PES (polyether sulfone) toughened bisphthalonitrile resin material and preparation method thereof

A technology of diphthalonitrile resin and diphthalonitrile is applied in the field of biphenyl type polyethersulfone toughened diphthalonitrile resin material and preparation field thereof, and can solve problems such as unreported , to achieve the effect of improving interaction, high carbon residue rate and increasing tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1. preparation PPSU-CN content is the toughened two phthalonitrile resin material of 4.63wt%

[0032]Add 6g of bisphthalonitrile oligomers, 0.18g of p-BAPS, 0.3g of biphenyl type polyethersulfone containing nitrile side groups and 30mL of NMP into a 100mL Erlenmeyer flask, and stir magnetically for 12h at room temperature to make All components are fully dissolved. Then, the mixed solution was filtered through a 200-mesh nylon filter cloth, poured on a 10cm in diameter, horizontal and clean oil-free aluminum sample pan, dried in an oven at 60-120°C for 48 hours, and the obtained samples were continuously dried in a high-temperature oven. Curing (curing conditions: 240°C for 5h, 260°C for 4h, 280°C for 4h, 300°C for 4h, 325°C for 4h, 350°C for 4h). Thus, a bisphthalonitrile resin material toughened by biphenyl polyethersulfone containing nitrile side groups is obtained. The mechanical properties and TGA test result data of the resin material sample strips ar...

Embodiment 2

[0033] Embodiment 2. preparation PPSU-CN content is the toughened bisphthalonitrile resin material of 8.85wt%

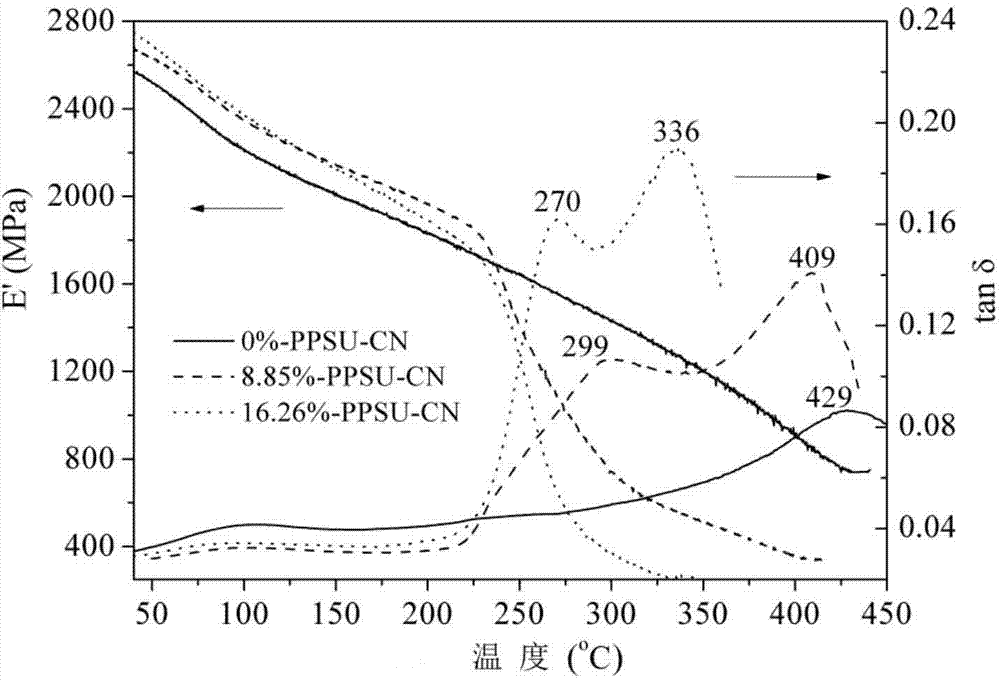

[0034] Except that the quality of the added nitrile side group biphenyl polyethersulfone is 0.6g, the preparation conditions and process of the toughened resin material are the same as in Example 1, and the mechanical properties and TGA test result data of the resin material sample are listed in In Table 1, the DMA curve see figure 1 .

Embodiment 3

[0035] Embodiment 3. preparation PPSU-CN content is the toughened bisphthalonitrile resin material of 12.71wt%

[0036] Except that the quality of the added nitrile side group biphenyl polyethersulfone is 0.9g, the preparation conditions and process of the toughened resin material are the same as in Example 1, and the mechanical performance test results of the resin material sample are listed in Table 1. middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com