Sealant composition

A composition and sealant technology, applied in the field of sealants, can solve the problems of ageing and yellowing of sealants, unsightly joints, easy sagging or tailing, etc., to reduce density, solve yellowing resistance, reduce The effect of production and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

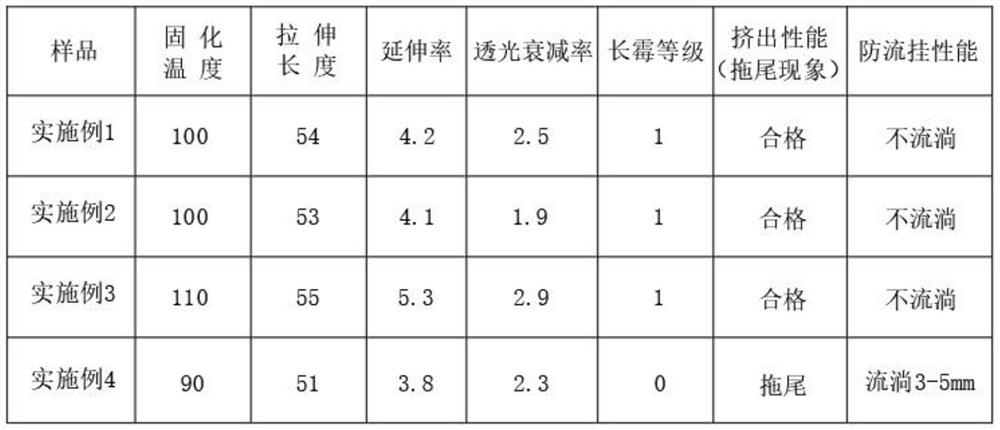

Embodiment 1

[0024] see figure 1 , the invention provides a sealant composition, which is formed by the following raw material ratio in parts by weight: 100 parts of base material, 20 parts of modified filler, 0.3 part of expanded microspheres, 6 parts of thixotropic agent, light stabilizer 0.5 parts, 0.5 parts of coupling agent, 3 parts of curing agent, 10 parts of plasticizer, 0.5 parts of catalyst and 2 parts of adhesion promoter.

[0025] Specifically, the base material is mainly prepared from the following raw materials in parts by weight: 100 parts of vinyl silicone oil, 30 parts of white carbon black, 5 parts of treatment agent, 3 parts of anti-aging agent and 5 parts of water.

[0026] Specifically, vinyl silicone oil is mainly prepared from the following raw materials in parts by weight: 800 parts of octamethylcyclotetrasiloxane, 12 parts of methyltrimethoxysilane, 16 parts of tetramethyldivinylsilicyloxane and Catalyst A 0.1 part.

[0027] Specifically, the modified filler is o...

Embodiment 2

[0035] see figure 1 , the invention provides a sealant composition, which is formed by the following raw material ratio in parts by weight: 100 parts of base material, 30 parts of modified filler, 0.5 part of expanded microspheres, 15 parts of thixotropic agent, light stabilizer 2 parts, 3 parts of coupling agent, 4 parts of curing agent, 15 parts of plasticizer, 2 parts of catalyst and 5 parts of adhesion promoter.

[0036] Specifically, the base material is mainly prepared from the following raw materials in parts by weight: 100 parts of vinyl silicone oil, 60 parts of white carbon black, 14 parts of treatment agent, 12 parts of anti-aging agent and 7 parts of water.

[0037] Specifically, vinyl silicone oil is mainly prepared from the following raw materials in parts by weight: 800 parts of octamethylcyclotetrasiloxane, 15 parts of methyltrimethoxysilane, 20 parts of tetramethyldivinylsilicyloxane and 0.3 parts of catalyst A.

[0038] Specifically, the modified filler is ...

Embodiment 3

[0046] see figure 1 , the invention provides a sealant composition, which is formed by the following raw material ratio in parts by weight: 100 parts of base material, 40 parts of modified filler, 0.9 part of expanded microspheres, 20 parts of thixotropic agent, light stabilizer 3 parts, 5 parts of coupling agent, 5 parts of curing agent, 20 parts of plasticizer, 3 parts of catalyst and 8 parts of adhesion promoter.

[0047] Specifically, the base material is mainly prepared from the following raw materials in parts by weight: 100 parts of vinyl silicone oil, 100 parts of white carbon black, 20 parts of treatment agent, 18 parts of anti-aging agent and 10 parts of water.

[0048] Specifically, vinyl silicone oil is mainly prepared from the following raw materials in parts by weight: 800 parts of octamethylcyclotetrasiloxane, 19 parts of methyltrimethoxysilane, 27 parts of tetramethyldivinylsilicyloxane and 0.4 parts of catalyst A.

[0049] Specifically, the modified filler i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com