Epoxy polyhedral oligomeric silsesquioxane modified phenolic resin and preparation method thereof

A technology of silsesquioxane and phenolic resin, which is applied in the field of epoxy-based cage silsesquioxane modified phenolic resin and its preparation, and can solve the problems of decreased mechanical properties, uneven dispersion, and agglomeration of polymers , to achieve the effect of widening the curing window, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

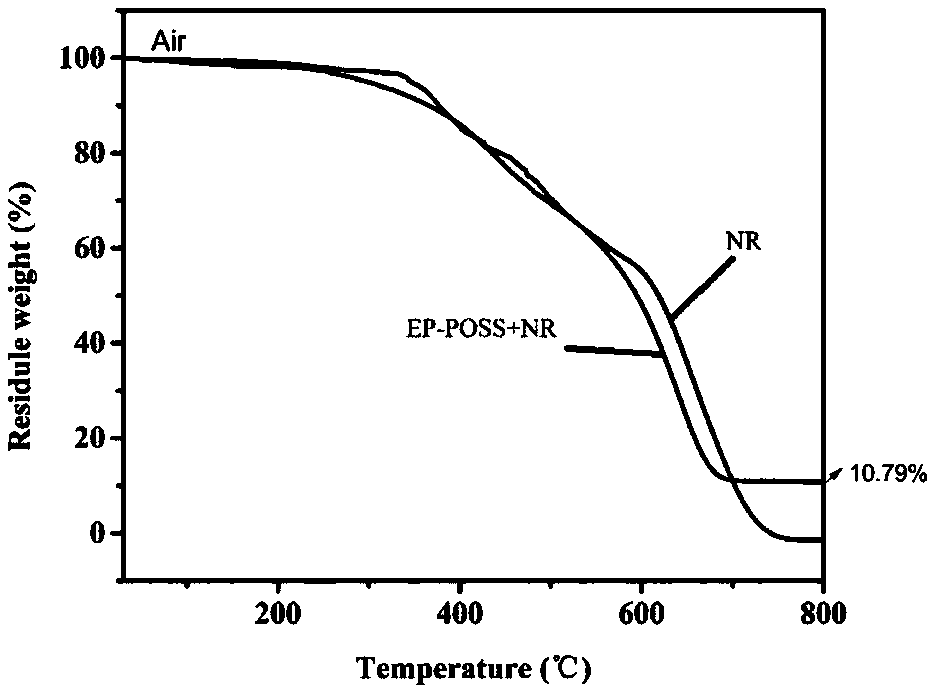

Image

Examples

preparation example Construction

[0030] The preparation method of epoxy cage type silsesquioxane modified phenolic resin of the present invention comprises the following steps:

[0031] 1) Weigh the thermoplastic phenolic resin, epoxy cage silsesquioxane and catalyst, then add solvent to the thermoplastic phenolic resin to dissolve the thermoplastic phenolic resin, then add epoxy cage silsesquioxane and catalyst , stirred to obtain a uniformly dispersed solution;

[0032] 2) Place the uniformly dispersed solution obtained in step 1) in a nitrogen atmosphere for a constant temperature reflux stirring reaction, and remove the solvent after the reaction is completed to obtain an epoxy-based cage silsesquioxane-modified phenolic resin.

[0033] Epoxy cage silsesquioxane modified phenolic resin is a light greenish brown solid.

[0034] The mass ratio of the thermoplastic phenolic resin, the epoxy cage silsesquioxane and the catalyst is 100: (10-300): (0.1-1).

[0035] The temperature during the constant temperat...

Embodiment 1

[0051] The preparation method of epoxy cage type silsesquioxane modified phenolic resin of the present invention comprises the following steps:

[0052] 1) Weigh the thermoplastic phenolic resin, epoxy cage silsesquioxane and catalyst, then add solvent to the thermoplastic phenolic resin to dissolve the thermoplastic phenolic resin, then add epoxy cage silsesquioxane and catalyst , stirred to obtain a uniformly dispersed solution;

[0053] 2) Place the uniformly dispersed solution obtained in step 1) in a nitrogen atmosphere for a constant temperature reflux stirring reaction, and remove the solvent after the reaction is completed to obtain an epoxy-based cage silsesquioxane-modified phenolic resin.

[0054]Epoxy cage silsesquioxane modified phenolic resin is a light greenish brown solid.

[0055] The mass ratio of thermoplastic phenolic resin, epoxy cage silsesquioxane and catalyst is 100:100:1.

[0056] The temperature during the constant temperature reflux stirring reacti...

Embodiment 2

[0061] The preparation method of epoxy cage type silsesquioxane modified phenolic resin of the present invention comprises the following steps:

[0062] 1) Weigh the thermoplastic phenolic resin, epoxy cage silsesquioxane and catalyst, then add solvent to the thermoplastic phenolic resin to dissolve the thermoplastic phenolic resin, then add epoxy cage silsesquioxane and catalyst , stirred to obtain a uniformly dispersed solution;

[0063] 2) Place the uniformly dispersed solution obtained in step 1) in a nitrogen atmosphere for a constant temperature reflux stirring reaction, and remove the solvent after the reaction is completed to obtain an epoxy-based cage silsesquioxane-modified phenolic resin.

[0064] Epoxy cage silsesquioxane modified phenolic resin is a light greenish brown solid.

[0065] The mass ratio of the thermoplastic phenolic resin, the epoxy cage silsesquioxane and the catalyst is 100:10:0.1.

[0066] The temperature during the constant temperature reflux s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com