Bi-component polysulfide sealant composition, bi-component polysulfide sealant and preparation method

A polysulfide sealant, a two-component technology, applied in the field of sealants, can solve the problems of difficult dispersion, large density difference between microbeads and the system, inconvenient storage and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present application also provides a method for preparing a mercapto-terminated liquid polysulfide rubber sealant, comprising the following steps:

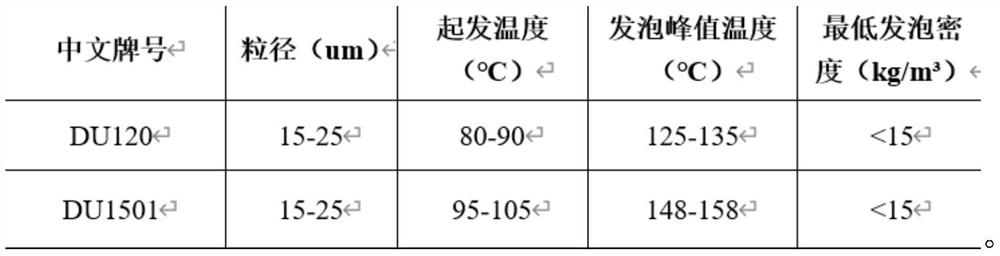

[0035](1) Weigh 100 parts of liquid polysulfide rubber, 10-70 parts of reinforcing filler, 0.5-5 parts of expandable microspheres, 5-15 parts of thixotropic agent, and 0.5-1.5 parts of catalyst into a planetary mixer and stir evenly. That is, component A is obtained;

[0036] (2) Store the component A and the epoxy resin constituting the component B in airtight storage respectively. When using, mix well and evenly according to the weight ratio to obtain a two-component polysulfide sealant.

[0037] In one embodiment, the weight ratio may be 100:(5-15), preferably, the weight ratio may be 100:(10-15).

[0038] The embodiment of the present application also provides a two-component polysulfide sealant, which is prepared by the above-mentioned two-component polysulfide sealant preparation method.

[0039...

Embodiment 1

[0041] 1. Stir 100 parts of calcium carbonate at 70°C for 10 minutes at high speed, add 0.1 part of stearic acid, and continue stirring for 40 minutes to obtain surface-modified calcium carbonate.

[0042] 2. Weigh 100 parts of liquid polysulfide rubber, 10 parts of modified calcium carbonate, 1 part of expandable microspheres, 15 parts of fumed silica, and 0.5 parts of tetramethylethylenediamine and stir them evenly in a planetary mixer to obtain A components.

[0043] 3. B component is bisphenol A epoxy resin.

[0044] 4. When using, mix components A and B uniformly at a ratio of 100:10.

Embodiment 2

[0051] 1. Stir 100 parts of silicon dioxide at 90°C for 15 minutes at high speed, add 3 parts of lauric acid, and continue stirring for 30 minutes to obtain surface-modified silicon dioxide.

[0052] 2. Weigh 100 parts of liquid polysulfide rubber, 70 parts of modified silicon dioxide, 0.5 parts of expandable microspheres, 5 parts of hydrogenated castor oil, and 1.5 parts of dimethyl benzylamine and put them into a planetary mixer and stir evenly to obtain Group A point.

[0053] 3. B component is bisphenol A epoxy resin.

[0054] 4. When using, component A and component B are mixed uniformly at a ratio of 100:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com