Forward and reverse roller matte UV coating material and preparation method thereof

A matte and coating technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of uneven surface, rough graininess, etc., and achieve the effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

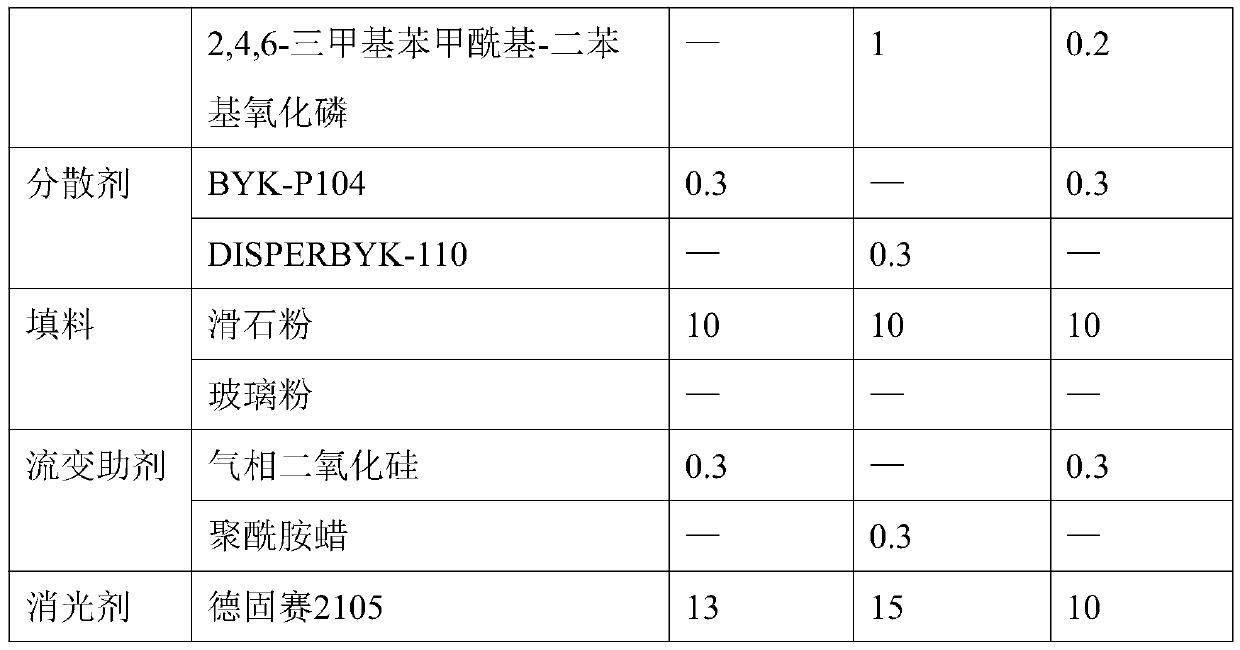

[0022] The formula is as shown in Table 1:

[0023]

[0024]

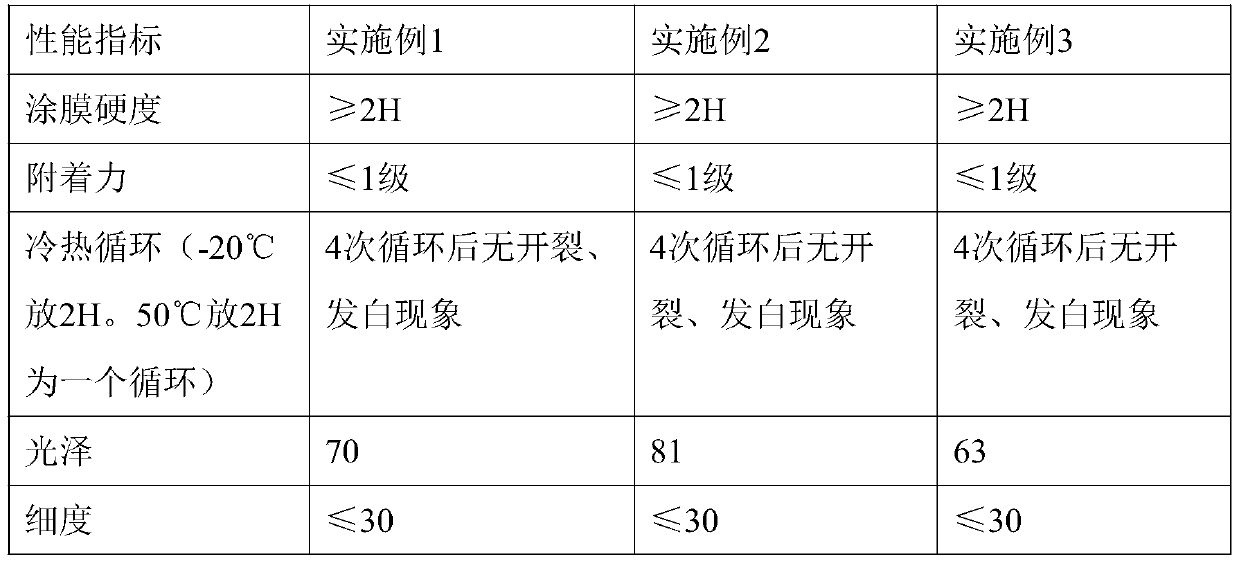

[0025] Table 2 performance index of the present invention

[0026]

[0027] According to the formula in Table 1, the matte UV coating material for front and back rollers is prepared by the following method: uniformly disperse UV resin, reactive diluent, and photoinitiator at a low speed in sequence, and disperse the dispersant, leveling agent, and defoamer at a low speed in sequence. After dispersing for 5 minutes (500 rpm), add fillers, rheological additives, and matting agents and disperse at high speed for 30 minutes (1000 rpm) until the fineness is ≤30 microns. After filtering, the front and reverse roller matte UV coating materials can be prepared .

Embodiment 4-6

[0029] The formula is shown in Table 3

[0030]

[0031]

[0032] Table 4 performance index of the present invention

[0033]

[0034] According to the formula in Table 3, the reverse roll matte UV coating material is prepared by the following method: uniformly disperse the UV resin, reactive diluent, and photoinitiator at a low speed in sequence, and disperse the dispersant, leveling agent, and defoamer at a low speed in sequence After 5 minutes (500 rpm), add fillers, rheological additives, and matting agents and disperse at high speed for 30 minutes (1000 rpm) until the fineness is ≤20 microns. After filtering, the forward and reverse roller matte UV coating materials can be prepared.

[0035] A kind of front and back roller matt UV coating material and its preparation method obtained through the above examples are suitable for the field of wood furniture, with high production efficiency and no organic volatile emissions. The coating surface is "full, delicate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com