A kind of preparation method of intelligent thermal and sound insulation PVB film and the preparation method of PVB film laminated glass

A technology of intelligent heat insulation and laminated glass, applied in parallel glass structures, chemical instruments and methods, flat products, etc., can solve the problems of insignificant effect and no guarantee of safety, etc., to improve the sound insulation effect, significantly economic and social effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of an intelligent heat-insulating and sound-insulating PVB film, comprising the steps of:

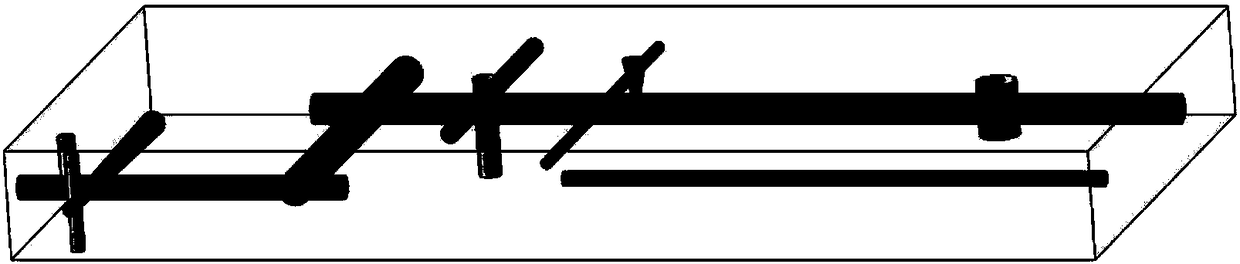

[0029] (1) Preparation of the second sound insulation layer: adding vanadium dioxide nanopowder into alcohol to dissolve to form VO 2 solution, the VO 2 The solution is blended with the resin powder, or the vanadium dioxide nano-powder is directly blended with the resin powder to obtain VO with a mass percentage of 0.1-5%. 2 The resin masterbatch of the powder is the masterbatch of the second sound insulation layer, and the second sound insulation masterbatch is obtained by co-extrusion at 200 °C containing VO 2 The PVB diaphragm is processed into a second sound insulation layer containing a three-dimensional channel structure functional layer;

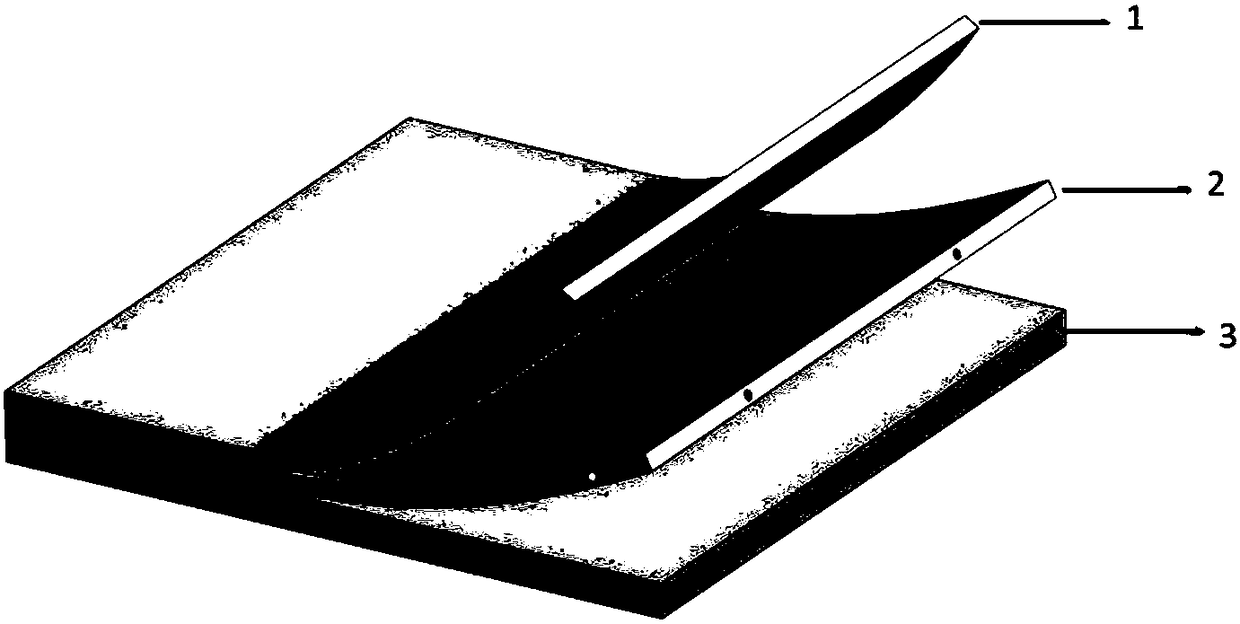

[0030] (2) Preparation of intelligent heat and sound insulation PVB film: blend the second sound insulation layer prepared in step (1) with PVB resin powder and co-extrude at 200°C or 130°C to obtain the intelligen...

Embodiment 1

[0033] Take VO with a particle size of 10nm 2 The powder is added to ethanol to form a solution, then added to the PVB resin powder and blended by stirring to obtain a solution containing VO 2 0.1% PVB resin masterbatch of powder, ethanol volatilizes during the stirring process, and VO 2 The PVB diaphragm is obtained by 3D printing with a connected circular hole with a diameter of 0.5mm 2 PVB diaphragm with a porosity of 0.5%, through 200-degree co-extrusion, the first layer thickness is 10um, the second layer thickness is 300um, the third layer is 80um, and the total thickness is 0.38mm. Heat and sound insulation PVB diaphragm, The target laminated glass is obtained by thermoforming with ordinary glass.

Embodiment 2

[0035] Take VO with a particle size of 20nm 2 Powder, added to PVB resin powder by stirring and blending to obtain 21% PVB resin masterbatch of powder, obtained by co-extrusion technology containing VO 2 The PVB diaphragm is obtained by 3D printing with connected circular holes with a diameter of 0.1mm containing VO 2 PVB diaphragm with a porosity of 3%, through 200-degree co-extrusion, the first layer thickness is 10um, the second layer thickness is 350um, and the third layer is 20um. The total thickness of the heat and sound insulation PVB film is 0.38mm, and Ordinary glass is hot-pressed to obtain the target laminated glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com