Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "4,4'-Oxydianiline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

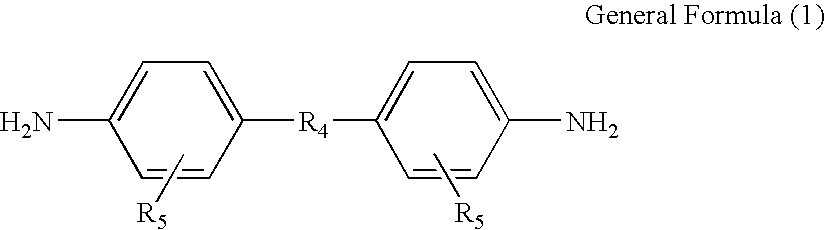

4,4’-Oxydianiline is an organic compound with the formula O(C₆H₄NH₂)₂. It is an ether derivative of aniline. This colourless solid is a useful monomer and cross-linking agent for polymers, especially the polyimides, such as Kapton.

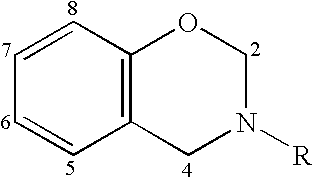

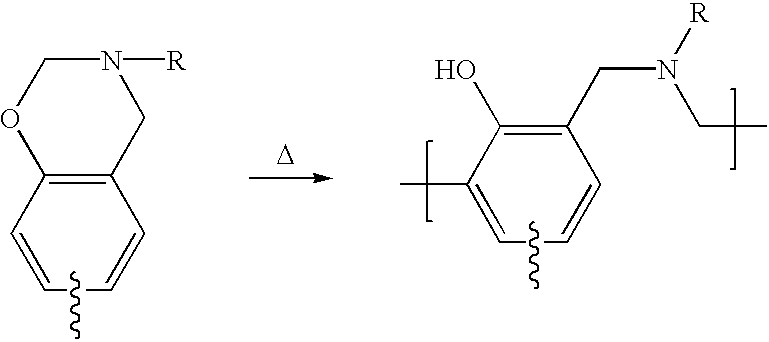

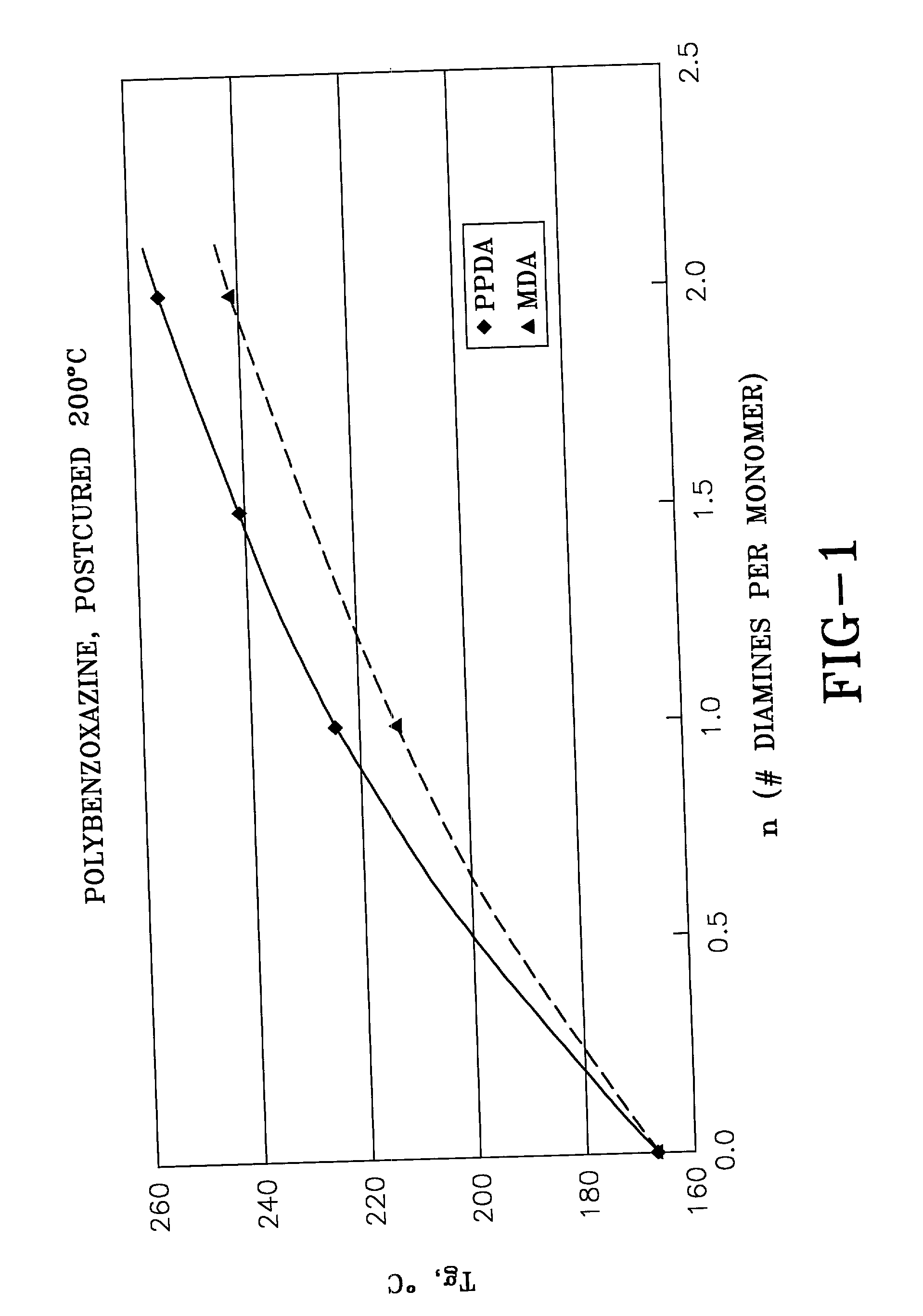

Enhancement of thermal properties of benzoxazine polymers by use of aromatic polyamines to incorporate internal benzoxazine groups within the monomer

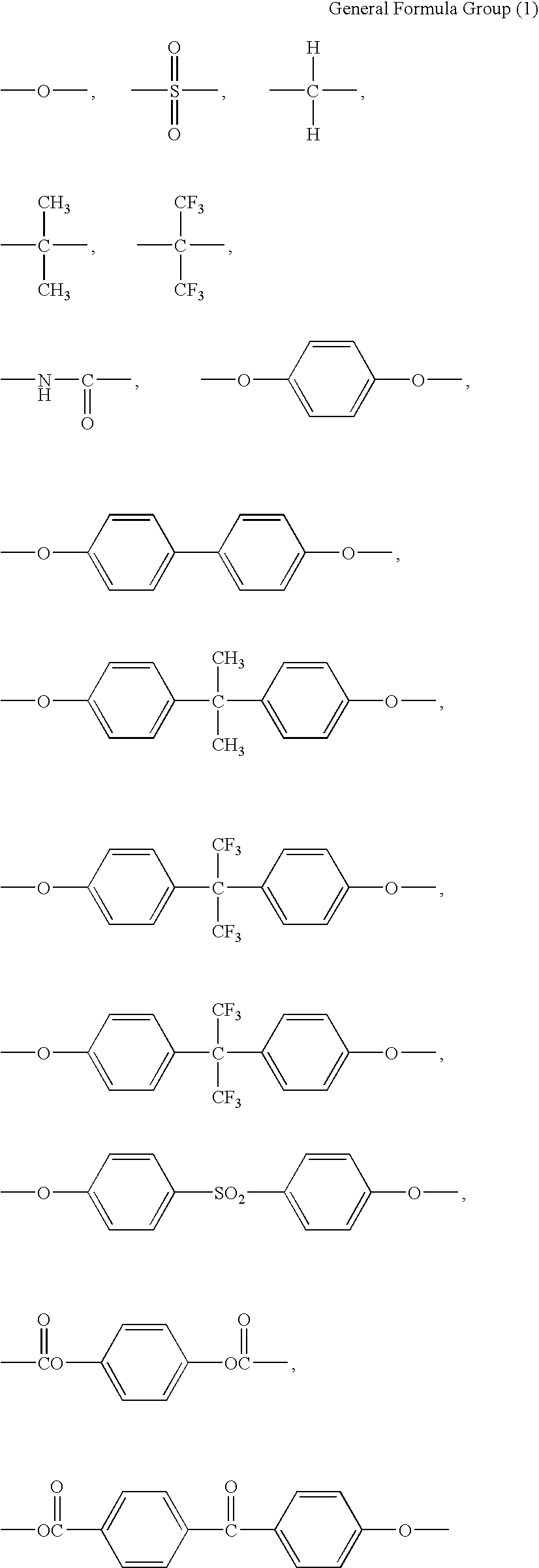

A benzoxazine polymer having improved thermal properties. The properties are improved by inserting aromatic polyamines into the monomer, such as phenylenediamine, methylenedianiline, oxydianiline, diaminodiphenylsulfone, 2,2-bis(4-[aminophenoxy]phenyl)propane, 4,4'-oxydianiline, 4,4'-diaminodiphenyl sulfone, and diaminobenzanilide, to introduce internal benzoxazine groups that are crosslinking sites. The improved polymers can be converted into molding compounds, towpregs, and prepregs by being compounded with reinforcing fibers.

Owner:HYCOMP

Binder resin composition for electrode, electrode mixture paste, and electrode

ActiveUS20120168688A1Small degree of swellingIncreased fracture energyHybrid capacitor electrodesElectrolytic capacitorsDiaminodiphenyl etherCarboxylic acid

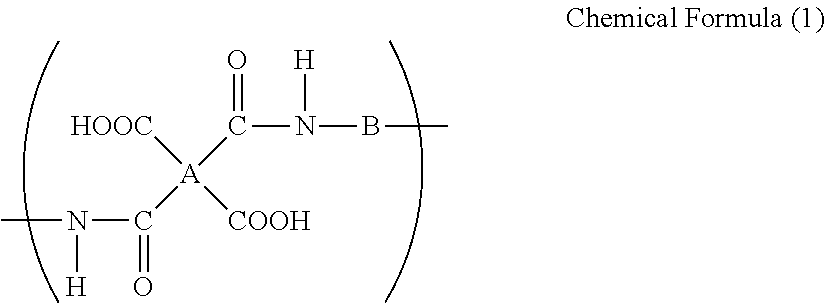

The present invention relates to a binder resin composition for an electrode, including a polyamic acid and a solvent, wherein the polyamic acid is (i) a polyamic acid which includes a tetracarboxylic acid component including 10 to 100 mol % of 4,4′-oxydiphthalic acid and 90 to 0 mol % of 3,3′,4,4′-biphenyltetracarboxylic acid and / or pyromellitic acid and a diamine component including an aromatic diamine having 1 to 4 aromatic rings, (ii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 10 to 90 mol % of p-phenylene diamine and 90 to 10 mol % of 4,4′-diaminodiphenyl ether, or (iii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 40 mol % or more of a bis[4-(4-aminophenoxy)phenyl] compound.

Owner:UBE IND LTD

Compounds of use in the treatment of epilepsy, seizure, and electroconvulsive disorders

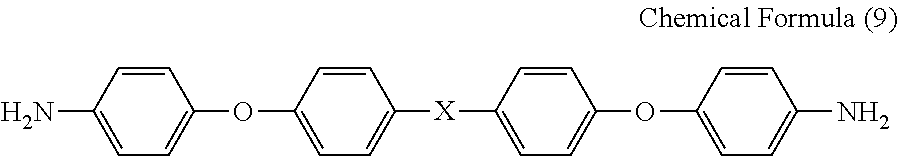

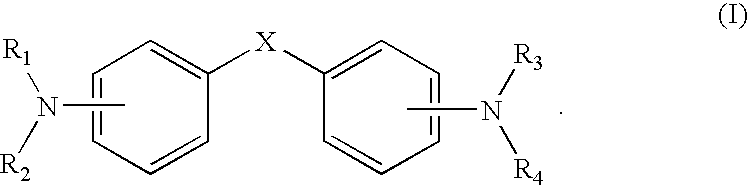

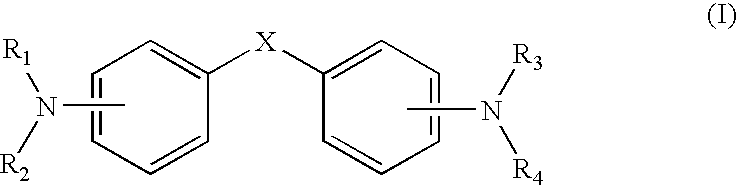

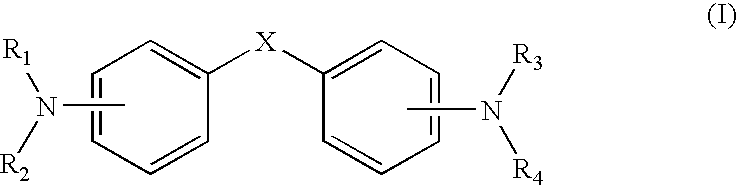

The present invention provides pharmaceutical preparations and the uses thereof for preventing and / or treating seizures and other electroconvulsive disorders by administering a pharmaceutically effective amount of a therapeutic compound having the following formula (I):Embodiments include administering an effective amount of 4,4′-thiodianiline, 4,4′-diaminobenzophenone, 4,4′-methylenedianiline, 4,4′-diaminodiphenyl ether, or (3-aminophenyl)-(4-aminophenyl) amine, an analog, or a pharmaceutically accepted salt or complex thereof to a mammal in need of treatment or prevention of epilepsy, seizure, or other electroconvulsive disorder.

Owner:UNIVERSITY OF KENTUCKY

High-temperature-resistant thermoplastic shape memory polyimide and preparation method thereof

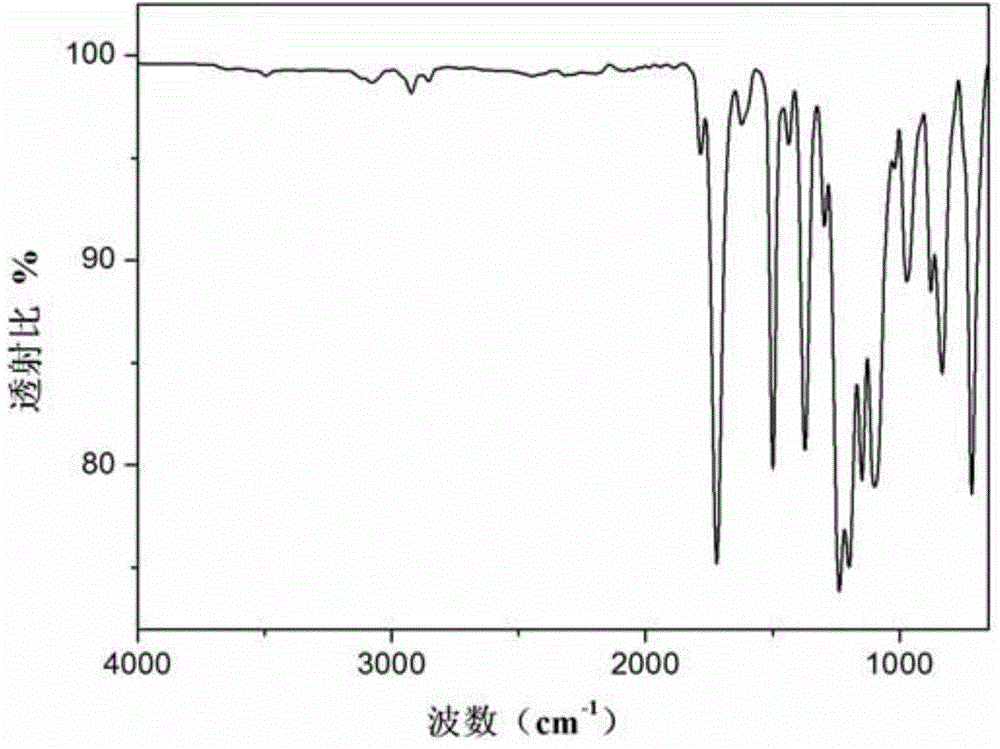

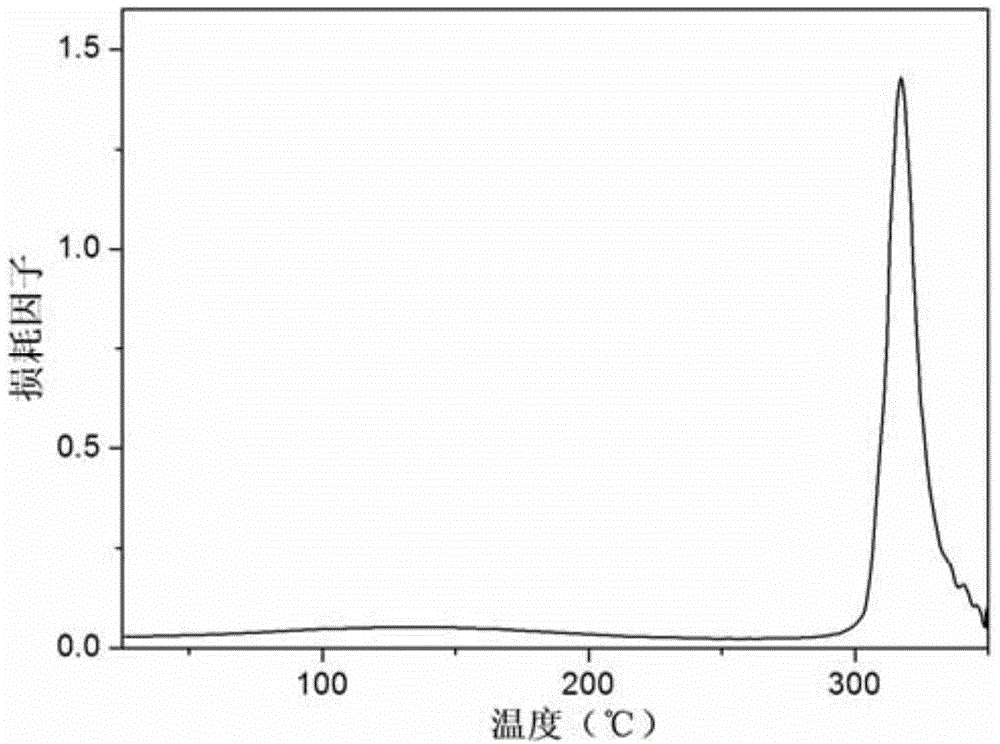

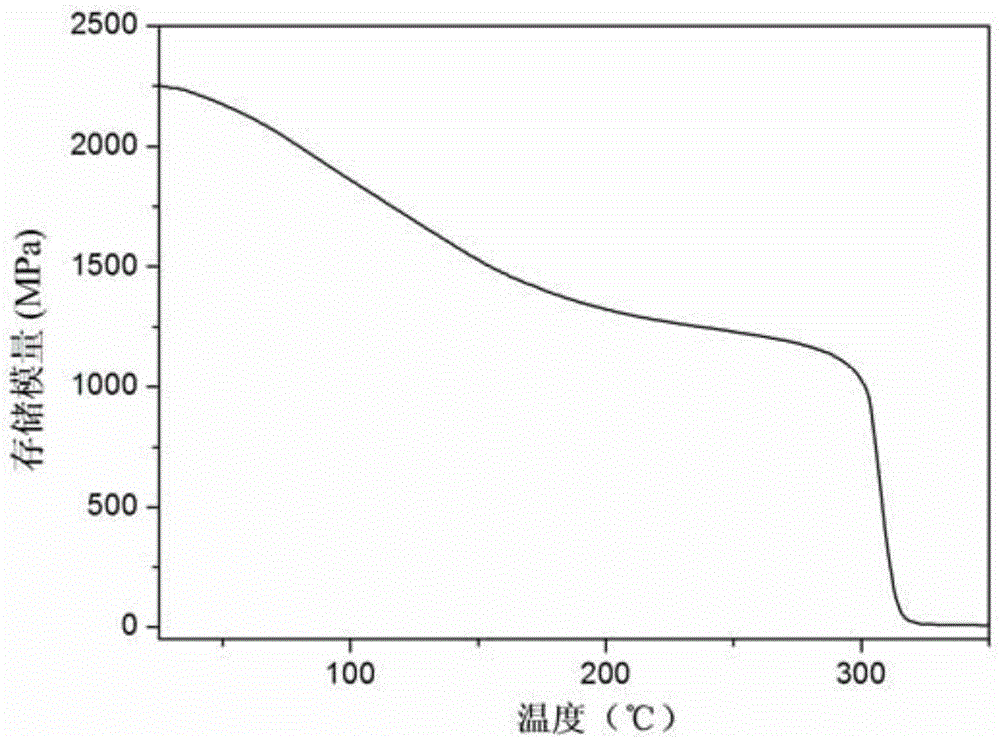

The invention discloses a high-temperature-resistant thermoplastic shape memory polyimide and a preparation method thereof and relates to a polyimide and a preparation method thereof. The invention aims to solve the problems of low glass transition temperature Tg, poor processing properties, thermal properties, mechanical properties and shape memory properties and inapplicability in the field of high temperature of the existing shape memory polymer. The high-temperature-resistant thermoplastic shape memory polyimide is prepared from 4,4'-(hexafluoroisopropylidene) diphthalic anhydride and 4,4'-diaminodiphenyl ether as reaction monomers and has a structural formula shown in the specification. The preparation method comprises the steps of firstly, dissolving the 4,4'-diaminodiphenyl ether monomer; secondly, preparing sol-gel polyamide acid; thirdly, removing residual bubbles; fourthly, carrying out thermal imidization; and fifthly, demoulding. The high-temperature-resistant thermoplastic shape memory polyimide is obtained by the method disclosed by the invention.

Owner:HARBIN INST OF TECH

Thermoplastic polyimide, and laminated polyimide film and metal foil-laminated polyimide film using the thermoplastic polyimide

InactiveUS20090252957A1High elongationLower glass transition temperatureSynthetic resin layered productsFlat articlesDiaminodiphenyl etherMetal foil

Disclosed is a thermoplastic polyimide which has excellent heat resistance and can adhere to a metal foil by thermocompression bonding for a short-time. The thermoplastic polyimide comprising a tetracarboxylic dianhydride residue and a diamine residue wherein the biphenyl tetracarboxylic dianhydride residues account for 80 mol % or more of the total tetracarboxylic dianhydride residues, the 4,4′-diaminodiphenyl ether residues for 65 mol % or more and 85 mol % or less of the total diamine residues, and the paraphenylene diamine residues for 15 mol % or more and 35 mol % or less of the total diamine residues.

Owner:TORAY IND INC

Catalyst for preparing 4, 4'-diaminodiphenyl ether, preparation method and application of catalyst

InactiveCN102941096AImprove conversion rateHigh yieldOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsDiaminodiphenyl etherNitrate

The invention discloses a catalyst for preparing 4, 4'-diaminodiphenyl ether, a preparation method and application of the catalyst, and relates to a fine organic product synthesis method. Firstly, carriers are impregnated in nitrate mixed water solution to form mixture, and the mixture is dried in a drying oven and then roasted in nitrogenous atmosphere. Secondly, roasted solid is reduced in H2 and N2 mixed atmosphere to manufacture the catalyst comprising 10%-30% of elementary nickel, 5%-10% of other metal elementary substances except for the nickel and 60%-85% of carriers, and the catalyst is used for producing the 4, 4'-diaminodiphenyl ether. The catalyst is low in production cost and simple to operate, and is a supported nickel-based catalyst needed for preparing the high-yield 4, 4'-diaminodiphenyl ether from 4, 4'-dinitrodiphenyl ether by means of catalytic hydrogenation.

Owner:JIANGSU HUALUN CHEM

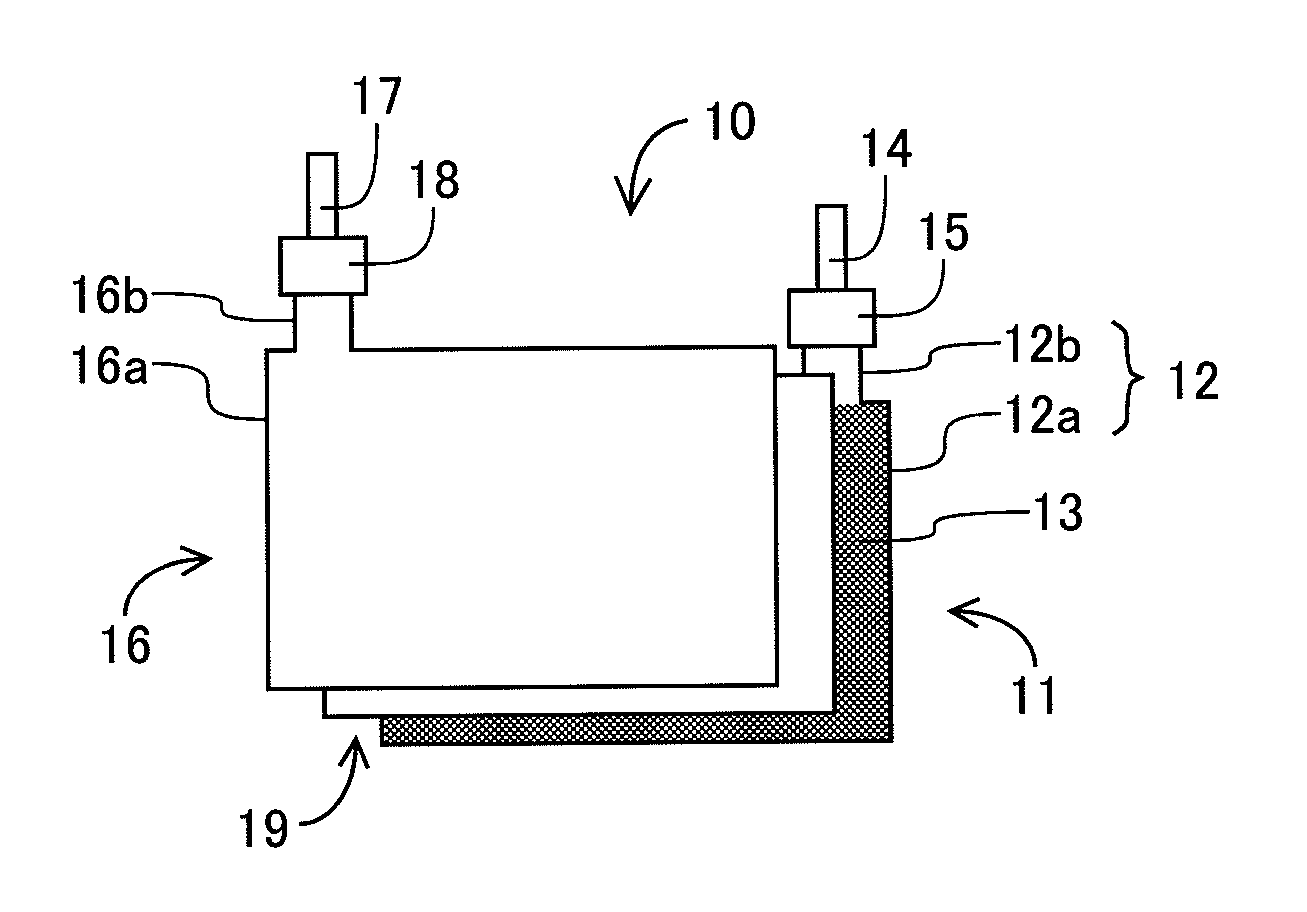

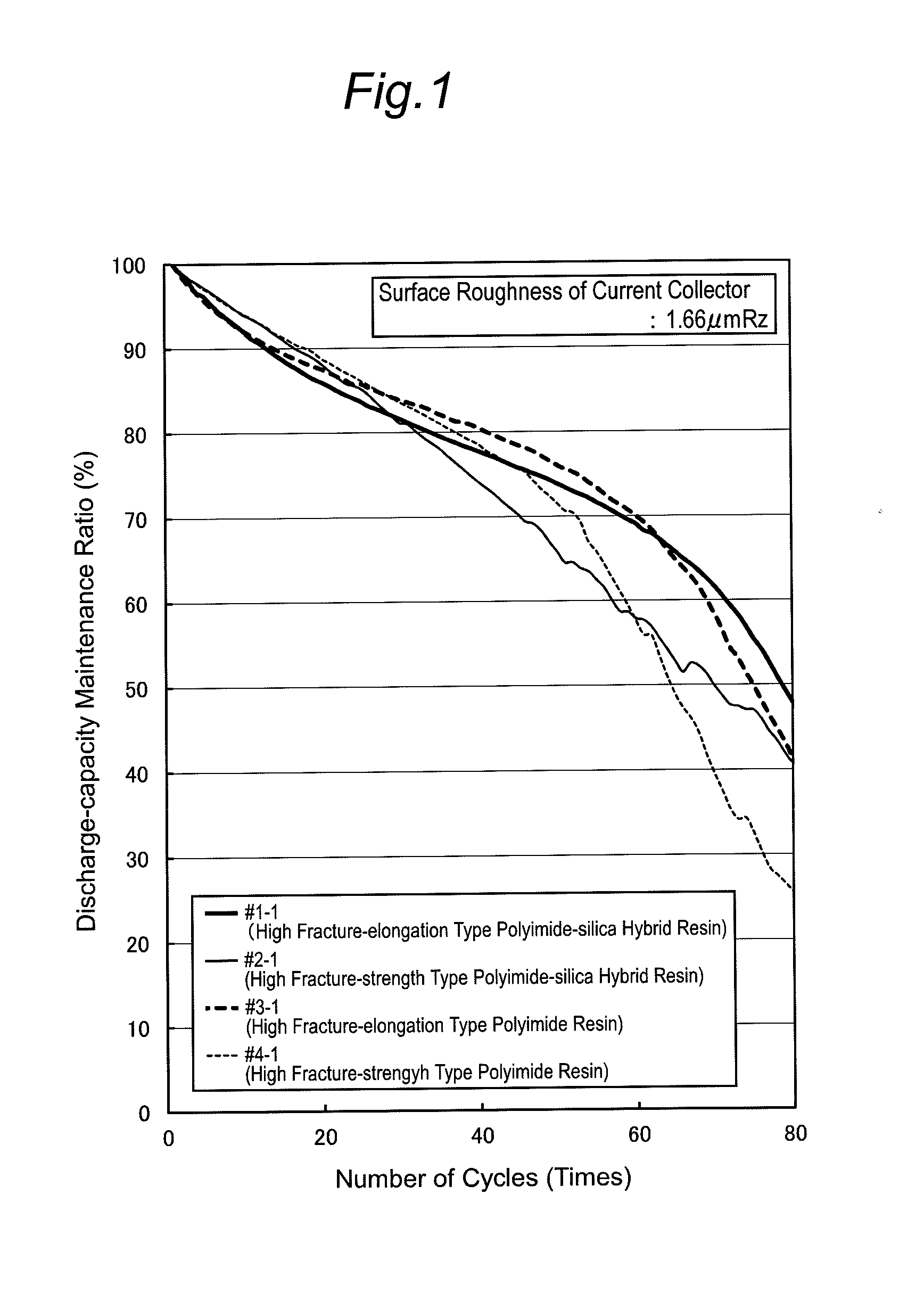

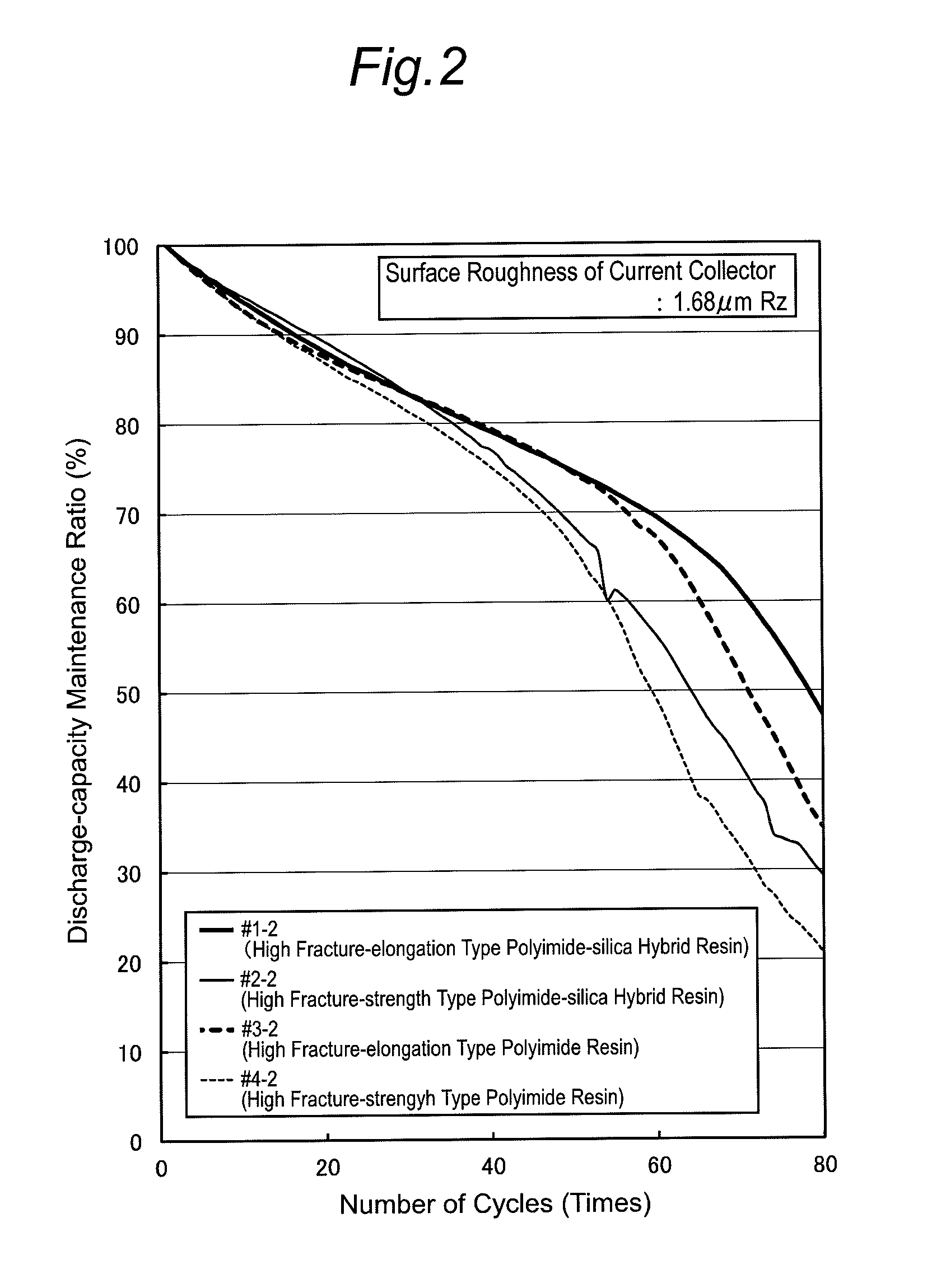

Negative electrode for non-aqueous-system secondary battery and manufacturing process for the same

InactiveUS20120202117A1Increased durabilityElectrode carriers/collectorsActive material electrodesDiaminodiphenyl etherSilanes

It is equipped with a negative-electrode current collector, and a negative-electrode mixture-material layer comprising a negative-electrode mixture material that includes a negative-electrode active material containing silicon (Si) and a binding agent at least, the negative-electrode mixture-material layer being formed on a surface of the negative-electrode current collector; andthe binding agent includes a polyimide-silica hybrid resin being made by subjecting a silane-modified polyamic acid to sol-gel curing and dehydration ring-closing, the silane-modified polyamic acid being expressed by the following formula (wherein: “R1” specifies an aromatic tetracarboxylic dianhydride residue including 3,3′,4,4′-biphenyltetracarboxylic dianhydride residue in an amount of 90% by mole or more; “R2” specifies an aromatic diamine residue including a 4,4′-diaminodiphenyl ether residue in an amount of 90% by mole or more; “R3” specifies an alkyl group whose number of carbon atoms is from 1 to 8; “R4” specifies an alkyl group or an alkoxy group whose number of carbon atoms is from 1 to 8 independently of one another; “q” is from 1 to 5,000; “r” is from 1 to 1,000; and “m” is from 1 to 100).

Owner:TOYOTA IND CORP

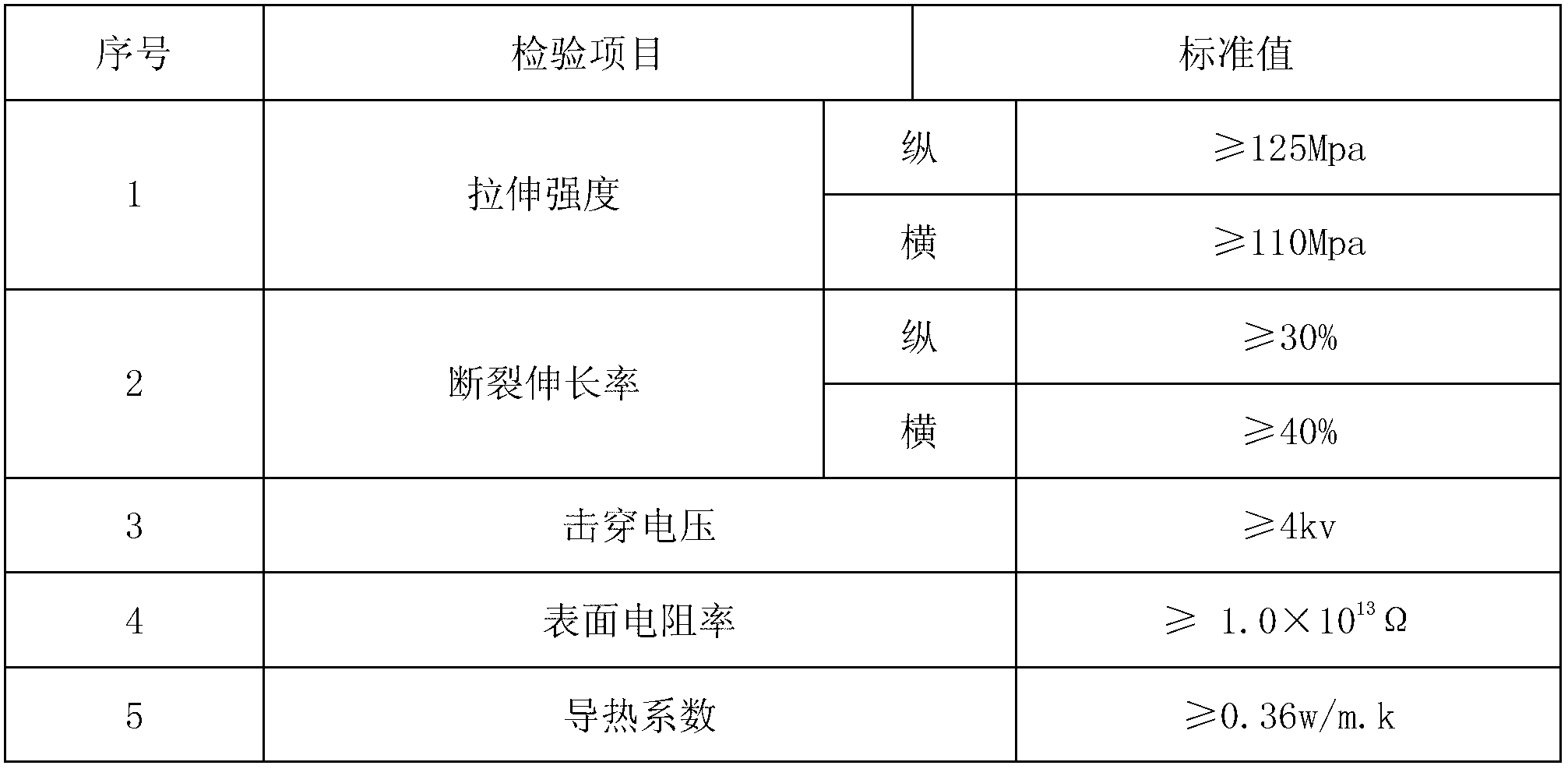

Polyimide resin synthesis method

InactiveCN102936341AExtended service lifeExcellent electrical performanceDiaminodiphenyl etherPowder mixture

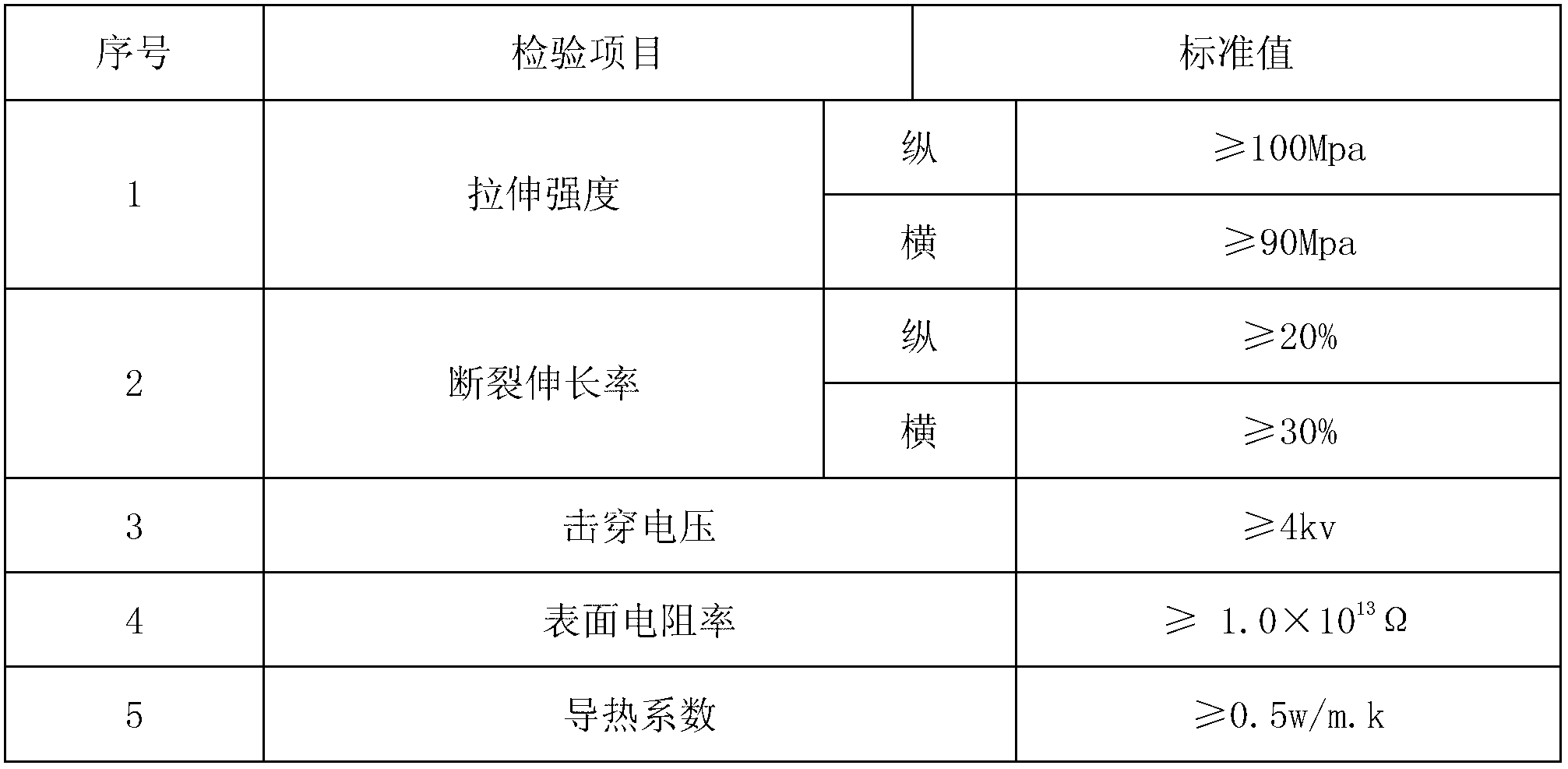

The present invention discloses a polyimide resin synthesis method. The polyimide resin comprises a thermally conductive nanometer powder mixture and a resin solid, wherein the resin solid is polyamic acid, and the thermally conductive nanometer powder mixture is a mixture of three thermally conductive nanometer powders such as Al2O3, NB and AlN, and is 10-30% of the total amount of the resin solid. During synthesis, pyromellitic dianhydride reacts with 4,4'-diaminodiphenyl ether to obtain polyamic acid, the grinded thermally conductive nanometer powder mixture is added to the polyamic acid according to a certain proportion, then pyromellitic dianhydride is added to control a viscosity of the final reaction product to reach 85000-95000 CP, and deaeration slobbering film formation is performed to obtain the finished product. According to the polyimide resin synthesized by the method, a thermal conductivity coefficient can be more than three times the thermal conductivity coefficient of the ordinary polyimide film, excellent electrical property, excellent thermal property and excellent mechanical property are provided, and a storage life of the electronic component can be substantially improved.

Owner:宁波今山电子材料有限公司

Polyamic acid solution composition having carbon black dispersed therein, process for production of semiconductive polyimide resin belt using the composition, and semiconductive polyimide resin belt

InactiveUS20100247888A1Evenly dispersedMinimize dispersionNon-metal conductorsConductive materialDiaminodiphenyl etherPolyamic acid

The present invention provides a carbon black-dispersed polyamic acid solution composition having a high solids content and a high carbon black content. The invention further provides an intermediate transfer belt using the polyamic acid solution composition. The carbon black-dispersed polyamic acid solution composition is obtained by uniformly dispersing carbon black in a polyamic acid solution obtained by reacting biphenyltetracarboxylic dianhydride and an aromatic diamine in an organic polar solvent. The biphenyltetracarboxylic dianhydride includes 2,3,3′,4′-biphenyltetracarboxylic dianhydride and 3,3′,4,4′-biphenyltetracarboxylic dianhydride. The aromatic diamine includes 4,4′-diaminodiphenyl ether and p-phenylenediamine. The polyamic acid solution has a solids content of 25 weight % or more.

Owner:GUNZE LTD +1

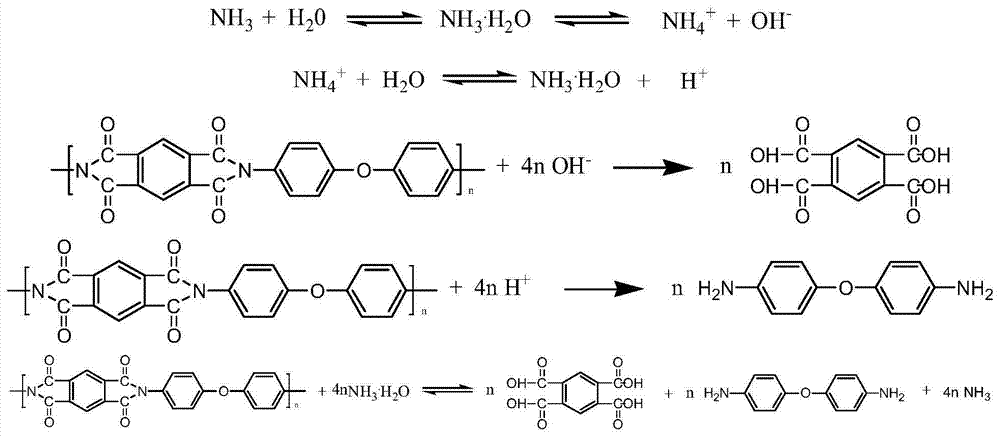

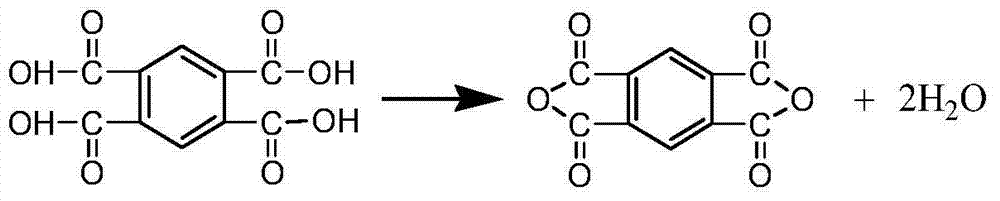

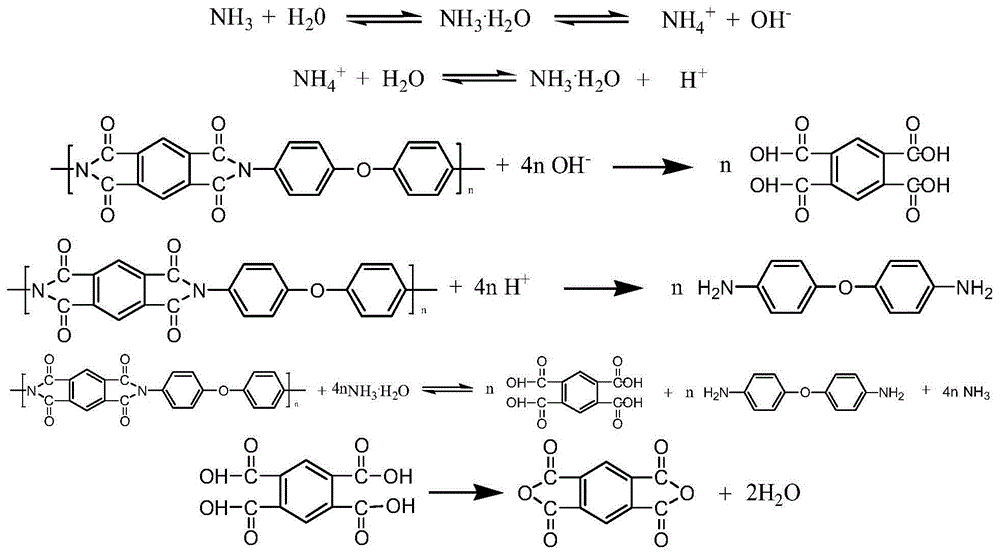

Modified polyimide film and modified polyimide precursor composite film waste material recovery processing method

The invention discloses a modified polyimide film and modified polyimide precursor composite film waste material recovery processing method. The method is characterized by comprising the following steps: crushing a modified polyimide precursor composite film waste material into modified polyimide film waste material fragments with length smaller than 5mm, placing the fragments into stronger ammonia water, hydrolyzing the fragments, and centrifuging or filtering the reaction solution after the reaction is ended; acidifying the separated filter liquid by utilizing hydrochloric acid, and precipitating coarse benzene tetracarboxylic acid; washing separated insoluble substances by utilizing hydrochloric acid or sulfuric acid, carrying out the secondary centrifuging or filtering, and obtaining a coarse 4,4minute-diaminodiphenyl ether aqueous solution; neutralizing the obtained 4,4minute-diaminodiphenyl ether aqueous solution by utilizing ammonia water until the pH value is equal to 8 to 10, and precipitating 4,4minute-diaminodiphenyl ether. By adopting the method, the reaction rate is increased, the time is shortened, inorganic filler in the modified polyimide film waste material can be effectively removed, and the purity of a hydrolysis product can be further improved.

Owner:WUXI SHUNXUAN NEW MATERIALS

Preparation method of low-linear expansion coefficient polyimide film

InactiveCN103772982AThe preparation process is simple and controllableImprove production efficiencyCoatingsDiaminodiphenyl etherPyromellitic dianhydride

The invention discloses a preparation method of a low-linear expansion coefficient polyimide film. The preparation method comprises the following steps: enabling 3,3',4,4'-Biphenyl tetracarboxylic diandhydride, pyromellitic dianhydride, p-phenylenediamine, 4,4'-diaminodiphenyl ether to react in a dimethylacetamide solvent so as to prepare a polyamide acid solution, carrying out tape casting by using a tape-casting method, clamping by using clamps at an inlet of a stretcher, wherein the clamps at the two sides synchronously move in the same direction, and the operating speed is 150-200g / min, realizing the longitudinal and transverse stretching orientation of the film through the movement of expanding with the help of the clamps and regularly and gradually increasing the interval between the clamps, finally carrying out heating treatment, cooling and rolling. The preparation method has the beneficial effects that the linear expansion coefficient of the obtained low-linear expansion coefficient polyimide film is only 14-16 (ppm / DEG C), which is obtained by complete imidization caused by high stretch rate and two-times high-temperature thermal treatment, the possibility of short-circuiting of circuit boards is greatly reduced, and the service life of the circuit boards is prolonged.

Owner:太湖华强科技有限公司

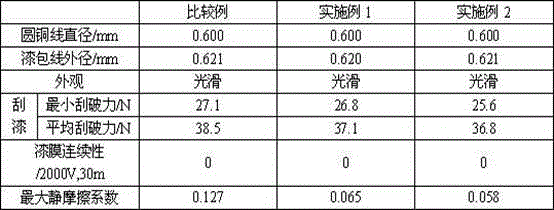

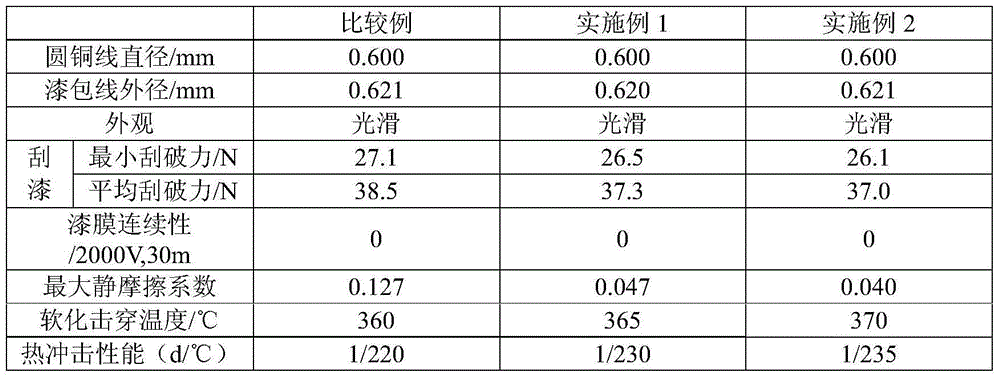

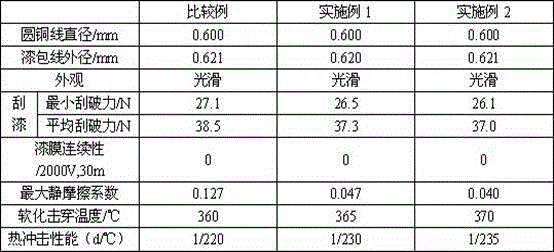

Self-lubricating polyamidoimide enamelled wire paint and preparation method thereof

InactiveCN104449341AReduce the maximum static friction coefficientSimple preparation processCoatingsStatic friction coefficientWax

The invention relates to a self-lubricating polyamidoimide enamelled wire paint preparation method, which comprises the following steps: 1)preparation method of polyamidoimide resin: employing dimethyl acetamide, 4,4'-diaminodiphenyl ether, dissolving and then adding pyromellitic dianhydride by eight batches, stirring and reacting until the color is transparent; 2)preparation method of wax slurry: adding xylene and wax under stirring, gradually heating from room temperature to 100-120 DEG C in 3-5 hours, insulating for 2-3 hours, cooling to room temperature; and 3)preparation method of the enamelled wire paint: taking polyamidoimide resin and wax slurry, stirring and uniformly mixing, heating to 160-180 DEG C, insulating for 10-20 hours, and cooling to room temperature to obtain the self-lubricating polyamidoimide enamelled wire. According to the invention, wax slurry with good lubricity is introduced in the polyamidoimide enamelled wire, maximum static friction coefficient of the enamelled wire is reduced, and the maximum static friction coefficient of the enamelled wire is about 0.060.

Owner:DANYANG STAR CHEM

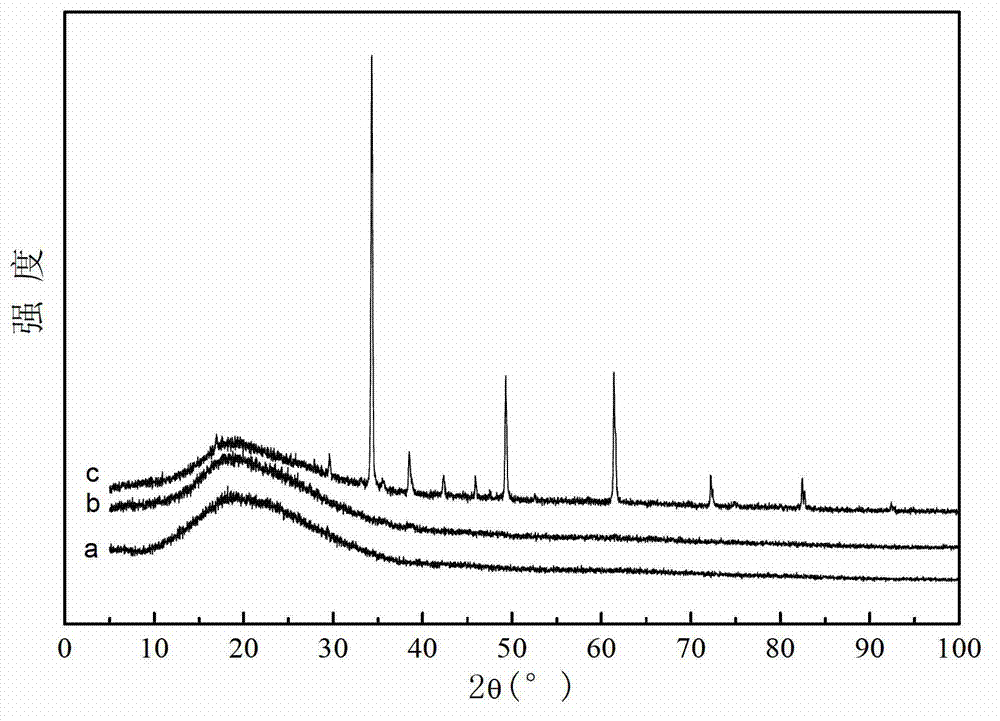

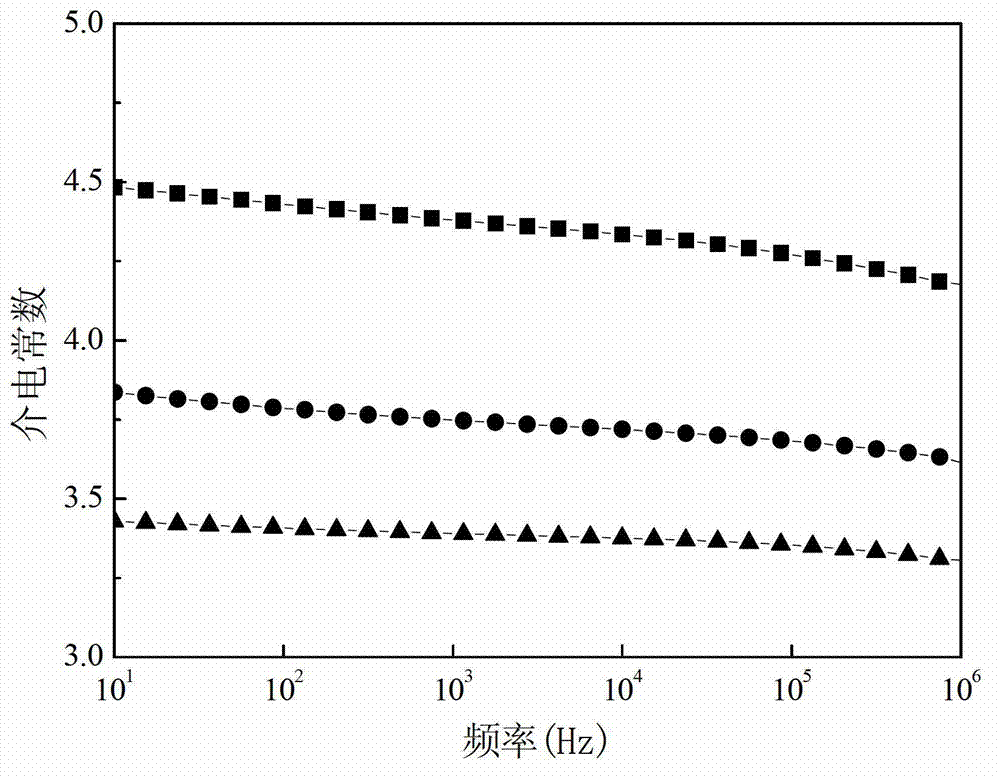

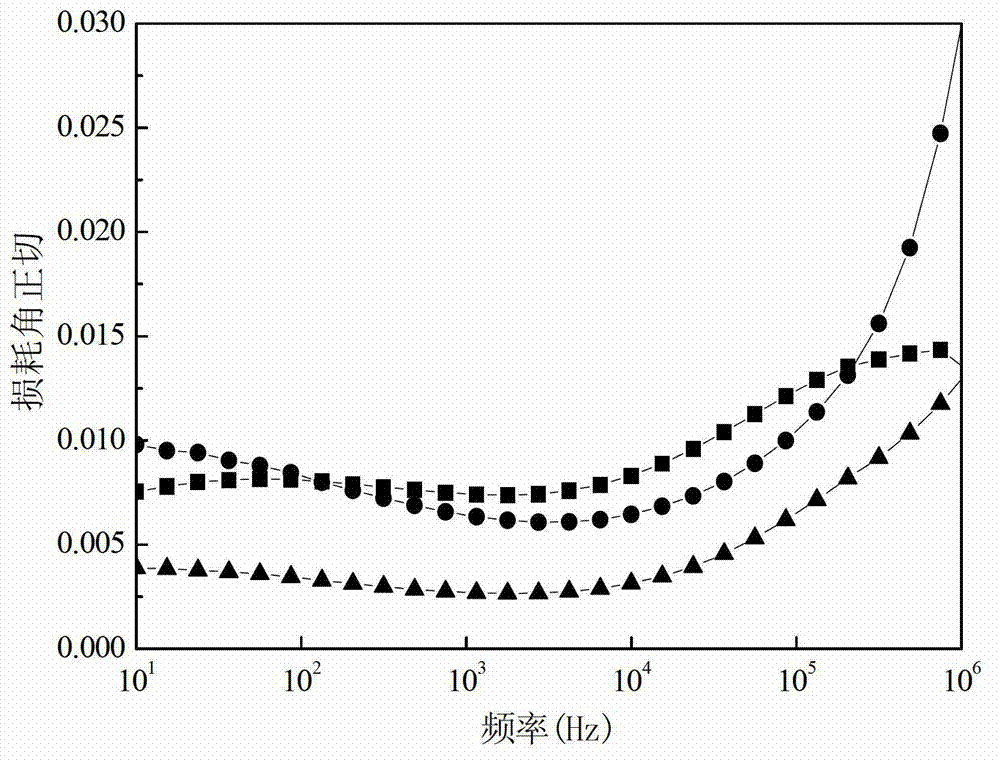

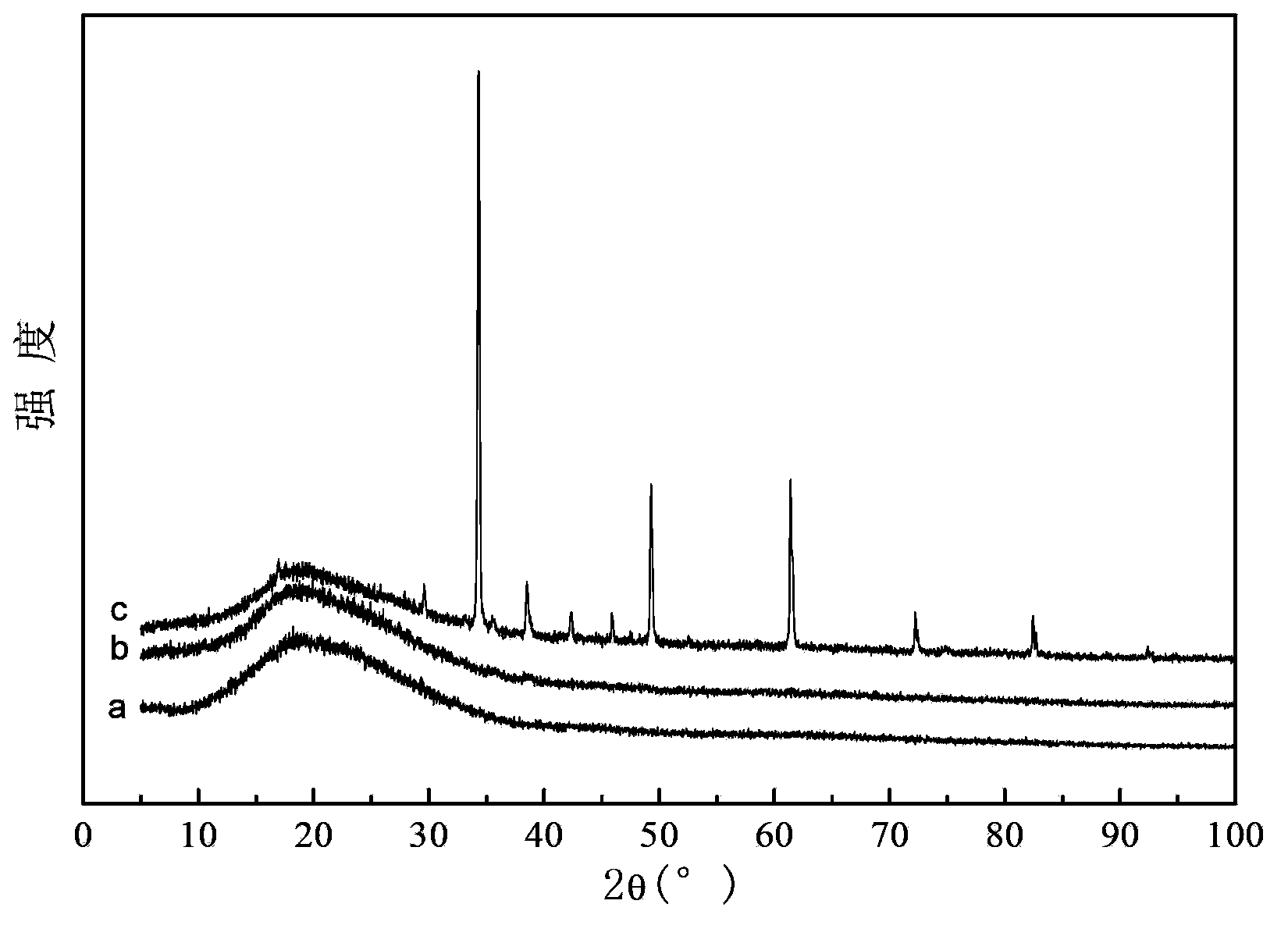

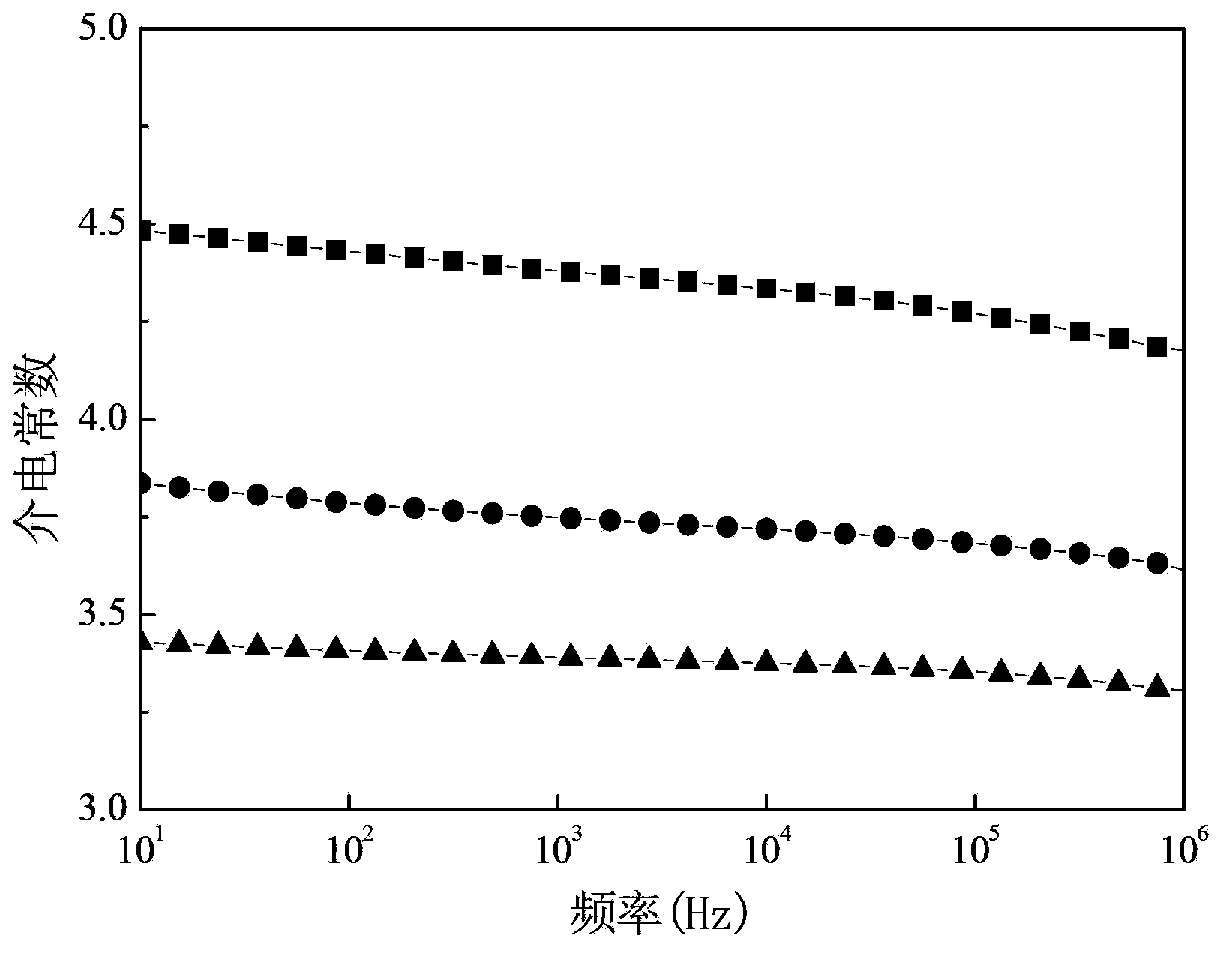

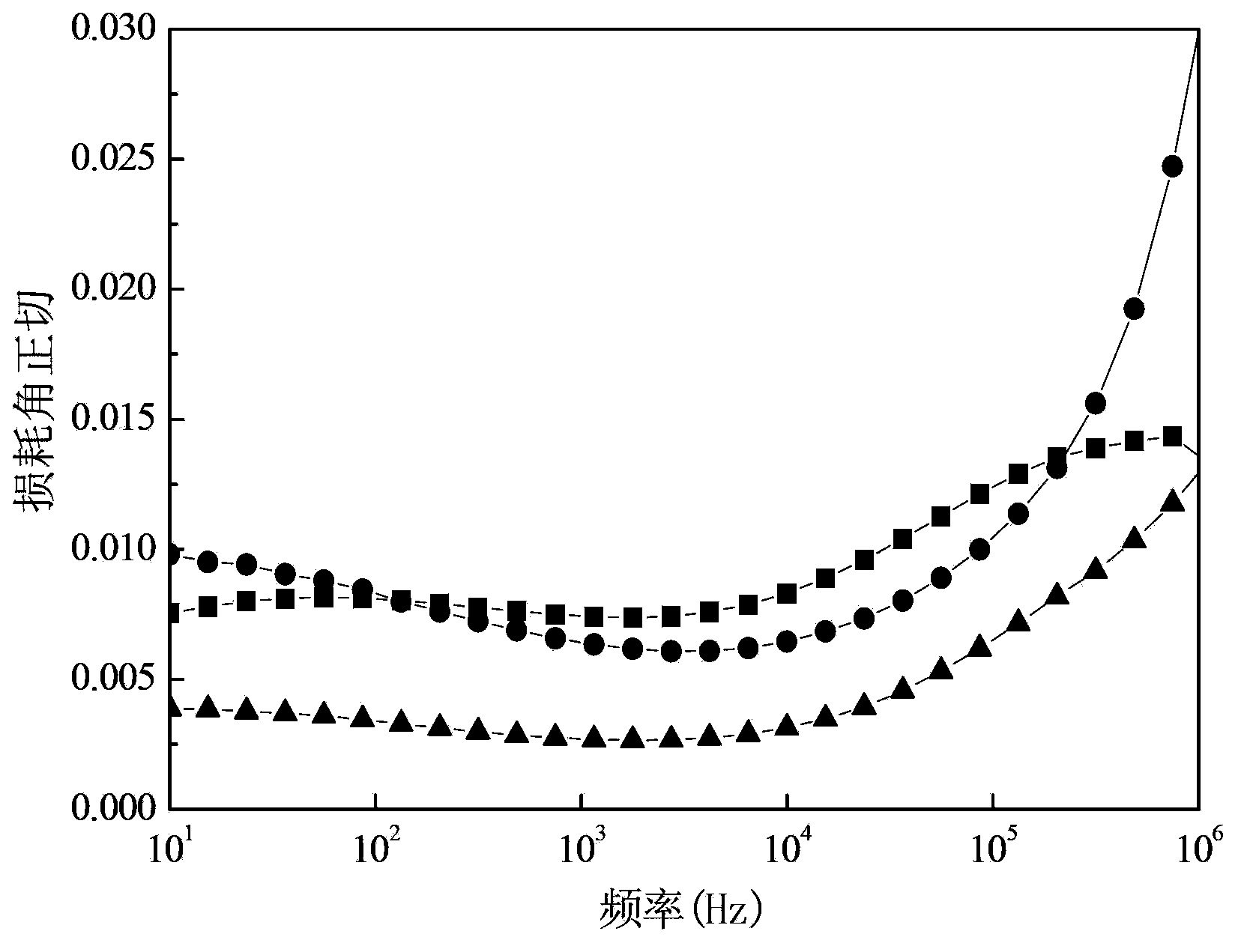

Amorphous calcium-copper-titanium-oxygen ceramic/polyimide composite film and preparation method thereof

The invention relates to the field of the ceramic / polyimide composite film and the preparation method thereof, and particularly discloses an amorphous calcium-copper-titanium-oxygen ceramic / polyimide composite film and a preparation method thereof.. The film and the method aim to solve the problems that the present crystalline calcium-copper-titanium-oxygen ceramic / polyimide composite film preparation method consumes high energy in sintering crystalline ceramics and the prepared crystalline calcium-copper-titanium-oxygen ceramic / polyimide composite film has lower specific inductive capacity during doping at low density (the mass percentage of the ceramics is lower than 20%). The amorphous calcium-copper-titanium-oxygen ceramic / polyimide composite film is prepared from amorphous calcium-copper-titanium-oxygen ceramic particles, (4, 4')- diaminodiphenyl ether, pyromellitic dianhydride and a solvent. The preparation method is as follows: I, preparing an amorphous calcium-copper-titanium-oxygen ceramic / polyamide acid mixed solution; and II, by the way of heating for imidization after coating application, preparing to obtain the amorphous calcium-copper-titanium-oxygen ceramic / polyimide composite film. The film and the method are applied to the fields of information, electronics and electricity.

Owner:HARBIN UNIV OF SCI & TECH

Copper clad laminate

A copper clad laminate that is suited to use in high-performance flexible printed circuit boards, which meets both dimensional change and heat resistance requisites, has a small percent dimensional change after etching, and has properties that are applicable to AOI, and which further has excellent slickness (slip) and adhesion is provided. A copper clad laminate that uses a polyimide film that primarily uses paraphenylenediamine and 4,4′-diaminodiphenylether as diamine ingredients, and pyromellitic dianhydride and 3,3′,4,4′-biphenyltetracarboxylic dianhydride as acid dianhydride ingredients, which further has slip caused by producing surface protrusions by adding inorganic particles. One copper foil is adhered to one side of the polyimide film using an adhesive; and a second copper layer is directly adhered to the second side of the polyimide film.

Owner:EI DU PONT DE NEMOURS & CO

Wear-resistant polyamidoimide enamelled wire paint preparation method

InactiveCN104449344AReduce the maximum static friction coefficientImprove the lubrication effectCoatingsStatic friction coefficientDiaminodiphenyl ether

The invention relates to a wear resistant polyamidoimide enamelled wire paint preparation method, which comprises the following steps: 1)preparation method of polyamidoimide resin: employing dimethyl acetamide, 4,4'-diaminodiphenyl ether, 4,4'-(hexafluoroisopropylidene)diphenylamine, pyromellitic dianhydride, 4,4'-(hexafluoroisopropylidene)diphthalic anhydride for resin synthesis, adding dimethyl acetamide, 4,4'-diaminodiphenyl ether and 4,4'-(hexafluoroisopropylidene)diphenylamine while stirring, adding pyromellitic dianhydride and 4,4'-(hexafluoroisopropylidene)diphthalic anhydride after dissolving, slowly heating to 100 DEG C, stirring for reacting until color is transparent; and 2)preparation method of the enamelled wire paint: taking polyamidoimide resin and xylene, uniformly stirring to obtain the self-lubricating polyamidoimide enamelled wire paint. According to the invention, a fluorine-containing group is introduced in the polyamidoimide enamelled wire, maximum static friction coefficient of the enamelled wire is reduced, lubrication effect of the produced enamelled wire is good, and the maximum static friction coefficient is about 0.040.

Owner:DANYANG STAR CHEM

Polyimide film and methods relating thereto

A polyimide film with advantageous handleability, flexibility, dimensional stability and heat resistance is provided. The polyimide film is characterized by block-copolymerizing an aromatic diamine component comprising 10˜25 mol % of paraphenylenediamine (a1) and 75˜90 mol % of 4,4′-diaminodiphenyl ether (a2) with an aromatic tetracarboxylic acid component consisting of 75˜99.9 mol % of pyromellitic acid dianhydride (b1) and 0.1˜25 mol % of 3,3′,4,4′-biphenyl tetracarboxylic acid dianhydride (b2). The Young's modulus, linear expansion coefficient, water absorption rate and glass transition temperature of such polyimide films can be controlled within very useful ranges.

Owner:DUPONT TORAY CO LTD

Method for manufacturing conductive polyimide film

InactiveUS20150090941A1High film strengthMaintain good propertiesNon-metal conductorsConductive materialProduction rateAcetic anhydride

A conductive polyimide film having an excellent film strength and electrical properties can be manufactured in a high productivity by a method for manufacturing conductive polyimide film which includes, in a manufacture method of a conductive polyimide film including an agent for imparting conductivity and a polyimide resin, drying a coating film including (A) and (B); and subjecting the film to imidation. (A) A polyamic acid including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride, 4,4′-oxydianiline, and 3,3′,4,4′-benzophenonetetracarboxylic acid dianhydride and / or p-phenylenediamine, which is obtained by reacting a tetracarboxylic acid dianhydride with a diamine compound. (B) A agent for imparting conductivity. (C) An imidation accelerator including a dialkylpyridine, and 0.1 to 1.6 molar equivalents of acetic anhydride per mol of an amic acid in a polyamic acid.

Owner:KANEKA CORP

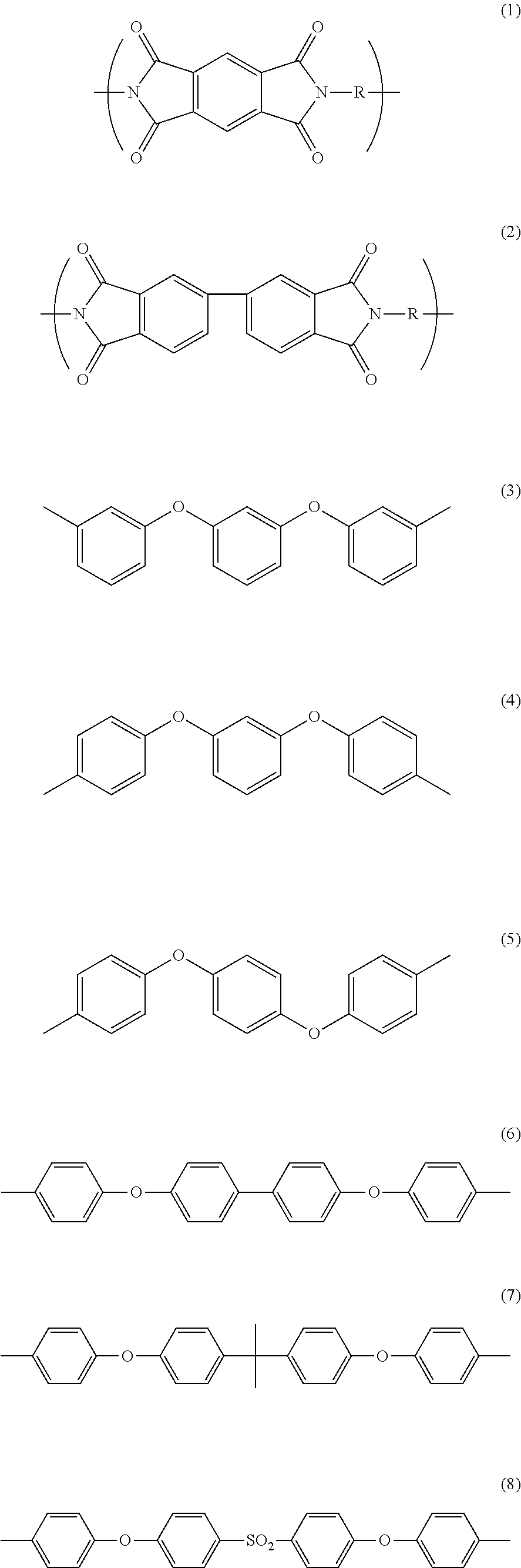

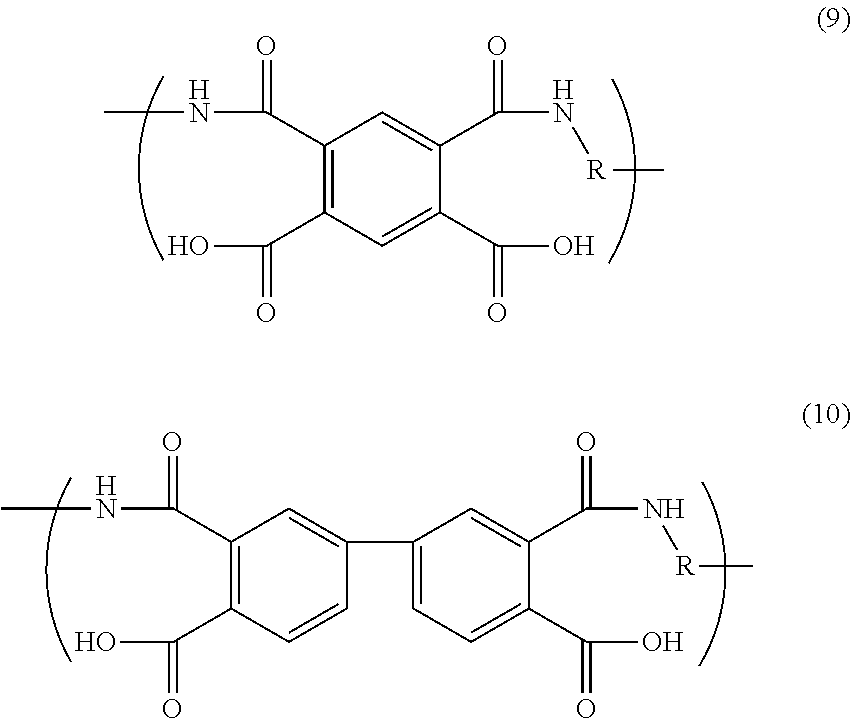

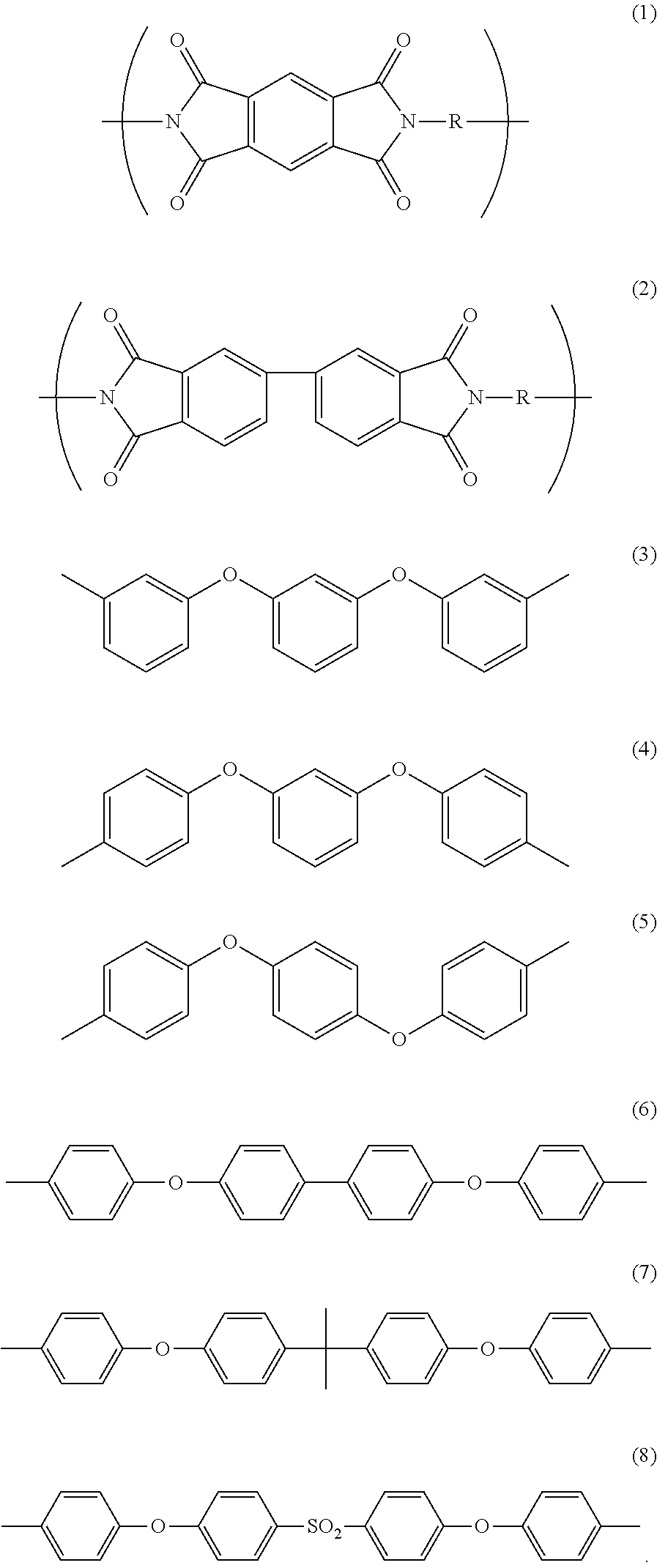

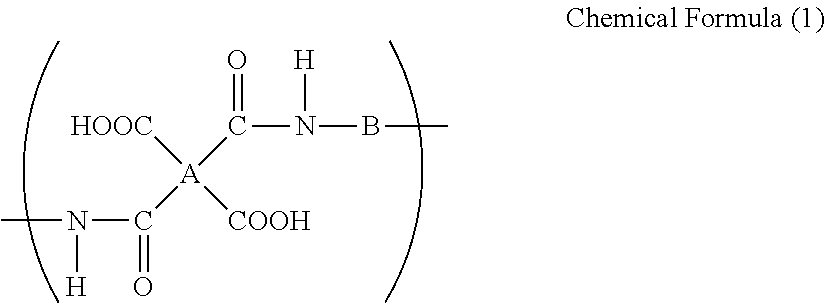

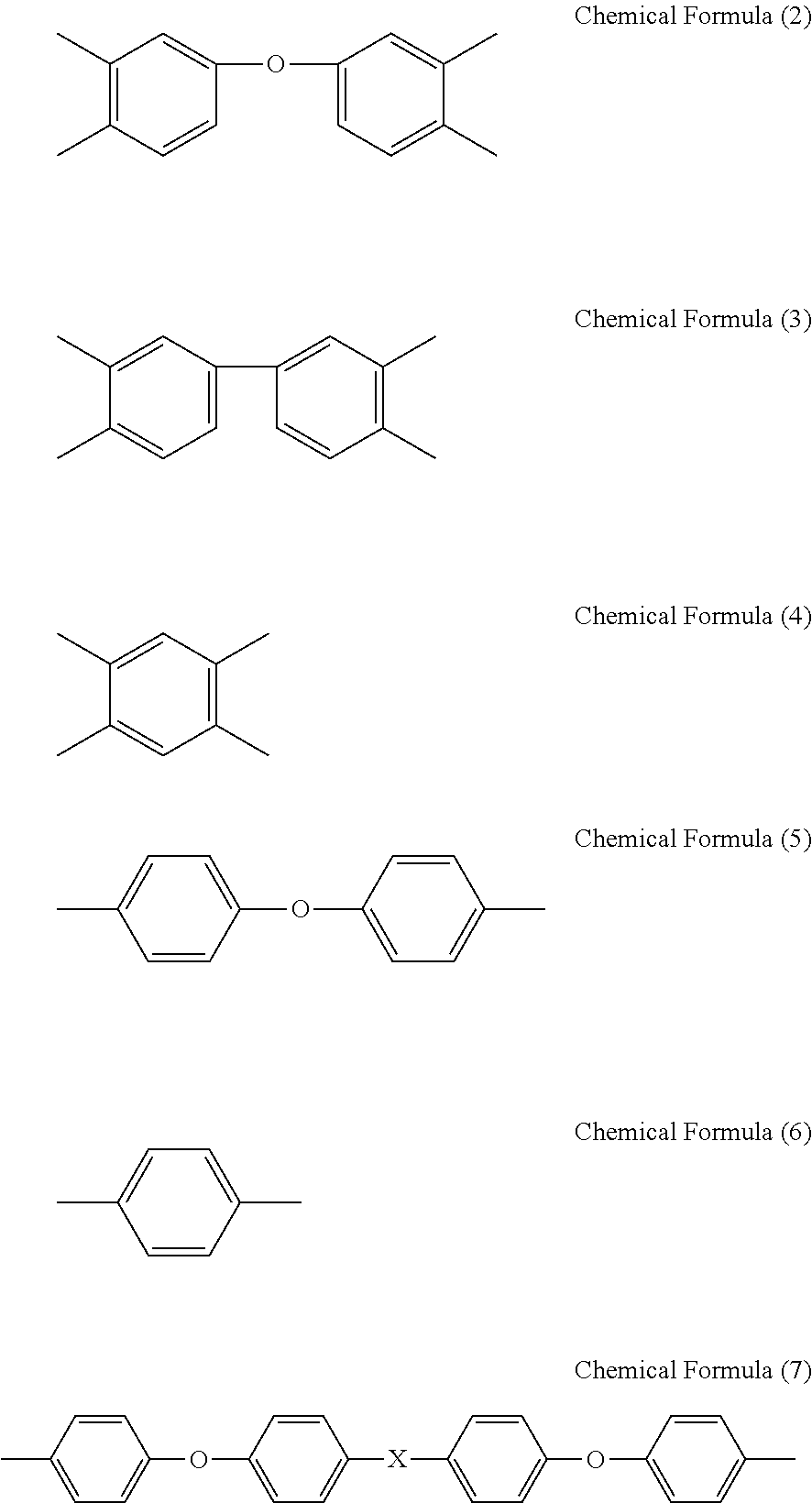

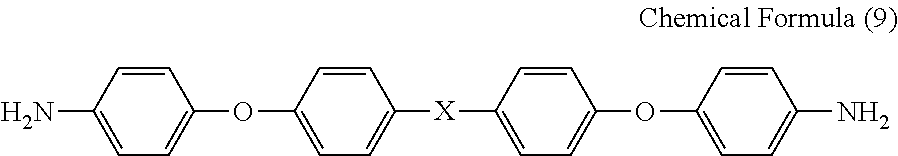

Insulated wire and coil using the same

ActiveUS20140065421A1Excellent in partial discharge resistanceEasy to processPlastic/resin/waxes insulatorsSynthetic resin layered productsDiaminodiphenyl etherInsulation layer

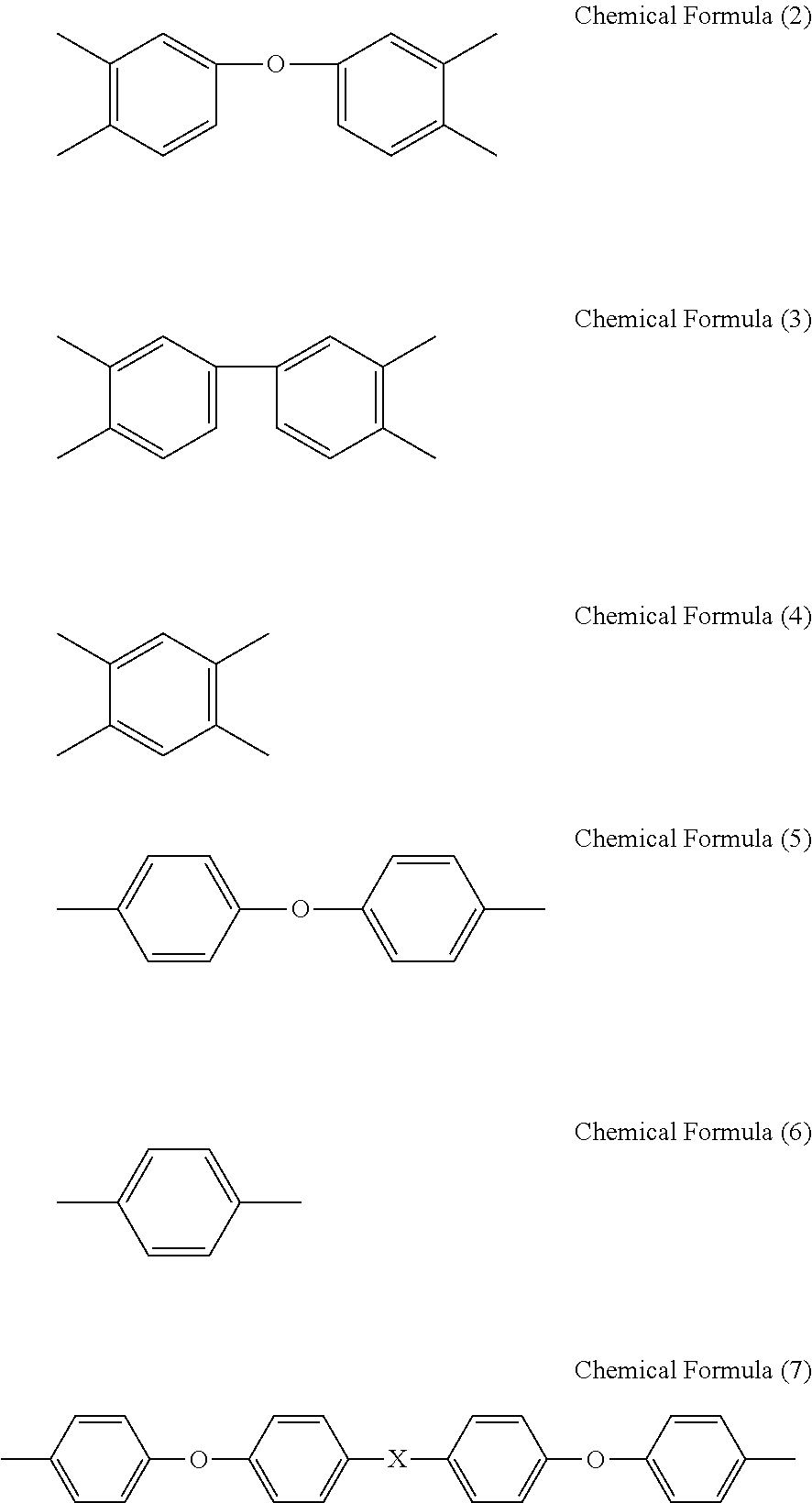

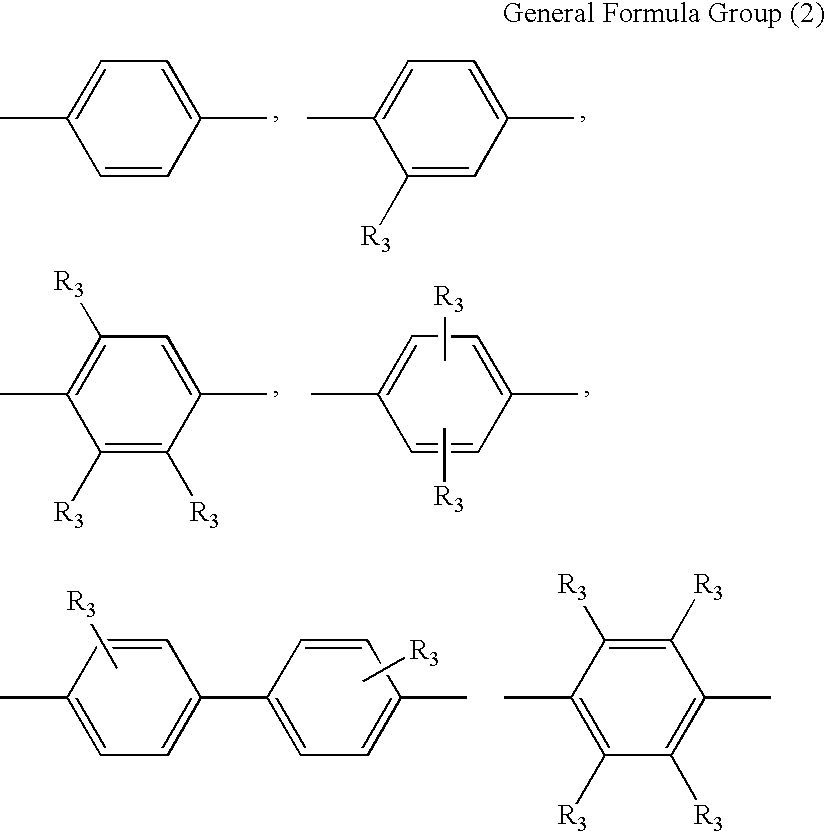

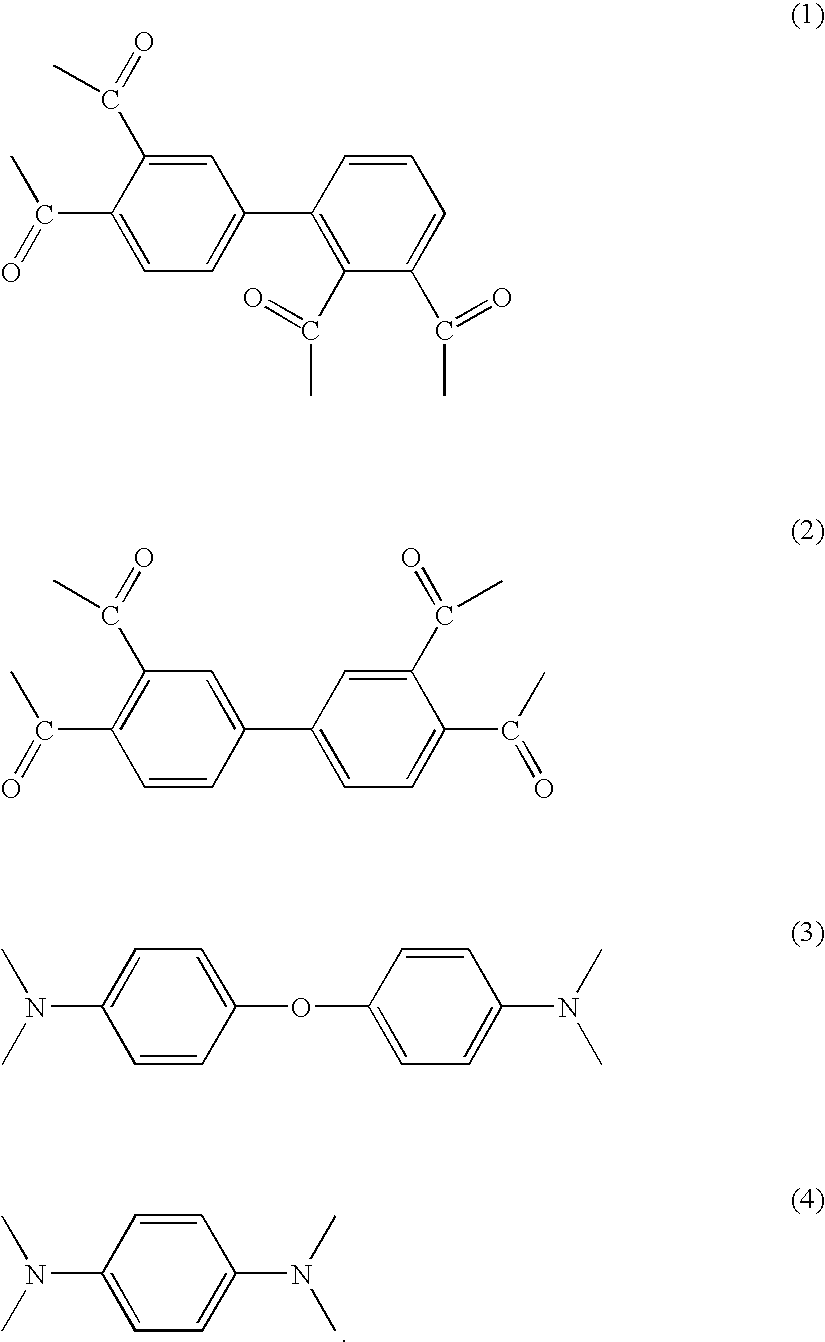

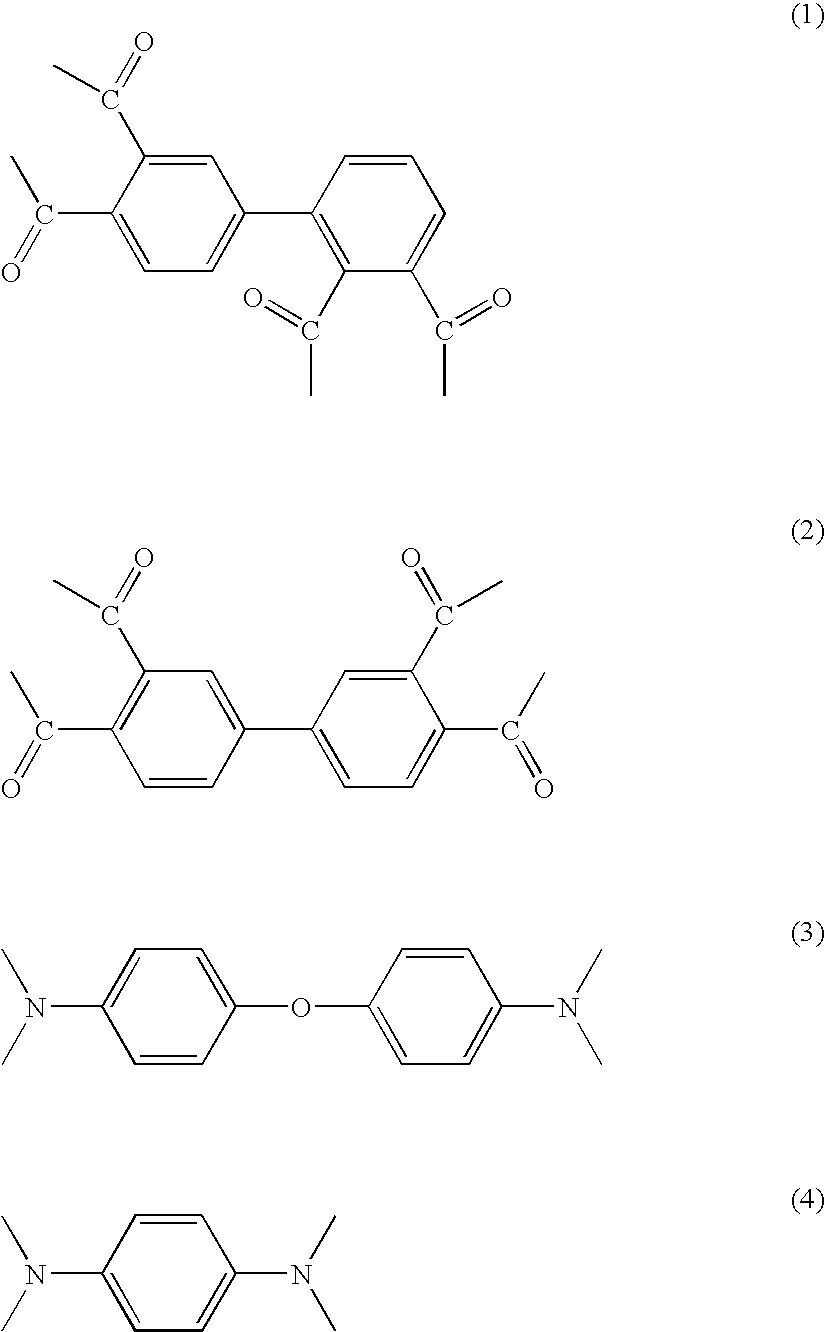

An insulated wire includes a conductor, and a polyimide insulation layer formed on an outer periphery of the conductor. The insulation layer includes a polyimide including a repeating unit represented by formula (1) and a repeating unit represented by formula (2). A first acid component in the repeating unit represented by the formula (1) and a second acid component in the repeating unit represented by the formula (2) are mixed in a molar ratio range of 85:15 to 40:60 as expressed by a molar ratio (the first acid component:the second acid component). R as a residue of a diamine component in the formulas (1) and (2) includes a residue of 4,4′-diaminodiphenyl ether and a residue of one selected from a group of diamines represented by the formulas (3) to (8). A storage elastic modulus of the polyimide at 325° C. is not less than 50 MPa.

Owner:HITACHI METALS LTD

Novel polyimide film with improved adhesiveness

InactiveUS20100003531A1Increase production capacityPrevent thermal deformationPrinted circuit aspectsPrinted circuit manufactureDiaminodiphenyl etherMetal foil

Disclosed is a polyimide film which exhibits high adherability to a metal foil via an adhesive layer containing a thermoplastic polyimide without requiring a special surface treatment. Specifically disclosed is a non-thermoplastic polyimide film obtained by imidizing a polyamic acid solution which is obtained from aromatic diamine and aromatic acid dianhydride. This non-thermoplastic polyimide film is characterized in that the aromatic diamine contains 4,4′-diaminodiphenylether and bis{4-(4-aminophenoxy)phenyl}propane, and the solution containing a polyamic acid is obtained by a specific production method.

Owner:KIKUCHI TAKASHI +1

Method for recovery processing of modified polyimide film wastes

InactiveCN104945268AHigh purityEfficient removalOrganic compound preparationPreparation from carboxylic acid amidesDiaminodiphenyl etherFiltration

The invention discloses a method for recovery processing of modified polyimide film wastes. The method comprises the following steps: crushing the modified polyimide film wastes into modified polyimide film waste scraps with the length of less than 5mm, hydrolyzing the scraps in concentrated ammonia water, and performing centrifuging or filtration after reaction; acidifying a separated filtrate by using hydrochloric acid, and separating out crude pyromellitic acid; washing separated undissolved substances by using hydrochloric acid or sulfuric acid, and then performing secondary centrifuging or filtration to obtain a crude 4,4'-diaminodiphenyl ether aqueous solution; and neutralizing the obtained crude 4,4'-diaminodiphenyl ether aqueous solution by using ammonia water until the pH value is equal to 8-10, and then separating out 4,4'-diaminodiphenyl ether. By adopting the method disclosed by the invention, the reaction rate is increased, the time is shortened, and meanwhile, inorganic fillers in the modified polyimide film wastes can be effectively removed to further improve the purity of a hydrolysis product.

Owner:WUXI SHUNXUAN NEW MATERIALS +1

Preparation method of high-performance organic fibers on basis of 4,4'-diaminodiphenyl ether

ActiveCN103243411AIncreased shear strengthHigh shear strength can improveWet spinning methodsMonocomponent synthetic polymer artificial filamentDiaminodiphenyl etherBound property

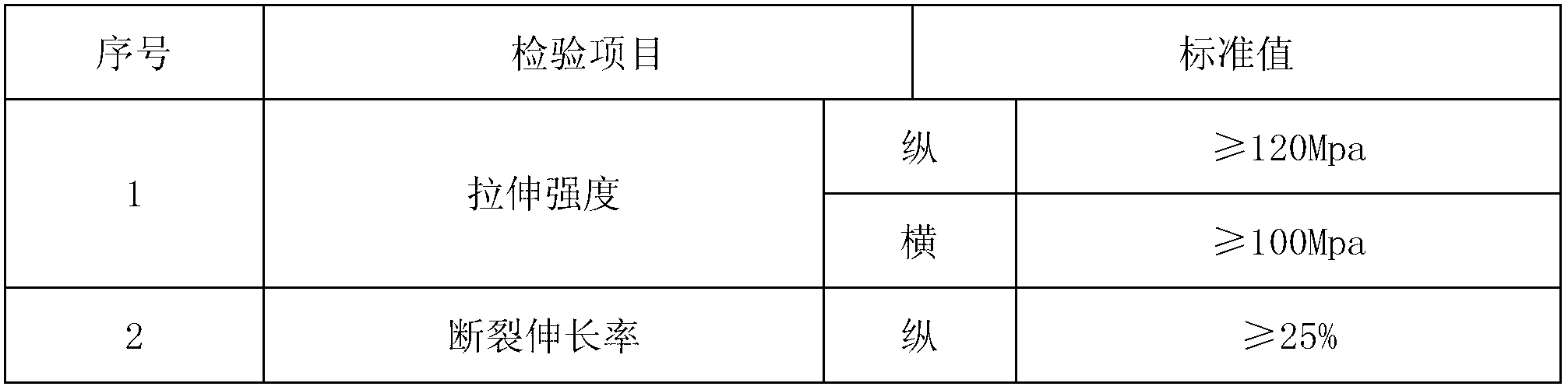

The invention relates to a preparation method of high-performance organic fibers, particularly a preparation method of high-performance organic fibers on the basis of 4,4'-diaminodiphenyl ether. The invention aims to solve the common problems of poor interfacial binding property and low interfacial shear strength between fibers and resin substrate due to smooth surface, low activity and low soakage tendency with resin in the traditional PBO (poly(p-phenylene-2,6-benzobisoxazole)) fibers. The method comprises the following steps: adding 4,6-diamino-resorcinol hydrochloride, 4,4'-diaminodiphenyl ether, 2,5-dihydroxyterephthalic acid, polyphosphoric acid and phosphorus pentoxide into a polymerization kettle, dissolving by heating, adding phosphorus pentoxide, heating, adding polymethylphenylsiloxane, heating, filtering, degassing, extruding, preparing protofibrils, washing with water, washing with alcohol, washing with alkali, drying, and heating in a nitrogen protective atmosphere to obtain the high-performance organic fibers. The tensile strength of the high-performance organic fibers reaches 2.5-5.5 GPa. The invention is applicable to the field of preparation of organic fibers.

Owner:浙江甬川聚嘉新材料科技有限公司

Polyamidoimide enamelled wire paint and preparation method thereof

InactiveCN104449342AReduce the maximum static friction coefficientImprove the lubrication effectFireproof paintsStatic friction coefficientDiaminodiphenyl ether

The invention relates to a polyamidoimide enamelled wire paint preparation method, which comprises the following steps: 1)preparation method of polyamidoimide resin: employing dimethyl acetamide, 4,4'-diaminodiphenyl ether, 4,4'-(hexafluoroisopropylidene)diphenylamine, pyromellitic dianhydride, 4,4'-(hexafluoroisopropylidene)diphthalic anhydride for resin synthesis, adding dimethyl acetamide, 4,4'-diaminodiphenyl ether and 4,4'-(hexafluoroisopropylidene)diphenylamine while stirring, adding pyromellitic dianhydride and 4,4'-(hexafluoroisopropylidene)diphthalic anhydride after dissolving, slowly heating to 100 DEG C, stirring for reacting until color is transparent; and 2)preparation method of the enamelled wire paint: taking polyamidoimide resin and xylene, uniformly stirring to obtain the self-lubricating polyamidoimide enamelled wire paint. According to the invention, a fluorine-containing group is introduced in the polyamidoimide enamelled wire, maximum static friction coefficient of the enamelled wire is reduced, lubrication effect of the produced enamelled wire is good, and the maximum static friction coefficient is about 0.040.

Owner:DANYANG STAR CHEM

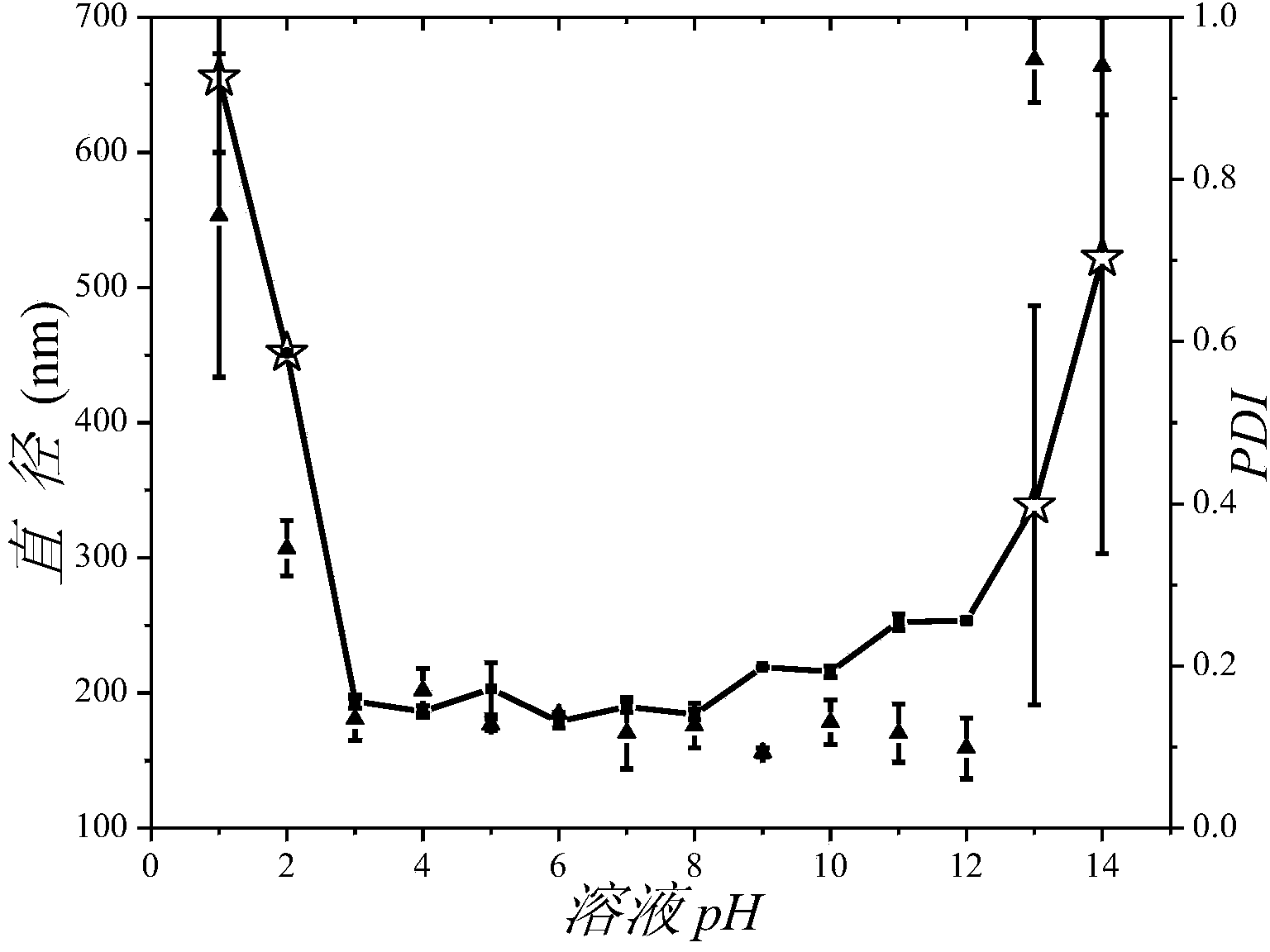

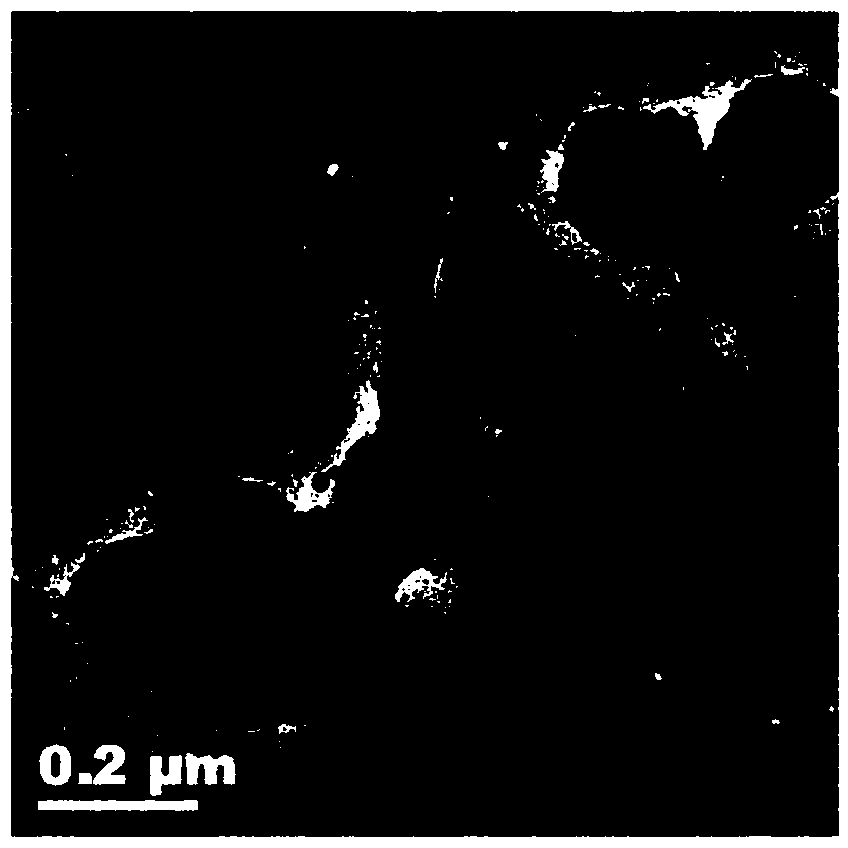

Homopolymer nanometer vesicle as well as preparation method and application thereof

ActiveCN104028303ASimple preparation stepsImprove productivityMaterial nanotechnologyBiocideAntibiosisDiaminodiphenyl ether

The invention provides a homopolymer nanometer vesicle as well as a preparation method and application thereof. The homopolymer nanometer vesicle comprises a homopolymer vesicle and nano silver, wherein the homopolymer vesicle is formed by self-assembling of a homopolymer; nano silver is deposited on the homopolymer vesicle; the homopolymer is formed by polymerizing 4,4'-diaminodiphenyl ether and benzenetetracarboxylic anhydride in the mole ratio of 1 to (0.2-4); the mole ratio of nano silver to carboxyl in the homopolymer is (1-20) to 1. The preparation method of the homopolymer nanometer vesicle comprises the following steps: firstly, carrying out condensation polymerization on anhydride and amine with polyfunctionality at normal temperature so as to generate the homopolymer; then self-assembling the homopolymer to obtain the homopolymer vesicle; and finally, depositing nano silver on the homopolymer vesicle so as to obtain the homopolymer nanometer vesicle. The homopolymer nanometer vesicle is simple and convenient in preparation process, is short in preparation cycle, has pH responsiveness, is relatively high in stability and catalysis, and has wide application prospects in the fields of catalysis and antibiosis.

Owner:TONGJI UNIV

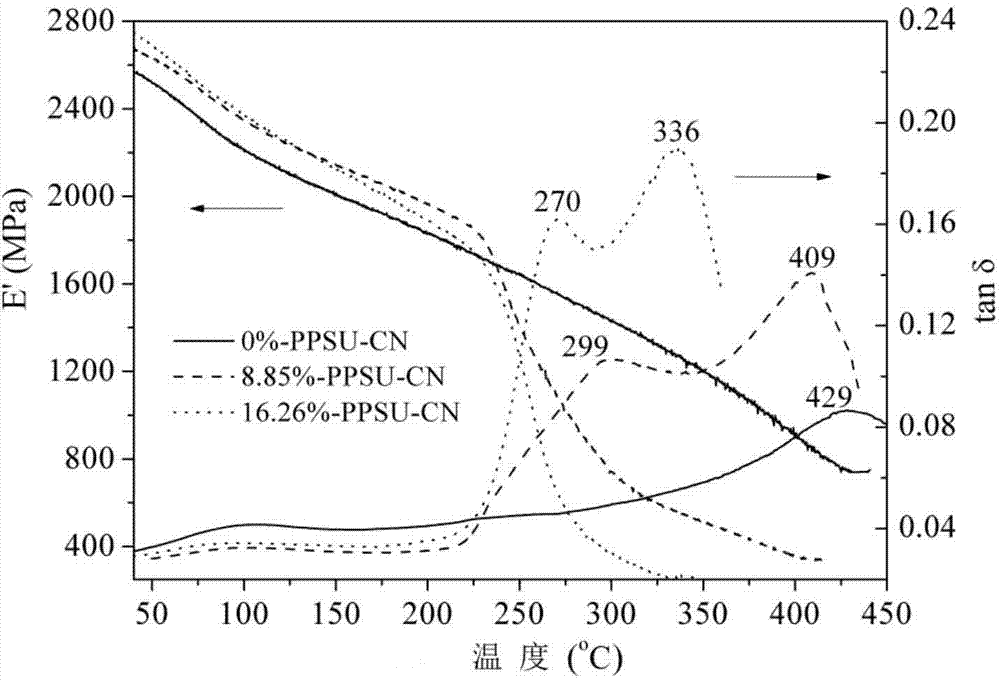

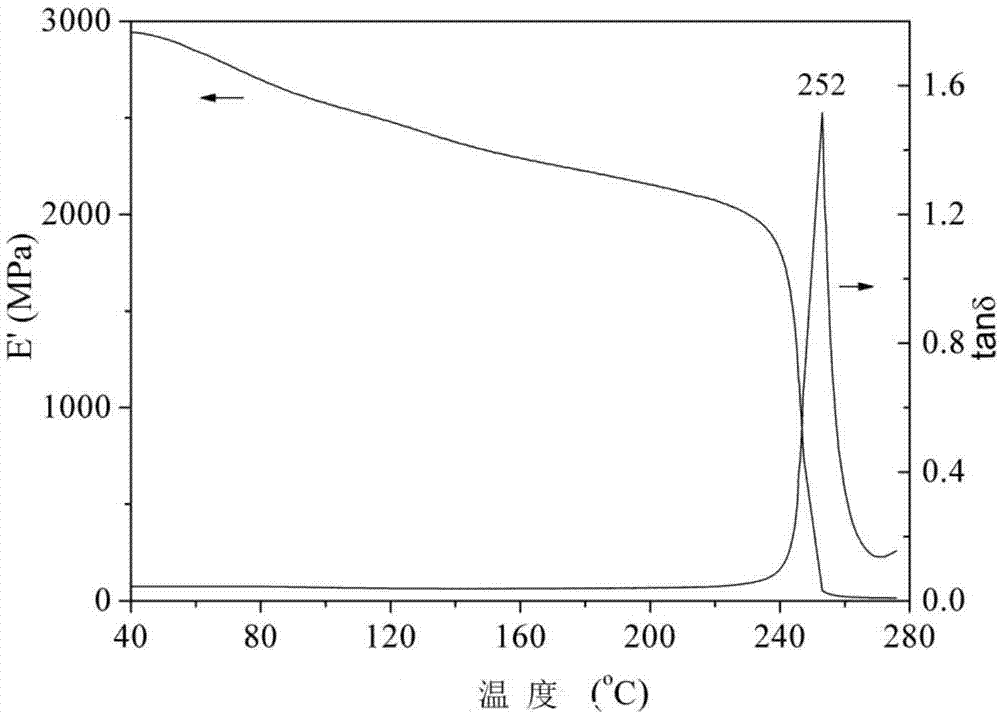

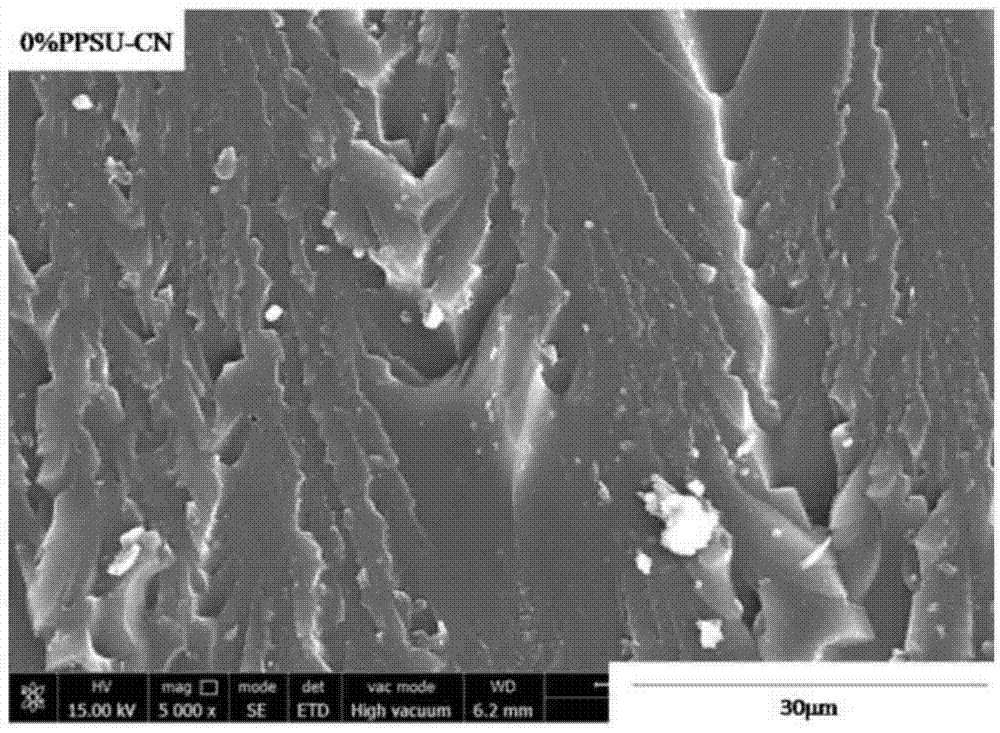

PES (polyether sulfone) toughened bisphthalonitrile resin material and preparation method thereof

The invention relates to a PES (polyether sulfone) toughened bisphthalonitrile resin material and belongs to the technical field of a thermosetting resin material. The disclosed nitrile-group and side-group containing PES toughened bisphthalonitrile resin material comprises the following components in part by mass: 5 to 20 parts of nitrile-group and side-group containing PES, 3 parts of curing agent 4,4minute-diaminodiphenyl ether sulfone and 100 parts of bisphthalonitrile low polymer. In the preparing process, the raw materials are mixed in part by mass and are stirred and blended in an NMP, filtrate is dried on a sample disk to obtain a sample sheet and then the sample sheet is heated and cured in the range of 240 to 350 DEG C. The nitrile-group and side-group containing PES toughened bisphthalonitrile resin prepared by the invention has higher mechanical intensity and toughness than common bisphthalonitrile resin and original heat resistance of a substrate is basically kept; a preparation method of the resin material disclosed by the invention has the characteristics of simple process, convenience for operation and suitability for industrial production.

Owner:JILIN UNIV

Preparation method of polyester enamelled wire paint with good heat resistance capable of being directly welded

InactiveCN104449338AImprove heat resistanceImprove rigidityFireproof paintsPolyamide coatingsDiaminodiphenyl etherSlag

The invention relates to a preparation method of a polyester enamelled wire paint with good heat resistance capable of being directly welded, which comprises the following steps: 1)preparation method of weldability resin: employing m-phthalic acid, glycol and 4,4'-diaminodiphenyl ether for resin synthesis, placing m-phthalic acid, glycol and 4,4'-diaminodiphenyl ether in a reaction apparatus in order, gradually heating to 200 DEG C while stirring from room temperature, insulating and reacting until color is transparent, pumping under vacuum to a theoretical liquid volume; and 2)taking polyester resin and methylphenol, stirring for one hour at 180 DEG C, cooling to room temperature, adding xylene and stirring for one hour to obtain the polyester enamelled wire paint with good heat resistance capable of being directly welded. The enamelled wire coated by the polyester enamelled wire paint is capable of being directly welded at 450 DEG C, no welding slag is generated after direct welding, thermal shock temperature is more than 175 DEG C, and cut-through temperature is more than 270 DEG C.

Owner:DANYANG STAR CHEM

Preparation method of high-performance organic fibers on basis of 4,4'-diaminodiphenyl ether

ActiveCN103243411BIncreased shear strengthHigh shear strength can improveMonocomponent synthetic polymer artificial filamentWet spinning methodsDiaminodiphenyl etherBound property

Owner:浙江甬川聚嘉新材料科技有限公司

Polyamic acid solution composition having carbon black dispersed therein, process for production of semiconductive polyimide resin belt using the composition, and semiconductive polyimide resin belt

InactiveUS8686106B2Evenly dispersedMinimize dispersionNon-metal conductorsConductive materialDiaminodiphenyl etherPolyamic acid

The present invention provides a carbon black-dispersed polyamic acid solution composition having a high solids content and a high carbon black content. The invention further provides an intermediate transfer belt using the polyamic acid solution composition. The carbon black-dispersed polyamic acid solution composition is obtained by uniformly dispersing carbon black in a polyamic acid solution obtained by reacting biphenyltetracarboxylic dianhydride and an aromatic diamine in an organic polar solvent. The biphenyltetracarboxylic dianhydride includes 2,3,3′,4′-biphenyltetracarboxylic dianhydride and 3,3′,4,4′-biphenyltetracarboxylic dianhydride. The aromatic diamine includes 4,4′-diaminodiphenyl ether and p-phenylenediamine. The polyamic acid solution has a solids content of 25 weight % or more.

Owner:GUNZE LTD +1

Circuit board

ActiveUS20150201490A1Synthetic resin layered productsPrinted circuit aspectsDiaminodiphenyl etherOptoelectronics

The present disclosure is directed to a circuit board having a first imaged metal layer, a first electrically insulating layer, a second imaged metal layer, a polyimide bondply derived from 100 mole % 3,3′,4,4′-biphenyl tetracarboxylic dianhydride, 20 to 90 mole % 2,2′-bis(trifluoromethyl)benzidine, and 10 to 80 mole % 4,4′-oxydianiline, a third imaged metal layer, a second electrically insulating layer and a forth imaged metal layer. The circuit board does not have an adhesive layer between the second imaged metal layer and the polyimide bondply or the third imaged layer and the polyimide bondply.

Owner:DUPONT ELECTRONICS INC

Amorphous calcium-copper-titanium-oxygen ceramic/polyimide composite film and preparation method thereof

The invention relates to the field of the ceramic / polyimide composite film and the preparation method thereof, and particularly discloses an amorphous calcium-copper-titanium-oxygen ceramic / polyimide composite film and a preparation method thereof.. The film and the method aim to solve the problems that the present crystalline calcium-copper-titanium-oxygen ceramic / polyimide composite film preparation method consumes high energy in sintering crystalline ceramics and the prepared crystalline calcium-copper-titanium-oxygen ceramic / polyimide composite film has lower specific inductive capacity during doping at low density (the mass percentage of the ceramics is lower than 20%). The amorphous calcium-copper-titanium-oxygen ceramic / polyimide composite film is prepared from amorphous calcium-copper-titanium-oxygen ceramic particles, (4, 4')- diaminodiphenyl ether, pyromellitic dianhydride and a solvent. The preparation method is as follows: I, preparing an amorphous calcium-copper-titanium-oxygen ceramic / polyamide acid mixed solution; and II, by the way of heating for imidization after coating application, preparing to obtain the amorphous calcium-copper-titanium-oxygen ceramic / polyimide composite film. The film and the method are applied to the fields of information, electronics and electricity.

Owner:HARBIN UNIV OF SCI & TECH

Binder resin composition for electrode, electrode mixture paste, and electrode

ActiveUS9418772B2Small degree of swellingIncreased fracture energyElectrolytic capacitorsHybrid capacitor electrodesDiaminodiphenyl etherCarboxylic acid

The present invention relates to a binder resin composition for an electrode, including a polyamic acid and a solvent, wherein the polyamic acid is (i) a polyamic acid which includes a tetracarboxylic acid component including 10 to 100 mol % of 4,4′-oxydiphthalic acid and 90 to 0 mol % of 3,3′,4,4′-biphenyltetracarboxylic acid and / or pyromellitic acid and a diamine component including an aromatic diamine having 1 to 4 aromatic rings, (ii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 10 to 90 mol % of p-phenylene diamine and 90 to 10 mol % of 4,4′-diaminodiphenyl ether, or (iii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 40 mol % or more of a bis[4-(4-aminophenoxy)phenyl] compound.

Owner:UBE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com