Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Uniform and fine structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

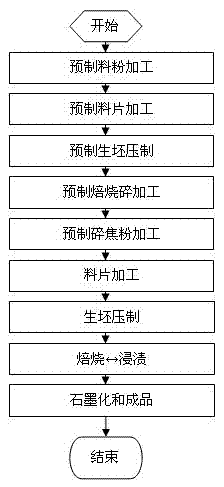

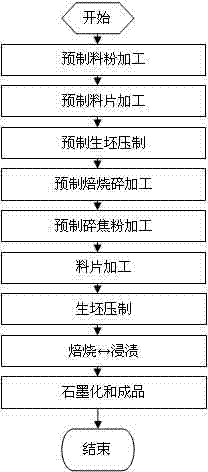

Production process of large isotropic and isostatic high purity graphite with fine particles

The invention discloses a production process of large isotropic and isostatic high purity graphite with fine particles, which comprises the following steps: processing prefabricated powder; processing prefabricated tablets; pressing prefabricated green bodies; processing prefabricated roasting scraps; processing prefabricated smashed coke powder; processing tablets; pressing green bodies; roasting and soaking; and graphitizing and finishing. A graphite product produced by the production process provided by the invention has a large size and has the diameter being more than phi 900; the strength, the density and the elasticity of the product are improved, and the mechanical behavior physical and chemical indicators of a final product is improved; and simultaneously, the produced graphite product has the characteristics of favorable isotropic performance, uniform and delicate structure, high volume density and the like.

Owner:雅安恒圣高纯石墨科技有限责任公司

355MPa thick steel plate with low-temperature toughness and preparation method thereof

The invention belongs to the technical field of steel material production, and particularly relates to a 355MPa thick steel plate with low-temperature toughness and a preparation method thereof. The 355MPa thick steel plate with the low-temperature toughness is composed of the following components according weight percent: 0.04 to 0.14% of C, 0.2 to 0.5% of Si, 1.0 to 1.6% of Mn, less than 0.018% of P, less than 0.005% of S, 0.015 to 0.045% of Nb, 0.02 to 0.05% of V, 0.008 to 0.020% of Ti, and the balance of Fe and inevitable impurities. The thick steel plate has good low-temperature (-60 DEG C) impact toughness, and additionally, high strength, high toughness and good welding performance of the thick steel plate are achieved in the condition of the low-carbon content by adopting the preparation method.

Owner:SHANDONG IRON & STEEL CO LTD

Formed konjak mask and preparation method thereof

ActiveCN103432008AImprove mechanical propertiesUniform and fine structureCosmetic preparationsToilet preparationsCelluloseGlycerol

The invention discloses a formed konjak mask and a preparation method thereof. The mask is prepared by utilizing konjak powder as a raw material, purifying, preparing glue, and then mixing the glue with carboxymethyl cellulose and xanthan gum, adding glycerin and sodium carbonate to prepare an emulsion, curing and forming, dealkalizing and sterilizing, and finally immersing into a skin moisturizer. The formed konjak mask prepared by the preparation method disclosed by the invention is strong in toughness, good in ductility, good in adhesion and hydrophilia and capable of being closely combined with skin to provide sufficient moisture for the skin and prevent the moisture in the stratum corneum of skin from evaporating so as to enable the additional nutritional skin moisturizer to be easily absorbed, maintain the face moistness and avoid the accelerated aging the face skin; in addition, the konjak powder is a pure plant source substance, thereby being free of stimulation, safe and free of toxic or side effect to the skin. The formed konjak mask is little in pollution in the production process and liable to degrade, thereby being environmentally-friendly.

Owner:HUBEI YIZHI KONJAC BIOTECH

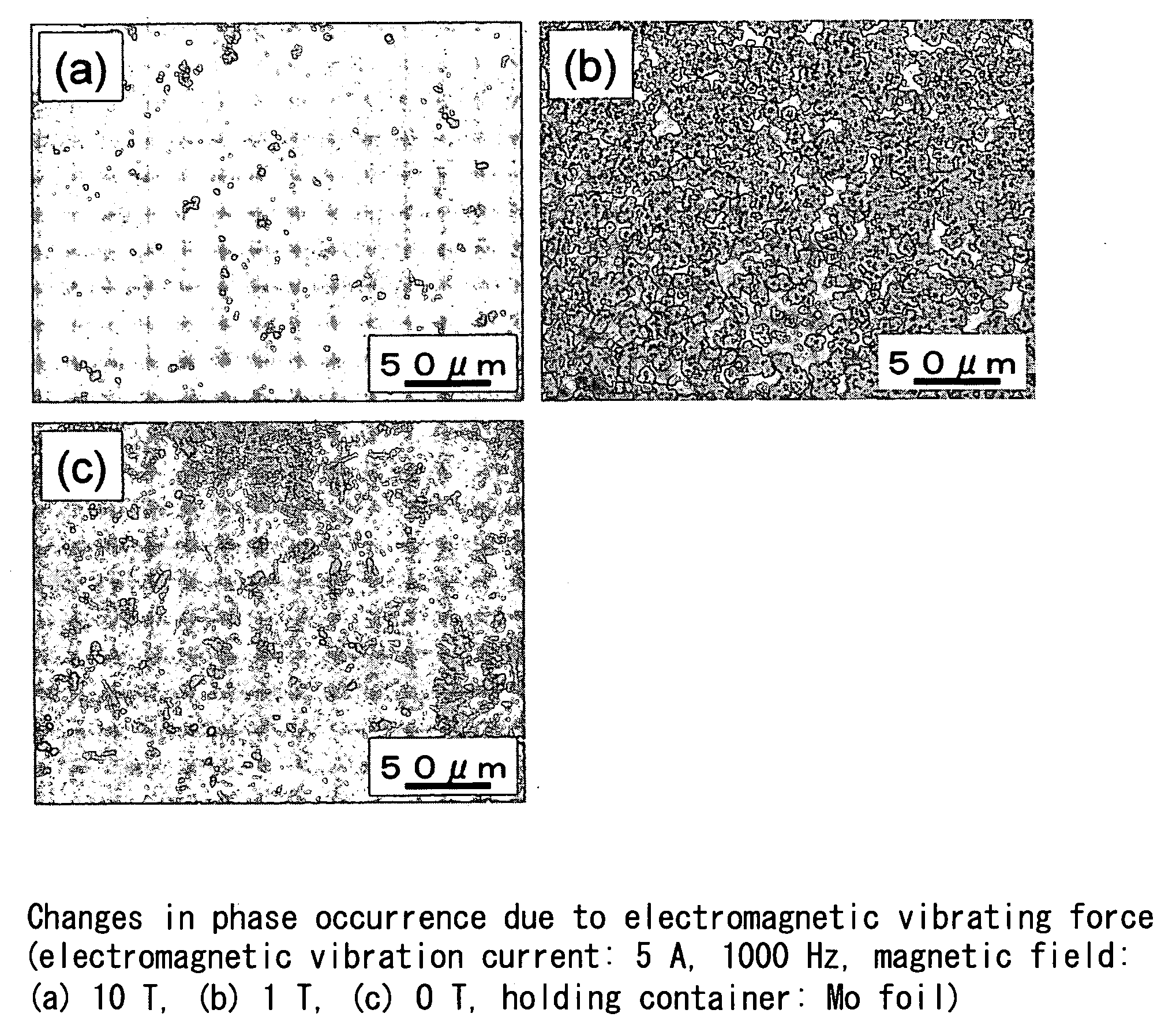

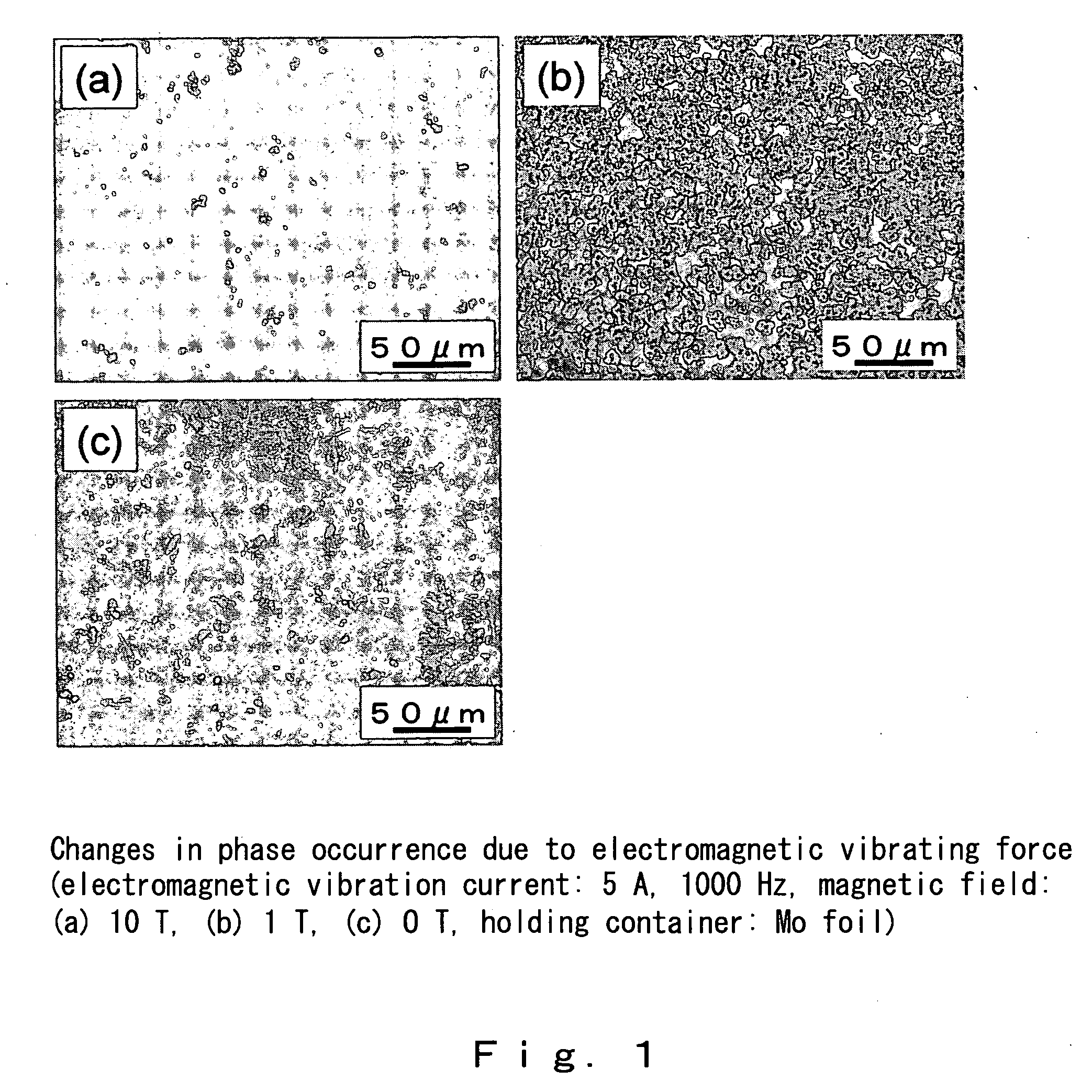

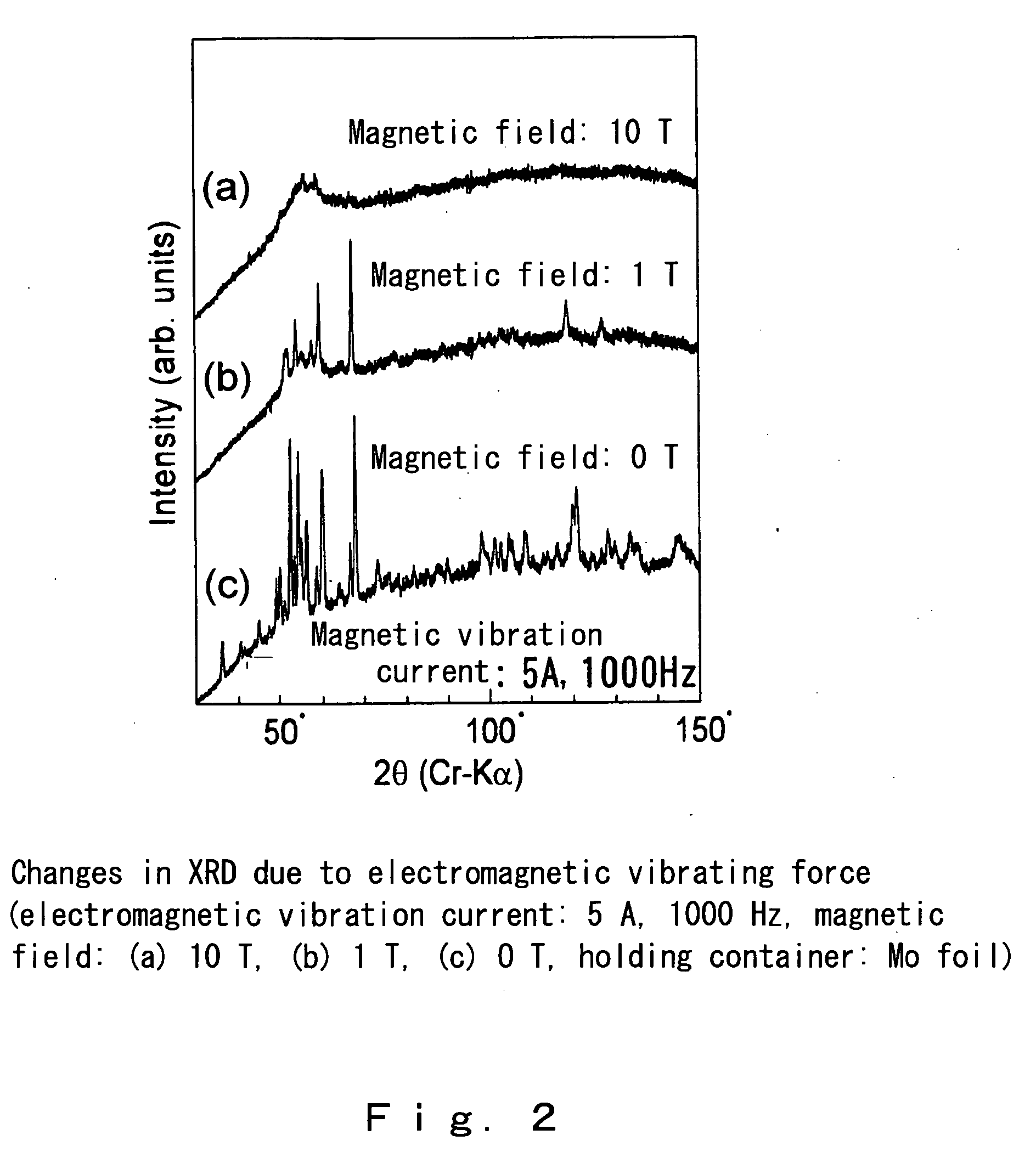

Metal glass body, process for producing the same and apparatus therefor

InactiveUS20070107467A1Improve abilitiesIncrease rangeGlass blowing apparatusVitreous BodiesAlternating current

The present invention relates to a metal glass body and to a manufacturing method and apparatus therefor, and the present invention relates to a metal glass body having a specific metal glass texture structure of fine crystals uniformly dispersed throughout a glass phase, to a metal glass body manufacturing method wherein the metal glass body is manufactured by solidifying a molten metal while applying electromagnetic vibrating force thereto to form a metal glass, during which a direct current magnetic field and an alternating current electrical field are applied simultaneously to generate electromagnetic vibration which is exerted on the molten metal, and to an apparatus for manufacturing a metal glass body. According to the present invention, it is possible to provide a method for manufacturing a novel metal glass body which allows mass production of metal glass members which hold promise as lightweight, highly-strong and highly-functional structural members, along with a metal glass body with a novel metal glass texture structure obtained by this method.

Owner:NAT INST OF ADVANCED IND SCI & TECH

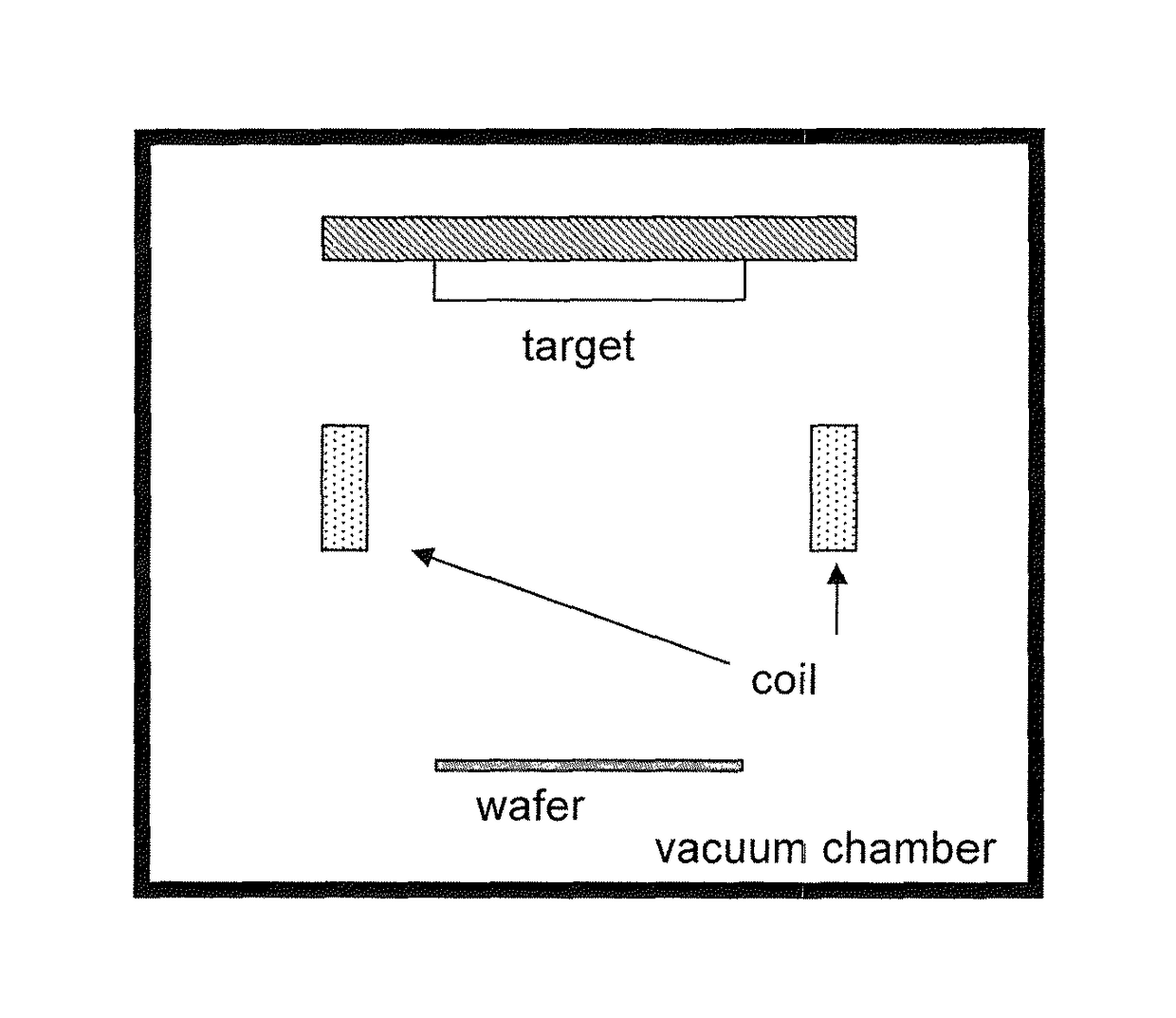

Tantalum Sputtering Target

ActiveUS20120031756A1Stable plasmaShorten aging timeCellsVacuum evaporation coatingSputteringFine structure

Provided is a tantalum sputtering target containing 1 mass ppm or more and 100 mass ppm or less of tungsten as an essential component, and having a purity of 99.998% or more excluding tungsten and gas components. Additionally provided is a tantalum sputtering target according to according to the above further containing 0 to 100 mass ppm of molybdenum and / or niobium, excluding 0 mass ppm thereof, wherein the total content of tungsten, molybdenum, and niobium is 1 mass ppm or more and 150 mass ppm or less, and wherein the purity is 99.998% or more excluding tungsten, molybdenum, niobium and gas components. Thereby obtained is a high purity tantalum sputtering target comprising a uniform and fine structure and which enables stable plasma and yields superior film evenness (uniformity).

Owner:JX NIPPON MINING& METALS CORP

Tantalum Sputtering Target

InactiveUS20130098759A1Uniform and fine structureShorten aging timeCellsVacuum evaporation coatingFine structureSputtering

Provided is a tantalum sputtering target, in which 30 mass ppm or more and 100 mass ppm or less of oxygen is contained as an essential component, and of which purity excluding oxygen and gas components is 99.998% or higher. Additionally provided is a tantalum sputtering target, wherein an average crystal grain size is 120 μm or less and variation in the crystal grain size is ±20% m or less. Thereby obtained is a high-purity tantalum sputtering target having a uniform and fine structure and enabling plasma stabilization and achievement of superior film evenness (uniformity).

Owner:JX NIPPON MINING& METALS CORP

Tantalum Sputtering Target

InactiveUS20120037501A1Uniform and fine structureStable plasmaCellsVacuum evaporation coatingFine structureSputtering

Provided is a tantalum sputtering target containing 1 mass ppm or more and 100 mass ppm or less of molybdenum as an essential component, and having a purity of 99.998% or more excluding molybdenum and gas components. Additionally provided is a tantalum sputtering target according to the above further containing 0 to 100 mass ppm of niobium, excluding 0 mass ppm thereof, and having a purity of 99.998% or more excluding molybdenum, niobium and gas components. Thereby obtained is a high purity tantalum sputtering target that has a uniform and fine structure and which yields stable plasma and superior film evenness, in other words, uniformity.

Owner:JX NIPPON MINING & METALS CO LTD

Tantalum Sputtering Target

ActiveUS20110266145A1Stable plasmaShorten aging timeCellsVacuum evaporation coatingSputteringFine structure

Provided is a tantalum sputtering target containing 1 mass ppm or more and 100 mass ppm or less of niobium as an essential component, and having a purity of 99.999% or more excluding niobium and gas components. Thereby obtained is a high purity tantalum sputtering target comprising a uniform and fine structure and which yields stable plasma and superior film evenness (uniformity).

Owner:JX NIPPON MINING& METALS CORP

Formula and making technology of carrot submicron powder thin pancakes

InactiveCN107897293AUniform and fine structureCrispy tasteDough treatmentModified nutritive productsFine structureCorn flour

The present invention relates to the field of food processing, and provides a carrot superfine powder pancake formula, which is composed of the following raw materials in parts by weight: 480-520 parts of flour, 880-1000 parts of coarse wheat flour, 900-1020 parts of corn flour, and 35 parts of carrot superfine powder. ‑43 parts, purified water 2000‑2300 parts. The superfine powder pancake of the invention has uniform and delicate structure, crisp and refreshing taste, yellowish green color, sweet taste, strong aftertaste and slight carrot aroma. It has high nutritional value, is good for digestion, and promotes absorption. It is suitable for people of all ages, especially for people with poor digestion.

Owner:郑效春

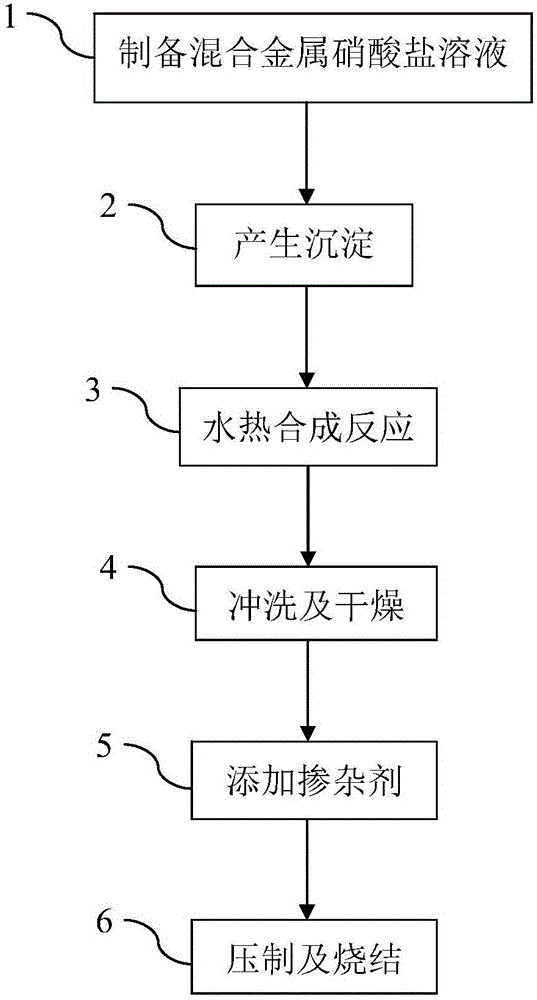

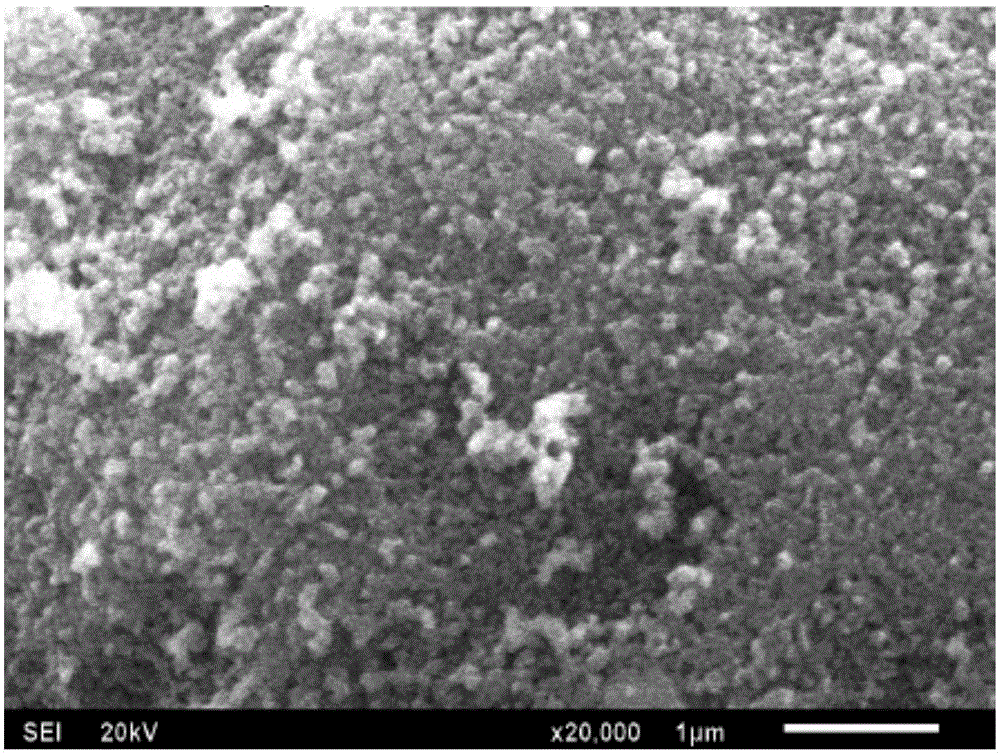

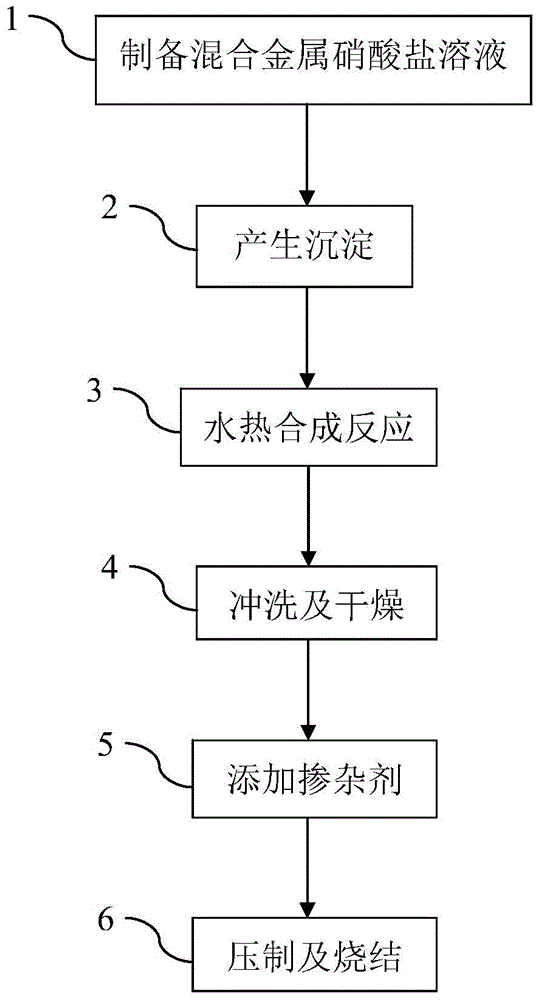

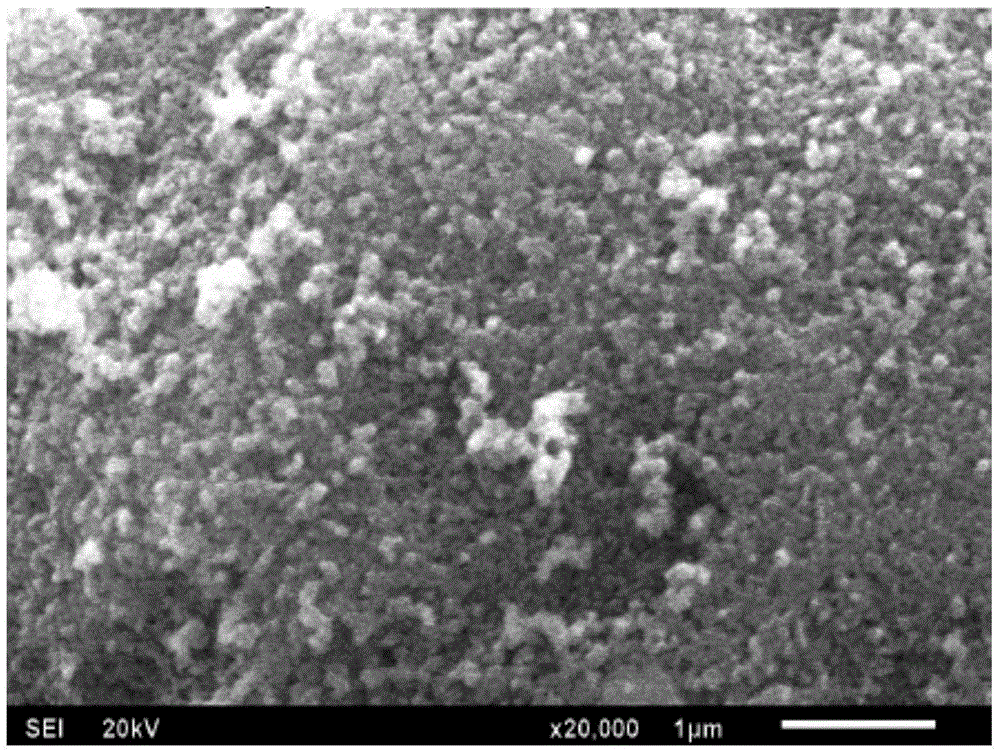

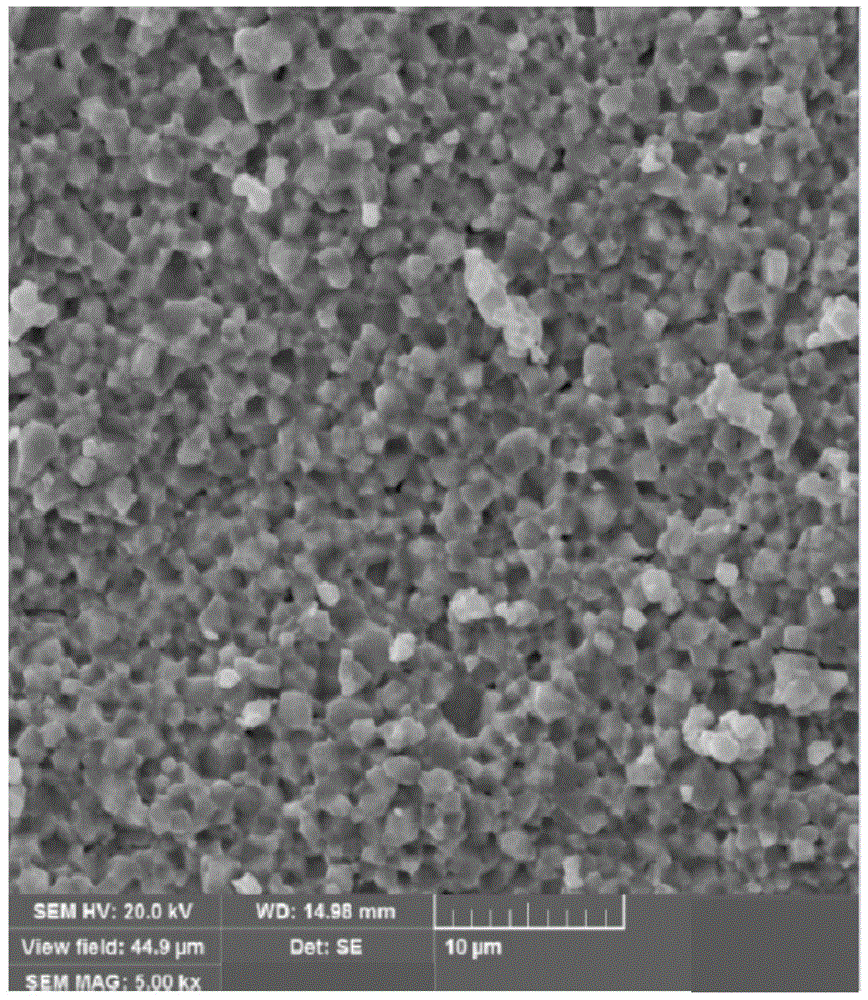

Nano ferrite material, and preparation method thereof

The invention discloses a nano ferrite material, and a preparation method thereof. The preparation method comprises following steps: 1) Fe(NO3)3, Zn(NO3)2, Ni(NO3)2, and Cu(NO3)2 are taken as initial raw materials, the weight of the materials is calculated based on a molecular formula Ni(1-a-b)ZnaCubFecO4, and a mixed metallic nitrate solution is prepared, wherein 0.4<=a<=0.45, 0.15<=b<=0.2, and 1.9<=c<=1.96; 2), a NaOH solution with a molar concentration ranging from 1 to 10mol / L is added into the mixed metallic nitrate solution so as to obtain a precipitate; 3), hydro-thermal synthesis is carried out; 4), the precipitate is washed and dried; 5) Bi2O3 with a weight ratio ranging from 0.05 to 0.5wt% and MoO3 with a weight ratio ranging from 0.05 to 0.2wt% are added, an obtained mixture is subjected to ball milling and drying, and a binder is added for pelleting; and 6) compacting and sintering are carried out. The nano ferrite material is high in magnetic conductivity and saturation magnetic induction intensity; and a crystal grain structure is uniform and fine.

Owner:SHENZHEN SUNLORD ELECTRONICS

Tantalum sputtering target

ActiveUS9085819B2Uniform and fine structureImprove evennessCellsVacuum evaporation coatingSputteringFine structure

Provided is a tantalum sputtering target, in which 1 mass ppm or more and 50 mass ppm or less of boron is contained as an essential component, and of which the purity excluding boron and gas components is 99.998% or higher. Thereby obtained is a high-purity tantalum sputtering target having a uniform and fine structure and enabling plasma stabilization and achievement of superior film evenness (uniformity).

Owner:JX NIPPON MINING & METALS CORP

Preparation method of moisture absorbent with high water absorbility

InactiveCN107051135AImprove fine crushing effectSimple processGas treatmentDispersed particle separationDistillationSurface-active agents

The invention discloses a preparation method of a moisture absorbent with high water absorbility. The method comprises the steps that firstly, starch grafted sodium polyacrylate and sodium alkyl diphenyl ether disulfonate are added into propylene glycol and stirred for a period of time, calcium chloride and magnesium sulfate are added, and a microwave reaction is performed; then, reduced pressure distillation is performed to remove propylene glycol, solids are dried, and the moisture absorbent is obtained. The novel moisture absorbent is prepared in the mode of mixing water absorbent resin and an inorganic water absorbent, and the using effect is greatly improved compared with that of independent use of the water absorbent resin or the inorganic water absorbent; the sodium alkyl diphenyl ether disulfonate surface active agent is added, the components are mixed under the microwave condition, the uniform and close structure can be formed, and the fine crushing effect of the water absorbent is improved; compared with the prior art, the moisture absorbent has the high absorbility, is simple in technology and long in service life and generates no environmental pollution.

Owner:JILIN UNIV FIRST HOSPITAL

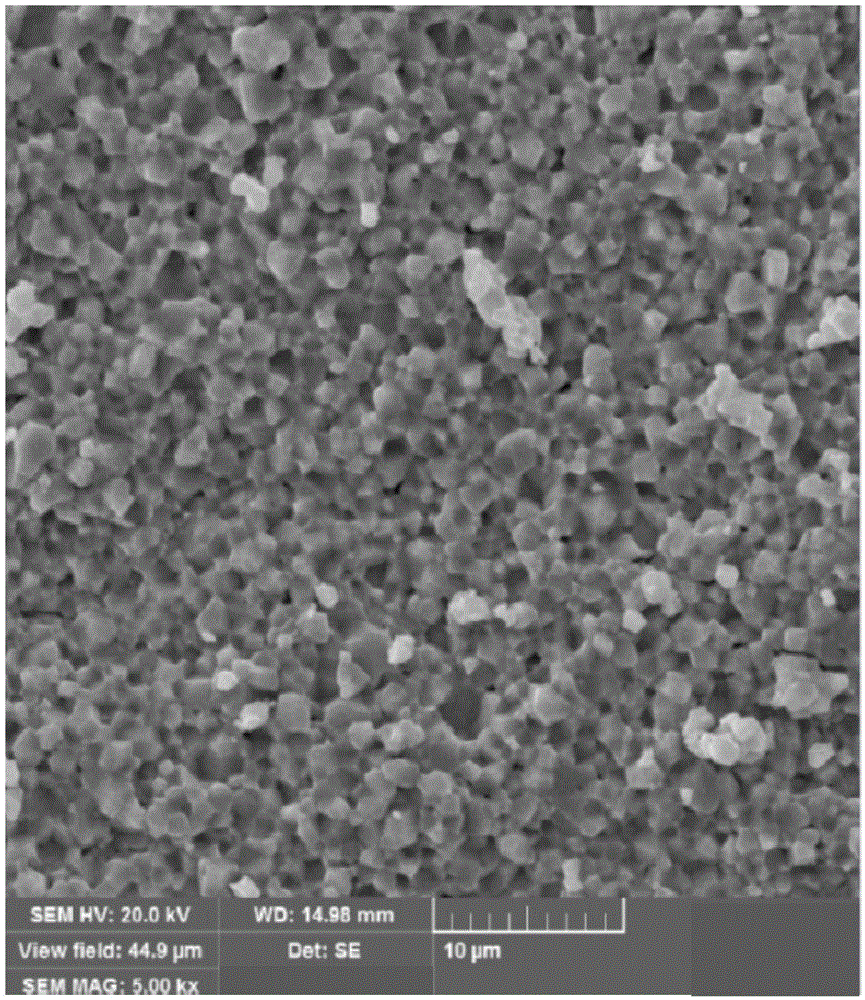

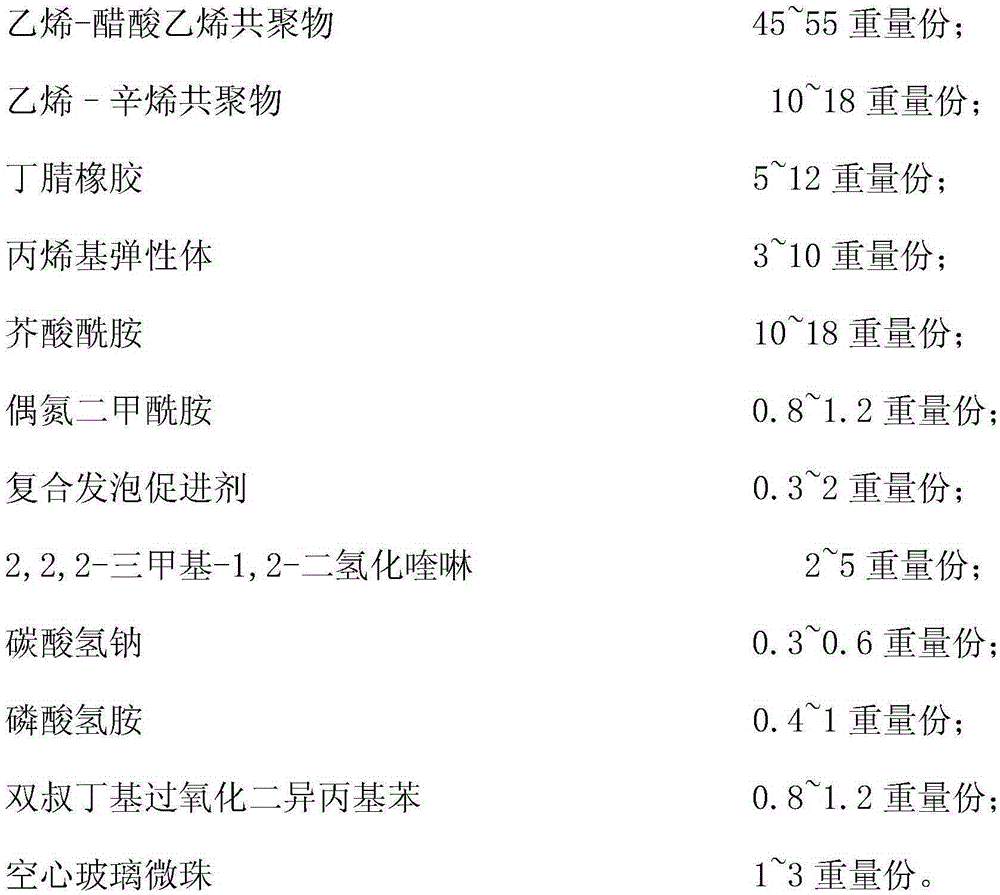

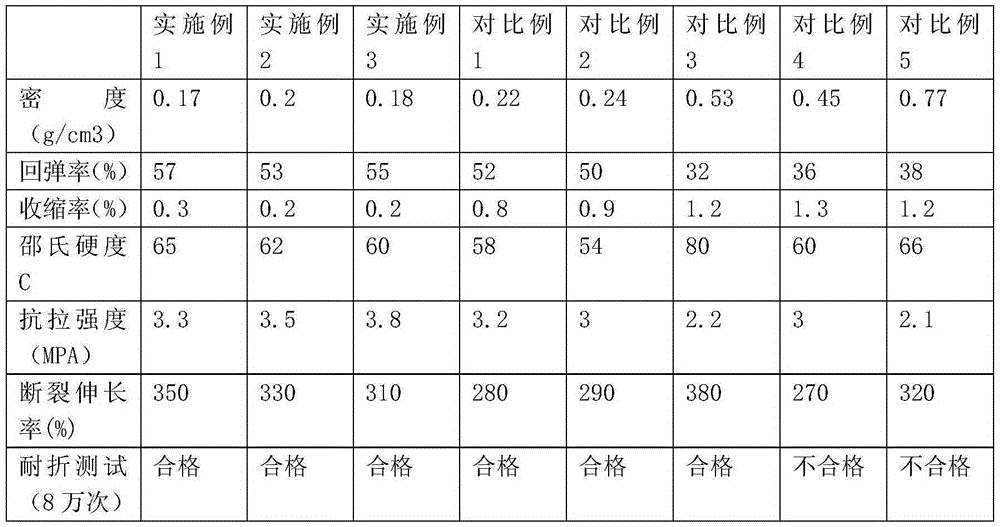

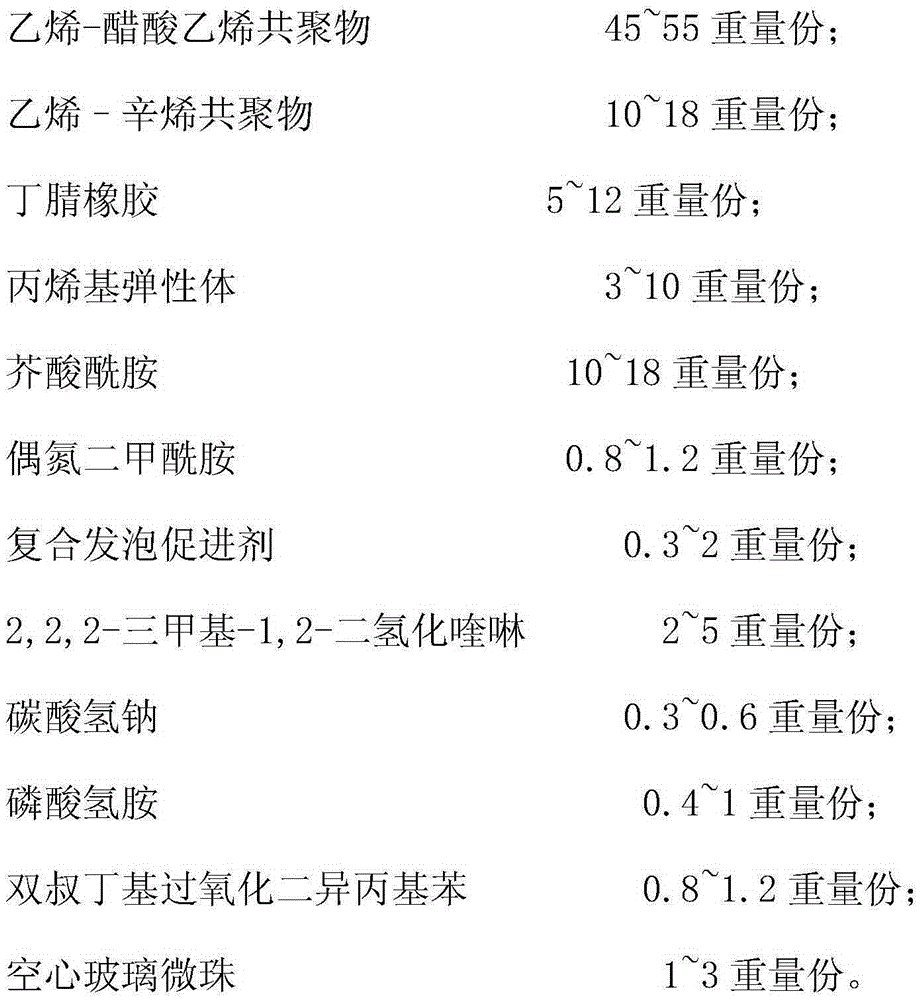

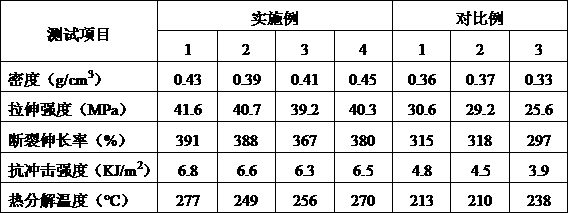

Rubber and plastic micropore shoe material and preparation method thereof

The invention discloses a rubber and plastic micropore shoe material which comprises the following components: ethylene-vinyl acetate copolymer, ethylene-octene copolymer, nitrile rubber, propenyl elastomer, erucicamide, 0.8 part of azodicarbonamide, 0.3 part of a compound foaming accelerator, 2,2,2-trimethyl-1,2-dihydroquinoline, stearic acid, zinc stearate, ditert-butyl peroxide diisopropyl benzene and hollow glass beads, wherein the compound foaming accelerator is a mixture consisting of chlorinated paraffin, ethylene acrylic acid copolymerized zinc salt and calcium oxide. According to the provided rubber and plastic micropore shoe material, the proper formula and auxiliaries are adopted to obtain a sizing material through secondary granulation, and the sizing material is foamed so as to prepare the shoe material; the shoe material is portable, aesthetic, rich in elasticity, good in compression resistance and small in shrinkage rate.

Owner:吴江市风尚鞋厂

Production process of layered colored crystal PU (Polyurethane) synthetic leather

InactiveCN107904970AImprove natural transitionAvoid floatingPolyurea/polyurethane coatingsTextiles and paperWork in processSizing

The invention discloses a production process of a layered colored crystal PU (Polyurethane) synthetic leather. The production process comprises the steps of coating a layer of scraper sizing agent ona surface of release paper through a No.1 coating head, coating a layer of middle-layer scraper sizing agent on an upper surface of a scraper material through a No.2 coating head, coating a layer of bottom material on an upper surface of the middle layer through a No.3 coating head, and after preheating, compounding base cloth and the bottom material, and drying to obtain a dry-process semi-finished product; secondly, sequentially coating a layer of surface layer on a surface of glossy paper through the No.1 coating head, and coating a layer of bottom layer on a surface of the surface layer through the No.2 coating head; finally, when drying to 20 to 30 percent of dryness, laminating the dry-process semi-finished product and the bottom material, and drying to obtain a finished product. When drying to 20 to 30 percent of dryness, a surface-layer scraper material is at a contraction state, and a middle-layer scraper material can permeate into contraction holes of the surface-layer scraper material, so that natural transition between layers during compounding is improved, and a floating layer feeling is avoided.

Owner:泉州静杰企业管理咨询有限公司

Processing method of special flour for fried bread stick

The invention discloses a processing method of special flour for fried bread stick, which is characterized by: (1) selection and purchase of the raw material (wheat): selecting 3-4 kinds of wheat for mixing and processing, with the hardness rate being 60-70 percent, the content of wet gluten being more than or equal to 30 percent, the water absorption rate being higher than or equal to 60 percent, the stabilizing period being more than or equal to 6 minutes, the ductility being more than or equal to 150mm, the tensile resistance being 400-500BU and other indicators in line with the second-grade requirements in the national standard; (2) cleaning process: removing various impurities, and ensuring that the impurity content in the wheat to be milled satisfies the national standard; and (3) milling process: completely milling and screening to reduce the floating impurities and the ash content in the flour; adopting the milling process of removing husks five times, removing cores eight times, removing slag twice and removing residues twice, purifying 5-6 times, using the coproduction technology so that the extraction proportion of the special flour for the fried bread stick reaches 12-15 percent, and extracting during the preceding husk milling, residue milling and rescreening. The fried food produced with the special flour for the fried bread stick of the invention can reduce the oil absorption rate of the product, and has an enlarged size, a fine and uniform structure, a crispy taste and a golden color.

Owner:ZHANGJIAGANG FLOUR FOOD

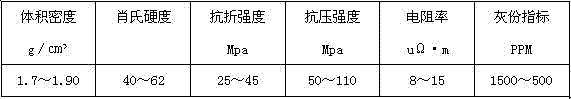

Preparation method of graphite thermal field material for czochralski silicon crystal furnace

The invention relates to the technical field of graphite thermal fields, in particular to a preparation method of a graphite thermal field material for a Czochralski silicon crystal furnace. An aggregate is needlelike petroleum coke; a powder is graphene, pitch coke, carbon black and carbon fibers; a binder is modified medium-temperature coal pitch; and an impregnating agent is impregnating asphalt. The selection of the raw materials is reasonable, and the preparation process is scientific; the prepared graphite thermal field material for the czochralski silicon crystal furnace is uniform andfine in structure and high in volume density; the physical and chemical indexes of graphite are excellent; the volume density of the graphite thermal field material is larger than or equal to 2.0 g / cm<3>, the resistivity is smaller than or equal to 6.0 mu omega m, the breaking strength is larger than or equal to 32 Mpa, the compressive strength is larger than or equal to 65 Mpa, the porosity is smaller than or equal to 10%, the ash content is smaller than or equal to 0.2%, and the thermal expansion coefficient is smaller than or equal to 2 * 10 <-6 > / DEG C.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

A kind of nano ferrite material and preparation method thereof

The invention discloses a nano ferrite material, and a preparation method thereof. The preparation method comprises following steps: 1) Fe(NO3)3, Zn(NO3)2, Ni(NO3)2, and Cu(NO3)2 are taken as initial raw materials, the weight of the materials is calculated based on a molecular formula Ni(1-a-b)ZnaCubFecO4, and a mixed metallic nitrate solution is prepared, wherein 0.4<=a<=0.45, 0.15<=b<=0.2, and 1.9<=c<=1.96; 2), a NaOH solution with a molar concentration ranging from 1 to 10mol / L is added into the mixed metallic nitrate solution so as to obtain a precipitate; 3), hydro-thermal synthesis is carried out; 4), the precipitate is washed and dried; 5) Bi2O3 with a weight ratio ranging from 0.05 to 0.5wt% and MoO3 with a weight ratio ranging from 0.05 to 0.2wt% are added, an obtained mixture is subjected to ball milling and drying, and a binder is added for pelleting; and 6) compacting and sintering are carried out. The nano ferrite material is high in magnetic conductivity and saturation magnetic induction intensity; and a crystal grain structure is uniform and fine.

Owner:SHENZHEN SUNLORD ELECTRONICS

Preparation method of high-silicon aluminum alloy electronic packaging material

InactiveCN110450510AEasy to operateReduce porosityLamination ancillary operationsLaminationPorosityMature technology

The invention discloses a preparation method of a high-silicon aluminum alloy electronic packaging material. The preparation method is characterized by comprising the steps: firstly, obtaining a high-silicon aluminum alloy plate with required silicon content through a traditional casting method; then refining the high-silicon aluminum alloy plate by a rapid solidification method to obtain thin strip-shaped high-silicon aluminum alloy; finally, superposing a plurality of pieces of thin strip-shaped high-silicon aluminum alloy according to the required thickness, and performing hot-press formingto obtain the high-silicon aluminum alloy electronic packaging material with the required silicon content. According to the preparation method, a plurality of advanced preparation processes such as arapid solidification method and a hot pressing method are comprehensively adopted, on the premise of keeping relatively high silicon content, and the high-silicon aluminum alloy electronic packagingmaterial which is nearly completely densified and has two uniformly distributed phases of aluminum matrix and fine silicon is obtained, and has the advantages of simple operation, simple equipment, low porosity, excellent performance, environmental friendliness, mature technology and the like.

Owner:HEFEI UNIV OF TECH

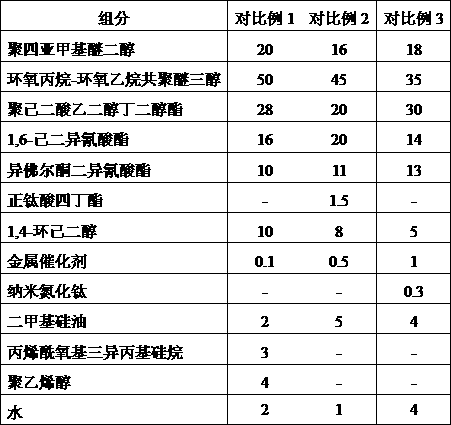

Heat-resistant foam double-side adhesive tape and preparation method thereof

InactiveCN109575828AUniform and fine structureImprove mechanical propertiesFilm/foil adhesivesSilanesAdhesive

The invention discloses a heat-resistant foam double-side adhesive tape which comprises a foam layer and adhesive layers arranged on the upper and lower surfaces of the foam layer. The foam layer is prepared from PTMEG, epoxypropane-ethylene oxide copolyether triol, polyethylene glycol, butanediol adipate, 1, 6-HDI, IPDI, tetrabutyl titanate, 1, 4-cyclohexanediol, metal catalyst, nano titanium nitride, dimethyl silicone oil, allyl triisopropyl silane, polyvinyl alcohol and water, wherein the metal catalyst is an organic bismuth catalyst and / or an organic tin catalyst. The heat-resistant foam double-side adhesive tape is good in mechanical performance, free of impact on structural stability caused by being less prone to deformation or breakage during use, high in resistance to high temperature, capable of meeting requirements of hot press process and wide in application prospect.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

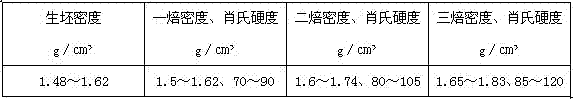

Preparation method of fine-structure isotropic isostatic pressing graphite

The invention relates to a preparation method of fine-structure isotropic isostatic pressing graphite, which is characterized by comprising the following steps: S1, primary grinding, S2, mixing, S3, secondary grinding, S4, pressing, S5, primary roasting, S6, dipping, S7, secondary roasting and S8, graphitizing. The invention aims to solve or at least alleviate the problems of complex technology, high technological process requirement and low product index of the existing preparation method, and provides the preparation method of the fine-structure isotropic isostatic pressing graphite.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

Formula and processing technology of pumpkin submicron powder thin pancakes

InactiveCN107969462AUniform and fine structureCrispy tasteDough treatmentBakery productsMillet flourNutrient

The invention relates to the field of food processing, and provides a formula of pumpkin submicron powder thin pancakes. The formula consists of the following raw materials in parts by weight of 480-520 parts of flour, 880-1000 parts of coarse wheat flour, 900-1020 parts of millet flour, 35-43 parts of pumpkin submicron powder and 2000-2300 parts of purified water, and preferably 500 parts of theflour, 1000 parts of the coarse wheat flour, 1000 parts of millet flour, 40 parts of the pumpkin submicron powder and 2000 parts of the purified water. The pumpkin submicron powder thin pancakes disclosed by the invention are uniform, fine and smooth in structure, crisp and chewable in mouth feel, greenish-yellow in color, fragrant and sweet after being put into mouths, rich in aftertaste, slightin pumpkin fragrance and high in nutrient value, can facilitate digestion and promote absorption, are suitable for crowds of different age stages to eat, and are particularly suitable for crowds poorin the digestion functions of the intestine and the stomach to eat.

Owner:张道松

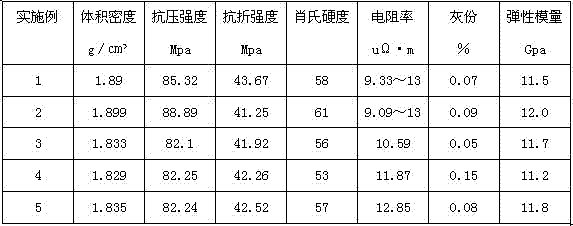

Preparation method of isotropic copper-based isostatic graphite composite material

The invention discloses a preparation method of an isotropic copper-based isostatic graphite composite material. The preparation method comprises the following steps: S1, material mixing: selecting petroleum coke, carbon black, special graphite powder and graphene and performing mixed treatment on the petroleum coke, the carbon black, the special graphite powder and the graphene to obtain mixed powder; S2, grinding treatment: adding the mixed powder in the S1 in a Raymond mill and performing grinding treatment on the mixed powder; S3, isostatic molding: putting the mixed powder in the S2 in apress for pressing molding and obtaining a green body; S4, impregnating treatment: putting the green body in the S3 in an impregnating tank and adding medium-temperature pitch. The isotropic copper-based isostatic graphite composite material prepared with the preparation method disclosed by the invention is uniform and fine in structure, high in volume density, excellent in graphite physical and chemical indexes, high in mechanical strength, high in load, little in wear, resistant to high temperature, strong in thermal conductivity, excellent in corrosion resistance, long in service life and strong in stability.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

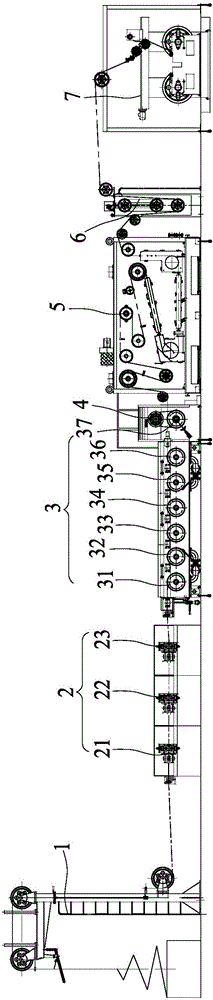

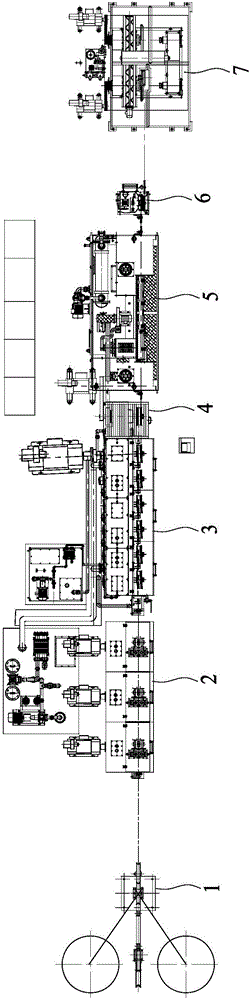

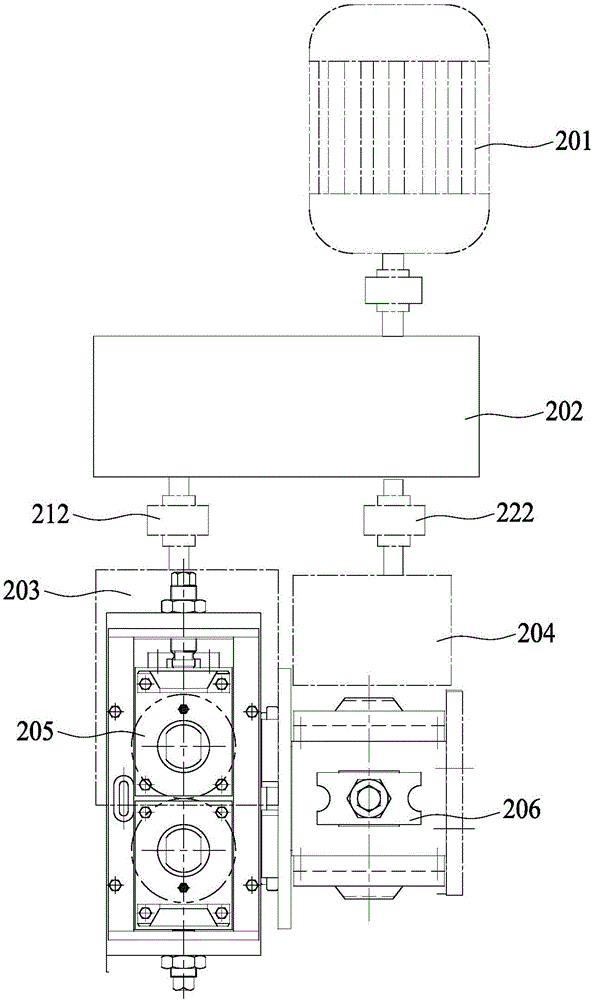

Combined continuous rolling and continuous drawing machine with three sets of double-roller rolling machine and seven die drawing machines

Owner:FUJIAN NANPING SUN CABLE +1

Corn starch-based foaming material and preparation method thereof

The invention discloses a corn starch-based foaming material and a preparation method thereof. The preparation method includes the steps: (1) uniformly stirring and mixing starch, hydrogen peroxide, ferrous sulfate, water and citric acid, heating mixture to perform oxidation reaction, and cooling and discharging the mixture to obtain a component A for standby application; (2) uniformly stirring and mixing polyvinyl alcohol (PVA), plasticizers and sodium hydrogen carbonate to obtain a component B for standby application; (3) uniformly stirring and mixing the component A, the component B, amideadditives, ethylene-acrylic acid (EAA) copolymers and talcum powder, extruding mixture by a single screw extruder with high compression ratio to obtain the starch-based foaming material. The starch-based foaming material has high resilience ratio and foaming ratio, the compression resilience ratio is higher than or equal to 95% when relative humidity is lower than or equal to 50%, the compressionresilience ratio is higher than or equal to 80% when relative humidity is higher than or equal to 90%, and the overall foaming ratio is higher than or equal to 25 times.

Owner:JIAXING BOFA NEW PLASTIC CO LTD

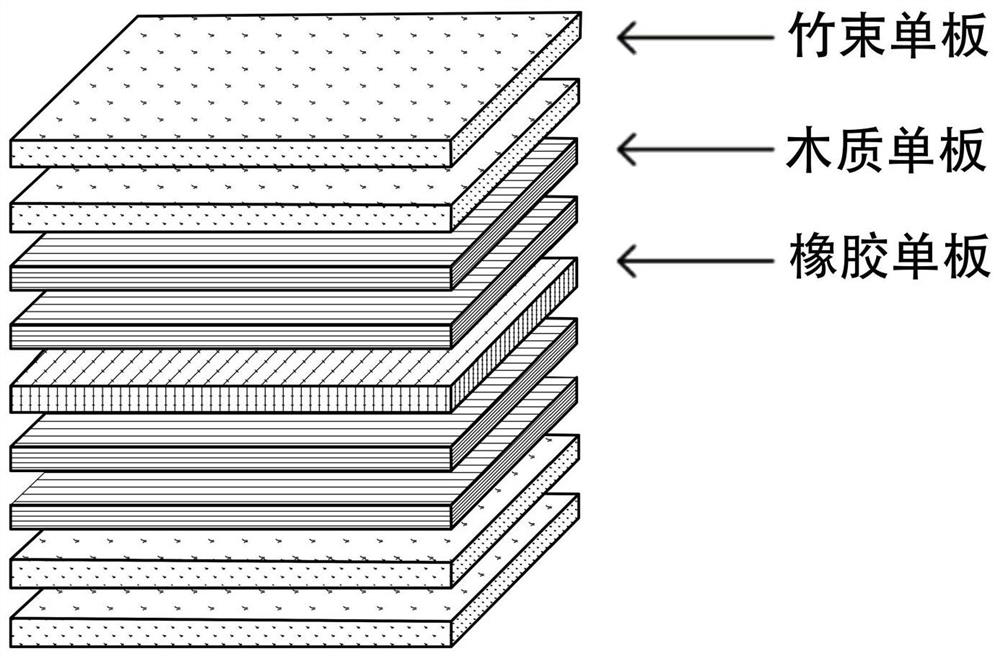

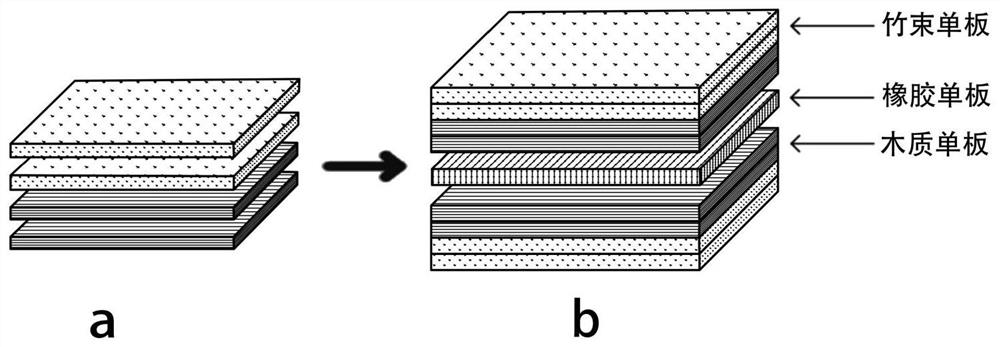

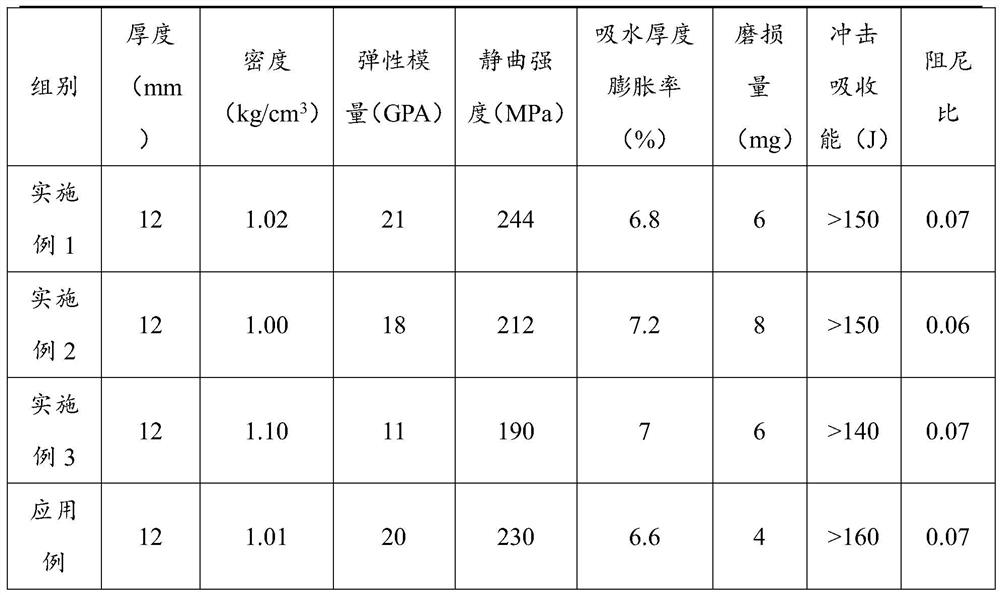

Impact-resistant bamboo bundle-rubber composite board as well as preparation method and application thereof

ActiveCN112829023AHigh strengthIncrease stiffnessLaminationLamination apparatusWood veneerSingle plate

The invention provides an impact-resistant bamboo bundle-rubber composite board as well as a preparation method and application thereof, and belongs to the technical field of artificial boards. A bamboo bundle veneer serves as a surface layer, a rubber veneer serves as a core layer, the performance advantages of the bamboo bundle veneer and the rubber veneer can be brought into full play, the functional strength requirement is met, meanwhile, safety and comfort are improved, the impact resistance of the artificial board is effectively improved, installation of additional damping facilities is omitted, the assembly efficiency is improved, and the installation cost is reduced; and the wood veneer is used as a middle layer of the bamboo bundle veneer and the rubber veneer, the effect of glue joint transition can be achieved, the glue joint strength of the composite board can be effectively improved, the interface bonding problem of the bamboo bundle veneer and the rubber veneer is solved, and meanwhile the lightweight design of the board is achieved.

Owner:HENAN POLYTECHNIC UNIV

Low-sugar yacon sweet dumpling

The invention relates to the technical field of quick-frozen food and specifically relates to a low-sugar yacon sweet dumpling. Yacon is taken as a main raw material of the sweet dumpling; the yacon is effectively prevented from browning and the flavor of yacon is kept in the manner of wrapping the yacon with starch paste; low-calorie sweet raw materials, including inulin, trehalose and xylitol, are also added, so that the low-sugar yacon sweet dumpling with nice taste can be acquired.

Owner:湖南金健速冻食品有限公司

Nutritional floating bath oil

InactiveCN104188839AGood skin compatibilityUniform and fine structureCosmetic preparationsToilet preparationsPhosphatePotassium

The invention relates to nutritional floating bath oil. The nutritional floating bath oil is prepared from the raw materials in percentage by weight: 71.0% of white oil, 1.0% of potassium laureth phosphate, 24.0% of isopropyl myristate and 4.0% of essence. According to the nutritional floating bath oil, the dosage and physicochemical properties of all the raw materials generate a synergetic effect, so that the effects of body cleaning and skin caring are achieved. The nutritional floating bath oil has the pH value close to that of the human skin and is non-irritant to the skin; after the nutritional floating bath oil is used, obvious comfortable and soft feeling is generated, and no greasy feeling is generated, so that the nutritional floating bath oil has obvious effects on cleaning and nourishing the skin.

Owner:谢朝阳

A kind of sealing graphite and preparation method thereof

The invention discloses a copper-based pantograph carbon contact strip made from a graphene copper-based nano selenium niobium composite material. The graphene copper-based nano selenium niobium composite material is prepared from, by weight, 70-75% of a mixture and 25-30% of an adhesive by mixing, pressing, calcining and copper impregnating. By adoption of a preparation method of the copper-basedpantograph carbon contact strip, the copper-based pantograph carbon contact strip is high in abrasion resistance, low in friction coefficient, high in conductivity and great in cost performance and impact resistance, problems in use of existing pantograph carbon contact strips are effectively solved, and high practicality is realized.

Owner:黑龙江省鑫顺石墨有限责任公司

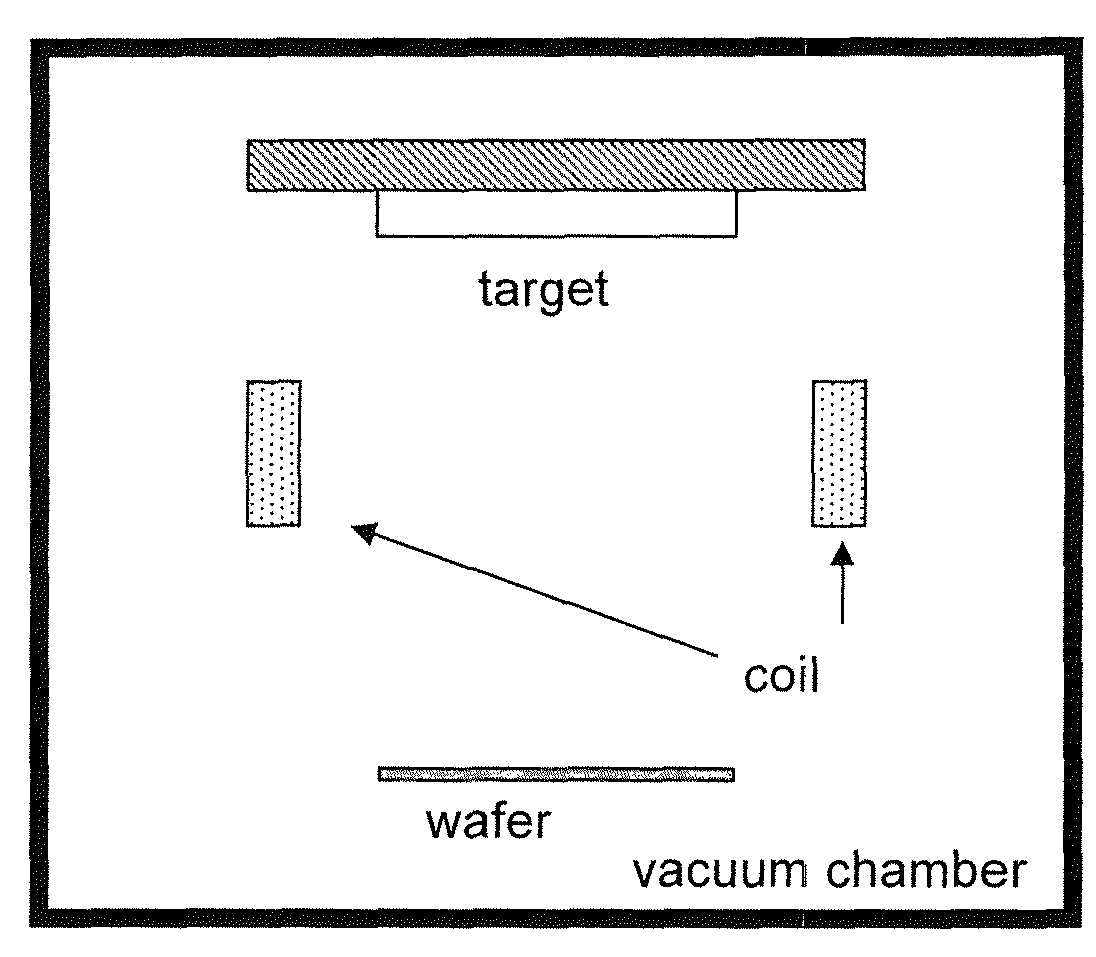

Sputtering target and/or coil, and process for producing same

ActiveUS9951412B2Reduces adsorption and occlusionDegree of improvementCellsElectric discharge tubesFine structureSputtering

Provided is a sputtering target and / or a coil disposed at the periphery of a plasma-generating region for confining plasma. The target and / or the coil has a surface to be eroded having a hydrogen content of 500 μL / cm2 or less. In dealing with reduction in the hydrogen content of the surface of the target and / or the coil, the process of producing the target and / or the coil, in particular, the conditions for heating the surface of the target and / or the coil, which is thought to be cause of hydrogen occlusion, are appropriately regulated. As a result, hydrogen occlusion at the surface of the target can be reduced, and the degree of vacuum during sputtering can be improved. Thus, the present invention provides a target and / or a coil that has a uniform and fine structure, makes plasma stable, and allows a film to be formed with excellent uniformity and provides a method of producing the target and / or the coil.

Owner:JX NIPPON MINING & METALS CORP

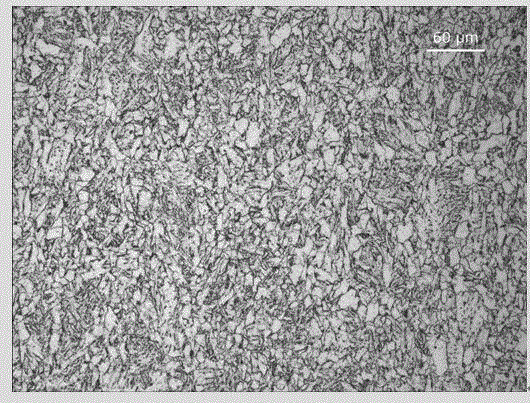

Large-specification fine-grain isotropic isostatic-pressing graphite

The invention discloses large-specification fine-grain isotropic isostatic-pressing high-purity graphite mainly composed of components of, by weight: 52-65 parts of material powder, and 35-48 parts of modified pitch. The material powder is composed of components of, by weight: 75-94 parts of prefabricated crushed coke powder, 2-18 parts of graphite powder, and 2-8 parts of an additive. The prefabricated crushed coke powder is composed of components of, by weight: 52-65 parts of prefabricated material powder, and 35-48 parts of modified pitch. The prefabricated material powder is composed of components of, by weight: 52-85 parts of petroleum coke, 2-20 parts of graphite powder, 6-45 parts of a carburant, and 3-12 parts of fine powder. The production specification of the graphite is large. According to the invention, production of graphite with a large-specification of phi900 can be realized. The graphite is advantaged in high strength, high density, good elasticity, excellent mechanical properties, and excellent physical chemical index. The graphite material is advantaged in low porosity, good quality, uniform and delicate structure, and relatively high volume density.

Owner:雅安恒圣高纯石墨科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com