Method for preparing hexamethylbenzene by taking 2-butyne as raw material

A technology for hexatoluene and butyne, applied in the field of preparing hexatoluene, can solve the problems of high requirements on reaction conditions, waste of raw materials, and high energy consumption, and achieve the effects of less chemical raw materials, less by-products, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

[0023] The following examples relate to a method for preparing hexamethylbenzene with 2-butyne as a raw material, comprising the following steps: adding solvent and 2-butyne sequentially in a three-necked flask according to the ratio of raw materials, and then adding a required amount of palladium chloride catalyst and copper chloride co-catalyst, turn on the low-temperature cooling water circulation of the condenser (provided by a low-temperature tank, the coolant is a mixture of ethylene glycol-water, the temperature is -10°C), immerse the flask in a preheated oil bath, and turn on the magnetic force Stir and time to maintain the desired reaction temperature until complete. The product was cooled and filtered to remove the catalyst.

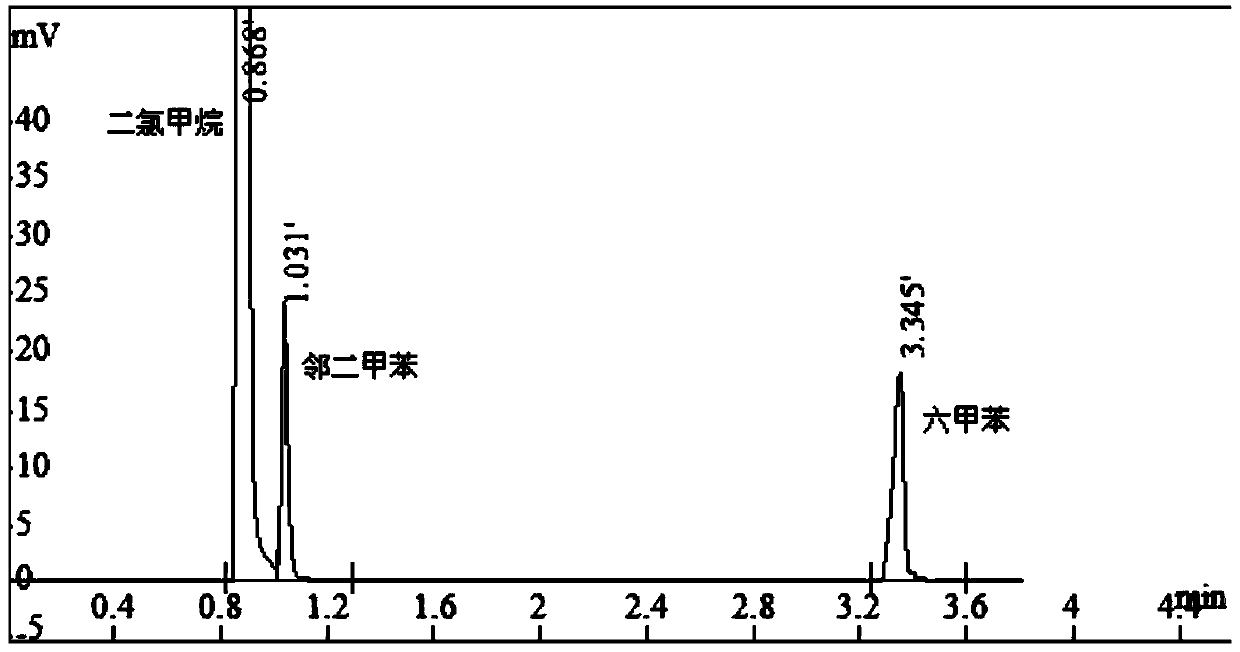

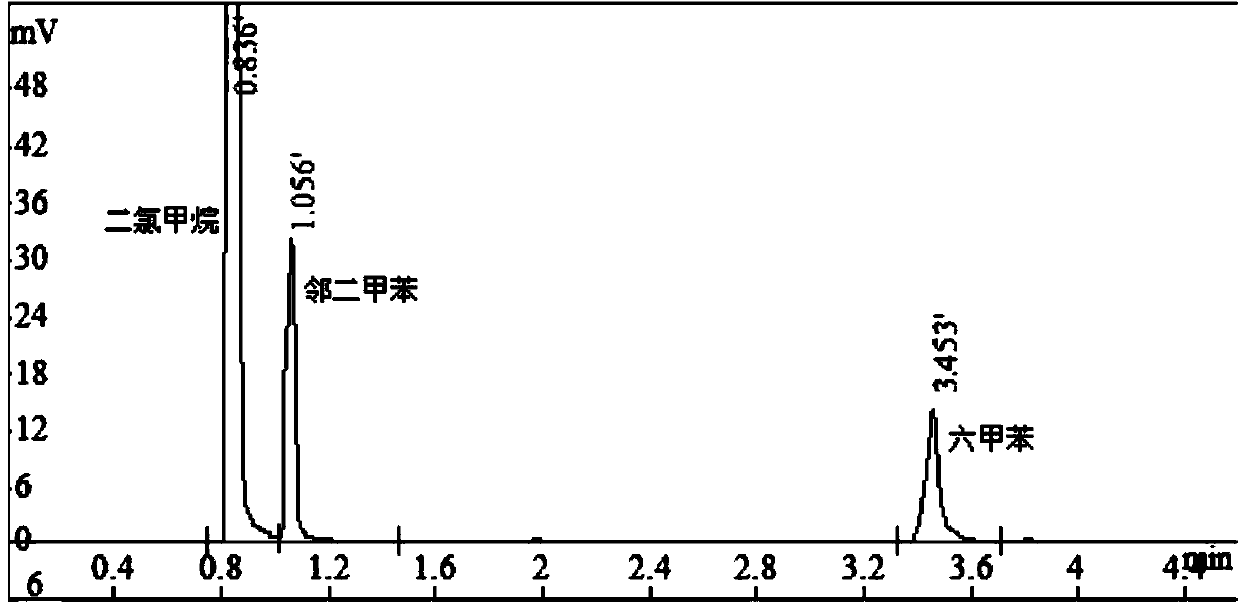

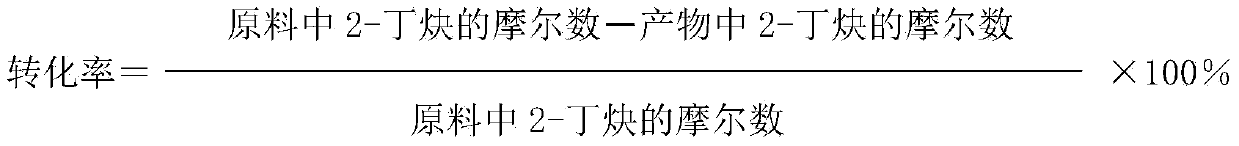

[0024] The composition of the reaction solution was obtained by gas chromatography analysis (see hexamethylbenzene spectrum analysis), hexamethylbenzene spectrum analysis: using GC-9800 gas chromatograph, the column specification is 30m×Φ0.32mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com