Method for removing alkynes from C5 fraction

A technology for C5 fractions and medium alkynes, which is applied in the field of removing alkynes in C5 fractions, can solve the problems of increased operating costs and energy consumption, high loss of isoprene, low alkyne content, and the like, and achieves reduced operating costs. Severity, product quality improvement, effect of reducing prenyne and 2-butyne content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0022] 1. Raw material of C5 distillate

[0023] The C5 fractions used in Examples 1-10 come from the C5 separation device and are in the isoprene production unit. The components of the C5 fraction are shown in Table 1.

[0024] Table 1. Components of the C5 fraction

[0025] components C5 fraction Total C4,% 0.02 3-Methylbutene-1,% 0.01 1.4-Pentadiene,% 0.02 2-Butyne,% 1.17 Prenyne,% 1.91 2-Methylbutene-1,% 0.02 Isoprene,% 98.23 2-Methylbutene-2,% 0.00 Cyclopentadiene,% 0.00 Cyclopentene,% 0.00 Other C5,% 0.00 Dimethylamine,% 0.5 pH 10

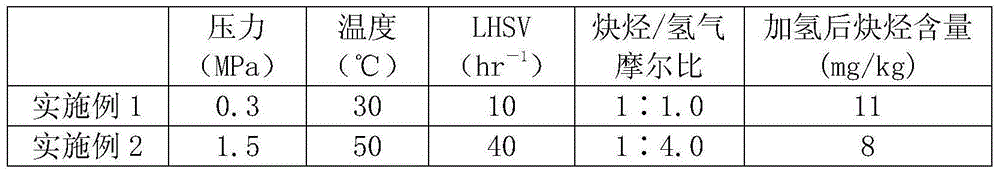

[0026] 2. Selective hydrogenation of C5 fraction

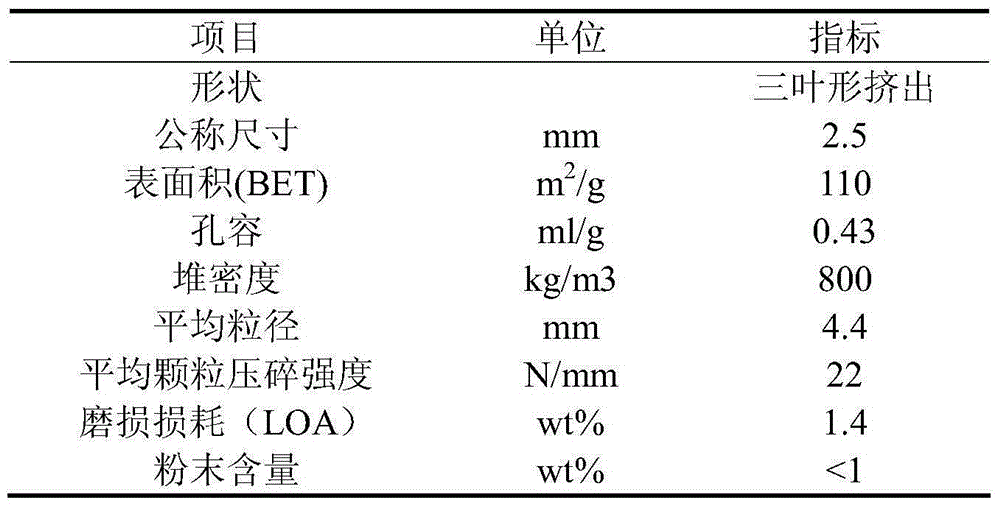

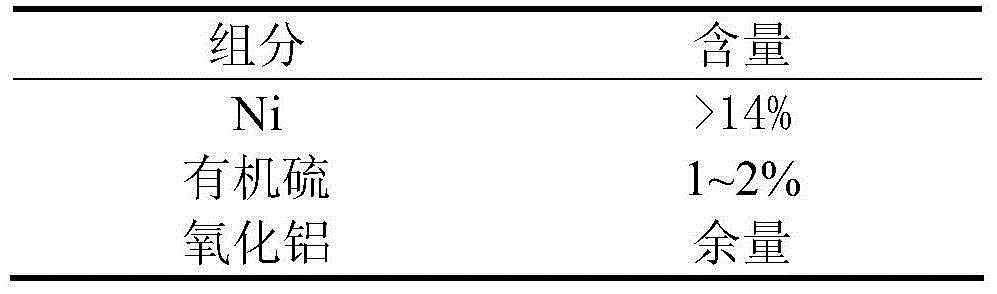

[0027] The selective hydrogenation of the C5 fraction is carried out in a stainless steel tubular bubbling bed reactor with a size of φ25mm×1500mm. 100ml of selective hydrogenation catalyst (HTC NI 400RPS 2.5mm) packed in the reactor. The catalyst was produced by Johnson Matthey Catalyst Company. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com