Diamondlike carbon hard multilayer film formed body and method for producing the same

a carbon hard, multi-layer technology, applied in the direction of superimposed coating process, transportation and packaging, vacuum evaporation coating, etc., can solve the problem of low adhesiveness to the substrate, large internal stress of dlc film with high hardness, and disadvantage of easy separation with low adhesiveness, etc. problems, to achieve the effect of improving adhesiveness, excellent adhesiveness and wear resistance, and improving adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

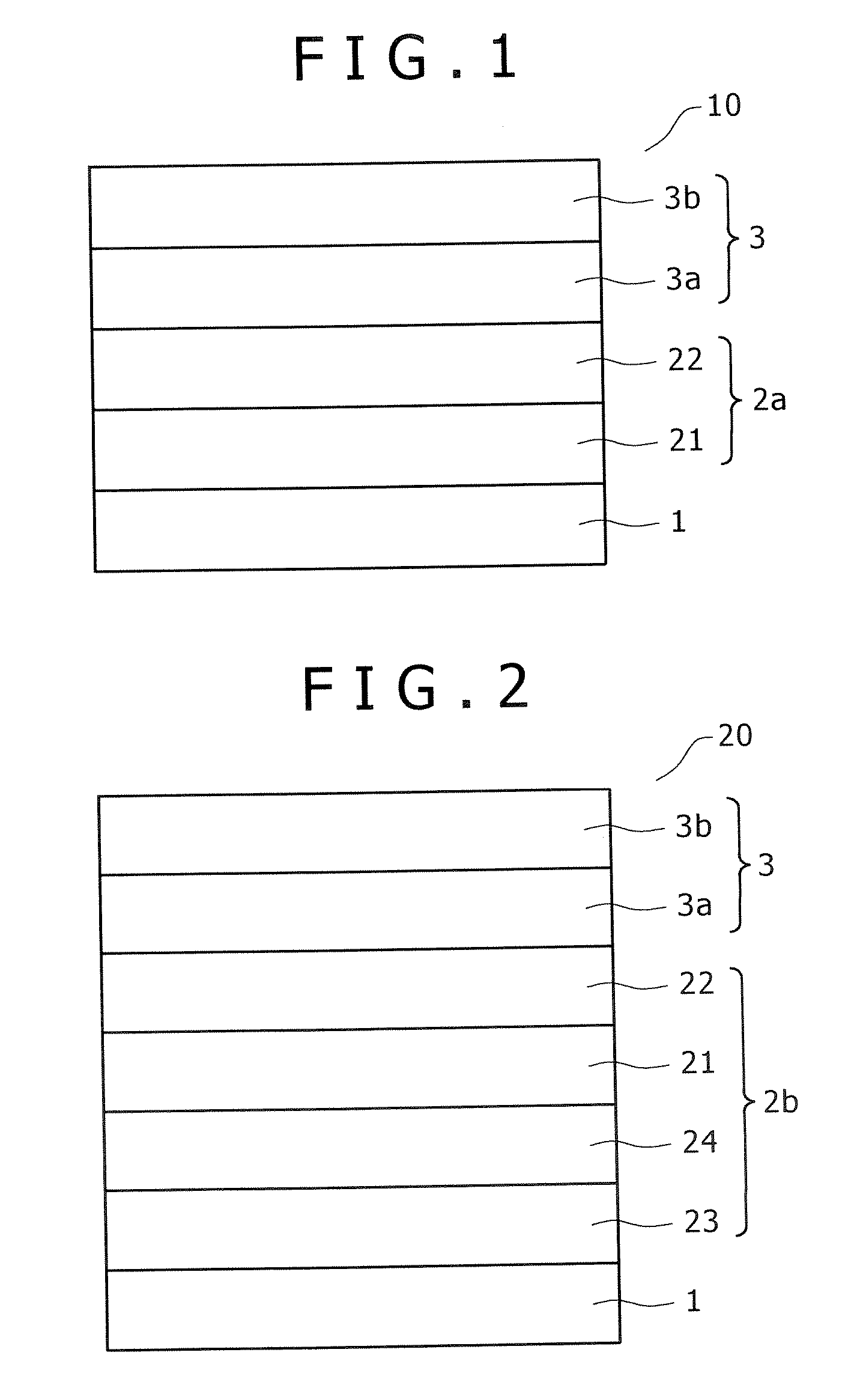

[0043] A first embodiment of the DLC formed body according to the present invention (referred to as first DLC formed body) is described in reference to FIG. 1. The first DLC formed body is useful, for example, for use of a substrate with relatively high hardness such as cemented carbide material, and the intermediate layer described in JP No. 2000-119843 is typically used as the intermediate layer.

[0044] A first DLC formed body 10, as shown in FIG. 1, comprises a substrate 1, a diamondlike carbon film mainly composed of diamondlike carbon (DLC film) 3, an intermediate layer 2 between the substrate 1 and the DLC film 3 (which may be called a first intermediate layer 2a for discrimination from a second intermediate layer described later).

[0045] The DLC film 3 is composed of, in order from the substrate 1 side, a first DLC film 3a and a second DLC film 3b, with the surface hardness of the first DLC film 3a being within the range from not less than 10 GPa to not more than 40 GPa based...

embodiment 2

[0061] A second embodiment of the DLC formed body according to the present invention (second DLC formed body) will be described in reference to FIG. 2. In FIG. 2, the same reference numbers as in FIG. 1 are assigned to parts overlapping with those of the first DLC formed body.

[0062] The second formed body is differed from the first formed body in the point that the intermediate layer is composed of four layers, and an iron-based material (preferably, a material with relatively low hardness such as bearing steel) is used as the substrate, as described below in detail. As the intermediate layer to be used in the second formed body, the intermediate layer described in JP No. 2003-171758 is typically given. Compared with the intermediate layer in the first DLC formed body, the third layer (metal layer) and the fourth layer (amorphous layer) in the second DLC formed body correspond to the first layer and the second layer in the first DLC formed body, respectively. Detailed descriptions ...

example

[0089] DLC formed bodies (Nos. 1 to 11) having various film structures shown in Table 1 were produced in the following manner, and evaluated for adhesiveness to the DLC film. Among them, Nos. 2 to 6 and 8 to 11 are inventive examples which satisfy the requirements of the present invention, and Nos. 1 and 7 are comparative examples which do not satisfy the requirements of the present invention. Each of Nos. 2 to 6 has a two-layer intermediate layer, and each of Nos. 8 to 11 has a four-layer intermediate layer.

(Substrate)

[0090] As shown in Table 1, cemented carbide (“UT120T” manufactured by Mitsubishi Materials Corporation) was used in Nos. 1 to 6, while SUJ2 of JIS standard was used in Nos. 7 to 12. Each substrate has a size of 12 cm square and 5 mm thickness, with a mirror-polished surface (Ra=about 0.02 μm).

[0091] These substrates were ultrasonically washed using an alkali tank in and a pure water tank in advance, and dried.

(Formation of Intermediate Layer and DLC Film)

(1) N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com