A kind of loudspeaker diaphragm material and preparation method thereof

A membrane material and loudspeaker technology, applied in the manufacture of rayon, single-component fibroin artificial filament, fiber chemical characteristics, etc., can solve the problems of complex preparation process, insufficient strength, and insufficient source of materials, and achieve uniform distribution , Excellent damping and vibration reduction performance, solvent recyclable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of silk fibroin film: after silk degumming, dissolve in 9.3 mol / L lithium bromide solution, the mass concentration of silk fibroin is 20%, filter the obtained solution, dialyze, and then centrifuge with a centrifuge to obtain pure Silk fibroin solution, the mass concentration of which is between 6% and 7%, is diluted with deionized water until the mass concentration of silk fibroin is 3%, and the evenly stirred silk fibroin solution is pressed into a petri dish with a diameter of 9 cm with a syringe , inject 15 mL of the solution into each Petri dish, remove air bubbles, and air-dry in a fume hood to obtain a pure silk fibroin film.

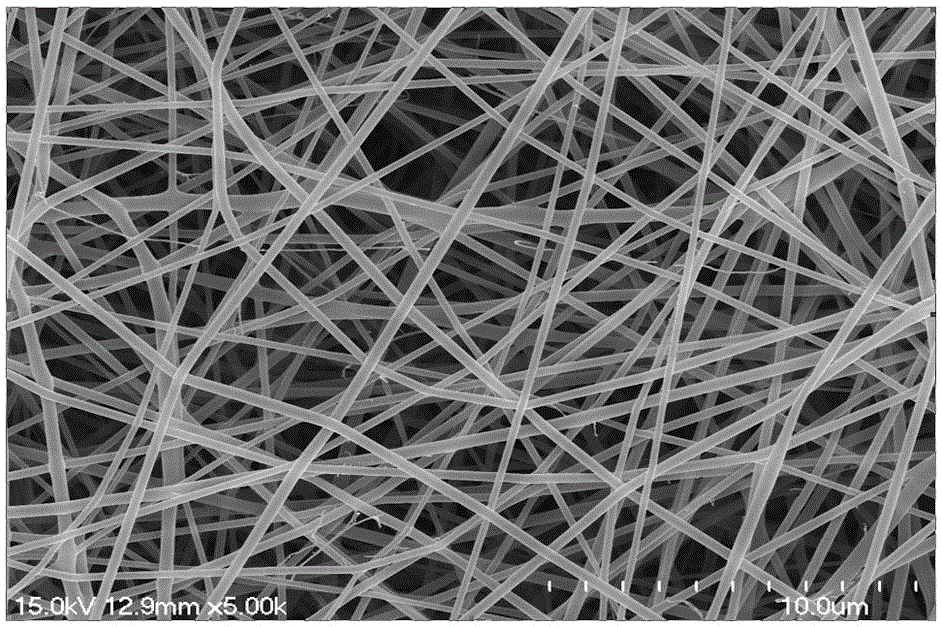

[0024] (2) Preparation of spinning solution: mix and dissolve the silk fibroin film and carbon nanotubes in (1) in anhydrous formic acid, the mass concentration of the spinning solution is 15%, the carbon nanotubes account for 0.5% of the mass of silk fibroin, and the solution is stirred After uniformity, spinning is carrie...

Embodiment 2

[0031] (1) Preparation of silk fibroin powder: after silk degumming, dissolve in 9.3 mol / L lithium bromide solution, the mass concentration of silk fibroin is 20%, filter the obtained solution, dialyze, and centrifuge with a centrifuge to obtain pure Silk fibroin solution, the mass concentration of which is between 6% and 7%, is diluted with deionized water until the mass concentration of silk fibroin is 3%, and the silk fibroin solution which is stirred evenly is prepared by freeze-drying method and ground into silk fibroin porous material Made into powder.

[0032] (2) Preparation of spinning solution: the silk fibroin film in (1) was cut into pieces and mixed with carbon nanotubes and dissolved in hexafluoroisopropanol. The mass concentration of the spinning solution was 6%, and the carbon nanotubes accounted for 1% of the mass of silk fibroin. %, the solution is stirred evenly before spinning.

[0033] (3) Adjust the electrospinning parameters. The voltage is 20 kV, the inj...

Embodiment 3

[0038] (1) Preparation of silk fibroin film: after silk degumming, dissolve in 9.3 mol / L lithium bromide solution, the mass concentration of silk fibroin is 20%, filter the obtained solution, dialyze, and then centrifuge with a centrifuge to obtain pure Silk fibroin solution, the mass concentration of which is between 6% and 7%, is diluted with deionized water until the mass concentration of silk fibroin is 3%, and the evenly stirred silk fibroin solution is pressed into a petri dish with a diameter of 9 cm with a syringe , inject 15 mL of the solution into each Petri dish, remove air bubbles, and air-dry in a fume hood to obtain a pure silk fibroin film.

[0039] (2) Preparation of spinning solution: the silk fibroin film in (1) was chopped and mixed with carbon nanotubes and dissolved in acetone. The mass concentration of the spinning solution was 10%, and the carbon nanotubes accounted for 2% of the mass of silk fibroin. The solution After stirring evenly, spinning is carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com