Large-strain mold integrating extrusion with C-mode equal channel angular pressing shear deformation

A technology of equal channel angle and shear deformation, applied in the field of large-strain deformation processing molds, can solve the problems of difficult to achieve industrialized production, inability to continuous production, change the properties of metal materials, and achieve the effect of convenient maintenance of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

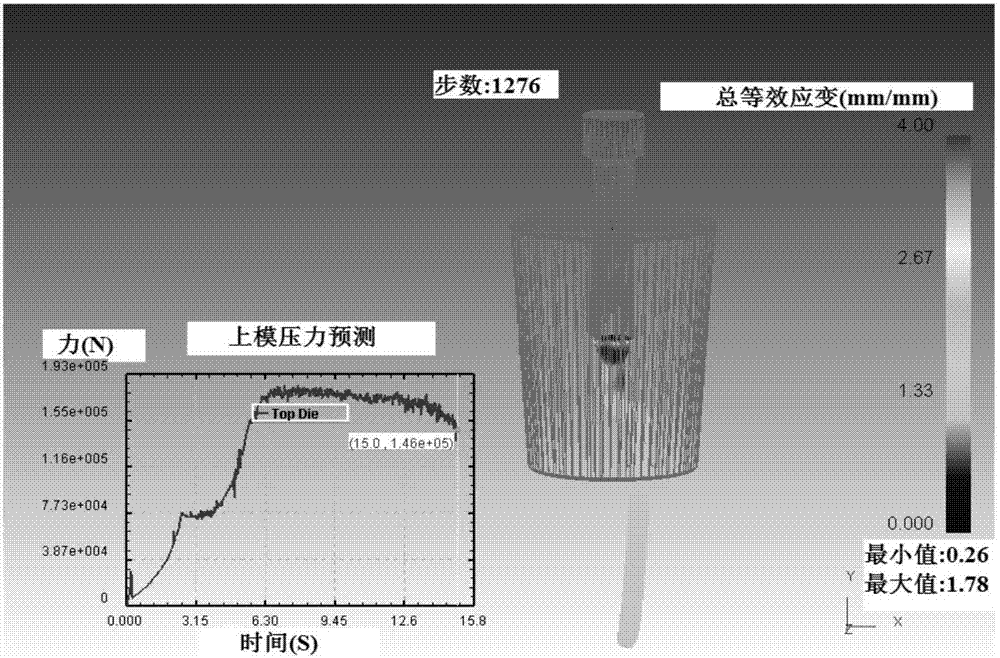

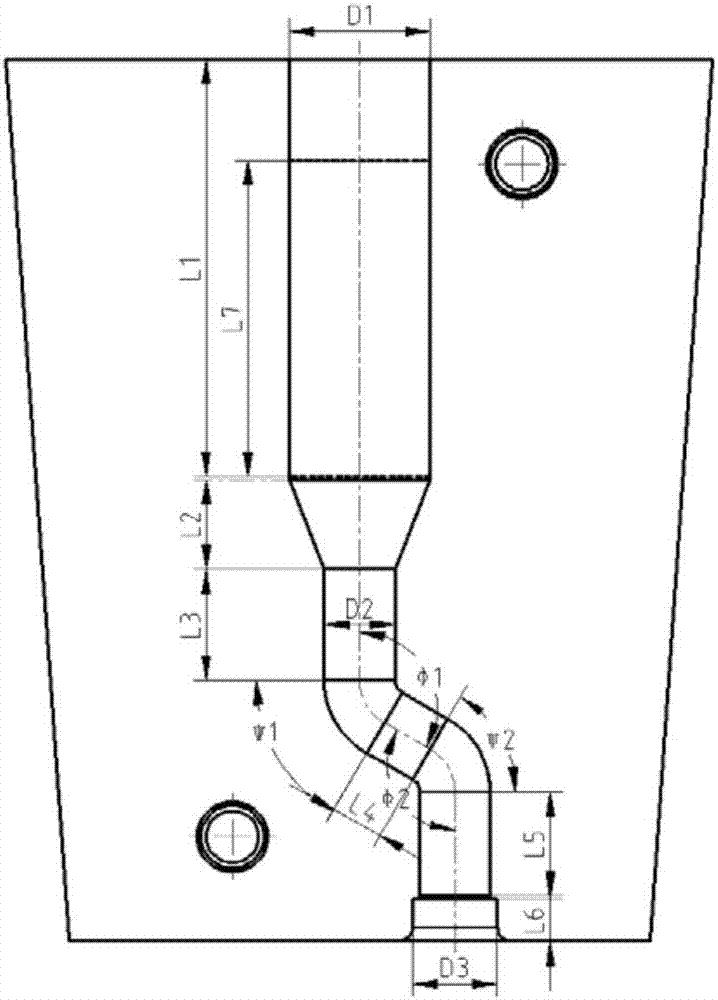

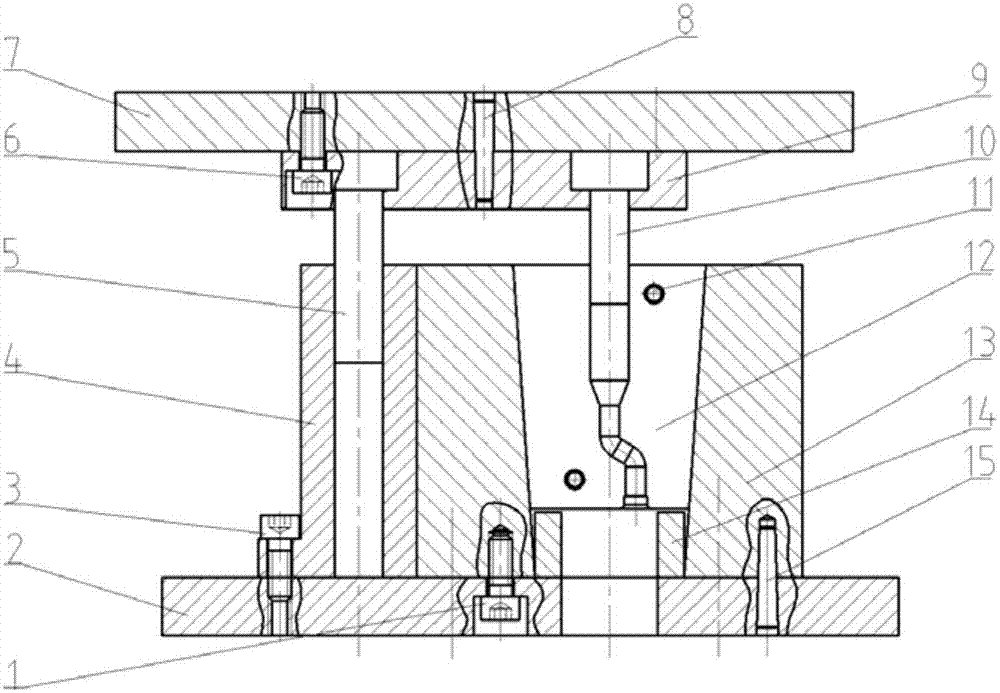

example 1

[0031] Example 1: When the extrusion ratio is equal to 4, L7 / L1=1; L2 / D1=0.5; L3 / D2=2 (L3 / D1=0.9); L4 / D2=0.75; L5 / D2=1.9, L6 / D2=0.2; Inner intersection angle Φ=110°, transition outer fillet ψ=60°. The downward speed of the punch during simulation is 3mm / s, and the initial temperature during processing is 400°C. In this case, the Von mises value of the equivalent strain becomes abnormally large. And the workpiece stops moving after being squeezed partly, that is, the frictional force and driving force on the workpiece are balanced. Therefore, the mold core under this parameter cannot smoothly extrude the processed 7075 aluminum alloy.

example 2

[0032] Example 2: When the extrusion ratio is equal to 4, L7 / L1=0.75; L2 / D1=0.5; L3 / D2=2 (L3 / D1=1); L4 / D2=0.75; L5 / D2=1.9, L6 / D2=0.2; Inner intersection angle Φ=120°, transition outer fillet ψ=60°. The downward speed of the punch during simulation is 3mm / s, and the initial temperature during processing is 400°C. In this case, the material stops moving down after being extruded for a period of time, that is, the friction force is equal to the driving force, and the workpiece cannot be extruded smoothly. Therefore, the mold core under this parameter cannot smoothly extrude the processed 7075 aluminum alloy.

example 3

[0033] Example 3: Similar to Example 2, the difference is that the inscribed angle Φ is changed to 135°. The downward speed of the punch during simulation is 3mm / s, and the initial temperature during processing is 400°C. In this case, according to the force diagram, it can be seen that there is a jump in the force during the extrusion process, and the extrusion ends smoothly, which is the same as the theoretical drop value of the punch in the Deform simulation of 52mm. However, the equivalent strain Von Mises becomes abnormally large, and the surface of the machined parts has defects, which indicates that the parameters of the mold cavity are unreasonable. Therefore, the mold core under this parameter also cannot smoothly extrude the processed 7075 aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com