Urethane foam composite board and preparation method thereof

A technology of polyurethane foam and composite boards, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of damping, noise reduction, sound absorption, sound insulation and heat insulation that are difficult to meet at the same time, and achieve Good heat insulation effect, simple preparation method, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

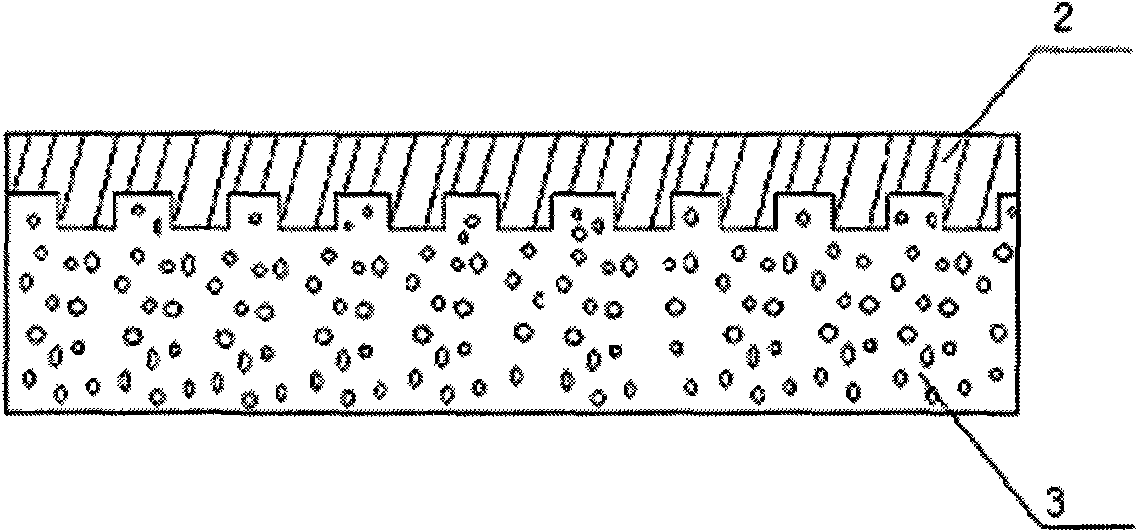

[0023] A polyurethane foam composite board, consisting of a panel and a core board, the two panels include a porous damping panel 1 and a smooth plane damping panel 4, the core board includes an open-cell polyurethane molding board 2 and a closed-cell polyurethane foam board 3; wherein, the smooth plane damping board Panel 4 is a solid flat panel with a self-adhesive layer on one side to form one side panel; porous damping panel 1 is a perforated panel formed by a plurality of through holes arranged in a square on the plane of another light flat damping panel as another On the side panel, the through hole diameter of the multiple through holes is 0.8mm, and the center distance of the through holes is 10mm; one side of the perforated polyurethane molding board is bonded with the self-adhesive layer of the porous damping panel to form a single-sided core board, and the single-sided core board is opened. The other side of the porous polyurethane molding board 2 and the non-adhesiv...

Embodiment 2

[0033] A polyurethane foam composite board, the preparation process steps are as follows:

[0034]a. Choose 2mm thick EPDM rubber material forming damping plate with one-side self-adhesive as the smooth flat damping panel on one side 4. Choose the damping plate of the same material as a spare as the porous damping panel on the other side 1 ;

[0035] b. Select the formed damping plate of the EPDM material in step a as the other side panel, and punch the damping plate to form a porous damping plate 1. Open holes in a square with a hole spacing of 10mm and an inner diameter of 0.8mm;

[0036] c. Other processing steps are the same as in Example 1 to prepare a polyurethane foam composite board.

[0037] After testing, the sound absorption frequency characteristics and sound insulation characteristics of polyurethane foam composite panels are: the average sound absorption coefficient of standing wave tube method and the average sound insulation value of sound intensity method in...

Embodiment 3

[0039] A polyurethane foam composite board, the preparation process steps are as follows:

[0040] a. Select a molded damping plate of polyurethane material with a thickness of 2 mm and one-sided self-adhesive as the flat damping panel 4 on one side, and select a damping plate of the same material as the porous damping panel 1 on the other side;

[0041] Composite single-sided core board is selected to form open-cell polyurethane board, and its open-cell polyurethane foam BFPU-7G: thickness is 10mm, density is 0.051g / cm 3 , the porosity is 94%, and the thermal conductivity is 0.042w / (m·k);

[0042] The closed-cell polyurethane after foaming and curing is WGY-1: the thickness is 30mm, and the density is 0.039g / cm 3 , the closed cell rate is 92%, and the thermal conductivity is 0.032w / (m k);

[0043] b. Other processing steps are the same as in Example 1 to prepare a polyurethane foam composite board.

[0044] After testing, the sound absorption frequency characteristics and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com