Welding bogie

A bogie and frame technology, which is applied in the directions of bogies, railway car body parts, railway braking systems, etc., can solve the problems that the stability of the bogie cannot meet the requirements, the transmission efficiency of the braking system is reduced, and the transmission of braking force is uneven. , to achieve the effect of improving brake mitigation performance, improving dynamic performance, and meeting strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

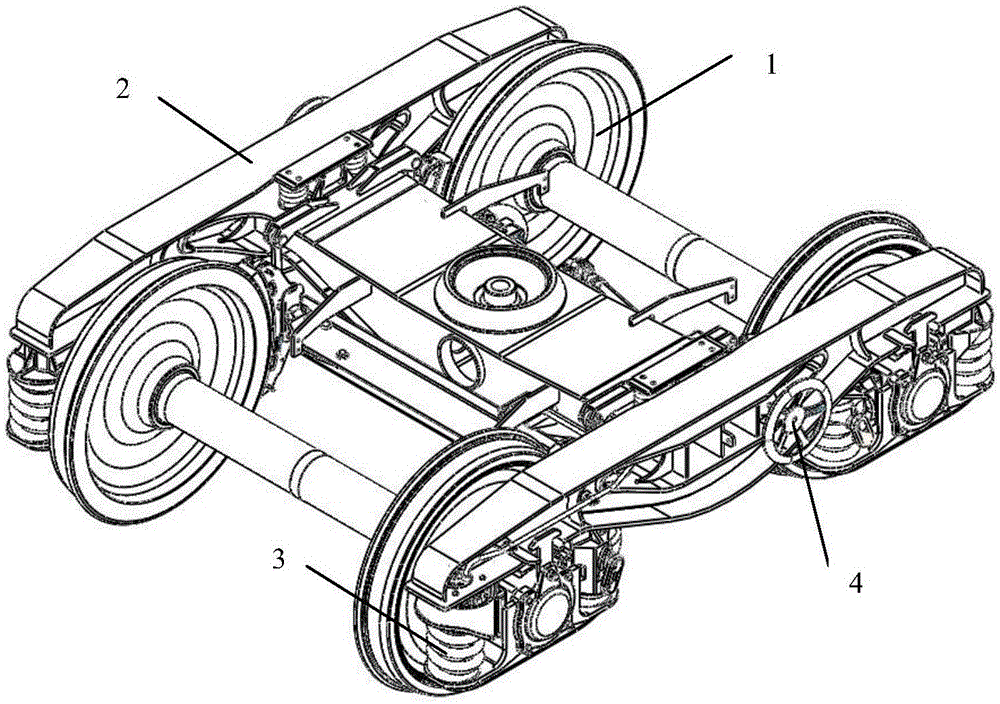

[0026] like figure 1 As shown, the new welded bogie includes a wheel set composition 1, a frame composition 2, an axle box suspension system 3, and a braking device 4.

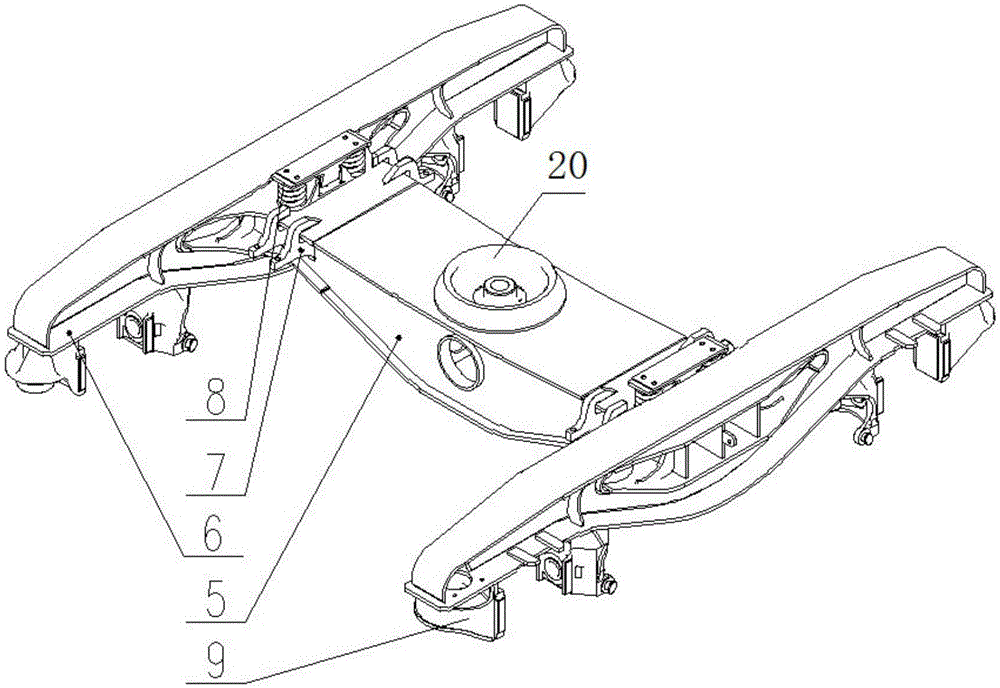

[0027] like figure 2 As shown, the frame composition 2 is formed by inserting the crossbeam 5 and two side beams 6, which meets the strength requirements and has a simple structure. The components 8 and the spherical center disk 20 on the beam 5 are connected with the vehicle body; the pedestal body 9 is connected with the axial suspension system 3 .

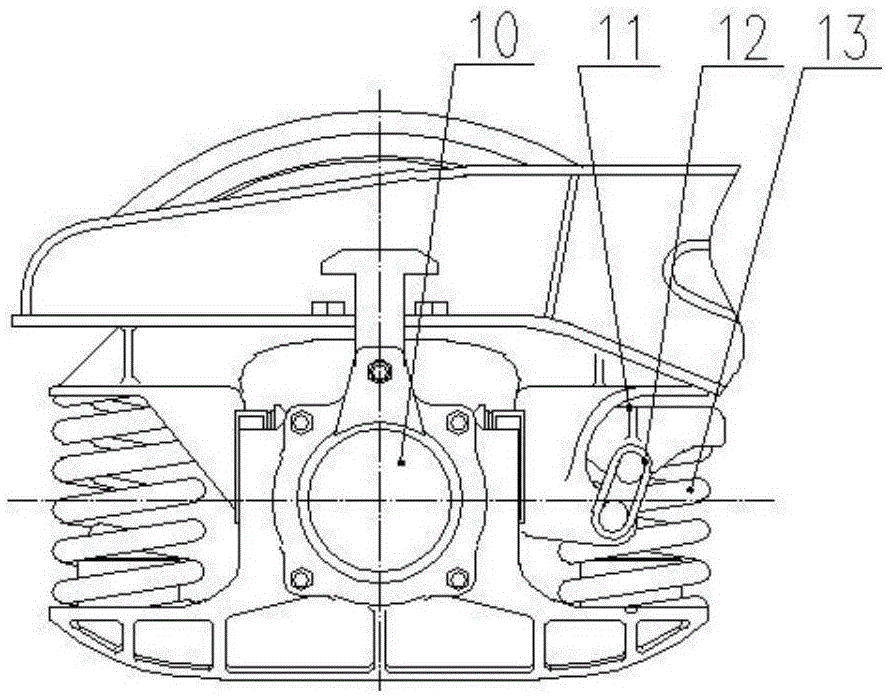

[0028] like image 3 As shown, the axle box suspension system 3 is a Linoer shock absorber structure, which is composed of an axle box component 10, a spring cap component 11, a suspension ring 12, a two-stage stiffness spring 13 and a top, which not only ensures the stability of linear operation, It also adapts to the passability of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com