Modified polyimide film and modified polyimide precursor composite film waste material recovery processing method

A polyimide precursor and polyimide film technology, applied in the chemical industry, can solve the problems of unspecified separation of inorganic nano-fillers, difficulty in recycling and processing, etc., and achieve the effects of shortening time, improving purity, and increasing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

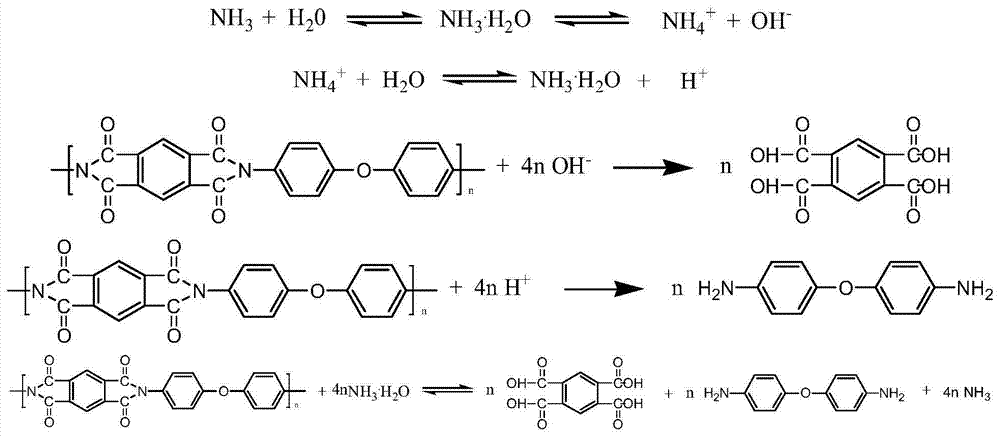

Problems solved by technology

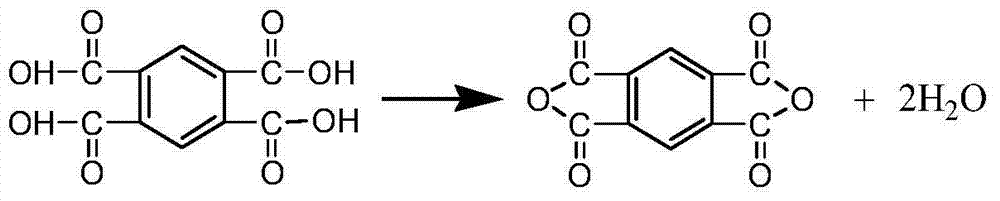

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of glass fiber (GF) suspension

[0032] Using 12.5g of nano-sized glass fiber (GF), add 2000ml of aprotic solvent N,N-dimethylacetamide (DMAc), under the condition of 20kHz ultrasonic dispersion, fully stir for 60min to make a stable suspension.

[0033] (2) Preparation of modified polyamic acid composite solution

[0034] Add the suspension obtained above into the polyamic acid polymerization reactor, control the temperature at 10-60°C, add 239.3g of 4,4'-diaminodiphenyl ether, and carry out mechanical stirring. After it is completely dissolved, the temperature Between 50 and 60°C, add 260.7 g of pyromellitic dianhydride in batches while stirring to prepare a polyamic acid composite solution with uniform viscosity and stability.

[0035] (3) Preparation of modified polyimide film and its polyimide precursor composition film

[0036] Put the polyamic acid composite solution obtained above to form a liquid film on a clean steel plate, put it in an oven,...

Embodiment 2

[0042] Replace the glass fiber (GF) in Example 1 with silica, the yield of 4,4'-diaminodiphenyl ether is 63.7g, the product purity is 99.9%, and the melting point is 191-192°C. The yield of the pyromellitic dianhydride product was 69.0 g. The product has a purity of 99.5% and a melting point of 284-285°C. Except above changes, other operation steps and product quality are consistent with embodiment 1.

Embodiment 3

[0044] Change glass fiber (GF) into alumina (Al 2 o 3 ), the yield of 4,4'-diaminodiphenyl ether was 63.5g. The purity of the product is 99.9%, and the melting point is 191-192°C. The yield of the pyromellitic dianhydride product was 68.5 g. The product has a purity of 99.5% and a melting point of 284-285°C. Except above changes, other operation steps and product quality are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com