Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Solve the problem of continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

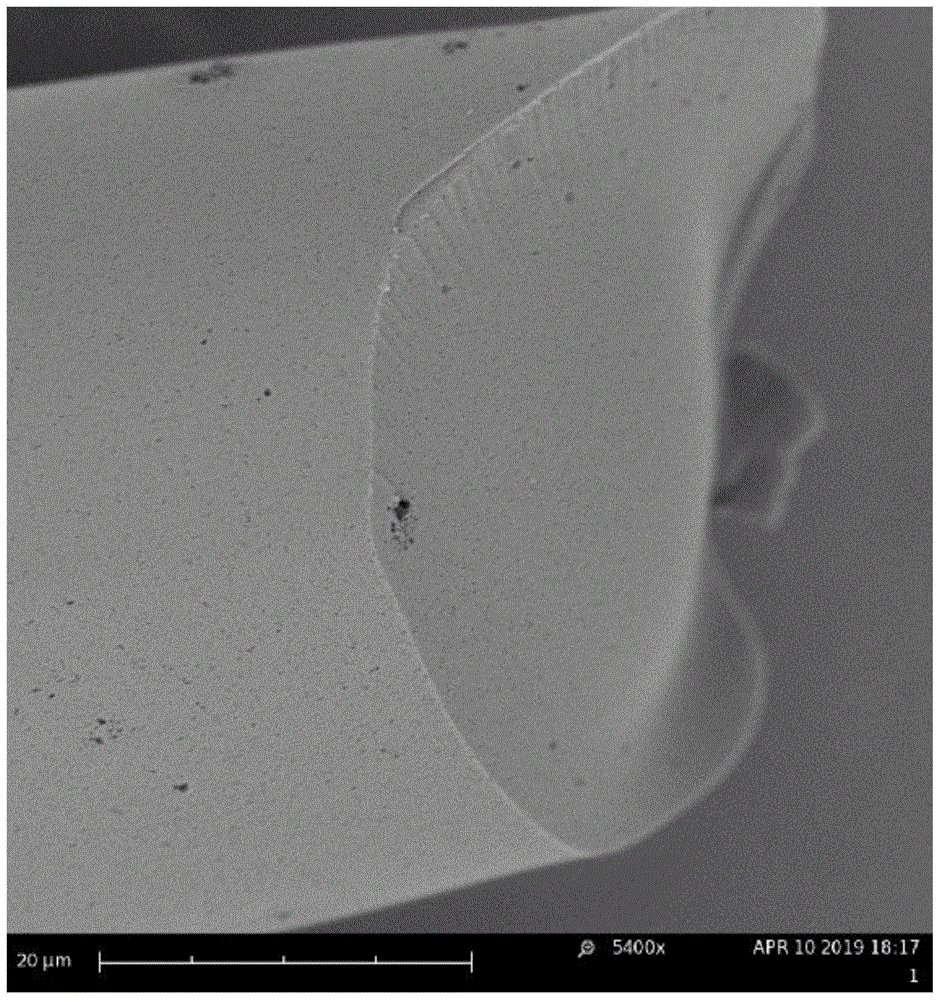

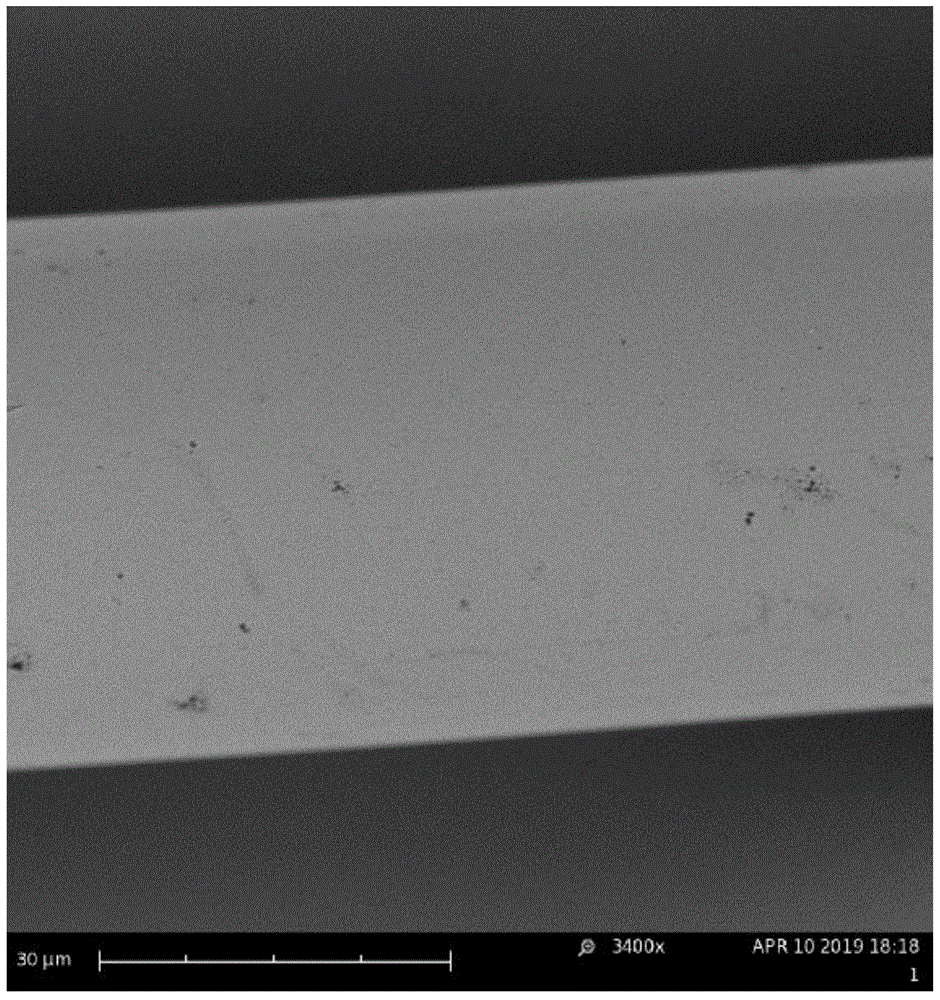

Preparation method of lignin-based carbon fiber

ActiveCN104593906AImprove spinnabilityImprove fiber qualityArtificial filament chemical after-treatmentUltimate tensile strengthCeramic membrane

The invention provides a preparation method of a lignin-based carbon fiber. The preparation method of the lignin-based carbon fiber comprises the following steps: dissolving lignin in an alkaline solution, filtering by using a ceramic membrane filtration device, adjusting pH value of a filtrate until the filtrate is acidic to obtain a lignin precipitate, washing and drying the lignin precipitate to obtain purified lignin; extruding the dried and purified lignin at 100-260 DEG C by a twin-screw extruder, removing volatile components and prilling; taking a thermoplastics polymer as a skin layer, taking lignin slices as a core layer to melt and spin by a melting and spinning device, wherein the spinning temperature of the thermoplastics polymer is 160-350 DEG C; the spinning temperature of the lignin is 160-260 DEG C; the mass ratio of the thermoplastics polymer adopted by the skin layer to the lignin slices adopted by the core layer is (1 to 9)-(9 to 1); oiling, curing, pre-oxidizing and carbonizing the fiber with a skin-core structure to obtain the lignin-based carbon fiber. The lignin-based carbon fiber has the advantages of being high in spinning property, small in diameter, high in strength, low in production cost and applicable to continuous production.

Owner:DONGHUA UNIV

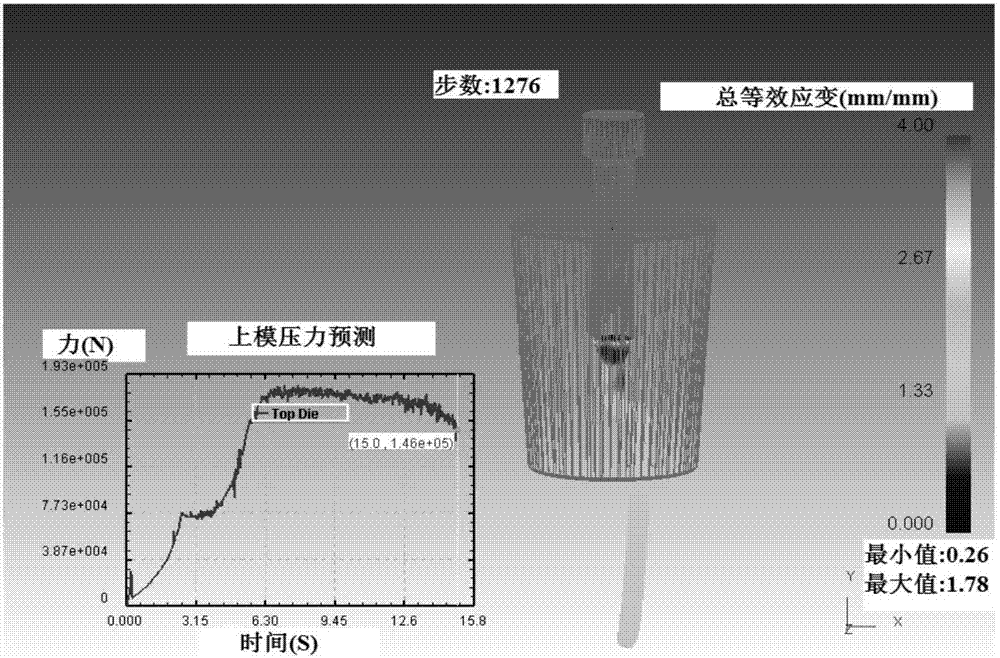

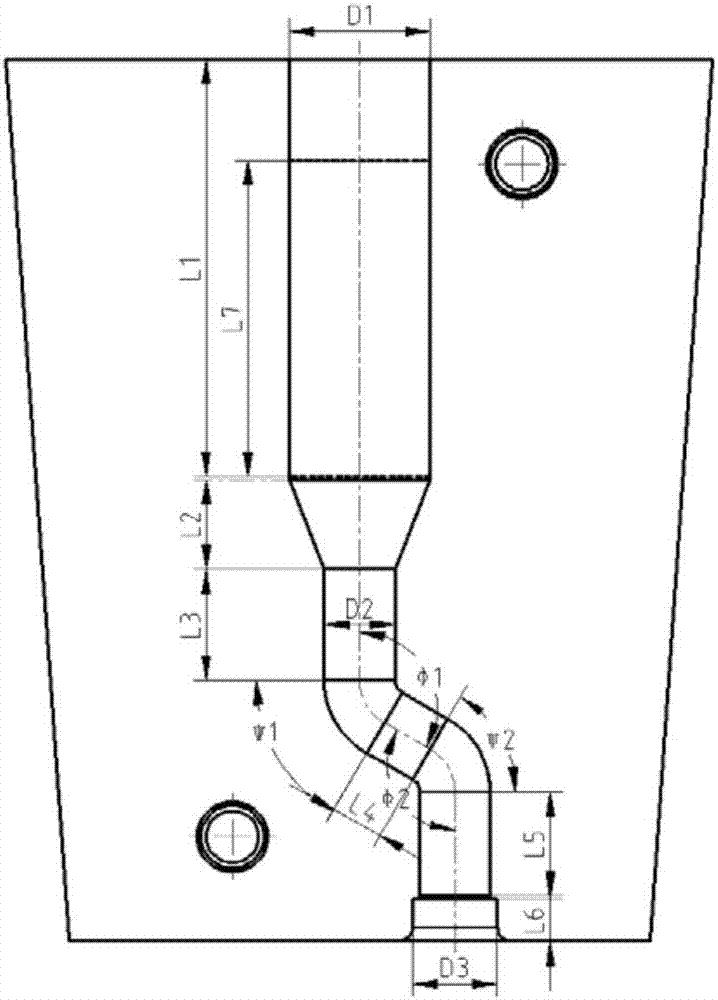

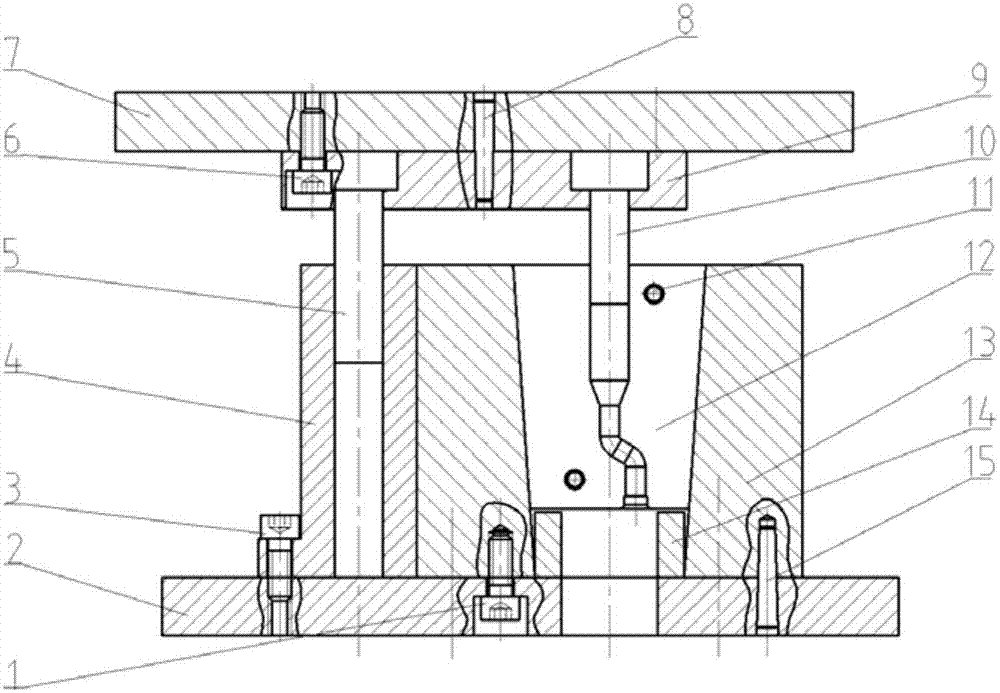

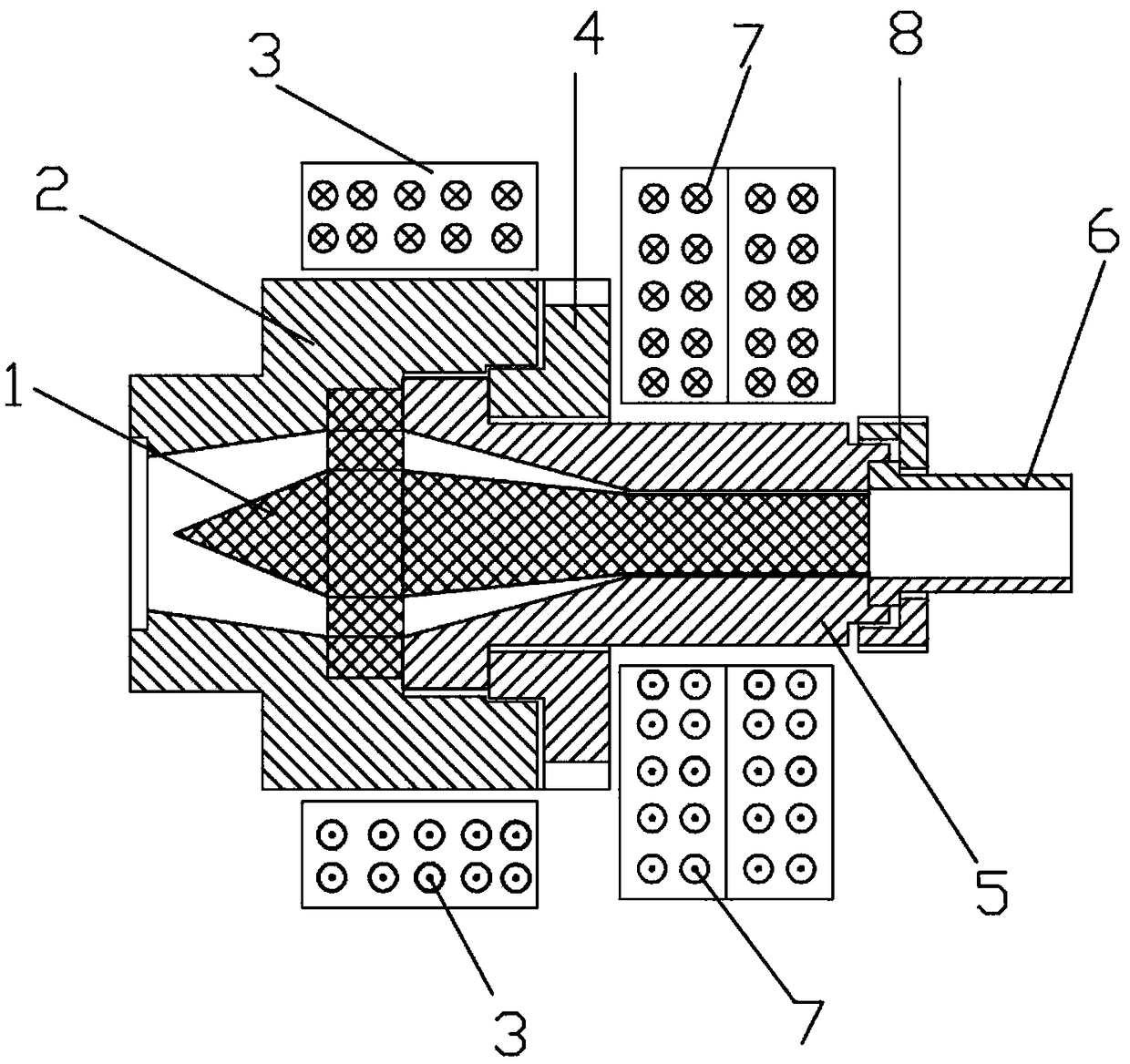

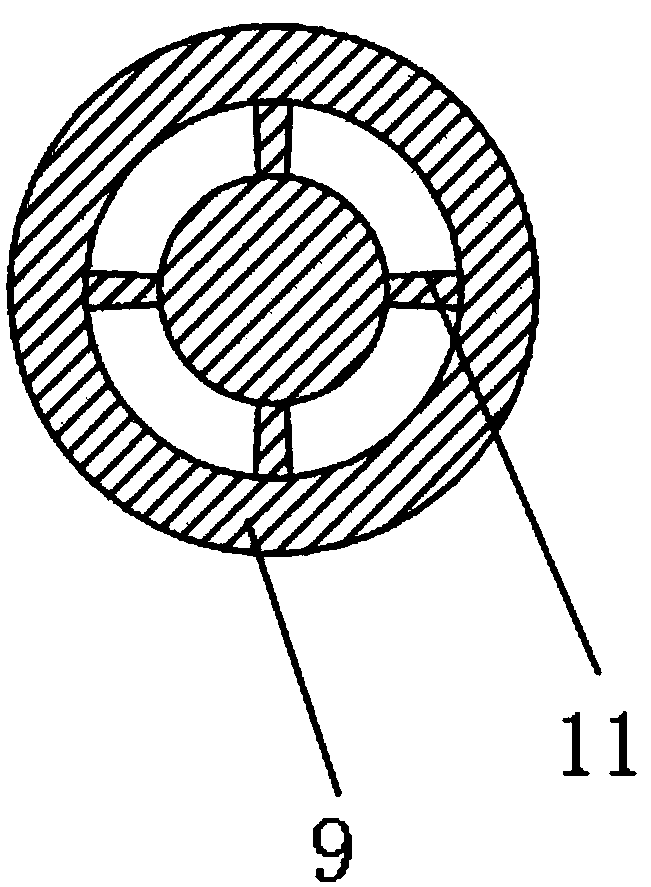

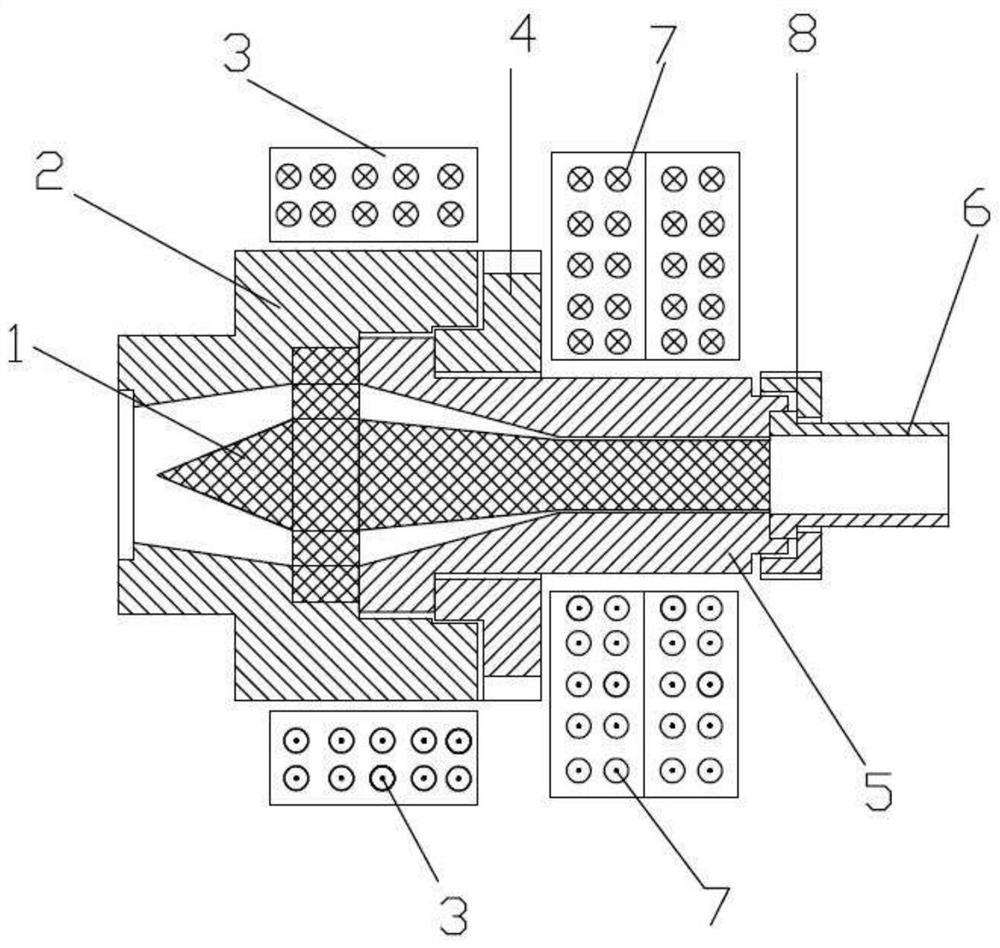

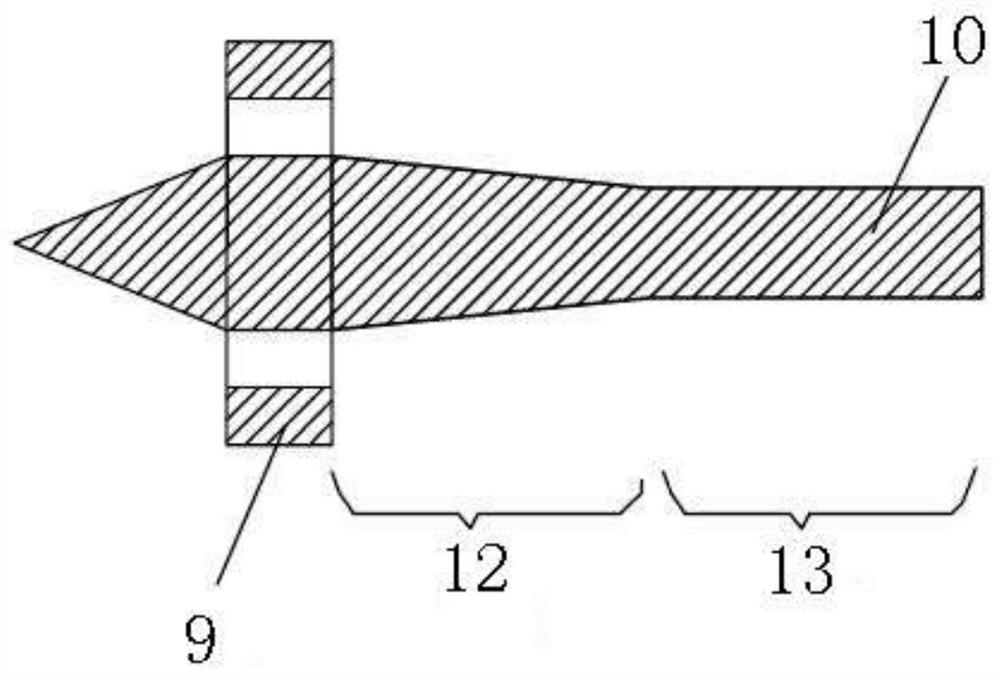

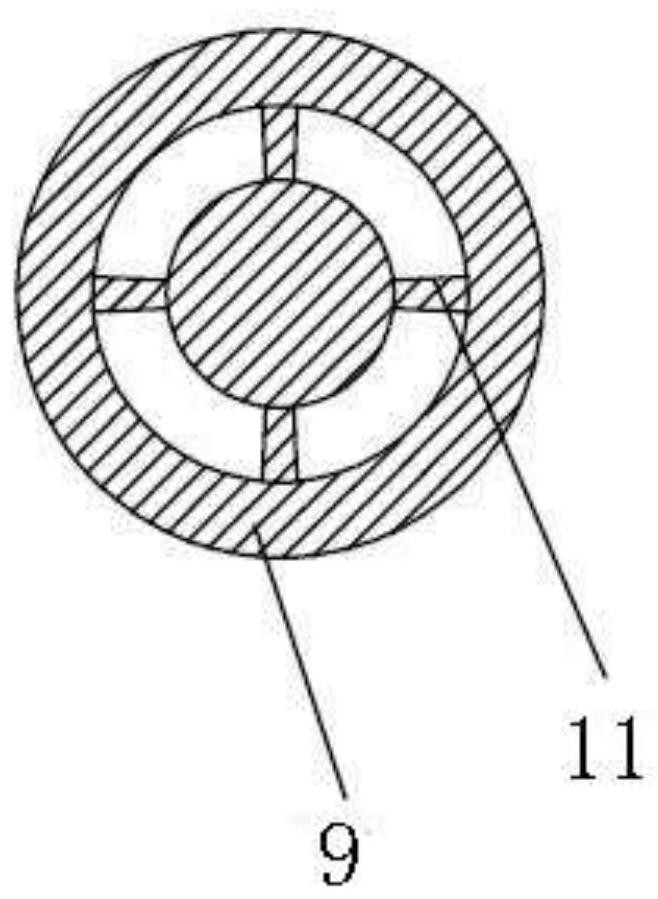

Large-strain mold integrating extrusion with C-mode equal channel angular pressing shear deformation

ActiveCN107321809AFlat surfaceEmphasis control functionExtrusion diesCrystal orientationMetallic materials

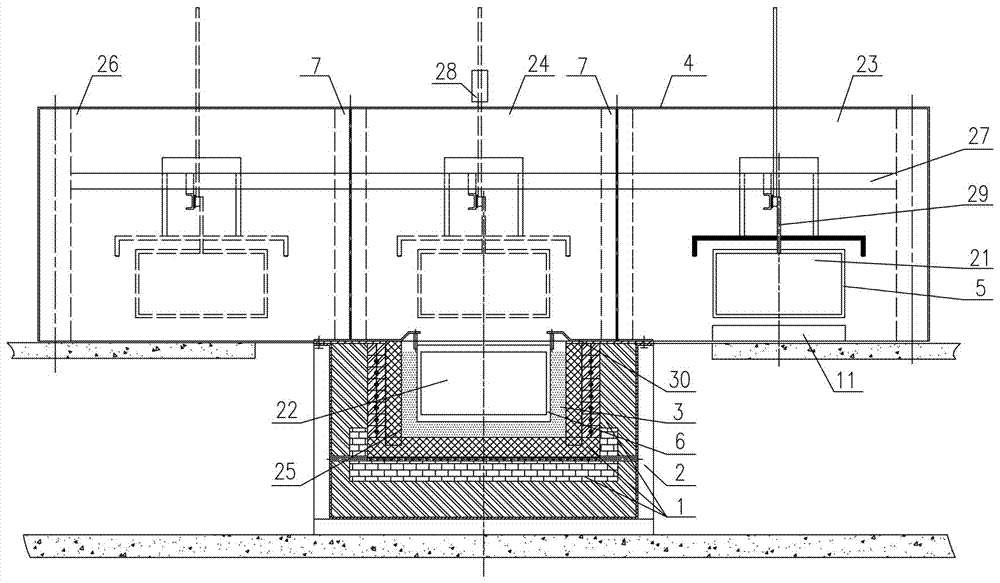

The invention discloses a large-strain mold integrating extrusion with C-mode equal channel angular pressing shear deformation. The large-strain mold comprises an upper mold base (7), a male mold fixing plate (9), a guiding rod (5), a male mold (10), a guiding sleeve (4), a front mold core (12), a back mold core (16), a female mold sleeve (13), a cushion block (14) and a lower mold base (2). The large-strain mold is characterized in that a cavity formed in the front mold core (12) and a cavity formed in the back mold core (16) are each composed of four portions, wherein each first portion is a segment of a cylinder, each second portion is a tapered variable-diameter hole, each third portion is composed of three segments of cylindrical equal channels intersecting with one another in sequence, the internal intersection angle formed through intersection of three segments of circular arcs is phi, and each fourth portion is a cylinder convenient for material mold stripping. According to the large-strain mold, the advantages of an extrusion technology and the advantages of an equal channel angular pressing technology are integrated, and efficient, continuous and steady surface levelling and uniform large-strain deformation machining having a high regulating function on crystal orientation can be conducted on a metal material.

Owner:JIANGSU UNIV

A kind of preparation method of carbon fiber precursor lignin/polylactic acid fiber

ActiveCN104911745BImprove qualityReduce manufacturing costConjugated synthetic polymer artificial filamentsCarbon fibersMelt spinning

The invention relates to a method for preparing a carbon fiber precursor lignin / polylactic acid fiber. The method comprises the following steps: carrying out intermittent heat treatment on purified lignin powder and polylactic acid slices in a vacuum drying oven; mixing the lignin powder subjected to heat treatment with the polylactic acid slices; pelleting at 160-250 DEG C through double screw rods to obtain lignin / polylactic acid composite master batches; and spinning the dried lignin / polylactic acid composite master batches at 190-250 DEG C through a melt-spinning machine, so as to obtain the carbon fiber precursor lignin / polylactic acid fiber. The carbon fiber precursor lignin / polylactic acid fiber provided by the invention has the advantages of renewable raw materials, excellent fiber quality, small diameter of obtained fiber, high strength and low cost; continuous production can be carried out; the carbon fiber precursor lignin / polylactic acid fiber is expected to be applied to the fields such as automobiles, high-speed rails, buildings and sports goods as a reinforcing material after being carbonized; and the market prospect is wide.

Owner:DONGHUA UNIV

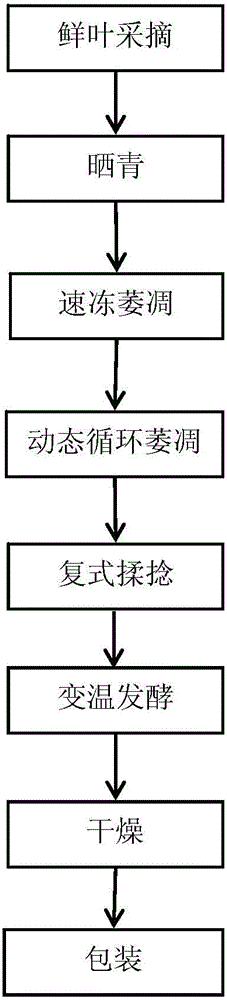

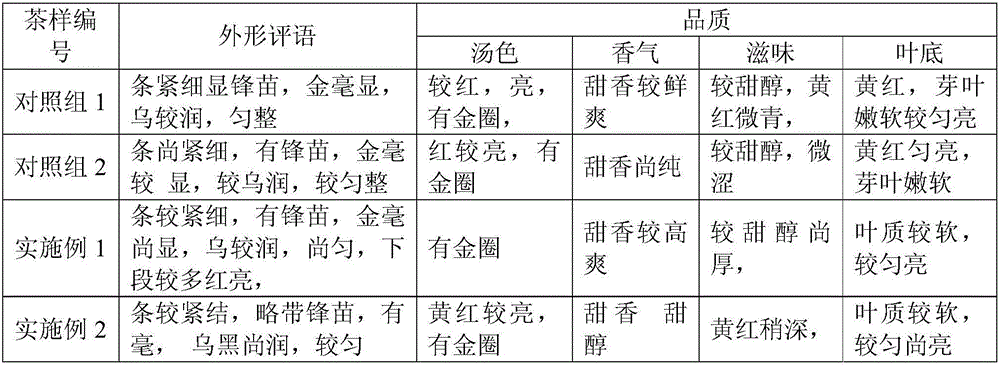

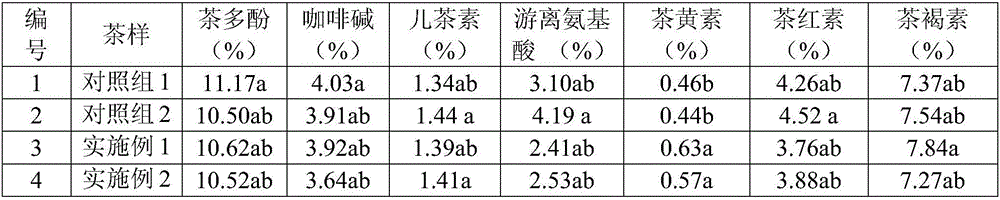

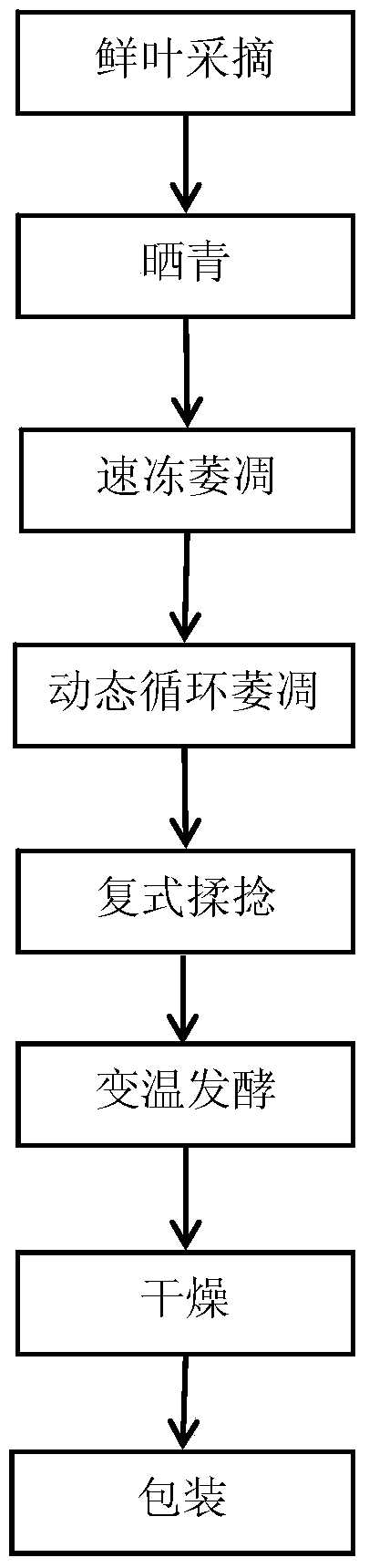

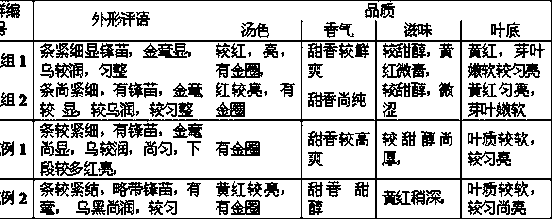

Automatic production process of flower fragrance type Kongfu black tea

ActiveCN106106869AAchieve a tight and even effectImprove processing qualityPre-extraction tea treatmentClimate change adaptationBlack teaFermentation

The invention discloses an automatic production process of flower fragrance type Kongfu black tea. The automatic production process comprises the following steps: picking fresh leaves, carrying out sun-withering in a sun-withering room, quickly freezing and withering, carrying out dynamic circulating withering on the fresh tea leaves by adopting a withering set, kneading by adopting a primary kneading-unblocking and sieving-re-kneading manner, carrying out temperature-variable fermentation, adopting a gross fire-re-moisturizing-complete fire manner, packaging and the like; automatic, continuous and clean processing requirements can be realized when a large-leaf tea variety is used for carrying out black tea processing and the quality of a product is guaranteed, so that the product has the quality style characteristics that strips are compact and uniform, the product has dark green color and luster and is glossy, the soup color is orange red and bright, the aroma is great and lasting, the taste is mellow and refreshing and infused leaf are bright and uniform; large-batch and continuous processing can be carried out when the large-leaf tea variety is processed into the Kongfu black tea.

Owner:广西西林京桂古道茶业有限公司

A method for continuously producing a hot extruded radiation ring

ActiveCN109166720AImprove pass rateImprove magnet performanceTransportation and packagingMetal-working apparatusAlloyQuenching

The invention relates to the technical field of manufacturing magnetic materials, in particular to a method for continuously producing a hot extrusion radiation ring, comprising the following steps: (1) preparing a nano composite phase fast-quenching belt by using a melt fast-quenching technology, and homogenizing and crushing the nano composite phase fast-quenching belt to prepare a hot-pressingmagnetic powder; (2), adding lubricant and mixing that homogeneou mixture, transferring the mixture to a hopper of a special extruder, and filling the mixture densely; (3) feeding into a continuous hot extrusion die, pressing into a hot pressing zone to obtain a full-density alloy, and then entering into a deformation zone to obtain a hot extrusion radiation ring. The invention skillfully places the hot pressing and the hot deformation of the hot extruding radiation ring in different segments in the same mold, The invention solves the problem that the hot-pressed radiation ring can not be continuously produced. The method has the advantages of high yield and material utilization ratio, uniform orientation, less grinding amount in the post-processing, greatly reducing the production cost and operation procedures, and is suitable for automatic batch production.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

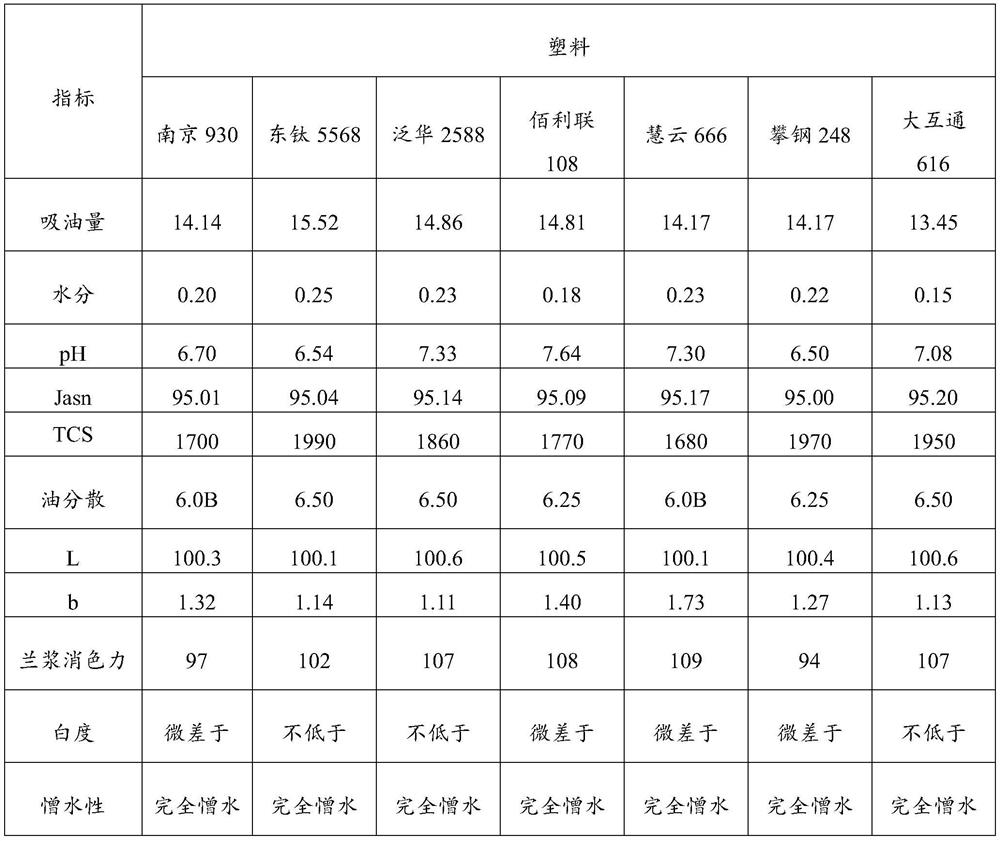

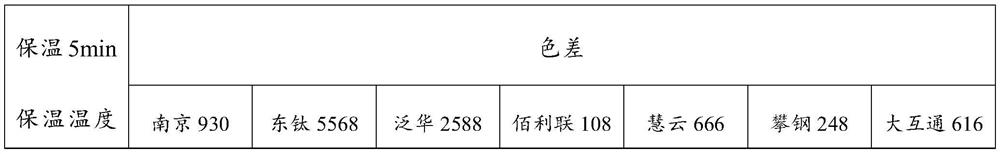

Color masterbatch plastic grade titanium dioxide and preparation method thereof

ActiveCN112646396AAvoid direct contactGood weather resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsOrganic filmMasterbatch

The invention provides color masterbatch plastic grade titanium dioxide which comprises an inner core and a coating layer coating the inner core, the inner core is titanium dioxide, and the coating layer comprises a first organic film layer coating the inner core, an inorganic film layer coating the first organic film layer and a second organic film layer coating the inorganic film layer. The preparation method of the titanium dioxide comprises the steps of pulping and dispersing, first organic coating, agent-free coating, filter pressing and second organic coating. According to the preparation method, surface coating and modification are carried out in a slurry state through organic matter before inorganic surface coating, so that the compatibility of titanium dioxide in an application system is greatly improved; in a flash evaporation drying link, amino silicone oil emulsion is adopted for further surface modification, and the compatibility and bonding force between powder particles and resin are enhanced; and a silane coupling agent is added in a steam flow crushing link for further modification, so that titanium dioxide particles are completely hydrophobic and oleophylic.

Owner:攀枝花大互通钛业有限公司

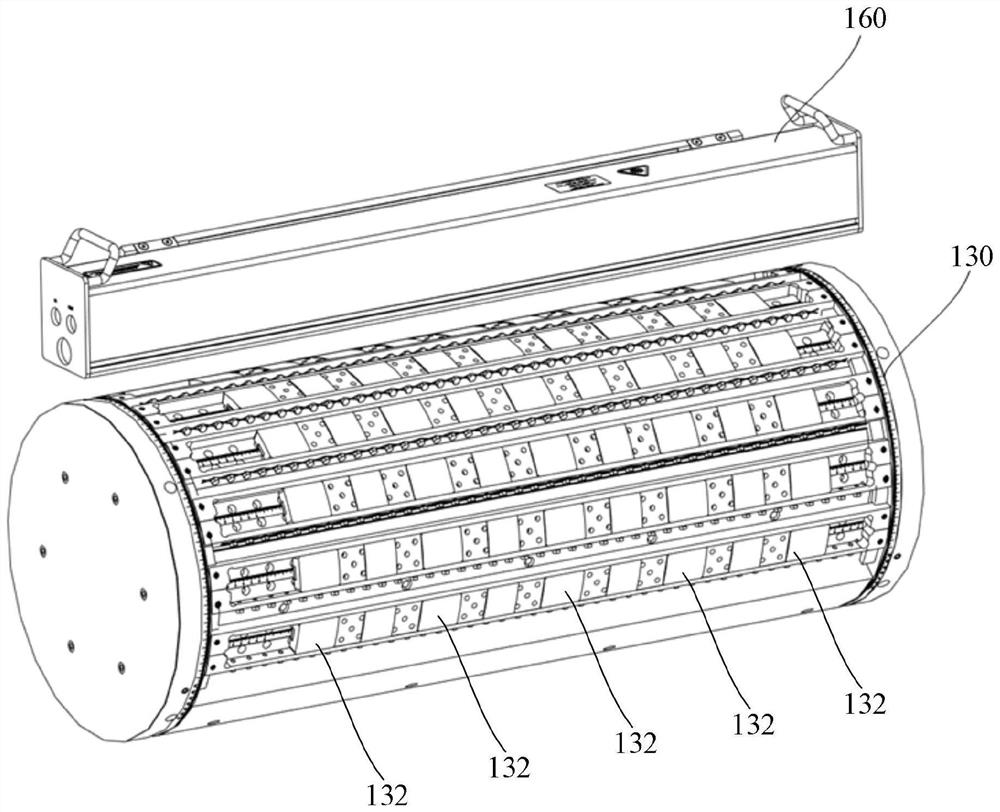

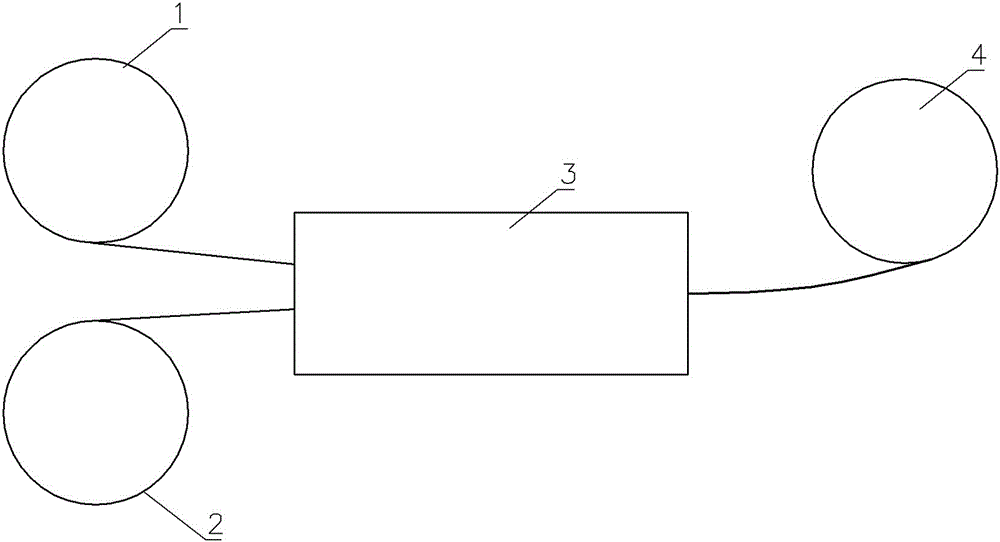

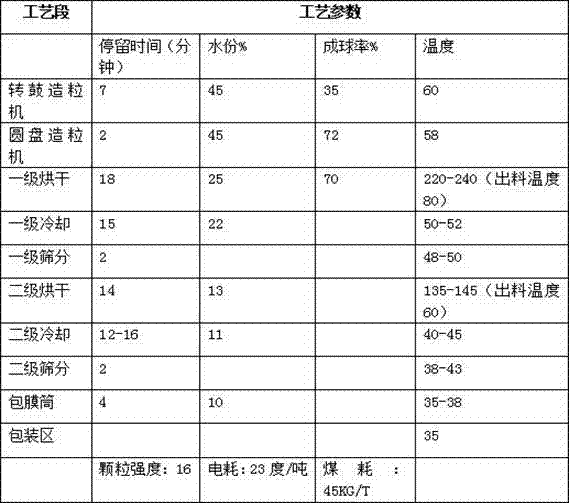

Multi-speed tail-drying-type mixed fertilizer granulation production process and special production equipment thereof

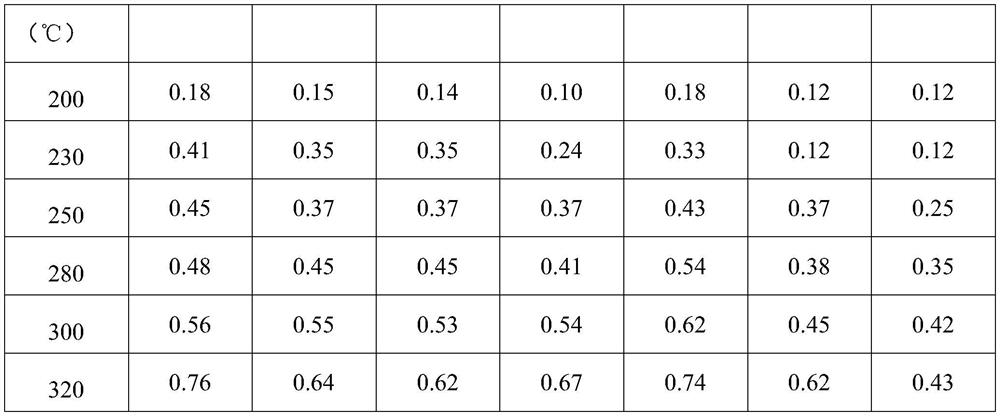

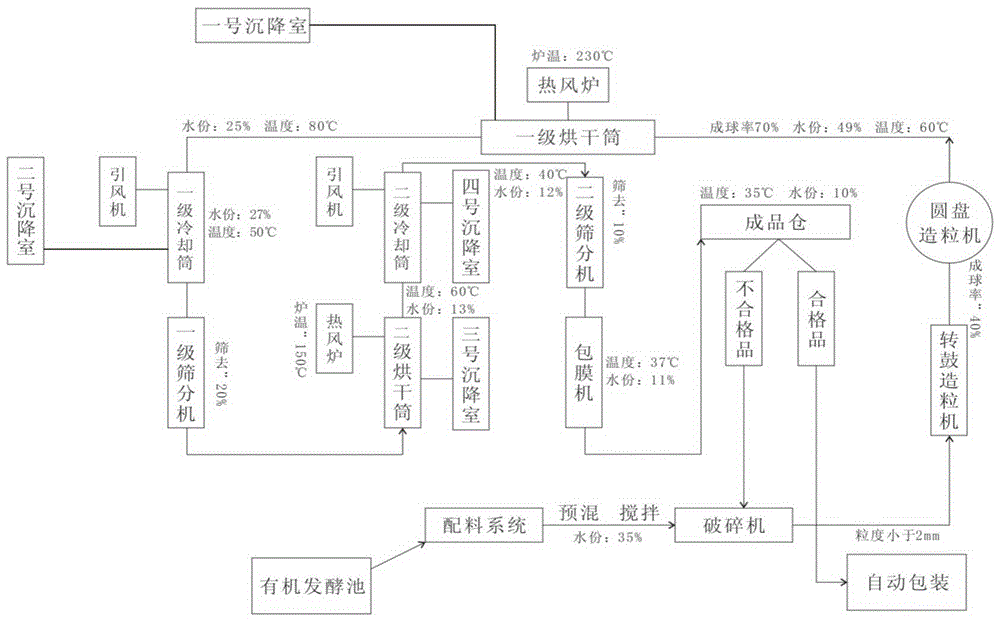

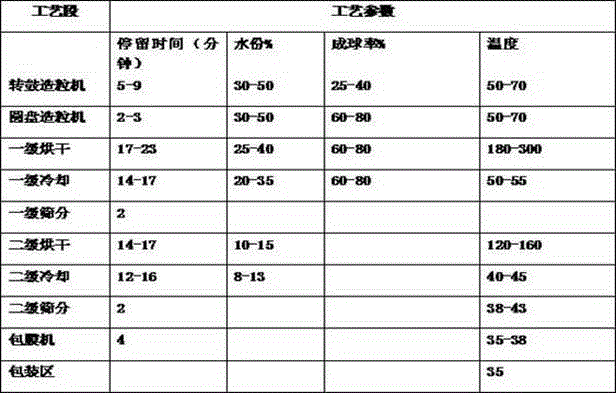

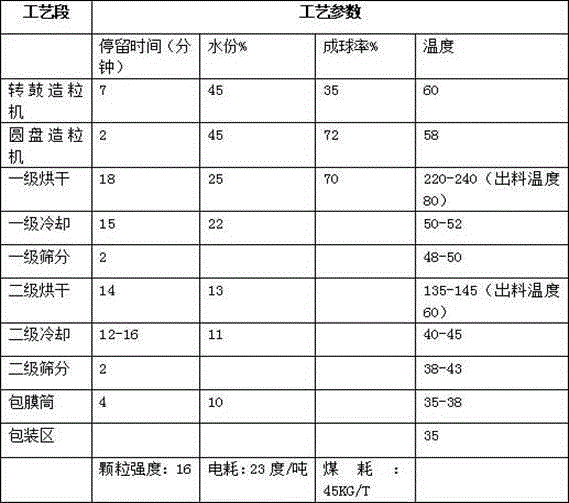

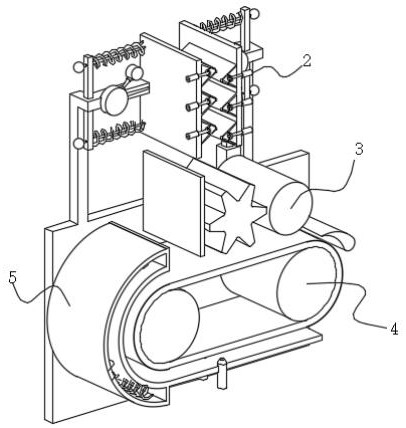

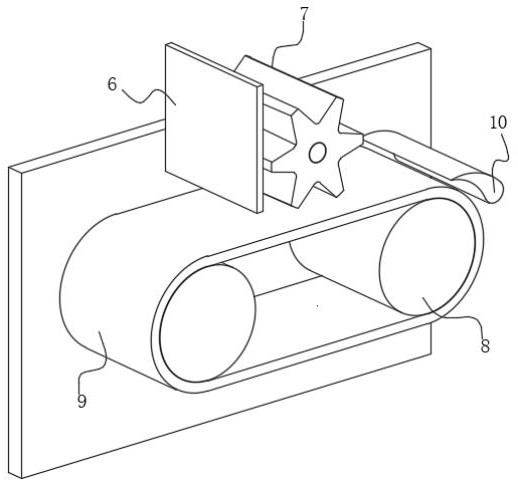

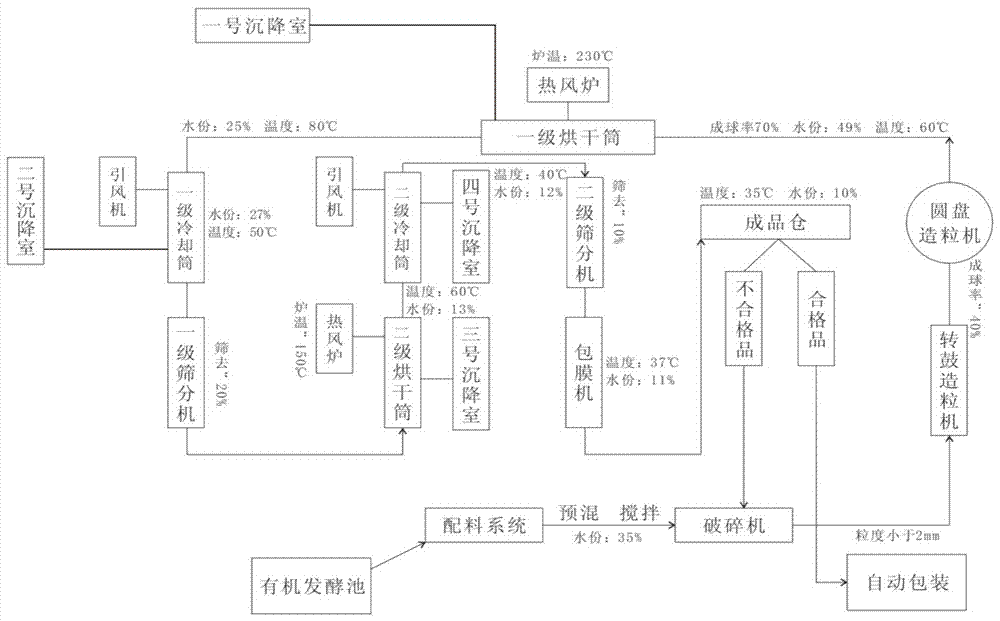

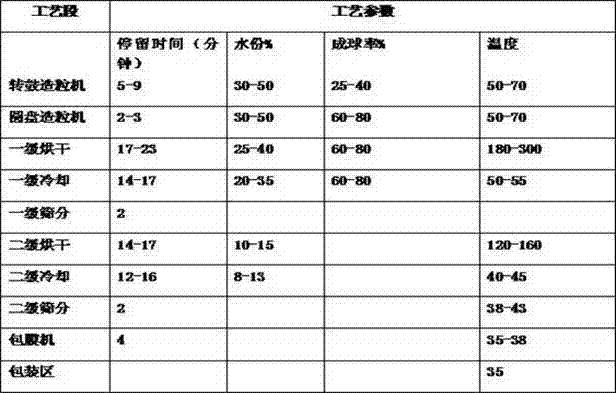

ActiveCN105198537AUniform temperatureSolve the problem of continuous productionFertilizer mixturesPrimary screeningCrusher

The invention relates to a multi-speed tail-drying-type mixed fertilizer granulation production process and special production equipment thereof. The special production equipment comprises a batching system, a crusher, a rotor drum granulator, a disc granulator, a primary drying drum, a primary cooling drum, a primary screening machine, a secondary drying drum, a secondary cooling drum, a secondary screening machine, a coating machine and a finished product warehouse, wherein the batching system, the crusher, the rotor drum granulator, the disc granulator, the primary drying drum, the primary cooling drum, the primary screening machine, the secondary drying drum, the secondary cooling drum, the secondary screening machine, the coating machine and the finished product warehouse are sequentially connected. The multi-speed tail-drying-type mixed fertilizer granulation production process and the special production equipment thereof provided by the invention have the advantages that the fertilizer particle granulation rate is high, the appearance is good, the water content is low, the roundness is high, the strength is high, no hardening occurs, the yield is high, organic fertilizers, inorganic fertilizers and organic and inorganic mixed fertilizers can be produced, the negative effect of the conventional process is solved, the industrial blank is filled and the popularization and application are greatly facilitated.

Owner:济宁中农大化肥业股份有限公司 +2

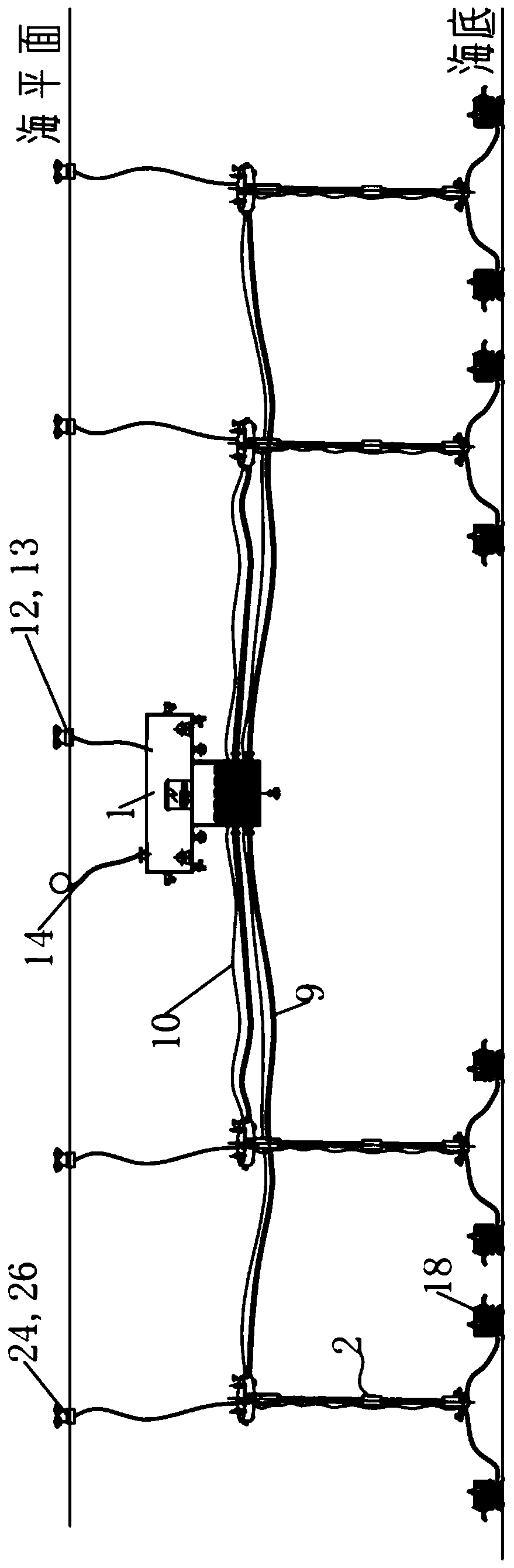

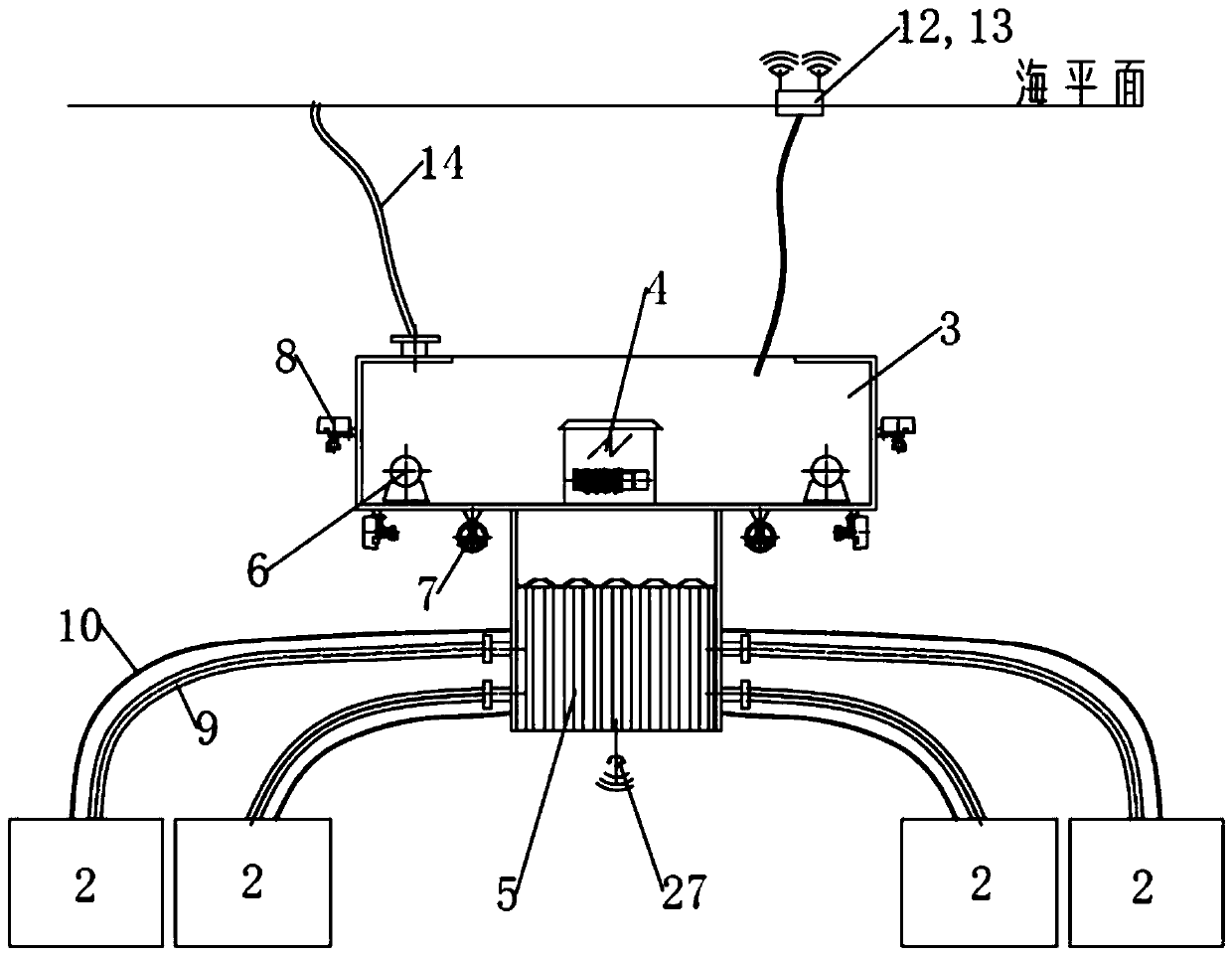

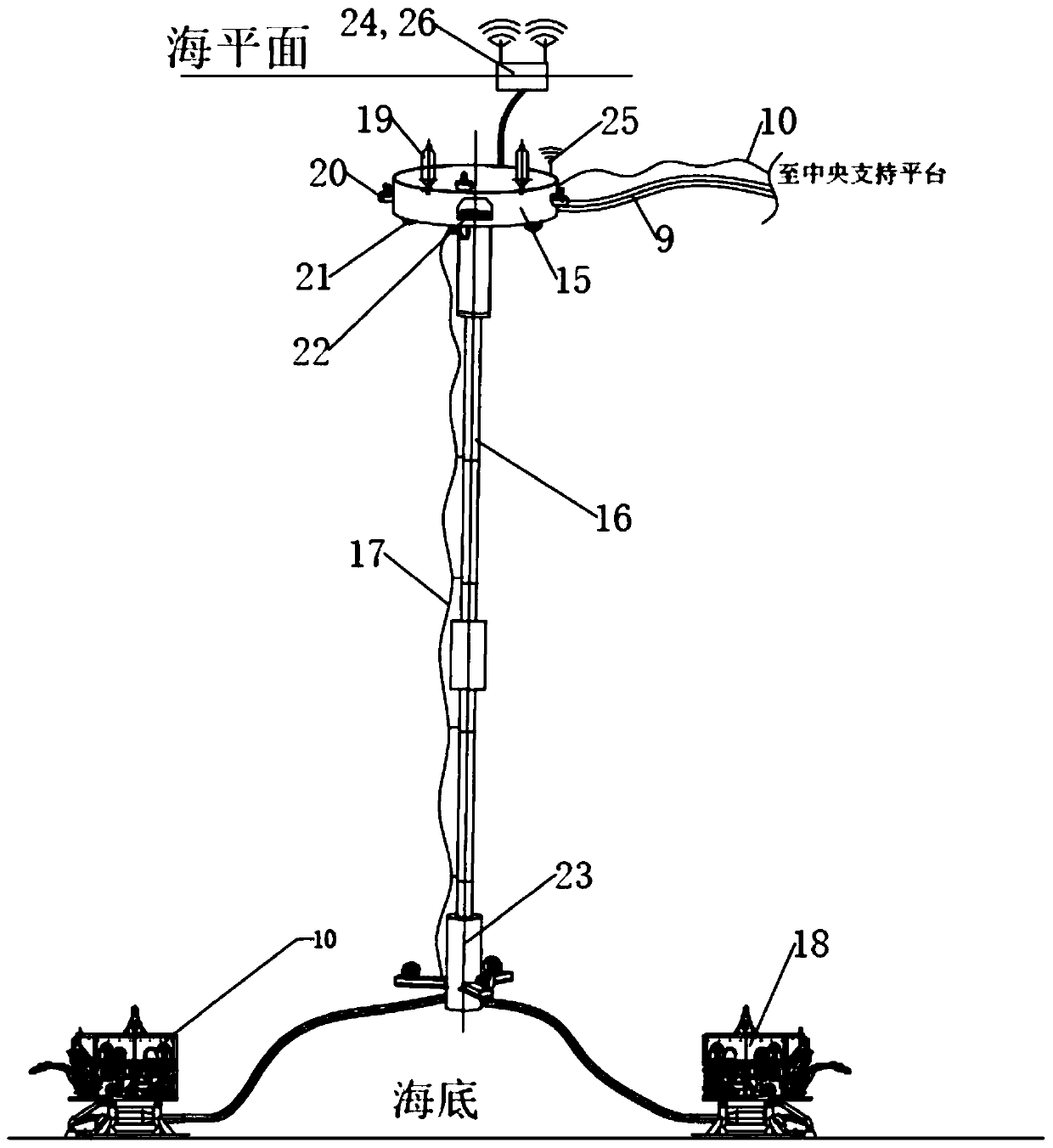

Distributed all-weather deep-sea mining system

PendingCN110242303ASolve dodging the stormSolve productivityMineral miningDeep sea miningMarine engineering

The invention provides a distributed all-weather deep-sea mining system. The distributed all-weather deep-sea mining system comprises a center supporting platform and a plurality of satellite mining lifting systems, and the center supporting platform is combined with the multiple satellite mining lifting systems for cooperative work; the center supporting platform has an underwater work mode for bad sea conditions and a water surface work mode for good sea conditions; and each satellite mining lifting system conveys collected mine sand to the center supporting platform. The distributed all-weather deep-sea mining system can dive into water for work, the purposes of eluding windstorms and continuous production under bad weather are realized, in addition, a distributed cluster operation mode realizes simultaneous operation of one center supporting platform matched with multiple mine collecting machines, and the operation efficiency is high.

Owner:北京先驱高技术开发有限责任公司

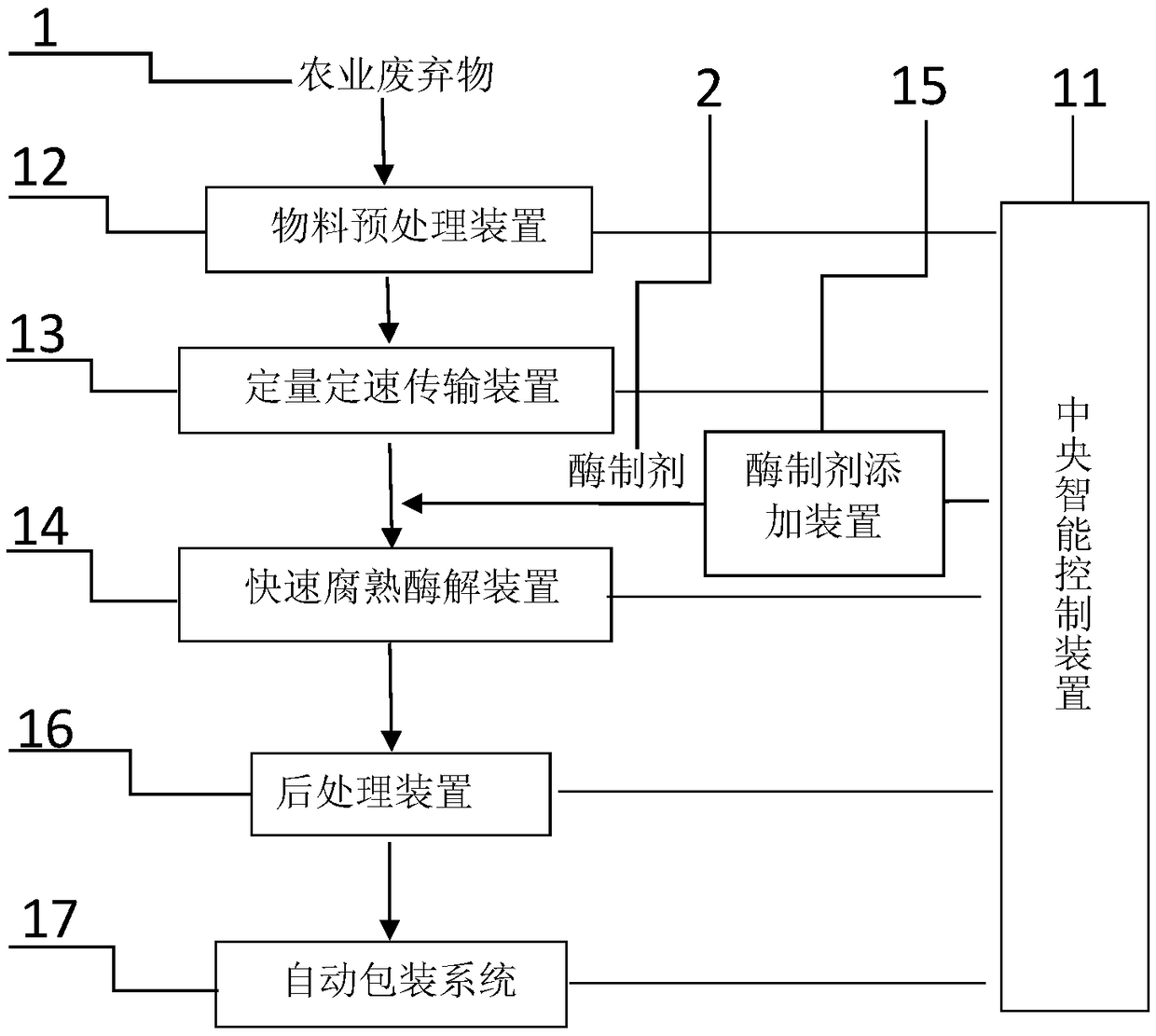

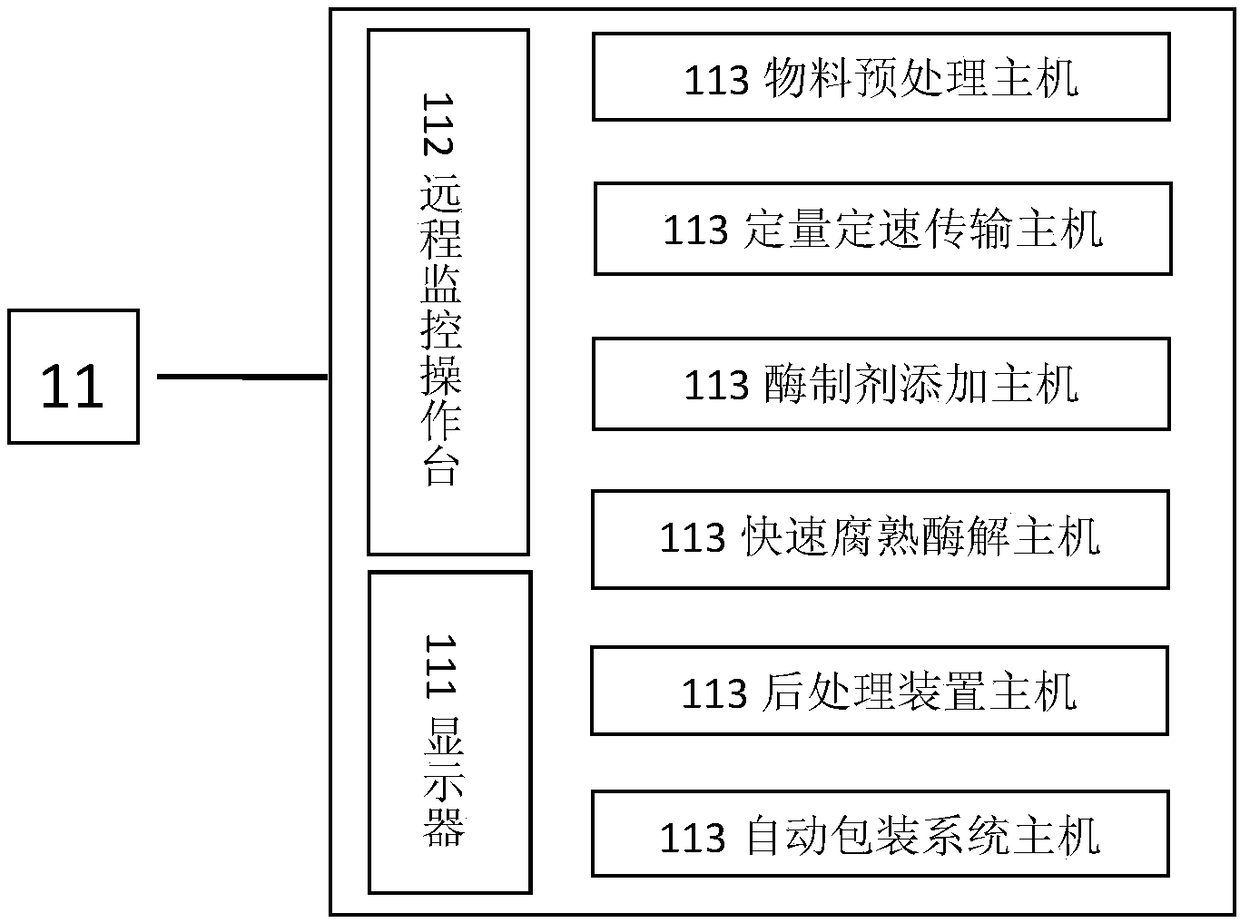

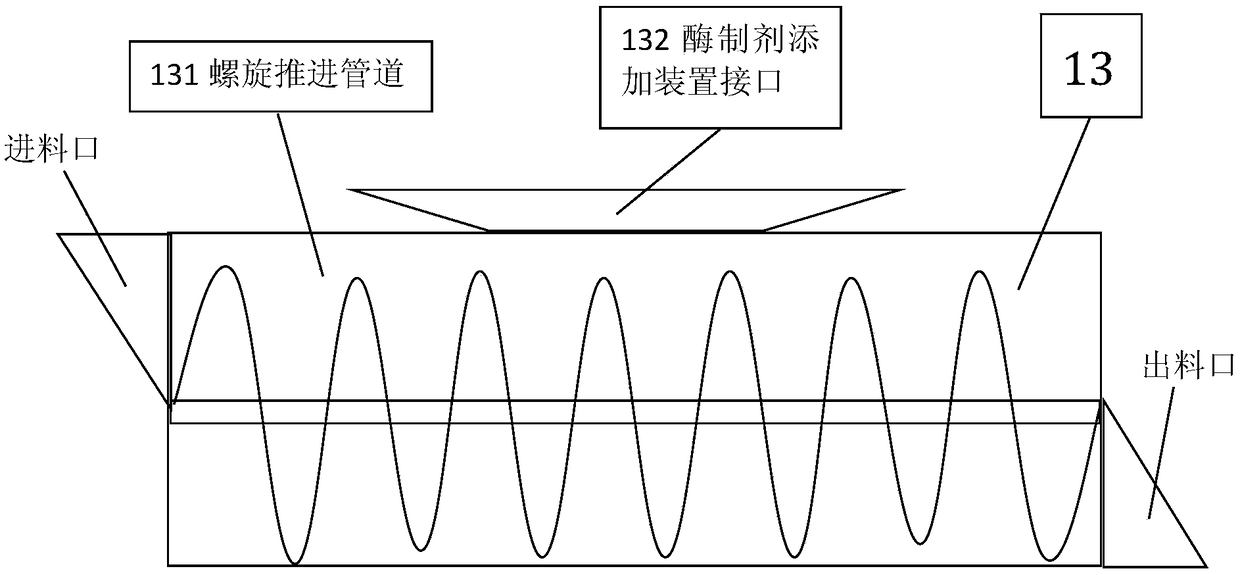

Continuous rapid organic fertilizer production process with agricultural waste enzymolysis method

InactiveCN109053246AShort maturation timeShort duration of actionMicroorganism based treatmentOrganic fertiliser apparatusControl systemTechnological system

The invention discloses a continuous rapid organic fertilizer production process with an agricultural waste enzymolysis method. A set of continuous rapid organic fertilizer production process with thecombination of an enzymolysis method and an automatic mechanical equipment control system is implemented; the enzymolysis method mainly refers to that multiple enzyme preparations of different functions are used in the production process, materials are subjected to enzymolysis under a specific temperature condition, and rapid composting of the materials can be achieved; the automatic mechanical equipment control system comprises a central intelligent control device, a material pretreatment device, a quantitative fixed-speed conveying device, an enzyme preparation addition device, a rapid composting enzymolyiss device, an aftertreatment device and an automatic packaging system. By adopting the technical systems, the novel process for rapid composting and continuous production of agricultural waste materials can be achieved.

Owner:鑫宏润(天津)农业生物技术服务有限公司

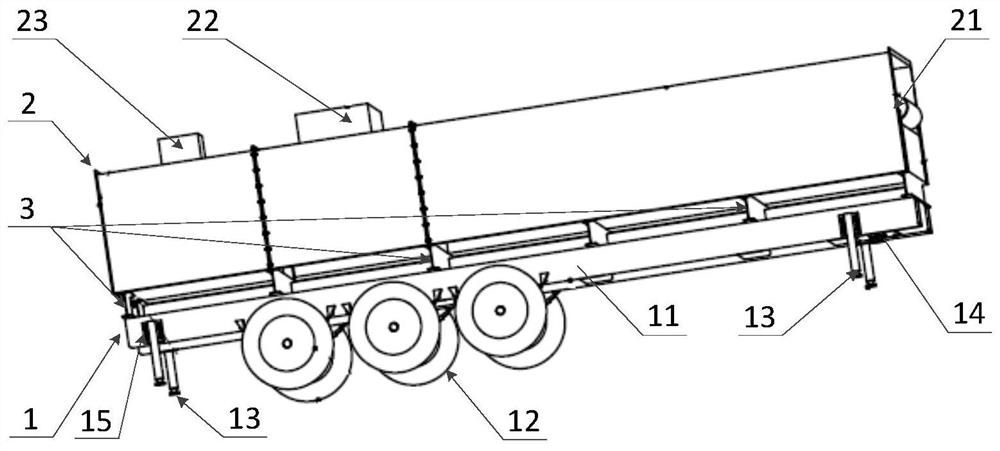

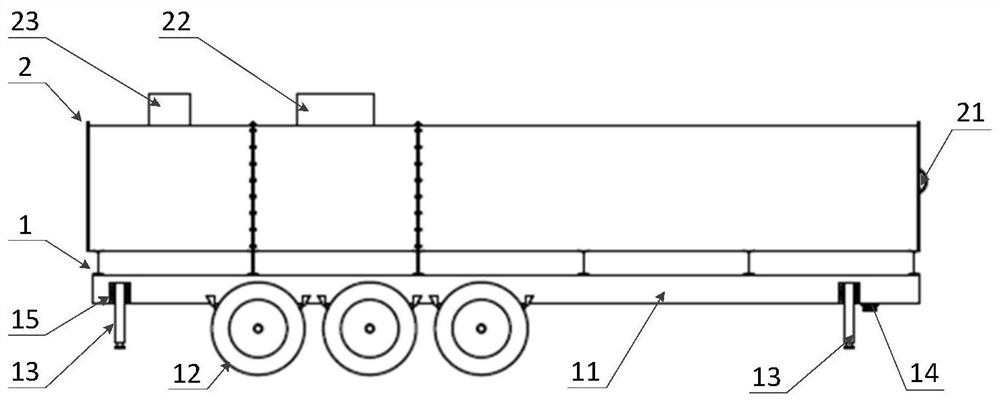

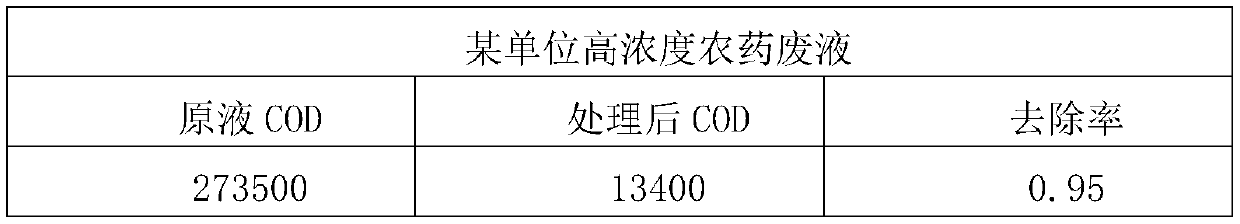

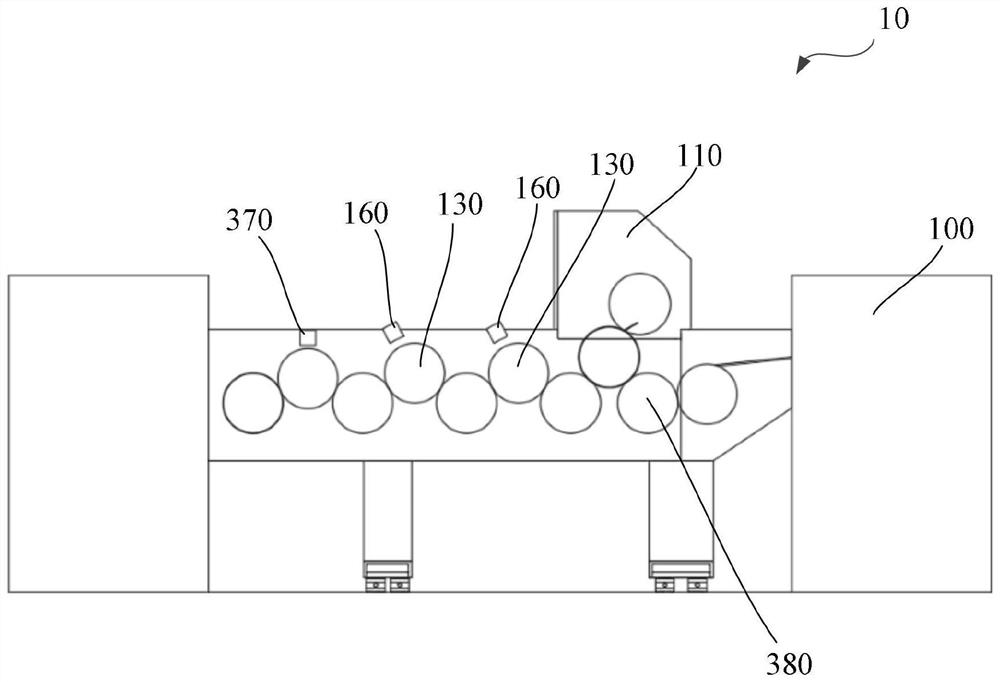

Movable sorting device

PendingCN113500016AAvoid sorting confusionGuaranteed stabilityPortable framesSortingControl engineeringProcess engineering

The invention provides a movable sorting device. The sorting device comprises a movable chassis and a sorting main machine; the sorting main machine is arranged on the movable chassis, and is used for sorting materials; the movable chassis has a walking state and a fixed supporting state; in the walking state, the movable chassis is used for driving the sorting main machine to move so as to switch working positions; and in the fixed supporting state, the movable chassis is used for providing fixed supporting for the sorting main machine so that the sorting main machine can sort the materials. According to the movable sorting device, the sorting main machine is supported through the movable chassis with the walking state and the fixed supporting state, in the walking state, the movable chassis can drive the sorting main machine to move so as to switch the working positions, and the problem that continuous production is affected by change of a fixed material receiving point or a material stacking point is solved; and in the fixed supporting state, the movable chassis provides fixed supporting for the sorting main machine, so that the stability of the sorting main machine is ensured, and material sorting is conducted.

Owner:HUZHOU HONEST INTELLIGENT TECH CO LTD

Method for preparing hard xylitol candy

InactiveCN108208285AReduce the temperatureReduce energy consumptionFood thermal treatmentConfectionerySugarEnergy consumption

The invention discloses a method for preparing hard xylitol candy. The method comprises the following steps: weighing 90% of a formula amount of xylitol, heating the weighed xylitol to 100 DEG C in order to melt the xylitol, and performing heat insulation at 93-95 DEG C; adding other raw materials and auxiliary materials to the obtained sugar solution in a heat insulation state, and performing heat insulation; stirring all above materials, adding the remaining 10% of the formula amount of xylitol, and performing uniform stirring; allowing the obtained sugar solution to automatically flow intoa casting trough through a 92-96 DEG C interlayer heat insulation pipeline; and cooling, demolding and packaging the sugar solution. The method solves a problem that the hard xylitol candy cannot be continuously produced for a long term. The casting temperature is increased, so the crystallizing and demolding time is prolonged, the obtained product has fine particles, a uniform size and a beautiful appearance, the yield is large, and the energy consumption is low.

Owner:李圣仓

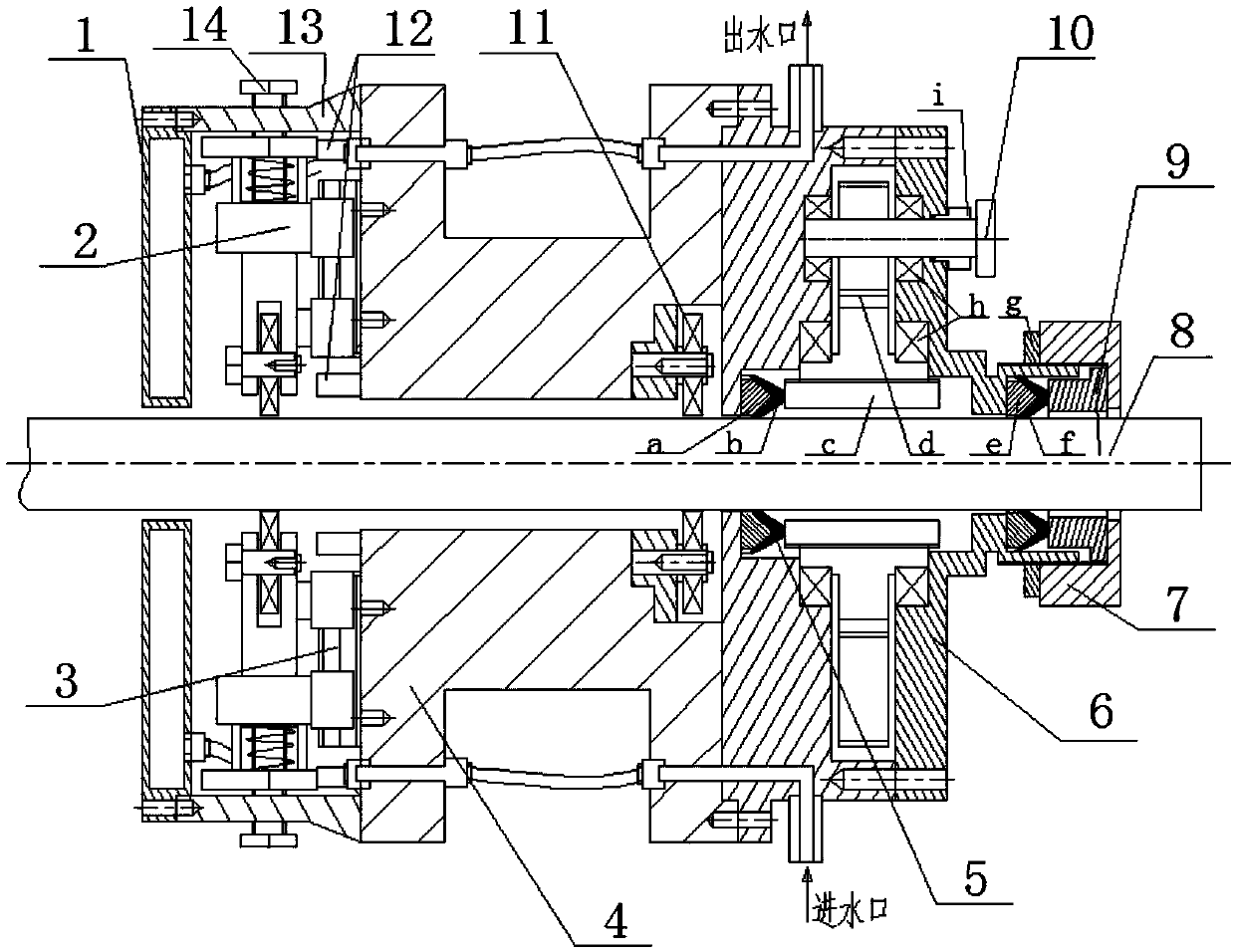

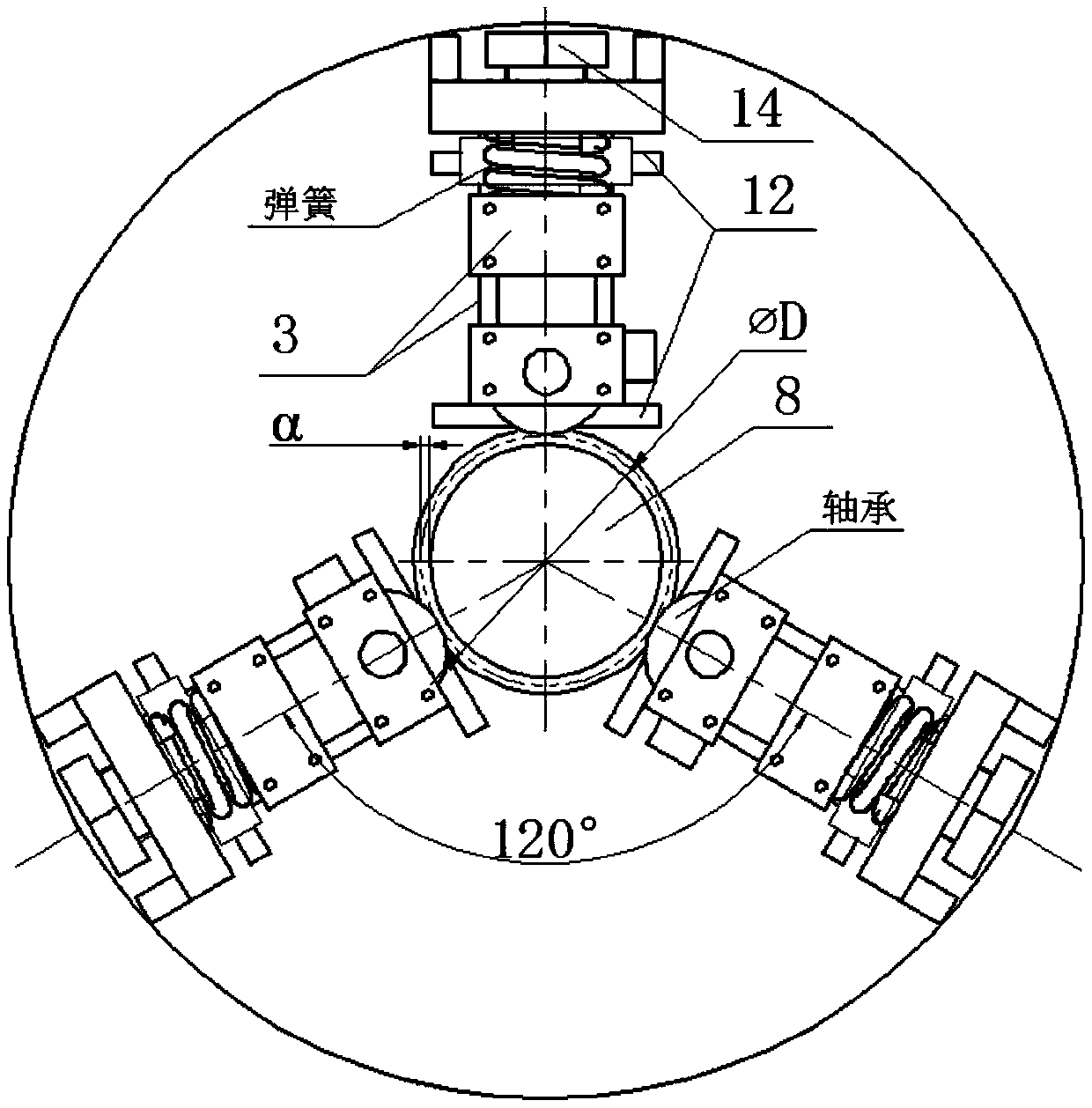

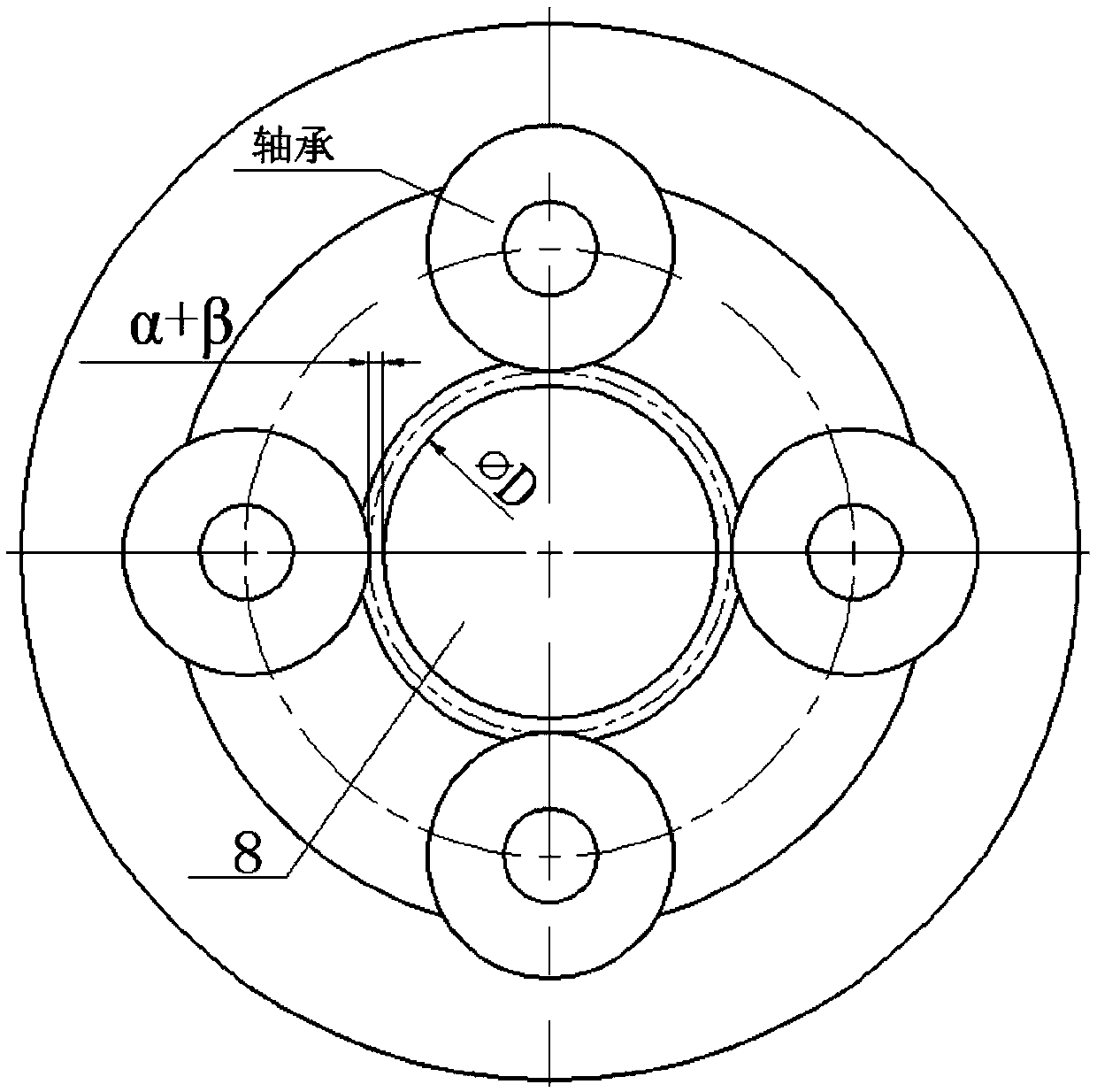

Double-layer dynamic seal device with damping function

PendingCN109595341AReduced precision requirementsReduce noiseEngine sealsNon-rotating vibration suppressionVacuum pumpingDamping function

The invention relates to a double-layer dynamic seal device with a damping function. According to an existing dynamic seal, a rigidity mechanism is adopted for support, huge noise is generated, and adverse influences are generated to the environment. In addition, most of existing dynamic seals adopt single-layer seal structures, and consequently the production efficiency is low. The double-layer dynamic seal device comprises a main fixing round shaft sleeve, and is characterized in that a front damping bearing supporting mechanism is arranged at the front end of the main fixing round shaft sleeve, a double-layer seal structure is fixed to the rear end of the main fixing round shaft sleeve and comprises an inner-layer seal mechanism and an outer-layer seal mechanism, and independent seal performance of the inner-layer seal mechanism and the outer-layer seal mechanism can be adjusted through an adjusting mechanism. The double-layer dynamic seal device solves the problems that due to sealring abrasion, continuous feeding cannot be achieved, and due to repeated vacuum pumping, the production efficiency is low.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

A kind of preparation method of lignin-based carbon fiber

ActiveCN104593906BImprove spinnabilityImprove fiber qualityArtificial filament chemical after-treatmentCeramic membraneMelt spinning

The invention provides a preparation method of a lignin-based carbon fiber. The preparation method of the lignin-based carbon fiber comprises the following steps: dissolving lignin in an alkaline solution, filtering by using a ceramic membrane filtration device, adjusting pH value of a filtrate until the filtrate is acidic to obtain a lignin precipitate, washing and drying the lignin precipitate to obtain purified lignin; extruding the dried and purified lignin at 100-260 DEG C by a twin-screw extruder, removing volatile components and prilling; taking a thermoplastics polymer as a skin layer, taking lignin slices as a core layer to melt and spin by a melting and spinning device, wherein the spinning temperature of the thermoplastics polymer is 160-350 DEG C; the spinning temperature of the lignin is 160-260 DEG C; the mass ratio of the thermoplastics polymer adopted by the skin layer to the lignin slices adopted by the core layer is (1 to 9)-(9 to 1); oiling, curing, pre-oxidizing and carbonizing the fiber with a skin-core structure to obtain the lignin-based carbon fiber. The lignin-based carbon fiber has the advantages of being high in spinning property, small in diameter, high in strength, low in production cost and applicable to continuous production.

Owner:DONGHUA UNIV

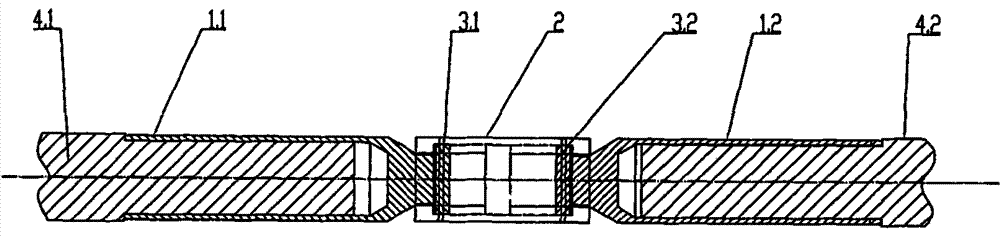

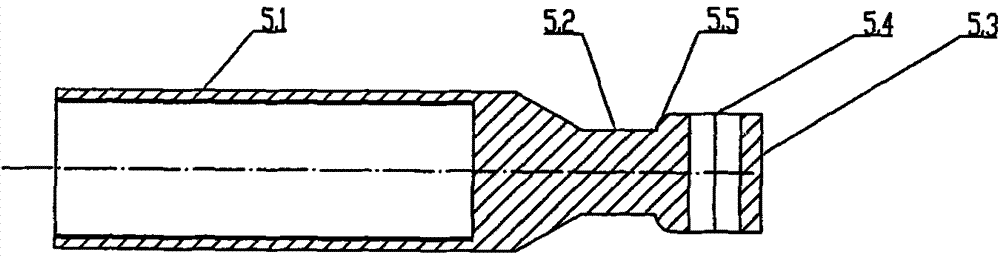

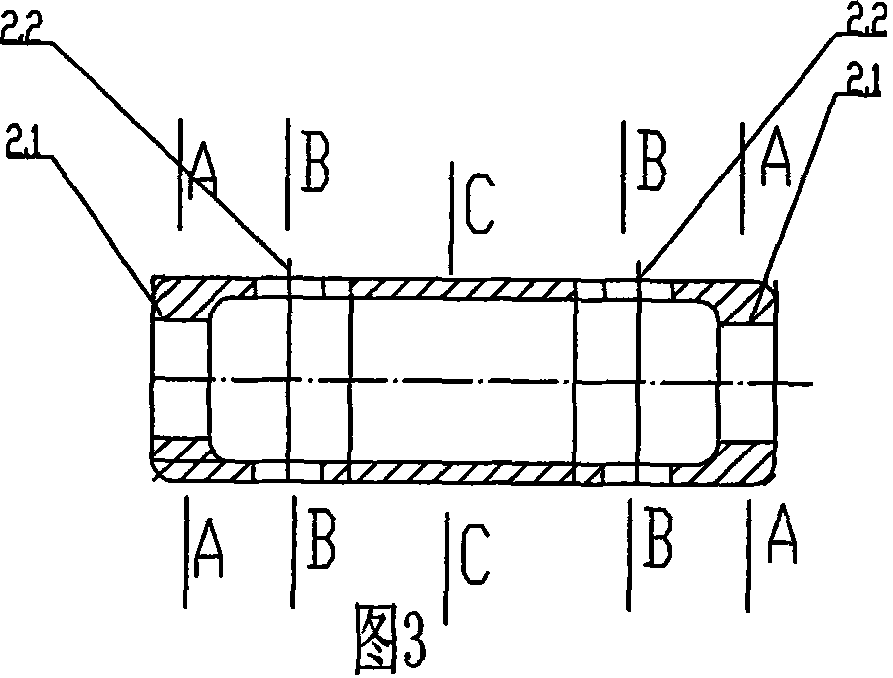

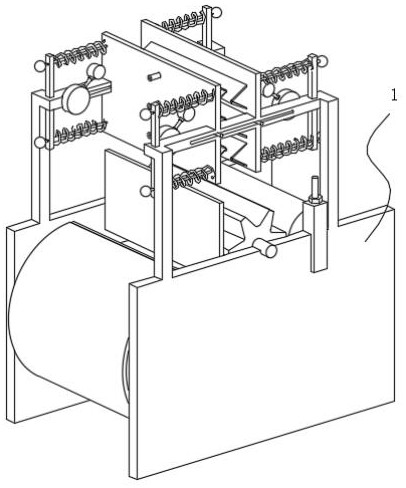

Conductor connector for catenary continuous vulcanization of cross-linked cables and catenary continuous vulcanization preparation method for cross-linked cables

ActiveCN101728032BWill not twistRealize continuous production without stoppingInsulating conductors/cablesCross-linkVulcanization

The invention relates to a discontinuous conductor connector for catenary continuous vulcanization (CCV) production of cross-linked cables and a non-stop connection preparation method. The connector is characterized in that front and rear splicing conductors are provided with a compaction sleeve respectively; one end of the compaction sleeve is in rotatable traction connection with a connecting sleeve or a connecting rod mutually or respectively; a connecting coincidence part is provided with insertable pins so as to form a conductor connector; after a front conductor and a rear conductor areassembled and connected, the conductor connector ensures that connected front and rear conductors can rotate respectively; and after the conductor connector is subject to up traction, the pins are immediately inserted to ensure that the front and rear conductors can only synchronously rotate. The connector and the preparation method can realize the CCV non-stop multi-conductor splicing continuousproduction of the cross-linked cables, avoid the waste caused by the on / off of each conductor, also greatly improve production efficiency, and solve the problem puzzled for a long time that the continuous production cannot be performed during cross-linking CCV production.

Owner:FAR EAST CABLE +2

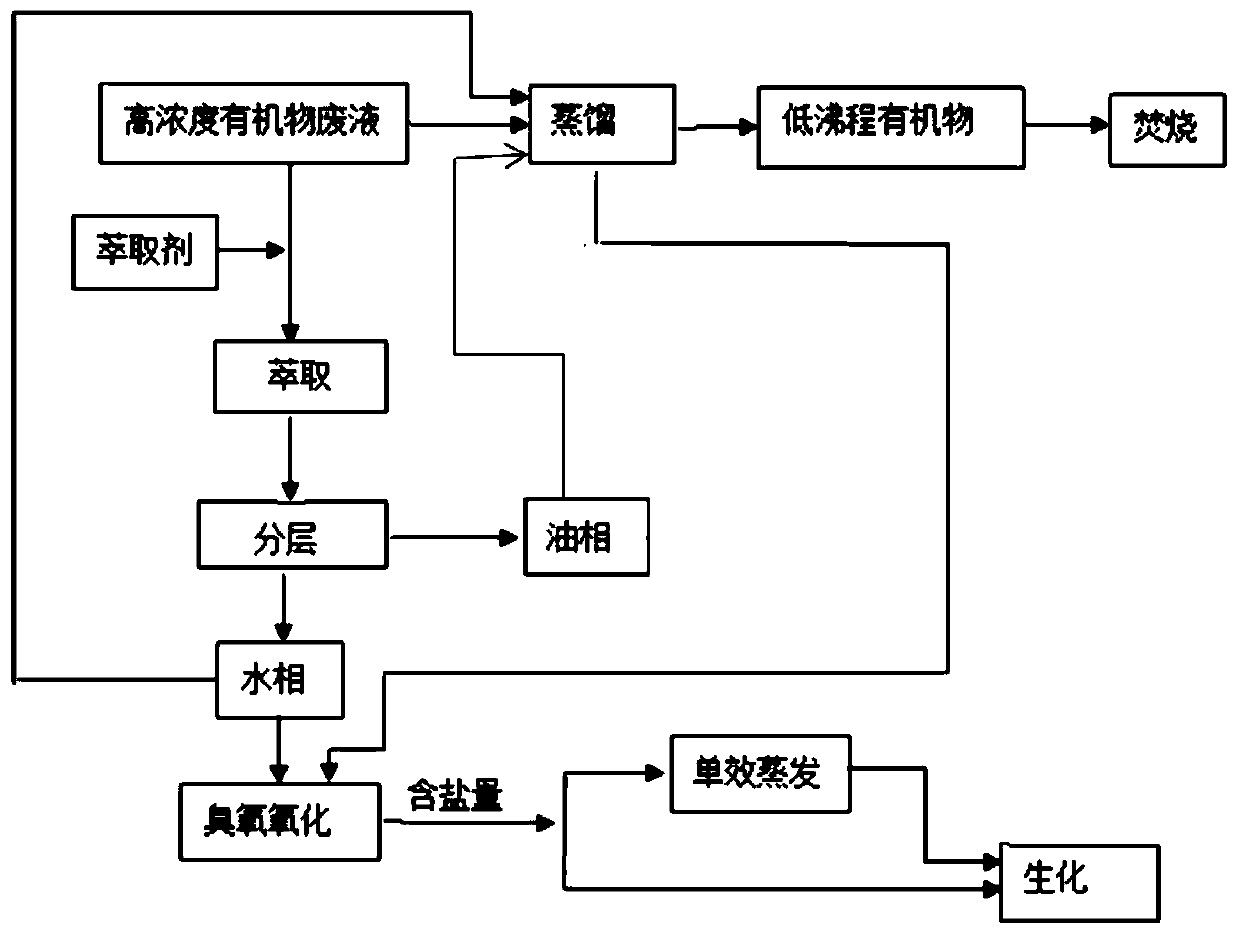

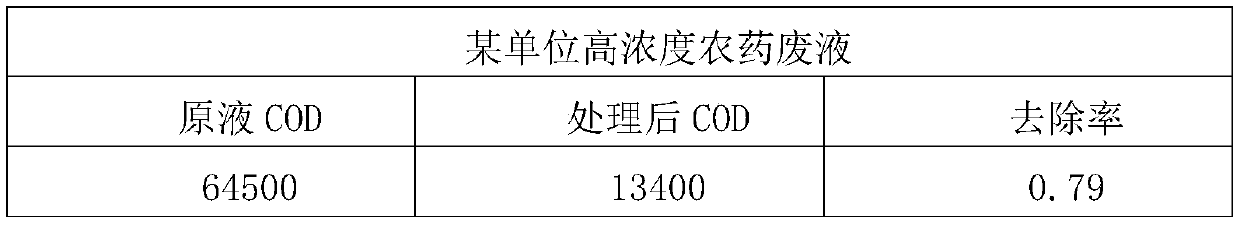

Harmless treatment method for high-concentration pesticide organic waste liquid

InactiveCN111484195ARelieve pressureReduce processWater contaminantsMultistage water/sewage treatmentExtractive distillationEnvironmental engineering

The invention discloses a harmless treatment method of high-concentration pesticide organic waste liquid, the harmless treatment method is divided into a channel a and a channel b for harmless treatment according to the components of the high-concentration pesticide organic waste liquid, and comprises the following steps: (a1) introducing the high-concentration pesticide organic waste liquid intoa distillation kettle, (a2) enabling the waste liquid in the step (a1) to enter an ozone oxidation section and then enter a biochemical facility, (b1) feeding the high-concentration pesticide organicwaste liquid and an extraction agent into a static mixer according to a flow ratio, then feeding into a separation tower, and enabling an oil phase to flow out from the upper part and a water phase toflow out from the lower part, (b2) feeding the oil phase into a simple distillation kettle, and (b3) enabling the water phase to enter an ozone oxidation section. The high-concentration pesticide organic waste liquid is subjected to effective pretreatment through extractive distillation before being subjected to catalytic ozonation and advanced oxidation, it is guaranteed that the high-concentration pesticide organic waste liquid enters ozone catalysis with a stable medium, the treatment pressure and the process burden of a workshop section are relieved by prolonging a process route, and thetreatment efficiency and the running state of equipment and facilities are effectively improved.

Owner:南京卓越环保科技有限公司

Multi-color light-variable printing device, printing method thereof and readable storage medium

PendingCN114801436ASolve the problem of continuous productionMagnetic bodiesScreen printersScreen printingEngineering

The invention provides a multi-color light-variable printing device, a printing method thereof and a readable storage medium. The multi-color light-variable printing device comprises a conveying unit, a printing unit and a printing unit, the silk-screen printing unit is used for printing ink or varnish containing magnetic substances on a printing stock; and a plurality of brilliant and light-variable pattern forming units, each brilliant and light-variable pattern forming unit comprises a magnetization roller, a magnetic orientation component is arranged on the magnetization roller, and the magnetic orientation component is used for carrying out magnetic orientation on the printing stock; the pre-drying curing device is used for pre-drying and curing the printing stock, the pre-drying curing device comprises an optical mask curing device, the optical mask curing device is fixedly arranged and is used for projecting a dynamic and refreshable variable light field image-text, and the variable light field image-text and the printing stock synchronously move by a preset distance. By means of the technical scheme, all-directional splicing, namely splicing in any direction, of fixed type and variable type multi-color light-variable images and texts can be completed.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

Corrugated paper core and honeycomb paper core cork surface layer composite board manufacturing processes

InactiveCN104985911AAchieving production quality stability issuesSolve the problem of continuous productionLaminationLamination apparatusProduction lineSurface layer

A corrugated paper core cork surface layer composite board manufacturing process comprises the following steps of: gluing a cork coil material and a paper coil material together by using a gluing device, winding the glued material to form a flexible cork and paper composite coil material; and placing the cork and paper composite coil material, as a surface layer paper for producing corrugated carbon boards, into an existing continuous production line of carton boards, and gluing the material with the corrugated paper core to make the cork surface layer composite board that has the cork layer as the surface layer and has the corrugated paper core inside. According to the process, firstly the cork coil material and the paper coil material are glued by using the gluing device to form the flexible cork and paper composite coil material; adding of the paper greatly improves the resilience of the composite coil material, thereby ensuring continuity of the following production; the cork and paper composite coil material is delivered as the surface layer of the corrugated paper core carton board to the continuous production line of corrugated paper core carton boards, so as to implement continuous production of the corrugated paper core cork composite board, thereby solving the continuous production problem of cork boards.

Owner:曹杜华 +1

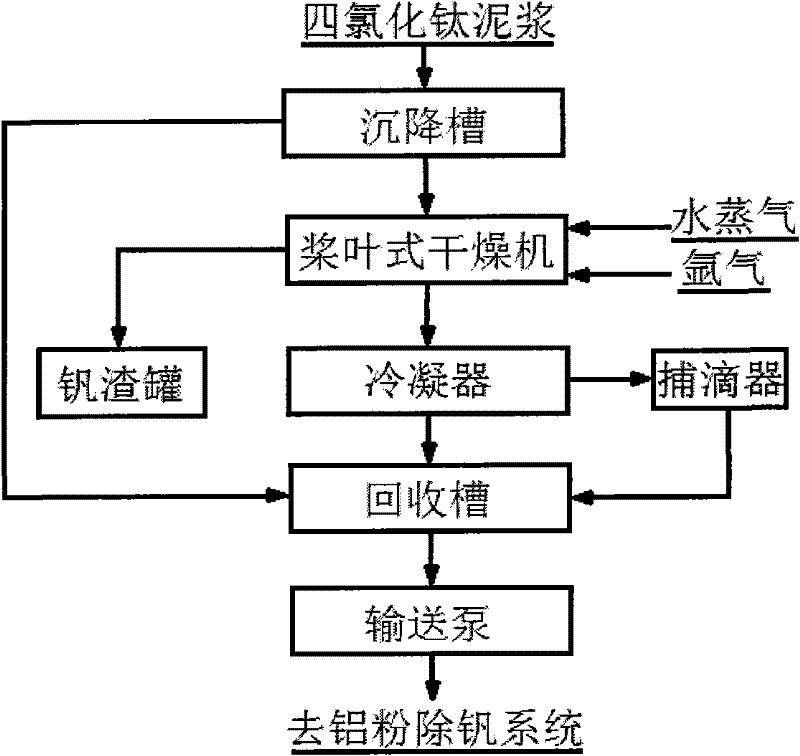

Method for recovering titanium tetrachloride

Owner:JINCHUAN GROUP LIMITED

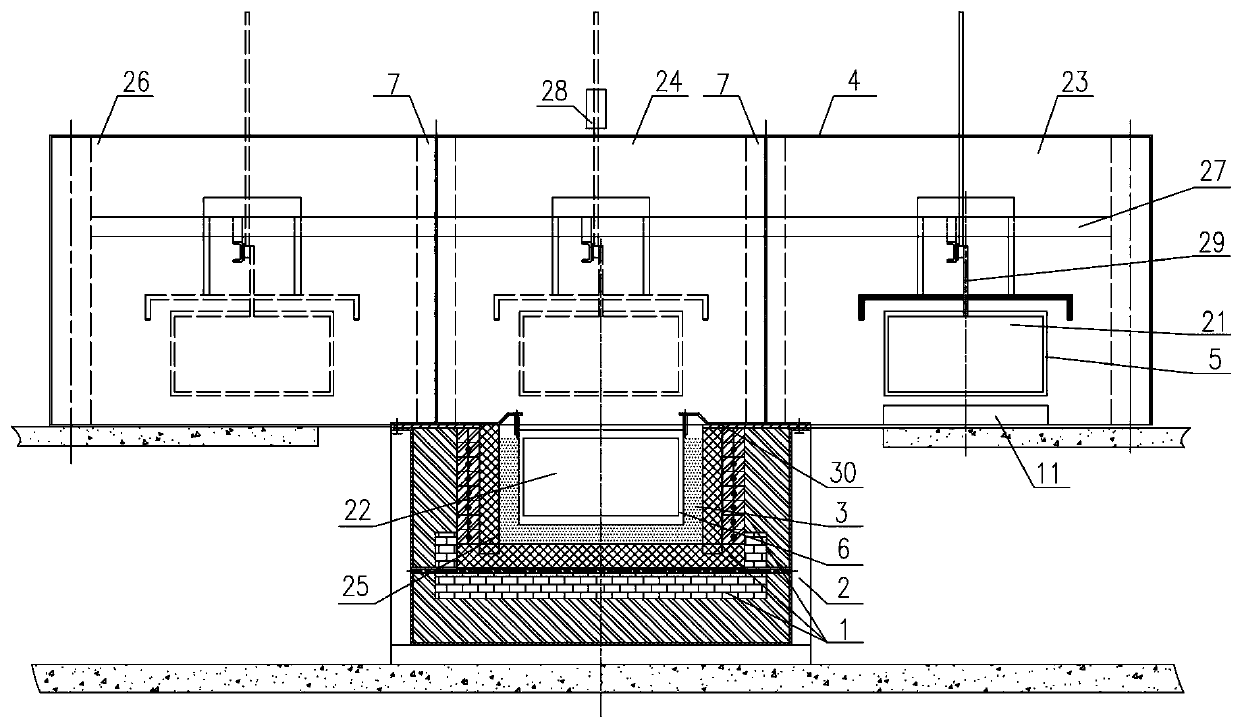

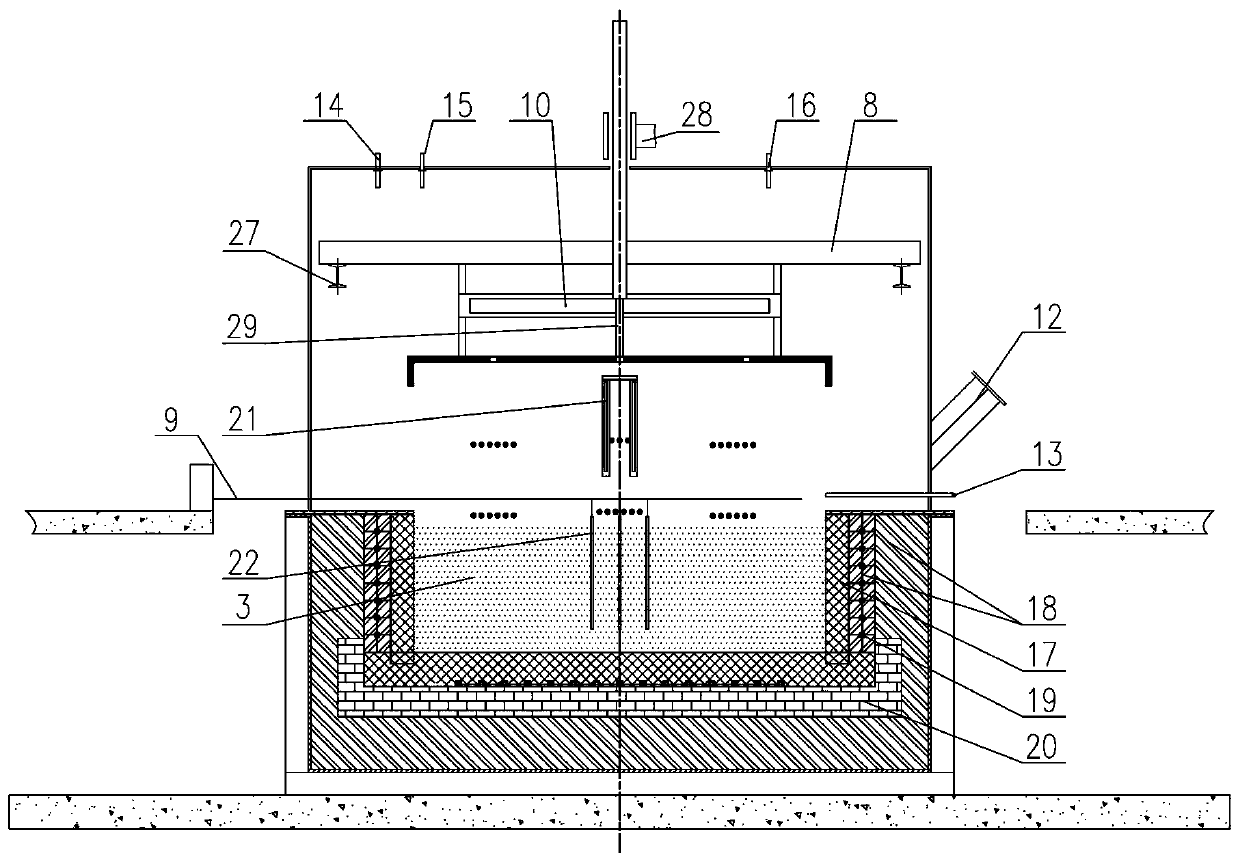

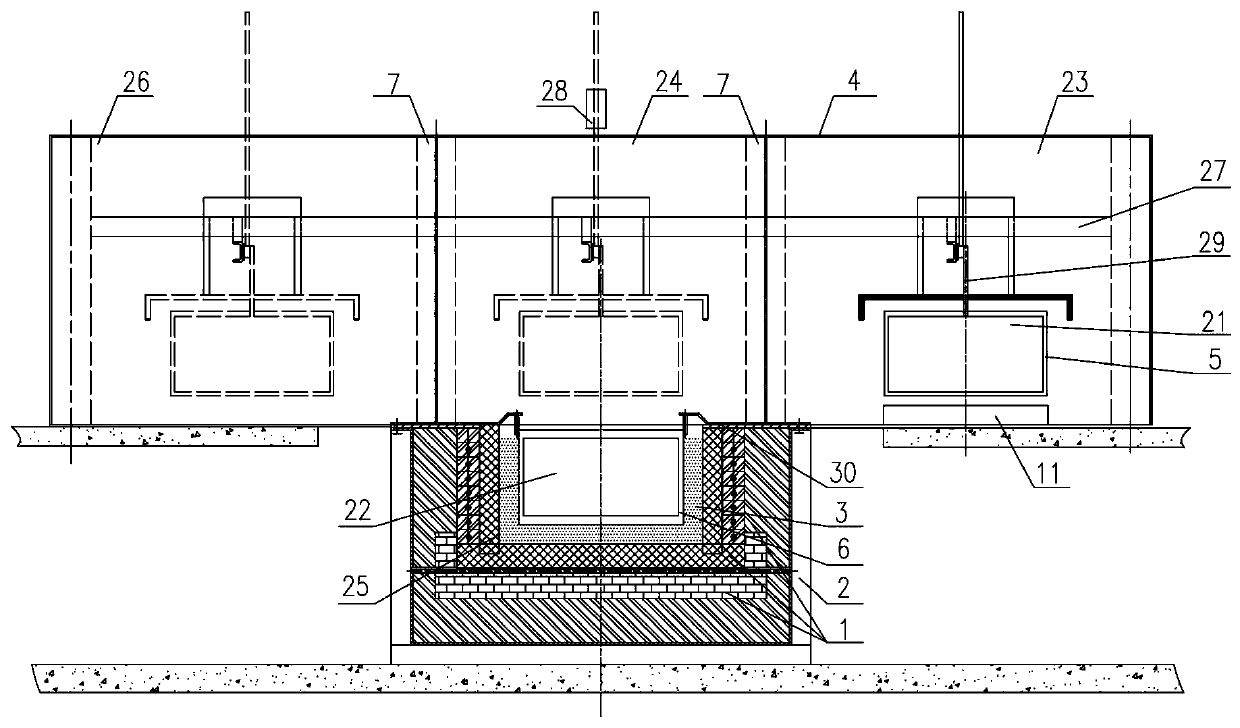

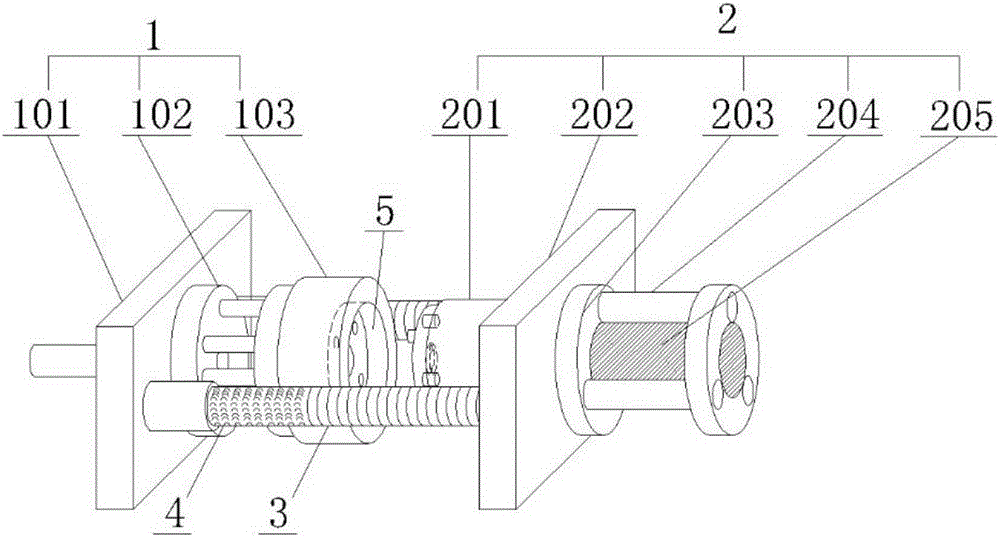

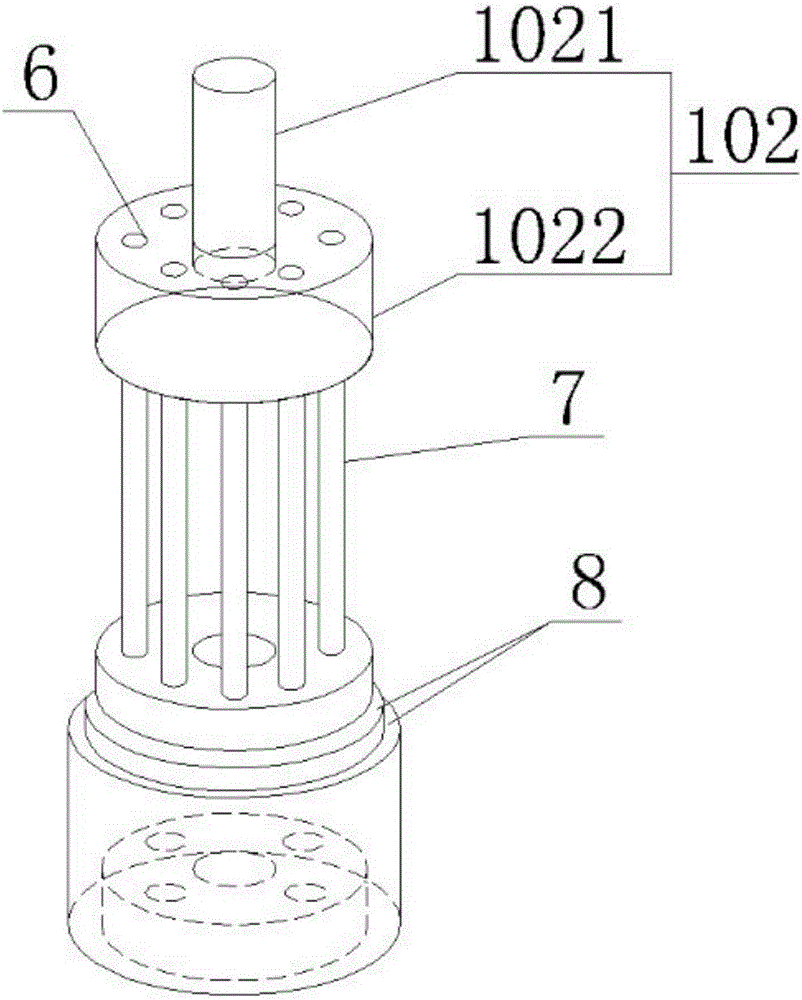

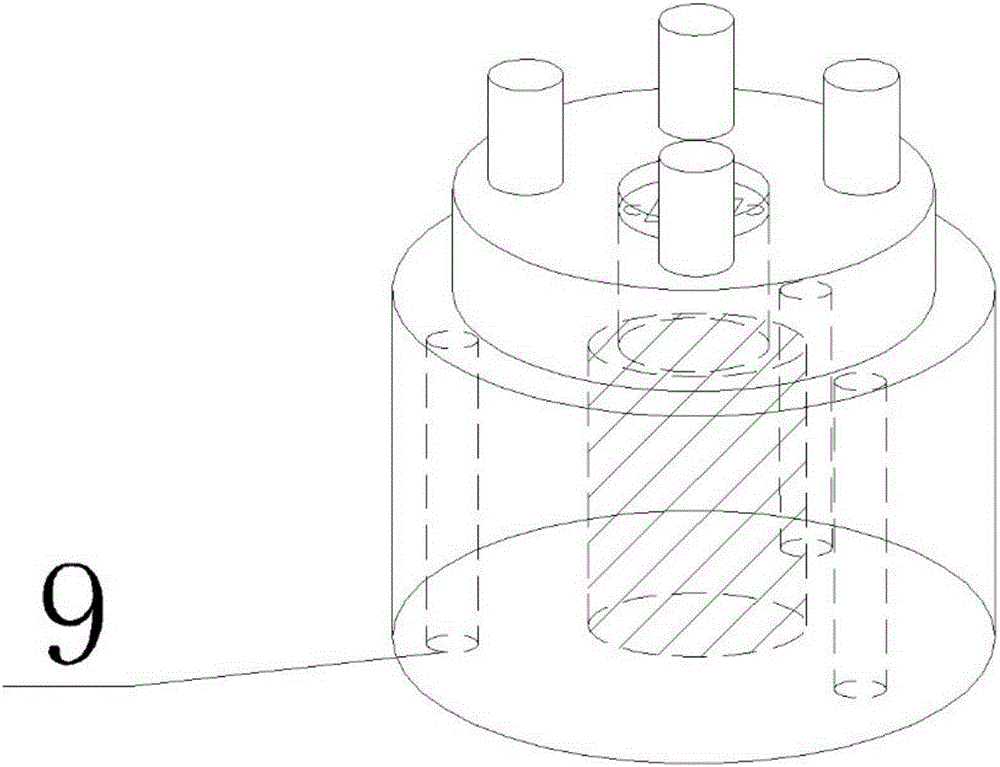

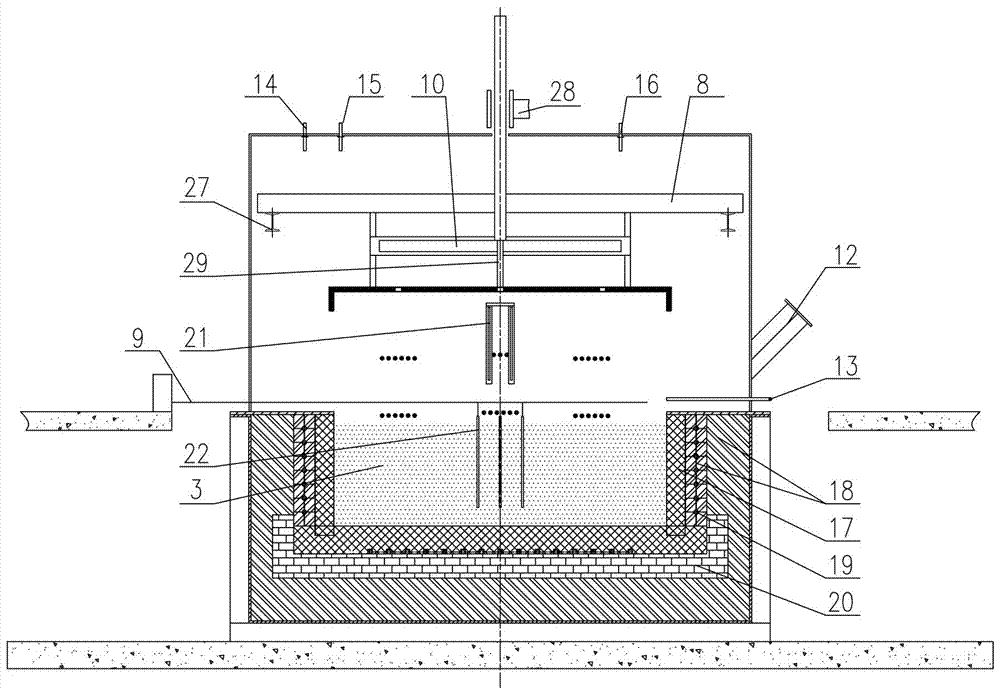

A silicon electrolytic cell for preparing high-purity silicon and its silicon preparation method

ActiveCN107345304BAvoid secondary oxidationExtended service lifeCellsElectrode shape/formsCooling chamberPole piece

The invention relates to a silicon electrolytic bath for preparing high-purity silicon and a silicon preparation method. The silicon electrolytic bath comprises three operation chambers, that is, the cathode pre-heating chamber, the middle operation chamber and the crystalline silicon cooling chamber which are arranged on the same layer, a folding door is arranged between every two adjacent operation chambers, and an electrolytic reaction chamber communicating with the middle operation chamber is arranged under the middle operation chamber. The electrolytic reaction chamber is internally provided with a fused electrolyte, an anode device is arranged in the fused electrolyte and used for fixing an anode pole piece, and the anode pole piece is connected with a positive pole of a direct current supply system through an anode connection wire. The upper portions inside the cathode pre-heating chamber, the middle operation chamber and the crystalline silicon cooling chamber are provided with tracks, the tracks are provided with movable cathode moving devices, cathode buses are arranged on the cathode moving devices, the lower portions of the cathode buses are connected with cathode devices through cathode guide rods, and the cathode devices are used for fixing cathode pole pieces. The silicon electrolytic bath for preparing the high-purity silicon, and the silicon preparation method have the advantages that the process is simple, operation is convenient, the mechanization degree and the automation degree are high, and environmental protection and energy saving are achieved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

A kind of masterbatch grade titanium dioxide and preparation method thereof

ActiveCN112646396BAvoid direct contactGood weather resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsOrganic filmOil emulsion

The invention provides a color masterbatch grade titanium dioxide, the titanium dioxide includes an inner core and a coating layer coated on the inner core, the inner core is titanium dioxide, and the coating layer includes a first coating layer coated on the inner core An organic film layer, an inorganic film layer coated on the first organic film layer, and a second organic film layer coated on the inorganic film layer. The preparation method of titanium dioxide includes beating and dispersing, first organic coating, agent-free coating, pressure filtration and second organic coating. In the present invention, the surface is coated and modified by organic matter in the slurry state before the inorganic surface is coated, which greatly improves the compatibility of titanium dioxide in the application system; the amino silicone oil emulsion is used for further surface modification in the flash drying link. To enhance the compatibility and bonding force between the powder particles and the resin; adding silane coupling agent in the steam crushing process is a further modification, so that the titanium dioxide particles are completely hydrophobic and lipophilic.

Owner:攀枝花大互通钛业有限公司

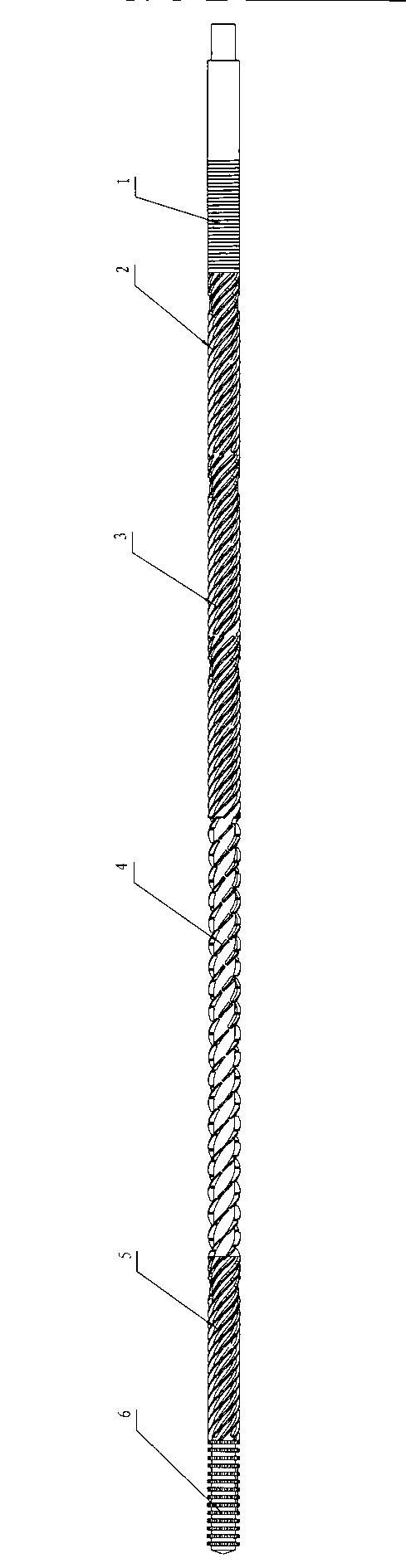

CO2 multi-component cooperative foaming and combined cooling screw rod

The invention provides a CO2 multi-component cooperative foaming and combined cooling screw rod which comprises a screw rod body, wherein the screw rod body is sequentially composed of a leakage-proof section, a pressurization section, a low shearing section, a large-lead multi-thread reversely-slotted reflux section, an intensive cooling and mixing section and a multi-thread slotted intensive mixing section from back to front. The screw rod provided by the invention can be used for continuously and stably producing CO2 foaming XPS (extruded polystyrene) sheet materials and solving the problems that large and irregular bubbles exist and the sheet materials can not be continuously produced by a method of producing the XPS sheet materials on a CFC foaming PS screw rod.

Owner:张建群

A kind of processing method of needle-shaped black tea

ActiveCN104719519BReduce labor intensityIncrease productivityPre-extraction tea treatmentEngineeringFermentation

A processing method of needle-shaped black tea, which comprises the steps of firstly selecting raw materials of fresh leaves with tenderness of single bud or one bud and one leaf for withering treatment, and then placing the tea green in the cool green room for cool green, and then putting the tea green into a disc Type kneading machine kneads and deblocks, and then puts the tea dhool that has been kneaded and deblocked in the fermentation room for fermentation, and then uses a dryer to dry the tea dhool to a certain moisture content, and then dries and spreads the tea that has been cooled The billet is moved into the fine kneading machine for shape, and finally the tea billet is moved into the slitting machine for drying. The tea base is shaped by the fine kneading machine, which greatly reduces the labor intensity of the needle-shaped black tea and improves the labor efficiency; it can realize continuous processing operations, realize standardized production, and improve product quality.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

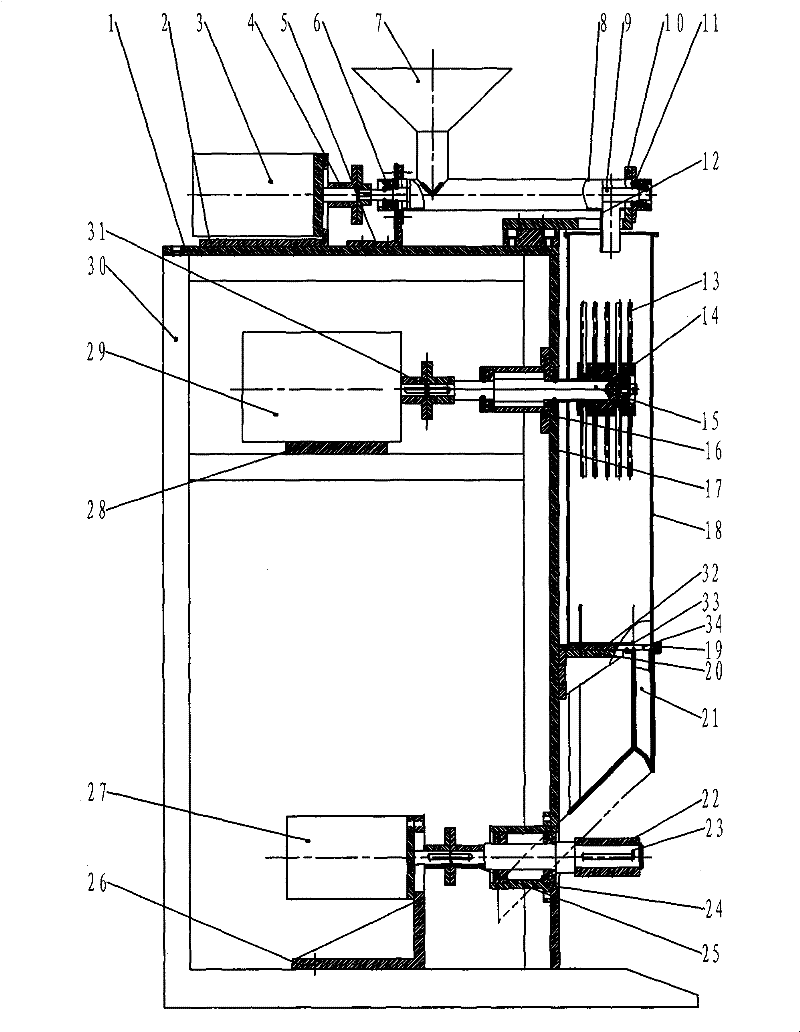

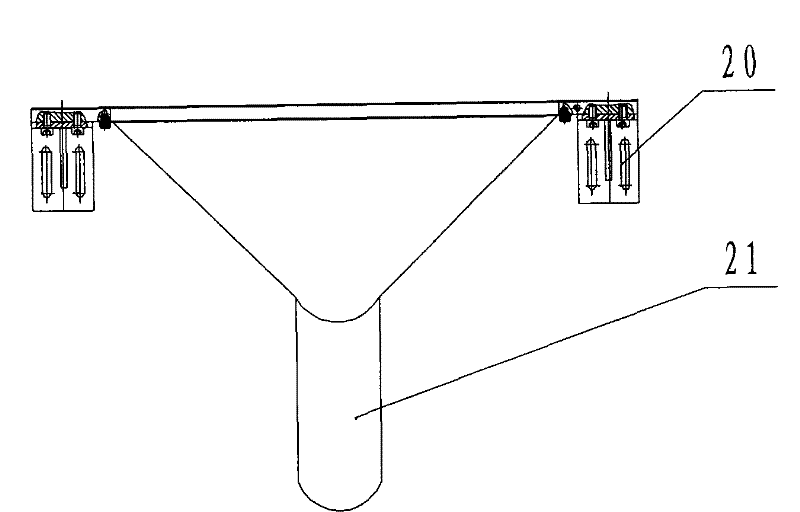

Material distributing machine

InactiveCN101577337BEvenly distributedSolve the problem of continuous productionCell electrodesFuel cell detailsManufacturing technologyCoupling

The invention relates to a material distributing machine used for dry-embedded molding manufacture technology of an air electrode for a zinc-air battery. The material distributing machine comprises four parts of a quantitative feeding mechanism installed on a rack, a casting mechanism, a nickel screen delivery mechanism and a material recycling bin; and the material distributing machine is characterized in that the quantitative feeding mechanism comprises a hopper, a screw feeding main shaft and a shell thereof, a feeding servo motor and the like; the casting mechanism comprises a material beating bar, a material beating roll, a material beating roll shaft, a material-sprinkling motor and the like; the nickel screen delivery mechanism comprises a nickel screen, a feeding roll, a feeding roll main shaft, a bearing cover, a nickel screen shaft coupler, a servo motor bracket, a servo motor and the like; and the material recycling bin is installed below a material distributing bin supporting plate. The material distributing machine can automatically complete material evenly-distributing work in the dry-embedded molding manufacture technology of the air electrode for the zinc-air battery.

Owner:HEBEI UNIV OF TECH

Rapid mold for novel impeller bottom cover of vertical pump

InactiveCN105195612AMeet the dimensional accuracy requirementsSuitable for mass production needsShaping toolsImpellerPunch press

The invention discloses a rapid mold for a novel impeller bottom cover of a vertical pump. The rapid mold comprises a rapid-pressing upper mold body and a double-positioning-column guide lower mold body, and is characterized in that the rapid-pressing upper mold body is composed of an upper flat plate, a fixed guiding connecting part and a bearing pressing forming part, a smooth cylindrical connecting rod is arranged at the upper portion of the fixed guiding connecting part, is embedded into the upper flat plate and can be fixed to a punching machine, and a disc-shaped pressure transmitting table is arranged at the lower portion of the fixed guiding connecting part; the bearing pressing forming part is a pressure applying table support, and the upper portion of the pressure applying table support is connected with the lower portion of the disc-shaped pressure transmitting table through eight slideable fixing lock rods with shaft sleeves; the double-positioning-column guide lower mold body is composed of a convex cylinder bearing table, a lower flat plate, a bottom table, guide screws and a damping beef tendon supporting column. The mold can meet the requirement for the size accuracy of the impeller bottom cover of the vertical pump, rapid punching forming can be carried out, noise is low, the service life is long, production efficiency is high, and the rapid mold meets the mass production requirement of the impeller bottom cover of the vertical pump.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

Silicon electrolytic bath for preparing high-purity silicon and silicon preparation method

ActiveCN107345304AAvoid secondary oxidationExtended service lifeCellsElectrode shape/formsElectrolysisCooling chamber

The invention relates to a silicon electrolytic bath for preparing high-purity silicon and a silicon preparation method. The silicon electrolytic bath comprises three operation chambers, that is, the cathode pre-heating chamber, the middle operation chamber and the crystalline silicon cooling chamber which are arranged on the same layer, a folding door is arranged between every two adjacent operation chambers, and an electrolytic reaction chamber communicating with the middle operation chamber is arranged under the middle operation chamber. The electrolytic reaction chamber is internally provided with a fused electrolyte, an anode device is arranged in the fused electrolyte and used for fixing an anode pole piece, and the anode pole piece is connected with a positive pole of a direct current supply system through an anode connection wire. The upper portions inside the cathode pre-heating chamber, the middle operation chamber and the crystalline silicon cooling chamber are provided with tracks, the tracks are provided with movable cathode moving devices, cathode buses are arranged on the cathode moving devices, the lower portions of the cathode buses are connected with cathode devices through cathode guide rods, and the cathode devices are used for fixing cathode pole pieces. The silicon electrolytic bath for preparing the high-purity silicon, and the silicon preparation method have the advantages that the process is simple, operation is convenient, the mechanization degree and the automation degree are high, and environmental protection and energy saving are achieved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

A kind of automated production process of flower-flavored Kung Fu black tea

ActiveCN106106869BAchieve a tight and even effectImprove processing qualityPre-extraction tea treatmentClimate change adaptationEngineeringFermentation

The invention discloses an automatic production process of flower fragrance type Kongfu black tea. The automatic production process comprises the following steps: picking fresh leaves, carrying out sun-withering in a sun-withering room, quickly freezing and withering, carrying out dynamic circulating withering on the fresh tea leaves by adopting a withering set, kneading by adopting a primary kneading-unblocking and sieving-re-kneading manner, carrying out temperature-variable fermentation, adopting a gross fire-re-moisturizing-complete fire manner, packaging and the like; automatic, continuous and clean processing requirements can be realized when a large-leaf tea variety is used for carrying out black tea processing and the quality of a product is guaranteed, so that the product has the quality style characteristics that strips are compact and uniform, the product has dark green color and luster and is glossy, the soup color is orange red and bright, the aroma is great and lasting, the taste is mellow and refreshing and infused leaf are bright and uniform; large-batch and continuous processing can be carried out when the large-leaf tea variety is processed into the Kongfu black tea.

Owner:广西西林京桂古道茶业有限公司

A method for continuous production of hot extruded radiant rings

ActiveCN109166720BSuitable for mass industrial productionIncrease profitTransportation and packagingMetal-working apparatusThermal deformationAlloy

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

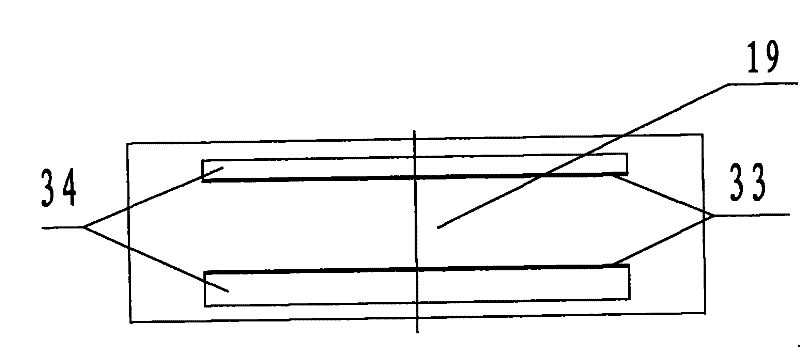

Electrostatic dust collection corrugated core and forming method thereof

ActiveCN114670462ASolve the problem of low efficiency of manual feedingSolve the problem of continuous productionDomestic articlesDust controlEngineering

The invention discloses an electrostatic dust collection corrugated core and a forming method thereof.The electrostatic dust collection corrugated core comprises an outer cover, an extrusion device is movably connected to the upper surface of the outer cover, a laminating device is arranged at the bottom of the extrusion device, a conveying device is arranged at the bottom of the laminating device, and a heating device is arranged outside the conveying device; the invention relates to the technical field of electrostatic dust collection. According to the electrostatic dust collection corrugated core and the forming method thereof, by arranging the adjusting device, when the clamping plates get close to each other, the outer surface of the right side of the folding plate makes contact with and extrudes the corrugated core, and when the break angle of the corrugated core is bent greatly, an adjusting rod shrinks, a lantern ring moves along with shrinkage of the adjusting rod, and a connecting rod pulls the folding plate to rotate; the outer surface of the left side of the folding plate slides along the outer surface of the clamping plate, the angle of the folding plate is reduced, the break angle of the wave core formed through extrusion is increased, otherwise, the extrusion degree of the wave core is controlled by controlling the adjusting rod, and the problem that traditional forming equipment can only extrude the wave core with the single angle is solved.

Owner:AMERIASIA ACTIVATED CARBON PROD CO LTD

Multi-stage variable speed tail-drying mixed fertilizer granulation production process and its special production equipment

ActiveCN105198537BUniform temperatureSolve the problem of continuous productionFertilizer mixturesPulp and paper industryCrusher

Multi-stage variable speed tail-drying mixed fertilizer granulation production process and its special production equipment, including batching system, crusher, drum granulator, disc granulator, primary drying cylinder, primary cooling cylinder, primary Primary screening machine, secondary drying cylinder, secondary cooling cylinder, secondary screening machine, coating machine and finished product warehouse, batching system, crusher, drum granulator, disc granulator, primary drying cylinder , a primary cooling cylinder, a primary screening machine, a secondary drying cylinder, a secondary cooling cylinder, a secondary screening machine, a coating machine and a finished product warehouse are connected in sequence. The multi-stage variable-speed end-drying mixed fertilizer granulation production process and its special production equipment described in the present invention can make fertilizer granules have high pelleting rate, good appearance, low water content, high roundness, high strength, hardened parts, and high yield. , can produce organic fertilizers, inorganic fertilizers and organic-inorganic mixed fertilizers, solve the negative effects of conventional processes, fill in the gaps in the industry, and are very beneficial to popularization and use.

Owner:济宁中农大化肥业股份有限公司 +2

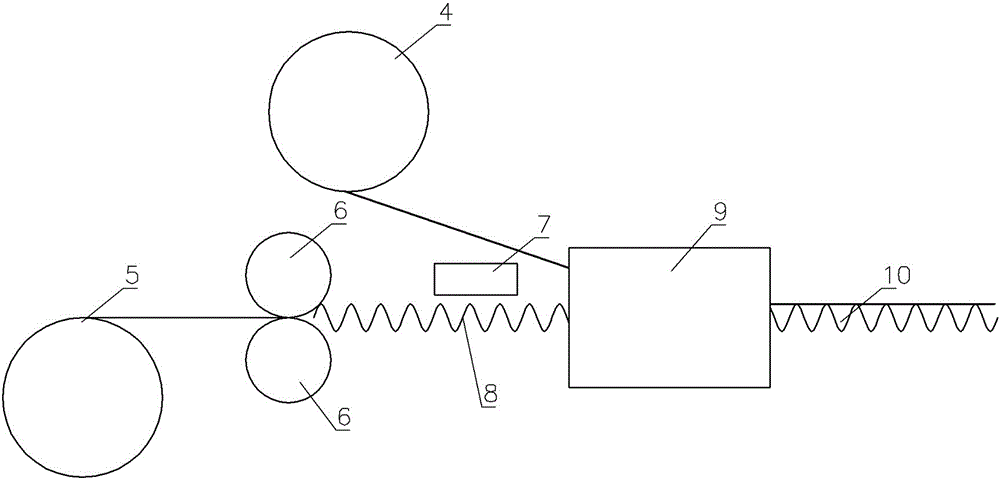

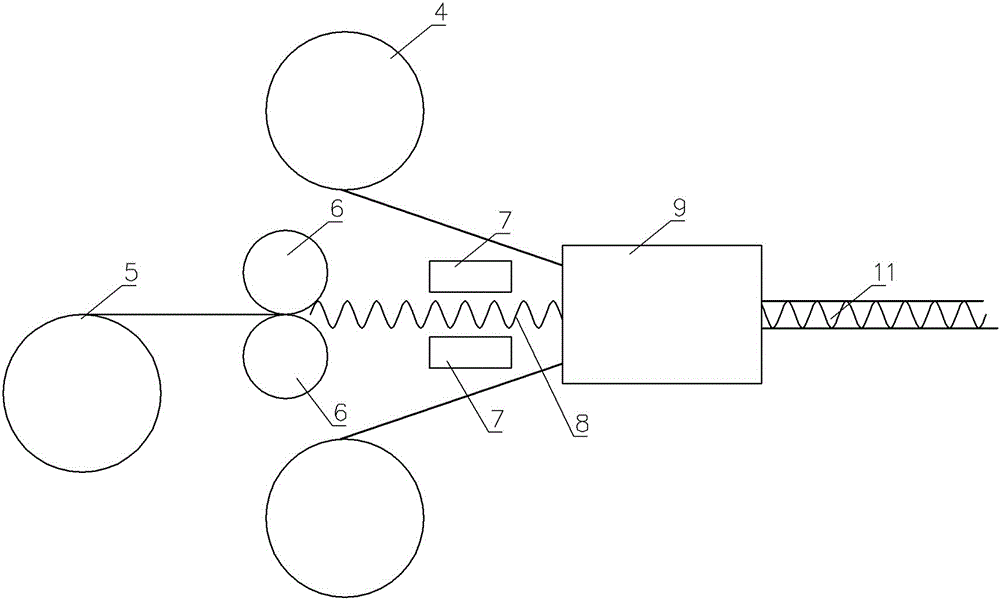

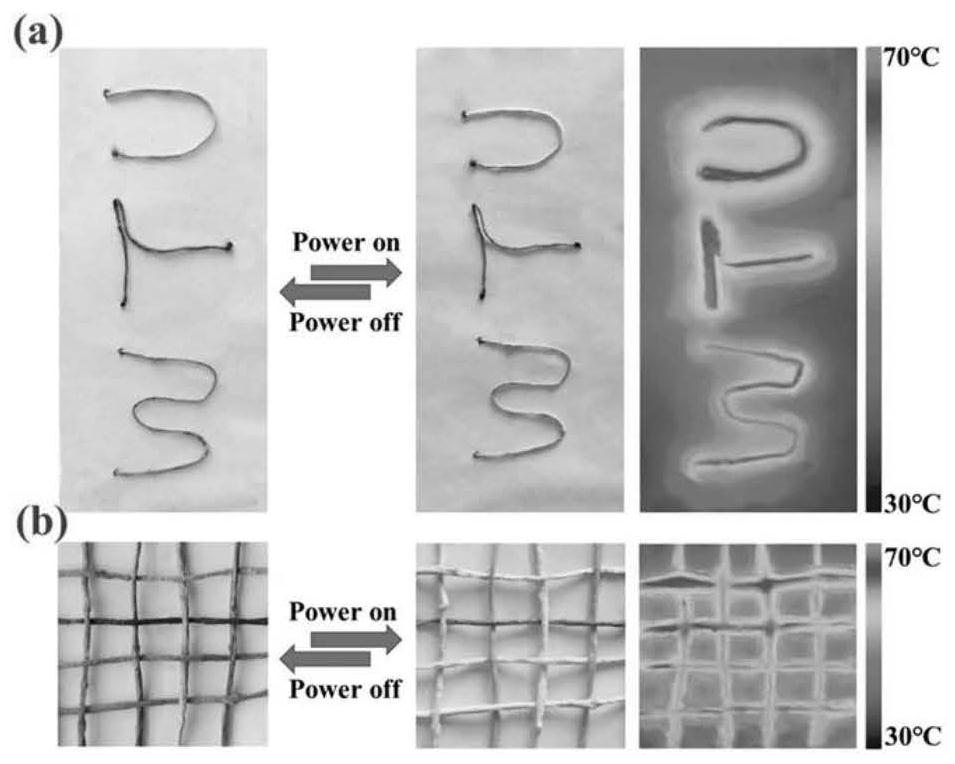

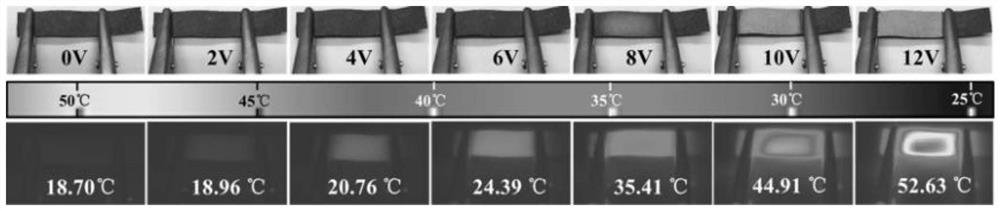

A kind of continuous electrothermochromic fiber based on polyester filament and preparation method thereof

ActiveCN113652859BSolve the problem of continuous productionSolve the problem of thicker diameterFibre typesPolyesterPolymer science

The invention discloses a preparation method of a continuous electrothermochromic fiber based on polyester filament, comprising: S1. winding the polyester filament into a ring shape, and removing grease and impurities on the surface; S2. using an electroless deposition process Deposit a metal copper coating on the surface of the polyester filament; S3. anneal the polyester filament to obtain a polyester conductive filament; S4. pass the polyester conductive filament through a tank equipped with temperature-sensitive color-changing ink, and then dry it through a heat device , wound on a roller to obtain a continuous electrothermochromic fiber; wherein, in step S2, a composite stabilizer is added to the electroless deposited copper plating solution, and the composite stabilizer is composed of potassium ferrocyanide and 2, 2'-bipyridine, the concentration of potassium ferrocyanide is 5-10mg / L, and the concentration of 2,2'-bipyridine is 5-10mg / L. The preparation method of the invention can realize the continuous production of electrothermally induced discoloration fibers, has low production cost, controllable fiber diameter, and high electrical conductivity of the obtained fibers.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com