Comfortable sole with slow resilience and preparation method of sole

A slow rebound and comfortable technology, applied in soles, footwear, applications, etc., can solve problems such as deformation, depression, and fast rebound speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] A slow rebound comfortable sole,

[0051] Comprising the following parts by weight:

[0052] Diisocyanate: 50 parts

[0053] Small molecule polyol: 50 parts

[0054] Polypolyol: 15 parts

[0055] Cross-linking agent: 5 parts

[0056] Foaming agent: 3 parts

[0057] Catalyst: 0.5 parts

[0058] Described polypolyol is:

[0059] 4-Amino-4-(3-hydroxypropyl)-1,7-heptanediol, 2-n-pentylpropane-1,3-diol, adipic acid, triethylene glycol divinyl ether polymer;

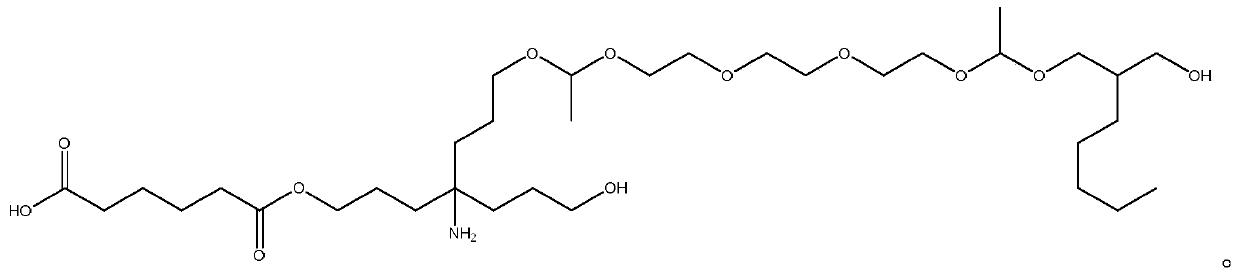

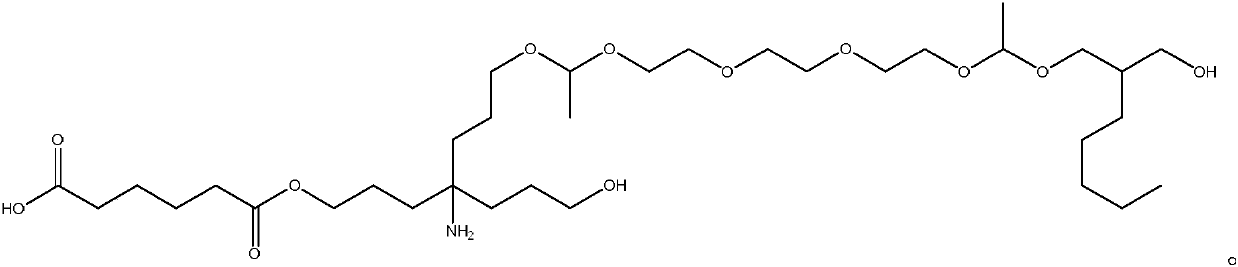

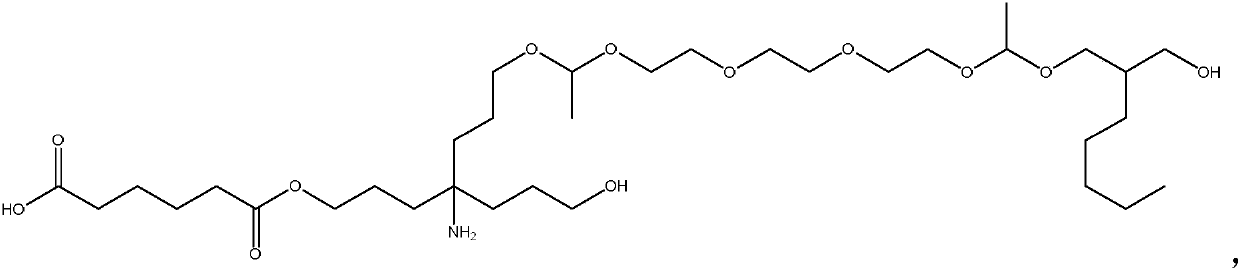

[0060] The molecular formula of polypolyol is:

[0061]

[0062] The preparation method of described polypolyol is:

[0063] Step 1: Mix adipic acid and 2-n-pentylpropane-1,3-diol, use toluene as solvent and 4-dimethylaminopyridine as catalyst, react at 30-50°C for 30-180 minutes, and polymerize to obtain Polyester compounds;

[0064] Step 2: mixing 4-amino-4-(3-hydroxypropyl)-1,7-heptanediol, a polyester compound, toluene as a solvent, and p-toluenesulfonic acid as a catalyst to obtain a mixed solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com