Large-specification fine-grain isotropic isostatic-pressing graphite

An isotropic, fine-grained technology, applied in the direction of graphite, can solve the problems of unsatisfactory physical and chemical indicators of mechanical properties, poor strength, density and elastic properties, uneven bulk density, etc., and achieve excellent physical and chemical indicators of mechanical properties, density and Good elasticity, uniform and delicate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

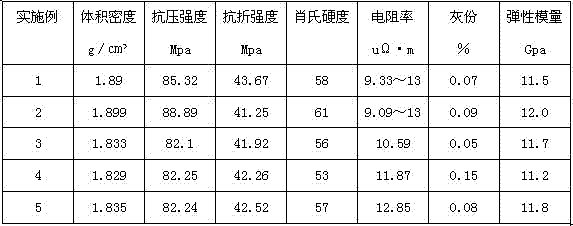

Embodiment 1

[0025] [Example 1] Large-scale fine particle isotropic isostatic graphite, which is mainly composed of the following components by weight:

[0026] Powder 52

[0027] Modified bitumen 35;

[0028] Wherein, described material powder is made of the component of following weight ratio:

[0029] Premade coke powder 75

[0030] Graphite powder 2

[0031] Additive 2;

[0032] Described prefabricated crushed coke powder is made of the following components in weight ratio:

[0033] Prefabricated Powder 52

[0034] Modified bitumen 35;

[0035] Described prefabricated powder is made of the following components by weight ratio:

[0036] Petroleum coke 55

[0037] Graphite powder 16

[0038] Carburizer 26

[0039] fine powder 3.

Embodiment 2

[0040] [Example 2] Large-scale fine particle isotropic isostatic graphite, which is mainly composed of the following components by weight:

[0041] Powder 65

[0042] modified bitumen 48;

[0043] Wherein, described material powder is made of the component of following weight ratio:

[0044] Premade coke powder 94

[0045] Graphite powder 6

[0046] Additive 2;

[0047] Described prefabricated crushed coke powder is made of the following components in weight ratio:

[0048] Prefabricated Powder 65

[0049] modified bitumen 48;

[0050] Described prefabricated powder is made of the following components by weight ratio:

[0051] Petroleum coke 85

[0052] Graphite powder 6

[0053] Carburizer 7

[0054] fine powder 2.

Embodiment 3

[0055] [Example 3] Large-scale fine particle isotropic isostatic graphite, which is mainly composed of the following components by weight:

[0056] Powder 60

[0057] Modified asphalt 40;

[0058] Wherein, described material powder is made of the component of following weight ratio:

[0059] Premade coke powder 85

[0060] Graphite powder 10

[0061] Additive 5;

[0062] Described prefabricated crushed coke powder is made of the following components in weight ratio:

[0063] Prefabricated Powder 60

[0064] Modified asphalt 40;

[0065] Described prefabricated powder is made of the following components by weight ratio:

[0066] Petroleum coke 70

[0067] Graphite powder 8

[0068] Carburizer 20

[0069] fine powder 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com