Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

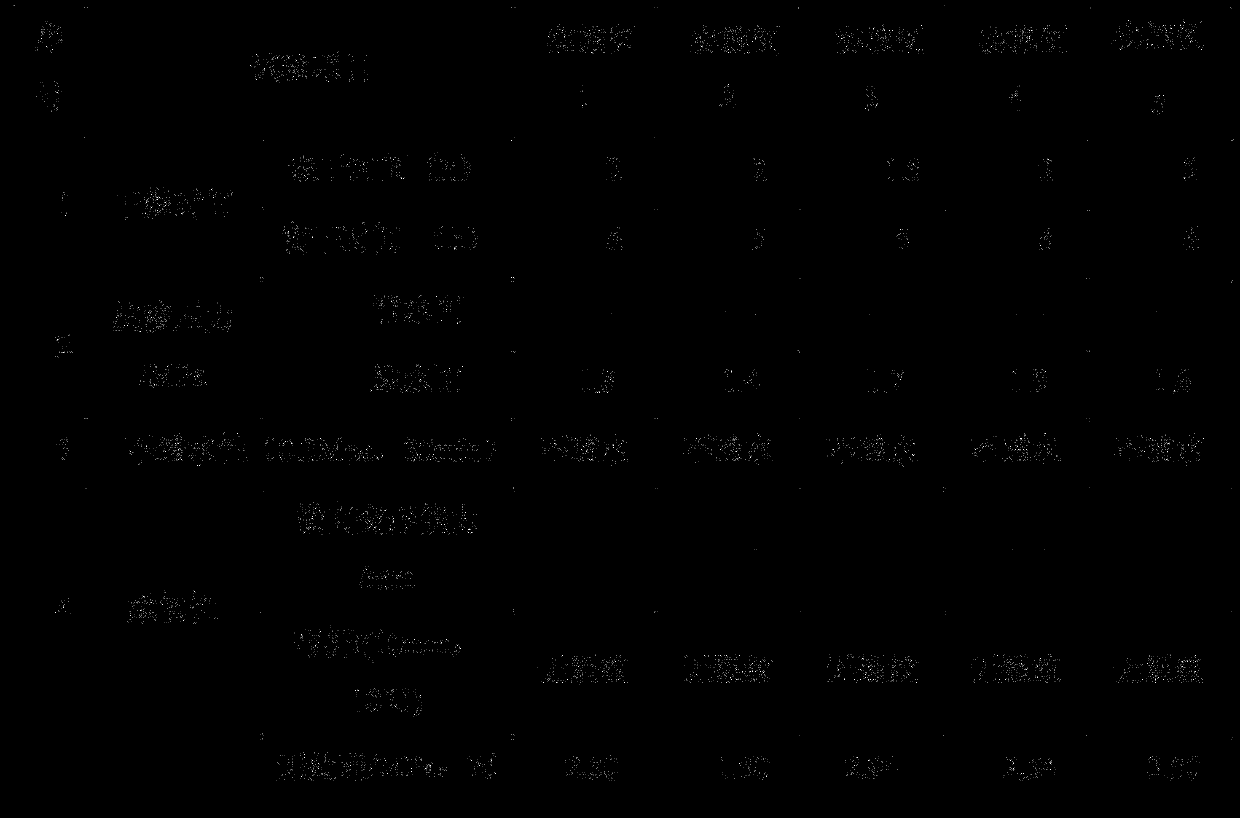

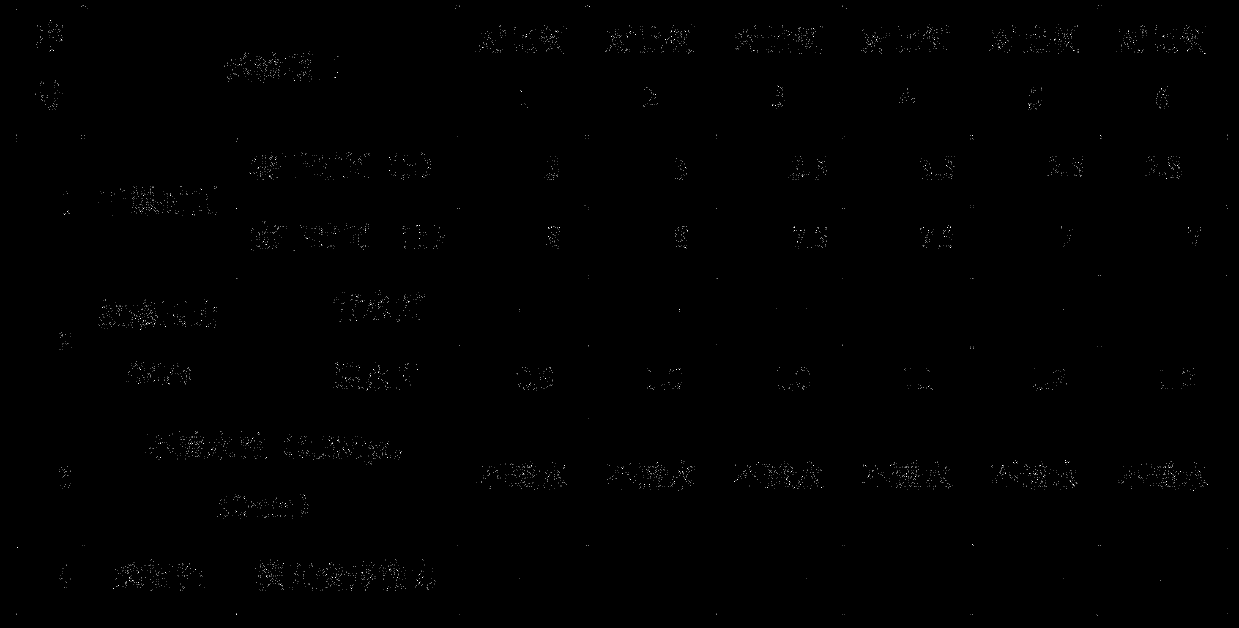

33results about How to "With heat and sound insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel composite insulating thin-wall external wall board and manufacturing method thereof

InactiveCN102733536ACorrosion resistanceImprove bearing capacityClimate change adaptationBuilding reinforcementsFiberReinforced concrete

The invention provides a novel composite insulating thin-wall external wall board. The novel composite insulating thin-wall external wall board mainly comprises the components of fiber-woven-mesh reinforced concrete and an insulating-wall-body material, wherein the fiber-woven-mesh reinforced concrete consists of the components of high-performance fine concrete and a fiber woven mesh; the fiber woven mesh is used as a reinforced material; the insulating-wall-body material comprises one or all of a cement-based material insulating board and insulating material powder. The invention also provides a preparation method of the novel composite insulating thin-wall external wall board. The external wall board provided by the invention integrates the advantages of being long in service life, having a light-weight thin wall, capacity of heat insulation, sound insulation, vibration resistance, impact resistance, fire resistance, and water resistance, being simple in installation and surface decoration processes and the like, is applicable to outer-wall insulation of buildings and is a novel composite insulating building outer-wall structure with a wide application prospect.

Owner:浙江固邦新材料有限公司

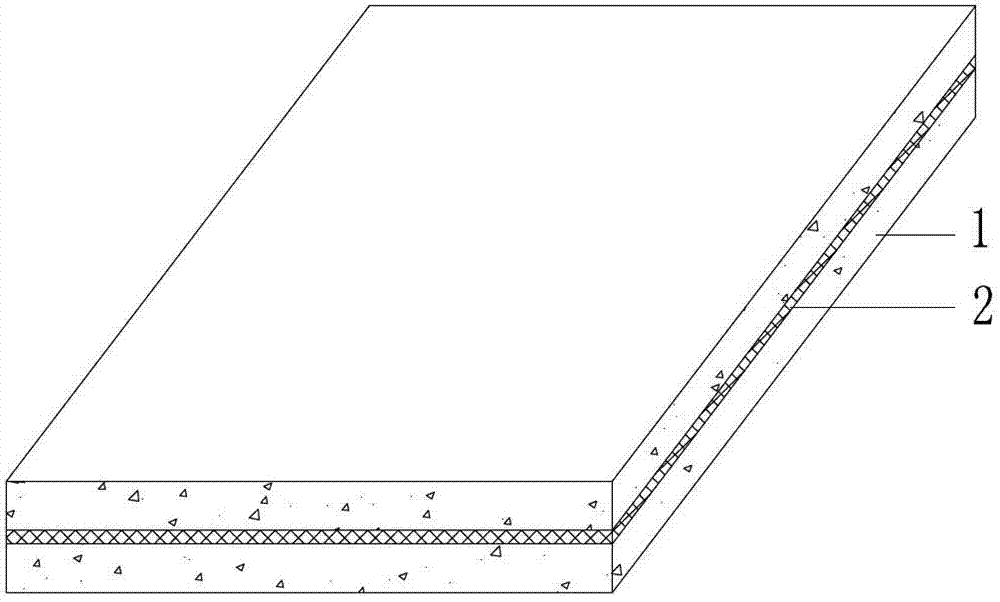

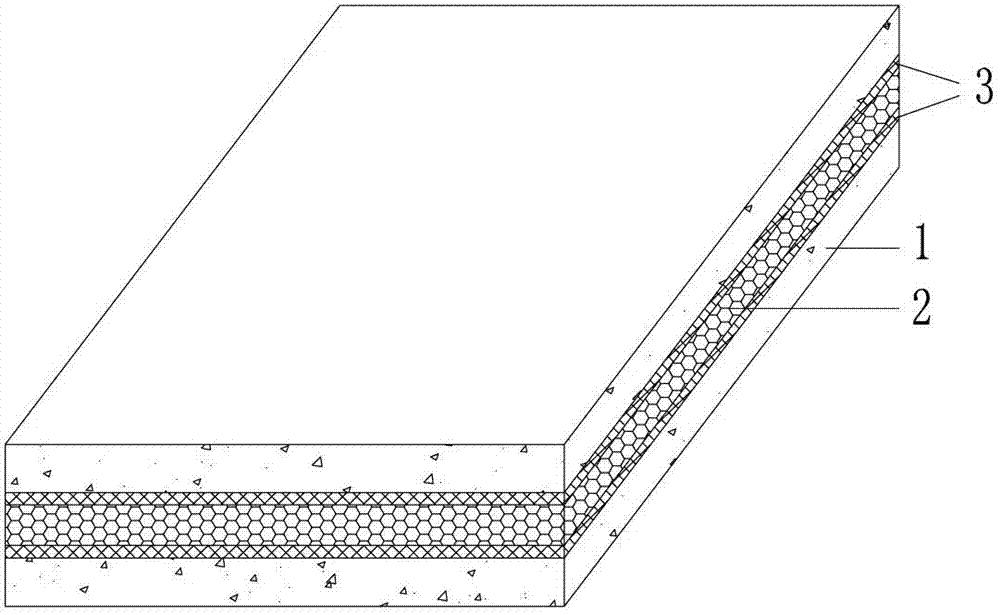

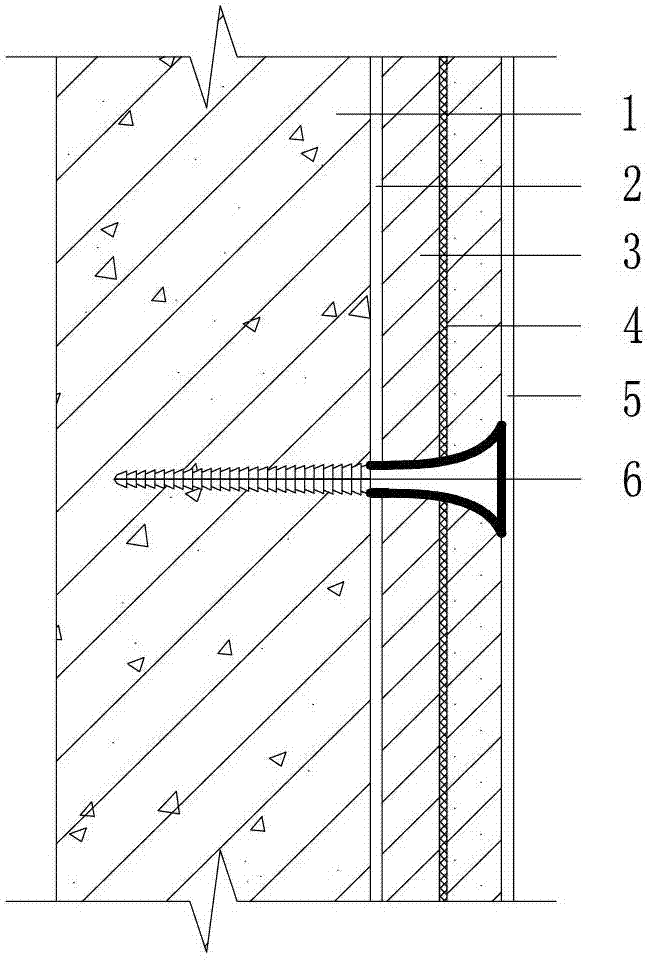

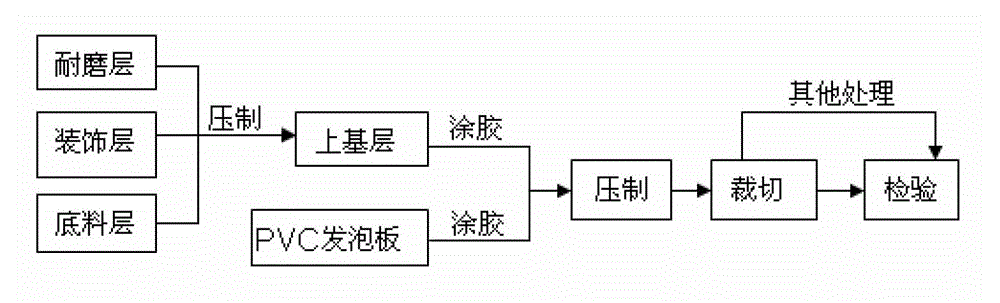

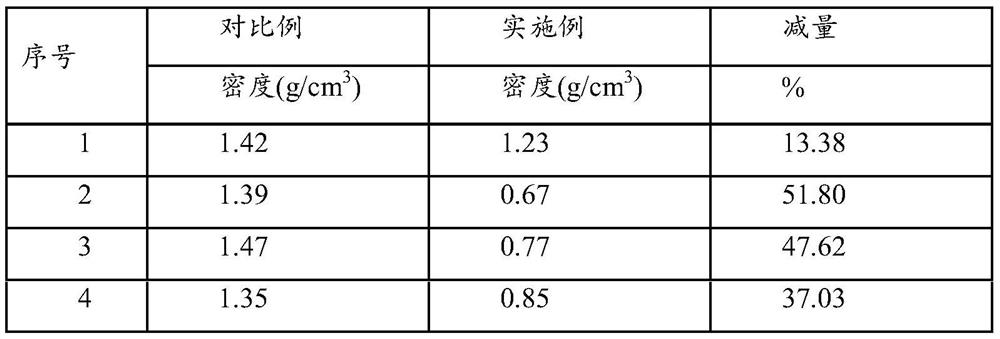

PVC expanded plastic composite board and production method and application thereof

InactiveCN103950267ALow densityHigh strengthCovering/liningsSynthetic resin layered productsAdhesiveComposite plate

The invention provides a PVC foam composite board and a production method and application thereof. An upper base and / or one surface of a PVC foam board is glued; the upper base and the PVC foam board are adhered through the glued side; the upper base and the PVC foam board are pressed to prepare the expanded PVC material composite board. The PVC expanded plastic composite board provided by the invention has low density, high strength, good adhesion between the layers, heat and sound insulation, and flame retardant properties. Due to the small density of the composite board, two simple usage methods can be employed: one is to directly combine the composite board with the matrix by a nail-free glue; and the other is to coat a proper adhesive on the back of the matrix, so that users can directly apply the composite board to the matrix (such as a wall) subjected to certain treatment by themselves. The composite board is simple for installation and convenient for operation, so it has excellent usage properties and processing performances, and has obvious advantages compared with the existing wall decorative materials.

Owner:ZHANGJIAGANG ELEGANT HOME-TECH CO LTD

Lightweight high-strength microcrystal ceramic insulation board and preparation method thereof

The invention discloses a lightweight high-strength microcrystal ceramic insulation board. The lightweight high-strength microcrystal ceramic insulation board comprises the following chemical components in percentage by weight: 30 to 75 percent of silicon dioxide (SiO2), 5 to 20 percent of aluminium oxide (Al2O3), 1 to 20 percent of calcium oxide (CaO), 1 to 15 percent of magnesium oxide (MgO), 1 to 10 percent of ferric oxide and ferrous oxide (Fe2O3+FeO), 1 to 10 percent of sodium oxide, potassium oxide and lithium oxide (Na2O+K2O+Li2O) and 1 to 8 percent of nucleating agent. The lightweight high-strength microcrystal ceramic insulation board is prepared by the following steps of: mixing and crushing waste minerals, a foaming agent and a sintering modifier; mixing the crushed mixture with the nucleating agent; after ball-milling, filter-pressing, pelleting and staling the mixture, directly paving the powder in a fire-resistant mould fully, scraping the mould smoothly and allowing the mould to enter a kiln; and after performing high-temperature sintering, quick cooling, nucleating treatment, quick heating and crystallization, cooling again and then annealing to prepare the product. The lightweight high-strength microcrystal ceramic insulation board has the advantages that: the average grain diameter is between 0.5 and 5 mu m; and crystal grains are dense and uniformly distributed and develop well.

Owner:NANJING UNIV OF SCI & TECH

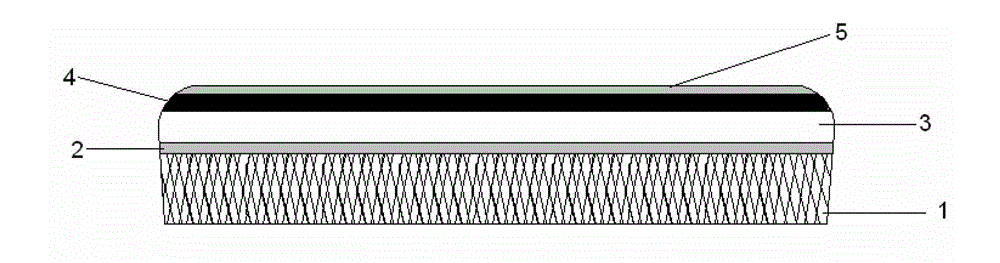

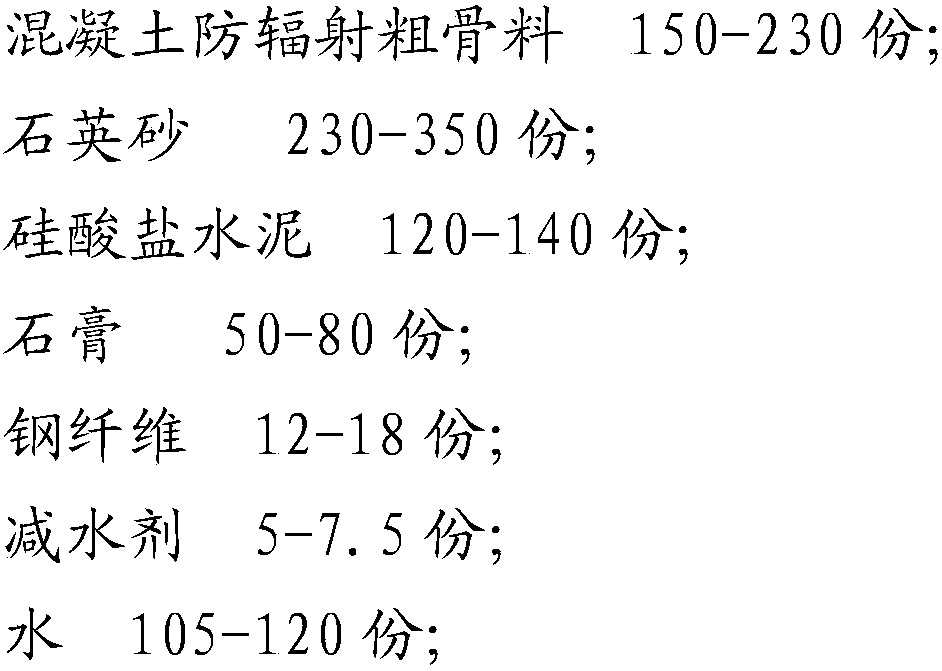

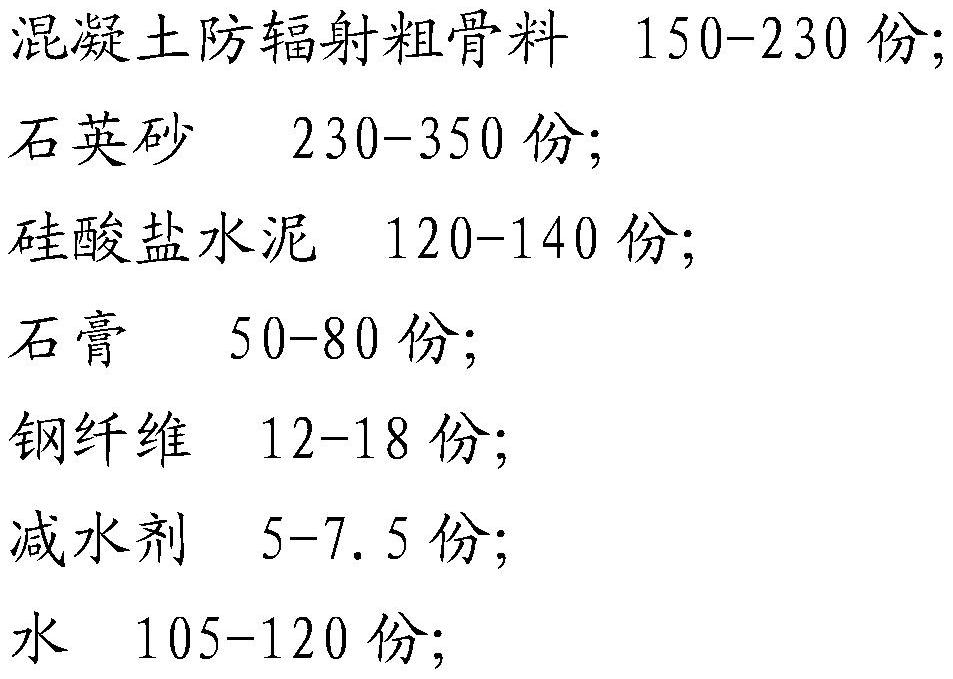

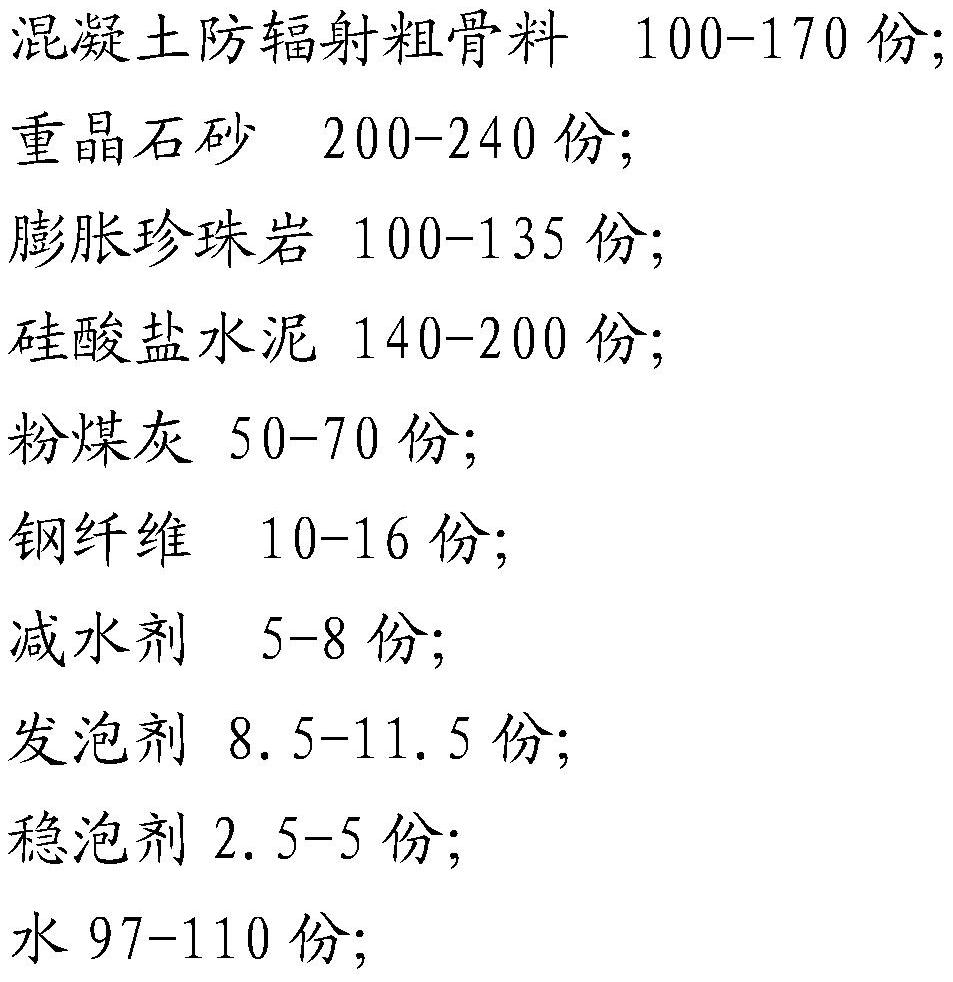

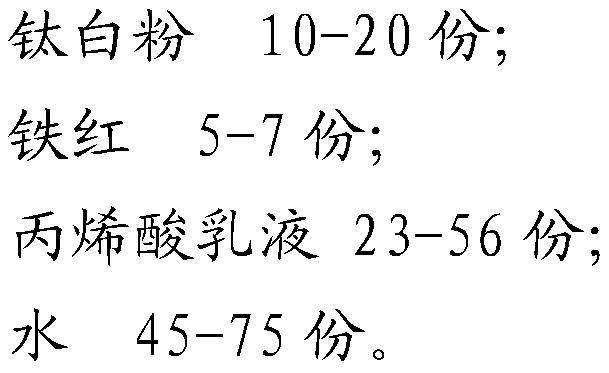

Anti-radiation heat insulation plate and preparation method thereof

ActiveCN108658488AMeet application requirementsHigh strengthCoatingsWater-setting substance layered productRed mudSlag

The invention provides concrete anti-radiation coarse aggregate, an anti-radiation heat insulation plate comprising the aggregate and a preparation method of the anti-radiation heat insulation plate.The method comprises the steps of preparing the concrete anti-radiation coarse aggregate from serpentine acid-leaching slag, red mud and barite powder, and then preparing the anti-radiation heat insulation plate in a four-layer structure. The heat insulation plate has performance such as heat insulation, sound insulation, flame retardance and light weight.

Owner:上海万骊家居有限公司

Wall of light steel structural house

The invention discloses a wall of a light steel structural house. The wall is divided into an inner wall and an outer wall, wherein the inner wall is composed of gypsum boards, wall surface OSBs and alight steel keel, with the light steel keel as a bearing framework, the two sides of the light steel keel are each provided with one wall surface OSB, and the gypsum boards are located on the outermost layers; the outer wall is composed of a gypsum board, one wall surface OSB, a light steel keel, the other wall surface OSB, an insulating layer, a ventilation layer and an outer wall hanging platefrom inside to outside. The middle of each light steel keel is filled with a heat preserving and insulating material, a wood keel is arranged in the middle of the ventilation layer, breathing paper isattached to the surface, close to the insulating layer, of the ventilation layer, and all layers of the inner wall and the outer wall are connected together by cold-rolled steel nails from the two sides in a fastened mode. The wall is low in weight and good in wind and quake resistance, has good features of heat preserving and insulating, sound insulating, fire resistance, moisture prevention, corrosion prevention and the like, and can be widely applied to office buildings, villas, storehouses, stadiums, entertainment venues and tourism buildings.

Owner:黎金莲

Polymer foam particles with skin and dilatancy and preparation method thereof

PendingCN111251500ALow densityWith heat and sound insulationCoatingsPolymer scienceThermal insulation

The present invention discloses polymer foam particles with skin and dilatancy and a preparation method thereof. The polymer foam particles with the skin and the dilatancy have skin structures and thedilatancy, wherein the dilatancy is realized by at least one mechanism in vitrification dilatancy, dynamic dilatancy, entanglement dilatancy, dispersion dilatancy and pneumatic dilatancy. The polymerfoam particles with the skin and the dilatancy can be used for producing package materials with the dilatancy and the slow rebound properties, anti-impact protective materials, damping materials, buffer materials, sound-absorbent materials, thermal insulation materials and the like, so that the polymer foam particles are widely applied.

Owner:厦门天策材料科技有限公司

Industrial light acoustic steel building and roof

InactiveCN1490476AFast installationGood qualityRoof covering using slabs/sheetsFloorsEngineeringSurface plate

Owner:杨大俦

Water-based waterproof coating with heat insulation and sound insulation functions and preparation method thereof

The invention discloses a water-based waterproof coating with heat insulation and sound insulation functions. The water-based waterproof coating is prepared from a liquid material and a powder material in a weight ratio of 1:(3-5), wherein the liquid material is prepared from the following raw materials in parts by weight: 25 to 30 parts of styrene-acrylic emulsion I, 25 to 30 parts of styrene-acrylic emulsion II, 0.10 to 0.20 part of a preservative, 0.20 to 0.30 part of a dispersing agent, 0.10 to 0.20 part of a defoaming agent and 40 to 50 parts of deionized water; wherein the powder material is prepared from the following raw materials in parts by weight: 35 to 55 parts of cement, 35 to 45 parts of quartz sand, 1 to 5 parts of quartz powder, 10 to 15 parts of a modified thermal insulation material, 5 to 10 parts of a modified sound insulation material, 0.02 to 0.05 part of cellulose ether and 0.4 to 0.5 part of a water reducing agent. The invention also discloses a preparation method of the waterproof coating, and the coating has waterproof, heat-insulating and sound-insulating functions by adding the sound-insulating and heat-insulating functional components and fusing the cement and the two styrene-acrylic emulsions with good compounding property.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

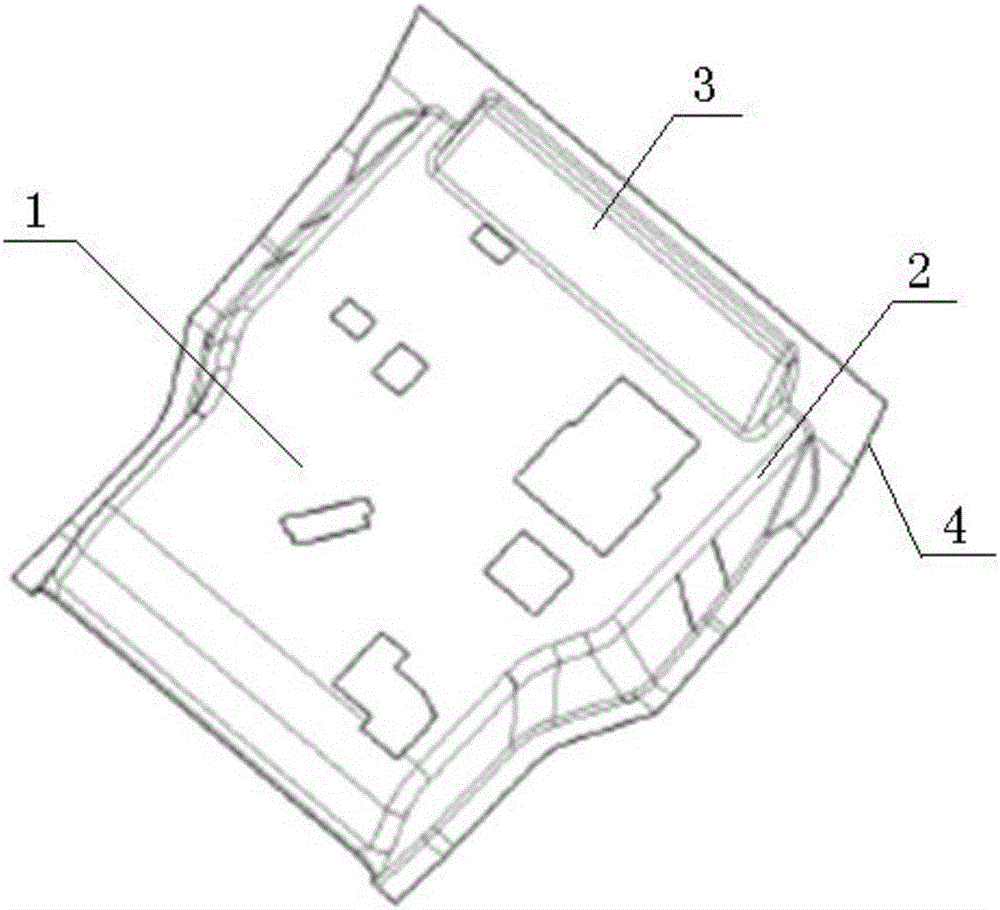

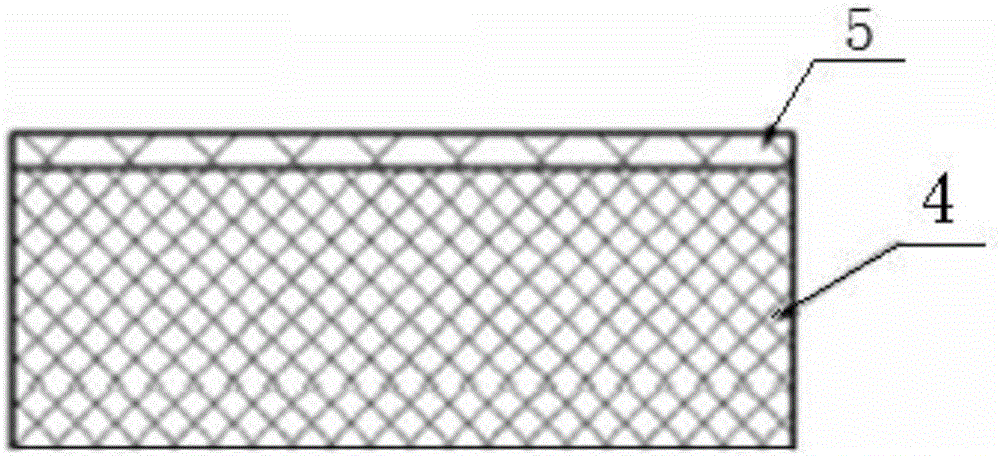

Carpet for commercial vehicle

InactiveCN105966010AWith heat and sound insulationAvoid harmVehicle arrangementsSynthetic resin layered productsThermoplasticPolyolefin

The invention discloses a carpet for commercial vehicles, which comprises a carpet body. The carpet body includes an upper surface layer and a lower bottom layer, and the lower layer is poured on the upper surface layer; the upper surface layer is a PE layer, a TPO layer and an EPDM layer from top to bottom. The lower layer is made of polyurethane PU foam material; the left and right sides of the carpet body are provided with ribs, and the front and rear ends of the carpet body are provided with edges and corners. In the present invention, the polyurethane PU foam layer is used as the lower bottom adhesive layer, which has the effect of heat insulation and sound insulation. The outer layer is made of PE+TPO+EPDM new environmental protection material, which is non-toxic, harmless to the human body, and light in weight. Excellent corrosion resistance and wear resistance, in line with the current environmental protection and lightweight development requirements for automotive interiors, and superior to existing PVC and SBR carpets in terms of product appearance and environmental performance.

Owner:HUBEI SHUANGOU AUTOMOTIVE TRIM

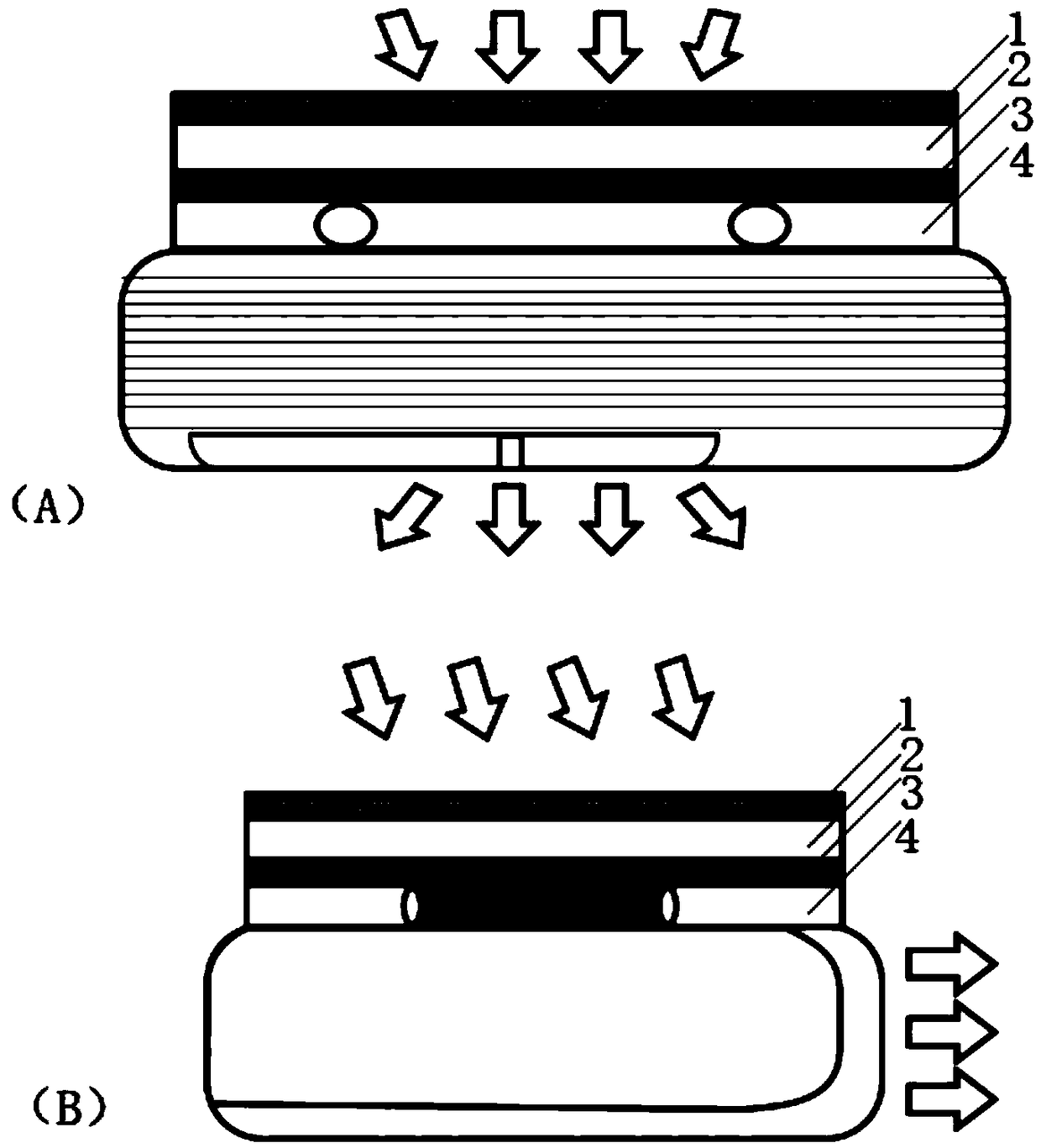

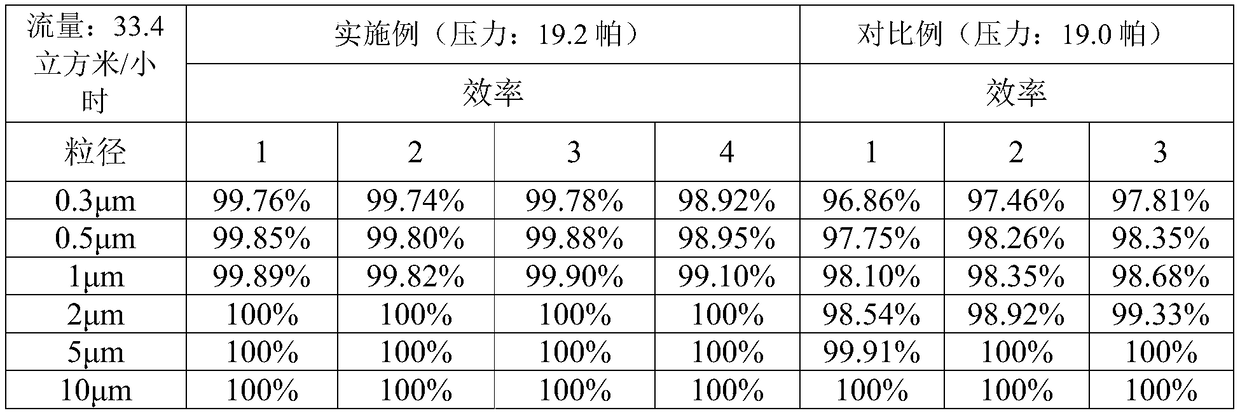

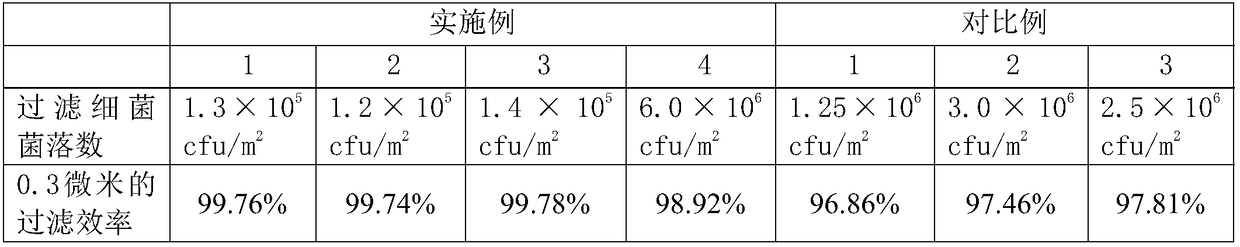

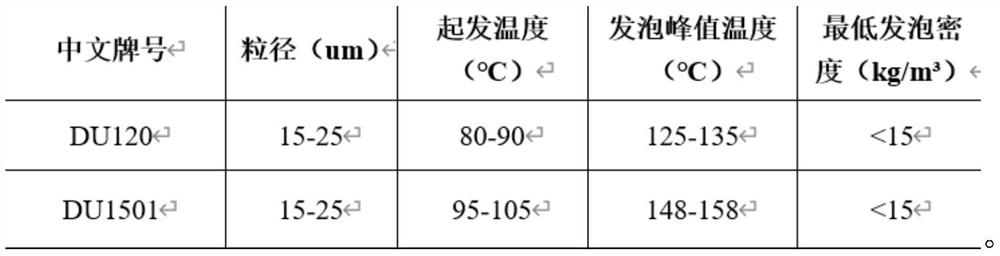

Air purification integrated device of air conditioner

PendingCN109282354ALight in massHigh strengthMechanical apparatusLighting and heating apparatusTemperature controlAir purification

The invention discloses an air purification integrated device of an air conditioner. The air purification integrated device comprises an air purification device fixedly connected to the indoor air conditioner. The device mainly comprises two small draught fans and air purification filter elements. The indoor air conditioner mainly serves as a temperature control device, the temperature control device is arranged in the indoor air conditioner, and the temperature control device comprises a circulating pipe, a pipeline route, a small compressor and the like. A compression solution is contained in the circulating pipe. When the air purification device automatically runs, the draught fans rotate to drive air to enter the purification device from a purification device air opening, and in the period, the air passes through the specially-made air purification filter elements, the air is filtered and purified after passing through the filter elements. The purified air continuously enters thetemperature control device downwards. The purified air makes contact with a backflow pipe of the temperature control device, and the air is heated or cooled and then blown to indoor space. The deviceis simple in structure and convenient to mount. The indoor air is purified, the purified air enters the temperature control device, and meanwhile the service life of the air conditioner is also prolonged.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Lightweight autoclaved brick containing carbonized rice husks and preparation method of lightweight autoclaved brick

PendingCN108033761ASolve the difficulty of usingWide variety of sourcesCeramic shaping apparatusCement mixing apparatusCelluloseBrick

The invention relates to a lightweight autoclaved brick containing carbonized rice husks and a preparation method of the lightweight autoclaved brick. The autoclaved brick comprises, by weight, 10-15parts of carbonized rice husks, 10-15 parts of dry calcium carbide residue, 15-20 parts of oil shale ash, 25-30 parts of fly ash, 25-30 parts of quartz sand powder, 0.2-0.5 part of cellulose ether, 0.2-0.5 part of polyvinyl alcohol, 0.1-0.3 part of triethanolamine and 0.1-0.3 part of aluminum ammonium sulfate dodecahydrate. The autoclaved brick is prepared by the materials above according to the weight. The autoclaved brick and the preparation method have the advantages that the application difficulty of the rice husks is solved, the carbonized rice husks are used as the pore-forming raw materials to produce the lightweight autoclaved brick, and the lightweight autoclaved brick is environmentally friendly, energy-saving, capable of insulating heat and sounds, and the like; the preparationmethod is simple in process, wide in raw material source and low in cost.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Bi-component polysulfide sealant composition, bi-component polysulfide sealant and preparation method

InactiveCN113372873ALow densityTight bondNon-macromolecular adhesive additivesEpoxynovolac adhesivesPolymer sciencePolysulfide rubber

The invention provides a bi-component polysulfide sealant composition, a bi-component polysulfide sealant and a preparation method of the bi-component polysulfide sealant, and belongs to the field of sealants. The bi-component polysulfide sealant composition specifically comprises a component A and a component B, the component A comprises the following components in parts by weight: 100 parts of liquid polysulfide rubber, 10-70 parts of a reinforcing filler, 0.5-5 parts of expandable microspheres, 5-15 parts of a thixotropic agent and 0.5-1.5 parts of an amine catalyst; and the component B comprises 5-15 parts of epoxy resin. By means of the treatment scheme, the density of the sealant can be remarkably reduced, and rapid curing can be achieved after the two components of the sealant are mixed.

Owner:快思瑞科技(上海)有限公司

Sealant composition, polyurethane sealant and preparation method of polyurethane sealant

InactiveCN113214775ALow densityWith heat and sound insulationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention provides a sealant composition, a polyurethane sealant and a preparation method of the polyurethane sealant, and belongs to the field of sealers. The sealant composition is specifically prepared from, by mass, 35-65 parts of prepolymer, 20-40 parts of modified filler, 0.1-2 parts of expanded microspheres, 5-25 parts of plasticizer, 0.1-5 parts of thixotropic agent, 0.01-0.5 part of water removal agent and 0.01-0.5 part of catalyst. The prepolymer is obtained by reacting 80-100 parts by mass of polyether polyol and 10-20 parts by mass of isocyanate for 5-8 hours; the modified filler is obtained by stirring 100 parts of filler and 0.1 to 3 parts of modifier for 30 to 40 minutes; the expanded microspheres are formed by wrapping a volatile expanding agent serving as a core agent in a shell formed by a polymer, the shell is formed by polymerizing a monomer mixture of polymerizable monomers, and the polymerizable monomers are at least one of acrylonitrile, acrylate monomers, acrylamide monomers and acrylic acid monomers. Through the treatment scheme, the density of the sealant is remarkably reduced, the sealant is convenient to store and transport, the production and transportation cost is reduced, and the sealant has good heat insulation and sound insulation effects.

Owner:CRERAX SCI & TECH CO LTD

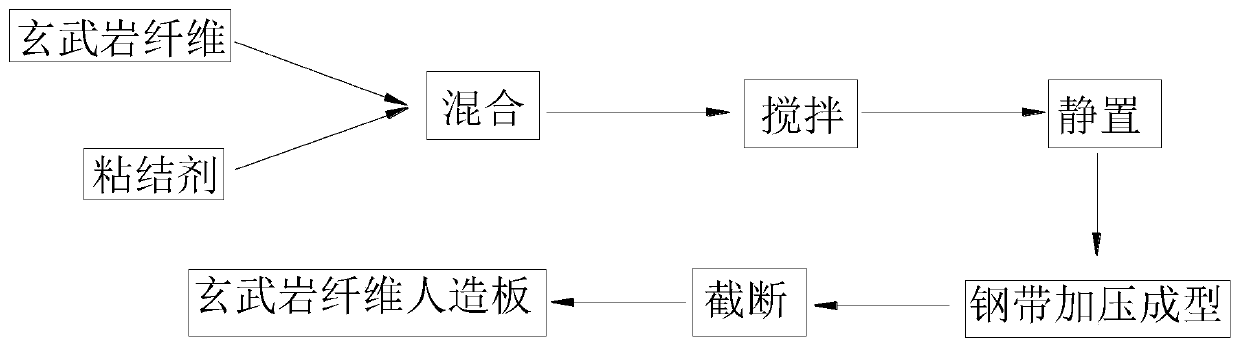

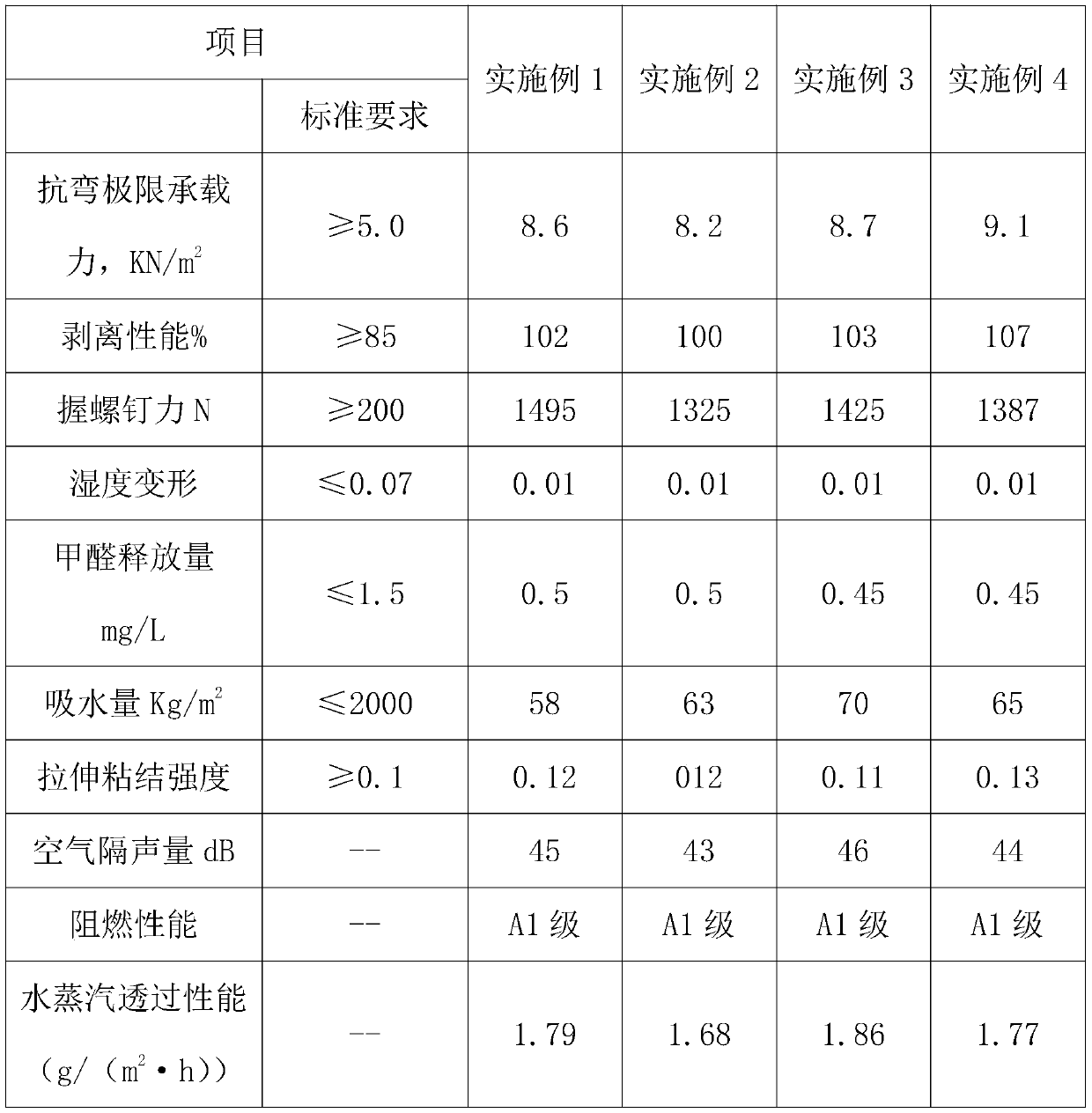

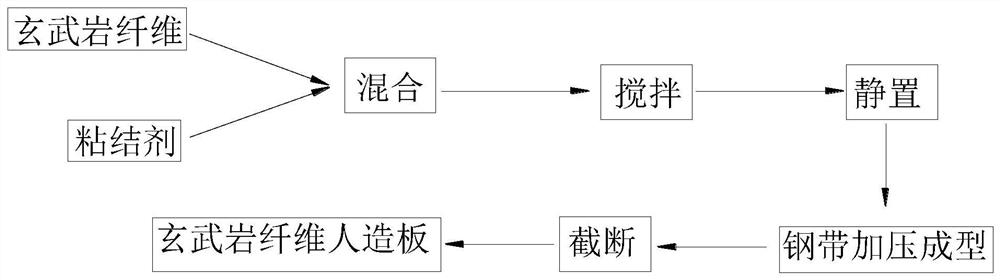

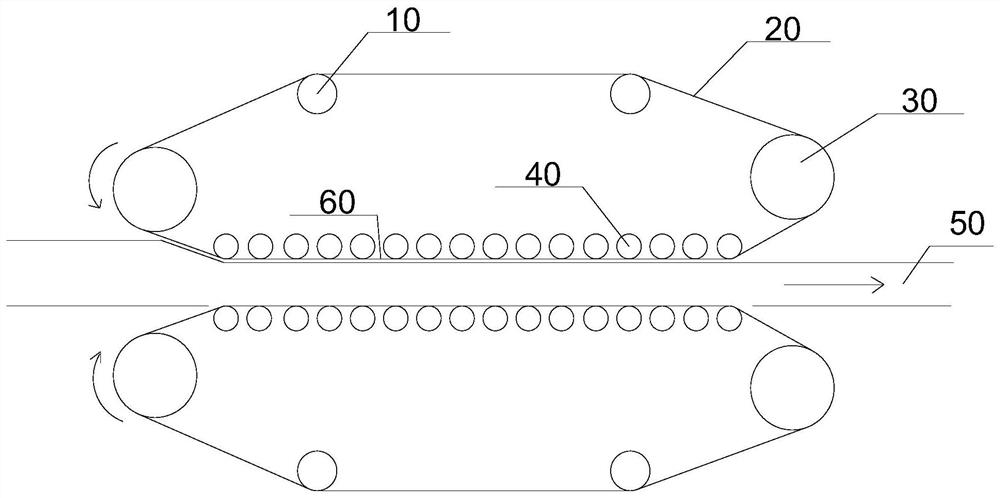

Basalt fiber artificial board and preparation method thereof

ActiveCN110423014ALow costChangeable shapeCeilingsCovering/liningsEnvironmental resistanceFiltration

The invention discloses a preparation method for a basalt fiber artificial board. The preparation method comprises the following steps of: mixing basalt chopped fibers and a binder according to a certain ratio to obtain a mixture; and subjecting the mixture to steel strip pressure forming to obtain the basalt fiber artificial board. According to the invention, the basalt chopped fibers and the binder are mixed to prepare the basalt fiber artificial board; and the prepared basalt fiber artificial board is environmentally friendly and has superior chemical resistance, high temperature resistance, flame retardancy, fire resistance, oxidation resistance, radiation resistance, heat insulation performance, sound insulation performance, filtration performance, compressive strength, shear strengthand the like compared with conventional artificial boards; the basalt fiber artificial board produced in the invention has high recovery property, is improved in recycling rate, and reduces environmental pollution of waste products to environment; even after scrapping, the basalt fiber artificial board can become soil or sand in subsequent degradation due to the usage of the basalt chopped fibers, so the recycling rate is high; and the method of the invention is more simplified in process, so corresponding economic cost can be saved for enterprises.

Owner:SICHUAN QIANYI COMPOSITE MATERIAL CO LTD

Porcelain algae silicon composite material and preparation method thereof

The invention discloses a porcelain algae silicon composite material and a preparation method thereof, and relates to the technical field of inorganic building materials. The porcelain algae silicon composite material is prepared from, by weight, 10-50 parts of kaolin, 20-60 parts of diatomaceous earth, 20-40 parts of cement, 5-10 parts of silica fume, 2-6 parts of basalt fibers, 3-20 parts of magnesium oxide, 5-40 parts of magnesium sulfate, 20-70 parts of bamboo powder and 0.2-2 parts of a condensate rock solution. The preparation method comprises the step that the material is prepared by uniformly mixing the raw materials. The prepared porcelain algae silicon composite material is poured into plates, walls, components and other products, and the products have the advantages of surface smoothness and cleanliness, fire proofing, flame retardancy, dampness proofing, mildew proofing, heat insulation, sound insulation, non-toxicity and ageing resistance and can adsorb harmful substancessuch as formaldehyde in air.

Owner:宁国格闰新材料科技有限公司

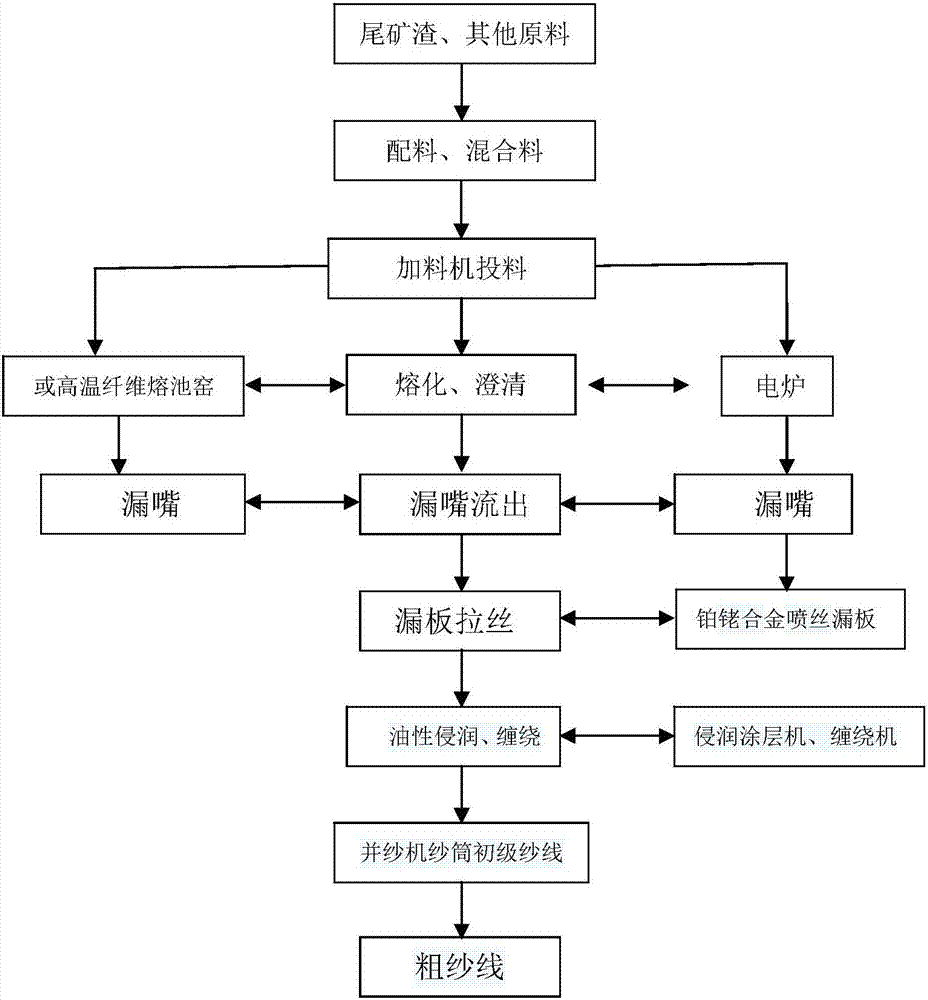

High-strength microcrystalline fibers produced by tailings and waste residues and preparation method thereof

InactiveCN107285638ALow raw material costReduce energy consumptionGlass making apparatusScrapCorrosion

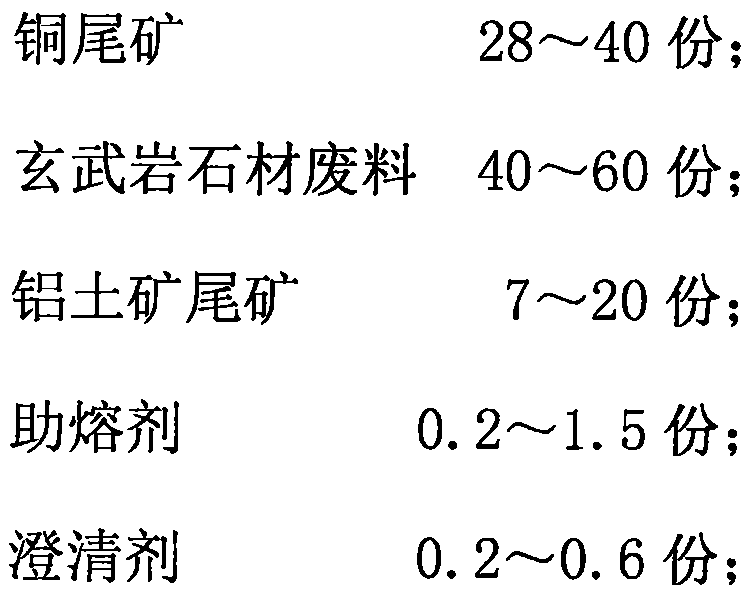

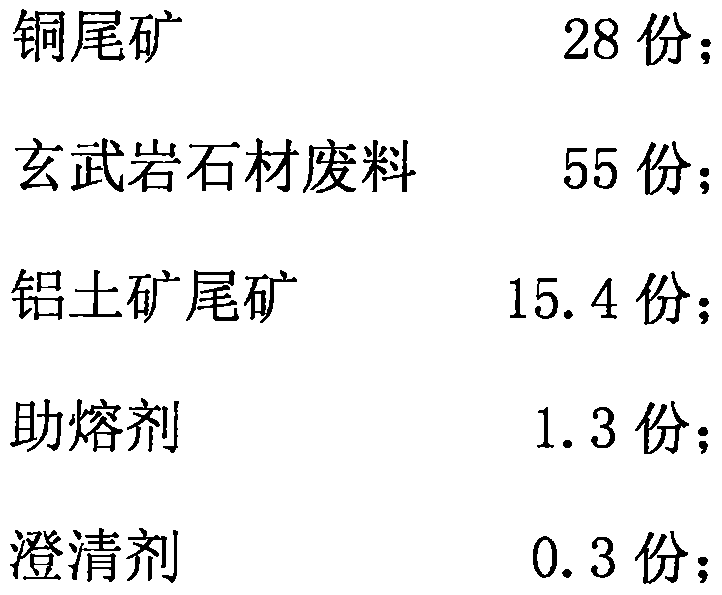

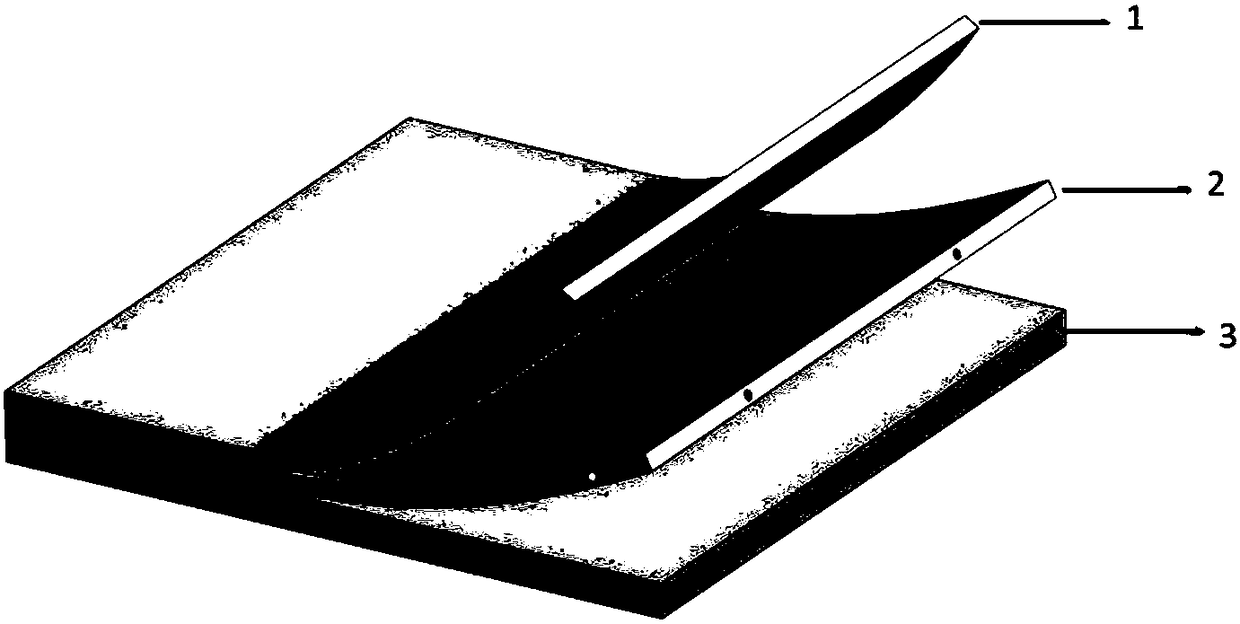

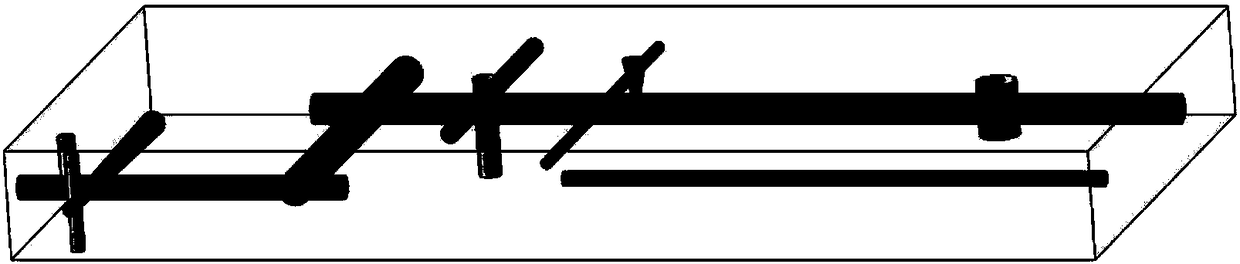

A high-strength microcrystalline fiber produced by using tailings waste slag and a preparation method thereof. The raw materials are composed of 28-40 parts by weight of copper tailings, 40-60 parts of basalt stone waste, and 7-60 parts of bauxite tailings. 20 parts, 0.2-1.5 parts of flux and 0.2-0.6 parts of clarifying agent. In its preparation process, the process of "feeding-melting-drawing" is used for production. The present invention uses copper tailings, basalt stone waste, and bauxite tailings as main raw materials, and the products do not burn at a temperature above 750°C, and the cost of production raw materials is reduced by 26-35%. Carbon fiber mainly produced with organic components and inorganic glass fiber are harmful to the health of human silicosis and pollute the environment; solve the problems of brittleness, poor corrosion resistance, wear resistance, easy breakage and short service life of existing glass fiber products , It also solves the problem that the natural production raw material source of basalt fiber fluctuates greatly, resulting in unstable product quality. At the same time, it can effectively alleviate the environmental problems and hidden dangers of safety accidents caused by the accumulation of tailings and stone waste.

Owner:张一唯 +1

A kind of preparation method of intelligent thermal and sound insulation PVB film and the preparation method of PVB film laminated glass

ActiveCN105835497BImprove sound insulationWith intelligent heat insulation and sound insulation performanceSynthetic resin layered productsFlat articlesTemperature controlVanadium dioxide

The invention discloses a preparation method for intelligent PVB laminated glass. The intelligent PVB laminated glass comprises a first PVB layer, a second sound-insulation layer and a third PVB layer which are successively connected. The preparation method comprises the following steps: (1) adding nanometer vanadium dioxide powder into alcohol for dissolving so as to obtain a VO2 solution, blending the VO2 solution with resin powder so as to obtain a master batch for the second sound-insulation layer and processing the master batch for the second sound-insulation layer so as to obtain the second sound-insulation layer containing a three-dimensional channel structure function layer; and (2) blending the second sound-insulation layer and PVB resin powder and carrying out co-extrusion or roll forming so as to obtain an intelligent heat-insulation sound-insulation PVB film. According to the invention, automatic temperature control and heat insulation are realized by using different light transmission and reflection properties of VO2 at different temperatures; sound insulation effect is realized via a three-dimensional channel structure and asymmetric damping; the sound insulation effect and the heat insulation effect are integrated on the PVB film so as to form the novel PVB sandwich film with heat insulation and sound insulation functions; so the functionality of the PVB film is improved, and security of the laminated glass is guaranteed.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

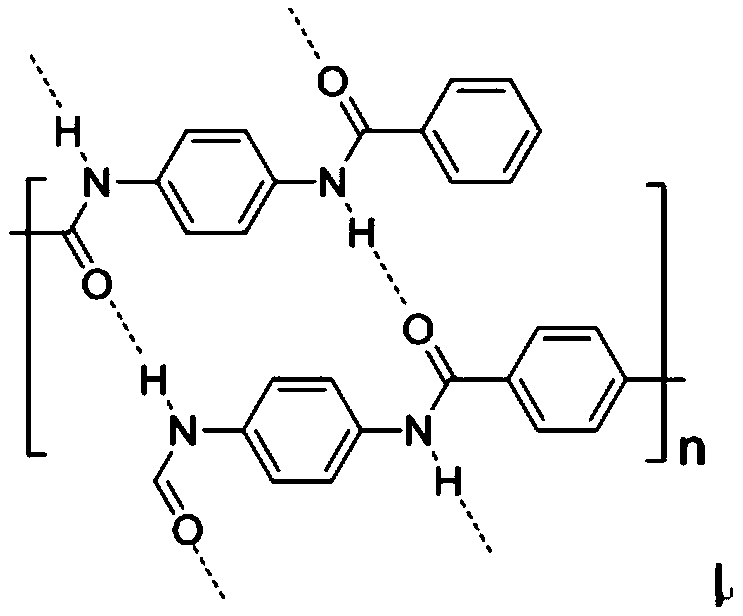

Heat-insulating poly-p-phenylene terephthalamide-foam glass sound-insulating composite material

The invention relates to the technical field of preparation of heat-insulating and sound-insulating composite materials, and discloses a heat-insulating poly-p-phenylene terephthalamide-foam glass sound-insulating composite material. The composite material is prepared from the following raw materials: waste glass slag, waste mineral wool board, poly-p-phenylene terephthalamide, a foaming aid, a foam stabilizer, a co-additive, a mixed co-solvent and a silane coupling agent, wherein the waste glass slag and the waste mineral wool board are recovered construction wastes such as soda lime glass wastes. The poly-p-phenylene terephthalamide-foam glass sound-insulating composite material adopts KOH as the foaming aid, and Na2B4O5(OH)4.8H2O is added as the co-additive; the KOH and the Na2B4O5(OH)4.8H2O react with SiO2 and CaO in soda lime glass to produce KNaCaSi2O6.6H2O crystals before foaming; in the heating and foaming process, the KNaCaSi2O6.6H2O crystals release steam to foam the raw materials. By adopting the method, the foaming porosity is improved, and the foaming process is stable; produced pores are very small and are uniformly distributed, so that sound waves are effectively absorbed, and the sound-insulating effect of foam glass is greatly enhanced.

Owner:沈阳鑫格绝热节能材料有限公司

A kind of basalt fiber wood-based panel and its preparation method

ActiveCN110423014BChemical resistantHigh temperature resistanceCeilingsCovering/liningsWaste productEngineering

The invention discloses a preparation method of a basalt fiber man-made panel, which comprises the following steps: stirring and mixing basalt chopped fibers and a binder according to a certain proportion to obtain a mixture; subjecting the mixture to steel belt pressure molding to obtain basalt Fiber-based panels. In the present invention, the basalt fiber wood-based panel is prepared by mixing the basalt chopped fiber and the binder. The wood-based panel is environmentally friendly and economical, and has chemical resistance, high temperature resistance, flame retardancy, fire resistance, oxidation resistance, radiation resistance and heat insulation. In terms of performances such as sound insulation, filtration, compressive strength and shear strength, due to the existing traditional man-made boards; the basalt fiber man-made boards prepared by the present invention have high product recyclability, improve the reuse rate, and reduce waste products. Even after being scrapped, the basalt chopped fibers can become soil or sand during subsequent degradation, and the reuse rate is high; the process of the invention is more simplified, and corresponding economic costs can be saved for enterprises.

Owner:SICHUAN QIANYI COMPOSITE MATERIAL CO LTD

A kind of anti-radiation insulation board and its preparation method

ActiveCN108658488BMeet application requirementsHigh strengthCoatingsWater-setting substance layered productRed mudEngineering

The invention provides concrete anti-radiation coarse aggregate, an anti-radiation heat insulation plate comprising the aggregate and a preparation method of the anti-radiation heat insulation plate.The method comprises the steps of preparing the concrete anti-radiation coarse aggregate from serpentine acid-leaching slag, red mud and barite powder, and then preparing the anti-radiation heat insulation plate in a four-layer structure. The heat insulation plate has performance such as heat insulation, sound insulation, flame retardance and light weight.

Owner:上海万骊家居有限公司

A heat-insulating poly(p-phenylene terephthalamide)-foam glass sound insulation composite material

ActiveCN110330222BImprove sound insulationEffective absorptionGlass shaping apparatusThermal insulationSound wave

The invention relates to the technical field of preparation of heat-insulating and sound-insulating composite materials, and discloses a heat-insulating poly(p-phenylene terephthalamide-foam glass) sound-insulating composite material, which includes the following raw materials, waste glass slag, waste mineral wool board, Polyparaphenylene terephthalamide, foaming aids, foam stabilizers, auxiliary additives, mixed auxiliary solvents, silane coupling agents, waste glass slag, and waste mineral wool boards are recycled construction waste soda lime glass waste. The poly-p-phenylene terephthalamide-foam glass sound insulation composite material uses KOH as a foaming aid, adding Na 2 B 4 O 5 (OH) 4 ·8H 2 O is an auxiliary additive, KOH and Na before foaming 2 B 4 O 5 (OH) 4 ·8H 2 O and SiO in soda lime glass 2 , CaO reaction to produce KNaCaSi 2 O 6 ·6H 2 O crystal, KNaCaSi 2 O 6 ·6H 2 During the heating and foaming process, the O crystal releases steam to make the raw materials foam. This method increases the foaming porosity, and the foaming process is stable. The generated pores are small and evenly distributed, which can effectively absorb sound waves and greatly enhance The sound insulation effect of foam glass.

Owner:沈阳鑫格绝热节能材料有限公司

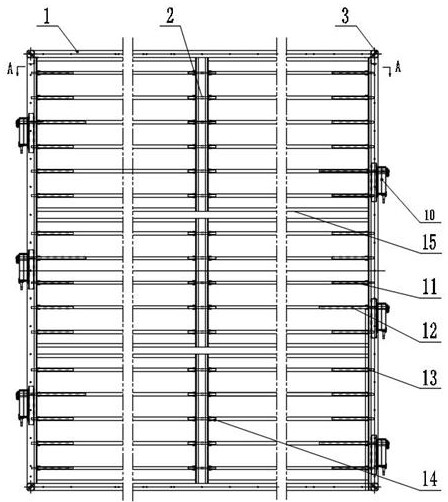

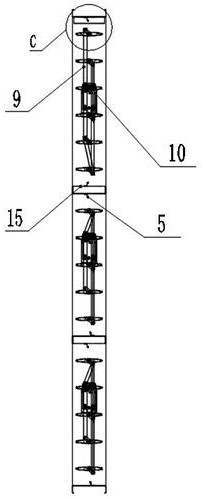

Fiber cement board production device and production method thereof

The invention relates to a fiber cement board production device and a production method thereof. The fiber cement board production device comprises a row of driven rollers, a rail beneficial to bottom formwork conveying, bottom formworks and pressure transmission rollers, wherein the bottom formworks are laid on the rail in sequence, and the pressure transmission rollers are arranged above the rail, can act on the upper surfaces of the bottom formworks and drive the bottom formworks to move; the rail is further provided with sponge used for coating a release agent to the upper surfaces of the bottom formworks, a first glass fiber discharge device for discharging a fiber cement board bottom layer glass fiber net on the bottom formworks, a cement paste discharging device, and a second glass fiber discharge device for discharging a surface layer glass fiber net on the surface layer of a fiber cement board. The fiber cement board production device is reasonable in structure, simple in operation and low in cost, and the produced fiber cement board has the advantages of fire prevention, insulation, water prevention, damp prevention, heat and noise insulation, light weight, high strength, simple construction, economy, attractiveness and the like.

Owner:FUJIAN AGEO NEW BUILDING MATERIALS

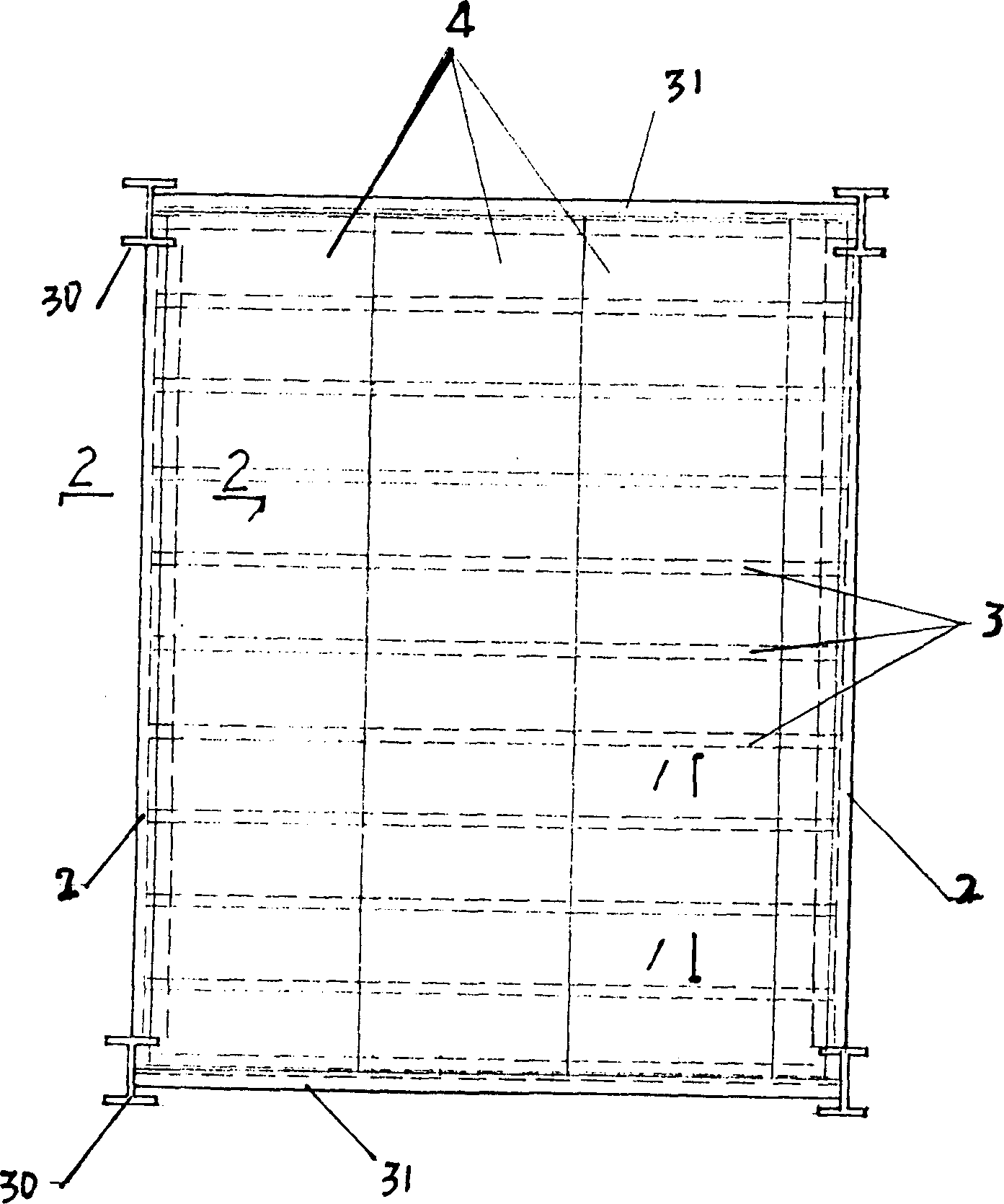

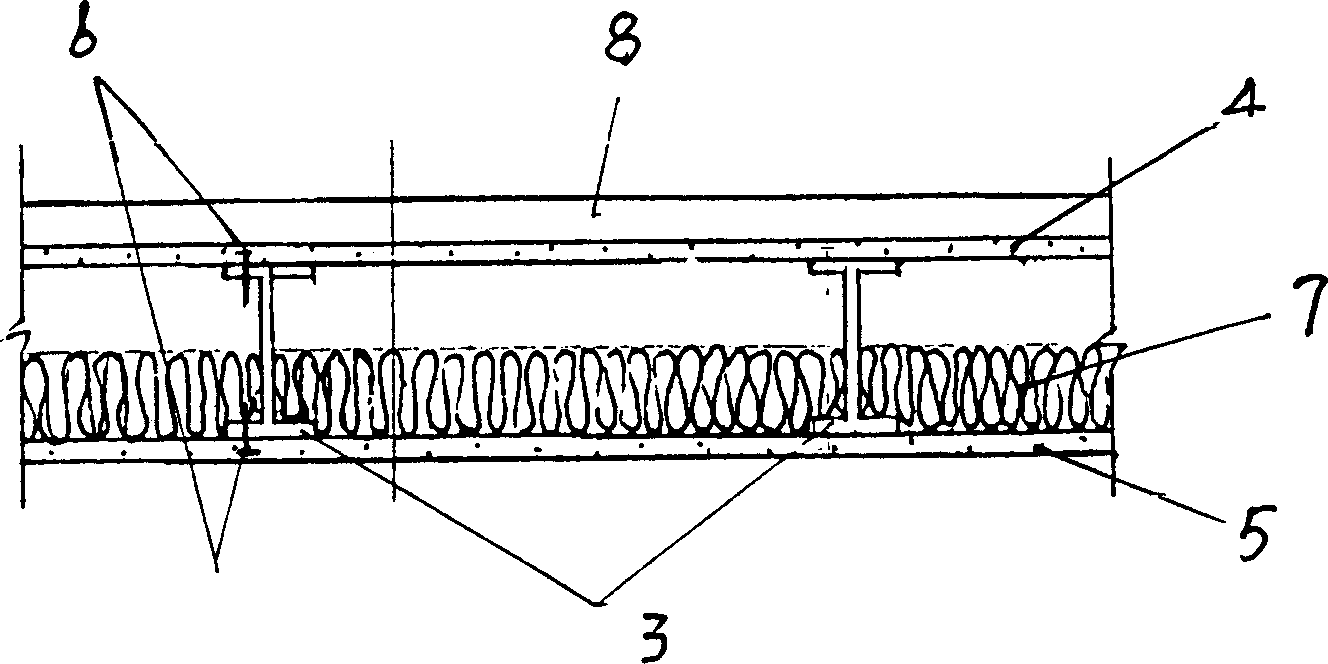

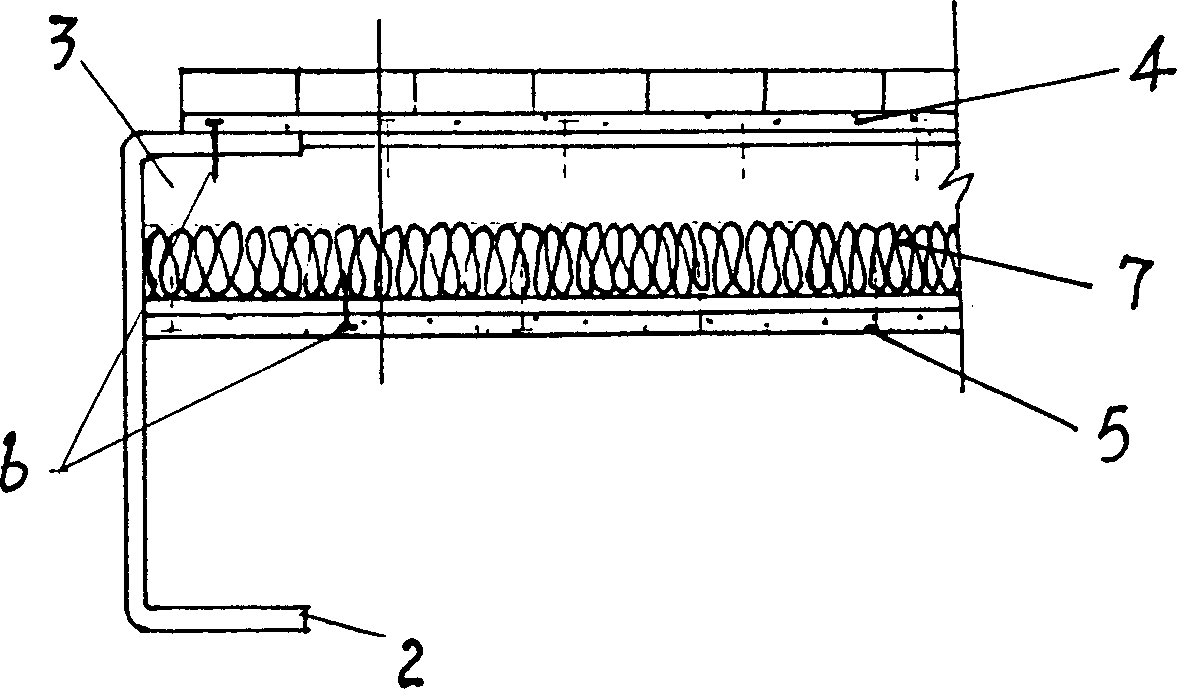

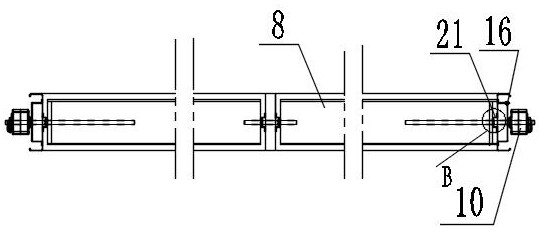

Heat preservation type electric airtight regulating valve

PendingCN112177964AWon't happenNovel and reasonable structurePump componentsPump controlDrive shaftEngineering

The invention discloses a heat preservation type electric airtight regulating valve comprising an outer frame A and electric actuators. A middle partition A is vertically arranged in the middle of theouter frame A, a plurality of middle partitions B are transversely arranged on the outer frame A, a plurality of middle shafts are arranged on the middle partition A, the two ends of each middle shaft are connected with combined blades correspondingly, and the other end of each combined blade is connected with a driven shaft or a driving shaft. The upper face and the lower face of each middle partition B are connected with wind shields attached to the corresponding combined blades through bolts. The driving shafts are connected with the electric actuators and transmission mechanisms, and thetransmission mechanisms are connected with the driven shafts. Supports A are arranged on the inner side of the outer frame A and the two sides of the middle partition A. The supports A are tightly attached to the combined blades. The heat preservation type electric airtight regulating valve is novel and reasonable in structure, easy and convenient to install, attractive in appearance and good in lighting, has the functions of heat insulation, sound insulation and cold bridge breaking, cannot generate condensate water, improves the heat preservation performance and the wear resistance, and prolongs the service life. The heat preservation type electric airtight regulating valve is suitable for sites such as machine rooms and grain depots needing constant temperature and constant humidity.

Owner:江苏慧聪空调设备有限公司

A kind of porcelain algal silica composite material and preparation method thereof

The invention discloses a porcelain algal silica composite material and a preparation method thereof, and relates to the technical field of inorganic building materials. Porcelain algal silica composite material includes 10-50 parts of kaolin, 20-60 parts of diatomite, 20-40 parts of cement, 5-10 parts of silica fume, 2-6 parts of basalt fiber, and 3-20 parts of magnesium oxide in parts by weight. 5-40 parts of magnesium sulfate, 20-70 parts of bamboo powder, and 0.2-2 parts of rock condensate; the preparation method is to mix the above raw materials evenly. The porcelain algae-silicon composite material prepared by the present invention is poured to form products such as plates, walls, and components. The obtained products have the advantages of smooth and smooth surface, fire and flame retardancy, moisture and mildew resistance, heat insulation and sound insulation, non-toxic and anti-aging, and can be adsorbed at the same time. Harmful substances such as formaldehyde in the air.

Owner:宁国格闰新材料科技有限公司

Sealant composition

PendingCN114350310ALow densityObvious weight loss effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention belongs to the technical field of sealants, and particularly discloses a sealant composition which is prepared from the following raw materials in parts by weight: 100 parts of a base material, 20-40 parts of modified filler, 0.3-0.9 part of expanded microspheres, 6-20 parts of a thixotropic agent, 0.5-3 parts of a light stabilizer, 0.5-5 parts of a coupling agent, 3-5 parts of a curing agent, 10-20 parts of a plasticizer, 0.5-3 parts of a catalyst and 2-8 parts of an adhesion promoter, the expanded microspheres with large volume and small mass are used as the light filler, an excellent weight reduction effect can be achieved by adding a small amount of the expanded microspheres, the density of the sealant is remarkably reduced, the sealant is convenient to transport, a small amount of the expanded microspheres can replace most of raw materials, and the production and transportation cost is greatly reduced; the ultraviolet absorbent, the light stabilizer and the antioxidant are effectively compounded through structure optimization to obtain the light stabilizer, the problem that the sealant is resistant to yellowing after being used for a long time is solved, and meanwhile, the tea polyphenol type antioxidant introduced into the light stabilizer also has antibacterial and mildew-proof effects.

Owner:常州科菲自动化科技有限公司

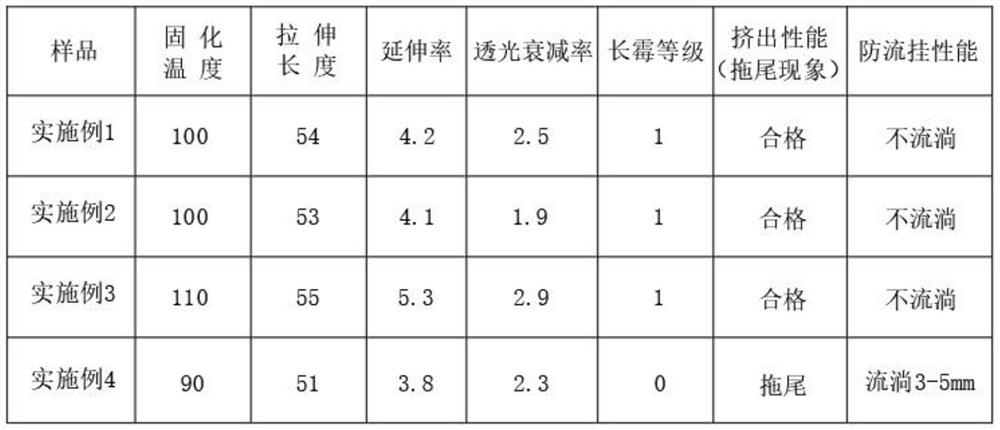

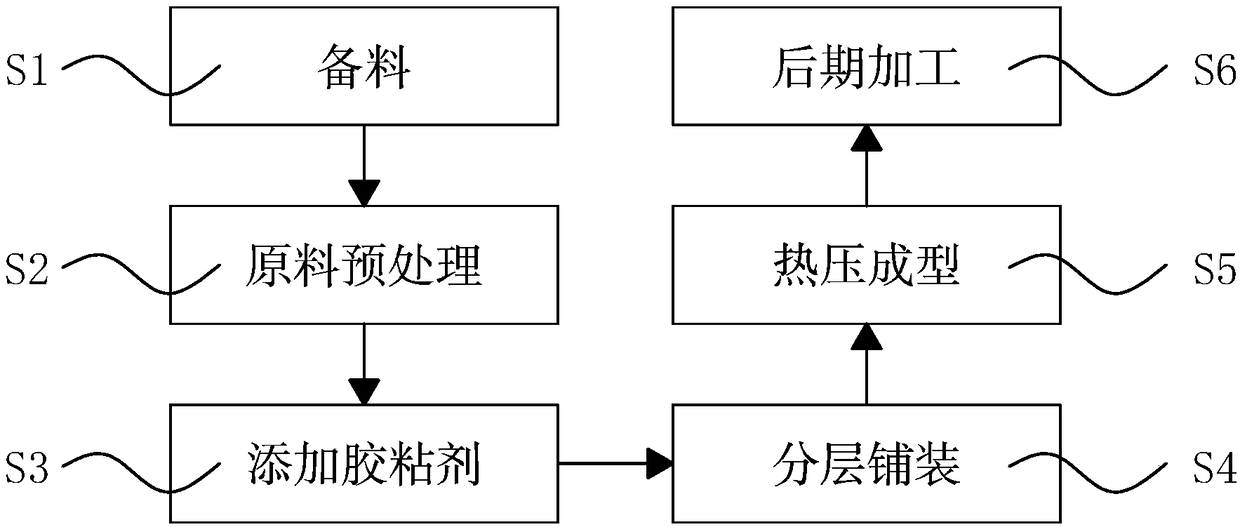

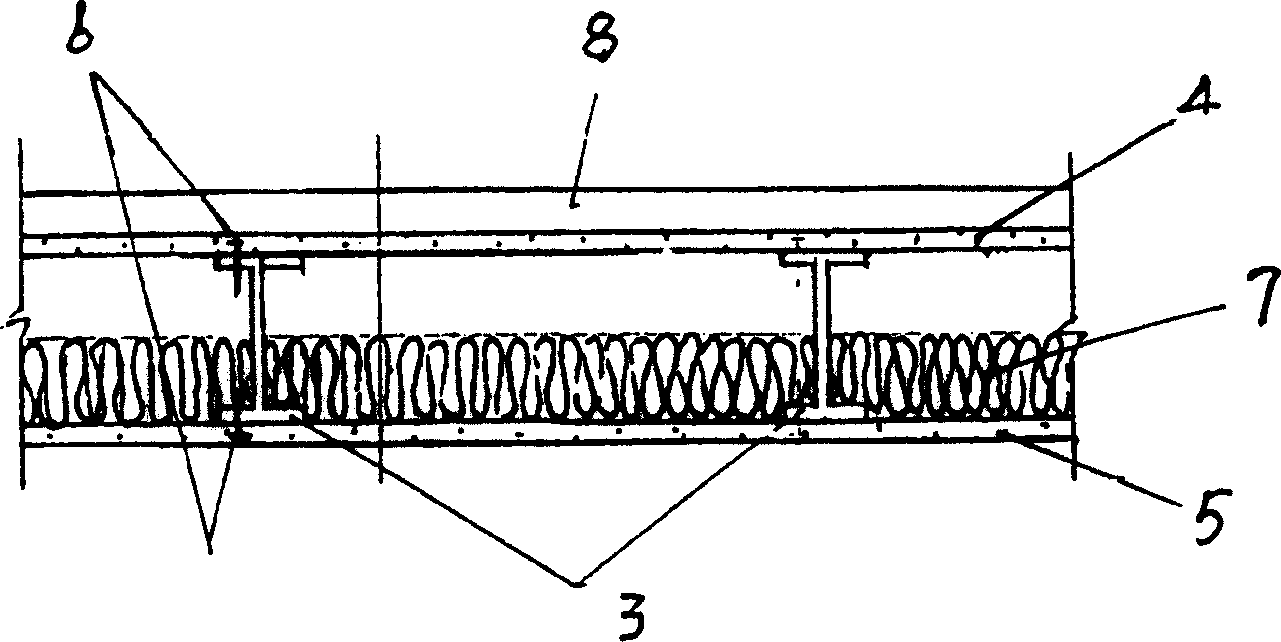

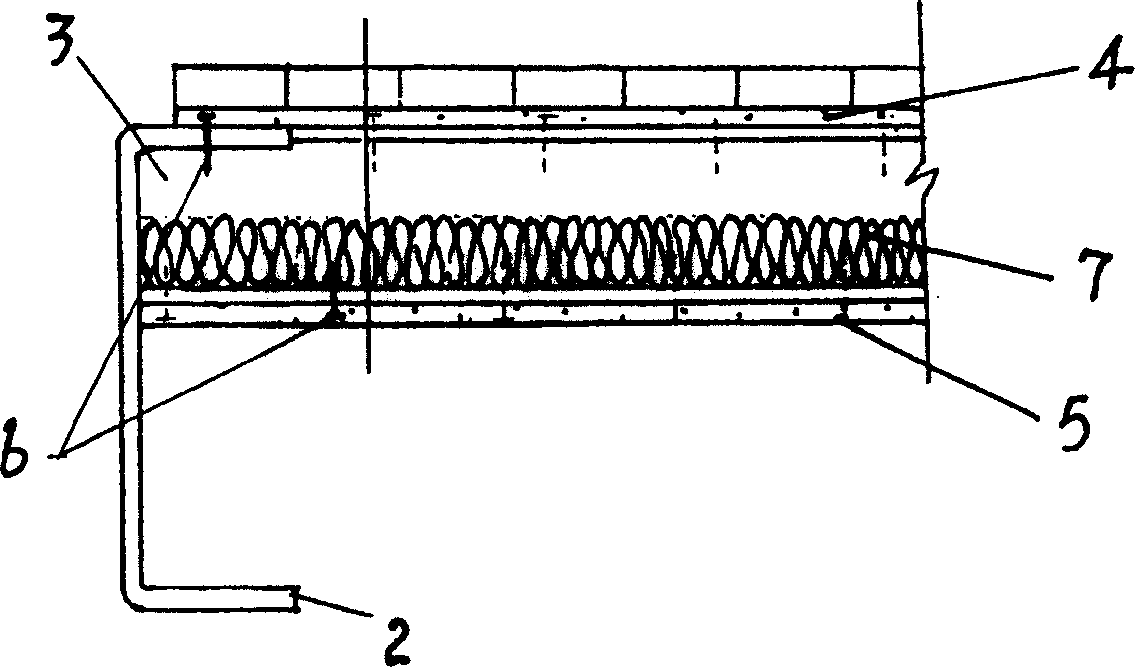

A method of manufacturing heat and sound insulation particleboard

ActiveCN106514829BTightly boundWith heat and sound insulationFlat articlesDomestic articlesMaterials preparationAdhesive

The invention discloses a manufacturing method of a heat and sound insulation particle board, aims to realize manufacturing of a high-strength sound and heat insulation particle board and solving of difficult formation of a closed vacuum environment by such wood composite materials as particle boards, aims to the problem that the particle boards cannot achieve better heat and sound insulation effect in the prior art, and proposes the manufacturing method of the heat and sound insulation particle board. The manufacturing method comprises the steps of: (S1) material preparation; (S2) raw material pretreatment; (S3) adhesive adding; and (S4) layered pavement: wood raw materials added with adhesive are divided into multiple parts; one part is taken out to uniformly pave in a mold; then, vacuum pipes prepared beforehand are paved in an oriented manner; another part of wood raw materials added with the adhesive is taken out to pave on the vacuum pipes paved in the oriented manner; and a plate blank is obtained by prepressing; (S5) hot-press forming; and (S6) later machining. The manufacturing method has the following beneficial effects: the closed vacuum environment is formed in the particle board, so that the particle board has part characteristics of a vacuum material, and the heat and sound insulating performance of the particle board is promoted.

Owner:BEIJING FORESTRY UNIVERSITY

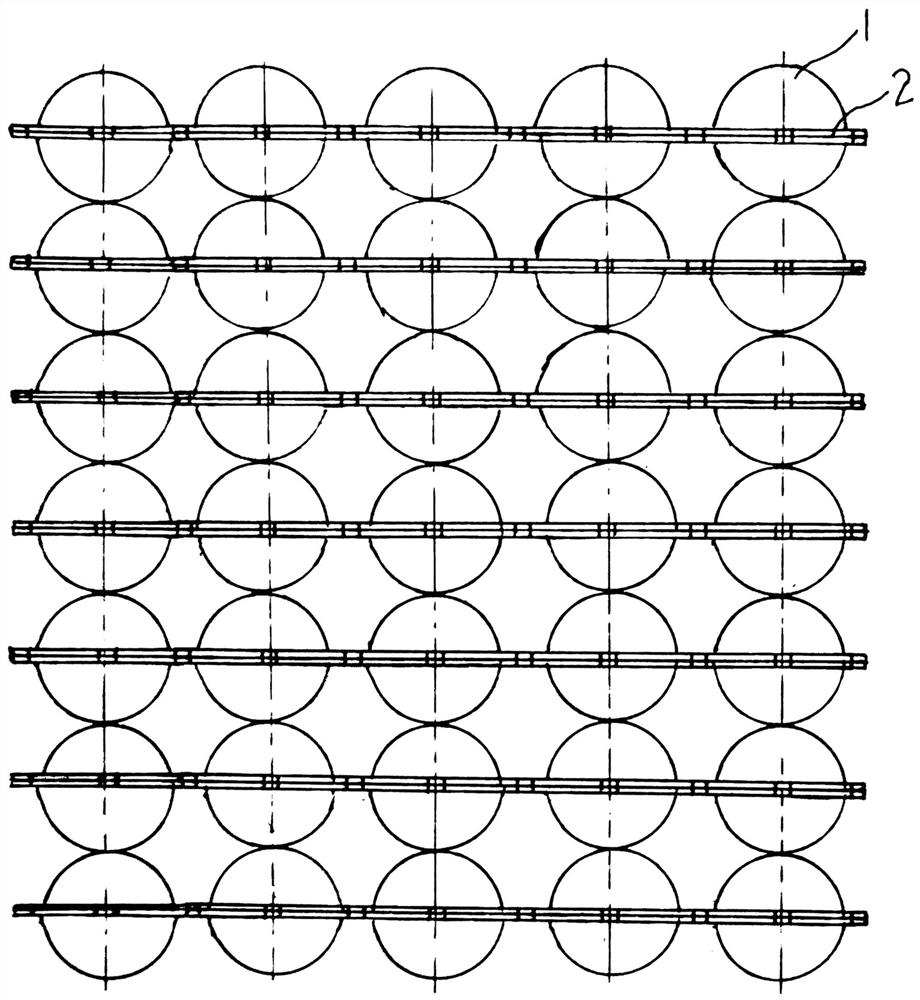

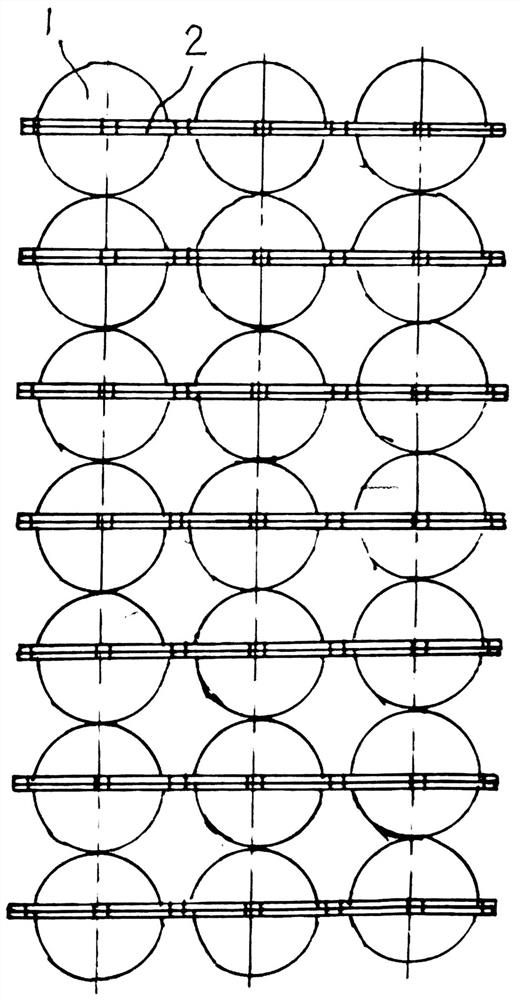

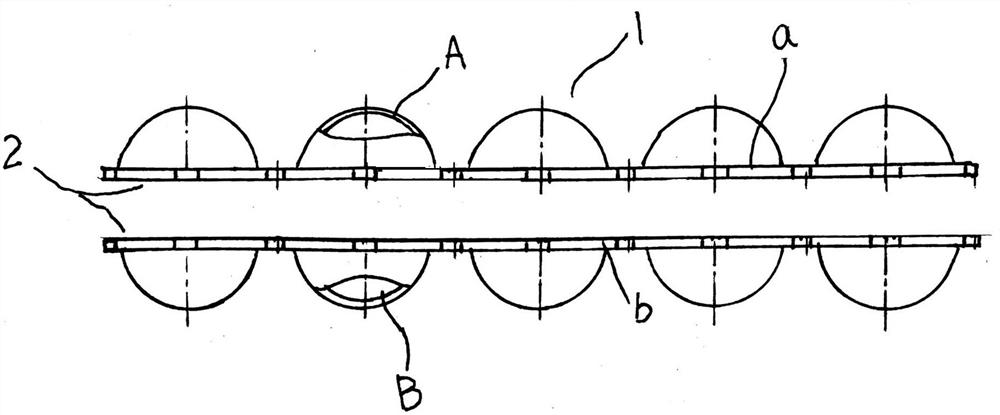

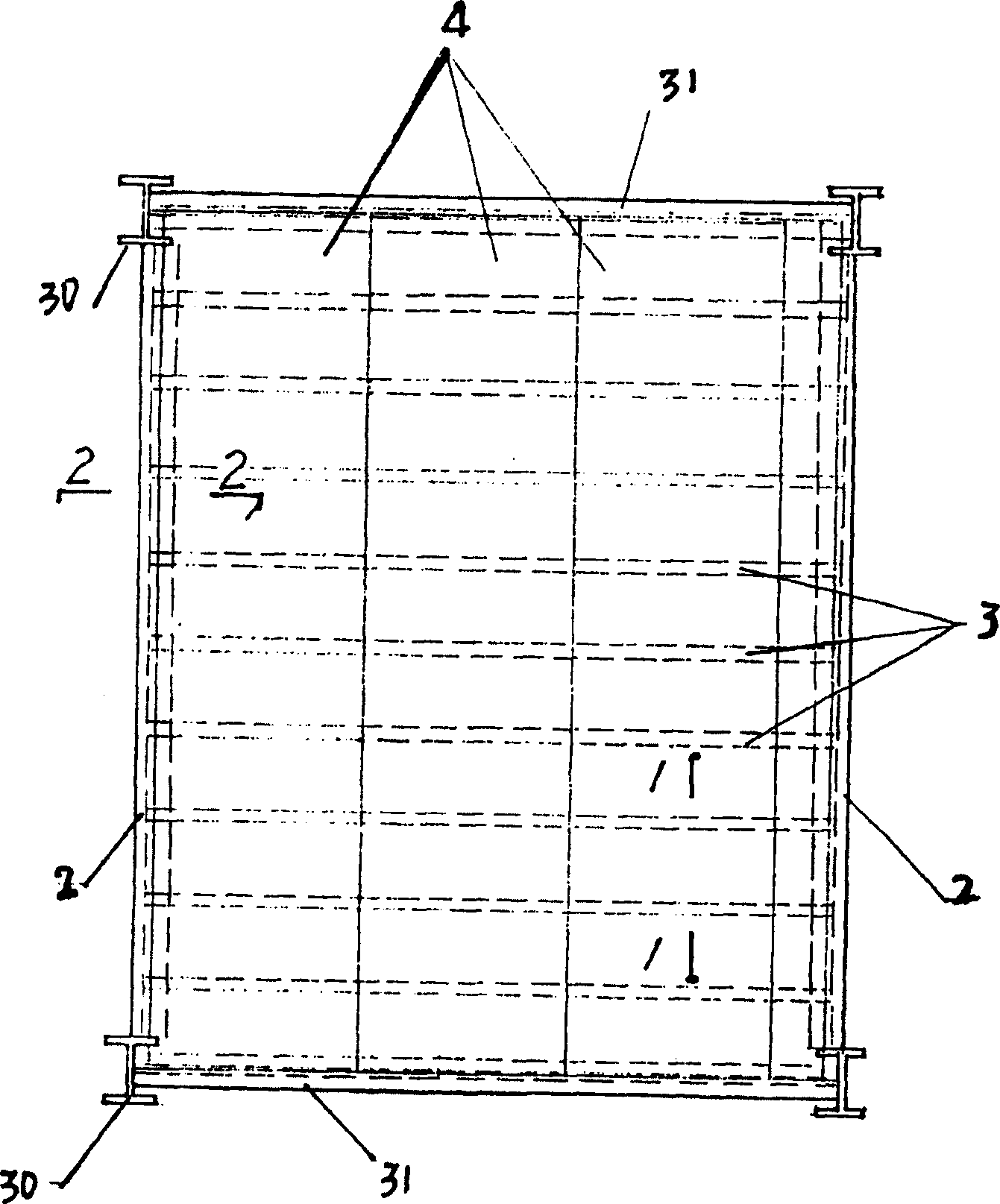

Lightweight framework and construction method for manufacturing partition board by using lightweight framework

PendingCN114673298AOverall light weightEliminate cracking and cracking problemsBuilding reinforcementsStructural engineeringManufacturing engineering

The invention discloses a light framework and a construction method for manufacturing a partition board by using the light framework, the light framework comprises an integral framework body which is composed of multiple layers and multiple columns of hollow balls and has the width, the thickness and the height, and filler channels used for being filled with filler are formed between the hollow balls on each layer and between the hollow balls on each column; the light partition board is formed by installing the framework, injecting the solidified filler into the filler channels in the framework, forming planes on the surfaces of the two sides of the framework, smearing plaster on the surfaces of the two sides of the framework, and striking off the plaster. Therefore, the light partition wall board manufactured by using the framework of the hollow sphere in the on-site construction mode has the advantages of being light in overall weight, heat-insulating and sound-insulating, and the key point is that the problems of cracking and crack generation at the joint position of the existing light partition wall board are eliminated.

Owner:张泽

Lightweight high-strength microcrystal ceramic insulation board and preparation method thereof

The invention discloses a lightweight high-strength microcrystal ceramic insulation board. The lightweight high-strength microcrystal ceramic insulation board comprises the following chemical components in percentage by weight: 30 to 75 percent of silicon dioxide (SiO2), 5 to 20 percent of aluminium oxide (Al2O3), 1 to 20 percent of calcium oxide (CaO), 1 to 15 percent of magnesium oxide (MgO), 1to 10 percent of ferric oxide and ferrous oxide (Fe2O3+FeO), 1 to 10 percent of sodium oxide, potassium oxide and lithium oxide (Na2O+K2O+Li2O) and 1 to 8 percent of nucleating agent. The lightweighthigh-strength microcrystal ceramic insulation board is prepared by the following steps of: mixing and crushing waste minerals, a foaming agent and a sintering modifier; mixing the crushed mixture with the nucleating agent; after ball-milling, filter-pressing, pelleting and staling the mixture, directly paving the powder in a fire-resistant mould fully, scraping the mould smoothly and allowing themould to enter a kiln; and after performing high-temperature sintering, quick cooling, nucleating treatment, quick heating and crystallization, cooling again and then annealing to prepare the product. The lightweight high-strength microcrystal ceramic insulation board has the advantages that: the average grain diameter is between 0.5 and 5 mu m; and crystal grains are dense and uniformly distributed and develop well.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com