Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "With damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

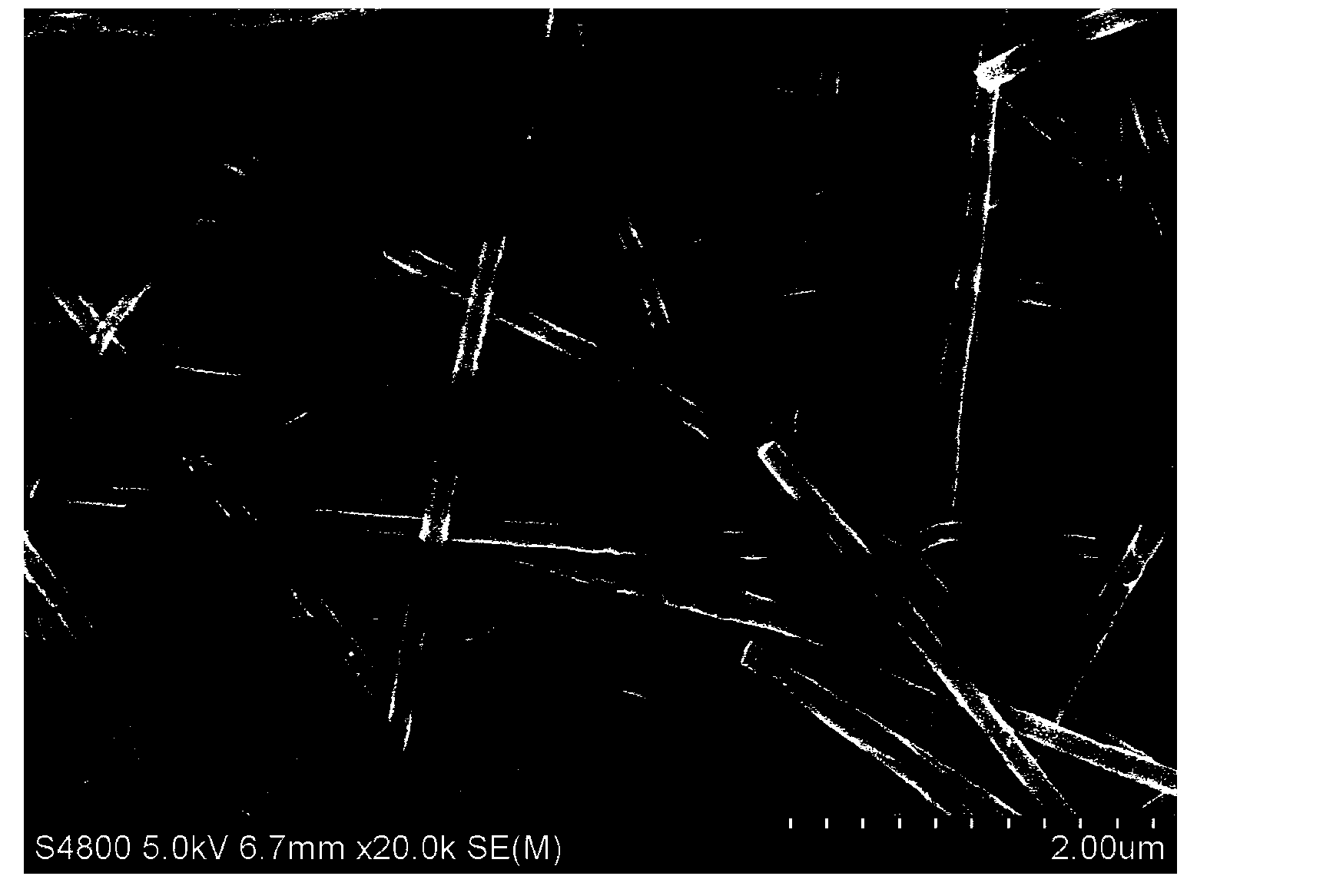

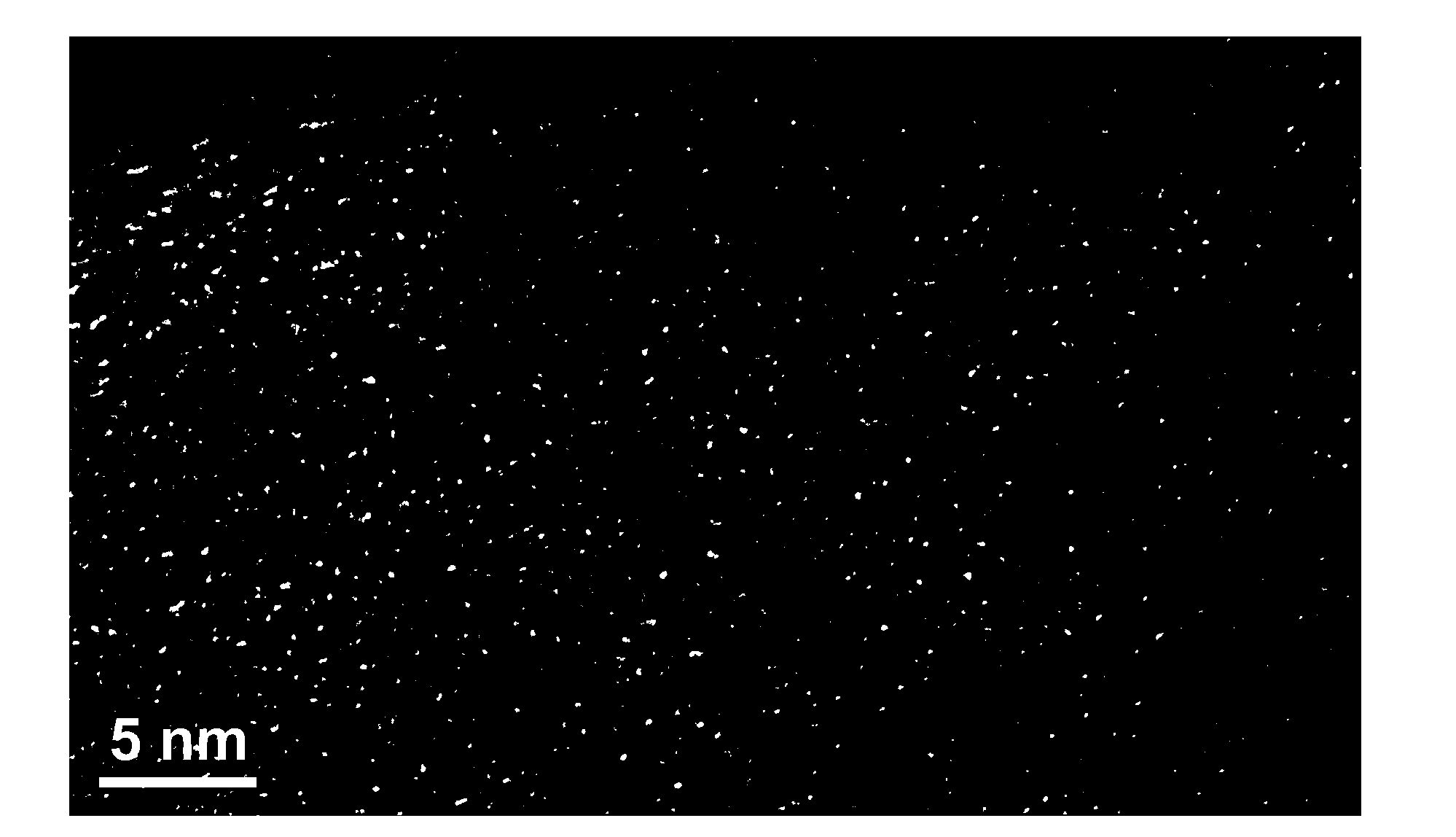

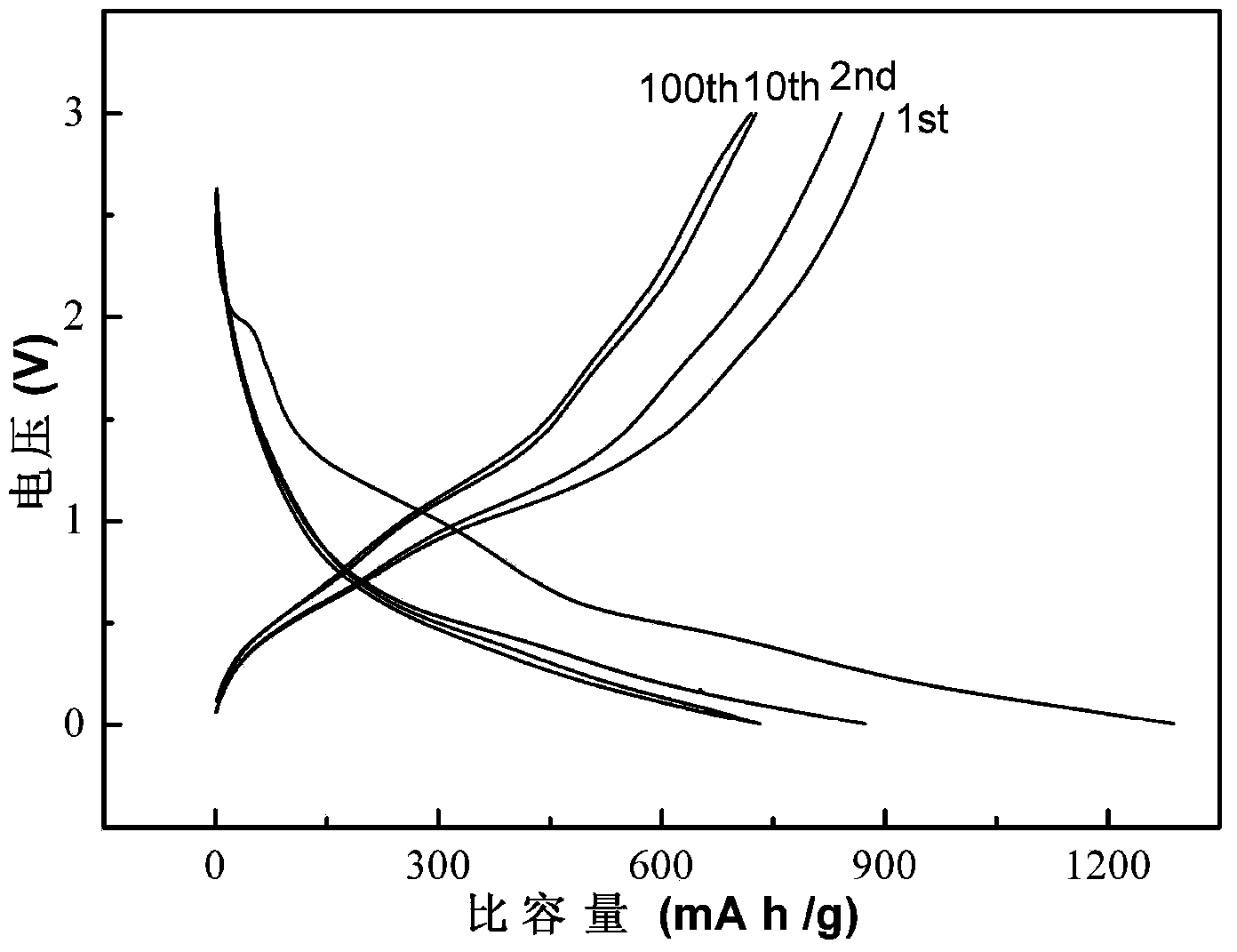

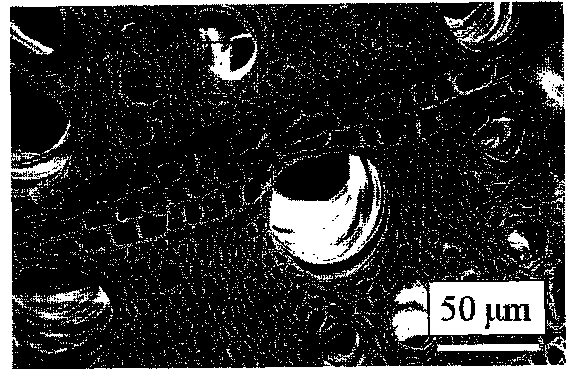

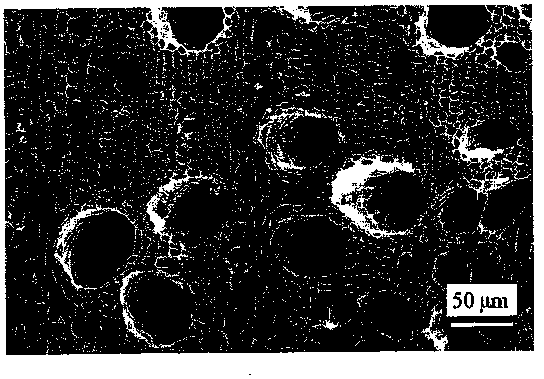

Convenient method for preparing binder-free stannic oxide/carbon fibrofelt for negative pole of high-performance lithium ion battery

InactiveCN104319372AImprove mechanical stabilityInhibition of agglomerationCell electrodesCarbon fibersElectrospinning

The invention discloses a convenient method for preparing binder-free stannic oxide / carbon fibrofelt for a negative pole of a high-performance lithium ion battery. The method disclosed by the invention comprises the following steps: dissolving polyacrylonitrile and stannous chloride which have certain concentrations to a N'N-dimethyl formamide solution, magnetically stirring the solution of polyacrylonitrile, the stannous chloride and the N'N-dimethyl formamide solution until the solution is clarified, electrostatically spinning the solution, and finally annealing the obtained solution which is obtained at a high temperature twice to obtain Sn-SnOx uniformly loaded nanometer composite materials of the carbon fibrofelt. For a compound which is prepared by the method disclosed by the invention, since the electrostatic spinning method is adopted, nanometer particles of metal-metallic oxide are uniformly dispersed into buffer substrate carbon fiber, and the circulation specific capacity and the stability of materials for the negative pole of the lithium ion battery are effectively improved. The preparation technology disclosed by the invention has the advantages that the operation is simple, the cost is low, the efficiency is high, the large-scale and industrial production is easy to realize, and the application range is broad.

Owner:HUNAN UNIV

Rubber reinforced cement functional composite material and preparation method thereof

InactiveCN101857399AWith noise reductionWith sound insulationSolid waste managementNoise barrierAdhesive

The invention discloses a rubber reinforced cement functional composite material and a preparation method thereof. The rubber reinforced cement functional composite material is prepared from waste rubber and cement or cement mortars by the following steps of: applying coupling adhesives to surfaces of waste rubber grains and / or powder by using coupling agents; mixing the waste rubber grains and / or powder with the cement or the cement mortars; adding water into the rubber-cement mixed materials for uniform stirring, and performing pavement, pressing, demoulding and maintaining to obtain the functional composite material product having a high mechanical strength and endurance. The composite material has the characteristics of noise reduction, sound isolation, high impact resistance, damping vibration attenuation, wear resistance, static resistance, water resistance and the like, has the advantages of insulation, environmental protection and the like and can be used in the field of functional materials, such as buildings, roads, railways, tunnels, noise barriers and the like. The functional composite material and the method thereof also provide a new way for solving the global problem of 'black pollution' of increasing waste tyres and have a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

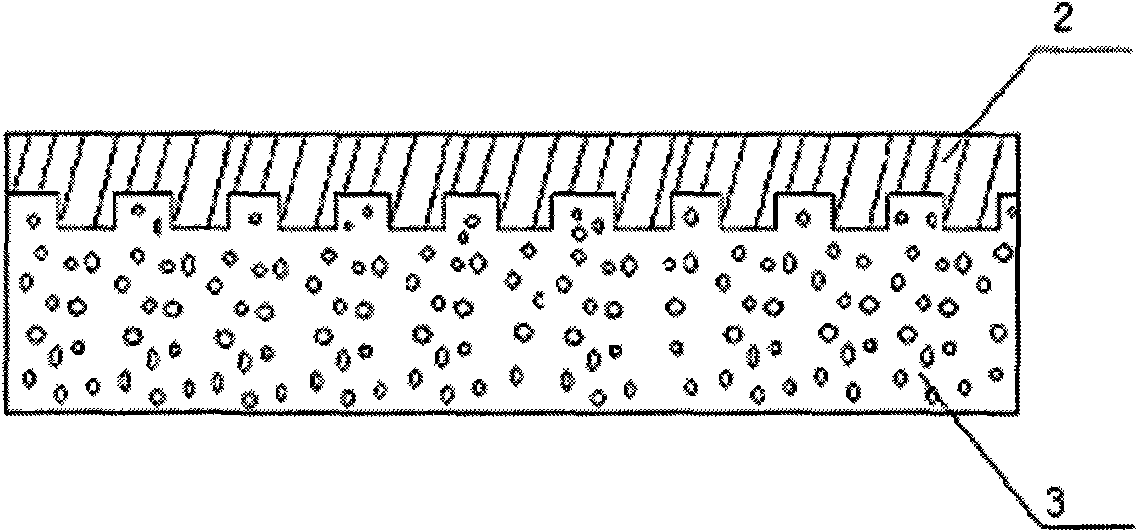

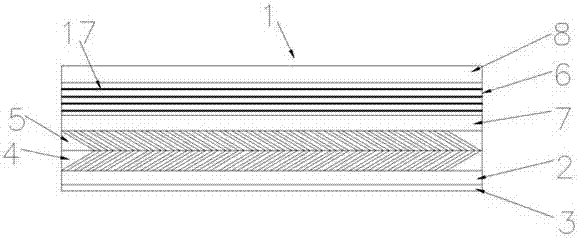

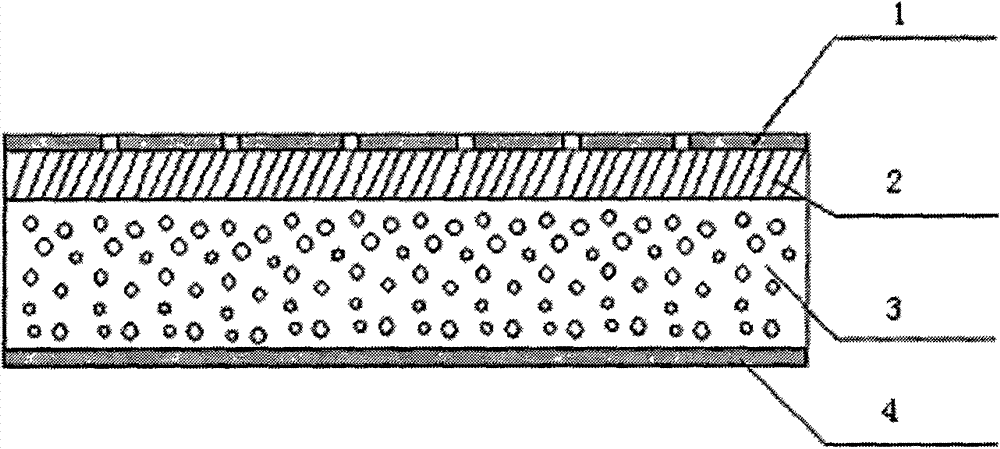

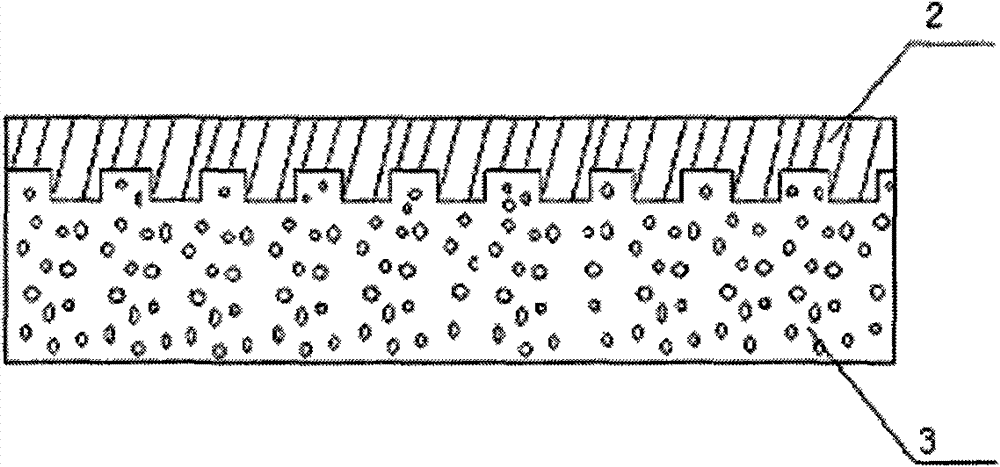

Urethane foam composite board and preparation method thereof

ActiveCN101618611AGood heat insulationIncrease temperatureSynthetic resin layered productsLaminationEngineeringNoise reduction

The invention discloses a urethane foam composite board comprising panels and a composite core plate, wherein the two panels comprise an optically flat damping sheet and porous damping sheets, wherein one surface of the optically flat damping sheet is provided with a non-setting adhesive layer, and the porous damping sheets are arranged in a square or a triangle shape regularly; the composite core plate forms a single-side core plate by splicing one side of a perforated urethane forming board with the porous damping sheets; the single-side core plate and the optically flat damping sheets are foamed, cured and bound to be a multi-layer structure complex by A and B constituent urethane foam composite materials in a forming die, and the urethane foam composite board is obtained after deburring the multi-layer structure complex. The invention has the integrated function of damping, noise reduction, heat and sound insulation and sound absorption, and has simple preparation method and convenient installation and use, thereby being beneficial to popularization and application.

Owner:BEIJING RADIATION APPL RES CENT

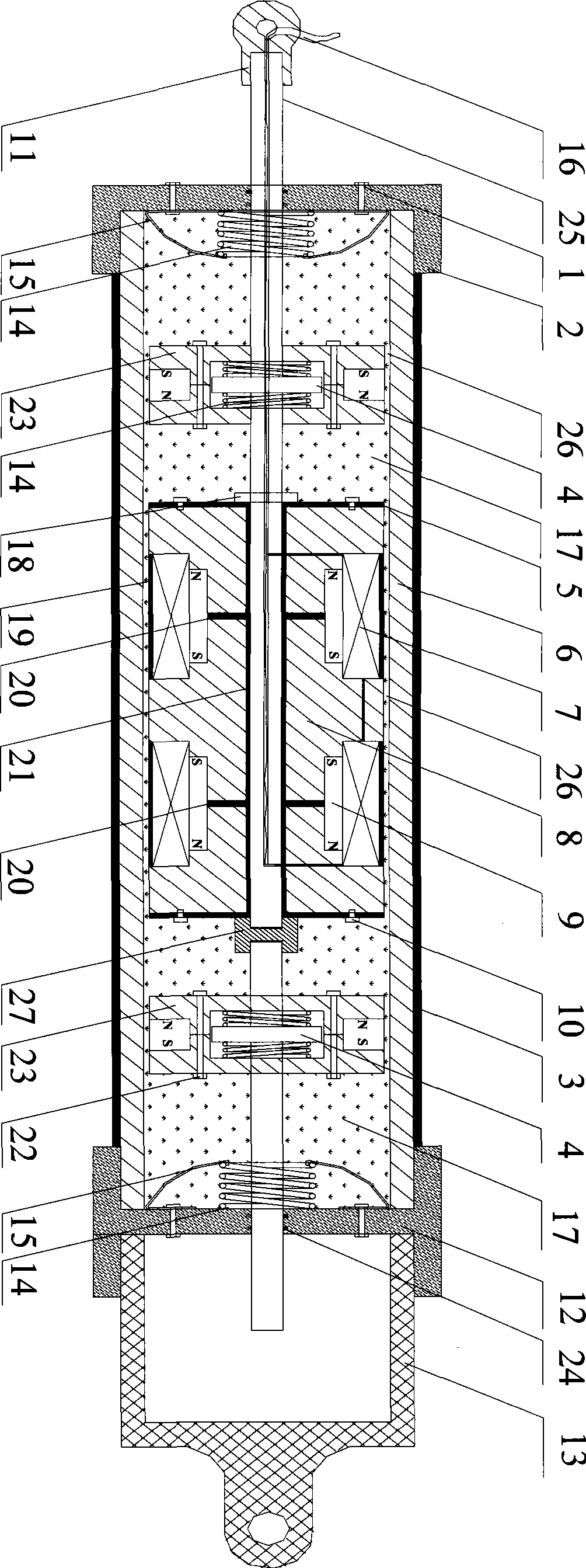

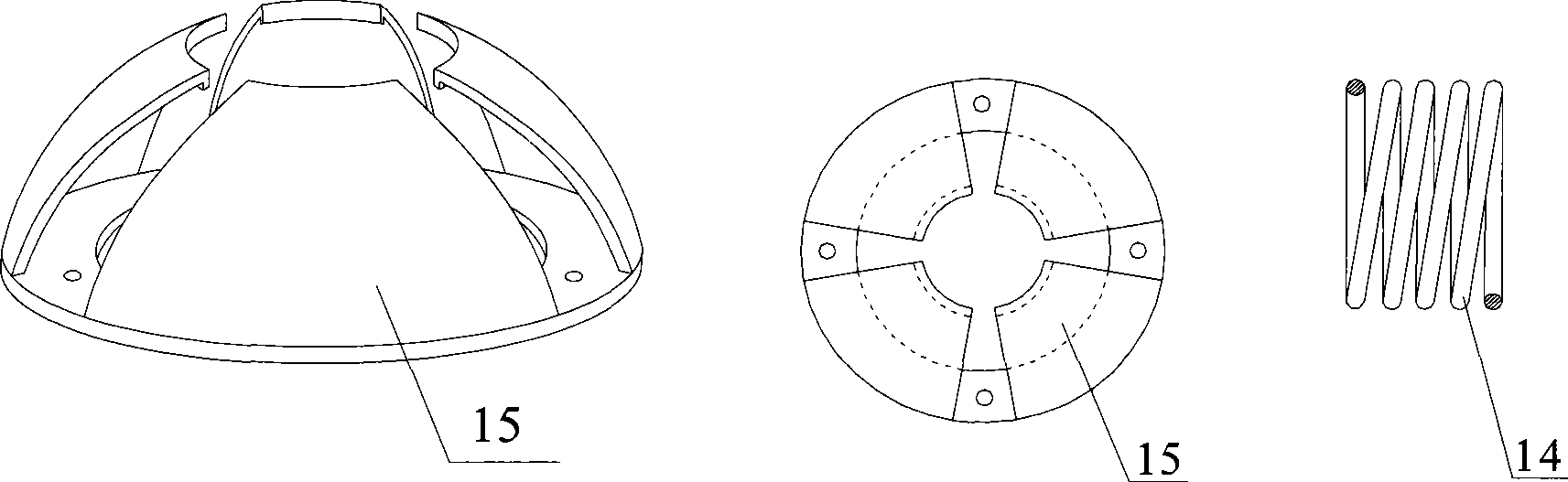

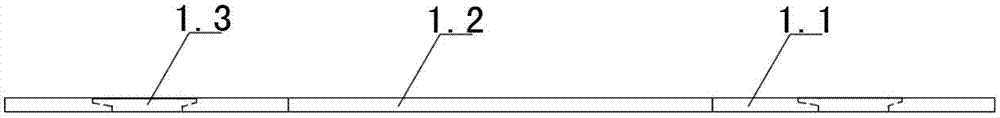

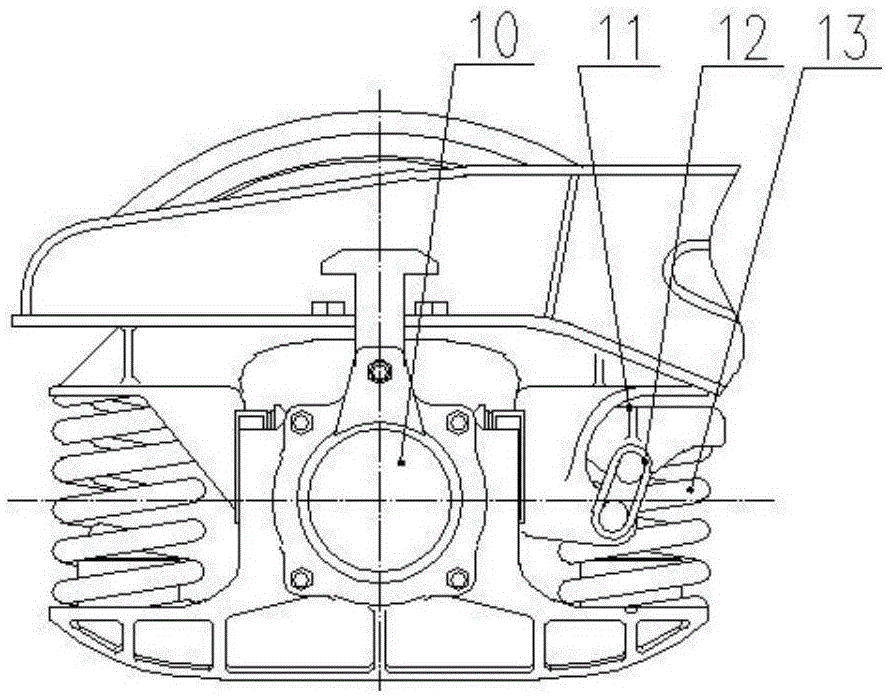

High-energy consumption self-decoupling magnetorheological damper

The invention relates to a high-energy consumption self-decoupling magnetorheological damper with damping force decoupling property and failure self-protection function. The damper not only has high energy consumption and output, but also can effectively prevent subsidence of magnetorheological fluid, therefore, the invention is suitable for civil engineering structures. The damper mainly comprises a master cylinder body (6), an auxiliary cylinder body (13), a main piston (8), two auxiliary pistons (23), a piston rod (25), and novel composite-structure energy accumulators (14 and 15). Permanent magnets (9) arranged in the main piston (8) and the two auxiliary pistons (23) can effectively prevent subsidence of magnetorheological fluid, and can still provide corresponding damping force under the condition of power supply failure to enhance the safety of the structure. Magnetic circuit guiding components improve the utilization factor of the magnetic field. A mechanical spring self-decoupling device is mainly operated on the condition that the damper is under low-frequency driving, thereby overcoming the disadvantage of low output of the damper under low-frequency driving.

Owner:HOHAI UNIV +1

Preparation method of hemp fabric construction morph-genetic ceramic composite material

InactiveCN101838146AGood sensing and electromagnetic shieldingBroaden the field of applicationHot pressOxide

The invention discloses a method for preparing a hemp fabric construction morph-genetic ceramic composite material, comprising the following steps: preparing a hemp fabric construction formwork or hemp fabric construction / precursor composite formwork; placing into a vacuum hot-pressing furnace; heating the two formworks at vacuum or inert gases protective atmosphere; cooling in the furnace or cooling by temperature control to prepare a morph-genetic carbon formwork or the morph-genetic ceramic composite material; performing liquidoid silicon seepage or gases phase silicon seepage on the morph-genetic carbon formwork at vacuum or inert gases protective atmosphere; repeatedly dipping precursor solution or precursor sol on the morph-genetic carbon formwork, a morph-genetic carbonization composite material, a nitride ceramic composite material or an oxidization ceramic composite material; performing carbon heat returning reaction to obtain the hemp fabric construction morph-genetic ceramic composite material. The preparation method of the invention not only leads the morph-genetic material to inherit manually manufactured arrangement manner and arrangement structure of hemp fabric and multi-layer multi-dimensional intrinsic fine structure of the hemp fabric organism, but also endows new functions thereof.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Biomass composite material and preparation method thereof

The invention belongs to the technical field of composite materials and preparation thereof, and relates to a biomass composite material and a preparation method thereof. The biomass composite material is prepared from bio-based epoxy resin reinforced by plant fiber fabric, wherein on or two of continuous-filament woven fabric of ramie, flax, jute, China-hemp, kenaf or sisal hemp can be adopted as the plant fiber fabric; the fabric is twill, plain or satin fabric, or gridding cloth, and has the surface density of 80-300g / m<2>; the source of biomass epoxy resin is rosin, itaconic acid, gallic acid or epoxy soybean oil; an abietic anhydride-based curing agent is used as the resin; one or two of organic urea derivatives, thiourea derivatives, quaternary ammonium salts, quaternary ammonium phosphate, imidazole salts and acetylacetone metal complexes are used as accelerants; the glass transition temperature of the composite material is adjustable in a range of 80-160 DEG C. A prepreg is prepared by using a solution method or a hot melting method; the prepreg is good in viscosity and long in shelf life, and can be cured at high temperature or medium temperature.

Owner:ACC BEIJING SCI & TECH CO LTD

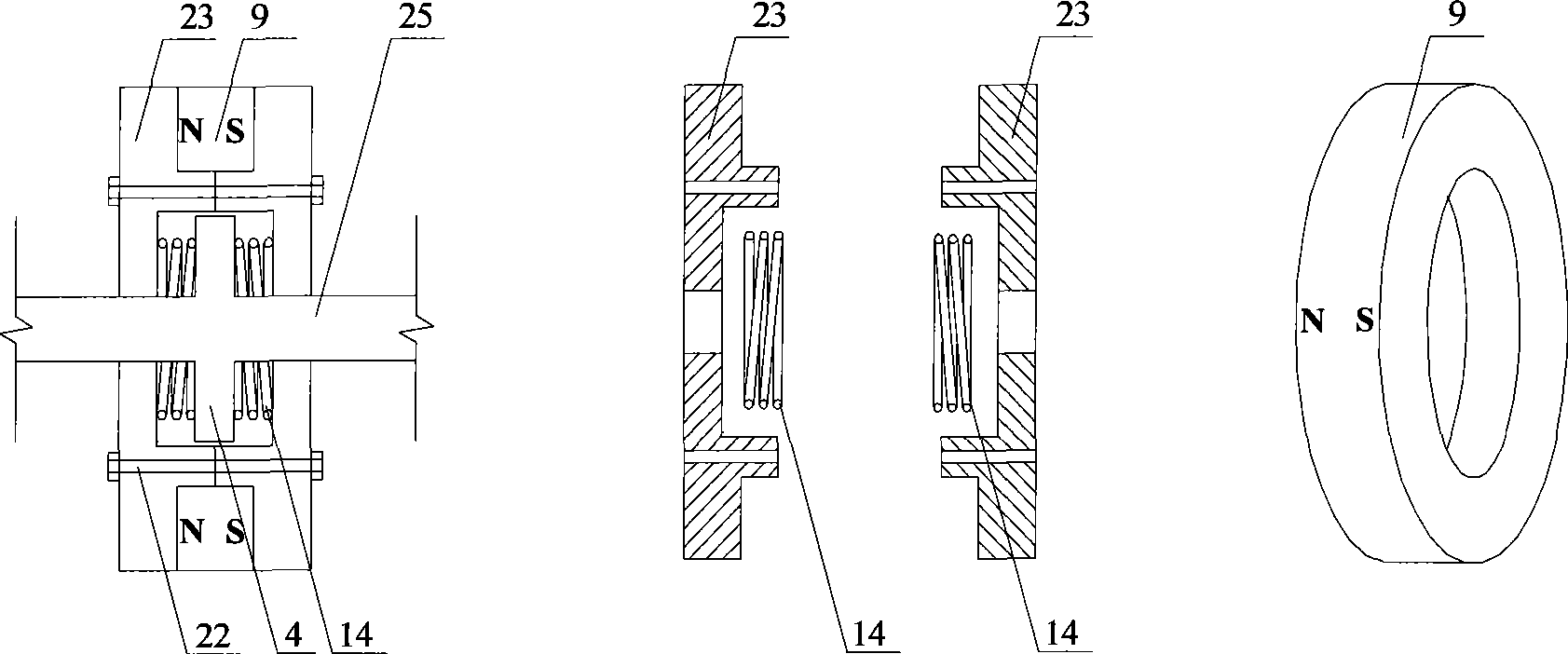

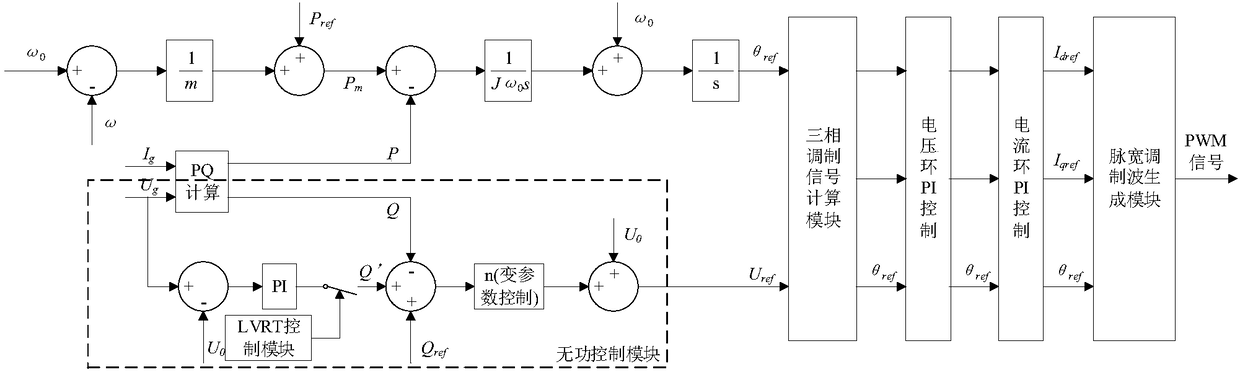

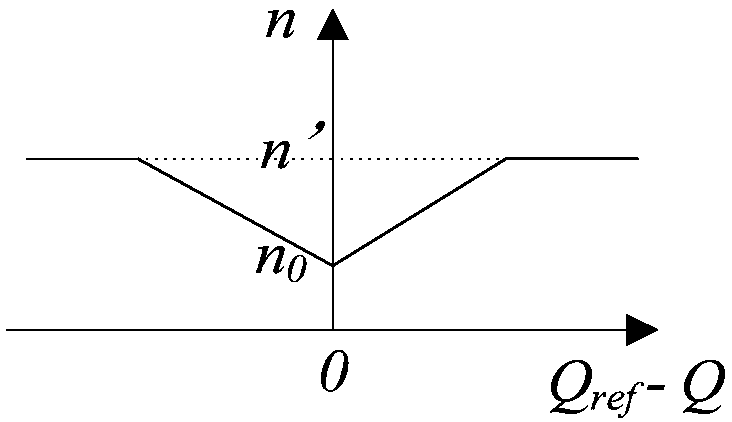

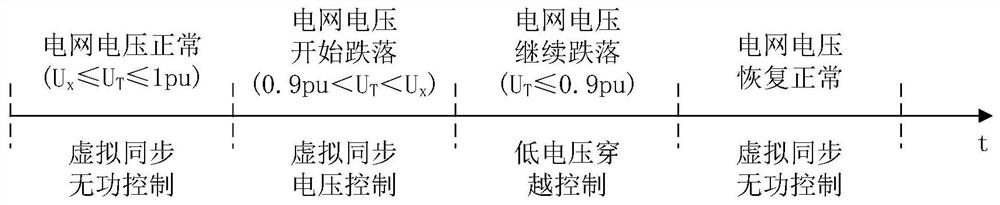

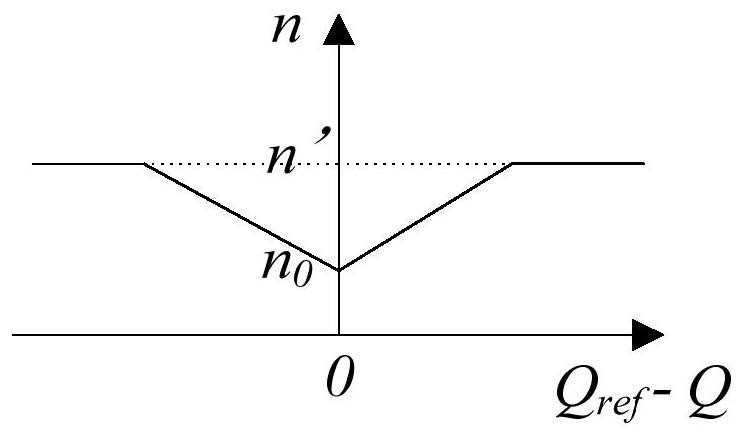

Inverter reactive power control method based on virtual synchronization mechanism

ActiveCN108521130AReduce shockImprove reactive power utilizationSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationVoltage dropPower grid

The invention discloses an inverter reactive power control method based on a virtual synchronization mechanism. At present, the inverter reactive power control method is not accurate in control. Whenthe grid voltage fluctuates slightly, the voltage cannot be controlled without any difference; when the grid voltage drops deeply, and the whole reactive power ability of the inverter cannot be played. The reactive power control method is divided into three phases: when it is monitored that the voltage of the grid-connected point is normal, a reactive power control module aims to control the output reactive power of the inverter; when the voltage drop of the grid-connected point is monitored, the reactive power control module superimposes the voltage of the grid-connected point to reduce the voltage drop; and when it is monitored that the voltage of the grid-connected point is further dropped, an LVRT control module controls the inverter to switch to a low voltage ride-through control modeto perform low voltage ride through. The invention can automatically and flexibly control the output reactive power of the inverter, improve the reactive power utilization rate of the inverter, stabilize the grid-connected point voltage, reduce the grid voltage drop degree, and does not affect the low voltage ride through capability of the inverter.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

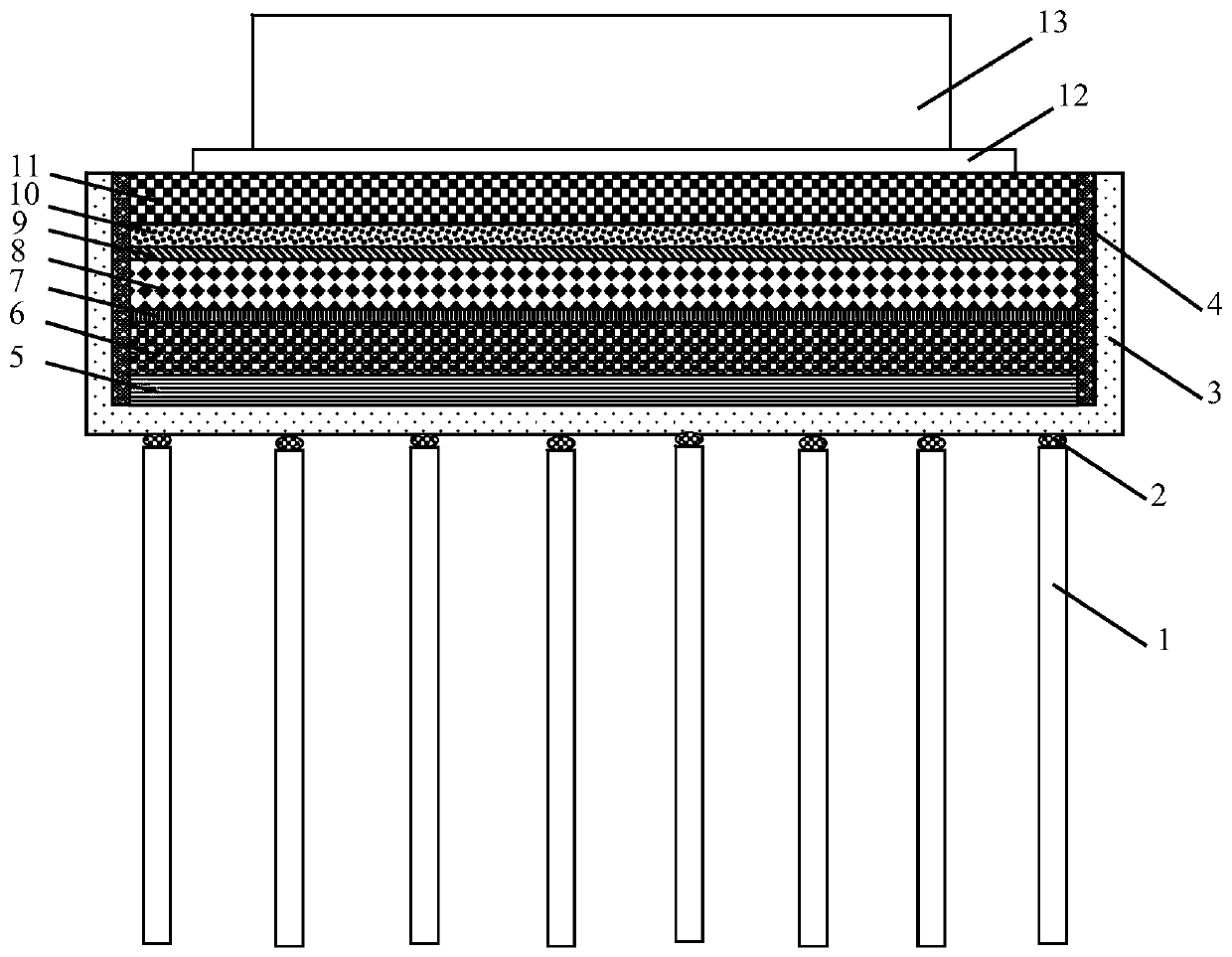

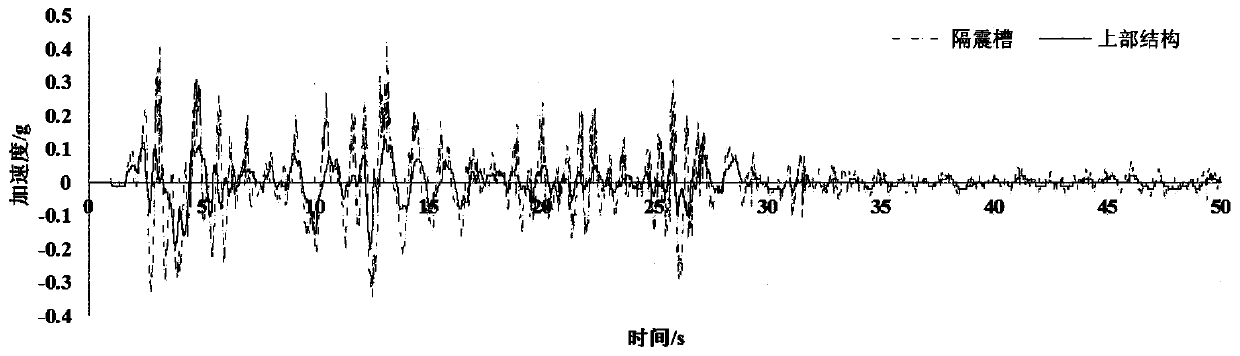

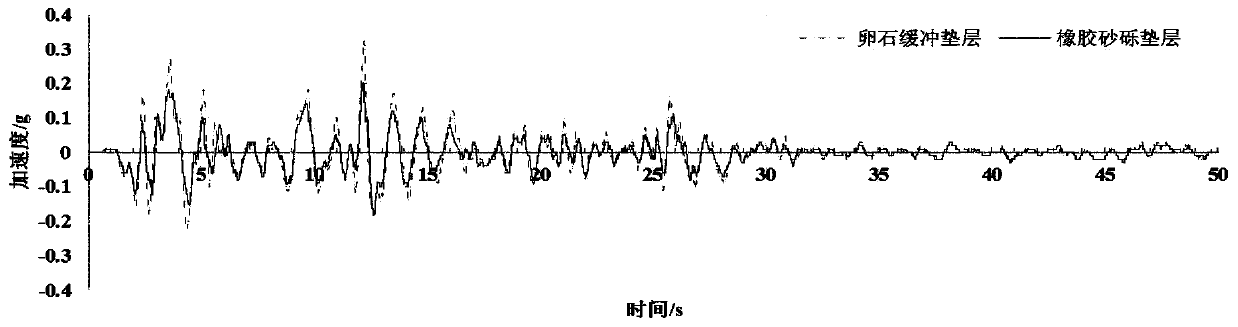

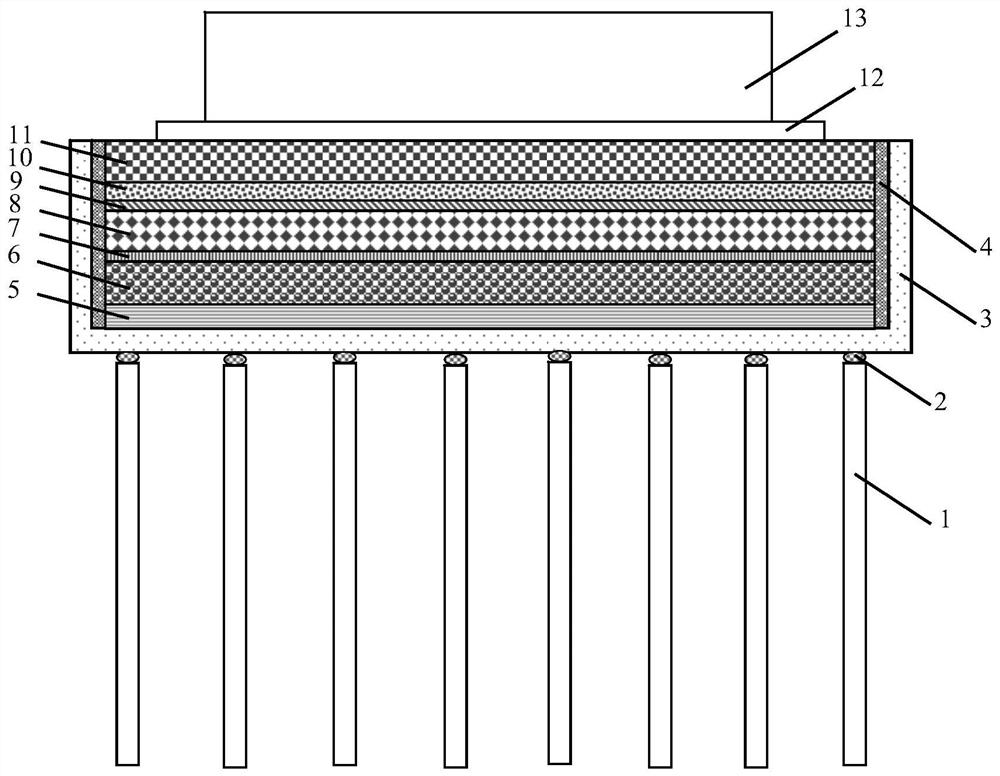

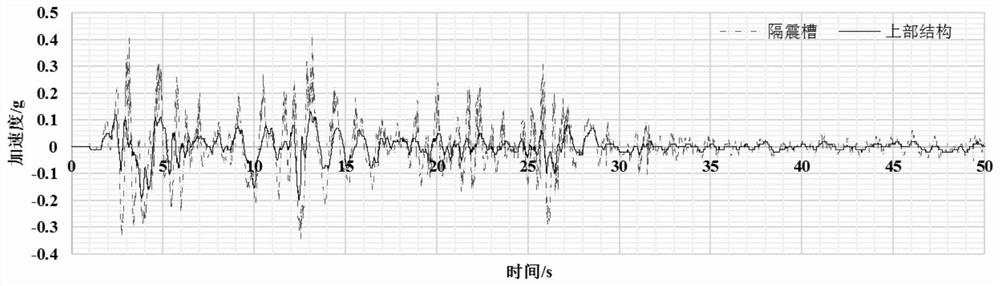

Pile-raft composite shock isolation trough foundation structure under strong shock

The invention provides a pile-raft composite shock isolation trough foundation structure under strong shock. The pile-raft composite shock isolation trough foundation structure under strong shock comprises a plurality of pile foundations, a plurality of shock isolation supporting seats and shock isolation troughs; the plurality of the pile foundations are distributed in a foundation; the shock isolation supporting seats are fixedly mounted at the pile top of each pile foundation; the shock isolation troughs are mounted on the shock isolation supporting seats; hot melt rubber layers are paved on the inner side walls of the shock isolation troughs; and rubber cushion layers, pebble buffering cushion layers, geogrids, rubber gravel cushion layers, composite geo-membranes, epoxy resin castinglayers, asphalt sand cushion layers and rafts are paved in the shock isolation troughs in sequence from bottom to top. The pile-raft composite shock isolation trough foundation structure under strongshock can effectively attenuate or eliminate seismic energy, avoid shaking and shock of an upper building and reduce the disaster caused by an earthquake. An earthquake resisting effect is outstanding; the construction is simple; the construction period is short; and the cost is reduced.

Owner:JIAMUSI UNIVERSITY

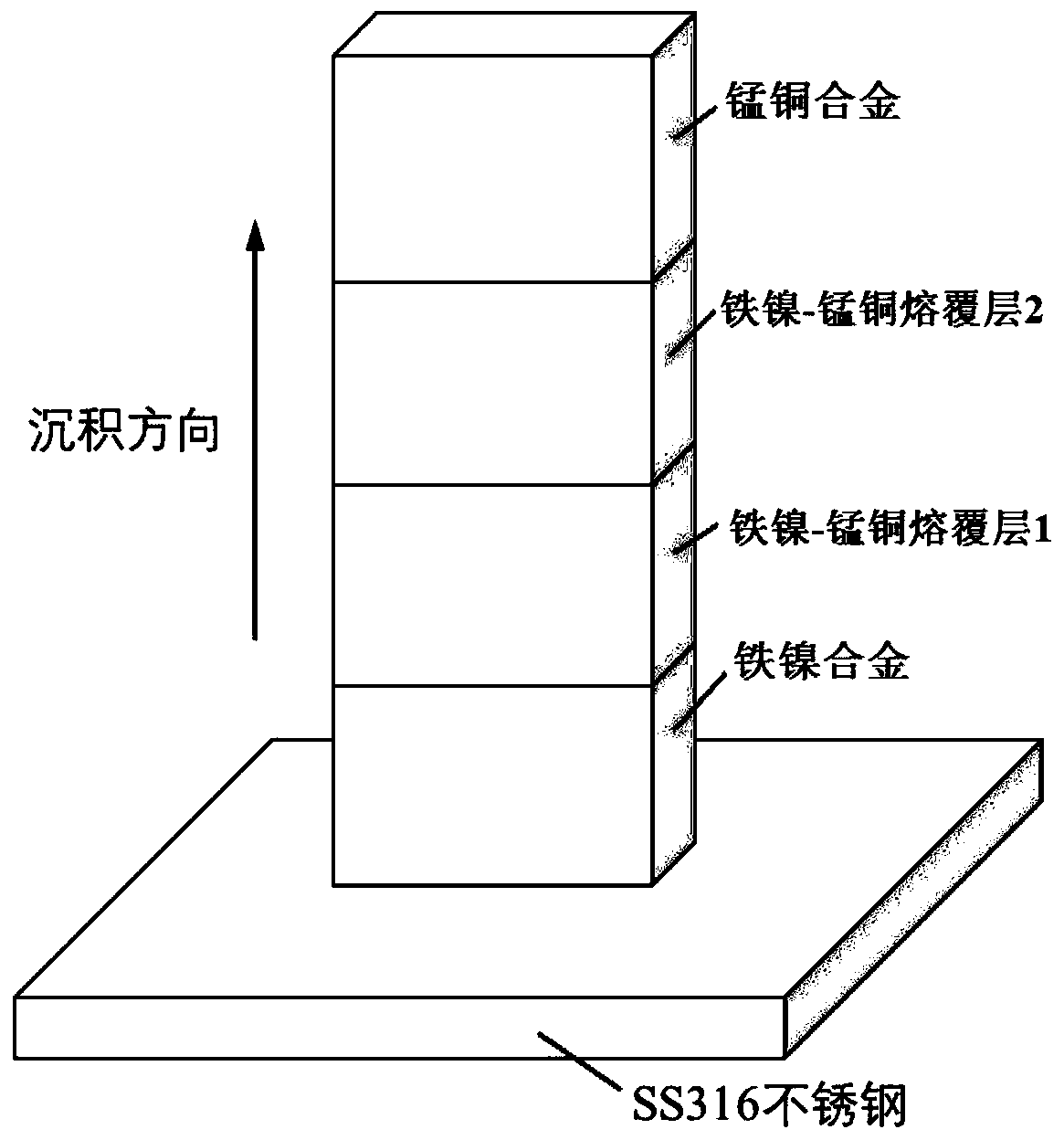

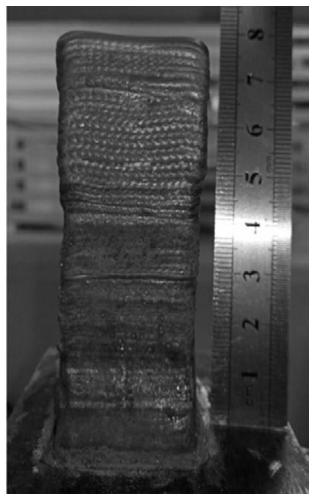

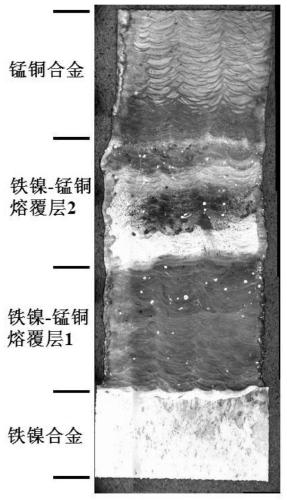

Laser additive manufacturing method for iron nickel-manganese copper dissimilar material metal part

ActiveCN111408720AAvoid crackingAvoid defects such as undissolved particlesAdditive manufacturing apparatusIncreasing energy efficiencyFernicoManganese

The invention discloses a laser additive manufacturing method of an iron nickel-manganese copper dissimilar material metal part. The method comprises the following steps that firstly, an iron-nickel alloy is deposited on a substrate by adopting a laser additive manufacturing method; secondly, mixed powder composed of iron-nickel alloy powder with the iron-nickel alloy powder mass content larger than 70% or smaller than 50% and manganese-copper alloy powder serves as a raw material, and an iron nickel-manganese copper transition area is formed through deposition with the laser additive manufacturing method; and thirdly, manganese-copper alloy is deposited on the iron nickel-manganese copper transition area through the laser additive manufacturing method, the substrate is removed, and the iron nickel-manganese copper dissimilar material metal part is obtained. According to the method, by adjusting the deposition direction and controlling the transition path of the mixed powder, the defects of cracking, undissolved particles and the like of the iron nickel-manganese copper gradient material are overcome, and the obtained iron nickel-manganese copper dissimilar material metal part is compact in structure and small in transition area size, has the damping performance and low expansion performance and is wide in application range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

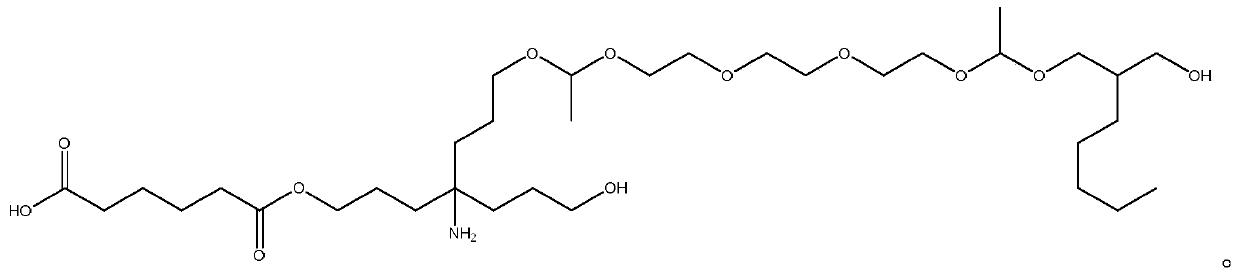

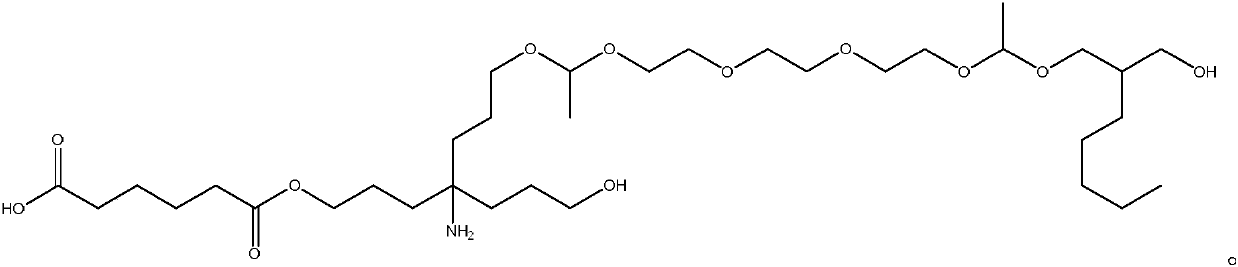

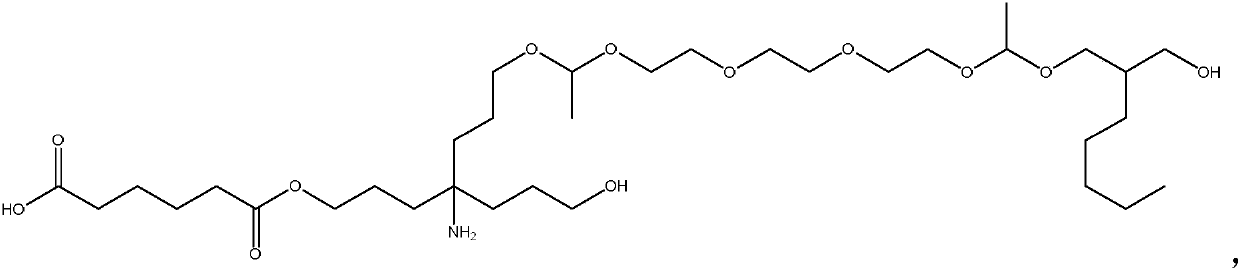

Comfortable sole with slow resilience and preparation method of sole

The invention discloses a comfortable sole with slow resilience. The comfortable sole with the slow resilience comprises the following components in parts by weight: 30-50 parts of diisocyanate, 30-50parts of a small molecule polyol, 5-15 parts of a polyol, 3-5 parts of a crosslinking agent, 1-5 parts of a foaming agent, 0.1-0.5 part of a catalyst. The polyol is a polymer of 4-amino-4-(3-hydroxypropyl)-1, 7-heptanediol, 2-n-pentylpropane-1, 3-diol, adipic acid and triethylene glycol divinyl ether. According to the comfortable sole with the slow resilience, the polyalcohol can react with the diisocyanate, and by a polymer chain segment, the integral material has the characteristic of slow resilience in actually produced sole products.

Owner:温州市显兴新材料有限公司

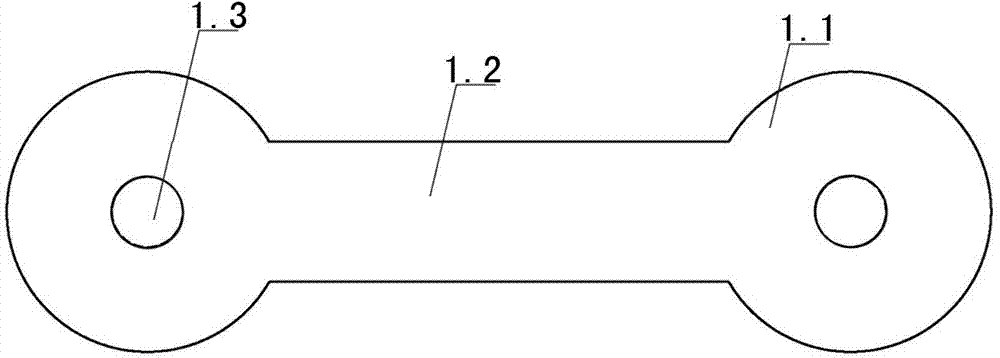

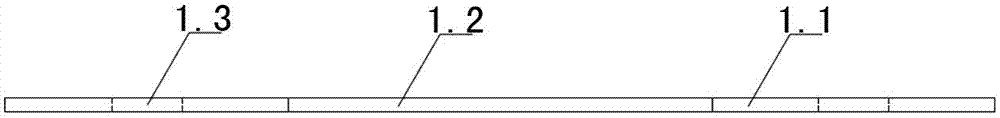

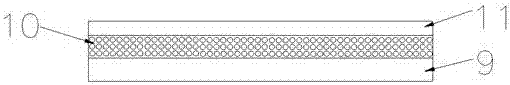

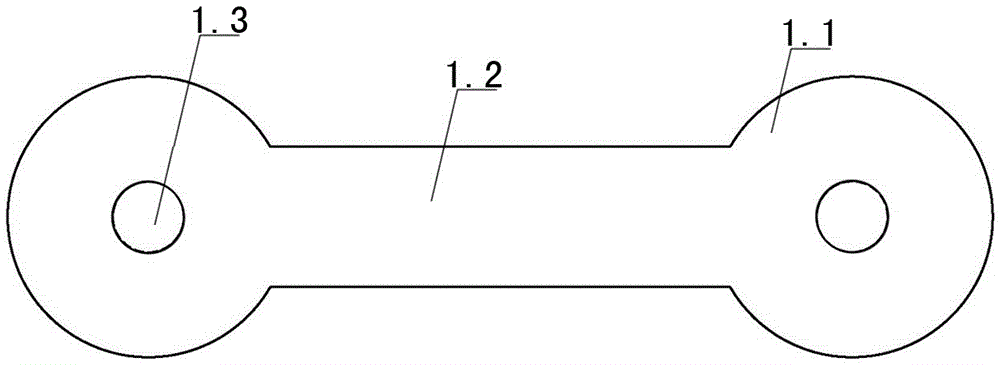

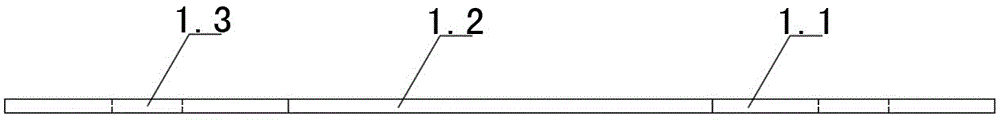

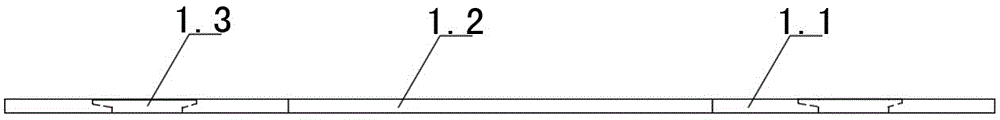

Glass fiber net reinforcement part, exterior wall heat-preservation anti-cracking structure and construction method thereof

ActiveCN104499651AOvercome strengthOvercoming easy crackingHeat proofingBuilding reinforcementsGlass fiberSurface layer

The invention relates to a glass fiber net reinforcement part, an exterior wall heat-preservation anti-cracking structure and a construction method of the exterior wall heat-preservation anti-cracking structure. The glass fiber net reinforcement part is of an integral sheet structure formed by two fixing sheets with the same shape and a connecting bridge connected between the two fixing sheets, and a threaded hole penetrating through a screw is formed at the center position of the fixing sheet. In addition, the glass fiber net reinforcement part is designed to be used for reinforcing the connecting strength of an anti-cracking mortar layer and a heat preservation layer, the glass fiber net reinforcement part has a simple structure, has low cost, can be constructed conveniently, and has a good fixing effect, can compensate the strength loss when the binding power between the anti-cracking mortar layer and the heat preservation layer is low, and can ensure the bonding quality and the construction reliability of the follow-up surface layer, the construction operation is simple, the construction difficulty is not increased, the original construction quality and the construction efficiency are not influenced, the using amount of the anti-cracking mortar can be used to a certain extent, the cost is reduced and the glass fiber net reinforcement part can be widely applied to exterior wall construction.

Owner:BUCG THE EIGHTH CONSTR DEV

High-energy consumption self-decoupling magnetorheological damper

The invention relates to a high-energy consumption self-decoupling magnetorheological damper with damping force decoupling property and failure self-protection function. The damper not only has high energy consumption and output, but also can effectively prevent subsidence of magnetorheological fluid, therefore, the invention is suitable for civil engineering structures. The damper mainly comprises a master cylinder body (6), an auxiliary cylinder body (13), a main piston (8), two auxiliary pistons (23), a piston rod (25), and novel composite-structure energy accumulators (14 and 15). Permanent magnets (9) arranged in the main piston (8) and the two auxiliary pistons (23) can effectively prevent subsidence of magnetorheological fluid, and can still provide corresponding damping force under the condition of power supply failure to enhance the safety of the structure. Magnetic circuit guiding components improve the utilization factor of the magnetic field. A mechanical spring self-decoupling device is mainly operated on the condition that the damper is under low-frequency driving, thereby overcoming the disadvantage of low output of the damper under low-frequency driving.

Owner:HOHAI UNIV +1

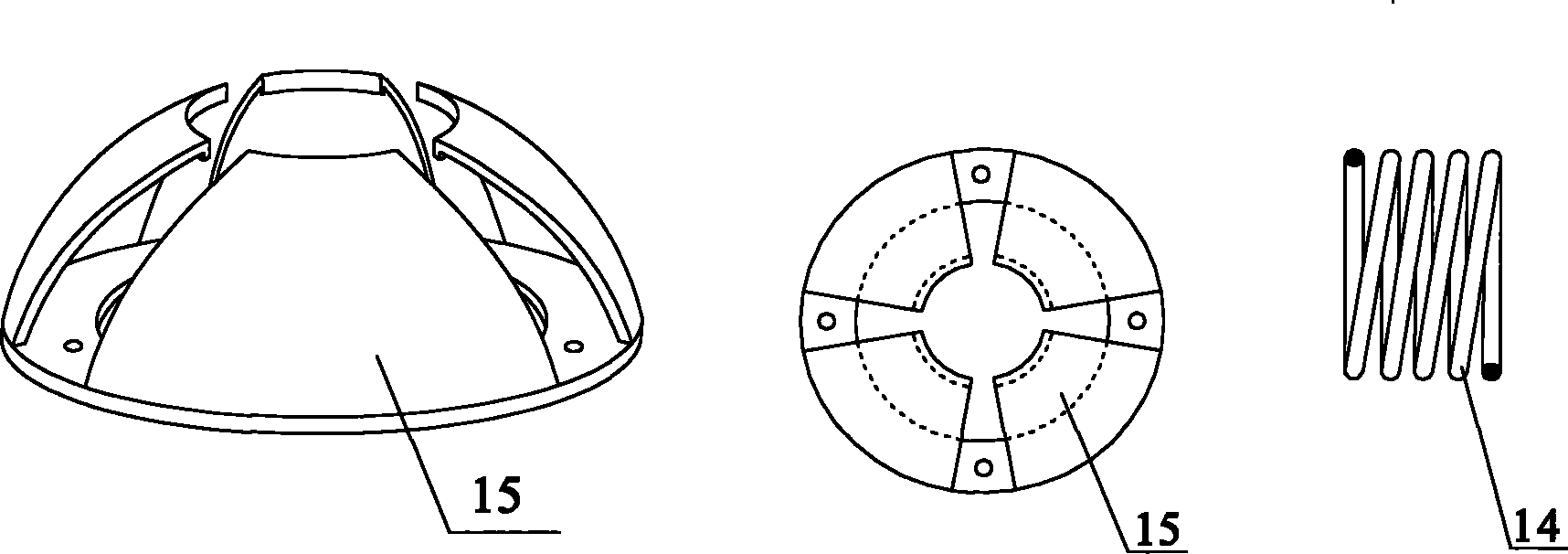

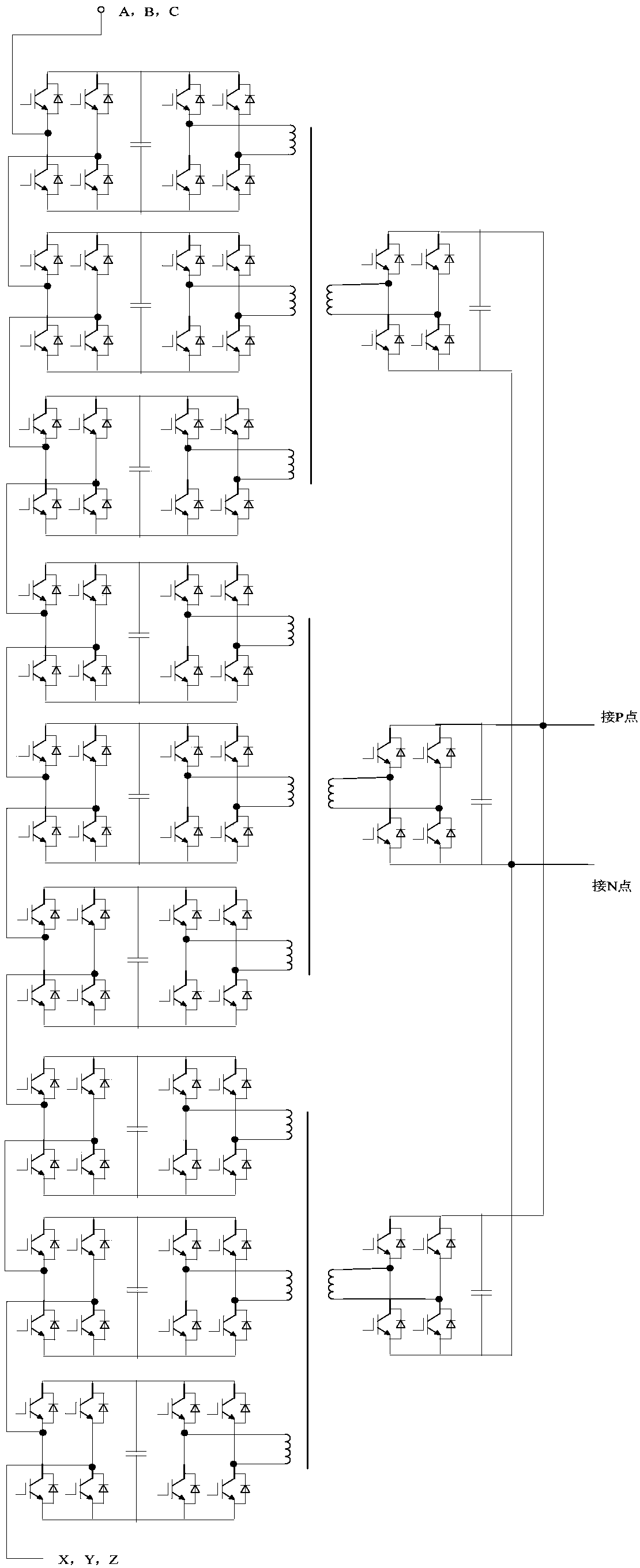

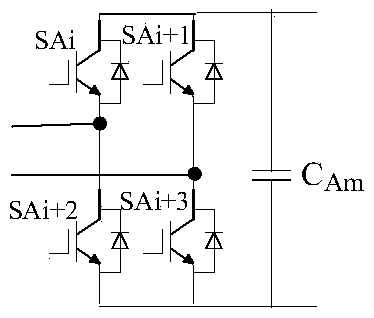

A power electronic transformer with an energy storage device

InactiveCN109067195AImprove power densityReduce in quantityAc-dc conversionDc-dc conversionZ-source inverterPower quality

The invention discloses a power electronic transformer with an energy storage device and relates to the technical field of electric engineering. The power electronic transformer includes a power electronic transformer with high voltage side connected to 10kV distribution network, A low-voltage side of the power electronic transformer is connected with a 400V class distribution network, and a three-phase 10kV alternating voltage is divided and isolate through a A-phase circuit, a B-phase circuit and a C-phase circuit, and the high-voltage alternating current is converted into direct current, all of which are connected with DC buses P and N, and the DC buses P and N are electrically connected with energy storage type Quasi-Z-source inverter converts DC to three-phase 400V AC to low-voltage distribution network. The power electronic transformer reduces the number of high-frequency transformers and sub-modules, The power density of the power electronic transformer is increased, and the harmonics brought by the power electronic transformer to the upper distribution network can be effectively restrained. Under the condition of ensuring the power quality, the low-voltage distribution network can be kept stable, and the voltage / frequency regulation of the upper distribution network can be participated in, and the power electronic transformer has certain inertia and damping.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Novel building decorative board

InactiveCN106930495ASimple structureLow production costCovering/liningsLayered productsWear resistantInsulation layer

The invention discloses a new type of building decoration board, which comprises a board body, a base layer is provided at the bottom of the board body, the bottom of the base layer is coated with a wear-resistant coating, the upper end of the base layer is bonded with a moisture-proof board, and the upper end of the moisture-proof board is bonded with a fireproof board, which is fireproof. A reinforcement layer is provided on the top of the board, and a sound insulation layer is provided between the fire prevention board and the reinforcement layer, and a decorative panel layer is provided on the top of the reinforcement layer. long.

Owner:MAANSHAN RUNQI NEW MATERIAL SCI & TECH

Urethane foam composite board and preparation method thereof

ActiveCN101618611BGood heat insulationIncrease temperatureSynthetic resin layered productsLaminationEngineeringNoise reduction

The invention discloses a urethane foam composite board comprising panels and a composite core plate, wherein the two panels comprise an optically flat damping sheet and porous damping sheets, wherein one surface of the optically flat damping sheet is provided with a non-setting adhesive layer, and the porous damping sheets are arranged in a square or a triangle shape regularly; the composite core plate forms a single-side core plate by splicing one side of a perforated urethane forming board with the porous damping sheets; the single-side core plate and the optically flat damping sheets are foamed, cured and bound to be a multi-layer structure complex by A and B constituent urethane foam composite materials in a forming die, and the urethane foam composite board is obtained after deburring the multi-layer structure complex. The invention has the integrated function of damping, noise reduction, heat and sound insulation and sound absorption, and has simple preparation method and convenient installation and use, thereby being beneficial to popularization and application.

Owner:BEIJING RADIATION APPL RES CENT

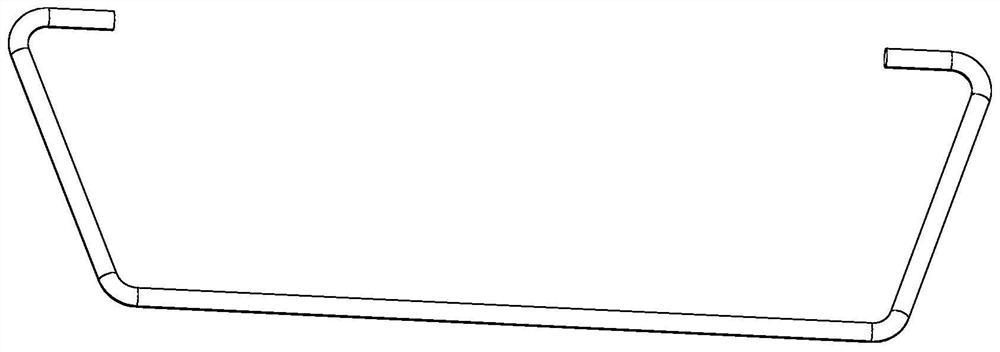

Preparation method of composite transverse stabilizer bar and transverse stabilizer bar prepared by preparation method

The invention discloses a preparation method of a composite transverse stabilizer bar and the transverse stabilizer bar prepared by the preparation method. The preparation method comprises the following steps of step 1, preparing a transverse stabilizer bar preform according to the designed size and shape of the transverse stabilizer bar, specifically, preparing a central layer and a wrapping layer of the transverse stabilizer bar according to design requirements, and splicing a central layer material rod and the wrapping layer to form the transverse stabilizer bar preform; step 2, curing thetransverse stabilizer bar preform, specifically, putting the transverse stabilizer bar preform into a mold, and injecting resin into the mold to be cured; and step 3, post-curing and post-processing the transverse stabilizer bar. According to the preparation method, the bar body of the manufactured transverse stabilizer bar comprises the central layer and one or more wrapping layers wrapping the central layer, the wrapping layer is a composite material weaved by reinforced fibers, and the bar body is of a solid structure or an internal hollow structure. The preparation method is high in efficiency, and the prepared stabilizer bar has the advantages of being light in weight, high in strength and not prone to rusting.

Owner:ZHEJIANG SCI-TECH UNIV

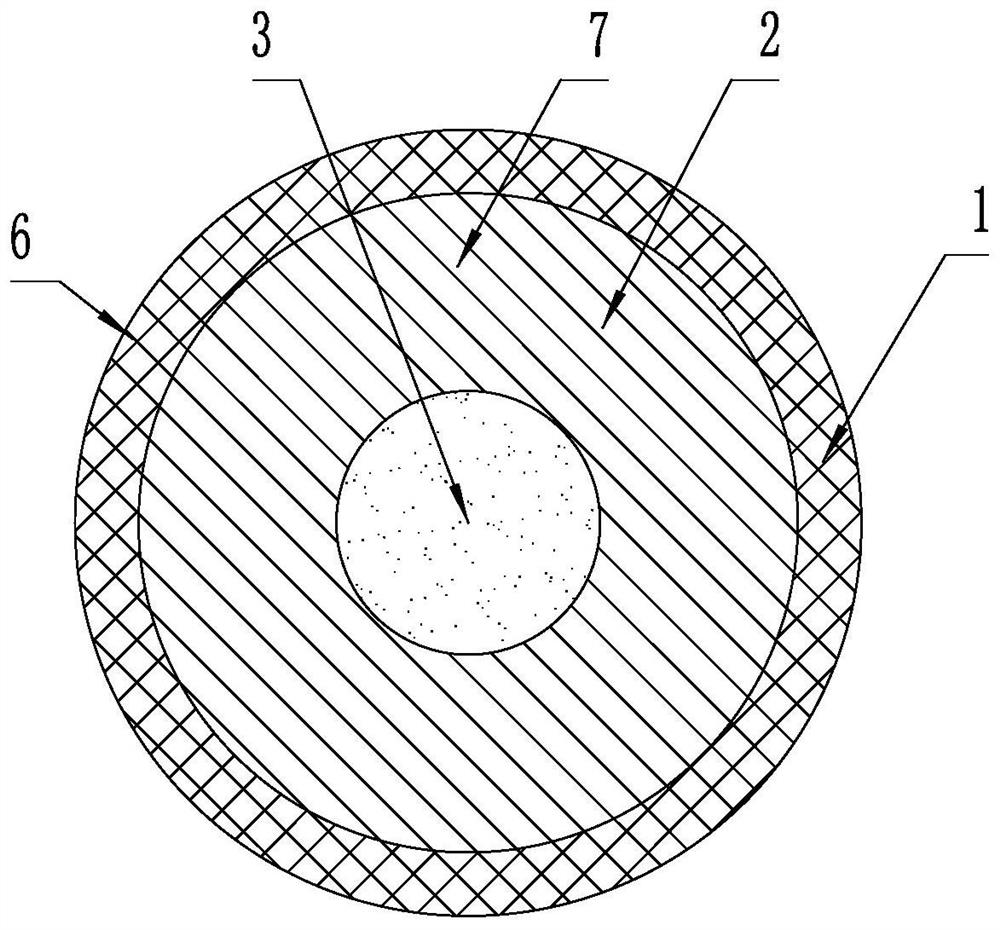

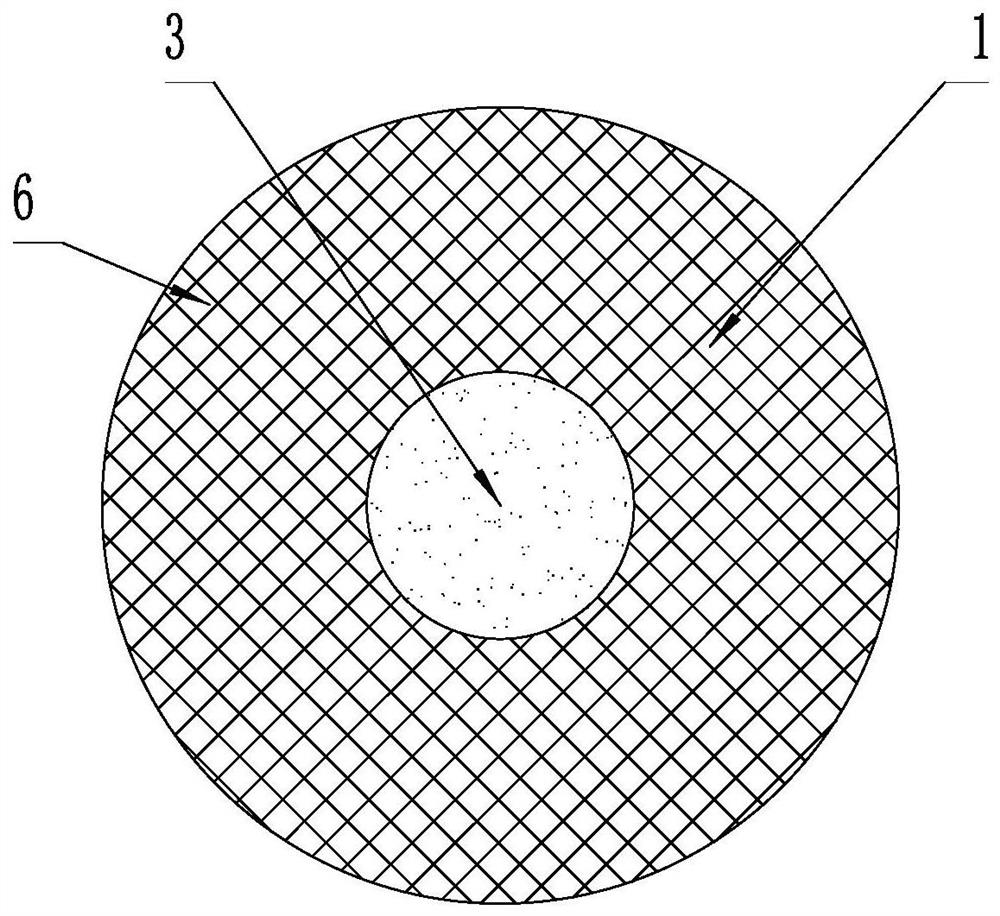

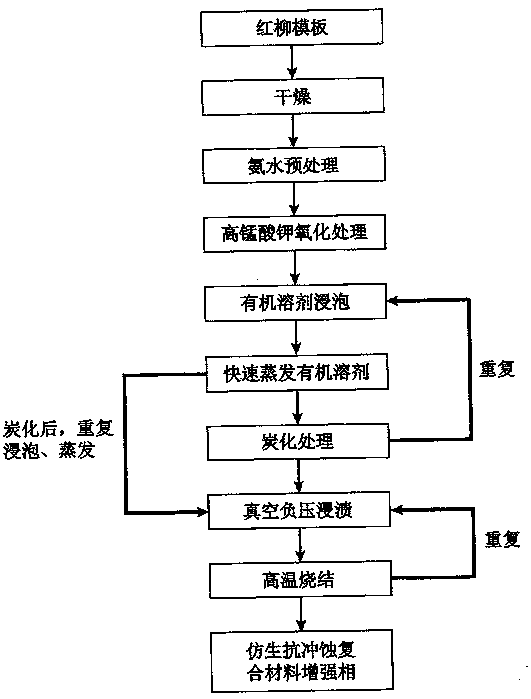

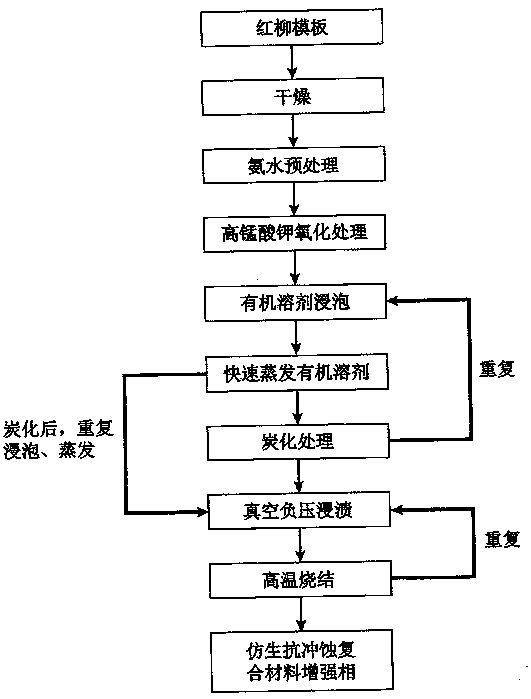

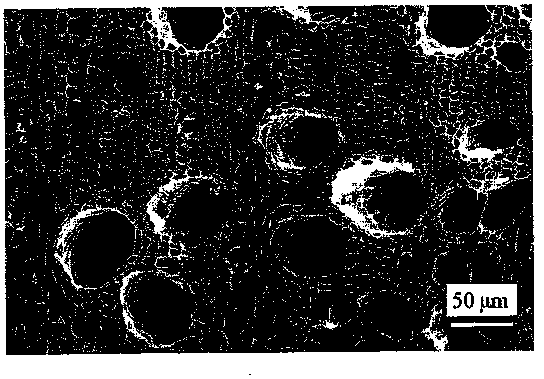

Preparation method of bionic erosion-resisting composite material enhanced phase based on rose willow

InactiveCN103739287AImprove erosion resistanceHigh hardnessCeramicwareFriction reductionOrganic solvent

The invention discloses a preparation method of a bionic erosion-resisting composite material enhanced phase based on rose willow. The preparation method comprises the following steps: step1, extracting the rose willow by utilizing ammonia water; step 2, oxidizing the extracted rose willow obtained in the step 1 by utilizing a KMNO solution; step 3, impregnating the rose willow obtained in step 2 by utilizing organic solvent, and rapidly evaporating the organic solvent; step 4, carbonizing the rose willow obtained in step 3; step 5, impregnating the carbonized matter obtained in the step 4 in organic silicon resin solution under the vacuum negative pressure condition; step 6, sintering the carbonized matter impregnated with the organic silicon resin obtained in the step 5 at a high temperature. By adopting the preparation method, while partial chemical components and the porous structural shape of the rose willow are maintained, the indexes of the composite material such as the erosion resistance, rigidness and the like are enhanced; the prepared bionic composite material has the characteristics of vibration absorption, friction reduction and abrasion resistance, and a better choice and various concepts can be provided for bionic erosion-resisting composite material.

Owner:JILIN UNIV

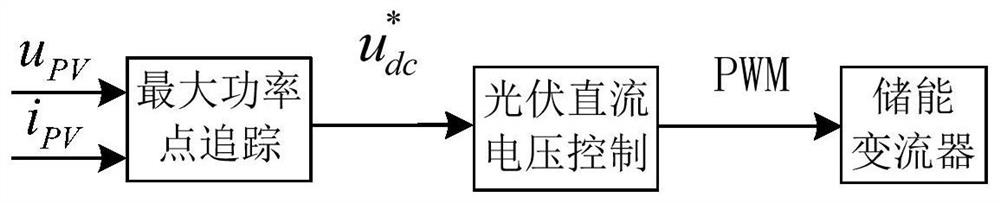

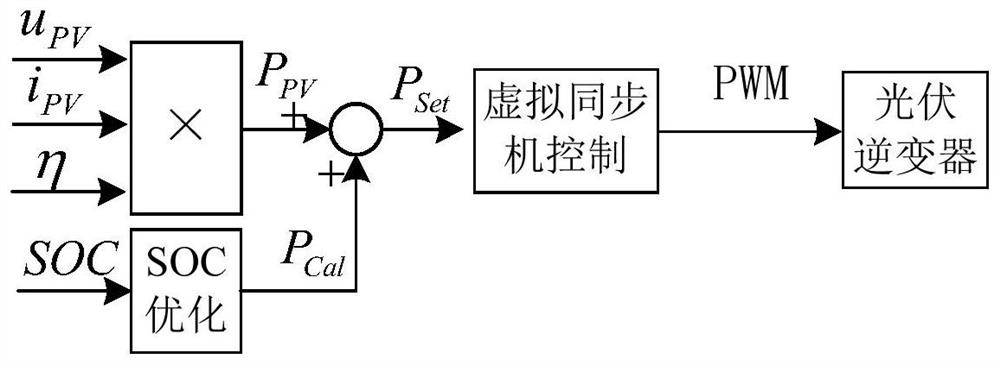

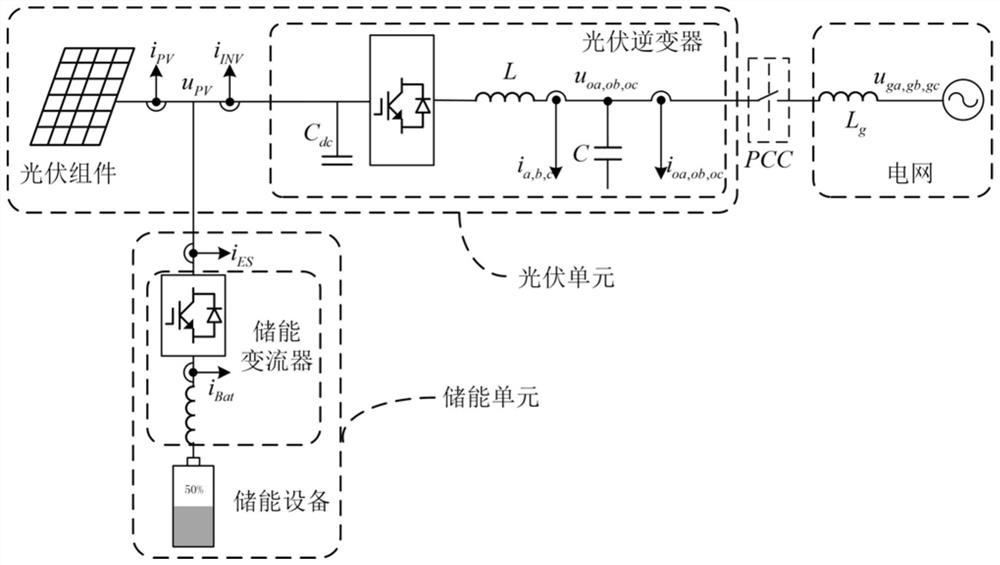

Photovoltaic power generation system virtual synchronous machine control method, device, converter and system

ActiveCN108923462BWith self-tuningWith inertiaBatteries circuit arrangementsSingle network parallel feeding arrangementsElectric networkControl theory

The invention discloses a photovoltaic power generation system virtual synchronous machine control method, a control device, a converter and a system. The present invention connects the energy storage device and the energy storage converter on the DC side where the photovoltaic inverter is connected to the photovoltaic module; collects the voltage and current of the photovoltaic module and executes the maximum power point tracking algorithm to obtain the target value of the DC voltage, according to the The DC voltage target value controls the energy storage converter to operate in a constant output DC voltage mode; the DC power output by the photovoltaic module is multiplied by the conversion efficiency of the photovoltaic inverter, and the SOC of the superimposed energy storage device is optimized to adjust the power component as the photovoltaic inverter. The active power command is used to control the photovoltaic inverter to operate in a virtual synchronous machine mode according to the active power command. The invention only needs a small battery capacity to meet the application requirements, ensures the maximum power generation of the photovoltaic panel, optimizes the availability and life of the battery, and provides power support for the grid.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

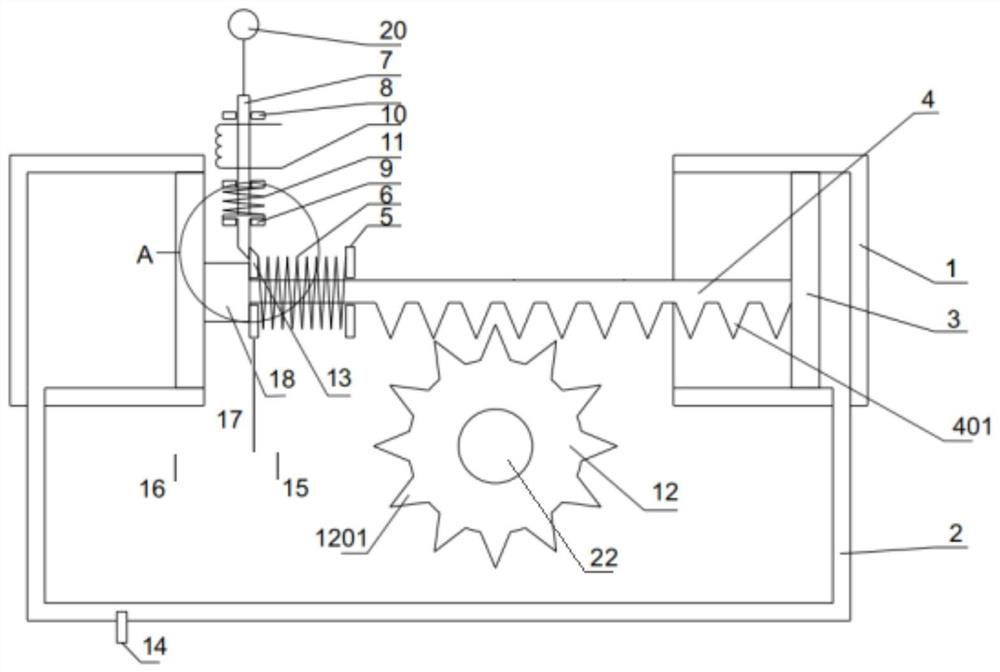

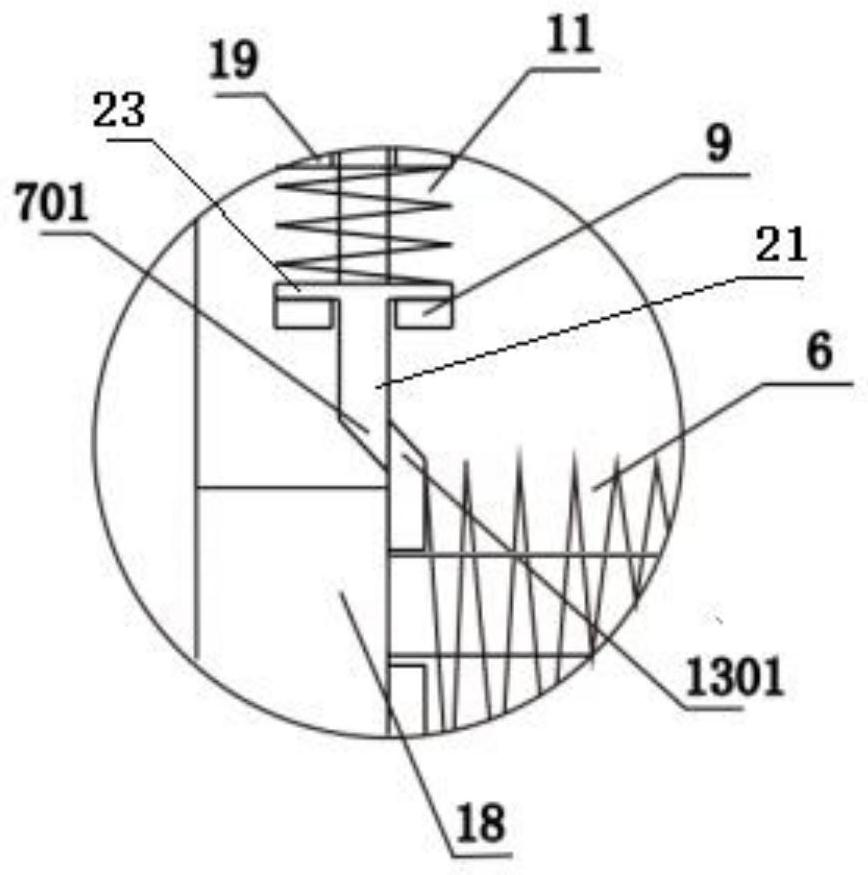

A door closer capable of self-locking and remote control

ActiveCN110984750BSelf-locking will notEasy to useBuilding braking devicesWing accessoriesRemote controlFire control

The invention discloses a door closer capable of self-locking and remote control, comprising a cylinder liner, a connecting pipe, a piston, a connecting rod, a right limit block, a first spring, a pull rod, an upper limit block, a lower limit block, and an electromagnetic switch , the second spring and the rotating shaft; the door closer of the present invention is designed with a self-locking device, so that after the door closer is self-locked, the door closing function becomes invalid, but at the same time, the damping effect is maintained, and the door with the door closer installed can be in any position , when a fire occurs, the fire door can be closed by remote fire control or manually triggering the self-locking device of the door closer, and the status is fed back to the fire control center at the same time; action, the fire door is closed. Secondly, when the door closer is self-locking, the fire door is in any state, which is convenient for people to use. Furthermore, unless the self-locking condition of the door closer is triggered, the door closer will not self-lock. In addition, the door closer still has a certain damping when it is self-locking, and the damping is adjustable.

Owner:胡武文

A Pile-raft Composite Seismic Isolation Trough Foundation Structure Under Strong Earthquake

ActiveCN111535348BImprove integrityAvoid or reduce friction damageProtective foundationEpoxyGeomembrane

Owner:JIAMUSI UNIVERSITY

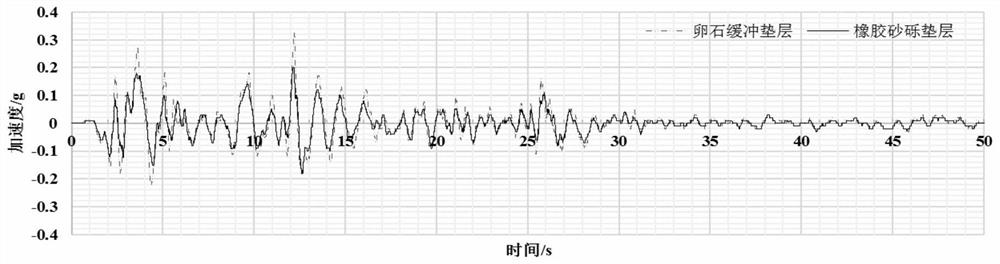

A kind of loudspeaker diaphragm material and preparation method thereof

ActiveCN105113038BImprove protectionPromote degradationMonocomponent fibroin artificial filamentFilament/thread formingMicro nanoCarbon nanotube

The invention discloses a material for a diaphragm of a loudspeaker and a preparation method thereof, belonging to the technical field of electroacoustic products. The material for the diaphragm is prepared by using electrospinning technique; fibroin and carbon nanotubes are blended to form the loudspeaker diaphragm with a micro-nano fibrous net structure; and in post-treatment, an ethanol solution is used for dipping and a polyurethane, polyacrylate or polyvinyl chloride coating is used for finishing, so the diaphragm has certain mechanical strength. According to the invention, supply of raw materials is sufficient; the preparation method is simple and has low energy consumption; the ultra-thin loudspeaker diaphragm is prepared while the strength of the diaphragm is guaranteed; the prepared diaphragm has high specific elasticity, good damping vibration attenuation performance and the characteristics of good sound effect and high fidelity; and the fibroin protein loudspeaker diaphragm has biodegradability, which is beneficial for environmental protection.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

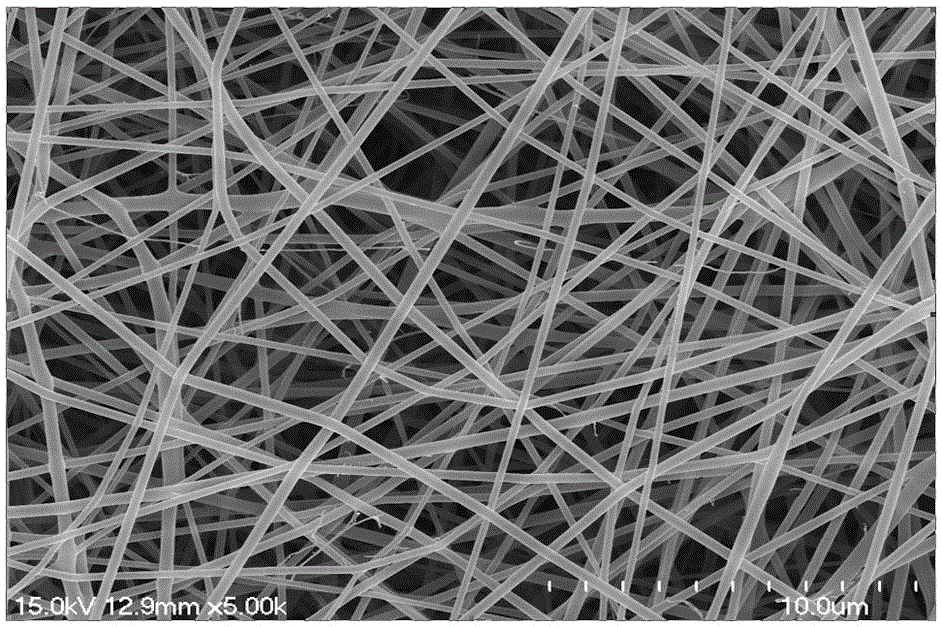

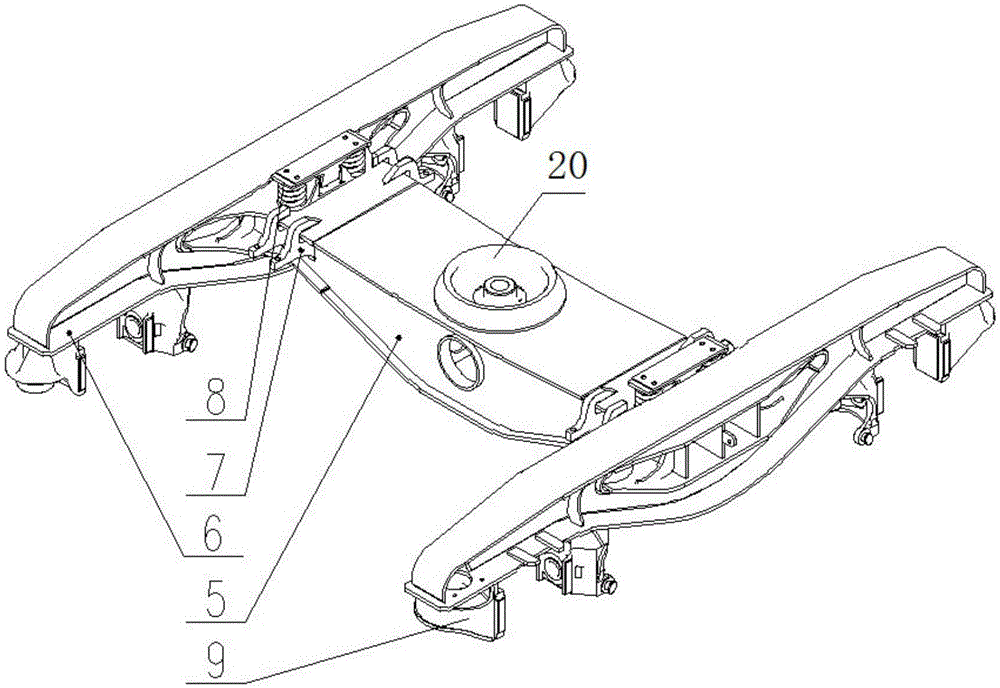

Welding bogie

The invention discloses a welding bogie. The welding bogie comprises wheel pair assemblies, a framework assembly, shaft box hanging systems and braking devices. The framework assembly is of an H-shaped structure formed by a beam and side beams in an inserting connection and installing and welding mode. The framework assembly is located on the two wheel pair assemblies through the shaft box hanging systems. Each braking device is an integrated foundation braking device. The integrated foundation braking devices are hung on the framework assembly through hanging rod assemblies. The framework assembly is formed by the beam and the side beams in the inserting connection and installing and welding mode. The requirement for strength is met, and the structure is simple. Linuoer shock absorber structures are adopted for the shaft box hanging systems, and therefore linear running stability is guaranteed, and the welding bogie adapts to curve passing capacity. Rubber springs are adopted for the shaft box hanging systems, and therefore the shaft box hanging systems have rigidity and damping in the vertical direction, the transverse direction and the longitudinal direction, the structure is simple, and maintaining is easy. The braking devices are the integrated foundation braking devices, and the best braking characteristic can be transmitted through the design principle of a parallelogram.

Owner:CRRC SHANDONG CO LTD

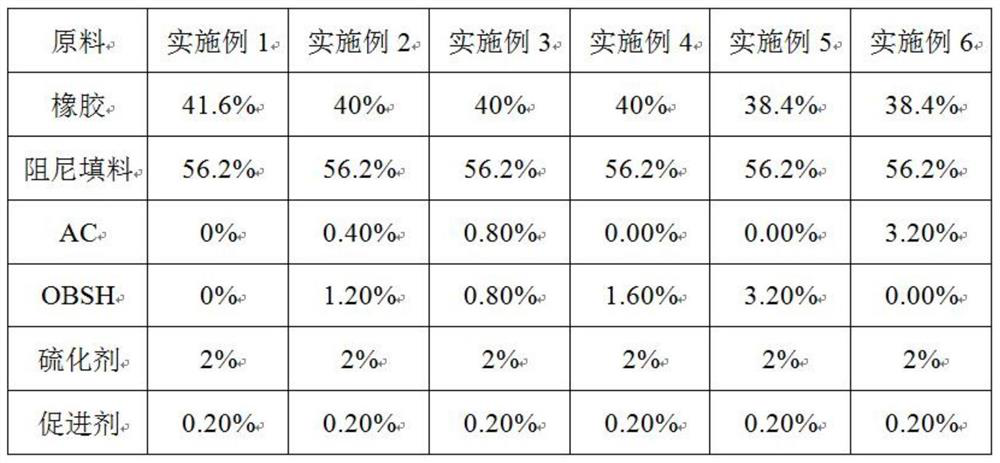

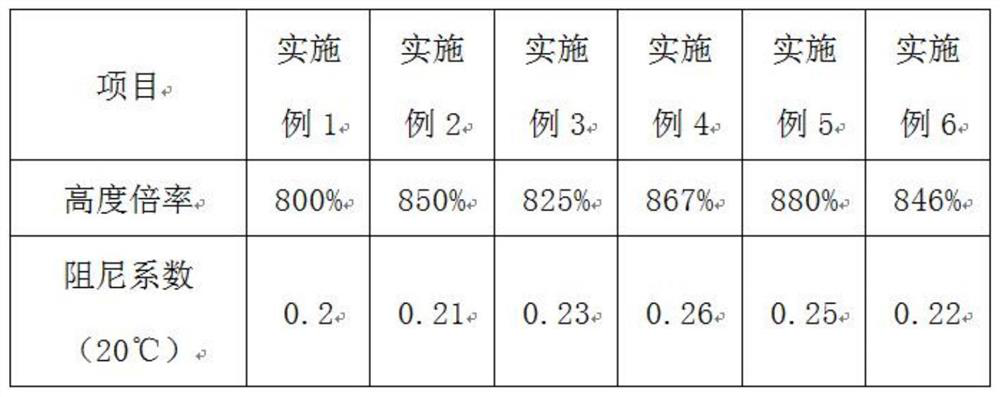

Damping type high-magnification rubber expansion film for vehicle and preparation method of film

The invention relates to a damping type high-magnification rubber expansion film for vehicles and a preparation method of the film. The damping type high-magnification rubber expansion film comprises the following components by weight: 38-42 parts of rubber, 55-57 parts of a damping filler, 2 parts of a vulcanizing agent, 0.2 part of an accelerator, and the balance of one or more foaming agents. A certain proportion of the damping filler and the specific foaming agent are added into an original system, so that the problems that an expansion film has no damping function and is low in rate in the automobile production process are solved, the film has damping performance and high expansion rate on the basis of sound absorption and insulation, the damping vibration attenuation performance is improved, and the thickness of the film is reduced when a same cavity gap is blocked, so that the cost can be reduced to a certain extent.

Owner:天津辰弘新材料科技有限公司

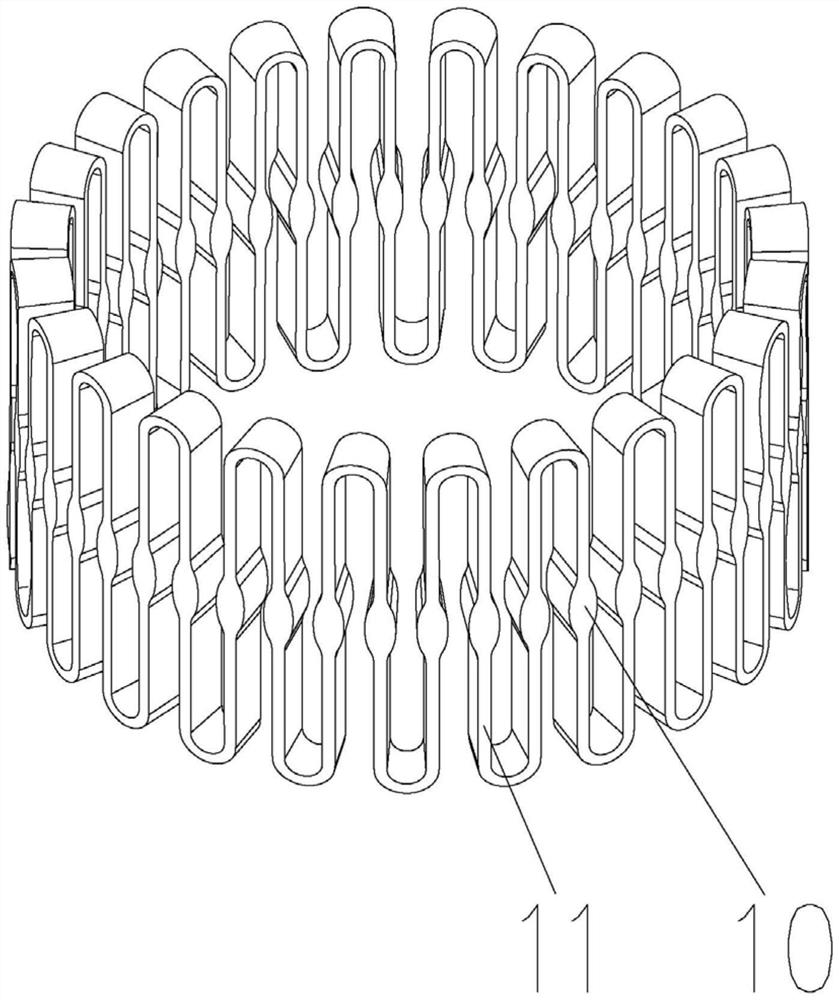

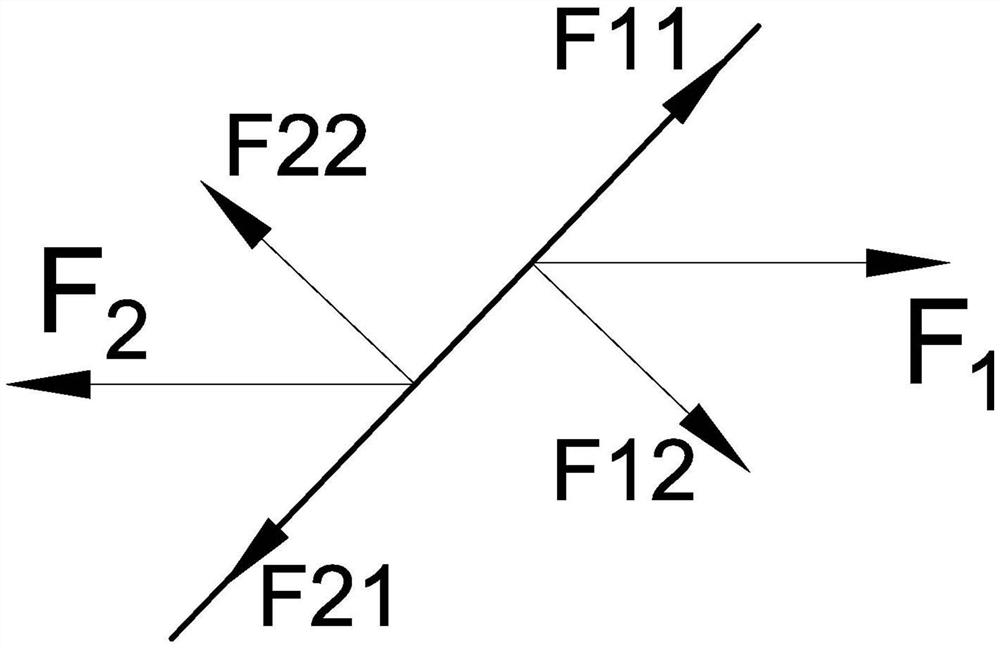

Preparation method of composite material serpentine spring

The invention relates to a preparation method of a composite material serpentine spring. The preparation method comprises the following steps that 1), basalt unidirectional cloth and resin are selected for later use; 2), basalt fiber unidirectional cloth is cut into the shape matched with the size characteristics of the designed composite material serpentine spring, the cut basalt fiber unidirectional cloth is infiltrated with resin, and the basalt fiber unidirectional cloth infiltrated with the resin is laid in a mold to form a preformed body; 3), an inner mold and an outer mold on which the preformed body is laid are closed, and proper temperature and mold pressure are selected, so that the composite material serpentine spring is cured and formed; 4), after curing forming and demolding of the composite material serpentine spring are completed, the composite material serpentine spring is put into a constant-temperature box to be subjected to post-curing, and after post-curing treatment is completed, deburring and polishing treatment is conducted on the composite material serpentine spring, and the composite material serpentine spring is obtained. The prepared composite material serpentine spring has the advantages of being light in weight, resistant to corrosion and the like, has a limiting function, and can remarkably improve the safety and reliability of a coupler.

Owner:ZHEJIANG SCI-TECH UNIV

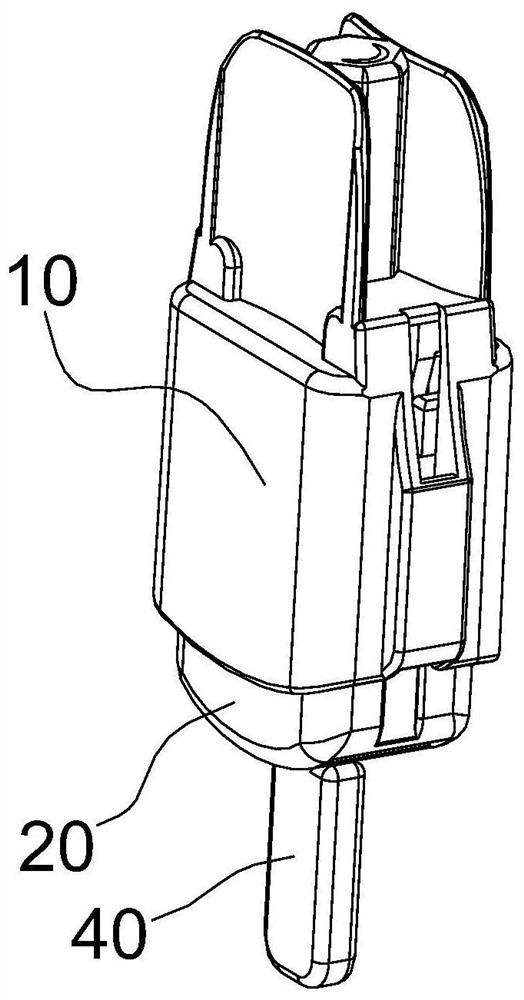

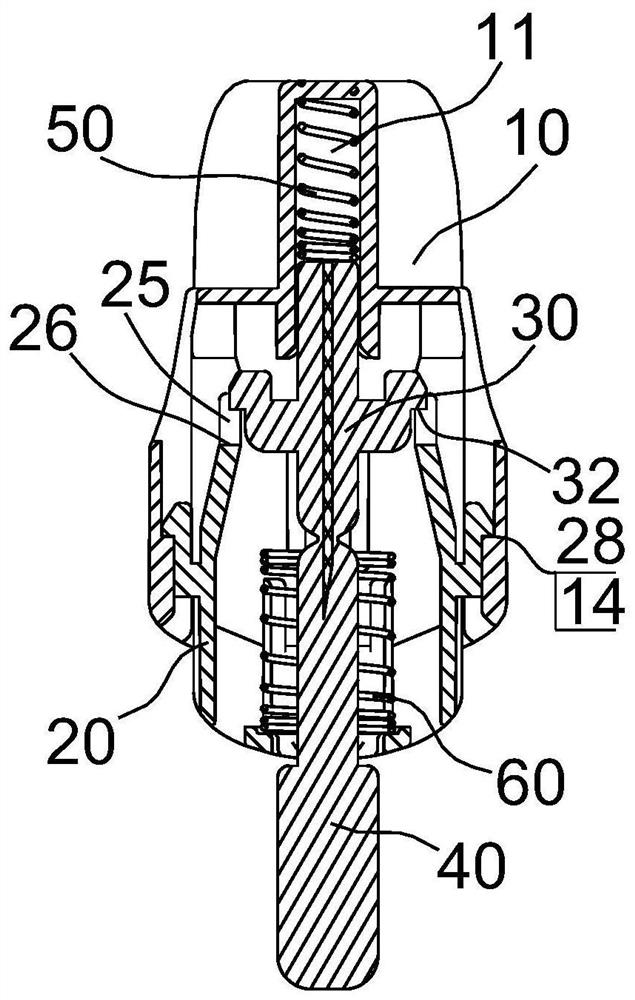

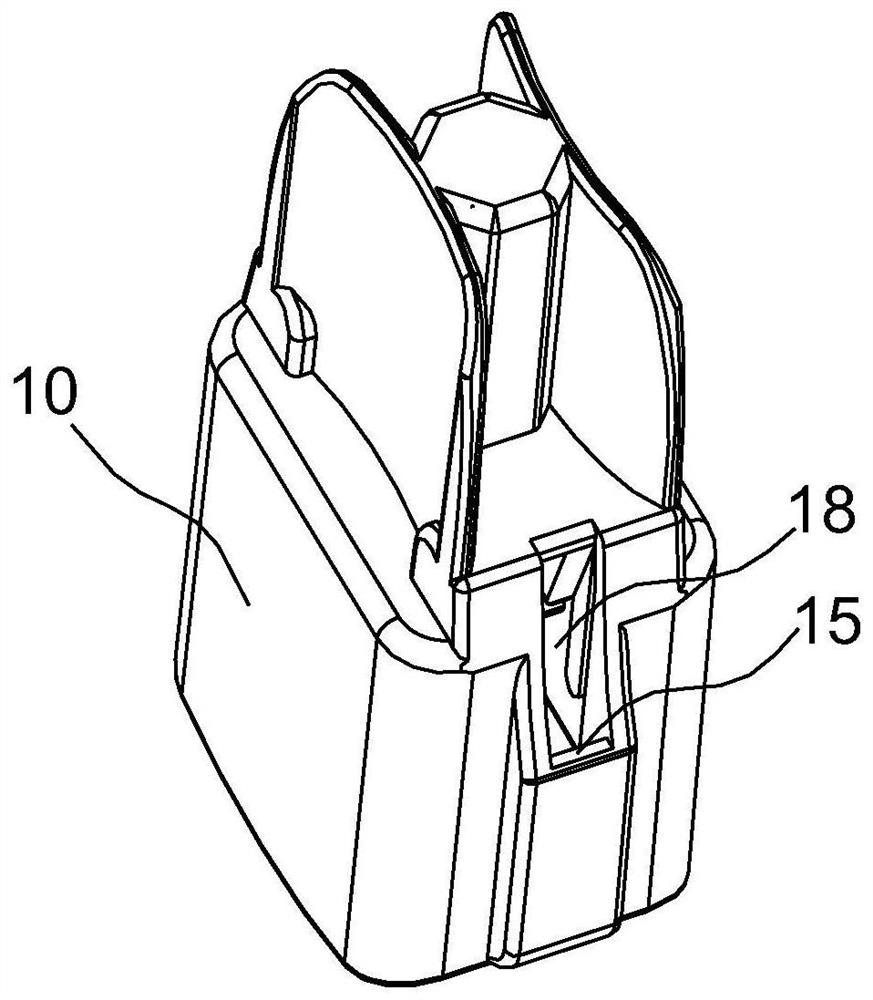

Disposable safety lancet

ActiveCN111759325BWith dampingAvoid triggerDiagnostic recording/measuringSensorsBlood collectionEngineering

The invention relates to the technical field of medical devices, and specifically discloses a disposable safety blood collection needle, which at least includes a housing, a needle core, a needle cap, an inner sleeve, a driving spring and a retracting spring. The inner sleeve has a first position and the second position, the driving spring is located between the needle core and the housing and has a first pre-tightened state; the needle core is provided with a pair of opposite first steps facing the side of the needle cap, and the inner sleeve A pair of oppositely disposed first elastic arms are provided, and a second step for abutting against the first step is provided on the first elastic arms; a separation mechanism is provided in the housing. The driving spring of the present invention has multiple functions. In the process of compressing the inner sleeve, due to the need to overcome the elastic force of the driving spring and compress the driving spring, the force required to trigger the ejection of the needle core is greater, which can prevent unconsciousness due to small The excessive force causes the needle core to be falsely triggered; the structural design is ingenious, and the state of whether the needle core is ejected is accurately judged.

Owner:PROMISEMED HANGZHOU MEDITECH

Glass fiber mesh reinforcement, external thermal insulation and anti-cracking structure of wall and its construction method

The invention relates to a glass fiber net reinforcement part, an exterior wall heat-preservation anti-cracking structure and a construction method of the exterior wall heat-preservation anti-cracking structure. The glass fiber net reinforcement part is of an integral sheet structure formed by two fixing sheets with the same shape and a connecting bridge connected between the two fixing sheets, and a threaded hole penetrating through a screw is formed at the center position of the fixing sheet. In addition, the glass fiber net reinforcement part is designed to be used for reinforcing the connecting strength of an anti-cracking mortar layer and a heat preservation layer, the glass fiber net reinforcement part has a simple structure, has low cost, can be constructed conveniently, and has a good fixing effect, can compensate the strength loss when the binding power between the anti-cracking mortar layer and the heat preservation layer is low, and can ensure the bonding quality and the construction reliability of the follow-up surface layer, the construction operation is simple, the construction difficulty is not increased, the original construction quality and the construction efficiency are not influenced, the using amount of the anti-cracking mortar can be used to a certain extent, the cost is reduced and the glass fiber net reinforcement part can be widely applied to exterior wall construction.

Owner:BUCG THE EIGHTH CONSTR DEV

A Reactive Power Control Method of Inverter Based on Virtual Synchronization Mechanism

ActiveCN108521130BReduce shockImprove reactive power utilizationSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationControl engineeringPower grid

The invention discloses an inverter reactive power control method based on a virtual synchronization mechanism. At present, the inverter reactive power control method is not accurate in control. Whenthe grid voltage fluctuates slightly, the voltage cannot be controlled without any difference; when the grid voltage drops deeply, and the whole reactive power ability of the inverter cannot be played. The reactive power control method is divided into three phases: when it is monitored that the voltage of the grid-connected point is normal, a reactive power control module aims to control the output reactive power of the inverter; when the voltage drop of the grid-connected point is monitored, the reactive power control module superimposes the voltage of the grid-connected point to reduce the voltage drop; and when it is monitored that the voltage of the grid-connected point is further dropped, an LVRT control module controls the inverter to switch to a low voltage ride-through control modeto perform low voltage ride through. The invention can automatically and flexibly control the output reactive power of the inverter, improve the reactive power utilization rate of the inverter, stabilize the grid-connected point voltage, reduce the grid voltage drop degree, and does not affect the low voltage ride through capability of the inverter.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

Method for preparing corn-cob structure morph-genetic ceramic-based composite material

The invention discloses a method for preparing a corn-cob structure morph-genetic ceramic-based composite material, which comprises the following steps of: preparing a corn-cob structure template or a corn-cob structure / precursor composite template; raising the temperature of the corn-cob structure template or the corn-cob structure / precursor composite template to the temperature of between 500 and 2,000 DEG C at the temperature rise speed of 3 to 20 DEG C per minute in the protective atmosphere of vacuum or inert gases; maintaining the temperature for 1 to 10 hours, and cooling to obtain a morph-genetic carbon template or morph-genetic ceramic composite material; after impregnating in the precursor solution or precursor sol, raising the temperature to the temperature of between 1,300 and 2,000 DEG C at the temperature rise speed of 3 to 20 DEG C per minute in the protective atmosphere of vacuum or inert gases; maintaining the temperature for 1 to 10 hours, and performing vacuum carbothermal reduction to obtain the corn-cob structure morph-genetic ceramic-based composite material; or performing liquid-phase siliconizing or gas-phase siliconizing on the morph-genetic carbon template in the protective atmosphere of vacuum or inert gases to obtain the corn-cob structure morph-genetic ceramic-based composite material. The composite material prepared by the invention has the advantages of light weight, shock absorption, sound absorption, high temperature resistance, antioxidation, antifriction and abrasive resistance, load bearing, excellent sensing property, and wide application prospects.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Preparation method of bionic erosion-resisting composite material enhanced phase based on rose willow

InactiveCN103739287BImprove erosion resistanceHigh hardnessProsthesisCeramicwareFriction reductionOrganic solvent

The invention discloses a preparation method of a bionic erosion-resisting composite material enhanced phase based on rose willow. The preparation method comprises the following steps: step1, extracting the rose willow by utilizing ammonia water; step 2, oxidizing the extracted rose willow obtained in the step 1 by utilizing a KMNO solution; step 3, impregnating the rose willow obtained in step 2 by utilizing organic solvent, and rapidly evaporating the organic solvent; step 4, carbonizing the rose willow obtained in step 3; step 5, impregnating the carbonized matter obtained in the step 4 in organic silicon resin solution under the vacuum negative pressure condition; step 6, sintering the carbonized matter impregnated with the organic silicon resin obtained in the step 5 at a high temperature. By adopting the preparation method, while partial chemical components and the porous structural shape of the rose willow are maintained, the indexes of the composite material such as the erosion resistance, rigidness and the like are enhanced; the prepared bionic composite material has the characteristics of vibration absorption, friction reduction and abrasion resistance, and a better choice and various concepts can be provided for bionic erosion-resisting composite material.

Owner:JILIN UNIV

Scaling structure type line dynamic and static pressure air bearing

ActiveCN103244560BReduce distractionsIncreased ability to withstand external loadsBearing componentsBearingsLow speedAir bearing

Scaling structure profile hydrodynamic air bearing. The traditional air bearing adopts a simple rectangular inner channel, and the profile of the channel cannot exert the best effect of dynamic pressure, which will lead to the problem of insufficient load at low speed and aerodynamic instability at high speed. The composition of the present invention includes: a bearing body (2), the inner surface of the bearing body has a dynamic pressure structure, and the dynamic pressure structure is a scaling linear pressurized channel groove (3), and the bearing body has a static Pressure structure, the static pressure structure includes an air supply hole (4), the air supply hole communicates with the throttle nozzle (5), and the elastic ring (6) is installed on the bearing body. The invention is used to support high-speed rotating machinery.

Owner:南京耦合动力工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com