High-strength microcrystalline fibers produced by tailings and waste residues and preparation method thereof

A technology of microcrystalline fiber and tailings waste, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as short service life, brittle glass fiber, and pollute the environment, and achieve reduced production raw material costs, reduced raw material costs, and shock resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

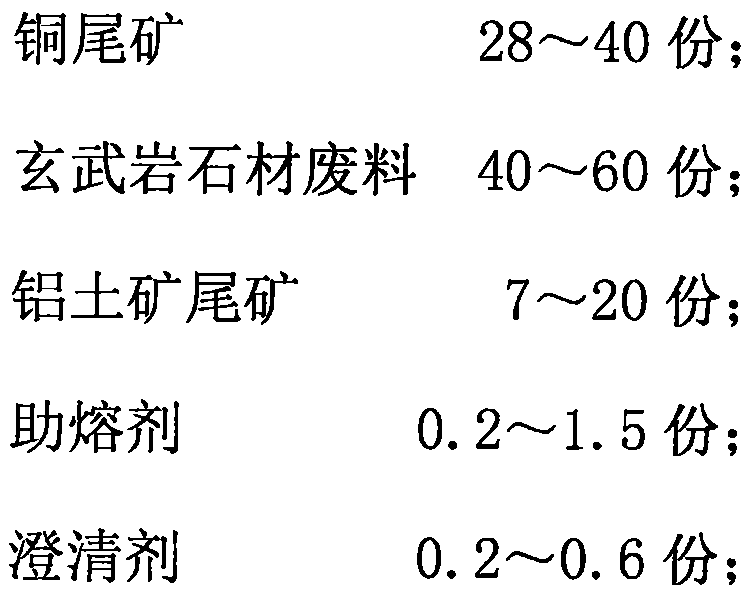

[0045] The high-strength microcrystalline fiber produced from tailings has the following raw material composition by weight:

[0046]

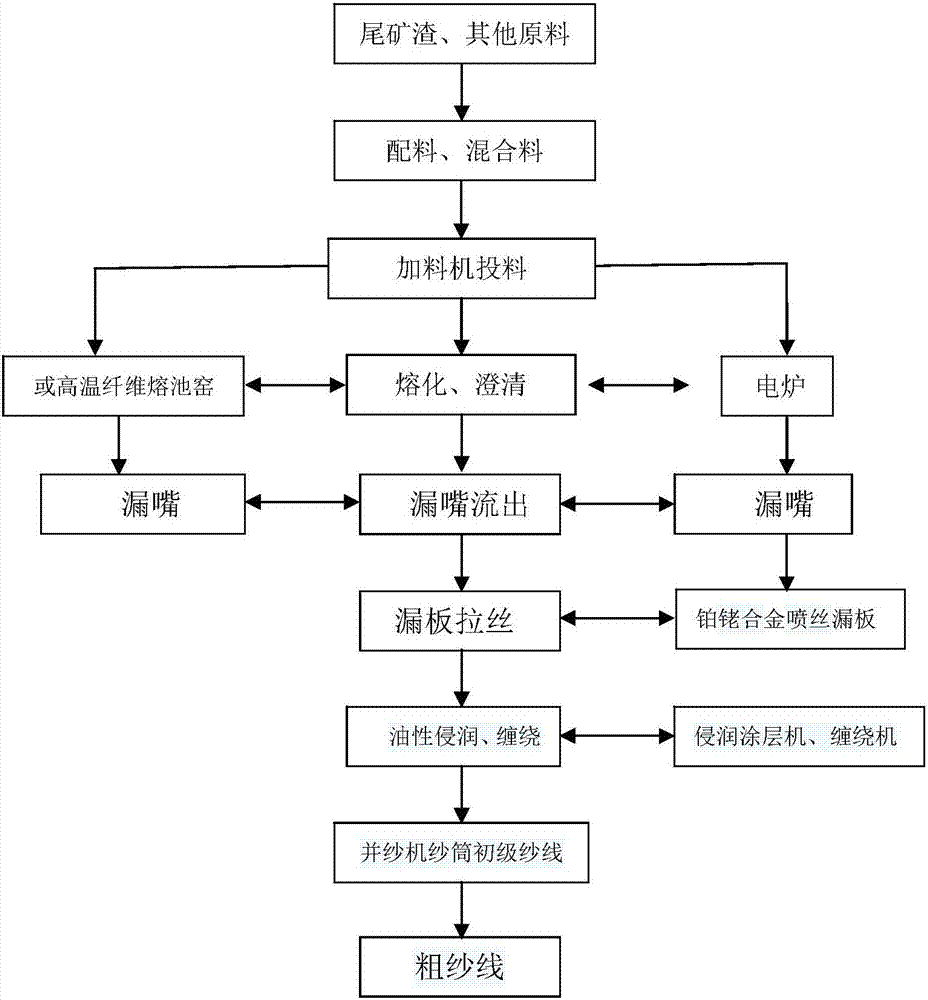

[0047] Flame blowing method is the main method of producing microcrystalline fiber, and its process is as follows: when preparing, send the prepared powder into the mixer for homogenization and mixing. The mixed microcrystalline fiber production raw materials are pushed into the electric furnace (or high-temperature fiber melting pool kiln) through a heat-resistant stainless steel screw feeder for high-temperature melting. The melting temperature is 1550°C. The drawing wire flows out from the bottom of the many small holes (800 holes or 1200 holes) of the wire leaking plate to form primary fibers; a single primary fiber with a diameter of 9-15 microns enters the oily infiltrating agent coating equipment, passes through the rotating rubber roller winding machine and the guide Under the guidance of the yarn device, the continuous fiber is wou...

Embodiment 2

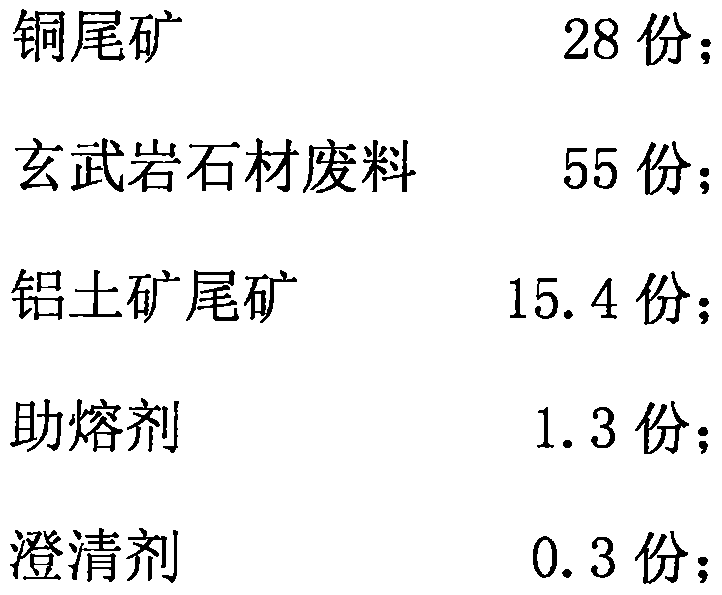

[0050] The high-strength microcrystalline fiber produced from tailings has the following raw material composition by weight:

[0051]

[0052] Flame blowing method is the main method of producing microcrystalline fiber, and its process is as follows: when preparing, send the prepared powder into the mixer for homogenization and mixing. The mixed microcrystalline fiber production raw materials are pushed into the electric furnace (or high-temperature fiber melting pool kiln) through a heat-resistant stainless steel screw feeder for high-temperature melting. The melting temperature is 1530°C. The drawing wire flows out from the bottom of the many small holes (800 holes or 1200 holes) of the wire drain plate to form primary fibers; a single primary fiber with a diameter of 9 to 15 microns enters the oily infiltrating agent coating equipment, passes through the rotating rubber roller winding machine and the guide Under the guidance of the yarn device, the continuous fiber is wo...

Embodiment 3

[0055] The high-strength microcrystalline fiber produced from tailings has the following raw material composition by weight:

[0056]

[0057] Flame blowing method is the main method of producing microcrystalline fiber, and its process is as follows: when preparing, send the prepared powder into the mixer for homogenization and mixing. The mixed microcrystalline fiber production raw materials are pushed into the electric furnace (or high-temperature fiber melting pool kiln) through a heat-resistant stainless steel screw feeder for high-temperature melting. The melting temperature is 1540°C. The drawing wire flows out from the bottom of the many small holes (800 holes or 1200 holes) of the wire drain plate to form primary fibers; a single primary fiber with a diameter of 9 to 15 microns enters the oily infiltrating agent coating equipment, passes through the rotating rubber roller winding machine and the guide Under the guidance of the yarn device, the continuous fiber is wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com