Basalt fiber artificial board and preparation method thereof

A basalt fiber, wood-based panel technology, applied in the direction of manufacturing tools, building structures, building components, etc., can solve the problems of easy aging and environmental protection performance, low strength of wood-based panels, and many manual operations, achieving outstanding economic benefits and a wide range of applications. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

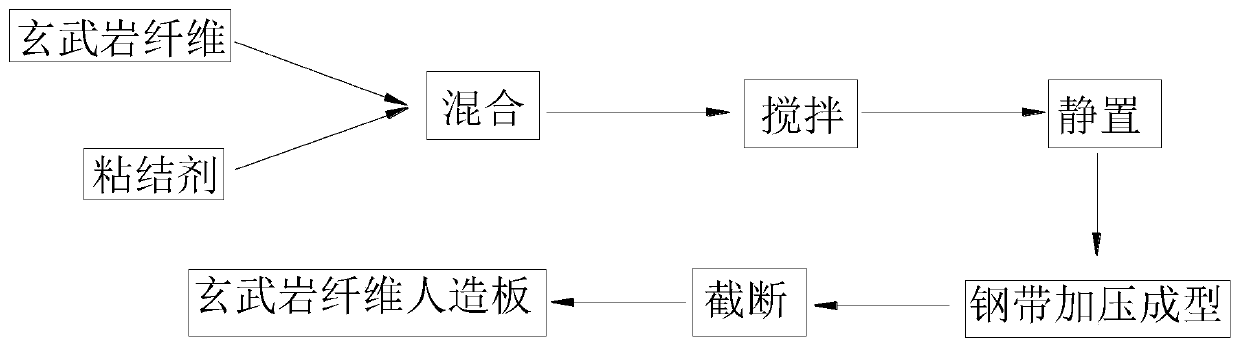

[0054] A preparation method of basalt fiber-based panel,

[0055] S1: Stir and mix the chopped basalt fiber and the binder according to a certain ratio to obtain a mixture;

[0056] S2: performing steel strip pressure molding on the mixture;

[0057] The strip pressurization includes

[0058] It includes a steel belt pressing mechanism, and the steel belt pressing mechanism includes:

[0059] A transmission assembly, the transmission assembly includes a transmission wheel and a steel belt 20, and the steel belt 20 is transmitted under the drive of the transmission wheel;

[0060] A straight section 60 is provided on the conveying assembly, and a pressurizing assembly is provided inside the straight section 60, and the mixture is pressurized and formed by the pressurizing assembly. , the pressure wheel 40 is provided with an oil outlet and an oil inlet, and the oil outlet and the oil inlet are connected to the hot oil pool through a conduit.

[0061] S3: Extruded and trunca...

Embodiment 2

[0064] A preparation method of basalt fiber-based panel,

[0065] S1: Stir and mix the chopped basalt fiber and the binder according to a certain ratio to obtain a mixture;

[0066] S2: The mixed material is subjected to steel strip pressure molding to obtain a basalt fiber-based panel.

[0067] The strip pressing device includes

[0068] Two said steel belt pressing mechanisms, the two said steel belt pressing mechanisms are arranged up and down and leave a gap for the mixture to pass through, and the distance between the gaps can be adjusted;

[0069] The transmission directions of the two steel belt pressurizing mechanisms are coordinated so that the mixture is extruded when the mixture passes through, such as figure 2 shown in;

[0070] S3: Extruded and truncated to obtain a basalt fiber-based panel.

[0071] The specific extrusion operation is: as figure 2 As shown in , the mixed material is conveyed in the conveying direction until it is delivered to the straight ...

Embodiment 3

[0087] A method for preparing a basalt fiber-based panel, the artificial panel comprising the following components: by mass percentage, the binder is 7%; basalt chopped fiber is 93%;

[0088] S1: Stir and mix the chopped basalt fiber and the binder according to the above ratio to obtain a mixture;

[0089] S2: performing steel strip pressure molding on the mixture;

[0090] S3: Extruded and truncated to obtain a basalt fiber-based panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com