A kind of nano ferrite material and preparation method thereof

A technology of nano-ferrite and raw materials, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of large and low grain size, difficulty in meeting high magnetic permeability, etc., and achieve uniform grain structure The effects of fineness, low agglomeration, and high saturation magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

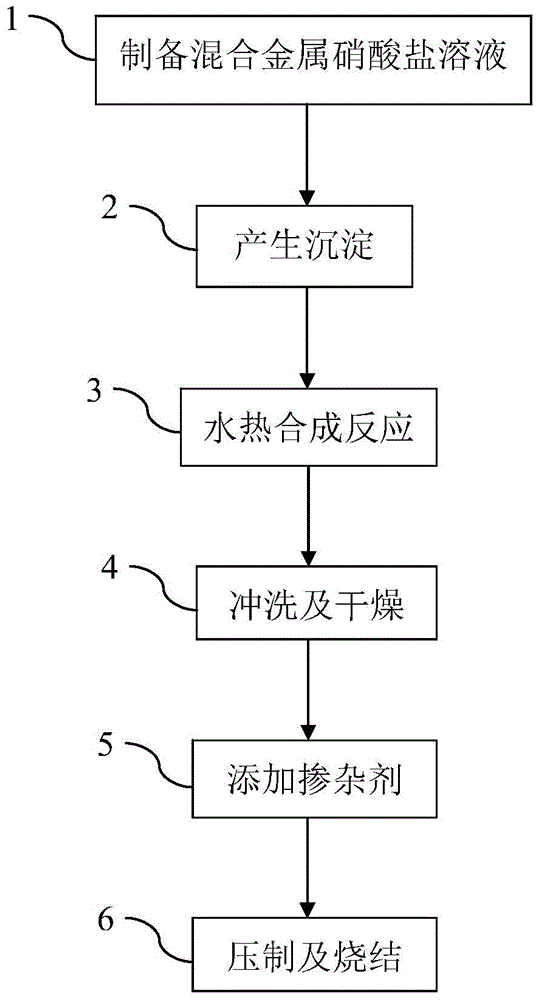

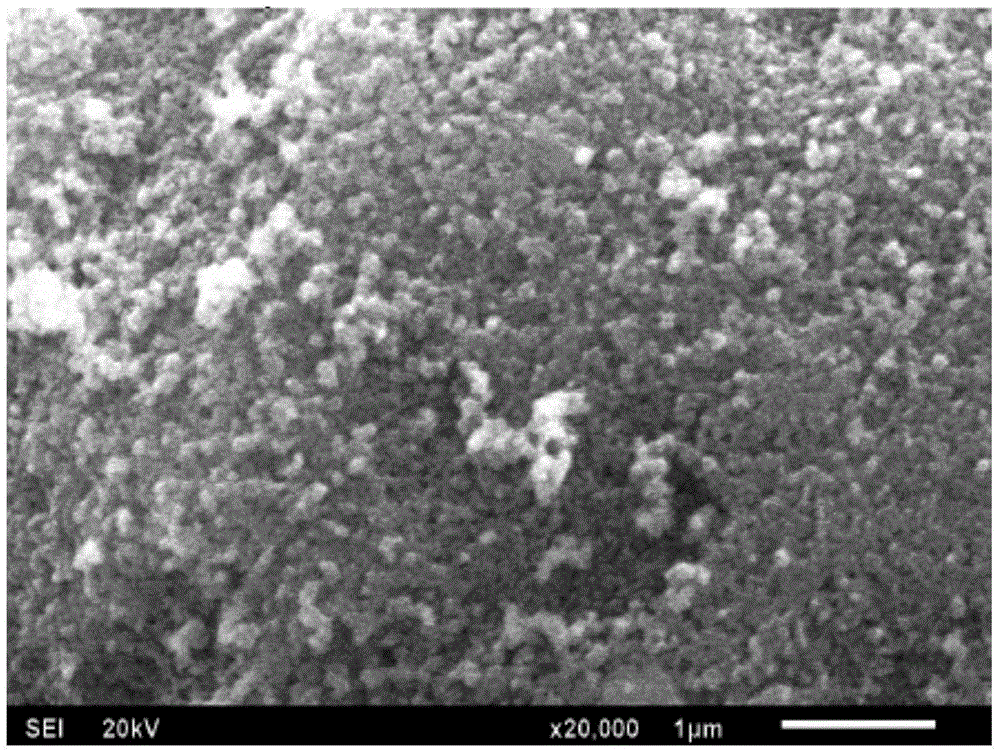

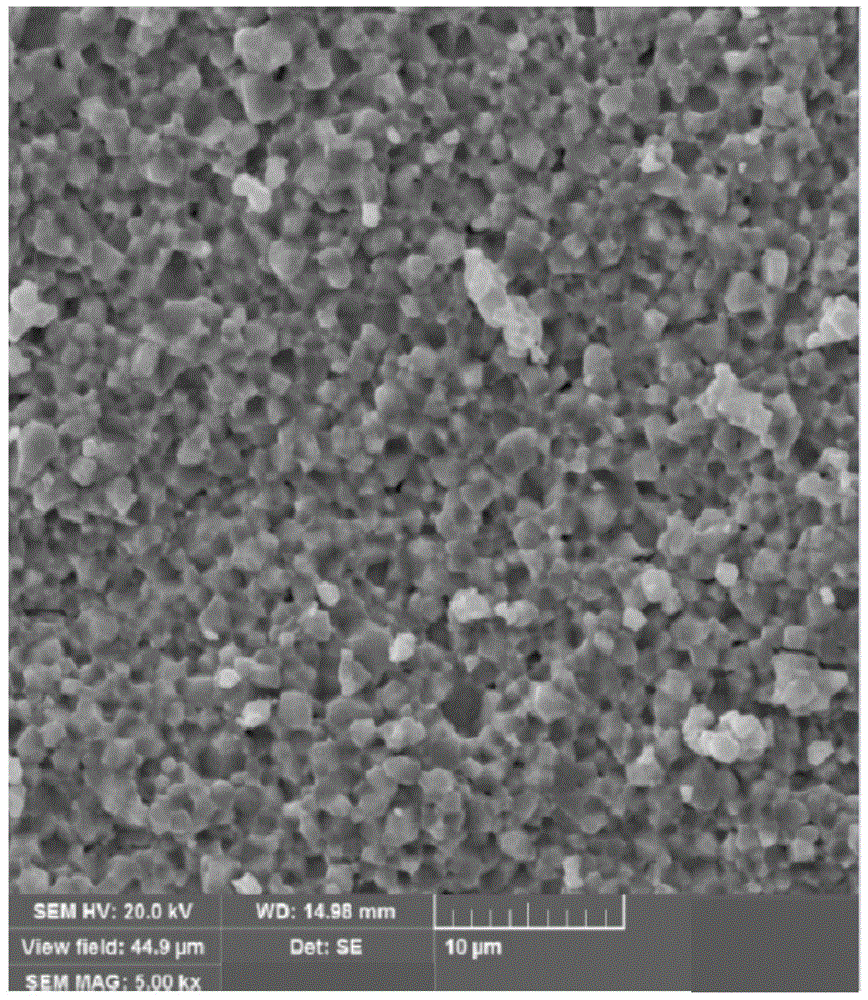

[0019] The idea of the present invention is to improve the ferrite powder through nanometerization. The ferrite particles obtained by the general solid-state reaction method are large and uneven, and are prone to impurities. The magnetic properties and specific surface energy of the particles are low. It is difficult to obtain better magnetic properties in the field of low-temperature sintering. Through the ferrite powder Nanometerization can be sintered at low temperature, so that the prepared ferrite material has better magnetic properties. There are many preparation methods for making ferrite powder nanometer, including chemical co-precipitation method, sol-gel method, microemulsion method, hydrothermal synthesis method and so on. However, the present invention uses the hydrothermal synthesis method without hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com