic measurement, is from 50° C. to 70° C., and (3) in a differential curve obtained by differentiation, by load, of a load-displacement curve provided by measurement of the strength of the toner by a nanoindentation procedure, with the horizontal axis being load (mN) and the vertical axis being displacement (μm), the load X that provides the maximum value in the differential curve in the load region from 0.20 mN to 2.30 mN is from 1.00 mN to 1.50 mN.

Owner:CANON KK

On-line automatic detector for mechanical parameters of materials under complex working conditions

ActiveCN111504826AReduce volumeHigh positioning accuracyInvestigating material hardnessScientific instrumentEngineering

The invention belongs to the technical field of precise scientific instruments, and particularly relates to an online automatic detector for the mechanical parameters of the materials under the complex working conditions. The online automatic detector comprises a shell, and a precise indentation test unit, a base magnetic force moving unit, a material surface polishing unit and a guide rail driving unit which are arranged in the shell. The precision indentation testing unit and the material surface polishing unit are arranged on the guide rail driving unit and are in sliding fit with the guiderail driving unit, and the guide rail driving unit is fixed on the base magnetic moving unit. The online automatic detector for the mechanical parameters of the materials under the complex working conditions is simple in structure, can carry out the indentation test under service conditions, can accurately solve the mechanical parameters, such as material hardness, elastic modulus, yield strength, residual stress, fracture toughness, etc., and can solve the system errors caused by displacement and load detection units in complex environments.

Owner:JILIN UNIV

Method for realizing inversion identification of crystal plastic material parameters based on nanoindentation experiment

ActiveCN111189699AHigh precisionSmall amount of calculationPreparing sample for investigationMaterial strength using tensile/compressive forcesElement modelMacroscopic scale

The invention belongs to the technical field of characterization of mechanical properties of materials, and provides a method for realizing inversion identification of crystal plastic material parameters based on a nanoindentation experiment. The method comprises the steps that firstly, the elasticity modulus of a material is obtained through an Oliver-Parr method; secondly, a piecewise linear / power law hardening material model is utilized to establish a nanoindentation macroscopic parameter inversion model by combining MATLAB and ABAQUS, the actual nanoindentation experimental data is corrected by utilizing accumulation / subsidence parameters, and the macroscopic constitutive parameters of the indentation material are calculated by combining a Kriging agent model and a genetic algorithm; and finally, a polycrystalline finite element model of the tensile test piece based on the crystal plasticity finite element is established by combining MATLAB and ABAQUS, and the parameters of the crystal plastic material are calculated according to the constitutive parameters of the material in combination with the Kriging agent model and the genetic algorithm. Compared with the prior art, the method has the advantages that the accuracy of calculation data can be improved, the calculation amount is remarkably reduced and the calculation convergence is improved, and the method has very high practical value and reference significance in inversion identification of the crystal plastic material parameters.

Owner:DALIAN UNIV OF TECH

Suspended rotary rapid positioning in-situ indentation/deepened arc indentation testing device

PendingCN107132139AQuick focusSimple structureInvestigating material hardnessMicro nanoElectric machine

The invention relates to a suspended rotary rapid positioning in-situ indentation / deepened arc indentation testing device and belongs to the field of mechanical and electronic integrated precise instruments. The device comprises a suspended rotary rapid positioning module, a deepened arc indentation testing module, a micro-nano indentation module and an in-situ observation module, wherein the micro-nano indentation module and the in-situ observation module are integrated on the suspended rotary rapid positioning module; the deepened arc indentation testing module is composed of an indentation tester and a test piece supporting platform together; and the test piece supporting platform is composed of two parts, namely a shear-type electric lifting table and an electric rotating platform. The device disclosed by the invention has the advantages that the device is novel in structure, has motor-driven rapid feed ability and micro-nano-level piezoelectric micro actuating ability, and can be used for accurately testing the hardness, elasticity modulus, scratching resistance and other mechanical property performances of the test materials. The loading displacement resolution reaches a micro-nano level, and the loading force resolution reaches a micro-Newton level. The effective test means is provided for mechanical behaviors and service behaviors of the materials.

Owner:JILIN UNIV

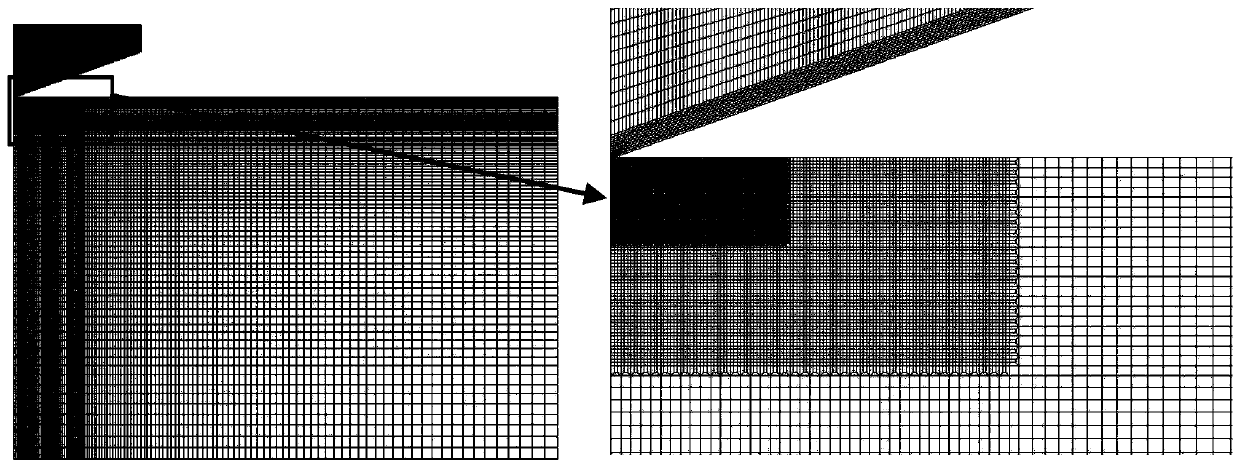

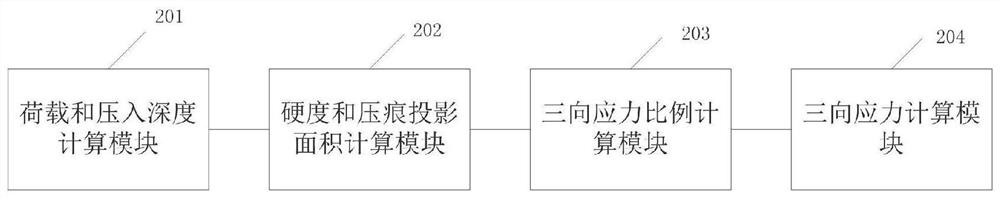

Method and system for testing three-dimensional stress of residual stress of material by utilizing nanoindentation method

ActiveCN111649858ARealize detectionGeometric CADDesign optimisation/simulationElement analysisStress ratio

The invention discloses a method and a system for testing three-dimensional stress of residual stress of a material by utilizing a nanoindentation method, and relates to the technical field of residual stress testing, and the method comprises the following steps: carrying out nanoindentation testing on a to-be-detected sample to obtain a relationship between a load and a press-in depth; obtainingthe hardness of the to-be-detected sample material and the indentation projection area of the to-be-detected sample according to the relationship between the load and the press-in depth; calculating athree-dimensional stress proportion by adopting a finite element analysis method according to the isomerism of the to-be-detected sample material; and according to the three-dimensional stress proportion, the hardness of the to-be-detected sample material and the indentation projection area of the to-be-detected sample, obtaining three-dimensional stress in an unstressed state and three-dimensional stress in a tensile stress state. The method and the system provided by the invention can realize the detection of the three-way residual stress of a test micro area.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

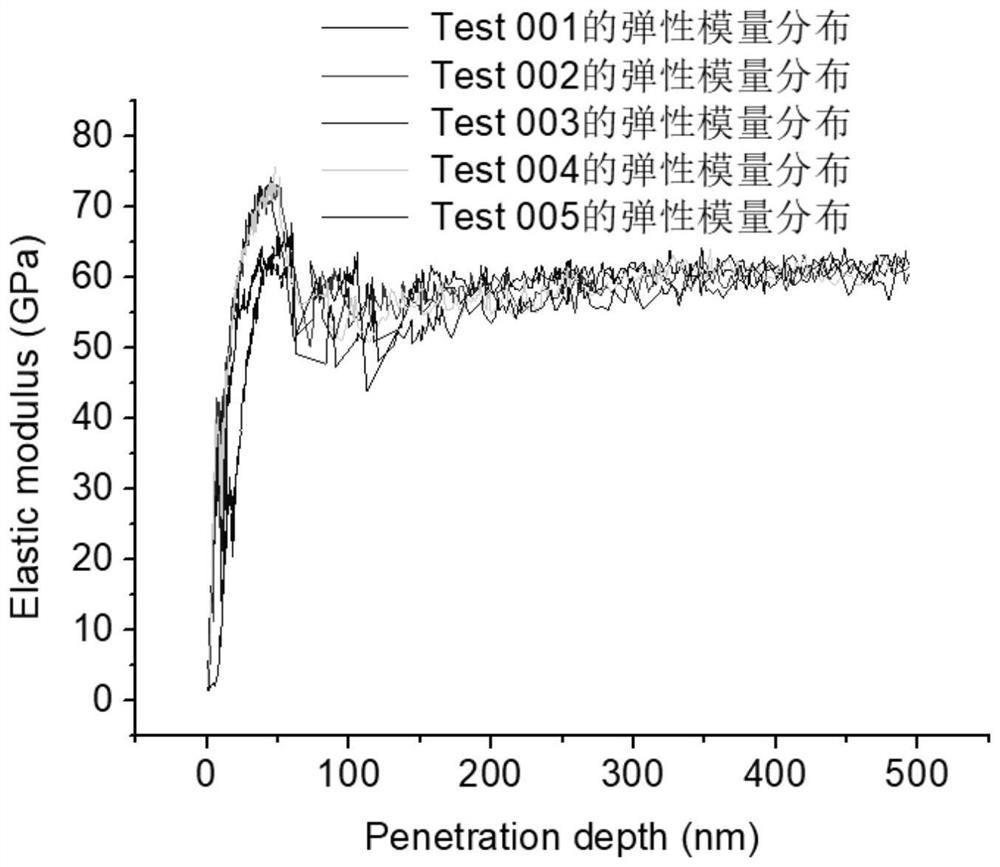

Porous material constitutive relation solving method based on nanoindentation theory

ActiveCN111855458ASimple methodGood precisionInvestigating material hardnessComplex mathematical operationsEngineeringElectronic packaging

The invention relates to the technical field of electronic packaging nanometer mechanical property testing, particularly to a porous material constitutive relation solving method based on a nanoindentation theory. According to the specific technical scheme, the method comprises the steps: carrying out indentation on a porous material matrix multiple times by using a nanoindenter to obtain a plurality of displacement-load curves, removing the curve with large error, carrying out average curve fitting on the rest curves to obtain an average curve, and taking the average elastic modulus of the average curve as an experimental elastic modulus E; then determining a characteristic stress sigma r, and determining a hardening index n according to a dimensionless function; determining characteristic strain epsilon r and yield stress sigma y; and finally obtaining a constitutive curve according to the hardening index n, the yield stress sigma y and the elastic modulus E. According to the method,the problems that in the prior art, material attributes and stress-strain curves are not in one-to-one correspondence, the number of iterations is large in the simulation process, and the consumed time is long are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Impact response modeling method for composite laminated plate

InactiveCN111353228ARealize numerical monitoringSolving Dynamic ResponsesDesign optimisation/simulationParticle dynamicsComposite laminates

The invention relates to the field of materials, and provides a composite laminate impact response modeling method. The method comprises the following steps: calculating Hertz contact stiffness kc; acquiring the indentation depth hc of the composite material laminated plate, and calculating the contact load Fimp between the composite material laminated plate and an impacted object; employing a smooth particle dynamics SPH discretization method in a Lagrange form, and calculating the motion of the composite material laminated plate, and calculating the longitudinal acceleration of the punch. According to the relationship between the contact force and the indentation of the composite material laminated structure, the laminated plate impact response SPH model is established, the displacementchange of the laminated plate and the punch is analyzed, the damage form and the expansion mode of the laminated plate when the laminated plate is impacted are established, and the numerical monitoring of the impact response of the composite material layer is realized.

Owner:SHANDONG UNIV

Mechanical characterization method for subsurface damage of optical glass

InactiveCN111024534AImprove measurement efficiencyImprove engineering applicabilityInvestigating material hardnessHardnessDepth direction

The invention discloses a mechanical characterization method for subsurface damage of optical glass, which comprises the following steps: cutting an optical glass sample to obtain a section vertical to the surface, and polishing the section; performing etching treatment on the polished sample, performing ultrasonic cleaning, and drying the sample; carrying out a nano-indentation test on the driedsample section, measuring the indentation hardness and indentation elastic modulus of the section along the depth direction, and recording the depth information of each test point, wherein the included angle between the indentation direction and the surface is theta; and finally, determining the subsurface damage depth of the sample by analyzing a gradient change curve of mechanical indexes (hardness and elasticity modulus) measured in the section along the depth direction. According to the mechanical characterization method for sub-surface damage of optical glass provided by the invention, gradient change of mechanical parameters in a damaged layer is tested by using a nanoindenter, and geometric indexes and mechanical indexes of the subsurface damage can be obtained by one-time testing.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for in-situ estimation of tensile deformation of rubber hyperelastic material based on spherical indentation method

The invention relates to a method for the in-situ estimation of the tensile deformation of a rubber hyperelastic material based on a spherical indentation method and belongs to the technical field ofmaterial analysis and testing. The feasibility of practical application mainly depends on the nonlinear mechanical properties of the type of material. After the material is deformed, a contact area formed by spherical indentation is an ellipse, and the eccentricity of the ellipse is changed along with the change of a deformation state. In addition, since the material is stretched and hardened, theindentation modulus can be increased along with continuous stretching. Therefore, the deformation state of the material can be estimated according to the contact area eccentricity and the indentationmodulus measured by a spherical indentation experiment. The method is used for estimating the tensile deformation of the rubber hyperelastic material and is expansion and attempt of the indentation method in engineering practical application.

Owner:CHONGQING JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com