Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141results about How to "Won't seep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low viscosity and high thermal conductivity organosilicon gel and preparation method thereof

Belonging to the technical field of thermal conductive interface materials, the invention relates to a low viscosity and high thermal conductivity organosilicon gel and a preparation method thereof. The low viscosity and high thermal conductivity organosilicon gel consists of a component A and a component B. Specifically, the component A comprises the following components: vinyl silicone oil, polyvinyl silicone oil, alkyl modified silicone oil, an active diluent, high thermal conductivity compound inorganic filler, a catalyst and pigment; and the component B comprises the following componentsby mass: vinyl silicone oil, polyvinyl silicone oil, alkyl modified silicone oil, an active diluent, high thermal conductivity compound inorganic filler, hydrogen-containing silicone oil, an inhibitorand a tackifier. The product provided by the invention has the characteristics of low viscosity, high extrudability and high thixotropy, and easy mixing, can be compressed into filling layers of different thicknesses and different shapes, can be quickly solidified into soft silicone gel at normal temperature and by heating, is suitable for filling the irregular gaps among various electronic devices and heat dissipators, and can play the role of heat conduction, insulation, buffering, shock absorption, etc.

Owner:GOLOHO TECH CHANGZHOU CO LTD

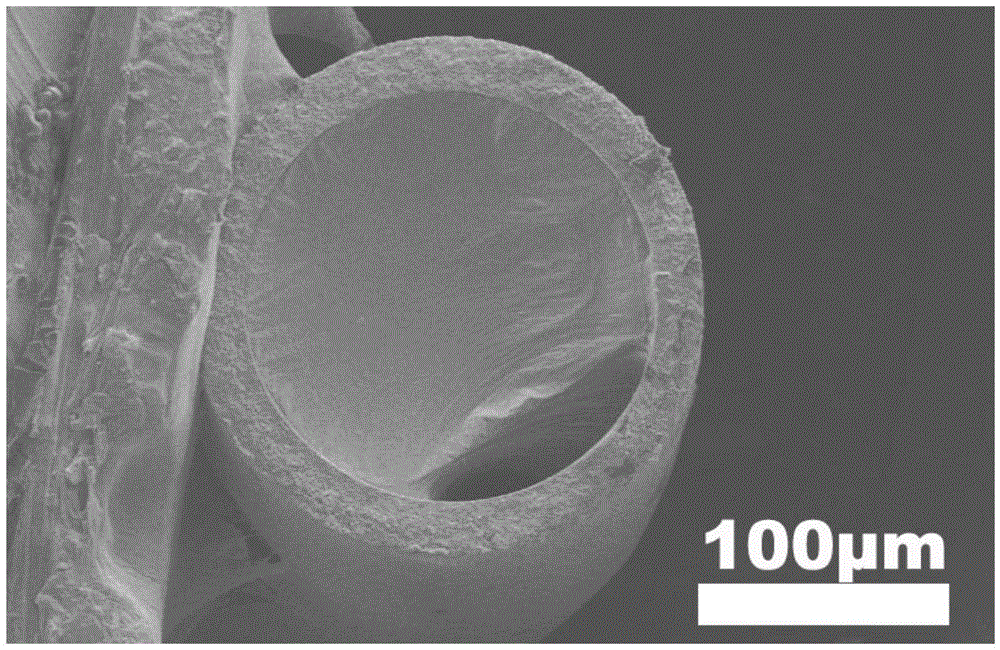

Heat-storing and temperature-regulating fiber and preparation method thereof

ActiveCN105113043AImprove mechanical propertiesHigh thermal conductivityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a heat-storing and temperature-regulating fiber and a preparation method thereof. The heat-storing and temperature-regulating fiber is prepared from a phase-change material and fiber-forming polymer by a solution composite spinning method. The cross section of the heat-storing and temperature-regulating fiber is in the shape of an island or concentric circles; the mass fraction of the phase-change material is 20-60wt%; the mass fraction of the fiber-forming polymer in the fiber is 80-40wt%; and the sum of the mass fraction of the phase-change material and the mass fraction of the fiber-forming polymer is 100%. The phase-change material is obtained by respectively fusing or dissolving functionalized graphene and comb-like polymer, mixing to obtain solvent, and evaporating the solvent thoroughly. The preparation method comprises the step of preparing the heat-storing and temperature-regulating fiber by using the phase-change material and the fiber-forming polymer through conventional wet spinning. The method is simple and has an industrialization prospect. The prepared heat-storing and temperature-regulating fiber is high in heat conduction efficiency and good in heat-storing and temperature-regulating performance, has conductivity, and has a certain antistatic effect.

Owner:TIANJIN POLYTECHNIC UNIV

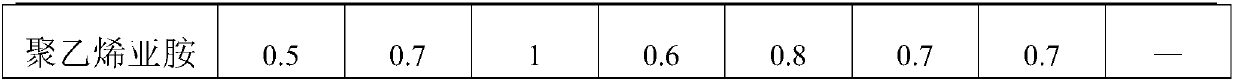

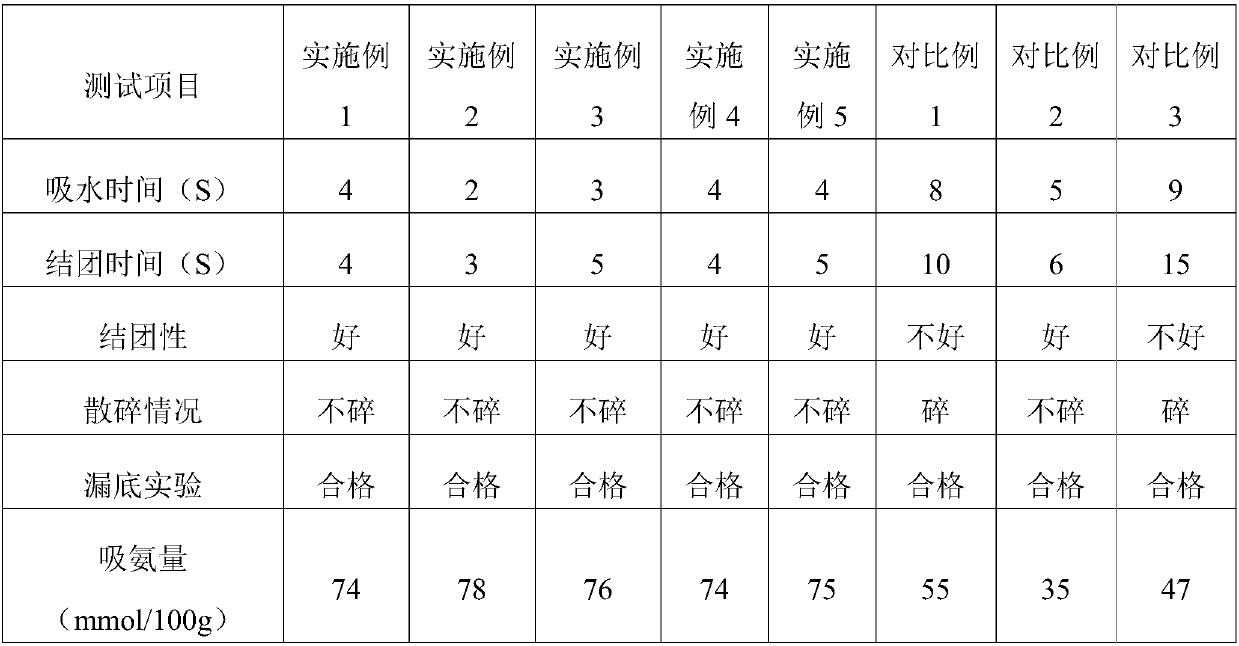

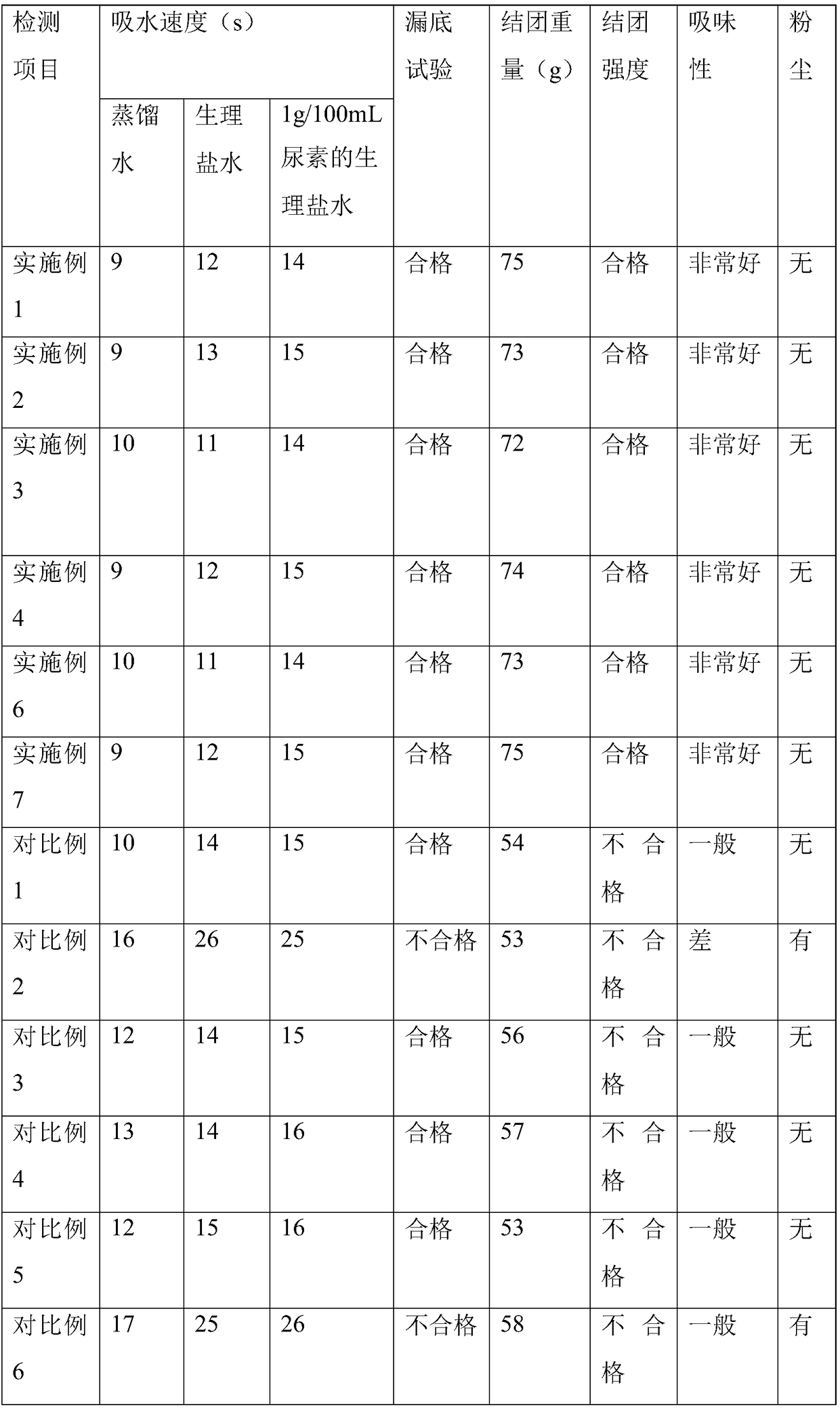

Deodorant plant cat litter and preparing method thereof

InactiveCN109566426AGood sterilization and deodorization effectHigh ammonia uptakeAnimal housingFiberSodium bicarbonate

The invention belongs to the technical field of cat litter, and provides deodorant plant cat litter and a preparing method thereof. The deodorant plant cat litter is prepared from, by weight, 60-70 parts of soybean fibers, 25-35 parts of corn starch, 10-20 parts of sodium bicarbonate, 5-10 parts of zeolite, 4-6 parts of citric acid, 1-3 parts of sodium phenylpropionic acid, 3-7 parts of active carbon, 2-5 parts of ammonium persulfate, 2-4 parts of guar gum, 1-5 parts of a garlic extract, 1-3 parts of tea residues and 0.5-1 part of polyethyleneimine. By means of the deodorant plant cat litter and the preparing method thereof, the technical problem that cat litter in the prior art is poor in antibacterial deodorant effect is solved.

Owner:涿州市浩森再生资源回收有限公司

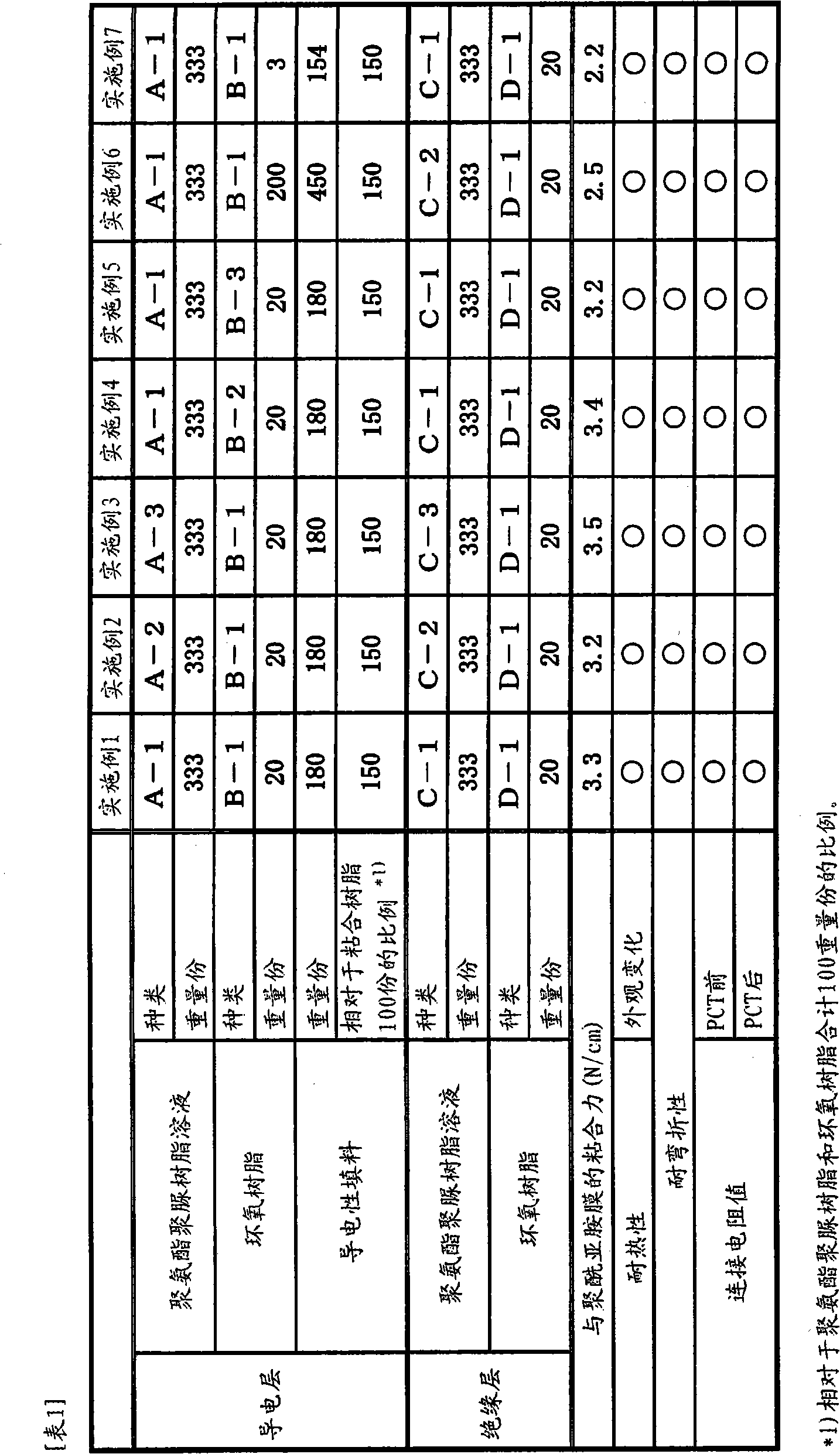

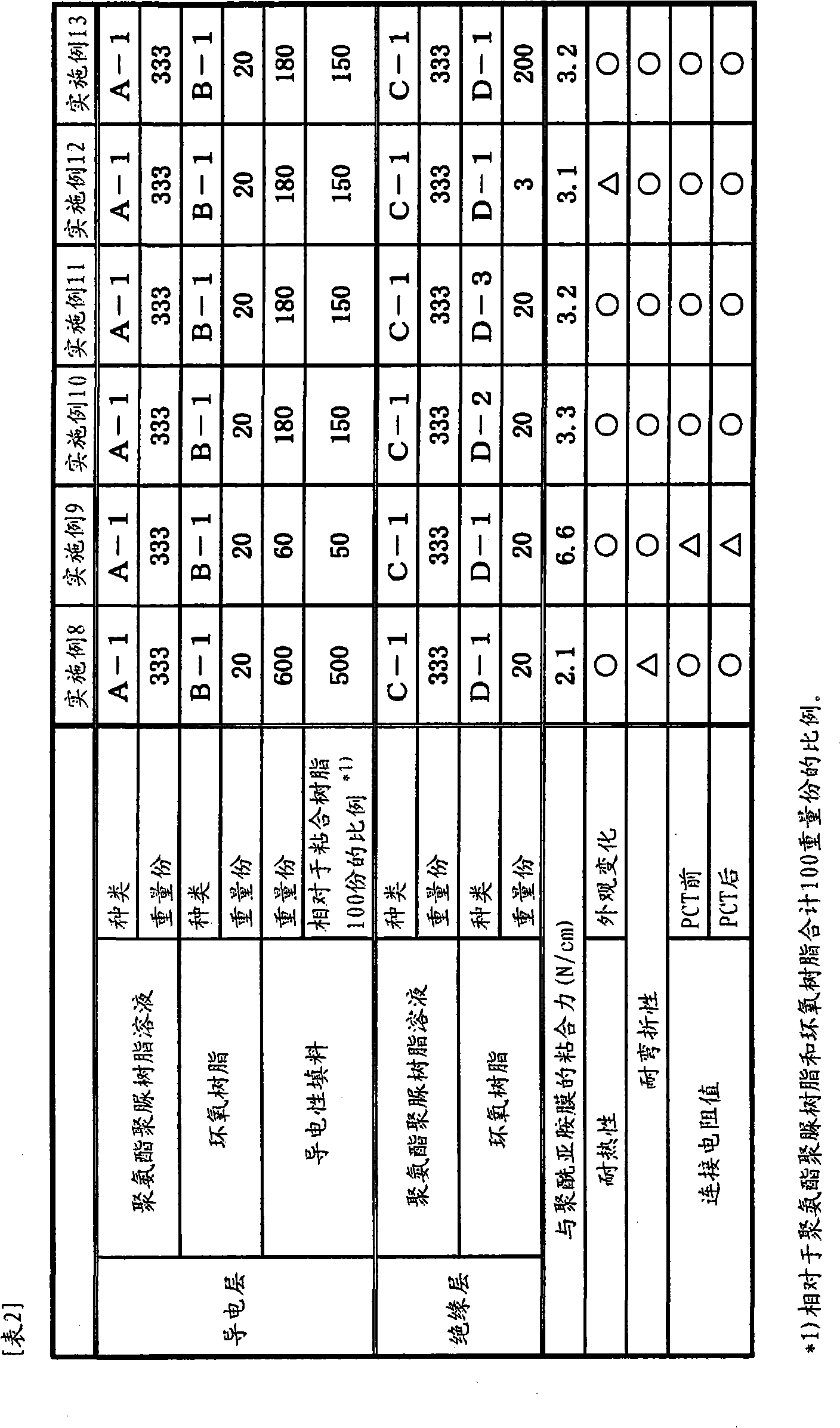

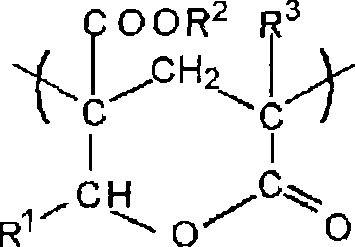

Curable electromagnetic shielding adhesive film, method for producing the same, use of the same, method for producing electromagnetic shielding article, and electromagnetic shielding article

ActiveCN101940080AConductivity does not decreaseExcellent heat and humidity resistanceNon-macromolecular adhesive additivesMagnetic/electric field screeningEpoxyPolyol

Disclosed is a curable electromagnetic shielding adhesive film having a curable conductive polyurethane-polyurea adhesive layer (I) and a curable insulating polyurethane-polyurea resin composition layer (II). The curable conductive polyurethane-polyurea adhesive layer (I) contains a polyurethane-polyurea resin (A) which is obtained by reacting a urethane prepolymer (a4) having an isocyanate groupat an end with a polyamino compound (a5), and an epoxy resin (B) having two or more epoxy groups. The urethane prepolymer (a4) is obtained by reacting a carboxyl group-containing diol compound (a1), a polyol (a2) having a number average molecular weight of 500-8,000 which is not a carboxyl group-containing diol compound, and an organic diisocyanate (a3). The curable conductive polyurethane-polyurea adhesive layer (I) also contains 10-700 parts by weight of a conductive filler per 100 parts by weight of the total of the polyurethane-polyurea resin (A) and the epoxy resin (B). The curable insulating polyurethane-polyurea resin composition layer (II) contains a polyurethane-polyurea resin (C) which is obtained by reacting a urethane prepolymer (c4) having an isocyanate group at an end with apolyamino compound (c5), and an epoxy resin (D) having two or more epoxy groups. The urethane prepolymer (c4) is obtained by reacting a carboxyl group-containing diol compound (c1), a polyol (c2) having a number average molecular weight of 500-8,000 which is not a carboxyl group-containing diol compound, and an organic diisocyanate (c3).

Owner:TOYO INK SC HOLD CO LTD

DBC (Direct Bonded Copper) substrate surface treatment process based on nano-silver soldering paste connecting chip

ActiveCN102560488ANo oxidation reactionWon't seepVacuum evaporation coatingSputtering coatingPre treatmentSurface finishing

The invention discloses a DBC (Direct Bonded Copper) substrate surface treatment process based on a nano-silver soldering paste connecting chip. The process solves the technology that not only the copper on the DBC substrate surface is prevented from bleeding out of a silver plating surface, but also the combination strength between the nano-silver soldering paste connecting chip and the DBC substrate is ensured. The DBC substrate surface treatment process comprises the following steps of: firstly carrying out cleaning pretreatment on the surface of a DBC substrate; then carrying out electronickelling treatment on the pretreated DBC substrate; and finally, after thorough cleaning, carrying out silverplating treatment on the surface of the electronickelled DBC substrate by using a magnetron sputtering method. The DBC substrate surface treatment process based on the nano-silver soldering paste connecting chip has the following beneficial effects: when the electronickelled DBC substrate subjected to magnetron sputtering silver is sintered at high temperature by using a nano-silver soldering paste, the metal copper on the surface of the DBC substrate does not oxidize, i.e. the metal copper does not permeate the surface of a silvering layer; after being sintered, the nano-silver soldering paste has good bonding strength with the electronickelled DBC substrate subjected to magnetron sputtering silver; and the DBC substrate surface treatment process is green and environment-friendly and has no adverse effect on the environment.

Owner:TIANJIN UNIV

Cat litter with deodorization and desinsectization functions

InactiveCN106550894AEfficient dehumidificationEfficient dryingAnimal housingSodium BentoniteAnimal science

The invention discloses cat litter with deodorization and desinsectization functions. The cat litter is formed by the following raw materials comprising, by weight, 50-100 parts of attapulgite powder, 10-20 parts of calcium bentonite, 10-15 parts of green tea, 15-30 parts of nanometer magnesia, 15-30 parts of super absorbent resin, 10-15 parts of active carbon, 5-10 parts of sodium polyacrylate, 5-10 parts of Chinese medical stones and 10-15 parts of carboxymethyl cellulose. According to the invention, raw materials for preparing the cat litter are natural mineral resources and inorganic salts which are all easily available, the raw materials are low in price, and are nontoxic and environmentally-friendly, the cat litter has high-efficiency dehumidifying and drying effect, and is characterized by being long in service life, and the cat litter has strong deodorization and desinsectization effect.

Owner:明光市龙腾矿物有限公司

Pressure-sensitive adhesive for optical film, pressure-sensitive adhesive optical film, production method thereof, and image display

InactiveCN101423737AInhibit sheddingPrevent floatingPolarising elementsEster polymer adhesivesMeth-Optical thin film

A pressure-sensitive adhesive for an optical film of the present invention comprises a (meth)acrylic polymer comprising 50 to 99.99% by weight of alkyl (meth)acrylate monomer unit and 0.01 to 30% by weight of a photocrosslinkable monomer unit having an unsaturated double bond-containing polymerizable functional group and a photocrosslinkable moiety different from the functional group. A pressure-sensitive adhesive layer is formed from the pressure-sensitive adhesive on at least one side of an optical film, wherein the photocrosslinkable moiety of the (meth)acrylic polymer in the pressure-sensitive adhesive is crosslinked by active energy ray irradiation. The pressure-sensitive adhesive can form the pressure-sensitive adhesive layer with a high level of durability and preferable workability.

Owner:NITTO DENKO CORP

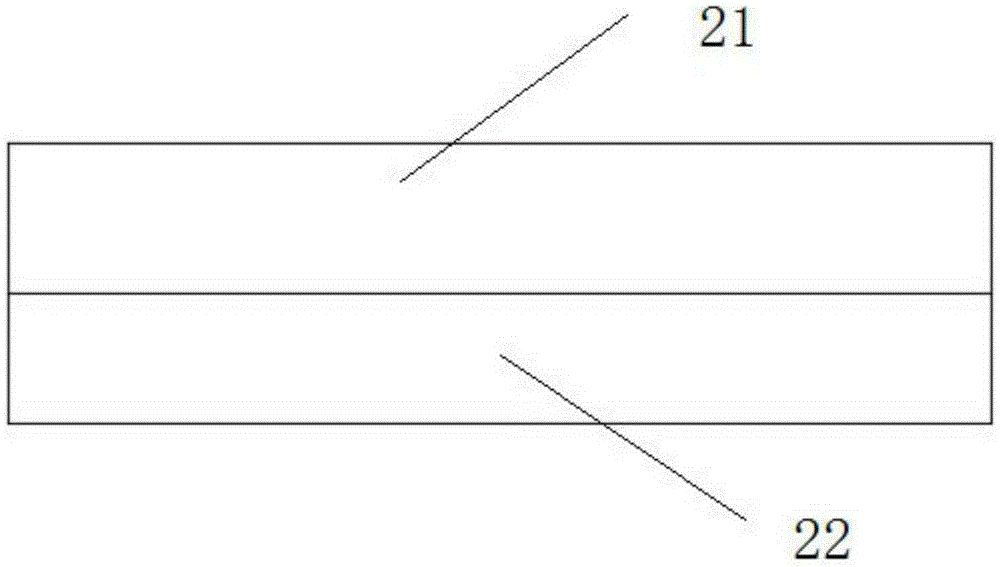

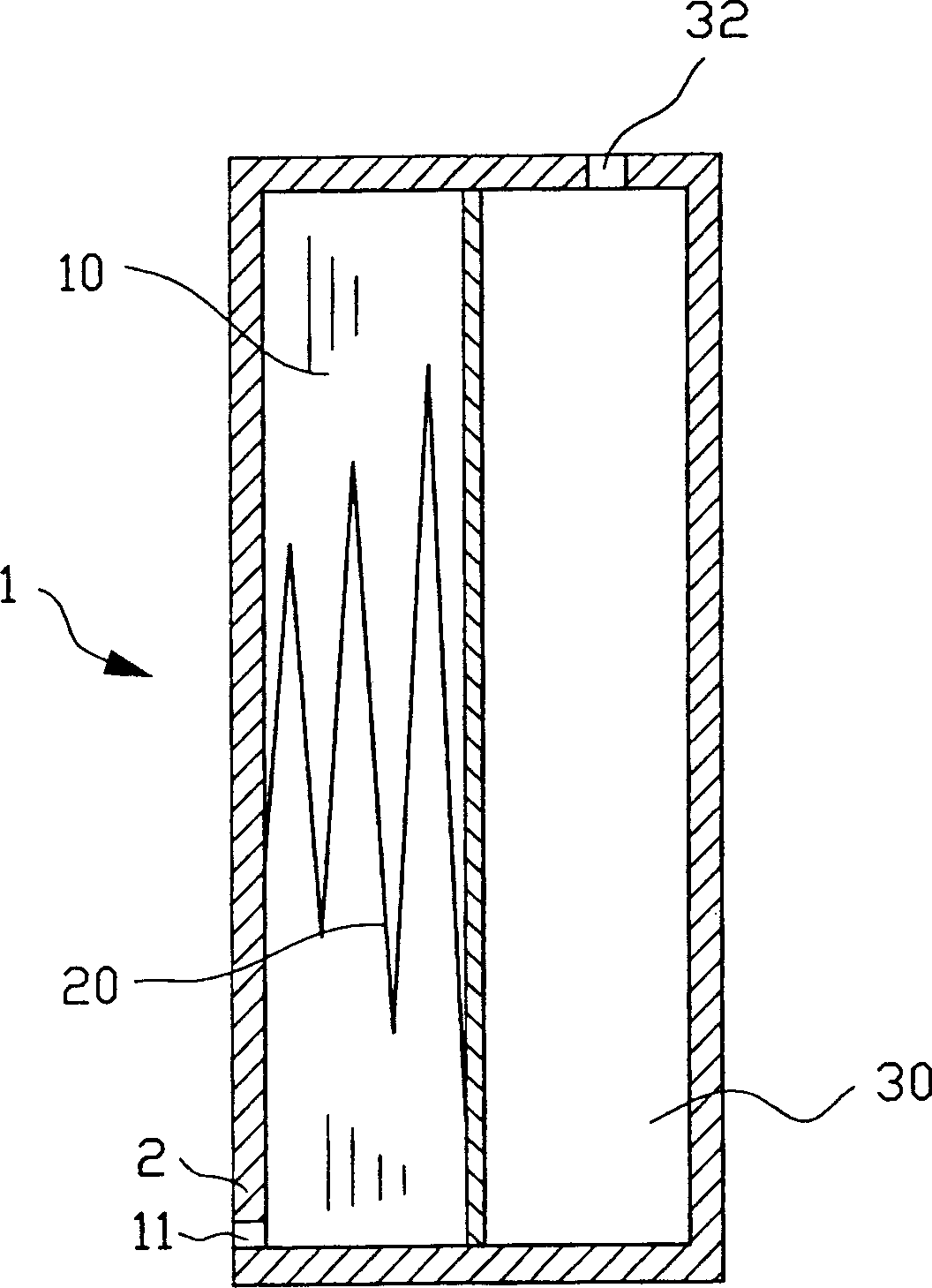

Electronic cigarette oil leakage preventing device adopting light-induced reversible deformation layer and oil leakage preventing method

ActiveCN105411010ASolve the oil spill problemSolve the problem of oil spillTobacco devicesEngineeringElectronic cigarette

The invention provides an electronic cigarette oil leakage preventing device adopting a light-induced reversible deformation layer. The electronic cigarette oil leakage preventing device comprises a housing (12), a light source accommodation cavity (2) provided with a light source (1) in the inside and provided with a transparent light outlet wall (2-1), a light-induced reversible deformation layer (5) provided with a lighted side surface and a back-lighted side surface, and an elastic layer (6) tightly attached to the back-lighted side surface of the light-induced reversible deformation layer (5), wherein the lighted side surface faces the light source (1), an airflow outlet channel is defined between the lighted side surface of the light-induced reversible deformation layer (5) and the light outlet wall (2-1) and the housing (12), and an air inlet hole (8) and an air outlet hole (3) of the airflow channel are respectively formed in the housing (12), one end of every one of the two holes is fixedly connected with the light outlet wall (2-1) or the housing (12), the other end of every one of the two holes is attached to the lighted side of the light-induced reversible deformation layer (5), and therefore blocking of the airflow channel is formed.

Owner:CHINA TOBACCO YUNNAN IND

Natural plant cat litter and preparation method thereof

The invention discloses natural plant cat litter and a preparation method thereof, and relates to the technical field of cat litter preparation. The natural plant cat litter is prepared from, by weight, 60-70 parts of vegetable fiber, 40-50 parts of pine bits, 20-45 parts of modified straw charcoal, 10-15 parts of salmon powder, 3-7 parts of houttuynia cordata, 4-8 parts of hyacinth bean residues,10-15 parts of green tea leaves, 6-10 parts of spinach extractives, 3-6 parts of coconut oil, 5-8 parts of chia seeds, 10-15 parts of coffee grounds, 3-7 parts of adhesives, 8-12 parts of activated carbon, 7-14 parts of bamboo charcoal, 3-6 parts of kieselguhr, 5-9 parts of bactericide and 100-150 parts of water. The preparation method comprises the steps of 1 raw material preprocessing, 2 raw material mixing, 3 raw material processing, 4 extrusion pelleting, 5 freezing drying, 6 screening and 7 packaging. The natural plant cat litter has the advantages of restraining cat appetite and lowering cat heat intake. In addition, the preparation method has the advantage of increasing the cat water suction amount.

Owner:内蒙古爱牧动物保健品有限公司

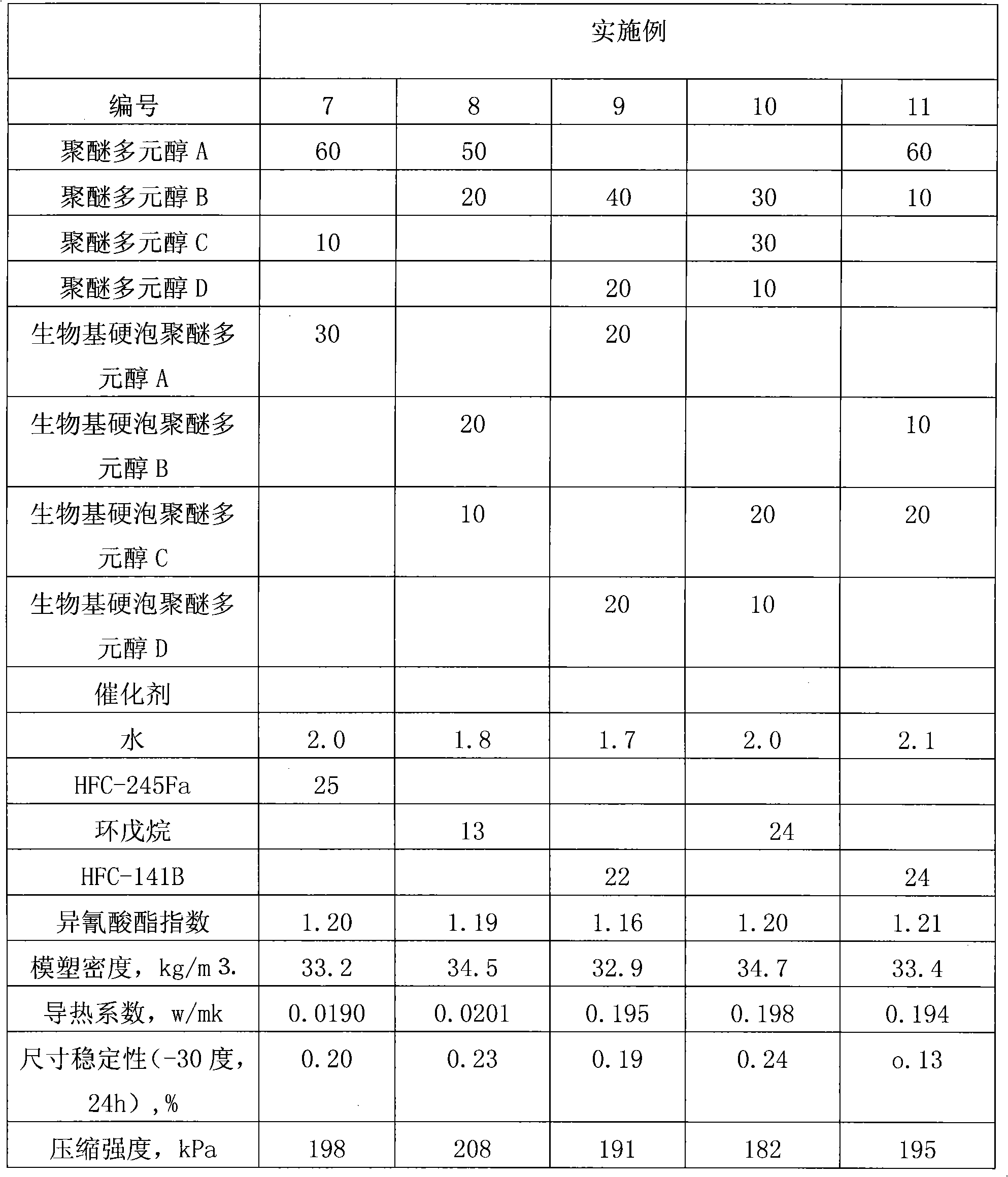

Method for preparing polyurethane foam from curcas oil base rigid foam polyether

The invention discloses a method for preparing polyurethane foam from curcas oil base rigid foam polyether. Curcas oil is hydroxylated and reacted with epoxide. A synthesis hydroxyl value of rigid foam polyether polyol is 300-550mg KOH / g. Curcas oil base rigid foam polyether polyol, polyether (polyester) polyol, a catalyst 3, a foam stabilizer, water, a foaming agent and isocyanate are stirred uniformly according to a certain proportion to obtain rigid polyurethane foam. The polyurethane rigid foam prepared from polyether polyol containing curcas oil biobase is mainly used in fields of pipeline insulation, refrigerator, freezer, building insulation, sheet material, substrate, solar energy and interior decoration, etc.

Owner:JIANGSU LVYUAN NEW MATERIALS

Essential oil patch and manufacturing method thereof

InactiveCN105310819AEasy to fixAchieve quantitative releaseMedical devicesTherapeutic coolingSilicone oilPetroleum engineering

The invention relates to an essential oil patch and a manufacturing method thereof. The essential oil patch sequentially comprises a silicon oil paper layer, an essential oil storage layer, a binding layer and a self-heating layer, wherein the essential oil storage layer is used for storing essential oil in a quantitative mode; the binding layer is used for binding; and the self-heating layer is used for taking a heat-insulation effect. The essential oil patch disclosed by the invention can achieve the quantitative release of the essential oil and can keep a lasting effect; and the essential oil patch is conductive to the implementation of various self-help moxibustion therapies, SPA and the like.

Owner:SUZHOU QIUSHIAIKANG MEDICAL APP TECH CO LTD

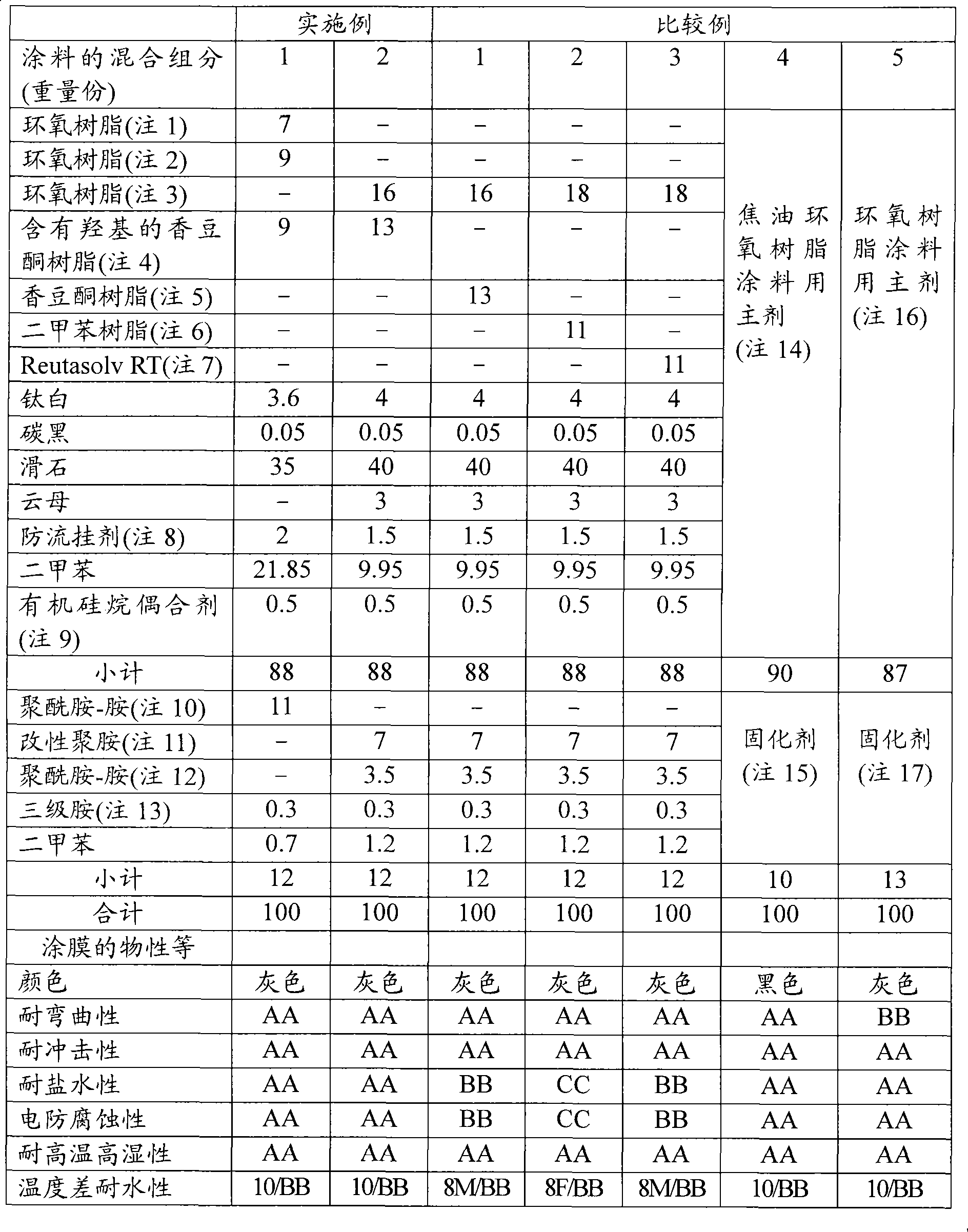

Anticorrosive coating composition

InactiveCN101443425AGood compatibilityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyTar

An anticorrosive coating composition comprising (A) an epoxy resin, (B) an amine-type curing agent, and (C) a hydroxyl-containing coumarone resin, characterized in that the coumarone resin (C) is contained in an amount of 1 to 500 parts by weight per 100 parts by weight of the epoxy resin (A). The coumarone resin (C) is preferably one which contains hydroxyl in an amount of 1 to 5% in one molecule and has a softening point of 200 DEG C or below. The coating composition can give coating films in which the plural resin components are homogeneously mixed and which are excellent in anticorrosion property, water resistance, and adhesion. Further, since the composition is free from tar unlike conventional anticorrosive coating compositions, it can give light-colored cured coating films free from bleed-out of any component and is clear of the problems of safety and hygiene in application.

Owner:CHUGOKU MARINE PAINTS

Tungsten copper alloy and preparation method thereof

InactiveCN109234597AReduce clumpingEvenly distributedTransportation and packagingMetal-working apparatusCopper platingSpherical form

Owner:JIANGSU JINGWEI VALVE

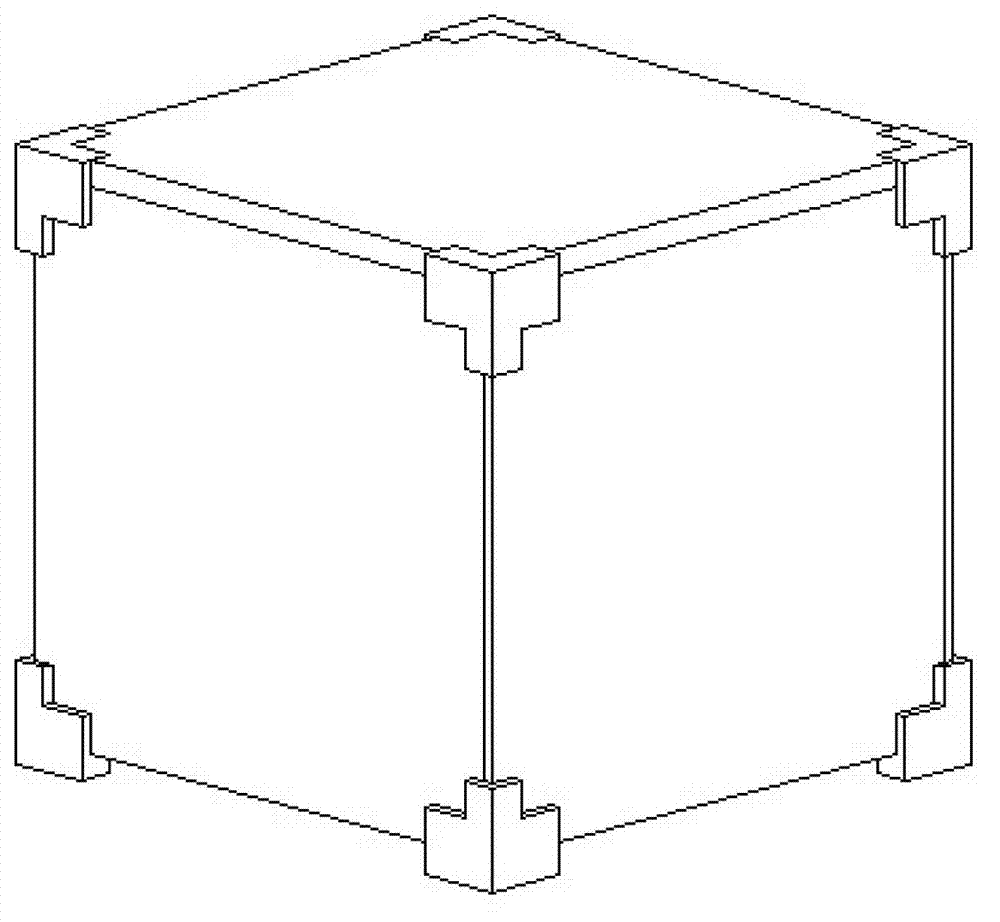

Splicing container for retaining freshness

ActiveCN103171813AInhibit growth and reproductionEasy to installDomestic cooling apparatusLighting and heating apparatusThermal insulationLiquid water

The invention provides a splicing container for retaining freshness. The container for retaining freshness comprises a container body for retaining freshness and a container cover matching with each other. The container body for retaining freshness comprises a bottom surface and a side wall. The side wall is of a double-layer structure with an inner side wall and an outer side wall. The inner side wall, the outer side wall and the bottom surface form a cavity for containing thermal insulation materials. The inner layer side wall is formed by splicing inner-layer boards for retaining freshness, and the outer side wall is formed by splicing outer-layer boards for retaining freshness. The inner-layer boards for retaining freshness, the outer-layer boards for retaining freshness and the bottom surface are all spliced to form the container body for retaining freshness. The inner-layer boards for retaining freshness, the outer-layer boards for retaining freshness and the container cover are all formed by waterproof and breathable particles and hydrophobic bonder by means of bonding and curing. Gaps through which gaseous molecules can permeate but liquid water molecules cannot permeate are formed between adjacent waterproof and breathable particles. The splicing container for retaining freshness can be installed in the field as required by the scale and has a good food freshness retaining effect.

Owner:BEIJING RECHSAND SCI & TECH GRP

Environment-friendly sand bag

InactiveCN103711251ALight in massReduce volumeConstruction materialEngineeringEnvironmentally friendly

The invention relates to the field of waterproof equipment and in particular relates to an environment-friendly sand bag. The environment-friendly sand bag comprises an outer layer bag, wherein a sand bag is arranged in the outer layer bag; the outer layer bag and the sand bag are made of a water-permeable material; the sand bag is filled with a water absorption material; the outer layer bag is covered with a sealed package bag. According to the environment-friendly sand bag provided by the invention, the sand bag is filled with the water absorption material; the package bag is opened to water the outer layer bag, so that the water absorption material in the sand bag is expanded after absorbing water to form the shape of a sand pouch, and then the sand bag is stacked at a required position. The environment-friendly sand bag is light in mass, small in size and convenient to carry, transport and store; furthermore, the water absorption material cannot leak, so that the environment cannot be polluted, and the sand bag is environmentally friendly and practical.

Owner:戚海山

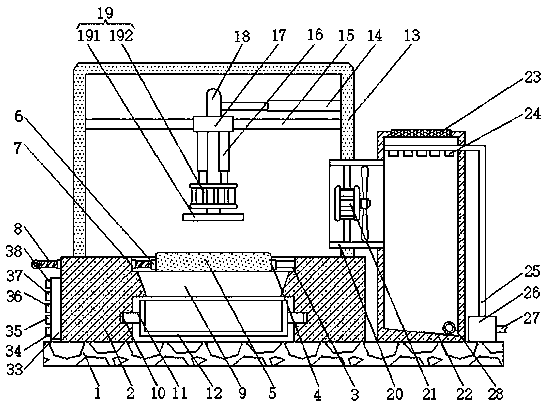

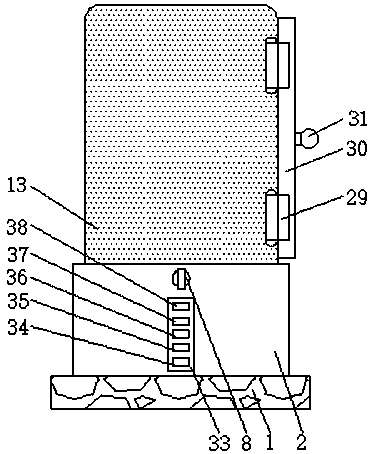

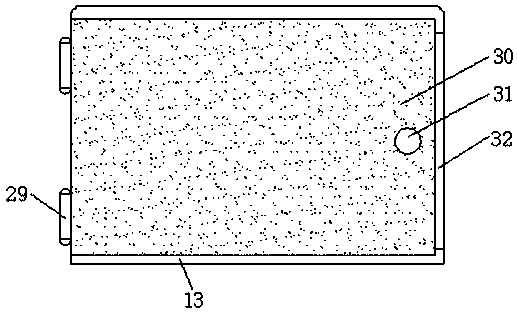

Planar polishing equipment for mobile phone shell

InactiveCN109590879AReduce pollutionEasy to cleanPolishing machinesGrinding drivesWater vaporSpray nozzle

The invention discloses planar polishing equipment for a mobile phone shell, and relates to the technical field of polishing. The planar polishing equipment comprises a bottom plate, wherein the uppersurface of the bottom plate is fixedly connected with the lower surface of the base; the upper surface of the base is provided with a groove; and the right side face of the inner wall of the groove is fixedly connected with a first pressing plate. According to the planar polishing equipment for the mobile phone shell, a dust collection air blower, a connecting tube, a box body, a filter plate, awater pump, a first water pipe, a second water pipe and spray nozzles, water ejected from the spray nozzles can remove water vapor in the gas and some toxic and harmful gas pollutants while dust-containing dust gas particles can be removed at the same time, so that gas in a box body can pass through the filter plate and can be discharged; and crumbs produced by polishing the mobile phone shell body through a polishing wheel can be fallen into a collection box through a through hole, so that the crumbs and the dust can be effectively treated, pollution to an environment is reduced, and moreover, the crumbs and the dust can be effectively collected and also can be conveniently cleared up by the working personnel.

Owner:湖南融灏实业有限公司

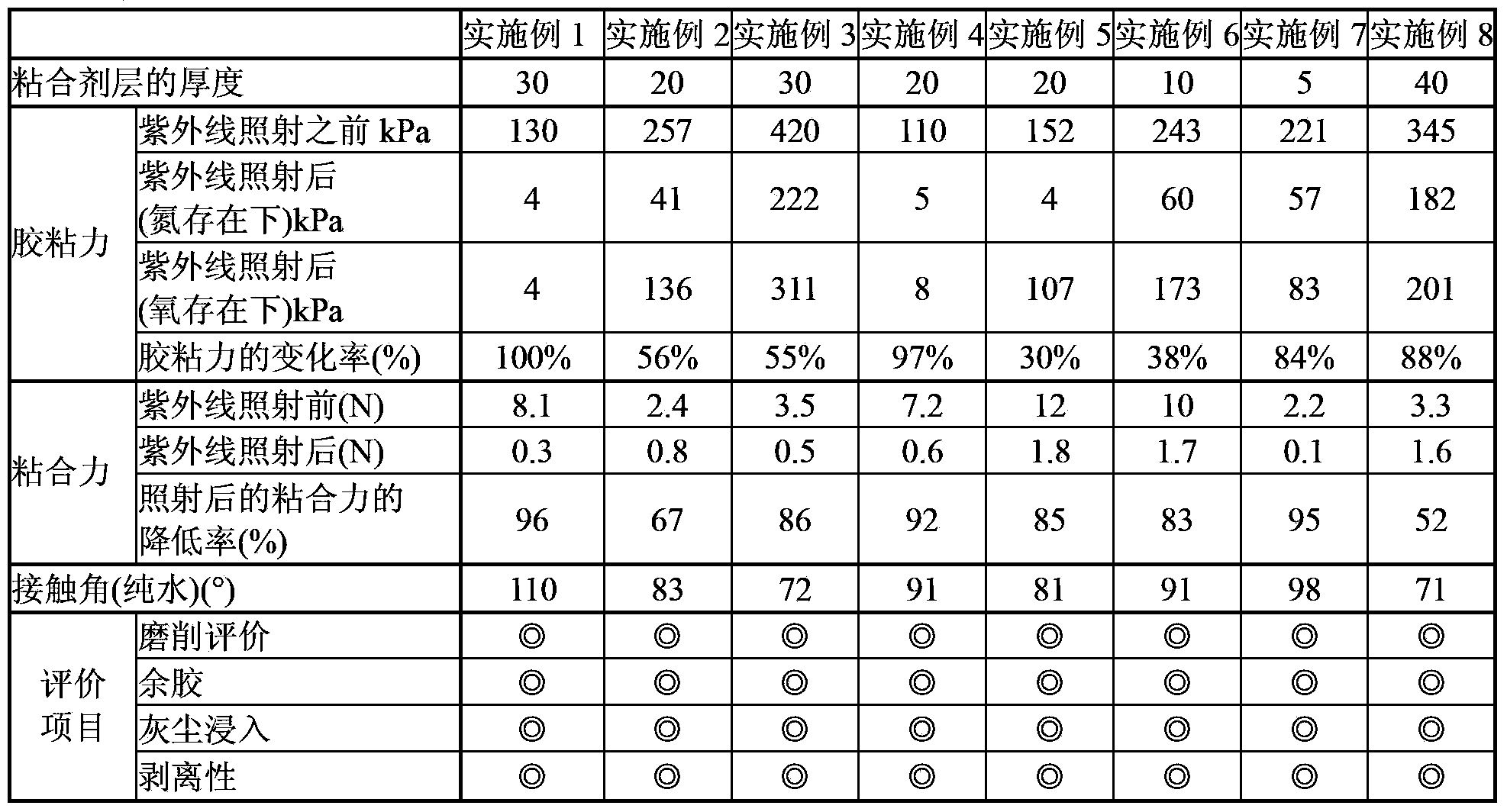

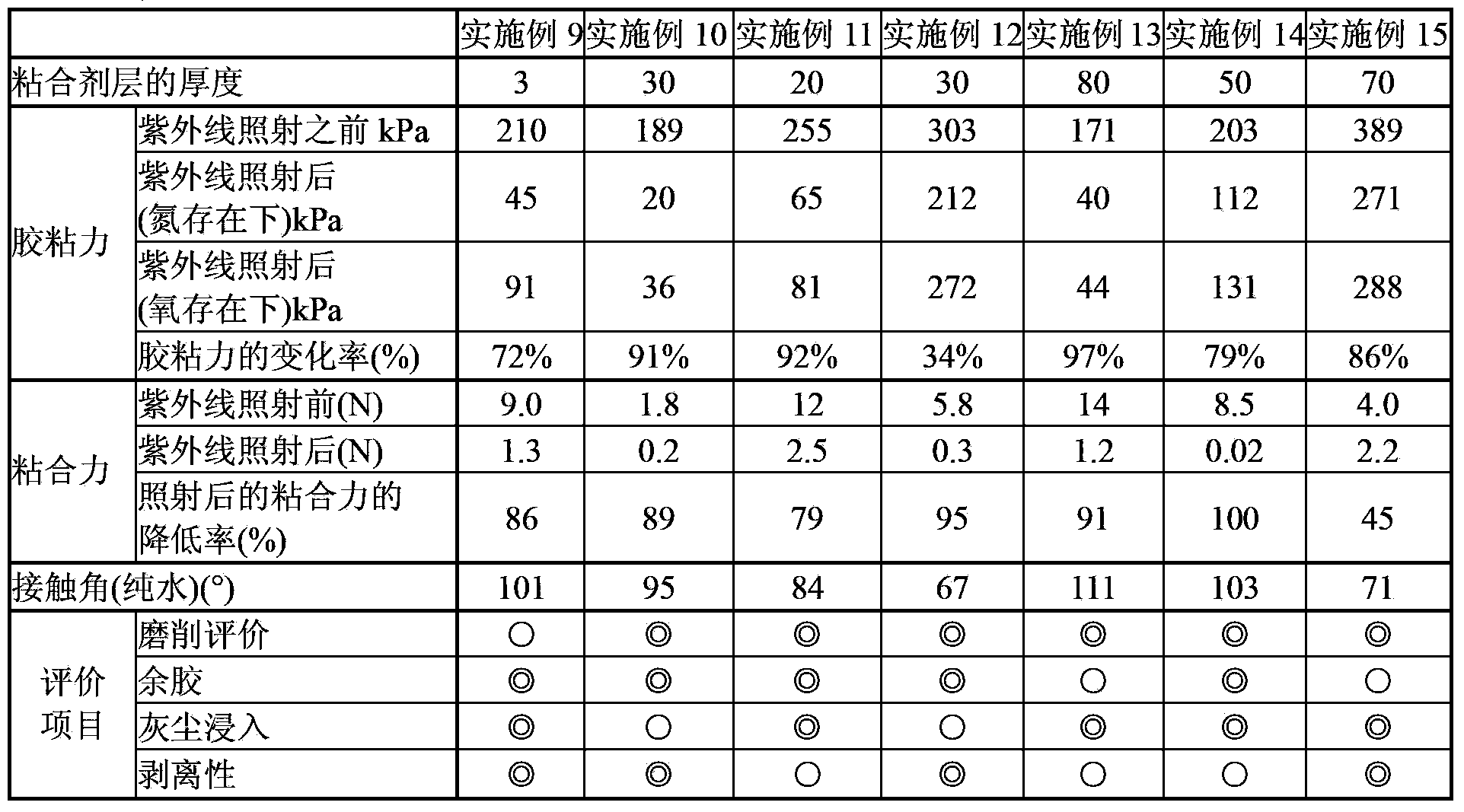

Adhesive tape for surface protection of a semiconductor wafer and method of producing a semiconductor wafer using the same

ActiveCN103525323AAvoid breakingWon't seepFilm/foil adhesivesSemiconductor/solid-state device manufacturingNitrogen atmosphereEngineering

The invention provides an adhesive tape for surface protection of a semiconductor wafer and a method of producing a semiconductor wafer using the same. The adhesive tape for surface protection of a semiconductor wafer is an adhesive tape for surface protection used when the back surface of the semiconductor wafer is grinded. A base material film comprises an adhesive layer which is a radioactive ray cured adhesive layer with a thickness less than protrusions on the surface of the semiconductor wafer. The change rate of adhesive tension acquired by a formula (1) is more than 30 percent. In the formula (1) [T[alpha]- T[beta]] / [ T[alpha]- T[beta] (N2)]*100, T[alpha] represents a measured value of the adhesive tension before the irradiation of the radioactive ray; T[beta] (air) represents a measured value of the adhesive tension after the irradiation of the radioactive ray with irradiation dose of 500mJ / cm2 in the air; T[beta] (N2) represents a measured value of the adhesive tension after the irradiation of the radioactive ray with irradiation dose of 500mJ / cm2 in a nitrogen atmosphere.

Owner:FURUKAWA ELECTRIC CO LTD

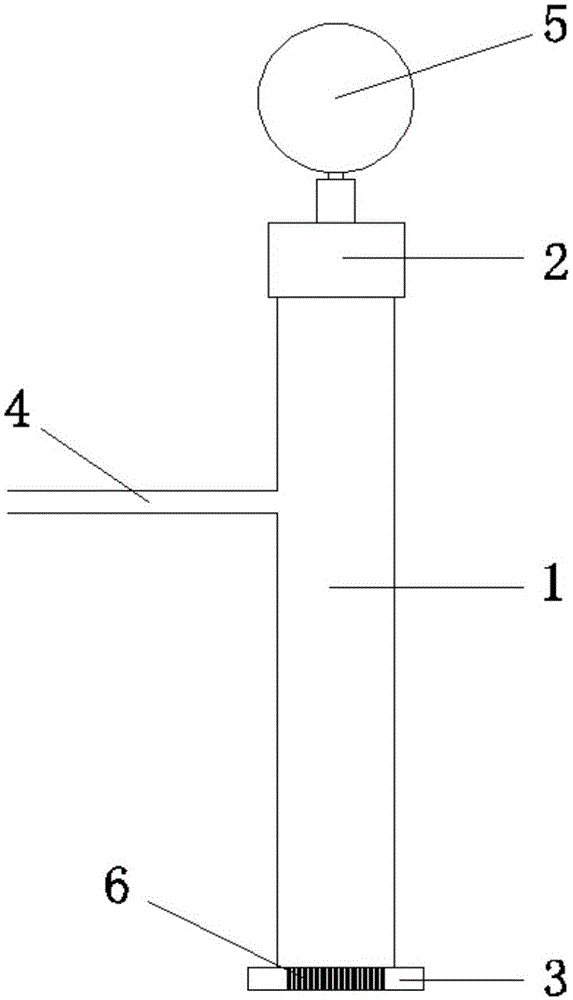

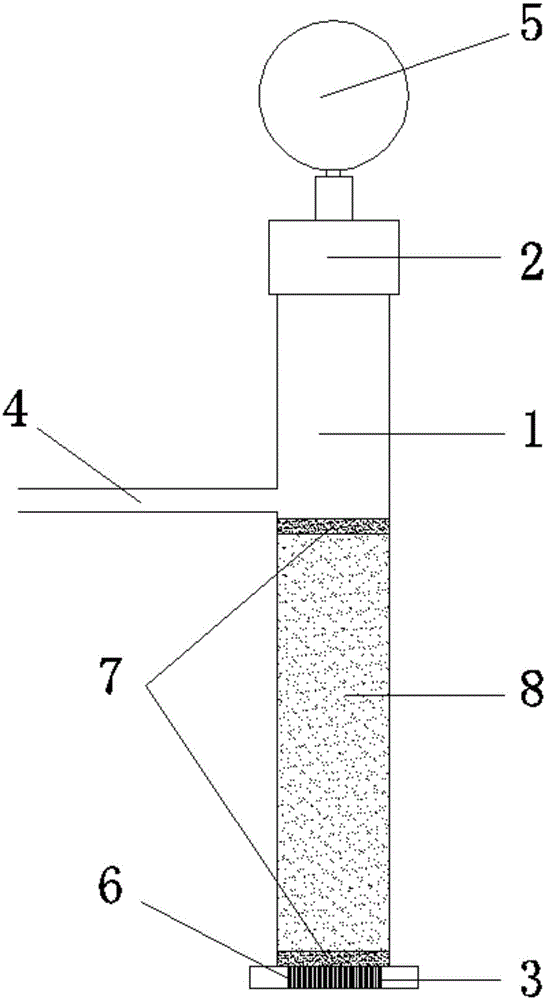

Grouting material pressure filter testing device and method

The invention provides a grouting material pressure filter testing device and method. The device comprises a grouting module and a testing module. The grouting module provides grout for the testing module through a grouting pipeline. The testing module comprises a testing cylinder. A testing cylinder base is arranged at the bottom end of the testing cylinder. A sealing cover connected with a pressure gauge is arranged at the top end of the testing cylinder. A grouting pipe for being connected with the grouting pipeline is arranged on the side wall of the testing cylinder. A filling medium is distributed in the portion, below the grouting pipe, of the testing cylinder. The upper end and the lower end of the filling medium are provided with water filter stone. The grout is pressed into the testing module through the grouting module and infiltrates the filling medium in the testing module so that testing can be completed. The testing device is small in size, easy and convenient to operate, recyclable and capable of reducing testing cost.

Owner:SHANDONG UNIV

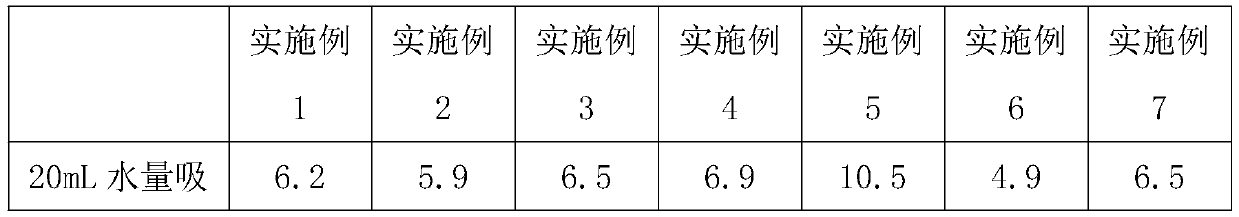

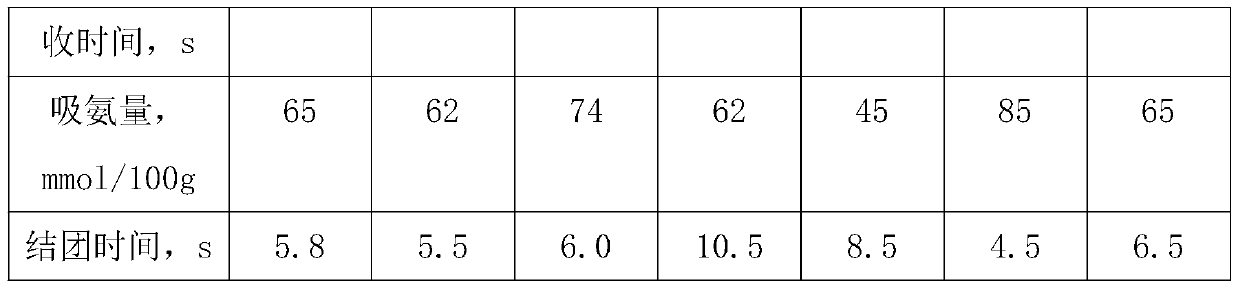

Agglomerable deodorizing pine cat litter and preparation method thereof

The invention discloses agglomerable deodorizing pine cat litter and a preparation method thereof. The agglomerable deodorizing pine cat litter is prepared from the following raw materials: pine powder, volcanic ash, a binder, starch, green tea powder, soybean fibers and a natural plant degerming agent. The preparation method comprises the following steps: cooking the pine powder in high-temperature steam, and crushing the cooked pine powder and the dried volcanic ash into mixed powder in a crusher; mixing the binder, the starch, the green tea powder, the soybean fibers and the natural plant degerming agent, and carrying out uniform mixing under stirring; and putting the mixed materials into a granulator for mixing, granulating and molding. The agglomerable deodorizing pine cat litter prepared by the invention can agglomerate after being used, is reduced in use amount and convenient for cat owners to clean, and overcomes the technical problem of discomfort of cats and consumers causedby strong pine flavor of the traditional pine cat litter.

Owner:涿州市浩森再生资源回收有限公司

Analysis device and method for directly measuring trace aluminum, silicon, phosphorus, sulphur and chlorine contents in sample

PendingCN109239117AReduce distanceReduce lossMaterial analysis using wave/particle radiationFluorescenceTest sample

The invention relates to an analysis device and method for directly measuring trace aluminum, silicon, phosphorus, sulphur and chlorine contents in a sample. The device comprises an X ray fluorescenceanalyzer unit (200), a charging unit (100), a sample cup (300) and a control unit, wherein the fluorescence analyzer unit (200) comprises a sample testing cavity (203) capable of carrying out gas filling; the charging unit (100) can controllably carry out air inflation and air exhaust on the sample testing cavity (203); and the control unit controls the analysis device, carries out integration and statistics on collected data, draws a work curve, and carries out calibration and other processing to obtain the contents of each element, including aluminum, silicon, phosphorus, sulphur and chlorine in the tested sample in one time. The analysis device has the advantages that the sample does not need to be subjected to preliminary treatment, and the analysis device is suitable for solid and liquid samples and has the characteristics of being nondestructive, direct, quick, high in sensitivity, low in use cost, convenient in field measurement and the like.

Owner:NCS TESTING TECH

High-temperate and high-strength carbon daub

The invention discloses a high-temperate and high-strength carbon daub, which is prepared from raw material anthracite, artificial graphite powder, comprehensive additive and liquid resin with the following method in the following steps of: firstly, processing the anthracite at high temperature in a graphitization furnace, and breaking into powder after the anthracite is cooled; evenly mixing thegraphitized anthracite, the graphite powder and the comprehensive additive at the mass ratio of 40+ / -10:30+ / -10:30+ / -10 into powder material; evenly stirring the powder material and the liquid resin at the ratio of 3:1; and standing and defoaming for 1 hour to obtain a finished product. The high-temperate and high-strength carbon daub has the advantages of high strength; when the temperature reaches 850 DEG C, the strength is only 6-8MPa; when the temperature rises to the 1150 DEG C, molten iron in the hearth of a blast furnace tends to the melting state, and the strength of the carbon daub disclosed by the invention is still maintained at 6-8MPa; when the temperature reaches 1600 DEG C, the strength of the carbon daub disclosed by the invention is maintained at 6-8MPa, and the molten iron does not ooze from carbon brick gaps so as to prevent from damaging the hearth; and the service life of the hearth is prolonged.

Owner:河南远洋新材料技术有限公司

Roller brush with extrusion and uniform liquid discharging structure

The invention discloses a roller brush with an extrusion and uniform liquid discharging structure. The roller brush comprises a roller capable of being connected onto a bracket, wherein the roller comprises a hollow roller body and a sponge layer covering the roller body; and the sponge layer is in sleeving joint with the roller body. The following technical measures are adopted: at least four rows of liquid discharging holes, which are formed in an equal radian, are formed in the periphery of the roller body; the liquid discharging holes are connected with a unidirectional liquid discharging structure in a matched manner; the unidirectional liquid discharging structure comprises a pulling piece with an opening and closing structure; one side of the pulling piece is connected with the roller body; and the other side of the pulling piece is in clearance fit with the roller body. By virtue of the roller brush, coating contained in the roller brush does not leak randomly when the roller brush is used for brushing a wall body; and the coating only can leak out at the position on which the roller is close to the wall body, and the coating does not leak out when the roller brush is pulled downwards.

Owner:宁波江东晟利工业产品设计有限公司

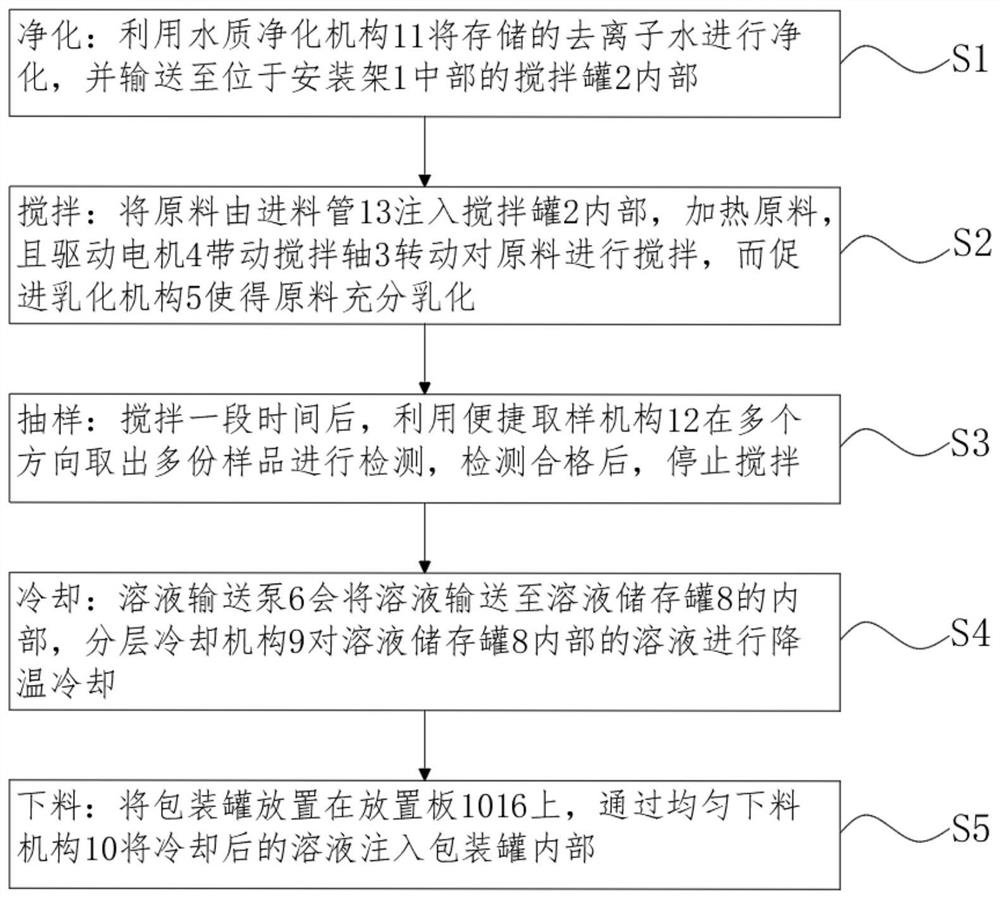

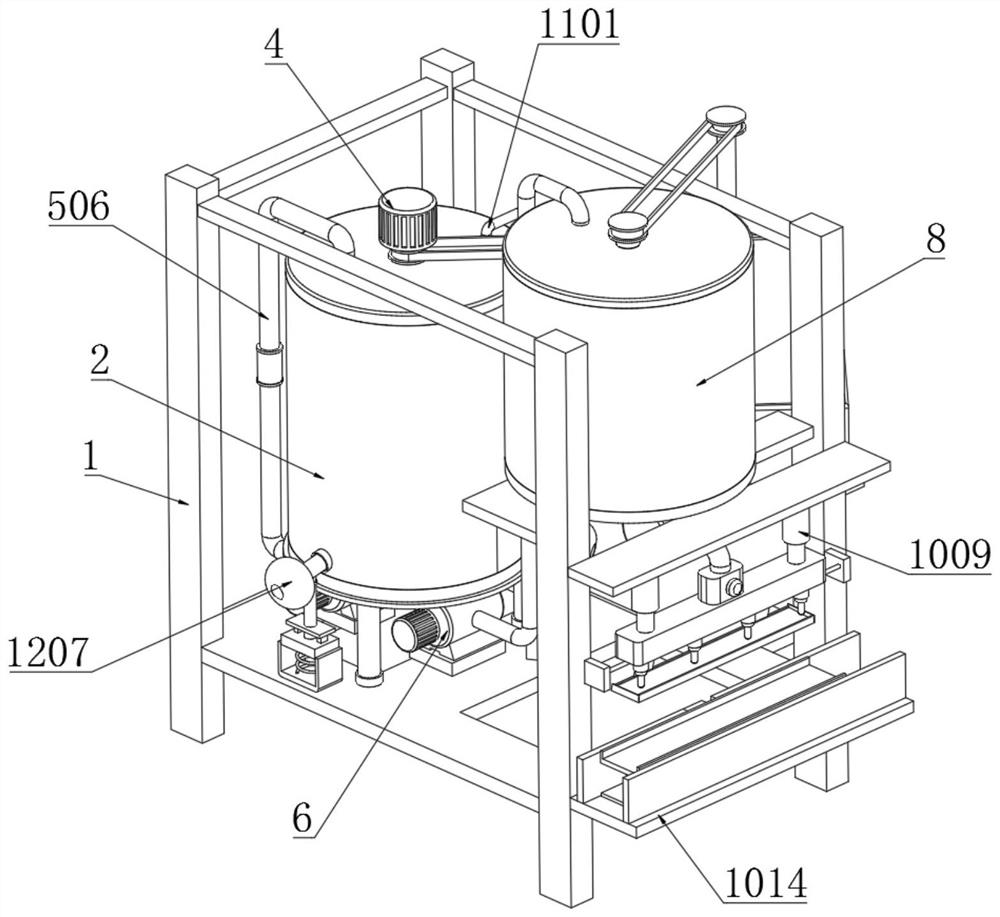

Preparation method of decontamination type laundry detergent

InactiveCN112169610AStir wellWell mixedWater/sewage treatment by irradiationFlow mixersProcess engineeringDrive motor

The invention discloses a preparation method of a decontamination type laundry detergent. The method comprises the following steps of: purification: purifying stored deionized water by using a water quality purification mechanism, conveying the purified deionized water into a stirring tank in the middle of a mounting frame; stirring: injecting raw materials into the stirring tank through a feedingpipe, heating the raw materials, and driving a stirring shaft to rotate by a driving motor so as to stir the raw materials, and fully stirring the raw materials through an emulsification promoting mechanism. The raw materials in the stirring tank can be fully mixed through the emulsification promoting mechanism, the raw materials can be fully mixed, and the situation that the quality of the prepared laundry detergent is unqualified due to uneven mixing of the raw materials is avoided, and meanwhile, through cooperative use of a circulating pump and a circulating conveying pipe, the mixed solution at the bottom of the stirring tank is pumped out and then re-injected into the stirring tank, the problem that the solution is deposited at the bottom of the stirring tank and cannot be fully mixed is avoided, raw materials are fully emulsified, raw material mixing is promoted, and the activity of the raw materials can be improved.

Owner:周燕芳

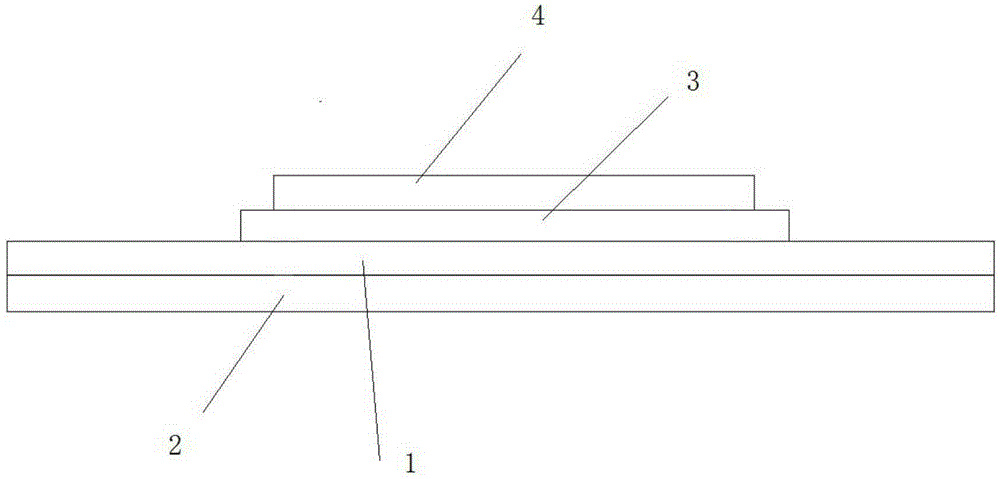

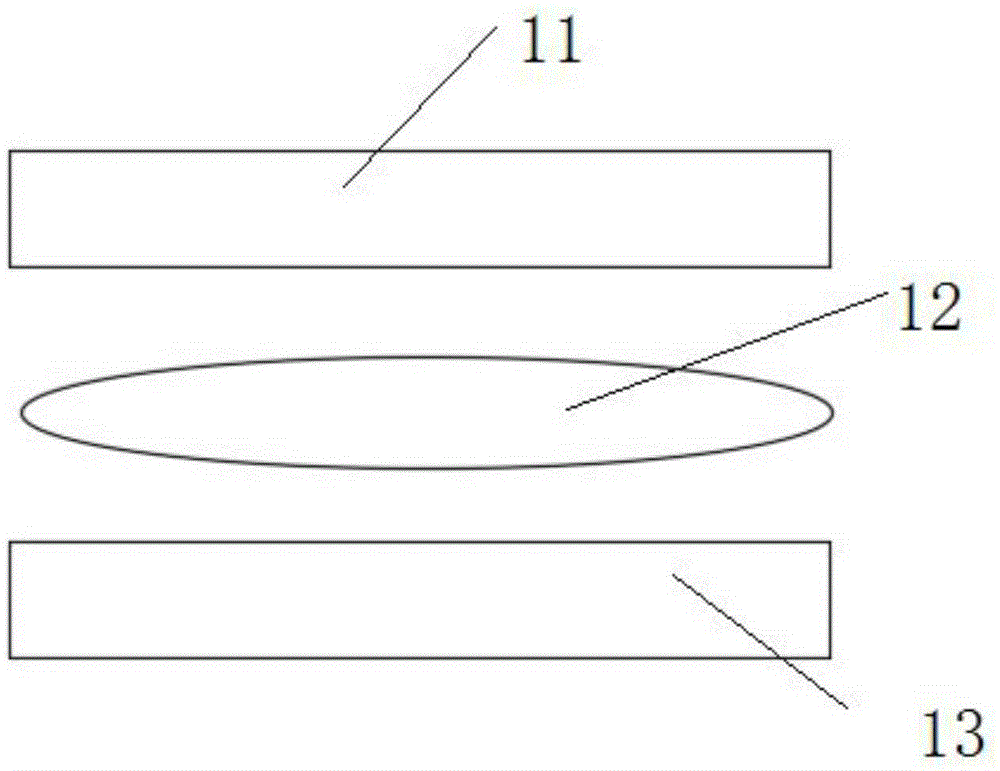

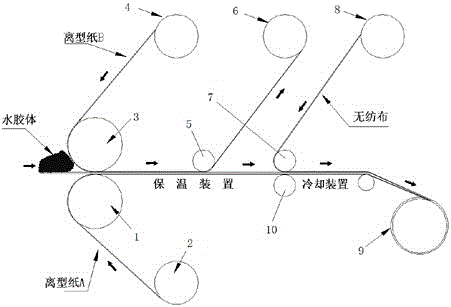

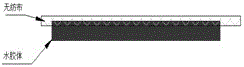

Non-woven fabric hot melt adhesive tape as well as coating method and coating device thereof

PendingCN107521213APrevent hot melt adhesive from seeping throughGuaranteed stickinessLamination ancillary operationsLaminationWoven fabricPolymer chemistry

The invention relates to a coating method of a non-woven fabric hot melt adhesive tape. The coating method comprises the following steps: (1) recombining for the first time: enabling release paper A and release paper B to be recombined together by utilizing hot melt adhesive, and preserving heat to enable the hot melt adhesive to keep a fluid state, wherein the release force between the release paper B and the hot melt adhesive is less than the release force between the release paper A and the hot melt adhesive; (2) peeling off the release paper B: peeling off the release paper B and the hot melt adhesive to enable one side of the hot melt adhesive to be exposed to become a to-be-recombined surface; (3) recombining for the second time: enabling non-woven fabric and the to-be-recombined surface of the hot melt adhesive to be recombined, cooling simultaneously to enable the hot melt adhesive to be solidified so as to obtain the non-woven fabric hot melt adhesive tape; and (4) rolling-up: rolling-up the obtained non-woven fabric hot melt adhesive tape. The invention further discloses a coating device of the non-woven fabric hot melt adhesive tape, and the obtained non-woven fabric hot melt adhesive tape has the following characteristics: (1) by enabling the hot melt adhesive and the non-woven fabric to be combined together, the dressing meets hydroscopicity and air permeability simultaneously; and (2) as the hot melt adhesive is recombined on the non-woven fabric, not only is the hot melt adhesive difficult to peel off, but also adhesive overflowing cannot happen.

Owner:ZHEJIANG HAICHUANG MEDICAL DEVICE CO LTD

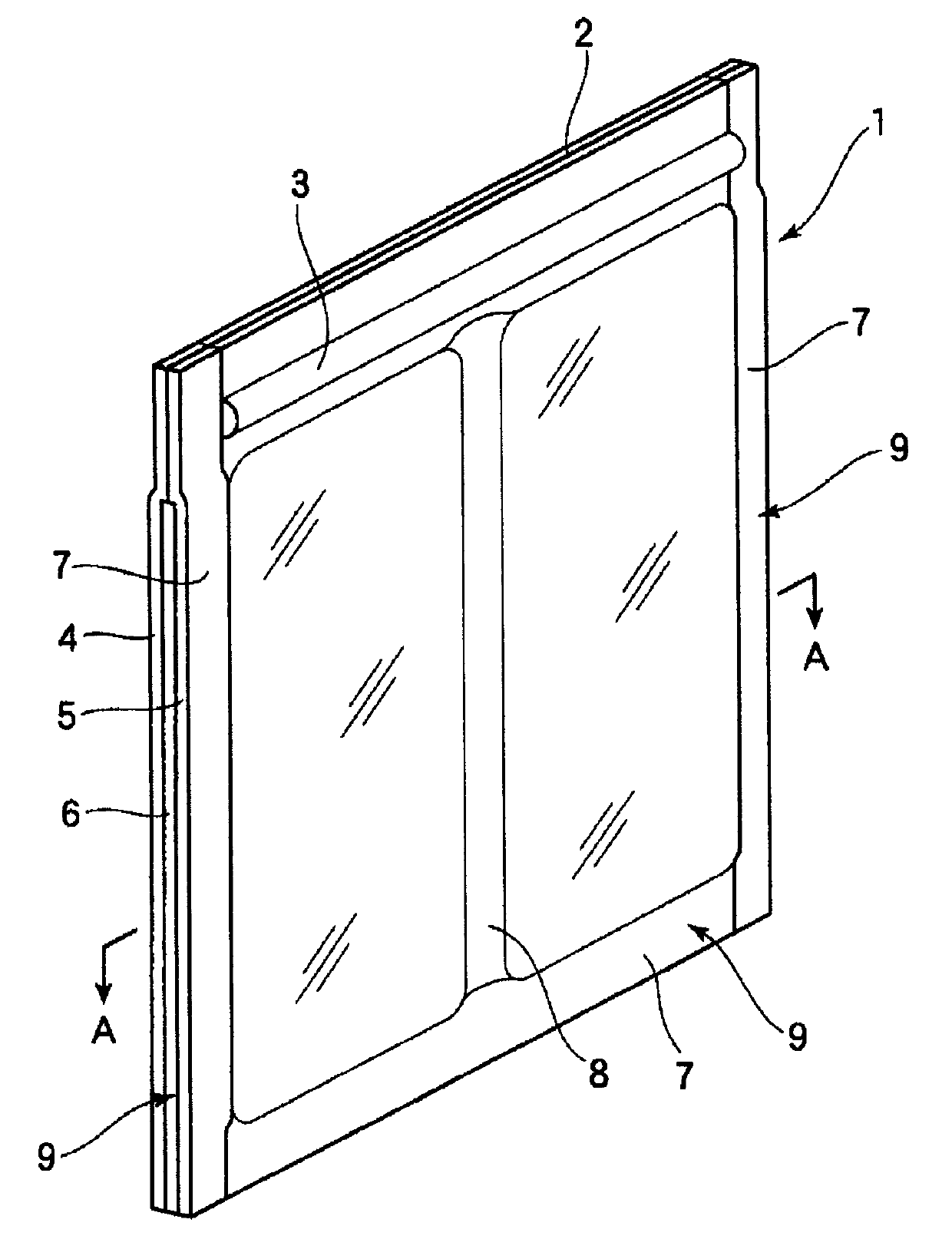

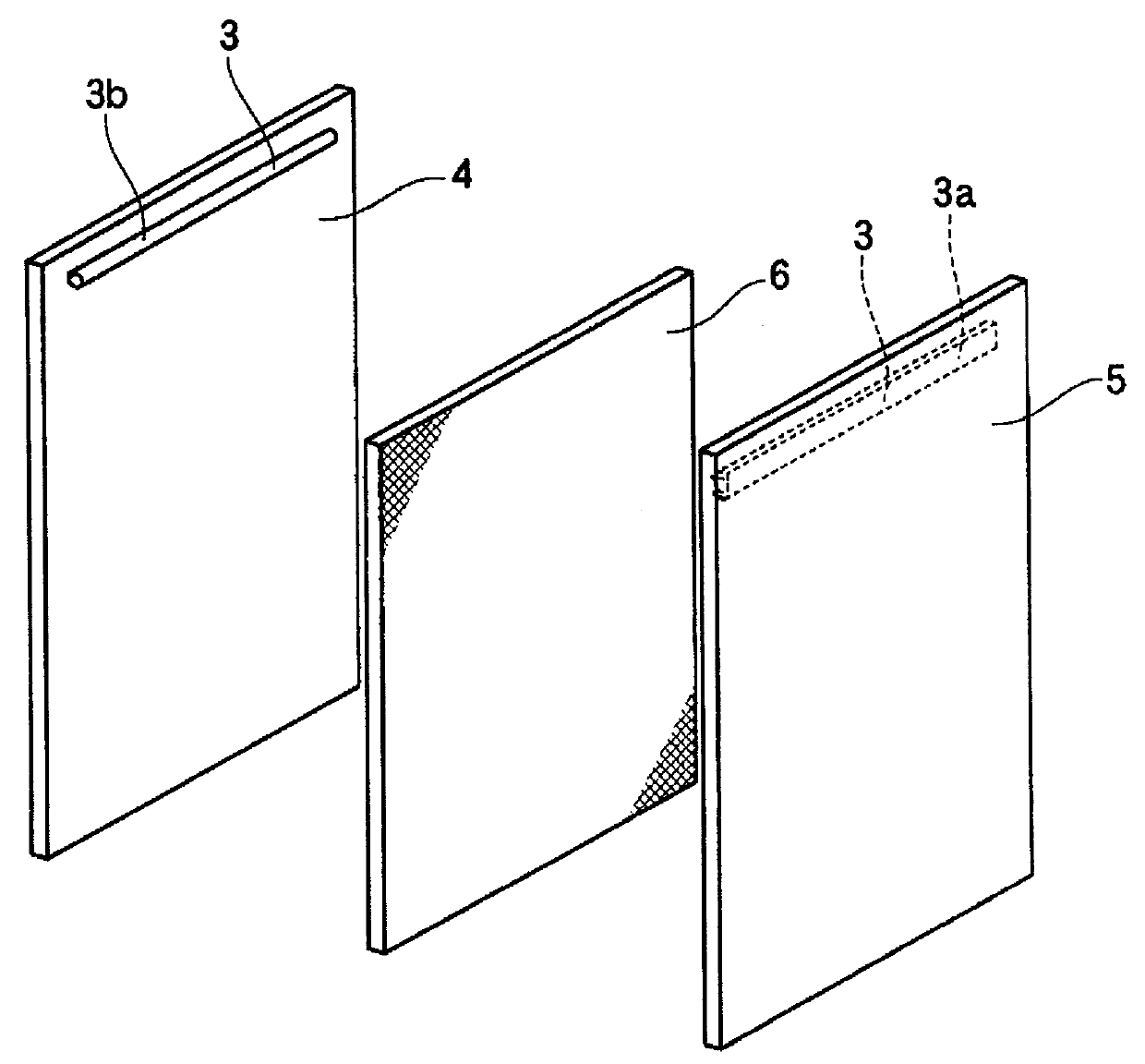

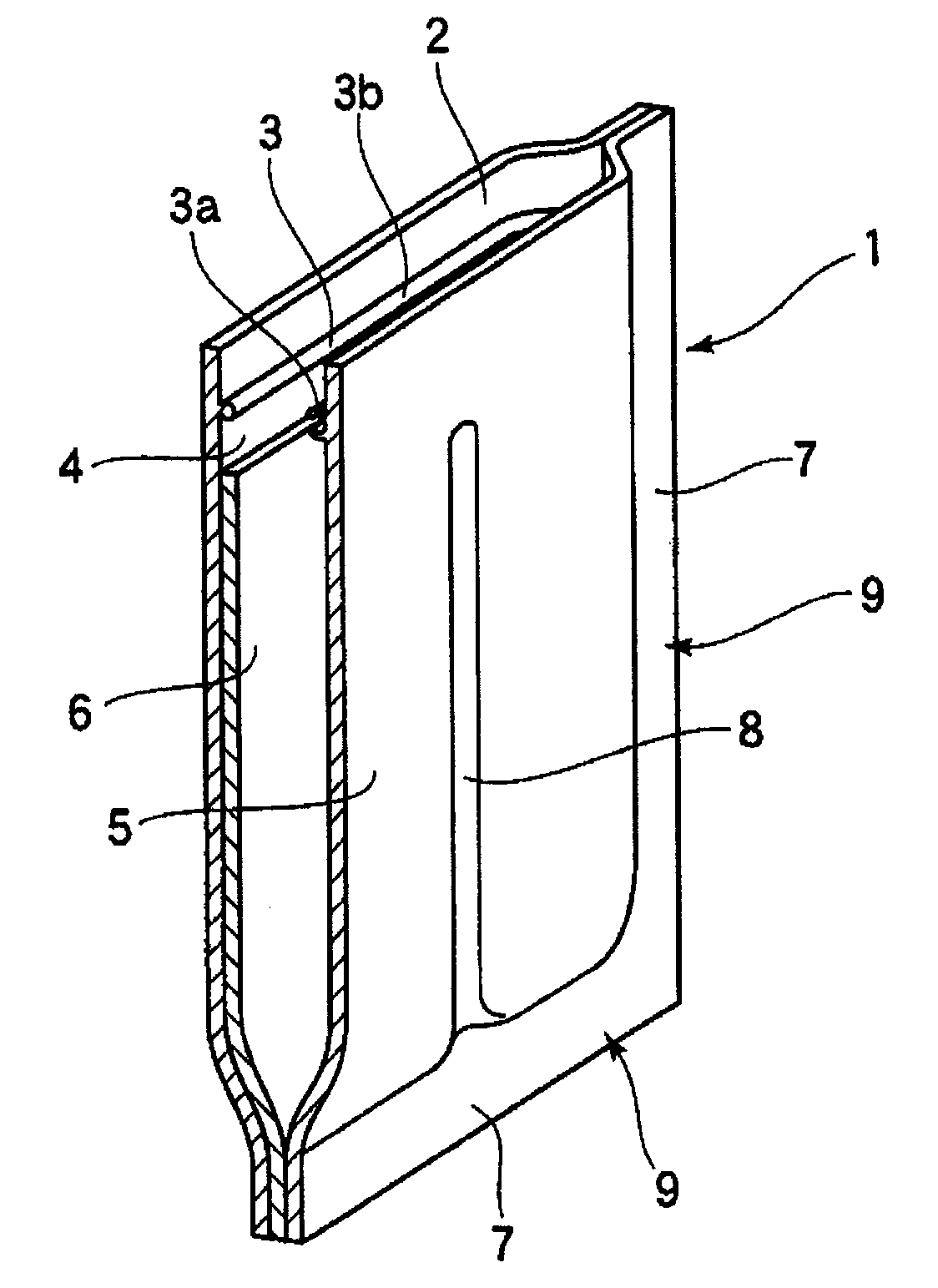

Packaging bag for transportation

A packaging bag for transportation, provided with an openable and closable sealing section (3) for sealing an opening (2). An absorbing material (6) which is a cloth-like material formed by providing synthetic fibers, which have been stretched into a fibrous form, with hydrophilic characteristics is sandwiched between two sheets of packaging materials (4, 5) consisting of a thermoplastic synthetic resin film, and edges (7) sandwiching the absorbing material (6) are fusion bonded together at portions excluding the opening (3). In this way, a bag body (1) is formed.

Owner:EIKEN KAGAKU +1

Anti-static sole material for clean room and manufacturing method thereof

The invention discloses an anti-static sole material for a clean room. The anti-static sole material comprises the following materials in parts by weight: 76-80 parts of ethylene-vinyl acetate copolymer micelle, 4-5 parts of a bridging agent, 1.2-1.5 parts of bridging additive, 9-11 parts of calcium carbonate, 2.5-3 parts of azobisformamide powder, 1.2-1.3 of dicumyl peroxide powder, 1.6-1.7 parts of zinc oxide powder, 1.2-1.3 parts of stearic acid powder, 3-6 parts of alkylphenol polyoxyethylene ether liquid, 3-6 parts of stearamide propyl dimethyl-b-hydroxyethyl ammonium nitrate liquid, 0.5-1.5 parts of glycerol monostearate particles, 0.5-1.5 parts of ethoxylated alkyl ammonium sulphate solid and 0.5-1.5 parts of ethoxylated alcohol solid. Meanwhile, the invention also discloses a manufacturing method of the anti-static sole material for the clean room. Shoe soles made of the anti-static sole material have excellent and enduring anti-static property; after the products are normally used for 6 mouths, the electrical resistivity of the products still can stabilize in the range from 1 megohm to 35 megohm; and the products are light in weight, have environmentally-friendly effect and are very suitable for application in dust-free plants.

Owner:深圳市兴业卓辉实业有限公司

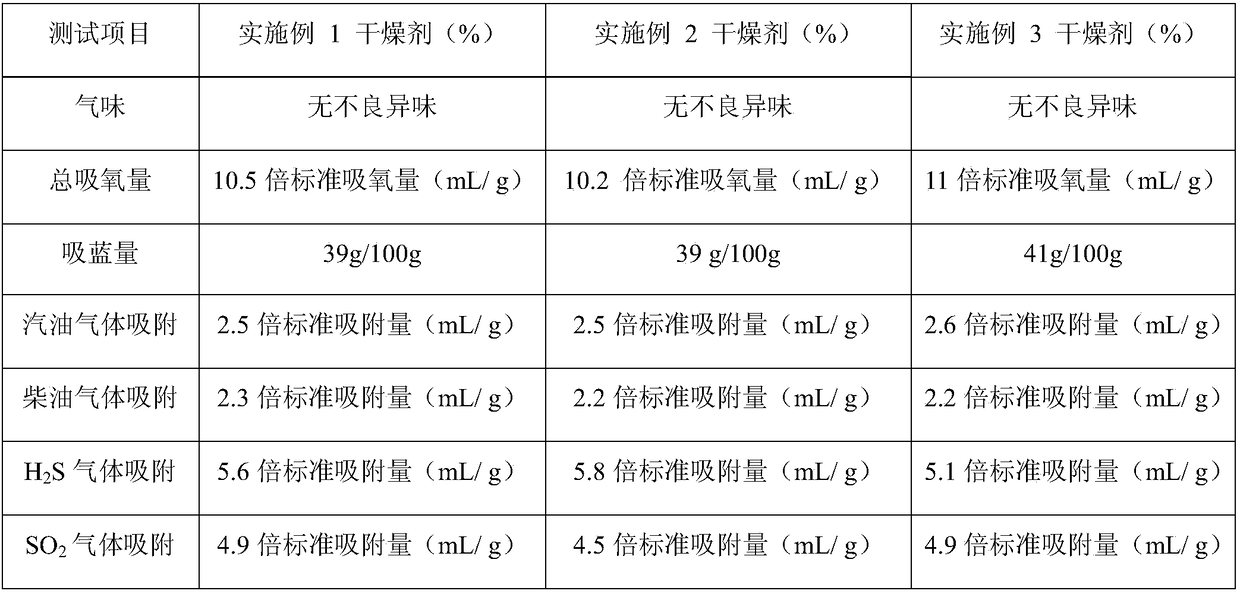

Military mildew-proof and anti-oxidation high moisture absorption desiccant and preparation method thereof

InactiveCN108927115AImprove water locking abilityInhibition of spit phenomenonOther chemical processesDispersed particle separationMicrosphereMoisture absorption

The invention discloses a military mildew-proof and anti-oxidation high moisture absorption desiccant, which comprises the following components by weight: 20-30 parts of montmorillonite; 20-30 parts of attapulgite; 5-10 parts of microsphere silica gel; 3-5 parts of lemon peel powder; 0.5-1 part of chitosan; 5-8 parts of pomelo peel powder; 10-15 parts of calcium chloride; and 5-8 parts of sodium carboxymethyl cellulose. The desiccant provided by the invention has the characteristics of fast drying speed, good moisture absorption effect, strong moisture absorption capacity and difficult re-damping, excellent oxidation resistance and mildew-proof and bacteriostatic functions, and is suitable for use on warships in high humidity and high salt sea surface environment.

Owner:中国人民解放军海军航空大学青岛校区

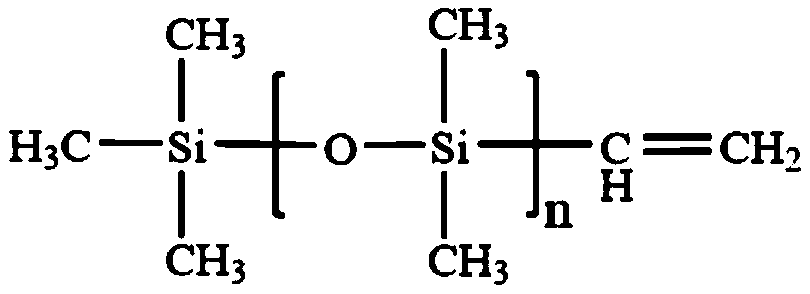

Mixing silicon rubber composition for anti-dynamic fatigue key

The invention discloses a mixing silicon rubber composition for an anti-dynamic fatigue key and relates to the technical field of rubber. The composition is characterized by consisting of the following components in part by mass: 50 to 80 parts of methyl vinyl silicone rubber crude rubber, 20 to 40 parts of alpha, omega-dihydroxyl polydimethyl siloxane of which the kinematic viscosity is 45,000m m<2> / s, 1 to 3 parts of alpha, omega-dihydroxydimethylpolysiloxane of which the kinematic viscosity is 90m m<2> / s, 20 to 50 parts of white carbon black, 0.1 to 0.5 part of 2,5-bis(tert-butylperoxy)-2,5-dimethylhexane, and 0.01 to 1 part of zinc stearate. By adding dihydroxyl siloxane, the processability of the mixing silicon rubber is improved, and low-molecular-weight cyclosiloxane cannot be oozed after the silicon rubber key is used repeatedly, so that the current conduction obstacles on a part of a pressed point can be avoided.

Owner:滁州天成有机硅高分子材料有限公司

Efficient dehumidification adhesive for plywood

InactiveCN106554730ALow priceIncrease surface contact areaNon-macromolecular adhesive additivesStarch adhesivesSodium BentoniteAdhesive

The invention discloses an efficient dehumidification adhesive for plywood. The efficient dehumidification adhesive for plywood is composed of, by weight, 50-100 parts of attapulgite powder, 10-20 parts of calcium bentonite, 10-15 parts of nanosilicon dioxide, 15-30 parts of nanometer magnesia, 15-30 parts of super absorbent resin, 10-15 parts of anhydrous calcium chloride, 5-10 parts of wheat flour, 5-10 parts of sodium hydroxide and 10-15 parts of carboxymethyl cellulose. The raw materials for preparation of the adhesive are all natural mineral resources and inorganic salt which are easy to obtain, and the raw materials are low in price, nontoxic and environmentally friendly. The adhesive can increase the surface contact area between resin and the plywood, has the effects of efficient dehumidification and drying, and has the advantages of high bonding strength and long service life.

Owner:明光市龙腾矿物有限公司

Suction pressure structure of cone-shaped spring in ink box

InactiveCN1445092ABig room for expansionSolve the ineffective use ofPrintingEngineeringMechanical engineering

A conic spring structure for generating negative pressure in ink box to prevent ink leakage is composed of an ink containing space and at least one conic spring able to be compressed in diameter direction. Under the action of said conic spring, a negative pressure in normally generated between ink-containing space and external environment. It also has an air space adjacent to the ink-containing space for regulating the negative pressure value applied to ink-containing space.

Owner:PRINTECH INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com