Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "2-Butyne" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

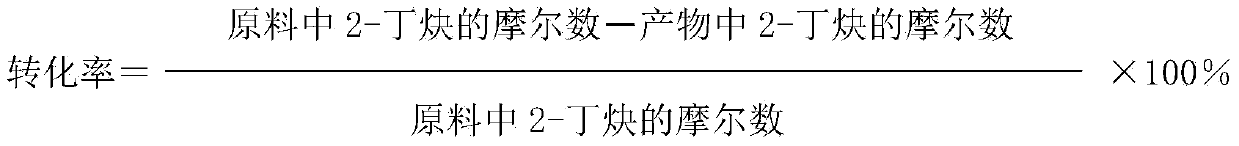

2-Butyne (dimethylacetylene, crotonylene or but-2-yne) is an alkyne with chemical formula CH₃C≡CCH₃. Produced artificially, it is a colorless, volatile, pungent liquid at standard temperature and pressure.

Method of dry etching, dry etching gas and process for producing perfluoro-2-pentyne

InactiveUS20050247670A1Improve etch selectivityImprove stabilityPreparation by hydrogen halide split-offDecorative surface effectsResist2-Pentyne

A dry etching method wherein a resist film is irradiated with radiation having a wavelength of not more than 195 nm to form a resist pattern having a minimum line width of not more than 200 nm, and the substrate having the resist pattern formed thereon is subjected to dry etching using a fluorine-containing compound having 4 to 6 carbon atoms and at least one unsaturated bond as an etching gas. As the fluorine-containing compound, perfuloro-2-pentyne, perfuloro-2-butyne, nonafluoro-2-pentene and perfluoro-2-pentene are preferably used. Perfuloro-2-pentyne is produced by a process wherein a 1,1,1-trihalo-2,2,2-trifluoroethane is allowed to react with pentafluoropropionaldehyde to give a 2-halo-1,1,1,4,4,5,5,5-octafluoro-2-pentene, and the thus-produced halo-octafluoro-2-pentene is dehydrohalogenated.

Owner:ZEON CORP

Preparation method of graphdiyne

ActiveCN105016962APromote formationEasy to assembleHydrocarbonsHydrocarbon preparationVacuum pumpingNitrogen

The invention relates to a preparation method of graphdiyne. The preparation method comprises that 1, in a nitrogen or argon protective atmosphere, a reaction substrate 1,3,5-tripropargylbenzene and a catalyst are put into a reaction container, a solvent is added into the reaction container to dissolve the materials in the reaction container, and the solution undergoes a heating reaction, 2, in the reaction process in the step 1, the solution is subjected to vacuum pumping process multiple times so that a reaction side product 2-butyne is removed and a solvent is supplied to make up for a loss of the solvent, and 3, after the reaction, the reaction product is purified so that the product graphdiyne is obtained. Compared with the prior art, the preparation method has simple processes. The prepared graphdiyne has the uniform surface and a low oxidation degree and can stably exist in air.

Owner:SHANGHAI NORMAL UNIVERSITY

Hexafluoropropylene-2-butyne synthesizing method

ActiveCN105348034AHigh yieldConvenient sourcePreparation by halogen replacementHexachlorobutadieneHexafluoropropylene

The invention discloses a hexafluoropropylene-2-butyne synthesizing method. Hexachlorobutadiene (CCl2=CCl-CCl=CCl2) is taken as the raw material to generate hexafluoropropylene-2-butyne under the action of a catalyst, the raw material hexachlorobutadiene is easy to obtain and low in cost. The gaseous-phase circulating fluorination method is adopted, the discharge level of three industrial wastes is low, the yield of products is high, and production cost is reduced greatly; the gaseous-phase circulating fluorination method is conducted at normal temperature, the traditional high-pressure telomerization process route is avoided, and risks in industrial safety production are reduced greatly; meanwhile, the method has the advantage that operation is easy and is totally suitable for industrial production.

Owner:TIANJIN MEDICAL UNIV

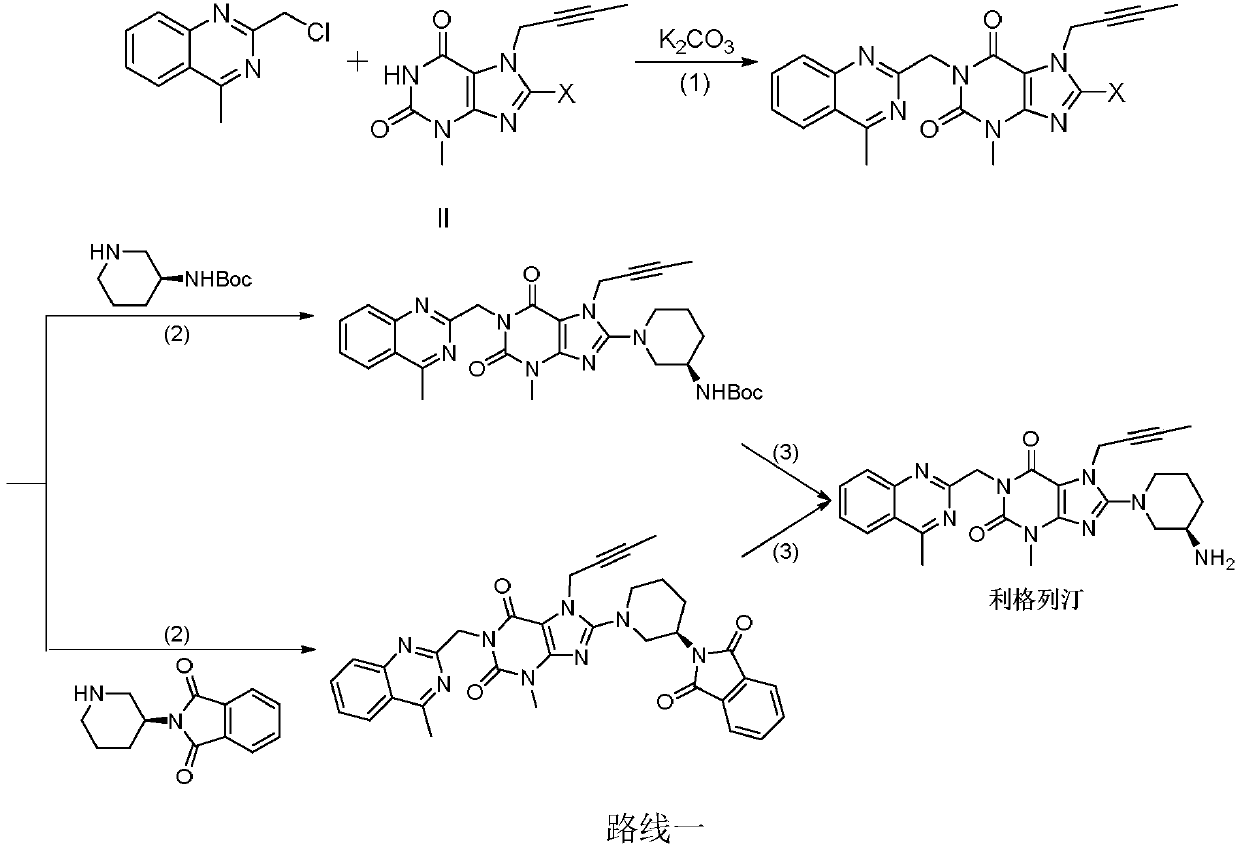

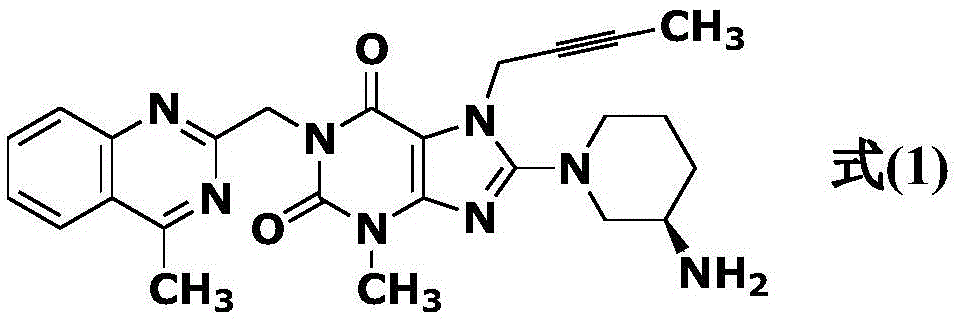

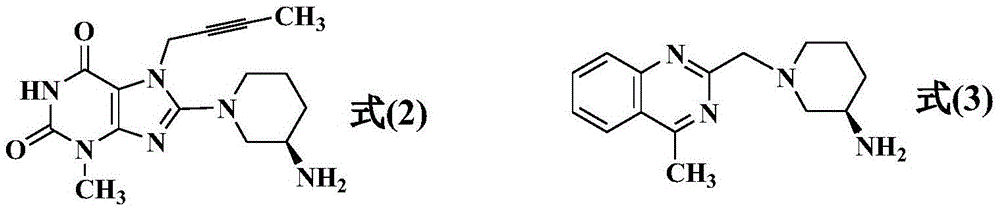

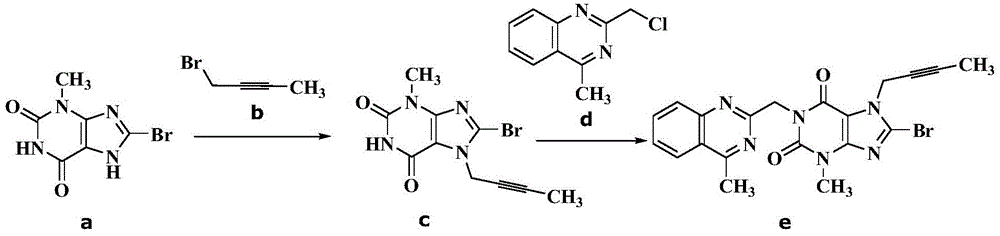

Industrial preparation process of linagliptin

The invention relates to the technical field of medicines and particularly relates to an industrial preparation process of linagliptin. The industrial preparation process comprises the steps of adding a reactant a (2-chloromethyl-4-methyl-quinazoline), an equal molar ratio of reactant b (8-bromo-7-(2-butynyl)-3-methylxanthine), an acid-binding agent and a proper amount of solvent into a reaction kettle to react at 0-140 DEG C for 3-8 hours, after TLC detection reaction is finished, directly adding a reactant c ((R)-3-phthalimide piperidine-tartaric acid) and an acid-binding agent, namely N,N-diisopropylethylamine without processing a reaction mother liquid to react at 0-125 DEG C for 3-10 hours, after the TLC detection reaction is finished, adding ethanolamine without processing the reaction mother liquid to react for 2-10 hours, after the TLC detection reaction is finished, dropwise adding purified water, carrying out suction filtration to obtain a linagliptin rough product, and refining by virtue of a refining method disclosed in a patent CN101437823A, so as to obtain a linagliptin refined product. According to the industrial preparation process, linagliptin is synthesized by virtue of a one-pot continuous feeding method, the consumption of the solvent is low, and the operation is easy; and the industrial preparation process is suitable for industrial production.

Owner:SHOUGUANG FUKANG PHARMA

2-butylene-1,4-diol synthesis method

InactiveCN1966480AMature production processRaw materials are easy to getPreparation by hydrogenationFuranSynthesis methods

The invention relates to a synthesis method for 2-butene-1, 4-diol through selective hydrogenation of 2-butyne-1, 4-diol. The method includes placing butynediol aqueous solution and lead poisoned catalyst of Pd-C in an autoclave, replacing air with nitrogen and then replacing nitrogen with hydrogen, heating to 35 ~ 45degreeC with stirring, increasing pressure and maintaining under 0.6-1.7 MPa, reacting for 60 ~ 390 min, stopping stirring and providing hydrogen, cooling rapidly and venting, replacing unreacted hydrogen with nitrogen , and obtaining the final product for sampling analysis after filtering to remove catalyst. The quality content of catalyst is 5 wt.% Pd-C, which is poisoned by 1 -3 wt.% lead poisoning catalyst. The amount of the catalyst is 0.33 ~ 0.99 wt.% of the total reaction products. The products of this invention is a multifunctional compound, which can be formed oxygenated heterocycle after closing loop and used as the intermediates for vitamin B6 and furan ring-containing drug. Therefore, butynediol production has good market prospects.

Owner:上海中远化工有限公司

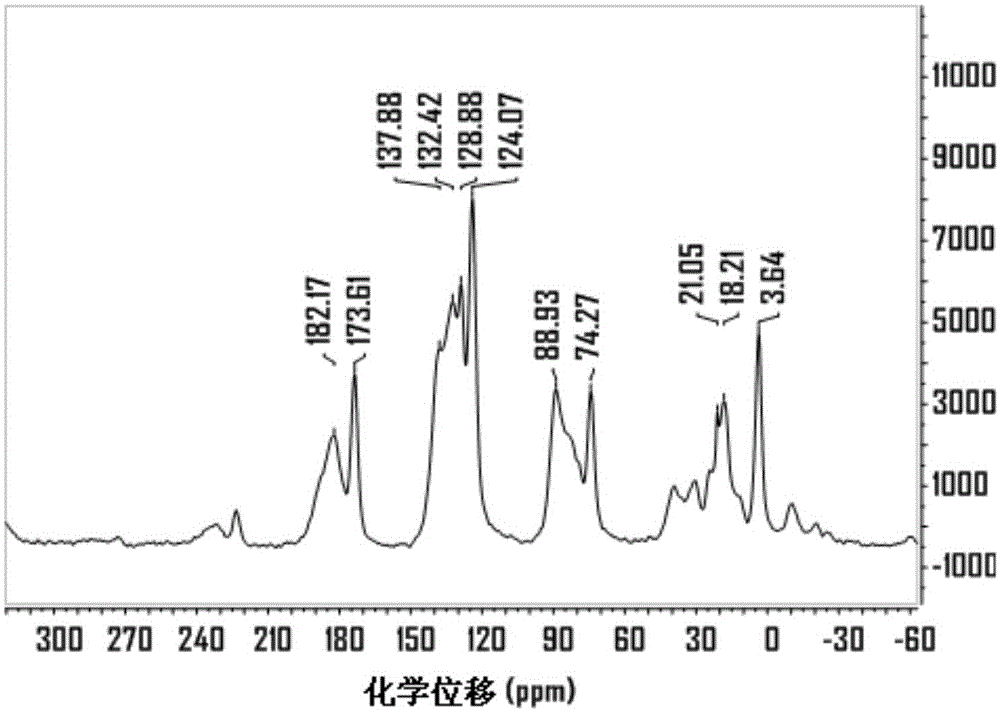

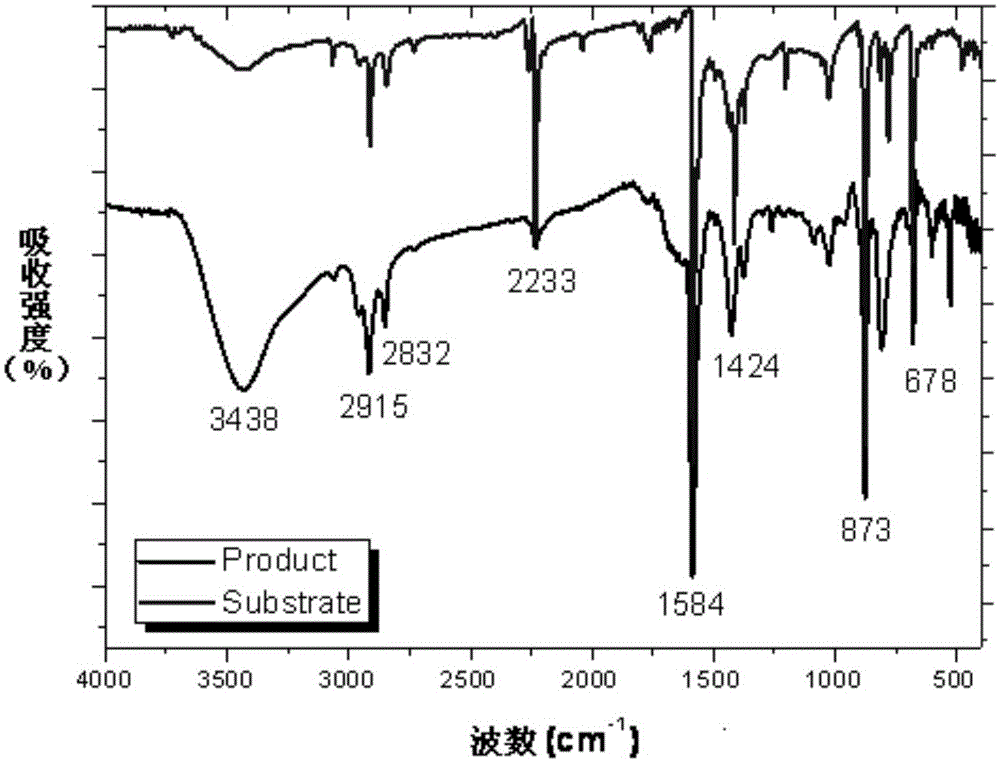

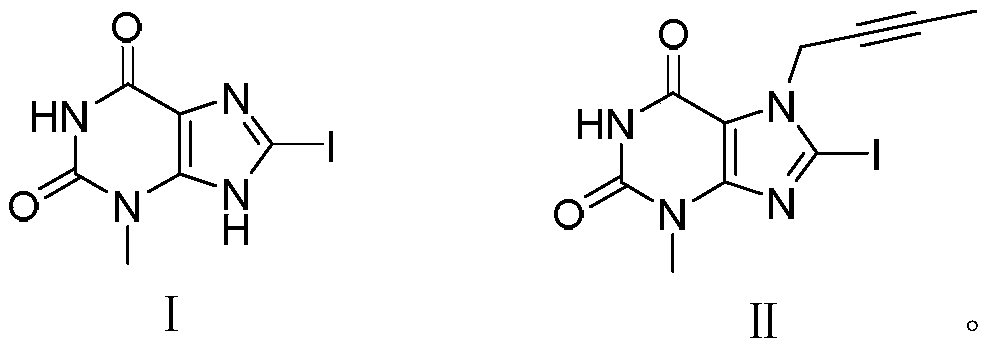

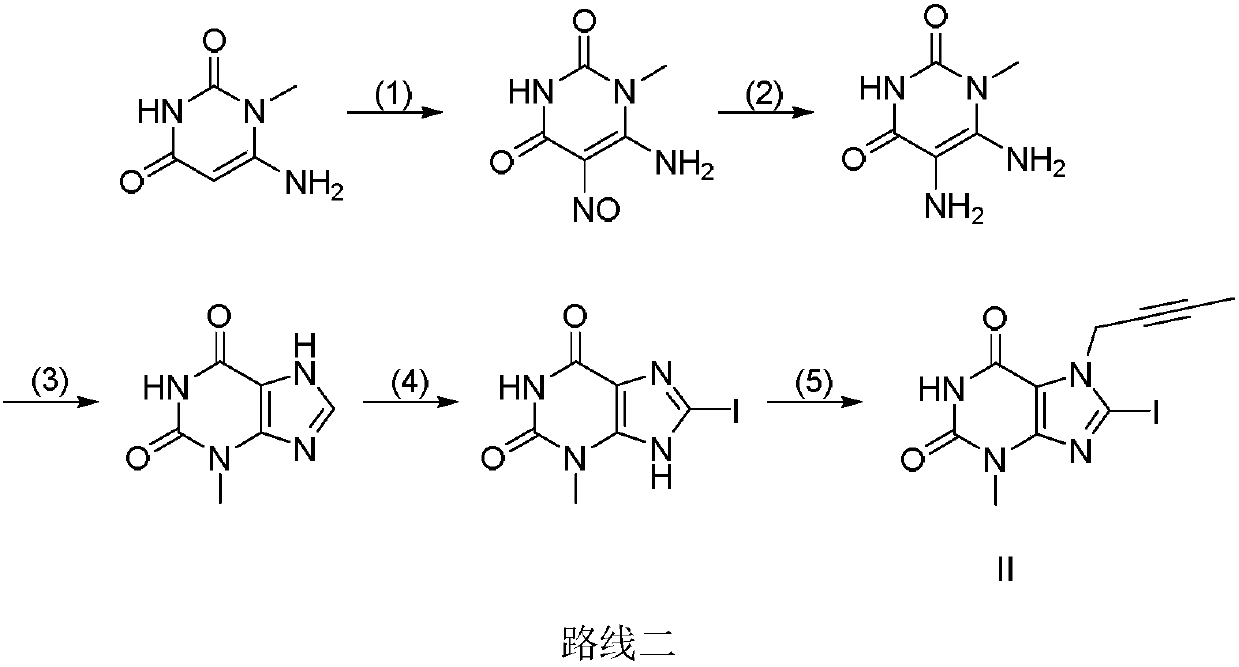

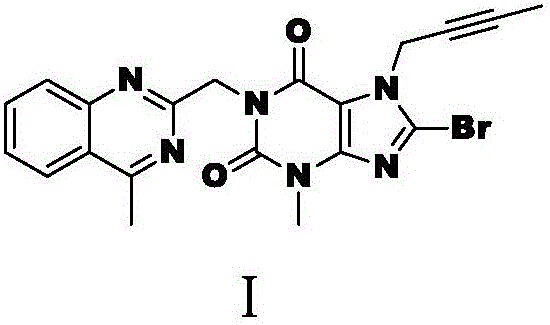

Synthesis method of trajenta intermediate

ActiveCN107936023ARaw materials are easy to getFew stepsOrganic chemistrySynthesis methodsSubstitution reaction

The invention discloses a synthesis method of a trajenta intermediate. The synthesis method comprises the following steps: reacting 1-methyluracil, urea, propiodal and an oxidant under the catalytic action of acid to obtain a compound shown as a formula I; then carrying out substitution reaction on the compound shown as the formula I and 1-bromo-2-butyne to obtain a compound shown as a formula II,namely the trajenta intermediate. The method disclosed by the invention has the advantages of easily-obtained raw materials, few steps, higher yield, mild reaction conditions and suitability for industrial production. (Refer to Description).

Owner:安庆奇创药业有限公司

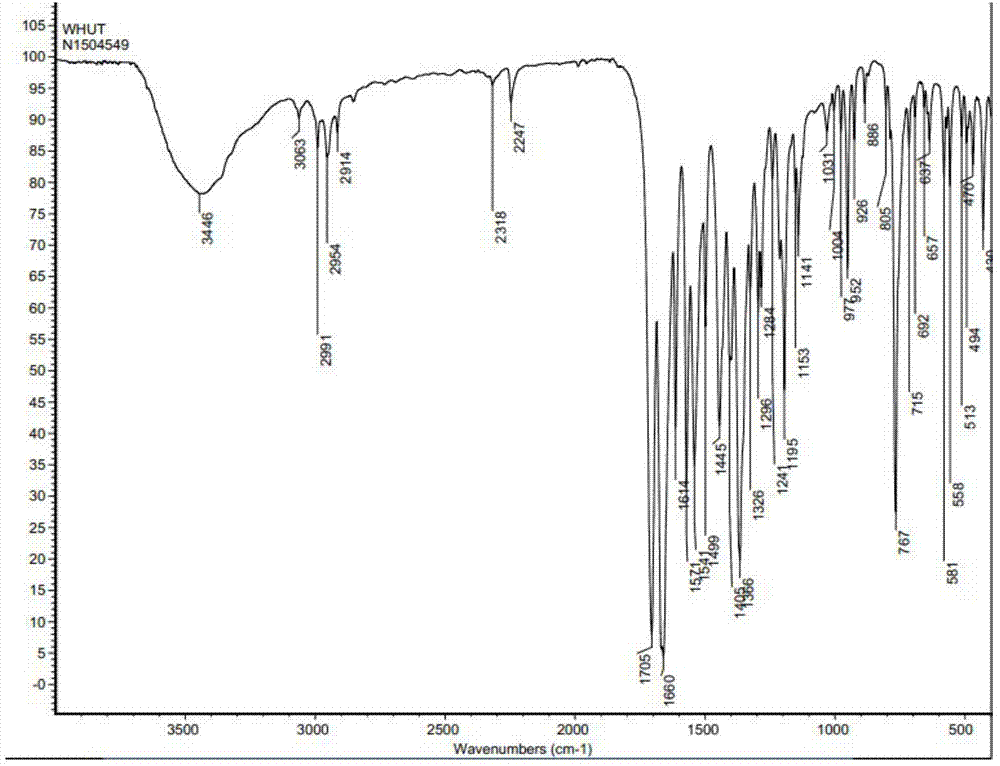

Simple preparation method of II-type antidiabetic drug linagliptin

InactiveCN104844603AEasy to operateShort reaction stepsOrganic chemistryMetabolism disorderFiltrationXanthine

The invention discloses a simple preparation method of II-type antidiabetic drug linagliptin which comprises the following steps: adding 3-methyl-7-(2-butyne-1-yl)-8-bromo-xanthine into a DMSO (dimethylsulfoxide) solution of 2-chloromethyl-4-methyl-quinazoline and potassium carbonate A, and under the catalysis of potassium iodide, reacting for 7-8 hours at a temperature of 70-80 DEG C; adding potassium carbonate B and (R)-3-aminopiperidine, and reacting for 7-8 hours at a temperature of 70-80 DEG C; after the reaction is completed, adding saturated salt water, separating out solids, and carrying out suction filtration to obtain a crude product linagliptin; and recrystallizing the crude product linagliptin with methyl alcohol, carrying out suction filtration and drying, thus obtaining a target product. The method disclosed by the invention is implemented by using a one-pot method, so that the method is simple and easy to operate and short in reaction steps, and raw materials are cheap and easily available, therefore, the method is applicable to industrial mass production; and the method overcomes the problems in the conventional method that impurities are difficult to remove, line operations are complicated and time-consuming, and too many raw materials are required.

Owner:WUHAN UNIV OF TECH

Environment-friendly high-brightness medium-phosphorus chemical nickel-plating additive

ActiveCN103726036AReduce dosageAchieve full brillianceLiquid/solution decomposition chemical coatingPorosityRhenium

The invention discloses an environment-friendly high-brightness medium-phosphorus chemical nickel-plating additive which is composed of components A and B, wherein the component A comprises the following raw materials: a 2-5mg / L mixture of nano copper and a soluble copper salt, 2-4mg / L rhenium sulfate, 1-4mg / L sodium allysulfonate (ALS), a complexing agent, a stabilizer, and 20-40g / L NaOH; the component B comprises the following raw materials: 1-4mg / L 1,4-bis(2-hydroxyethoxy)-2-butyne (BEO), 1-3mg / L N,N-diethylaminopropyne (DEP), 1-4mg / L dibenzenesulfonimide (BBI), and 2-4mg / L sodium hydroxymethanesulphonate (PN). The formula of the environment-friendly high-brightness medium-phosphorus chemical nickel-plating additive provided by the invention contains no heavy metal ions such as cadmium and lead, and is harmless to the environment; if applied to a chemical nickel-plating solution, the additive is capable of keeping the plating solution stable so that the obtained coating is even and compact, low in porosity, high in brightness and good in nitric acid resistance; more specifically, even though the nickel coating is soaked in concentrated nitric acid for 300 seconds, the nickel coating does not change color.

Owner:HARBIN SAN YONG GONG DA SCI & TECH

Simple preparation method of high-purity linagliptin

The invention relates to a simple preparation method of high-purity linagliptin. The method includes the steps of making 8-bromine-3-methyl xanthine and 1-bromo-2-butyne react, directly adding 2-chloromethyl-4-methylquinazoline without processing after reaction is completed, preparing a key intermediate 8-bromine-7-(2-butyne-1-yl)-3,7-dihydro-3-methyl-1-[(4-methyl-2-quinazolinyl)methyl]-1H-purine-2,6-diketone of linagliptin through a one-pot method, making the intermediate react with (R)-3-piperidinamine dihydrochloride after being filtered and separated to obtain a linagliptin solution, and obtaining a linagliptin pure product after processing the linagliptin solution. The key intermediate is prepared through the one-pot method, operation is convenient, and yield is increased; the key intermediate reacts with (R)-3-piperidinamine dihydrochloride after being separated, and therefore high-purity linagliptin is obtained, and the requirements for production and declaration of pharmaceutical enterprises are met to the maximum extent.

Owner:VALIANT CO LTD

Propargyl alcohol type quaternary ammonium salt surfactant and preparation method thereof

InactiveCN102049213AGood corrosion inhibitionHigh temperature resistanceOrganic chemistryTransportation and packagingQuaternary ammonium cationOrtho position

The invention relates to a propargyl alcohol type quaternary ammonium salt surfactant and a preparation method thereof, and the structural formula of quaternary ammonium salt is as follows: n is equal to 8, 10, 12, 14 or 16, and X is Cl or Br; and a substituent is positioned in the ortho-position, interposition or para-position. The preparation method is as follows: (1) adding 3-5g of NaH into a reactor, introducing nitrogen, adding 60-90ml of THF (tetrahydrofuran), stirring at room temperature, dropping 4-6g of propiolic alcohol, further slowly dropping 10-15g of chloromethylpyridine, stirring for 15-30h, separating water phase from organic phase, washing, drying, performing column chromatography, and then getting pyridyl-2-butynol; and (2) adding the pyridyl-2-butynol and alkyl halide into the reactor according to the molar ratio of 1: 1.5-1: 4, further adding 10ml-15ml of acetonitrile, refluxing and stirring for 20-30h at the temperature of 50-80 DEG C, washing, performing the column chromatography, and then getting the alkynol type quaternary ammonium salt surfactant. The series of the propargyl alcohol type quaternary ammonium salt surfactants have very high surface activity and very strong corrosion inhibition performance, the preparation method is simple and feasible, the operation is easy, the yield is higher, and the environmental pollution can be avoided.

Owner:CHINA WEST NORMAL UNIVERSITY

Method for making high-reflectance microprism reflecting film working mould with ultrasound-pulse electroforming

ActiveCN103422128AEasy to adjustControl retroreflection coefficientElectroforming processesPrismDissolution

The invention relates to a microprism, in particular to a method for making a high-reflectance microprism reflecting film working mould with ultrasound-pulse electroforming. Electroforming liquid is prepared, namely hot water is added into an electroforming groove, then nickel sulfate hexahydrate and nickel chloride are added in sequence, hot water is added into a container, then boric acid is added, boiling is carried out, then lauryl sodium sulfate is added, after dissolution, liquid is poured into the electroforming groove, saccharin and 2-butyne-1,4-diol are added into the electroforming groove, then water is injected until the electroforming groove is full, pH is adjusted to 4.2; an anode nickel plate is placed into an anode basket and is connected to a positive electrode, a nickel master mould is connected to a negative electrode, ultrasound power is adjusted to 210-300W, frequency is adjusted to 30-50kHz, pulse current density is adjusted to 1-6A / dm<2>, current frequency is adjusted to 1000Hz, working time ratio of forward currents and backward currents is adjusted to 5:1, duty ratio is adjusted to 10%-30%, electroforming is carried out, and the high-reflectance microprism reflecting film working mould is obtained after cathode demoulding.

Owner:福建跃发光新材料股份有限公司

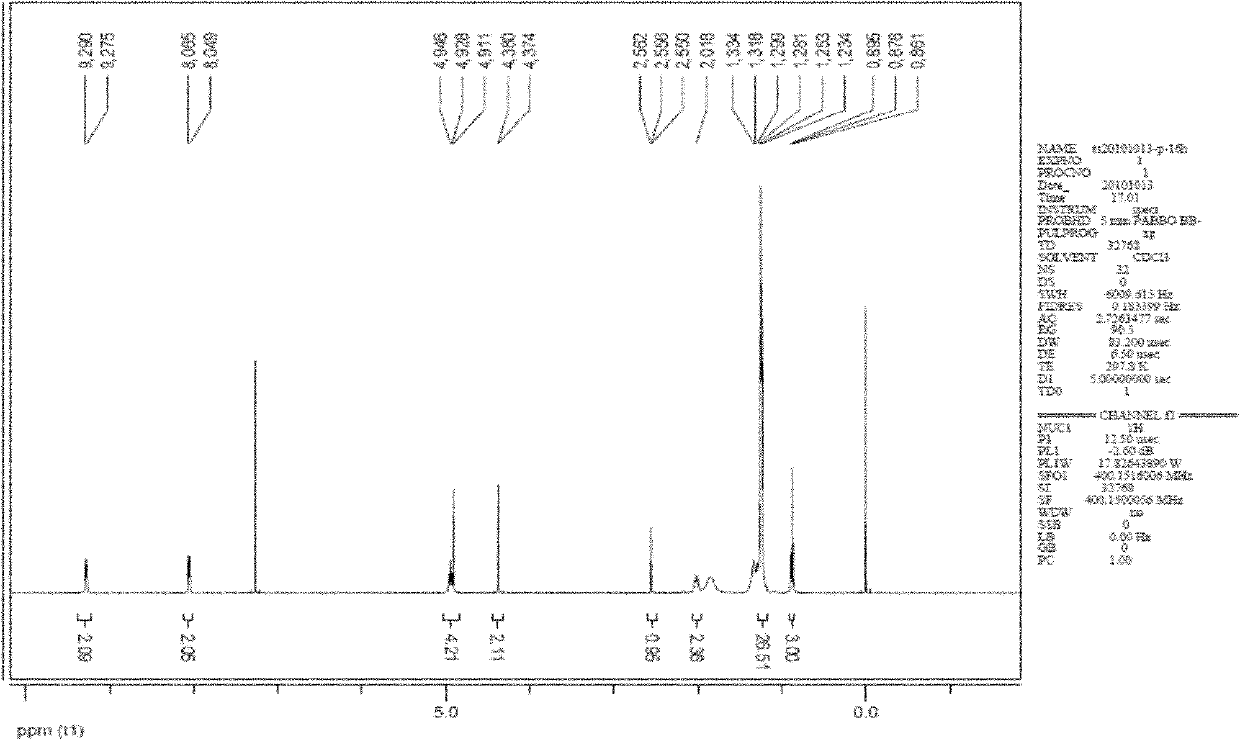

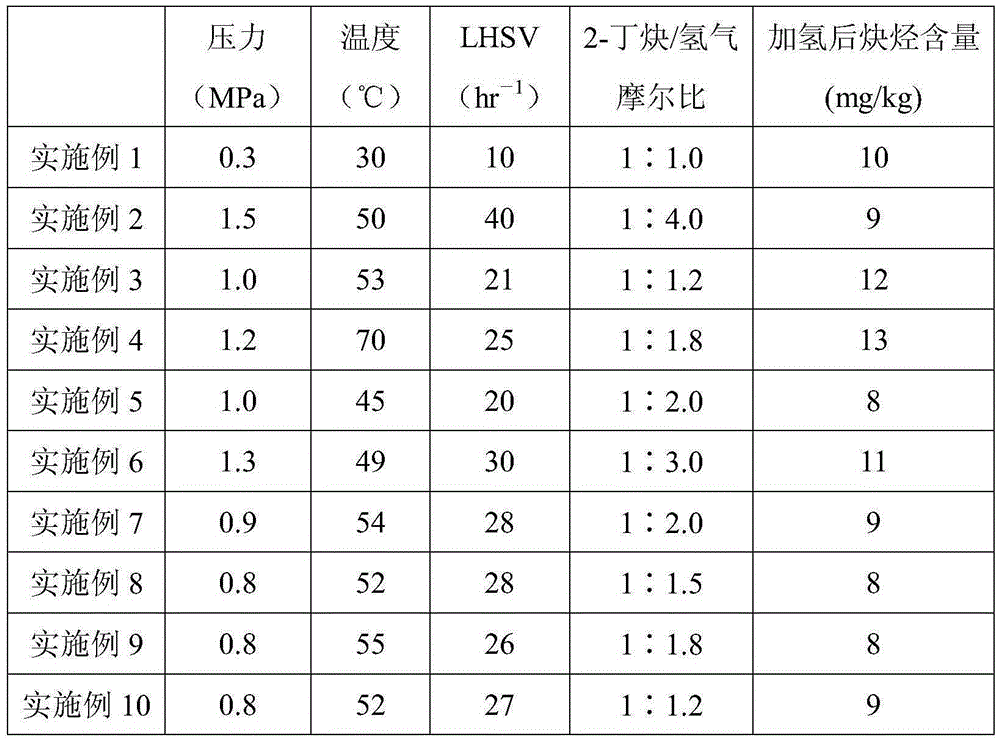

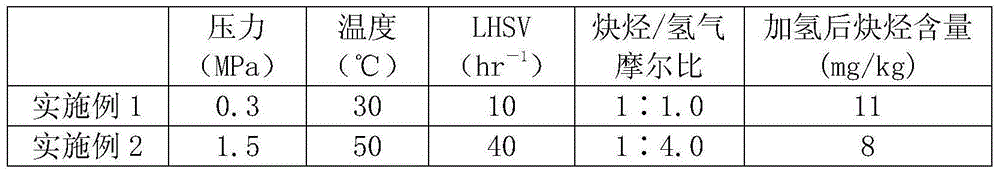

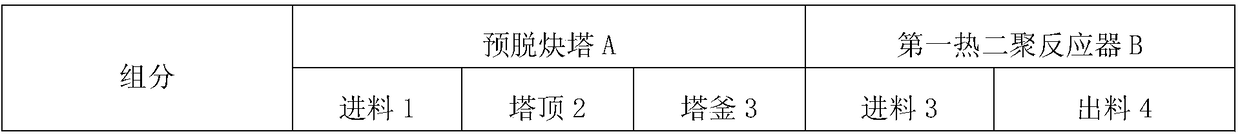

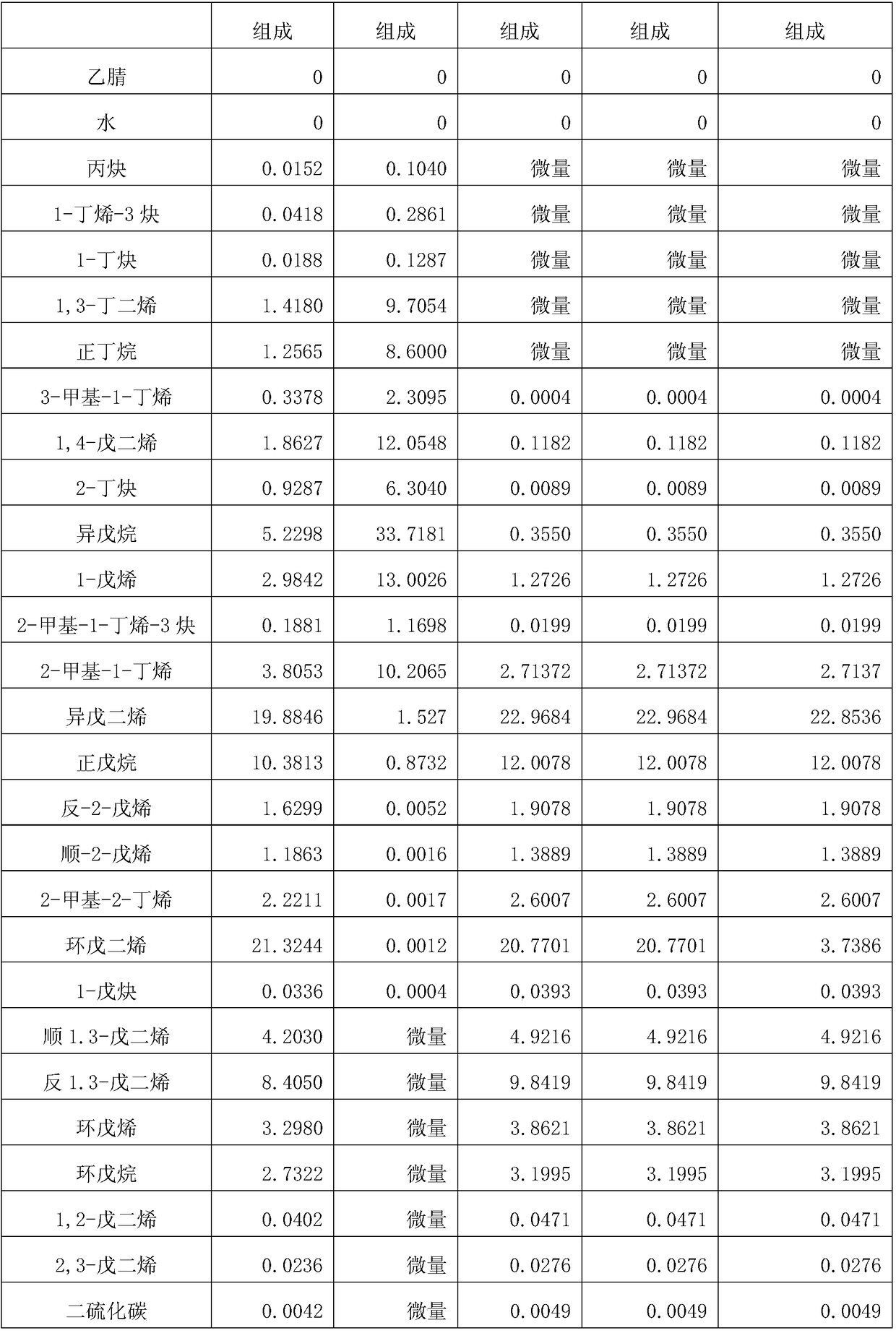

Method for removing 2-butyne by conducting selective hydrogenation on C5 fractions

InactiveCN106588553ANo emissionsNo lossHydrocarbonsAdsorption purification/separationWastewaterFixed bed

The invention belongs to the technical field of organic chemical industry, and particularly relates to a method for removing 2-butyne by conducting selective hydrogenation on C5 fractions. The method particularly comprises the following steps of 1 denitrification, wherein denitrification treatment is conducted on the C5 fractions through a fixed bed containing sulfonic group cation exchange resin and water; 2 selective hydrogenation, wherein selective hydrogenation is conducted on the C5 fractions obtained after denitrification through a bubbling bed reactor containing a Pd-Ni-Ag-M / Al2O3 catalyst, and then 2-butyne is converted into butane. The method has the advantages that the processes are simple, no wastewater is drained, the denitrification precision is high, no material is lost, and polymerization side reactions can be effectively inhibited.

Owner:CHINA PETROLEUM & CHEM CORP +1

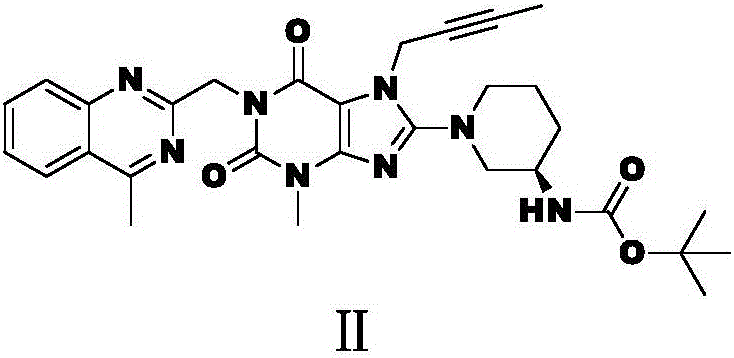

Industrial production method of linagliptin

InactiveCN106008508AHigh purityGood effect of removing impuritiesOrganic chemistryFiltrationTert-Butyloxycarbonyl protecting group

An industrial production method of linagliptin. According to the molar ratio, 8-bromo-7-(2-butyne)-3-methylxanthine and 2-chloromethyl-4-methylquinazoline are added to the dipolar aprotic organic solvent, and then the base is added and potassium iodide, crystallized, filtered and dried to obtain intermediate I; according to the molar ratio, intermediate I and (R)-3-tert-butoxycarbonylaminopiperidine were added to the dipolar aprotic organic solvent, and alkali was added to analyze crystallized, filtered and washed to remove inorganic salts, and the solvent was removed under reduced pressure to obtain the crude product, which was then crystallized from methanol and isopropanol to obtain intermediate II; according to the volume ratio, intermediate II and the deprotection reagent were added to the reaction solvent, and crystallized to obtain The crude product was recrystallized with ethanol, filtered and dried to obtain the final product of linagliptin. The method of the invention can greatly shorten the production cycle, save production cost, obtain intermediates with higher purity, and better effect of removing impurities. The method is safe, reliable, simple and easy to operate, and has good repeatability.

Owner:合肥远志医药科技开发有限公司

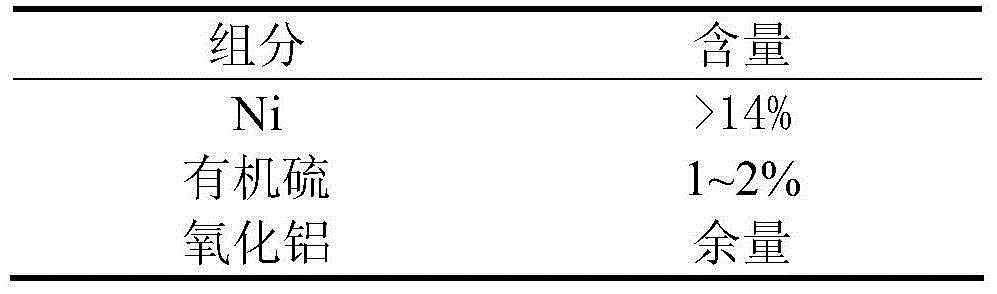

Method for removing alkynes from C5 fraction

InactiveCN106588554ANo emissionsReduce lossesHydrocarbon purification/separationHydrocarbonsHydrogenation reactionAlkyne

The invention belongs to the technical field of organic chemical engineering, and concretely relates to a method for removing alkynes from a C5 fraction. The method comprises the following steps: carrying out a selective hydrogenation reaction on a C5 fraction containing 2-butyne and pentone, obtained after an extraction and rectification process, by adopting a partially vulcanized Ni series catalyst, selectively hydrogenating the C5 fraction through a selective hydrogenation bubble column reactor to convert 2-butyne in the C5 fraction into 2-butylene, convert pentone into isoprene and effectively reduce the content of the alkynes to 15 mg / kg or less. The method allows the alkynes in the C5 fraction to be afresh used, and the hydrogenated C5 fraction and the C5 raw material are mixed to form an isoprene production raw material, so the isoprene yield and the isoprene quality are effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electro-deposition method for preparing foamed nickel-molybdenum alloy

The invention belongs to the technical field of hydrogen evolution material preparation, and particularly relates to an electro-deposition method for preparing a foamed nickel-molybdenum alloy hydrogen evolution material. The electro-deposition method comprises the following steps that (1) nickel sulfate, sodium molybdate or potassium molybdate, sodium citrate, sodium chloride or potassium chloride or nickel chloride are sequentially dissolved into deionized water to obtain a solution; (2) ethanolamine is dissolved into the solution obtained in the step (1), and the pH value of the solution is adjusted to 8.5-9.5; (3) 2-Butyne-1,4-diol and saccharin are added into the solution obtained in the step (2) so that an electro-deposition solution can be obtained; (4) electro-deposition is conducted in the single-cathode three-anode mode, wherein foamed nickel serves as the cathode, and nickel, molybdenum and titanium or nickel, molybdenum and carbon serve as the anodes; and (5) the obtained solution is heated to 50-60 DEG C, and electro-deposition is conducted with the apparent cathode current density being 125-155 mA / cm<2>. The method has the beneficial effects that ammonium hydroxide free operation can be conducted, an electro-deposition layer is good in quality, the pH value of the electro-deposition solution is stable, operation is convenient, and the content of molybdenum in nickel-molybdenum alloy reaches up to 25%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY +1

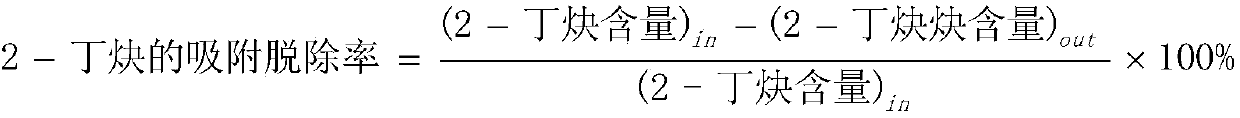

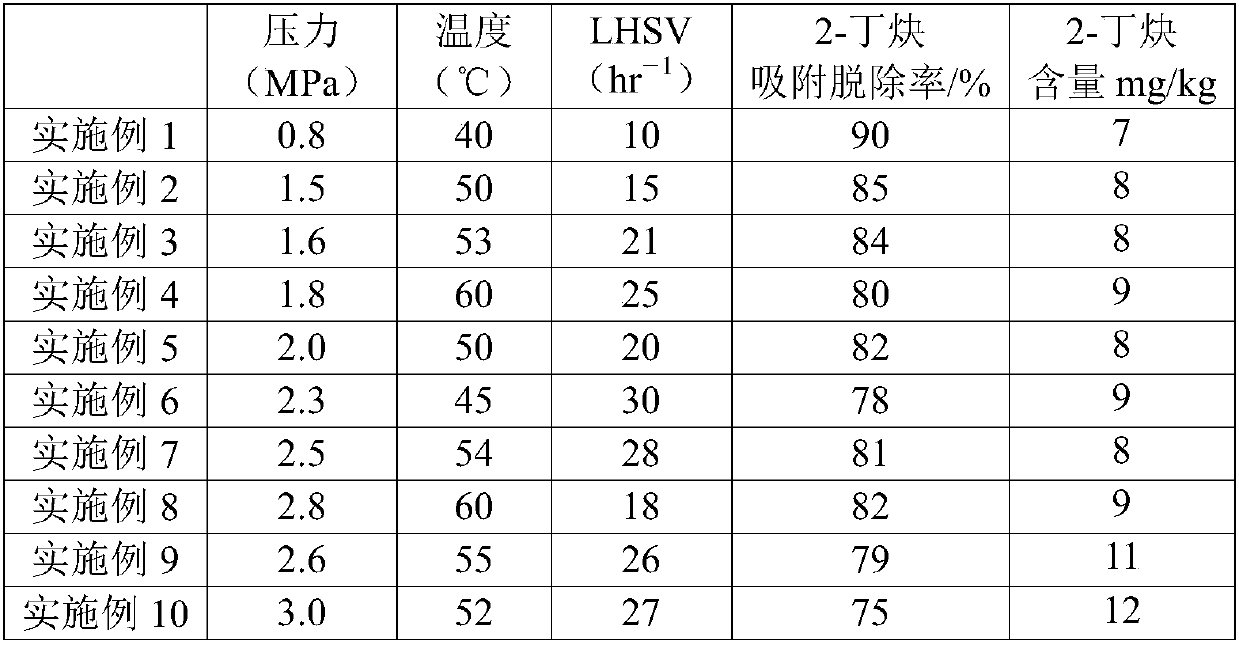

High-purity piperylene preparation method

InactiveCN109721454ANo pollution in the processHigh adsorption selectivityHydrocarbonsAdsorption purification/separationPiperyleneRaw material

The invention discloses a high-purity piperylene preparation method, wherein isoprene and cyclopentadiene are removed from C5 distillate, the obtained C5 distillate is used as a raw material, and treatment is performed through adsorption and extraction rectification to obtain the high-purity piperylene. With the method of the present invention, a small of difficultly-removed cyclopentadiene and 2-butyne can be effectively removed from piperylene; the process is simple and effective; and with the method, the high-purity piperylene with the cyclopentadiene content of less than 50 ppm and the 2-butyne content of less than 20 ppm can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

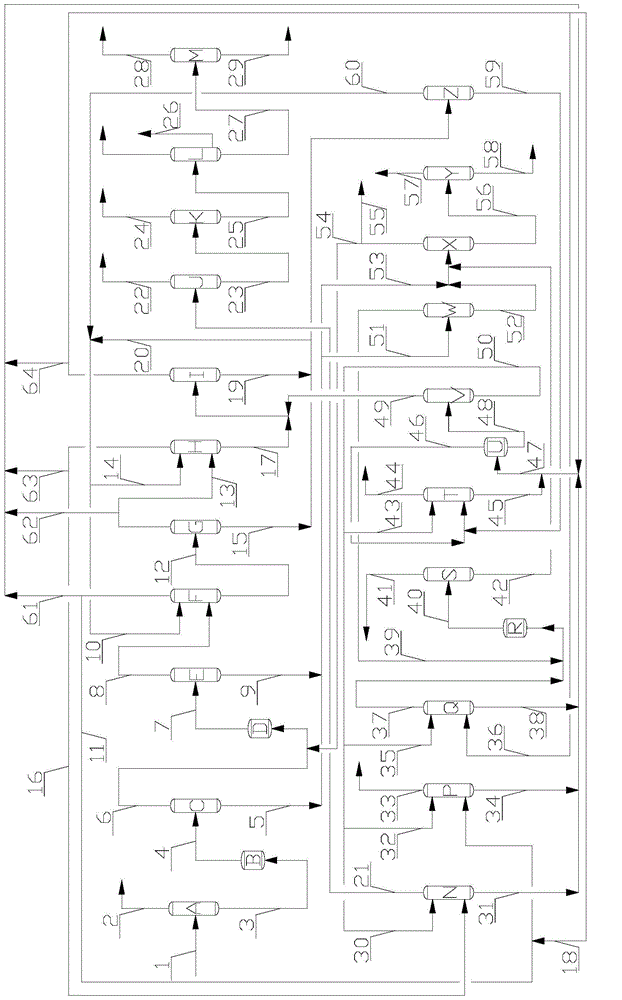

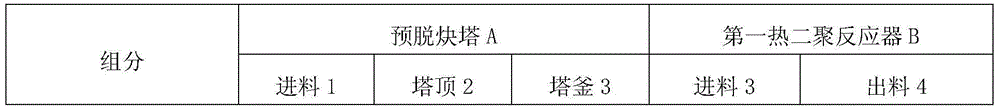

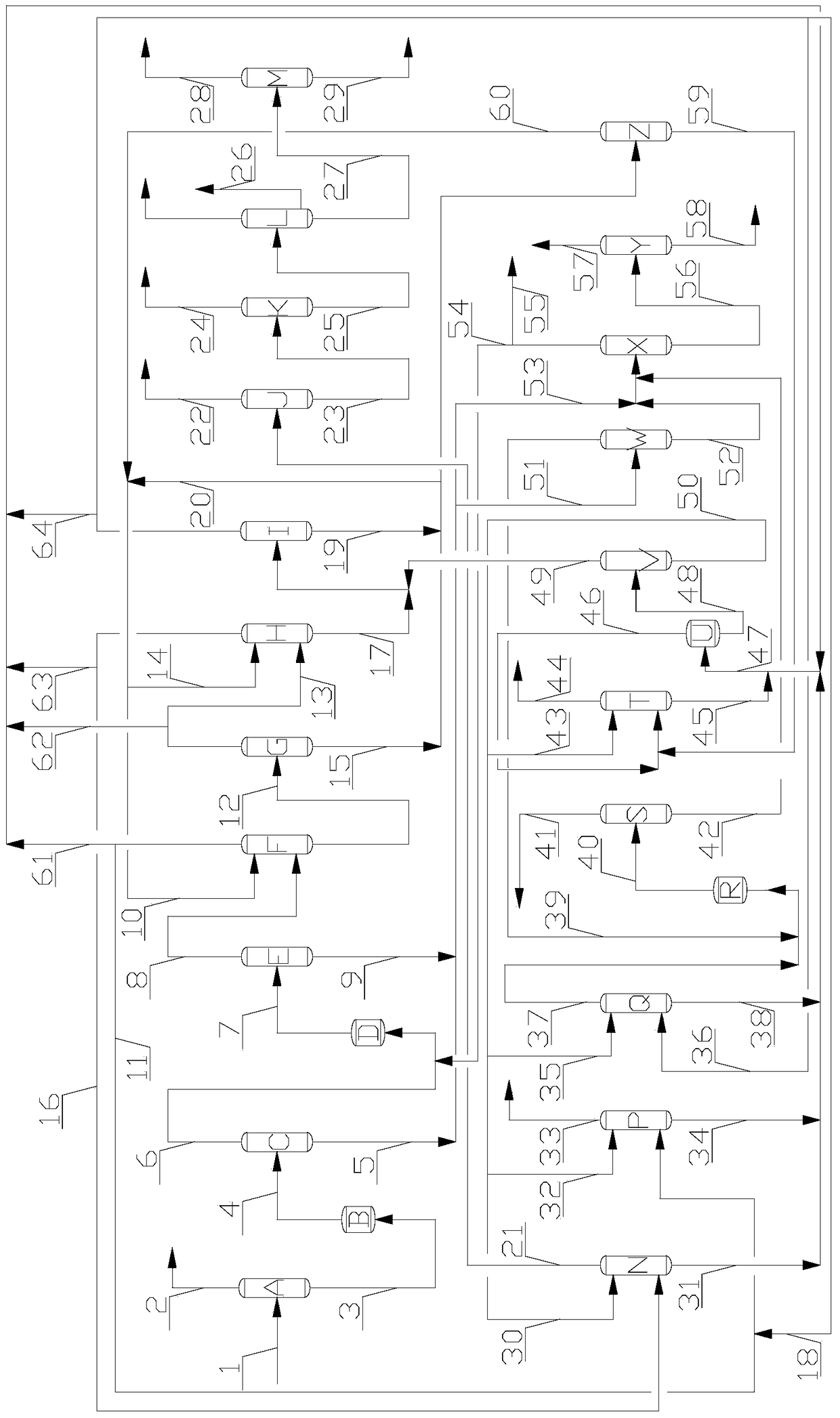

Method for separating petroleum cracking C5 fraction through acetonitrile process

ActiveCN105622327AAvoid selectivityReduced cyclopentadiene contentDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionCyclopenteneDesorption

A method for separating a petroleum cracking C5 fraction through an acetonitrile process comprises the following steps: removing most of 2-butyne and 2-methyl-1-butenyl-3-alkyne from the petroleum cracking C5 fraction in advance; adopting a continuous thermal dimerization-rectification-thermal dimerization-rectification process to make a reaction be carried out toward a dicyclopentadiene generation direction, and carrying out a series of separation processes to obtain highly pure polymeric isoprene; and carrying out flash evaporation on water washed acetonitrile, returning the evaporated acetonitrile to a double extraction desorption tower, pumping off parts of a circulating solvent, purifying, and removing polymers in the solvent. The method has the following advantages: the solvent keepshigh selectivity; production of an m-pentadiene product with the purity being greater than 70% and an m-pentadiene product with the purity being greater than 95% is realized by adopting the same flowaccording to different uses, and cyclopentene with the purity being greater than 99.5% and cyclopentane with the purity being greater than 99.8% can also be obtained; and long-term stable running ofa C5 separation device is guaranteed.

Owner:PETROCHINA CO LTD

Plastic-steel doors and windows

InactiveCN107177126AImprove impact resistanceImprove flame retardant performanceCoatingsSodium bicarbonateFiber

The invention provides plastic-steel doors and windows. The plastic-steel doors and windows are prepared from the following components of 75 to 100 parts of polyvinyl chloride resin, 15 to 25 parts of active calcium carbonate, 3 to 10 parts of plant fiber, 5 to 10 parts of flame-retardant agent, 5 to 7 parts of methacrylate-butadiene-styrene copolymer, 20 to 30 parts of water, 3 to 5 parts of nanometer barium sulfate, 5 to 7 parts of MBS (methyl methacrylate) emulsion, 2 to 3 parts of methyl (3,5-di-tert butyl-4-hydroxyphenyl)propionate, 3 to 4 parts of 2-butyne-1,4-diol, 6 to 9 parts of nanometer calcium carbonate, 2 to 3 parts of zinc laurate, 11 to 14 parts of shell powder, 1 to 2 parts of dioctyl adipate, 2 to 4 parts of lubricant, 1 to 2 parts of azodicarbonamide, 1 to 2 parts of sodium bicarbonate, 0.5 to 1 part of sodium bicarbonate, 5 to 15 parts of chlorinated polyethylene, 0 to 10 parts of acrylate anti-impact modifier, 3 to 5 parts of stabilizer and 0 to 1 part of plasticizer. The plastic-steel doors and windows have the advantages that the strength, toughness and anti-aging property are enhanced, the support is convenient, the application range is broad, the size adaptability is strong, the deformation is avoided, and the waterproof property and anti-corrosive property are greatly improved.

Owner:合肥市旺友门窗有限公司

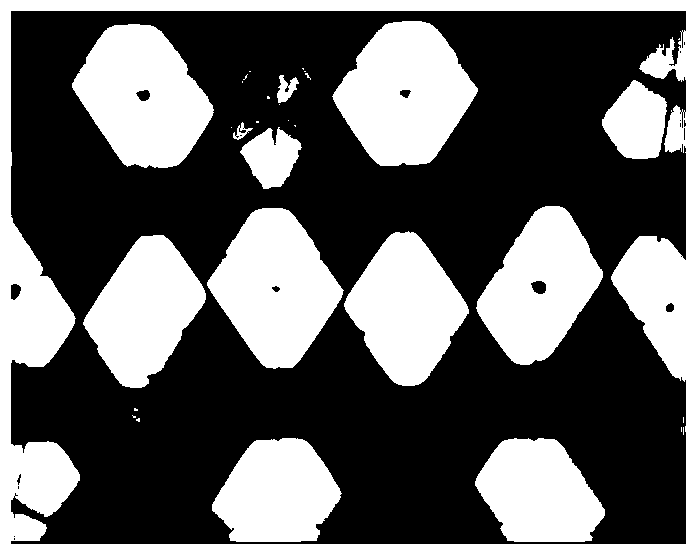

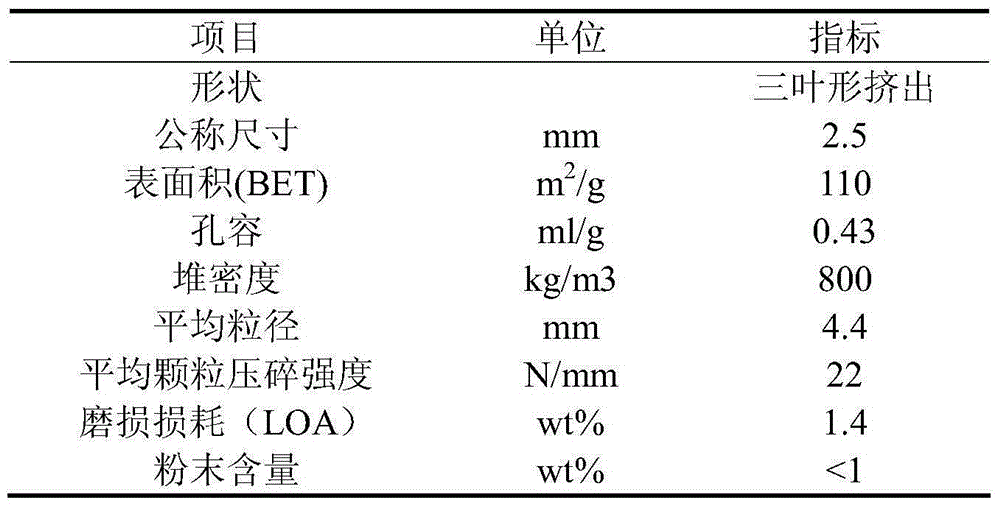

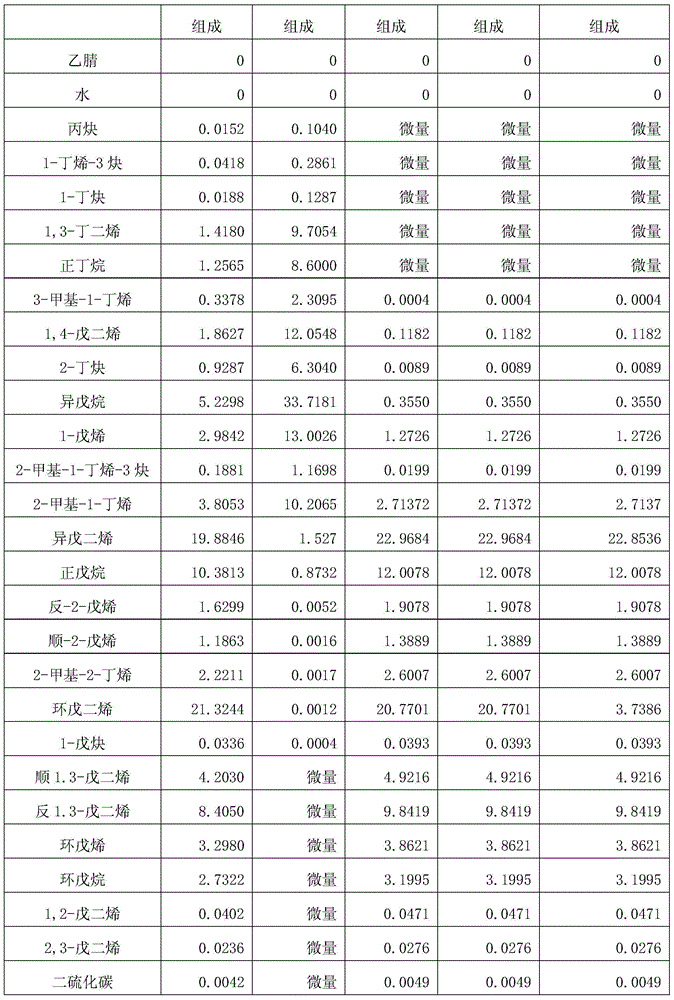

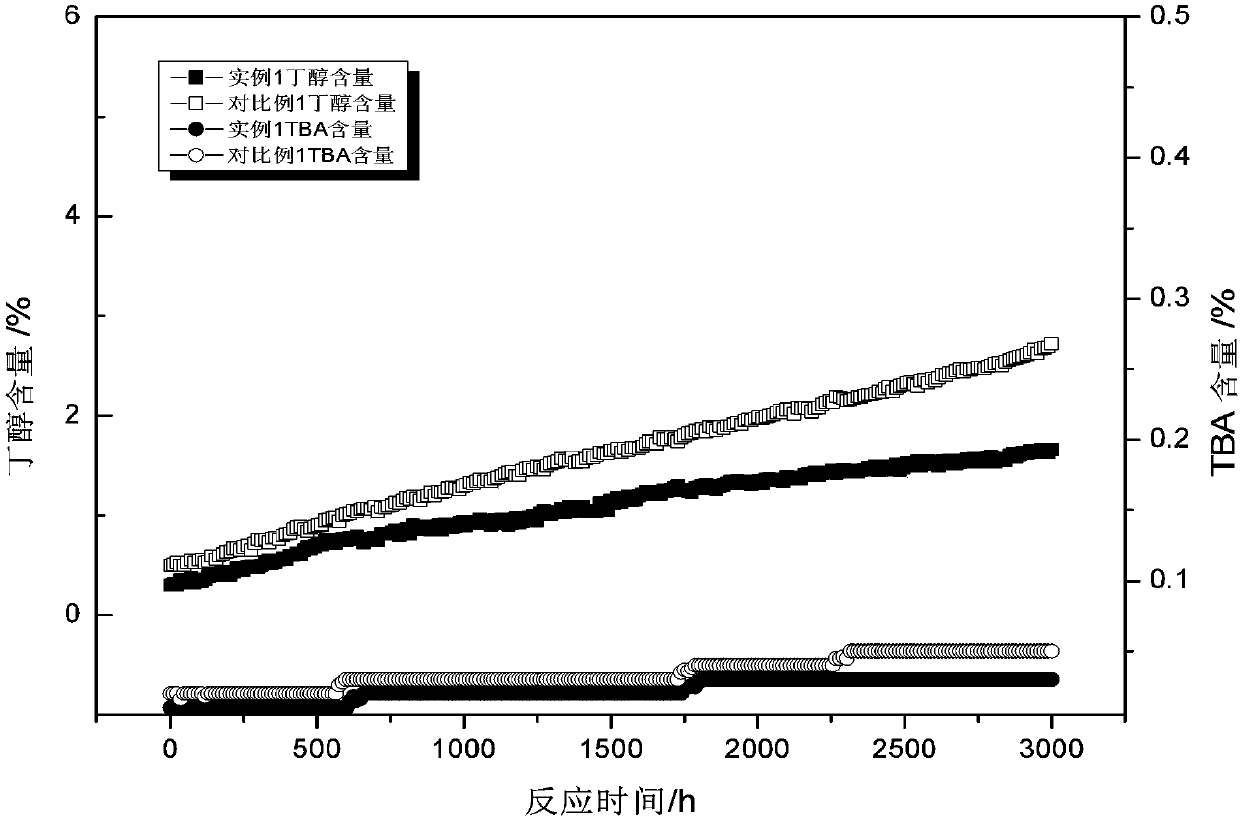

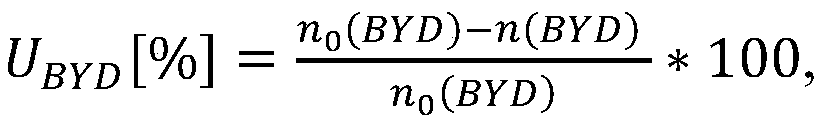

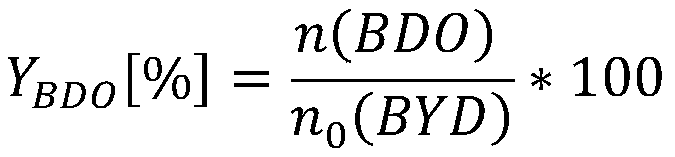

Hydrogenation catalyst filling method

ActiveCN107551959AReduce the impactExtended service lifePreparation by hydrogenationChemical/physical processesHydrogenation reactionHigh pressure

The invention discloses a hydrogenation catalyst filling method. According to the hydrogenation catalyst filling method, grading filling is adopted, and a fixed bed reactor and two hydrogenation catalysts of different sizes are provided; the larger hydrogenation catalyst is injected into the upper part and the lower part of an internal cavity of the fixed bed reactor, and the smaller hydrogenationcatalyst is injected into the middle part of the internal cavity of the fixed bed reactor. The invention also discloses a method used for preparing 1,4-Butanediol (BDO) via high pressure hydrogenation of 2-Butyne-1,4-diol (BYD) based on the hydrogenation catalyst filling method. The method is capable of reducing the contents of BYD high pressure hydrogenation by-product butanol and impurities, reducing influences of catalyst residue on BYD hydrogenation catalysts in BYD preparation process, and prolonging the service life of the BYD hydrogenation catalysts.

Owner:SHANGHAI XUNKAI NEW MATERIAL TECH

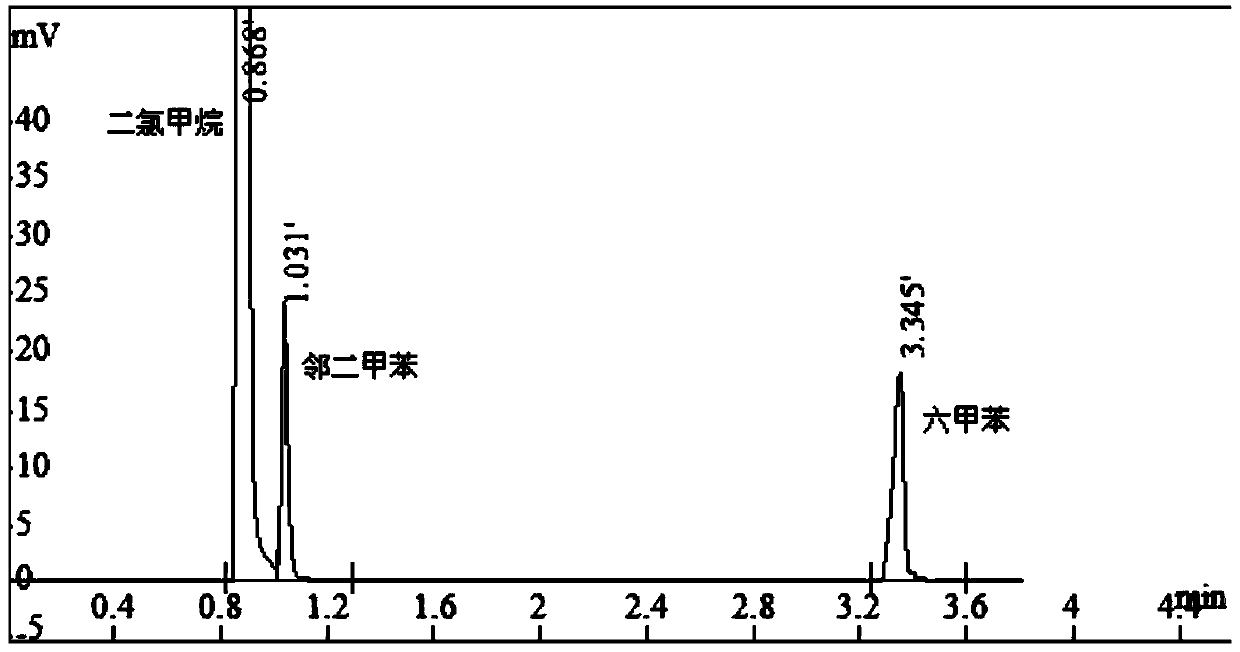

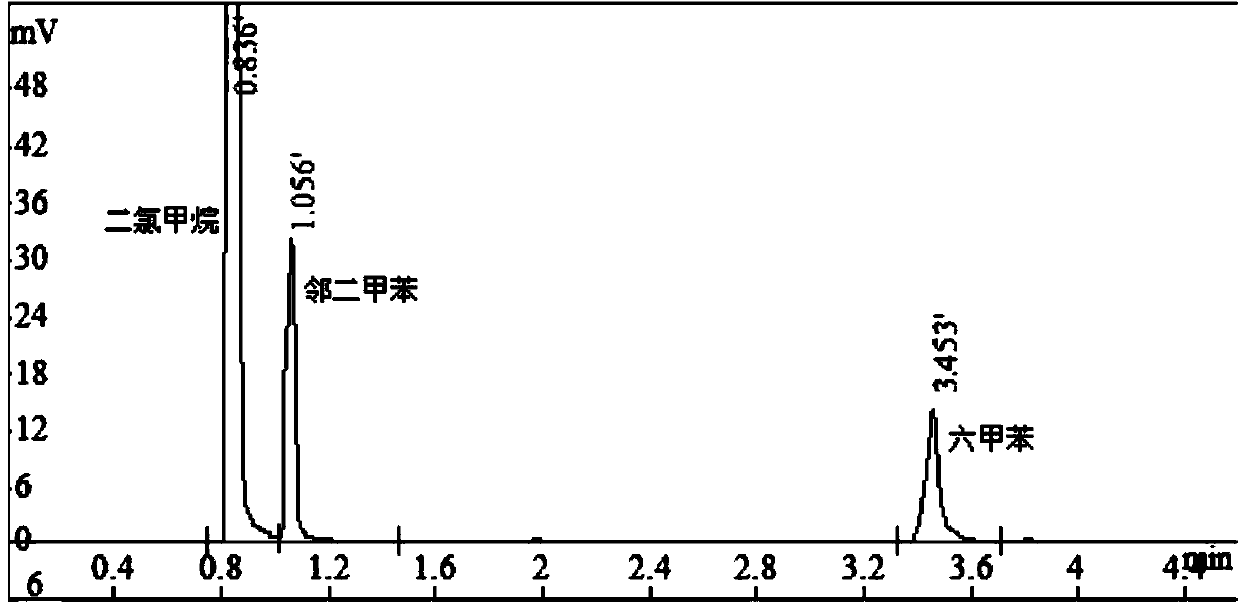

Method for preparing hexamethylbenzene by taking 2-butyne as raw material

InactiveCN104311379AHigh yieldIncrease profitHydrocarbonsHydrocarbon preparationHexamethylbenzeneCopper chloride

The invention relates to a method for preparing hexamethylbenzene by taking 2-butyne as a raw material in the technical field of organic synthesis. The method comprises the following step: in the presence of a palladium chloride catalyst and a copper chloride cocatalyst, taking 2-butyne and a solvent, carrying out reaction at normal pressure and at 45-65 DEG C to obtain hexamethylbenzene, wherein the mass ratio of the palladium chloride catalyst to 2-butyne is 1: (10-15), the mass ratio of the palladium chloride catalyst to the copper chloride cocatalyst is 1: (3-6), and the mass ratio of the solvent to 2-butyne is (3-8): 1. The production process provided by the invention is mild in reaction condition and only stirring at 45-65 DEG C is needed. The production process provided by the invention is relatively high in yield which is near 60%. Compared with the yield (20-30%) of the conventional process, the yield is nearly doubled. The production process and operation are relatively simple and convenient, the utilization ratio of raw materials is high, and less byproducts and three wastes (waste water, waste gas and industrial residue) are generated.

Owner:SHANGHAI CHENGYING NEW MATERIALS

Environment-friendly high-brightness medium-phosphorus chemical nickel-plating additive

ActiveCN103726036BReduce dosageAchieve full brillianceLiquid/solution decomposition chemical coatingPorosityRhenium

The invention discloses an environment-friendly high-brightness medium-phosphorus chemical nickel-plating additive which is composed of components A and B, wherein the component A comprises the following raw materials: a 2-5mg / L mixture of nano copper and a soluble copper salt, 2-4mg / L rhenium sulfate, 1-4mg / L sodium allysulfonate (ALS), a complexing agent, a stabilizer, and 20-40g / L NaOH; the component B comprises the following raw materials: 1-4mg / L 1,4-bis(2-hydroxyethoxy)-2-butyne (BEO), 1-3mg / L N,N-diethylaminopropyne (DEP), 1-4mg / L dibenzenesulfonimide (BBI), and 2-4mg / L sodium hydroxymethanesulphonate (PN). The formula of the environment-friendly high-brightness medium-phosphorus chemical nickel-plating additive provided by the invention contains no heavy metal ions such as cadmium and lead, and is harmless to the environment; if applied to a chemical nickel-plating solution, the additive is capable of keeping the plating solution stable so that the obtained coating is even and compact, low in porosity, high in brightness and good in nitric acid resistance; more specifically, even though the nickel coating is soaked in concentrated nitric acid for 300 seconds, the nickel coating does not change color.

Owner:HARBIN SAN YONG GONG DA SCI & TECH

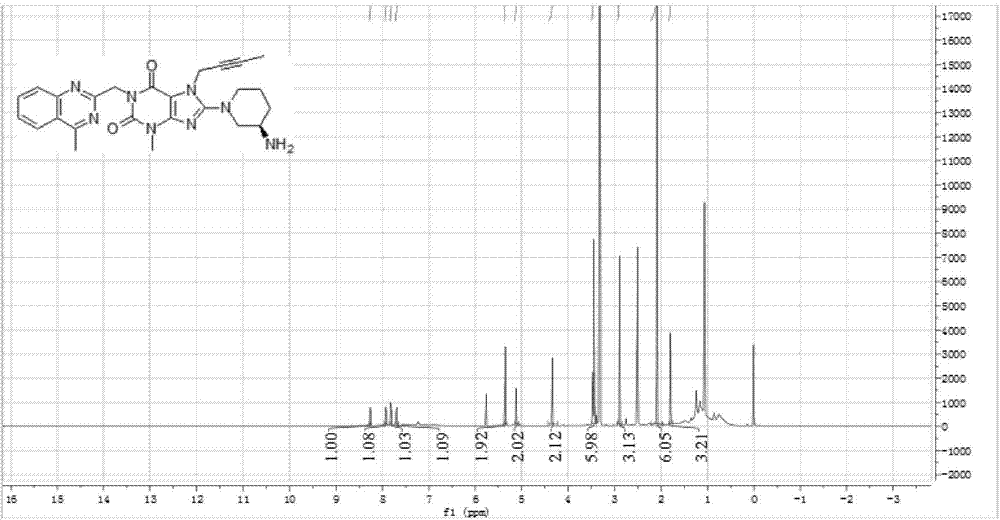

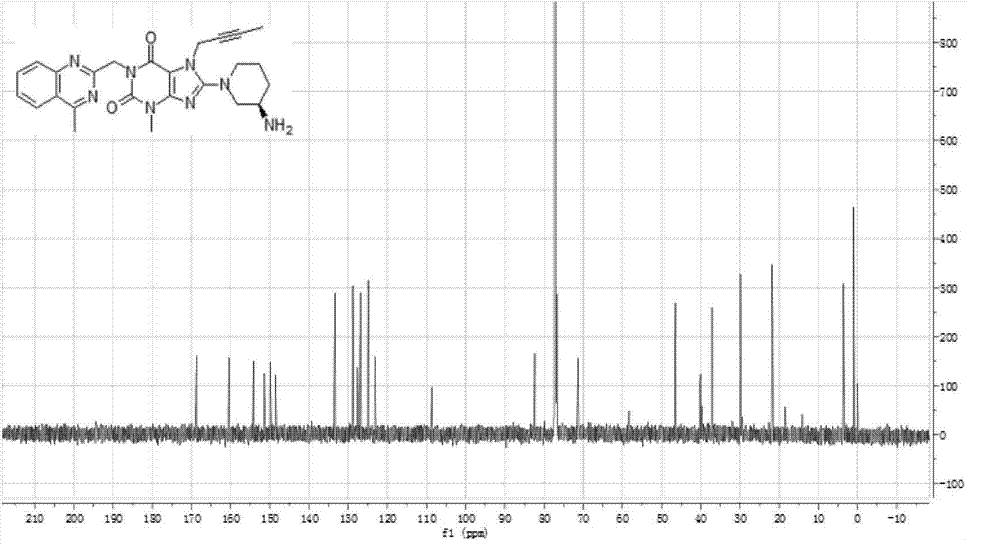

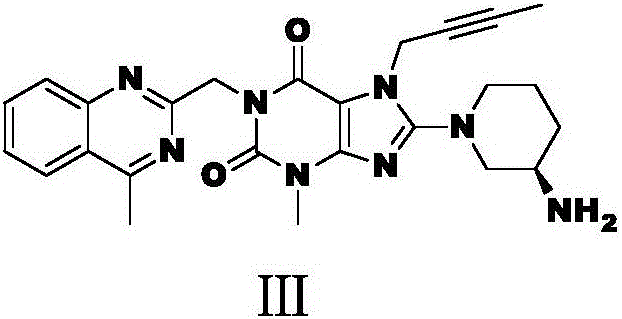

A kind of preparation method of linagliptin and its intermediate

ActiveCN105440034BMild reaction conditionsEasy to operateOrganic chemistrySolventNucleophilic substitution

The invention belongs to the field of pharmaceutical chemicals, and in particular relates to a preparation method of linagliptin and an intermediate thereof. The preparation method comprises the following steps: carrying out Mitsunobu reaction on a compound I and 2-butyne-1-alcohol in an organic solvent in the presence of trialkyl phosphine and an azo-reagent to obtain a linagliptin intermediate compound II; carrying out substitution reaction on the compound II and (R)-3-aminopiperdine by taking isopropanol as a solvent and tri-n-butylamine as an acid-binding agent to obtain a compound III; and carrying out alkylation reaction on the compound III and 4-methyl-2-chloro-methyl-quinazolin to obtain linagliptin. According to the preparation method provided by the invention, the Mitsunobu reaction is innovatively adopted to prepare the compound II, so that the preparation method has the advantages of mild reaction condition, reasonable operation, high selectivity, high product quality and the like. Moreover, by controlling the reaction condition, the compound III and R-3-aminopiperdine or an inorganic acid salt or an organic acid salt thereof are directly subjected to nucleophilic substitution to generate linagliptin, and the method does not have protection and de-protection processes of amino groups, so that the reaction steps are reduced, the reaction process is simpler, the cost is reduced, and the purity of an obtained product is relatively improved.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD

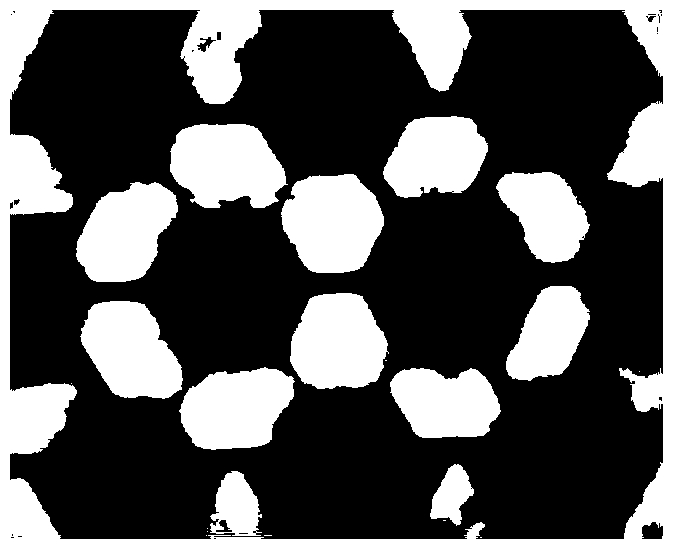

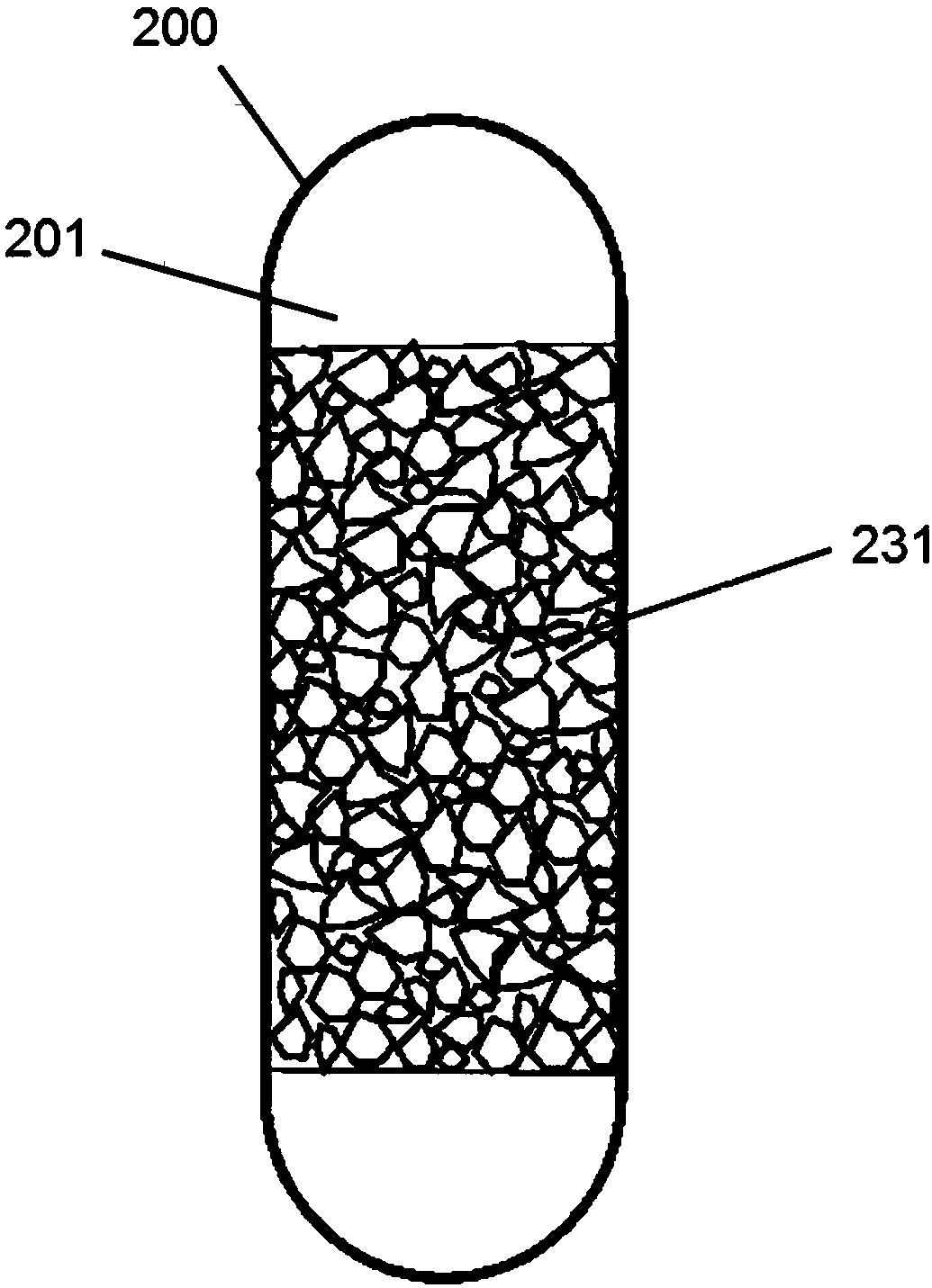

Process and catalyst for preparing 1,4-butanediol

PendingCN109789391AOrganic compound preparationPreparation by hydrogenationPolymer scienceVolumetric Mass Density

The present invention relates to a process for preparing 1,4-butanediol (BDO) by hydrogenating 2-butyne-1,4-diol (BYD) or 4-hydroxybutanal (4-HBA) in the presence of a catalyst of the Raney type having a porous foam structure, wherein the macroscopic pores have sizes in the range of 100 to 5000 mum, and a bulk density of up to 0.8 kg / L.

Owner:EVONIK OPERATIONS GMBH

Manufacturing method of nickel-tungsten plating layer

The invention provides a manufacturing method of a nickel-tungsten plating layer. A plating solution consists of 0.15-0.45 mol / L nickel chloride, 0.1-0.25 mol / L nickel sulfate, 0.1-0.2 mol / L sodium sulfate, 0.1-0.3 mol / L sodium hydrogen phosphate, 0.5-2 mol / L citric acid, 0.001-0.005 ml / L OP-10, 0.1-0.2 g / L 1,4-dihydroxy-2-butyne, and 0.1-0.4 mol / L sodium tungstate. An electrodeposition technology comprises the following steps of enabling the current density to be 3-15 A.dm<-2>, and enabling the temperature of the plating solution to be 20-40 DEG C. The manufacturing method disclosed by the invention has the advantages of being simple in technology, low in cost, simple in pre-processing, high in stability of the plating solution, long in cycle life and the like, so that large-scale production of the nickel-tungsten plating layer can be realized.

Owner:TIANJIN RUISAIKE NEW MATERIAL TECH CO LTD

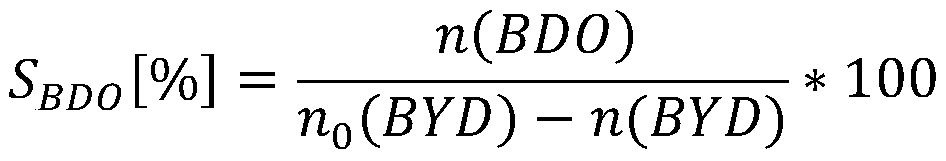

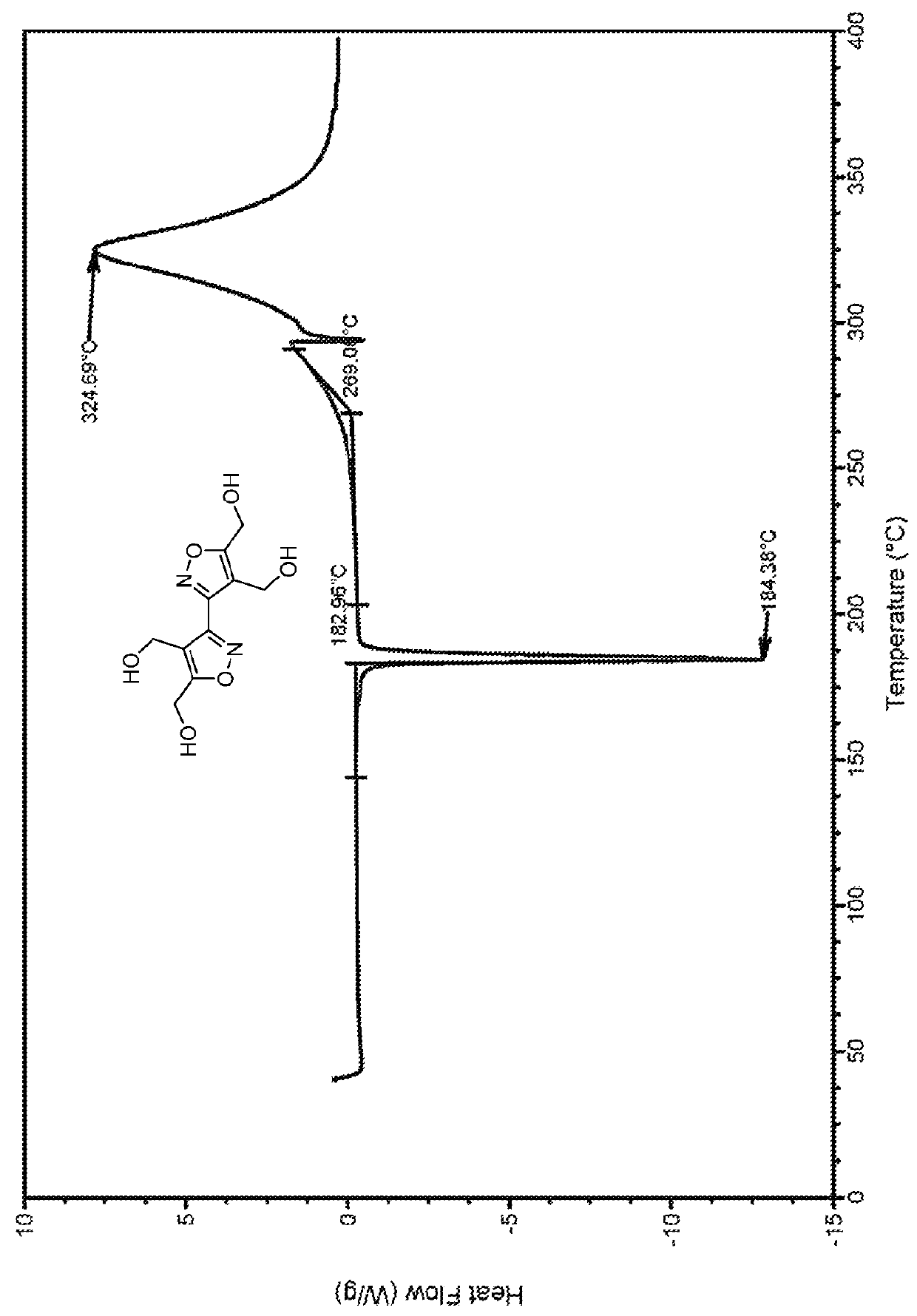

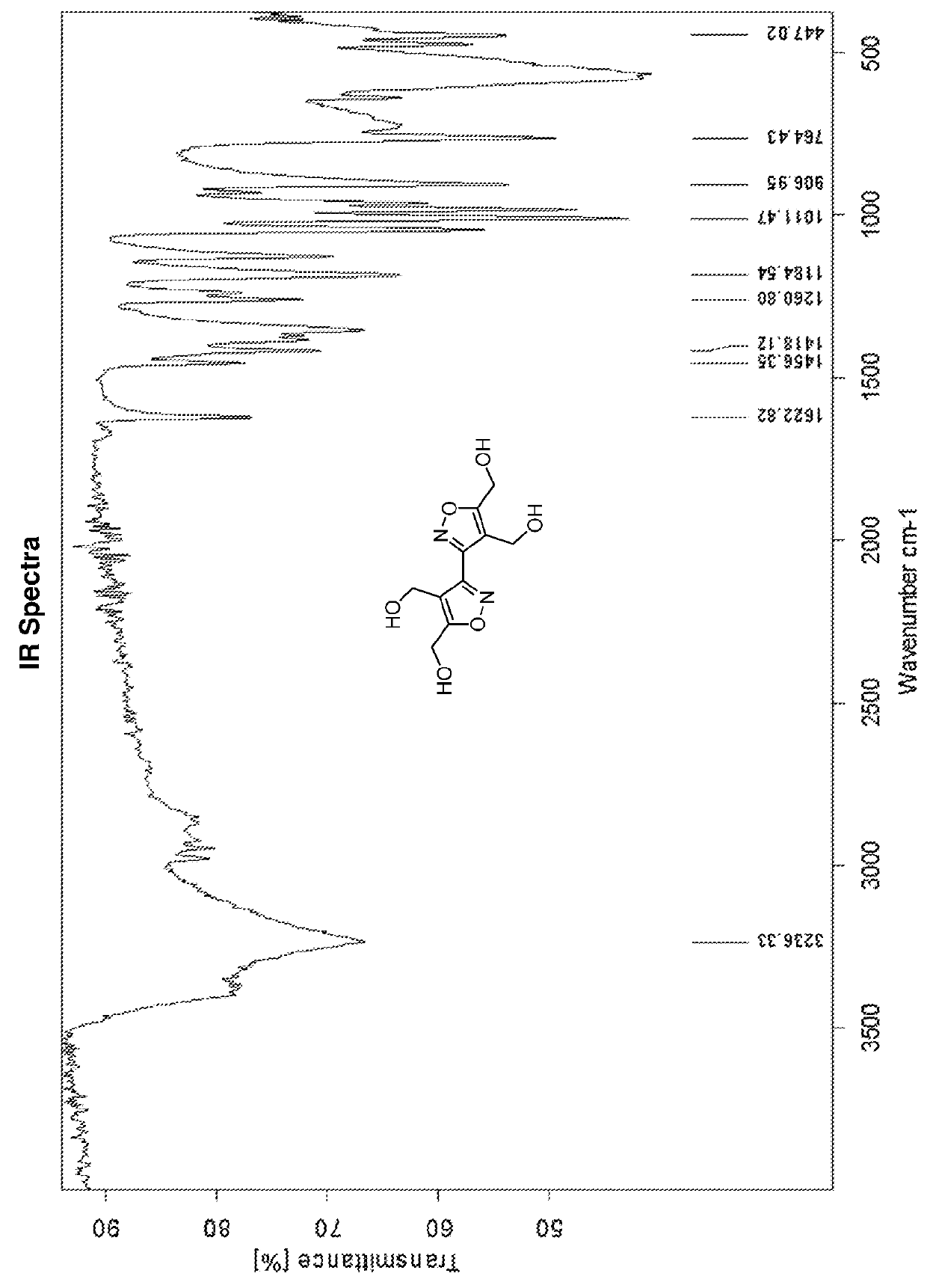

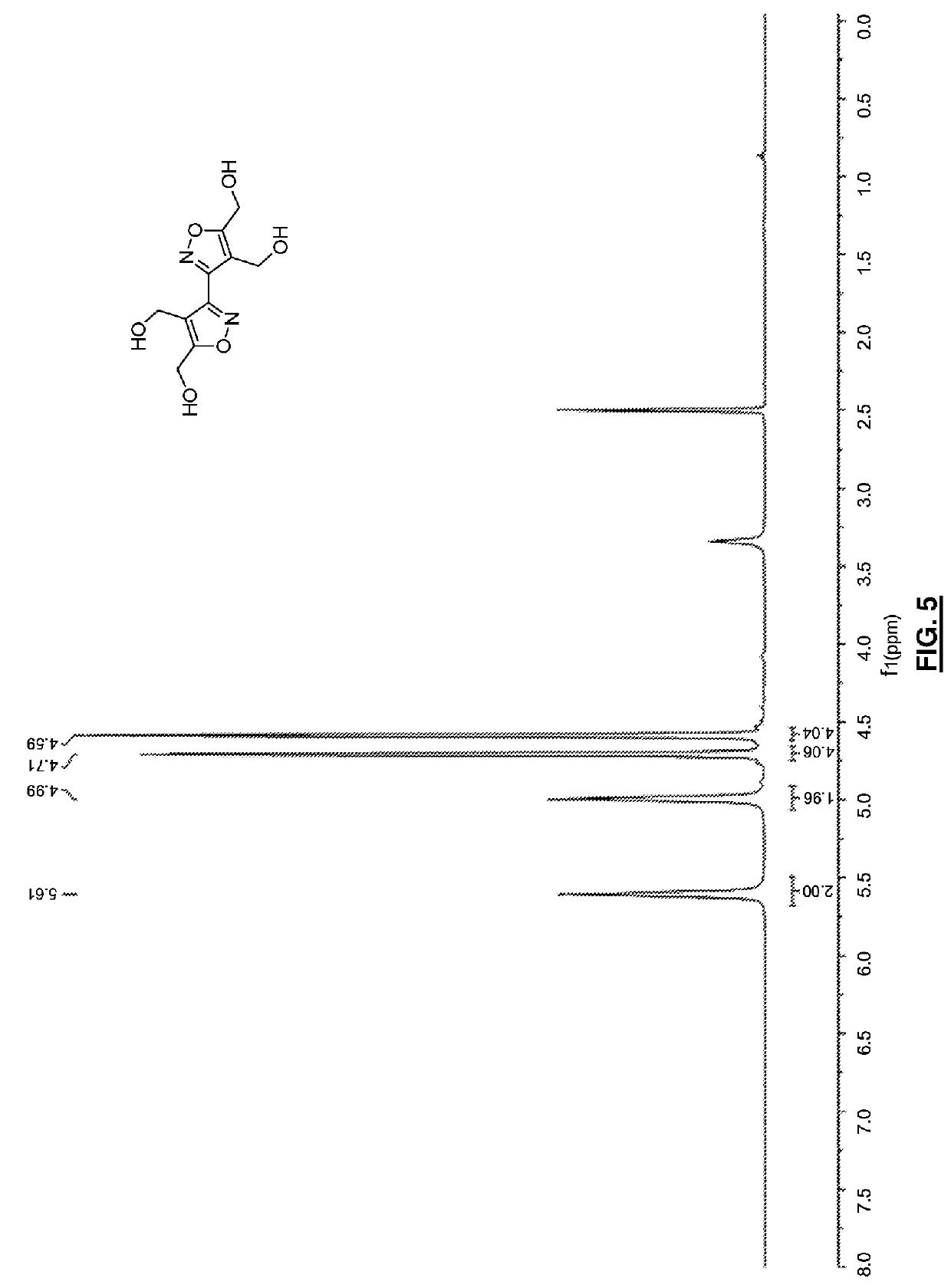

Bis-isoxazole tetranitrate (BITN): a high-energy propellant plasticizer and melt-castable eutectic explosive ingredient

A method and compound includes mixing a salt compound to 2-butyne-1,4-diol in an alcohol to create a mixture; adding a solution of dichloroglyoxime in an alcohol to the mixture to create 3,3′-bis-isoxazole-4,4′,5,5′-tetryltetramethanol; and nitrating the 3,3′-bis-isoxazole-4,4′,5,5′-tetryltetramethanol to create 3,3′-bis-isoxazole-4,4′,5,5′-tetrylbis(methylene) tetranitrate, which has the structural formula:The alcohol may include ethanol, wherein the adding may occur at 60° C., or alternatively the adding may occur at 80° C. The alcohol may include n-butanol, wherein the adding may occur at 100° C., or alternatively the adding may occur at 120° C. The mixing may occur at 120° C. The method may further include cooling the nitrated 3,3′-bis-isoxazole-4,4′,5,5′-tetryltetramethanol to 0° C.; stirring the cooled nitrated 3,3′-bis-isoxazole-4,4′,5,5′-tetryltetramethanol for at least four hours creating a precipitate; warming the precipitate; pouring the precipitate onto ice while stirring creating a solid material; collecting the solid material; and drying the solid material to yield the 3,3′-bis-isoxazole-4,4′,5,5′-tetrylbis(methylene) tetranitrate.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Preparation method for hexafluoro-2-butyne

InactiveCN110627613AShort reaction pathHigh yieldPreparation by halogen replacementHydrogen fluorideSolvent

The invention belongs to the technical field of chemical engineering, and particularly relates to a preparation method for hexafluoro-2-butyne. The preparation method for the hexafluoro-2-butyne provided by the invention comprises the following step: performing a reaction on hexachloro-2-butyne and hydrogen fluoride under the conditions of a catalyst and a solvent to obtain the hexafluoro-2-butyne. According to the method, the hexachloro-2-butyne is used as a starting material, the hydrogen fluoride is used as a fluorinating reagent, and the hexafluoro-2-butyne is prepared in one step by fluorine-chlorine exchange. The preparation method provided by the invention has the advantages of a short reaction route, a high yield, basically no three waste (waste water, waste gas and solid waste), and a mild and controllable reaction process, and is suitable for industrial scale-up production.

Owner:GUANGDONG POWER GRID CO LTD +1

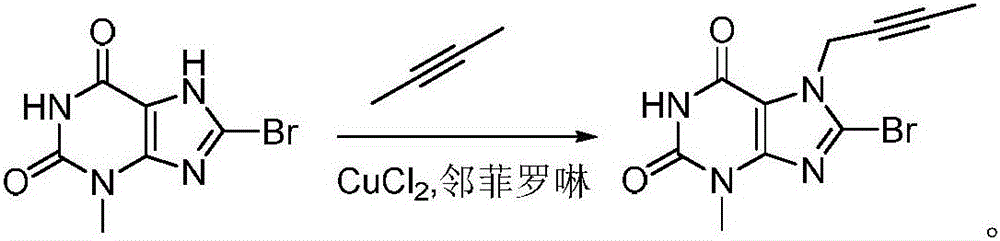

Preparation method of linagliptin intermediate for treating type-II diabetes mellitus

ActiveCN109705122AEasy to operateMild conditionsOrganic chemistryMetabolism disorderOrganic solventPurine

The invention provides a preparation method of a linagliptin intermediate for treating type-II diabetes mellitus. According to the preparation method of the intermediate 8-bromo-3,7-dihydro-3-methyl-9-(2-butynyl)-1H-purine-2,6-dione, 8-bromo-3,7-dihydro-3-methyl-1H-purine-2,6-dione reacts with 2-butyne in an organic solvent in the presence of a copper catalyst and a cocatalyst to prepare the 8-bromo-3,7-dihydro-3-methyl-9-(2-butynyl)-1H-purine-2,6-dione. Operation is simple, conditions are mild, relatively high yield and purity are obtained, and the preparation method is suitable for large-scale industrial production.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

A kind of method of acetonitrile method separation petroleum cracking carbon five distillates

ActiveCN105622327BAvoid selectivityReduced cyclopentadiene contentDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionCyclopenteneDesorption

Owner:PETROCHINA CO LTD

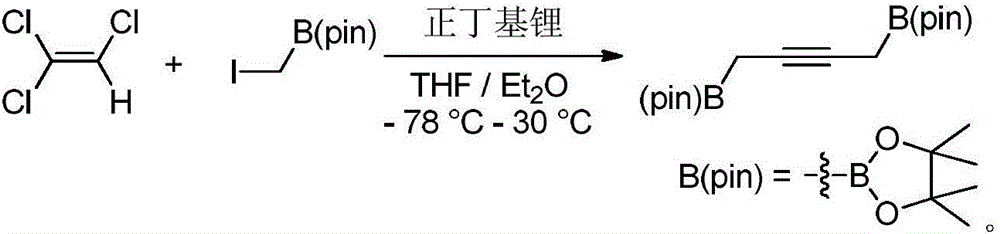

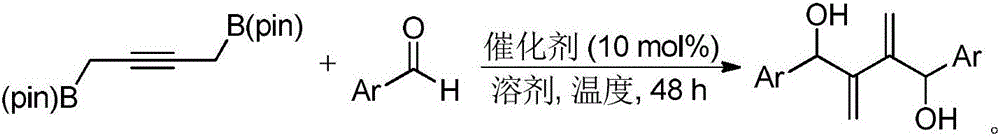

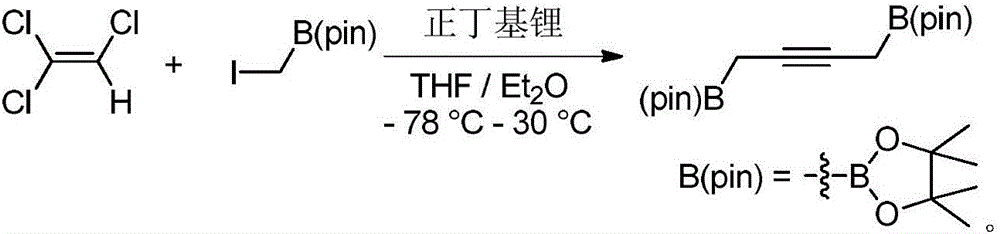

Preparation method and application of 1,4-diboric acid ester-2-butyne

ActiveCN106565759ASimple and fast operationOrganic compound preparationHydroxy compound preparationAlcoholOrganic synthesis

The invention relates to a preparation method and application of 1,4-diboric acid ester-2-butyne. The preparation method comprises the steps of performing pinacol ester reaction of trichloro ethylene and iodine methylene boric acid by regarding n-butyllithium as alkali, and obtaining a product 1,4-diboric acid ester-2-butyne through separation and purification; performing tandem propargyl / guildline alkenyl reaction on 1,4-diboric acid ester-2-butyne and aromatic aldehyde to prepare a 1,3-butadiene-2,3-di-secondary alcohol compound. The preparation method is simple and convenient to operate; the used reagents are nontoxic, green and environment-friendly; the prepared 1,3-butadiene-2,3-di-secondary alcohol compound can be further subjected to derivatization through Diels-Alder or Shapless epoxidation reaction, and is an important organic synthon.

Owner:湖北航聚科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com