Polyurethane resin, and preparation method and application thereof

A technology of polyurethane resin and polyester diol, applied in the field of polyurethane resin and its preparation, can solve the problems such as loss of drape of superfine fiber synthetic leather, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

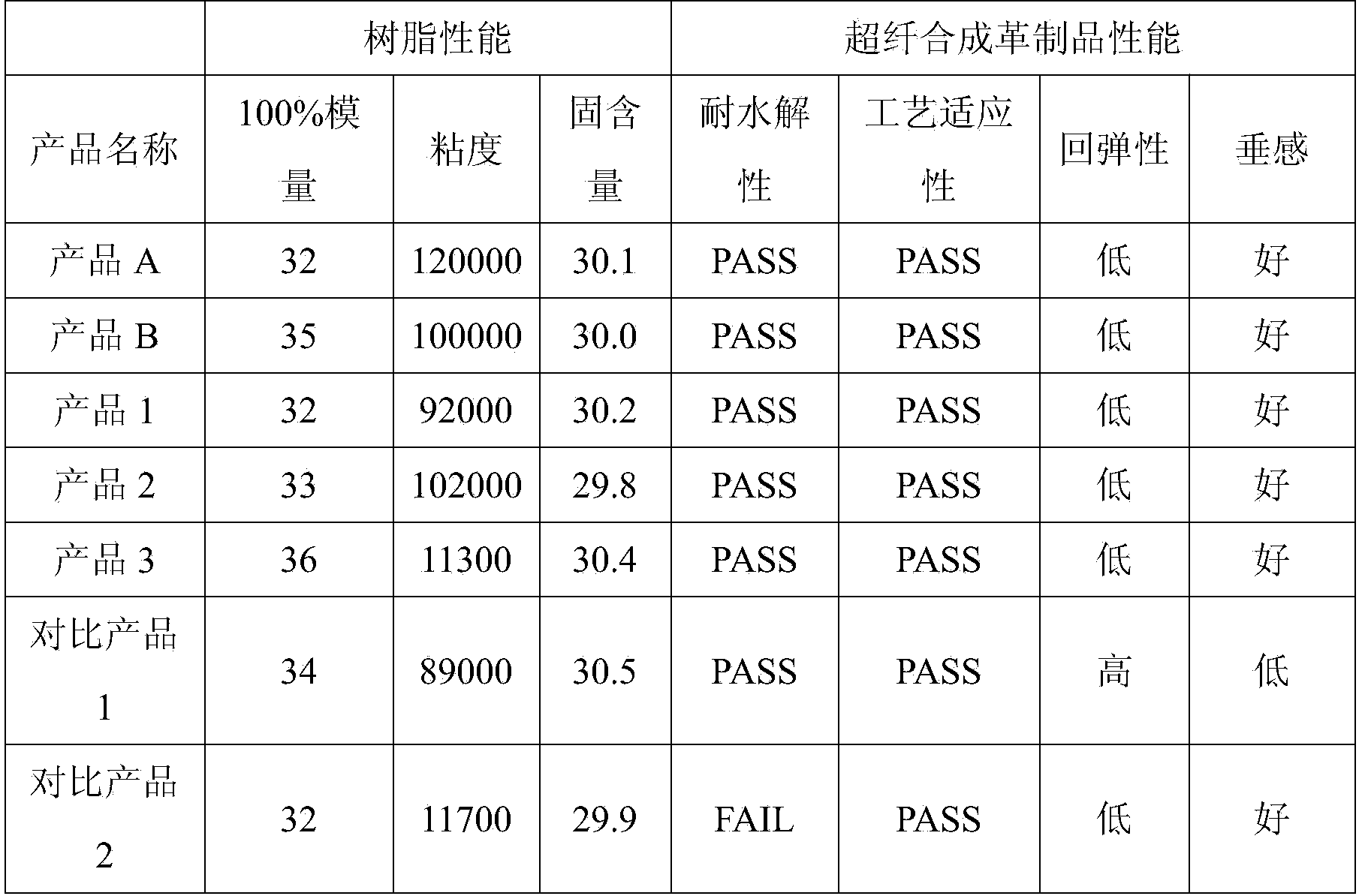

Examples

Embodiment 1

[0035] The synthesis of embodiment 1 polyester diol BEPD2000

[0036]Put 100g of adipic acid and 61.5g of 2-butyl-2-ethyl-1,3-propanediol (BEPD) into the reaction kettle, turn on nitrogen, raise the temperature to 90-100°C, start stirring, and heat up to 150-160°C Start to produce water, keep the temperature for 2 hours, then continue to heat up to 220-230°C, after the water output reaches 24g, start vacuuming, until the hydroxyl value (55-57mgKOH / g) and acid value (<0.5) pass, stop vacuuming, and Lower the temperature, and discharge the material after the temperature drops below 120°C.

[0037] The obtained dihydric alcohol is named: BEPD2000.

[0038] The actual detection result of BEPD2000 among the embodiment 1 is:

[0039] Hydroxyl value: 56.3mgKOH / g;

[0040] Acid value: 0.3mgKOH / g.

Embodiment 2

[0042] A polyurethane resin, made of the following components, wherein the mass percentages of each component are: polyol composition 20%, small molecule chain extender 1.1%, isocyanate 8.7%, solvent 70%, end-blocking agent 0.04% and Additive 0.16%. The polyol composition comprises polytetrahydrofuran diol and polyester diol, and the polyester diol is adipic acid and 2-butyl-2-ethyl-1,3-propanediol (BEPD) passed through high temperature The polyester diol BEPD2000 formed by dehydration polycondensation, wherein the contents of tetrahydrofuran diol (PTMG) and BEPD2000 are both 50% of the total weight of the polyol composition, and the molecular weight of the polyester diol is 1500. The dibasic acid is adipic acid, and the dibasic alcohol is 2-butyl-2-ethyl-1,3-propanediol. The small molecule chain extender is ethylene glycol, the isocyanate is 4,4-diphenylmethane diisocyanate, the solvent is N,N-dimethylformamide (DMF), and the blocking agent is Methanol and the additives are...

Embodiment 3

[0045] A polyurethane resin, made of the following components, wherein the mass percentages of each component are: polyol composition 24%, small molecule chain extender 1.5%, isocyanate 7.38%, solvent 67%, end-blocking agent 0.05% and Additive 0.07%. The polyol composition comprises polytetrahydrofuran diol and polyester diol, and the polyester diol is adipic acid and 2-butyl-2-ethyl-1,3-propanediol (BEPD) passed through high temperature The polyester diol BEPD2000 formed by dehydration polycondensation, wherein the contents of tetrahydrofuran diol (PTMG) and BEPD2000 are both 50% of the total weight of the polyol composition, and the molecular weight of the polyester diol is 3000. The dibasic acid is adipic acid, and the dibasic alcohol is 2-butyl-2-ethyl-1,3-propanediol. The small molecule chain extender is ethylene glycol, the isocyanate is 4,4-diphenylmethane diisocyanate, the solvent is N,N-dimethylformamide (DMF), and the blocking agent is Methanol and the additives ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com