A method for continuous production of hot extruded radiant rings

A radiation ring and hot extrusion technology, which is applied in the manufacture of inductors/transformers/magnets, manufacture of stator/rotor bodies, transportation and packaging, etc., can solve the problems of low efficiency, raw material utilization rate and yield rate in the production of heat-pressed and thermally deformed radiation rings No problems such as high, to achieve the effect of reducing production costs and operating procedures, high production efficiency and material utilization, and less post-processing grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

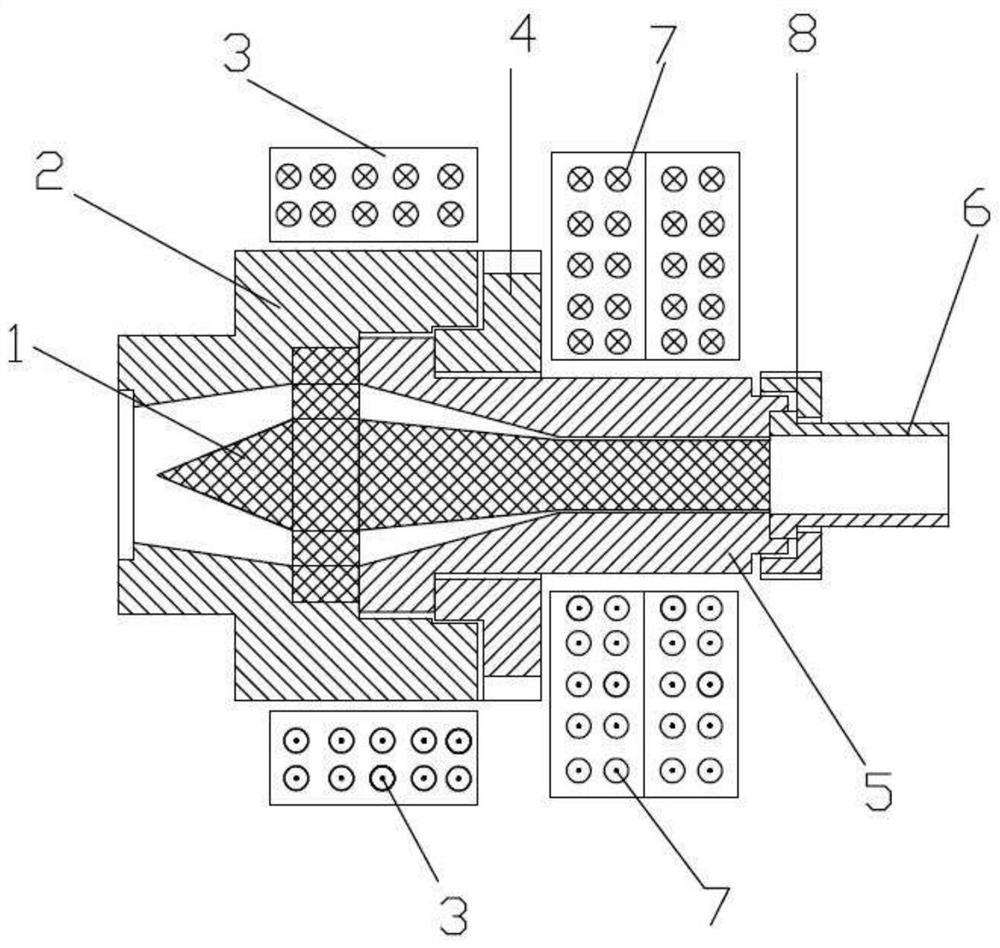

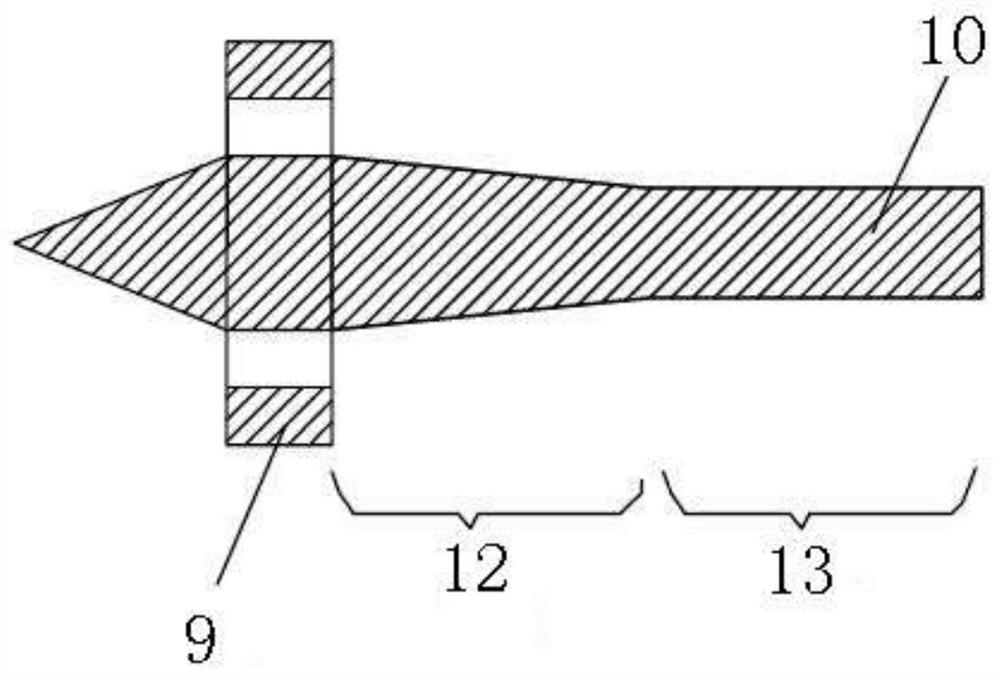

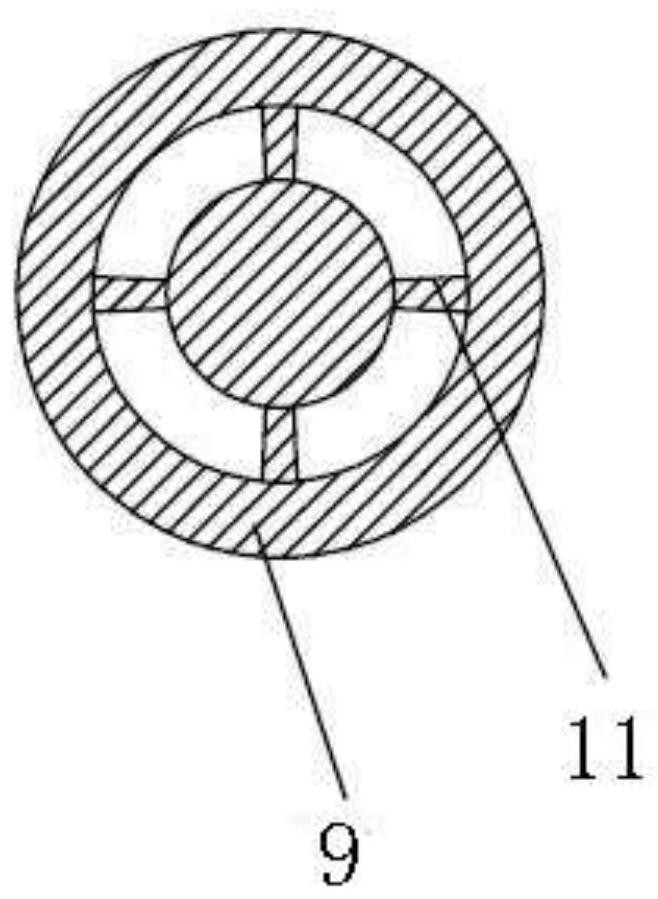

Method used

Image

Examples

Embodiment 1

[0033] (1) Prepare the raw materials according to the following mass percentages: Nd 21.452%, Pr 0.42%, Co 0.67%, B0.98%, Al 0.479%, Cu 0.11%, Nb 1.159%, the balance is Fe, and put it into the induction furnace The ingot is smelted, and when the smelted ingot is heated and melted to 1300°C, the molten liquid is sprayed on the cooling roll, the speed of the cooling roll is controlled at 20m / s, and the protective atmosphere is Ar gas to obtain a nano-composite phase quenching belt. And after homogenization treatment and crushing treatment, magnetic separation and screening are carried out to make hot-pressed magnetic powder with an average particle size of 90 mesh; (2) add 1wt% graphite powder to the hot-pressed magnetic powder, mix it uniformly and transfer it to In the silo of the special extruder, the worm conveys the material into the extrusion sleeve that has been preheated to 35°C, and the powder is pre-pressed by the pressure of 30 MPa on the worm and the extrusion sleeve,...

Embodiment 2

[0037](1) Prepare raw materials according to the following mass percentages: Nd 21.452%, Pr 0.42%, Co 0.67%, B0.98%, Al 0.479%, Cu 0.11%, Nb1.159%, the balance is Fe, put into the induction The ingot is smelted in the furnace. When the smelted ingot is heated and melted to 1300°C, the molten liquid is sprayed on the cooling roll. The speed of the cooling roll is controlled at 10m / s, and the protective atmosphere is Ar gas to obtain nano-complex phase quenching. belt, and homogenized and crushed into a powder with a grain size of 100 μm;

[0038] (2) The quick quenching powder is prepared by the quick quenching process, the average particle size of the powder is about 100 mesh, and the powder is added with 0.5wt% MoO 2 After the powder is mixed evenly, it is transferred from the mixer to the silo of the special extruder. The worm conveys the material into the extrusion sleeve which has been preheated to 40°C. , so that the material in the extrusion sleeve is filled densely;

...

Embodiment 3

[0042] (1) Prepare raw materials according to the following mass percentages: Nd 21.452%, Pr 0.42%, Co 0.67%, B0.98%, Al 0.479%, Cu 0.11%, Nb 1.159%, the balance is Fe, put into the induction furnace The ingot was smelted in a medium, and when the smelted ingot was heated and melted to 1300°C, the molten liquid was sprayed on the cooling roll, the speed of the cooling roll was controlled at 30m / s, and the protective atmosphere was Ar gas to obtain a nano-composite phase quenching belt. , and homogenized and crushed into a powder with a grain size of 100 μm;

[0043] (2) The quick-quenching powder is prepared by the quick-quenching process, and the average particle size of the powder is about 90 orders. After the powder is added with 0.8wt% paraffin and mixed evenly, it is sent from the mixer to the feed bin of the special extruder, and the worm conveys the material to In the extrusion sleeve that has been preheated to 43°C, the powder is pre-pressed by the pressure of 38 MPa o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com