Method for separating petroleum cracking C5 fraction through acetonitrile process

A C5 fraction, petroleum cracking technology, applied in the field of cyclopentene and cyclopentane, piperylene, isoprene, cyclopentadiene, can solve the problem that cyclopentene and cyclopentane are not separated, acetonitrile Solvent light hydrocarbon pollution, pollution of solvent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

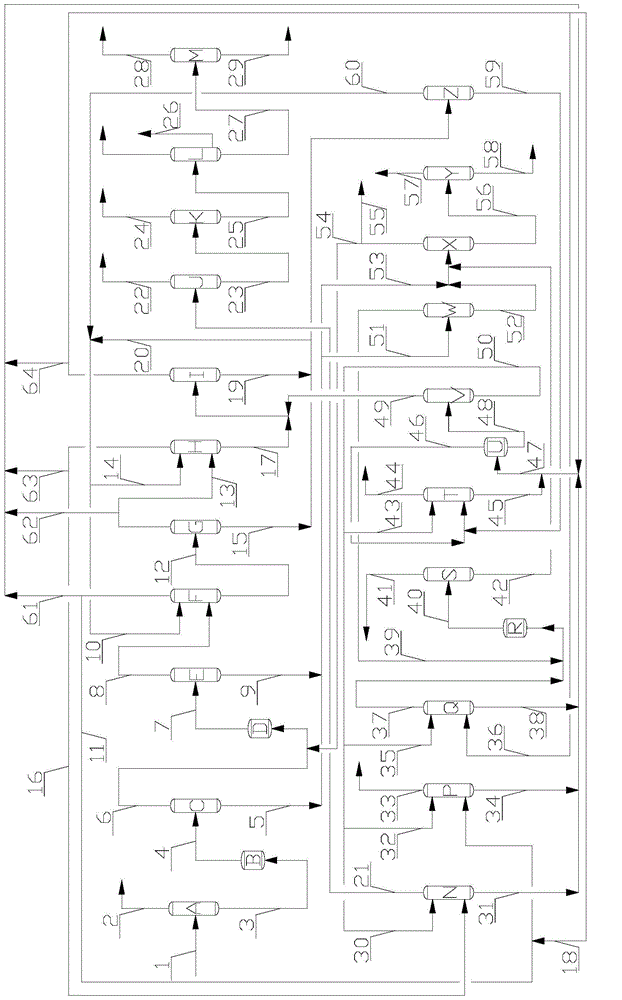

[0237] according to figure 1 The technical process, without using the cyclopentene refining tower L, the cyclopentane refining tower M and the piperylene washing tower Q, can obtain the isoprene product with a purity of 99.9%, and the piperylene with a purity of 77%. product, a dicyclopentadiene product with a purity of 95.7%.

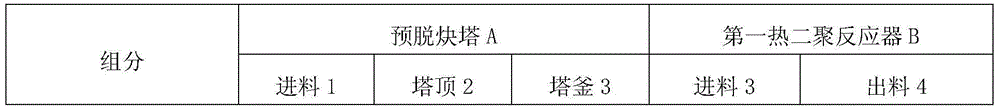

[0238] The first material 1 of the carbon five fraction produced by petroleum cracking is sent to the alkyne removal tower A from the 77th plate, and the second material 2 rich in isopentane and a small amount of isoprene is obtained at the top of the tower, and the column reactor is obtained A third feed 3 containing traces of alkynes. Alkyne removal tower A has 120 trays, feed temperature is 68°C, tower top temperature is 59°C, tower bottom temperature is 87°C, tower top pressure is 0.33MPa, tower bottom pressure is 0.39MPa, reflux The ratio is 17.

[0239] The third material 3 enters the first thermal dimerization reactor B, and the fourth materi...

Embodiment 2

[0300] according to figure 1 The technical process, without using the piperylene crude fractionation tower W, can obtain the isoprene product with a purity of 99.94%, the piperylene product with a purity of 96.5%, the dicyclopentadiene product with a purity of 95.7%, A cyclopentene product with a purity of 99.5%, a cyclopentane product with a purity of 99.8%.

[0301] The first material 1 of the carbon five fraction produced by petroleum cracking is sent from the 82nd plate to the alkyne removal tower A, and the second material 2 rich in isopentane and a small amount of isoprene is obtained at the top of the tower, and the tower reactor is obtained A third feed 3 containing traces of alkynes. Alkyne removal tower A has 123 trays, feed temperature is 62°C, tower top temperature is 59°C, tower bottom temperature is 88°C, tower top pressure is 0.34MPa, tower bottom pressure is 0.40MPa, reflux The ratio is 15.

[0302] The third material 3 enters the first thermal dimerization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com