Amorphous calcium-copper-titanium-oxygen ceramic/polyimide composite film and preparation method thereof

A calcium-copper-titanium-oxygen and polyimide technology is applied in the field of ceramic/polyimide composite film and its preparation, which can solve the problems of low dielectric constant and high energy consumption of sintered crystal ceramics, and improve the dielectric constant. , low cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

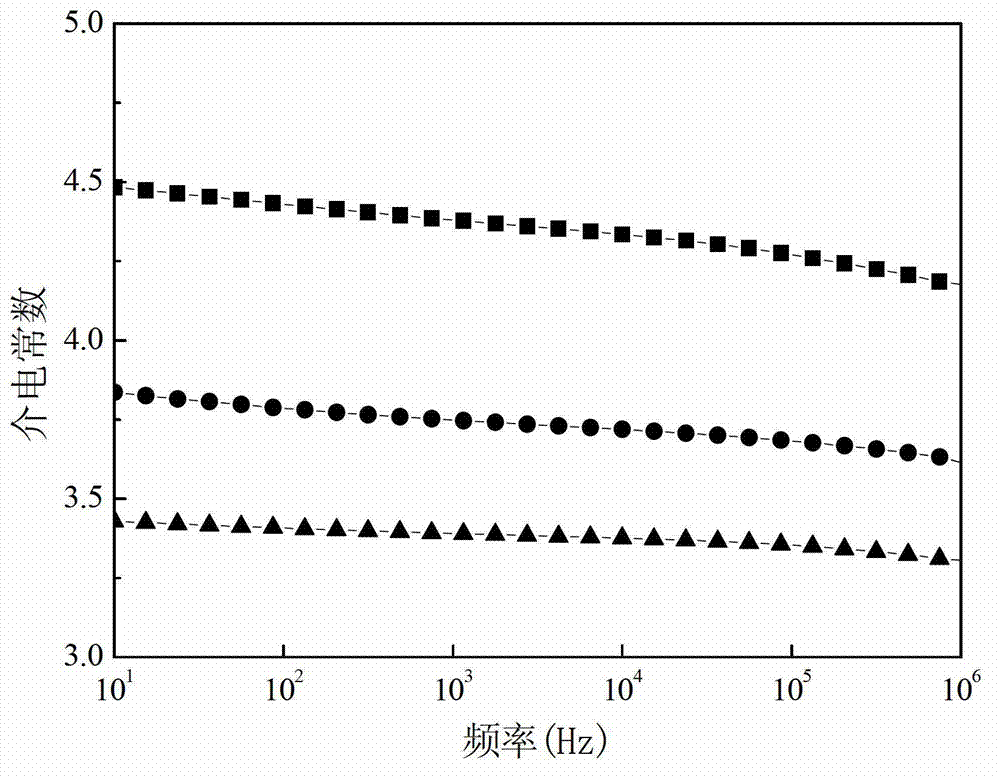

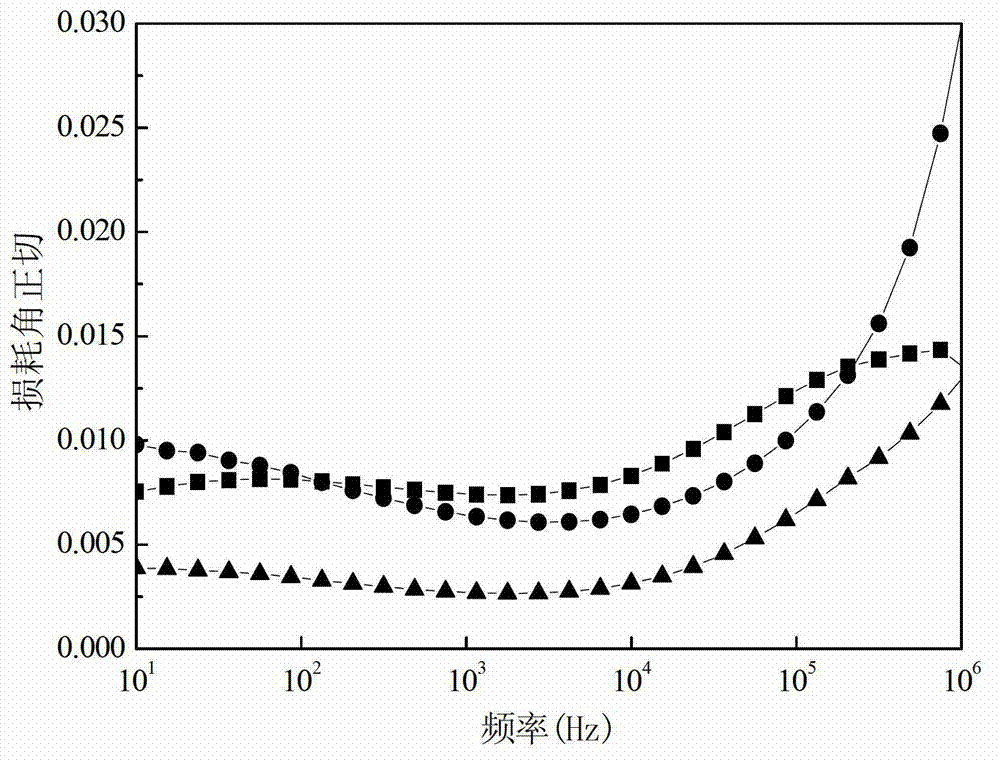

[0015] Embodiment 1: This embodiment provides an amorphous calcium copper titania ceramic / polyimide composite film, which is composed of amorphous calcium copper titania ceramic particles, 4,4'-diaminodiphenyl ether, phenylene The film prepared by tetraformic anhydride and solvent; wherein, the mass ratio of the 4,4'-diaminodiphenyl ether to the amorphous calcium-copper-titanium oxide ceramic particles is (2.70~15.39):1, and the added homobenzene The mass ratio of tetraformic anhydride to the amorphous calcium copper titanium oxide ceramic particles is (2.97~16.93):1, and the mass ratio of the volume of the solvent to the amorphous calcium copper titanium oxide ceramic particles is (45mL~254mL):1g.

[0016] This embodiment provides an amorphous calcium-copper-titanium oxide ceramic / polyimide composite film, which can be larger when doped at a low concentration (the mass fraction of amorphous calcium-copper-titanium oxide ceramics in the composite film is less than 20%). Increa...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solvent is dimethylacetamide. Others are the same as in the first embodiment.

specific Embodiment approach 3

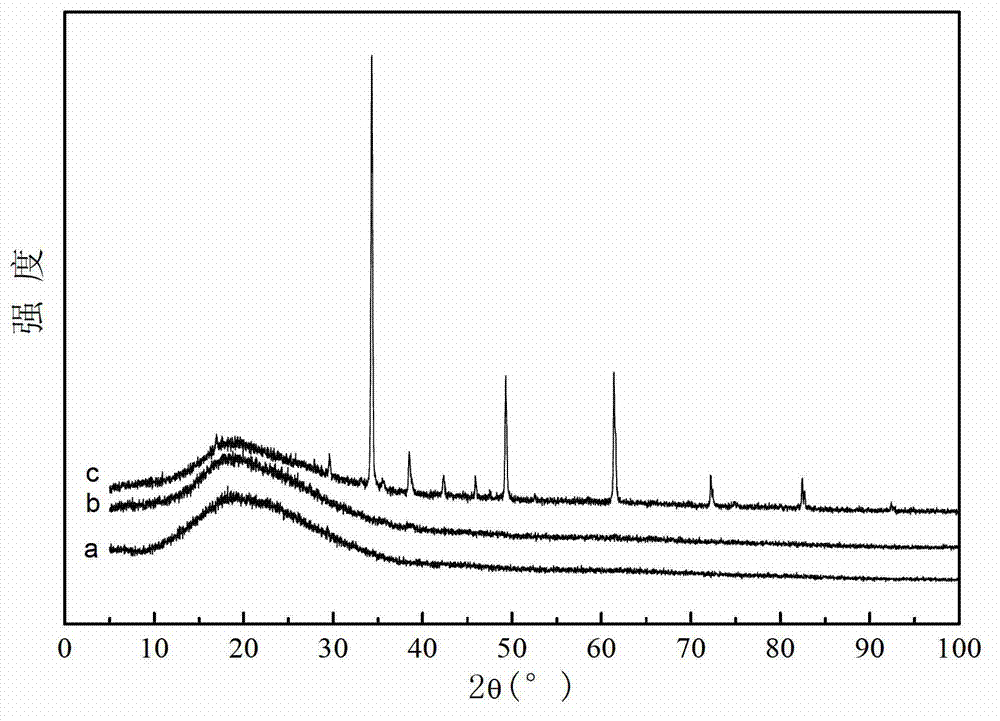

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the amorphous calcium-copper-titanium oxide ceramic particles are prepared according to the following steps:

[0019] a. Add calcium nitrate and copper nitrate to ethylene glycol methyl ether, stir at 40°C~60°C at a stirring rate of 300r / min~500r / min for 20min~40min, then cool to 20°C~30°C, To obtain a mixed solution, add tetrabutyl titanate to the mixed solution, stir at a stirring rate of 300r / min~500r / min for 40min~80min, then let stand for 20h~28h to obtain a sol; wherein, the ethylene glycol methyl The ratio of the volume of ether to the amount of calcium nitrate is (3.65L~8.65L):1mol, the molar ratio of copper nitrate to calcium nitrate is (2~4):1, and the molar ratio of tetrabutyl titanate to calcium nitrate The ratio is (3.5~4.5):1; b. Ignite the sol obtained in step 1 to obtain a powder, grind the powder with a mortar for 1h~2h, then raise the temperature at a rate of 4°C / min~8°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Ac conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com