Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Simplify the cleaning process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for purifying industrial silicon for preparing solar grade silicon

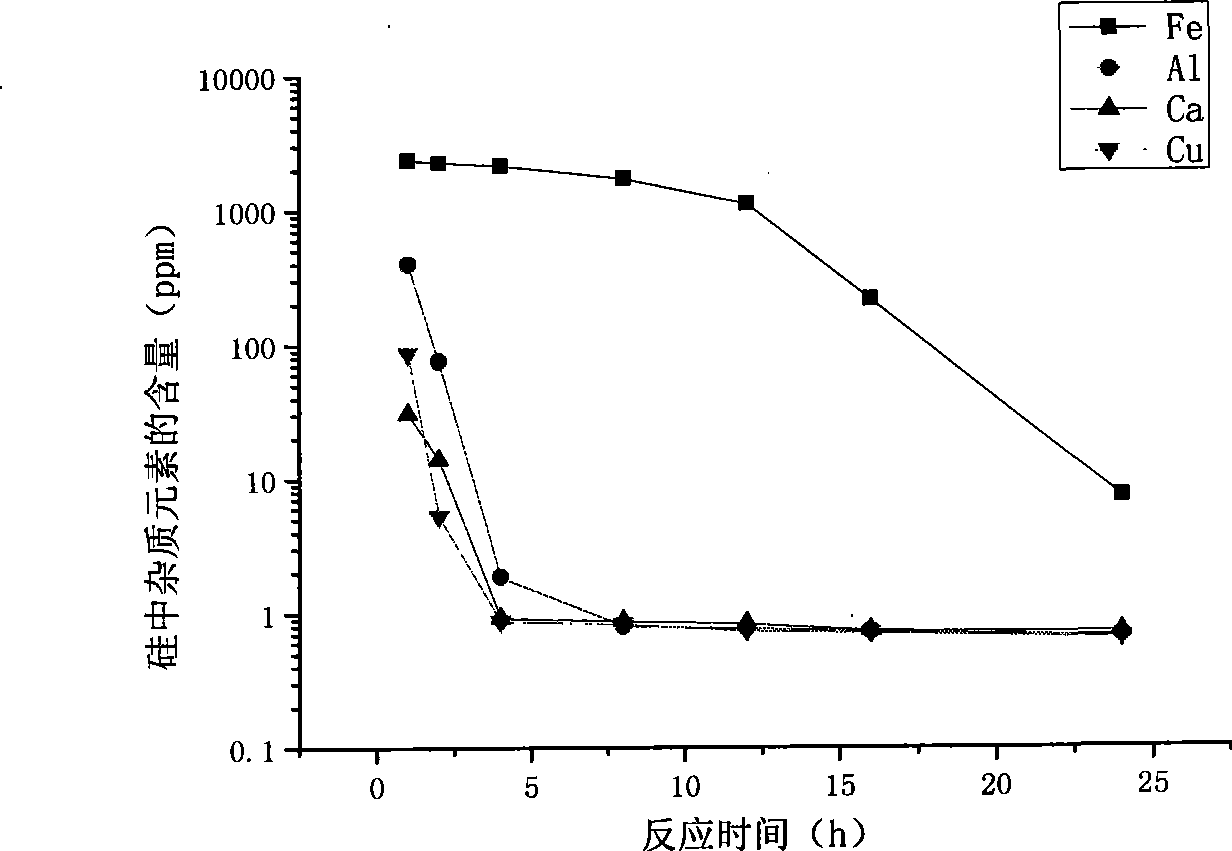

ActiveCN101475174ADirect preparationRemove difficult problemSilicon compoundsPre treatmentHigh activity

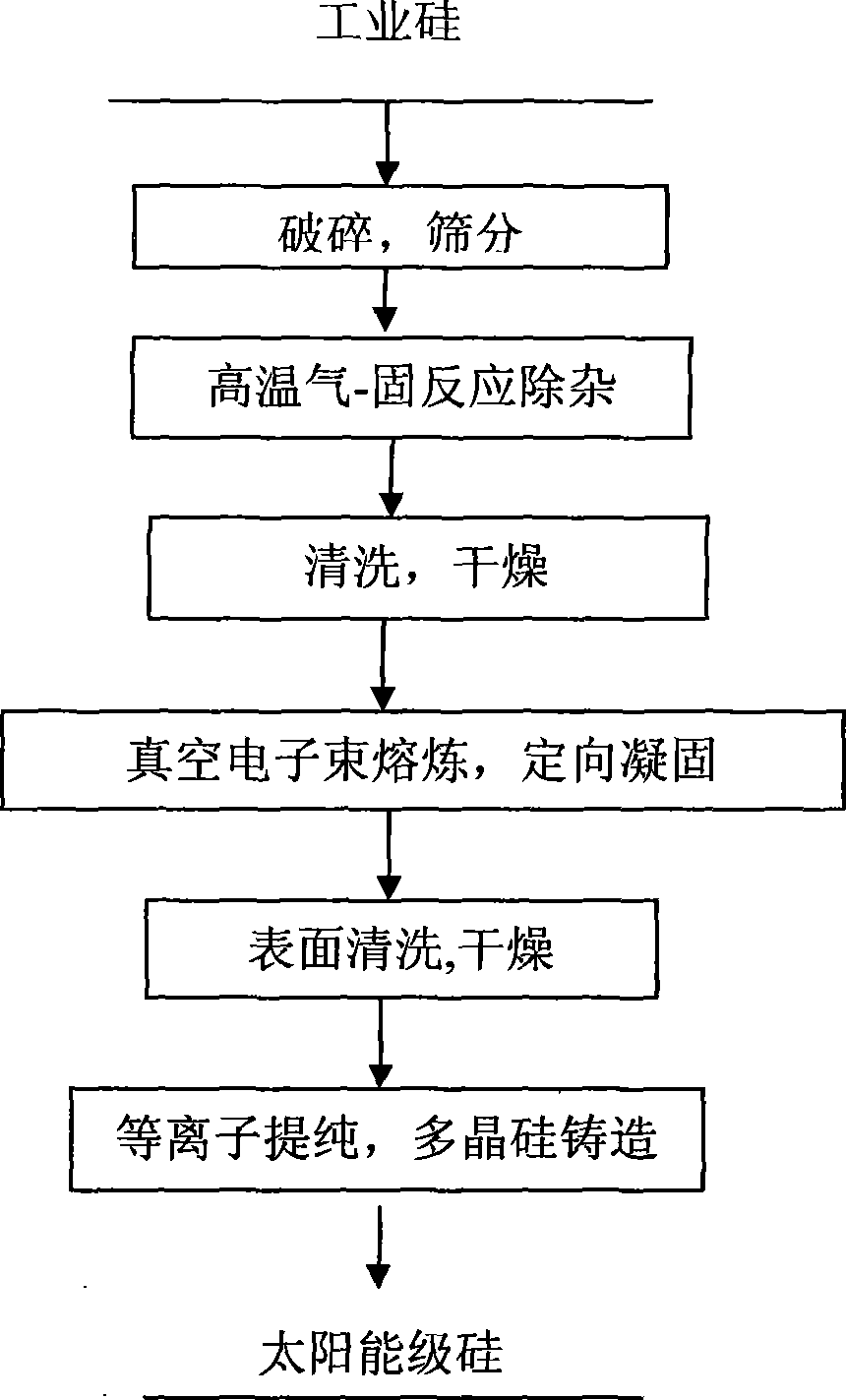

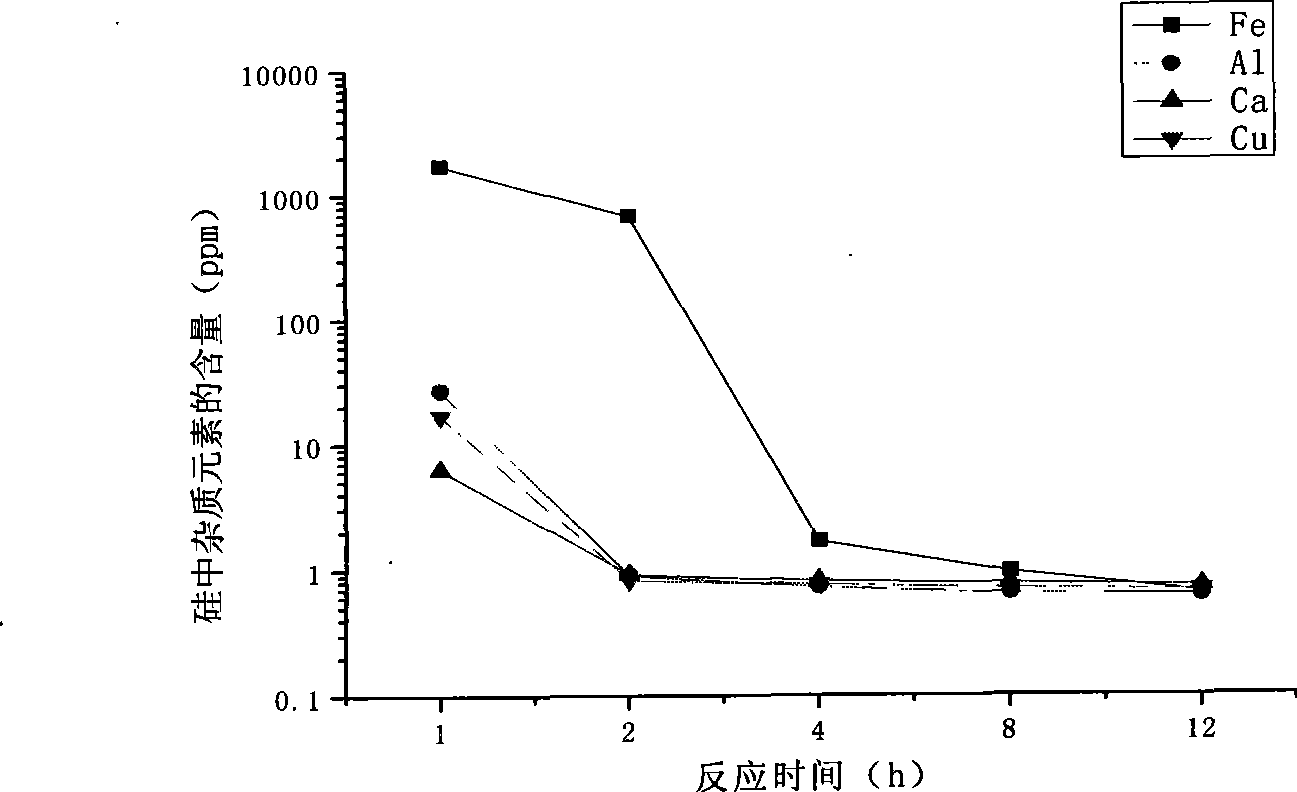

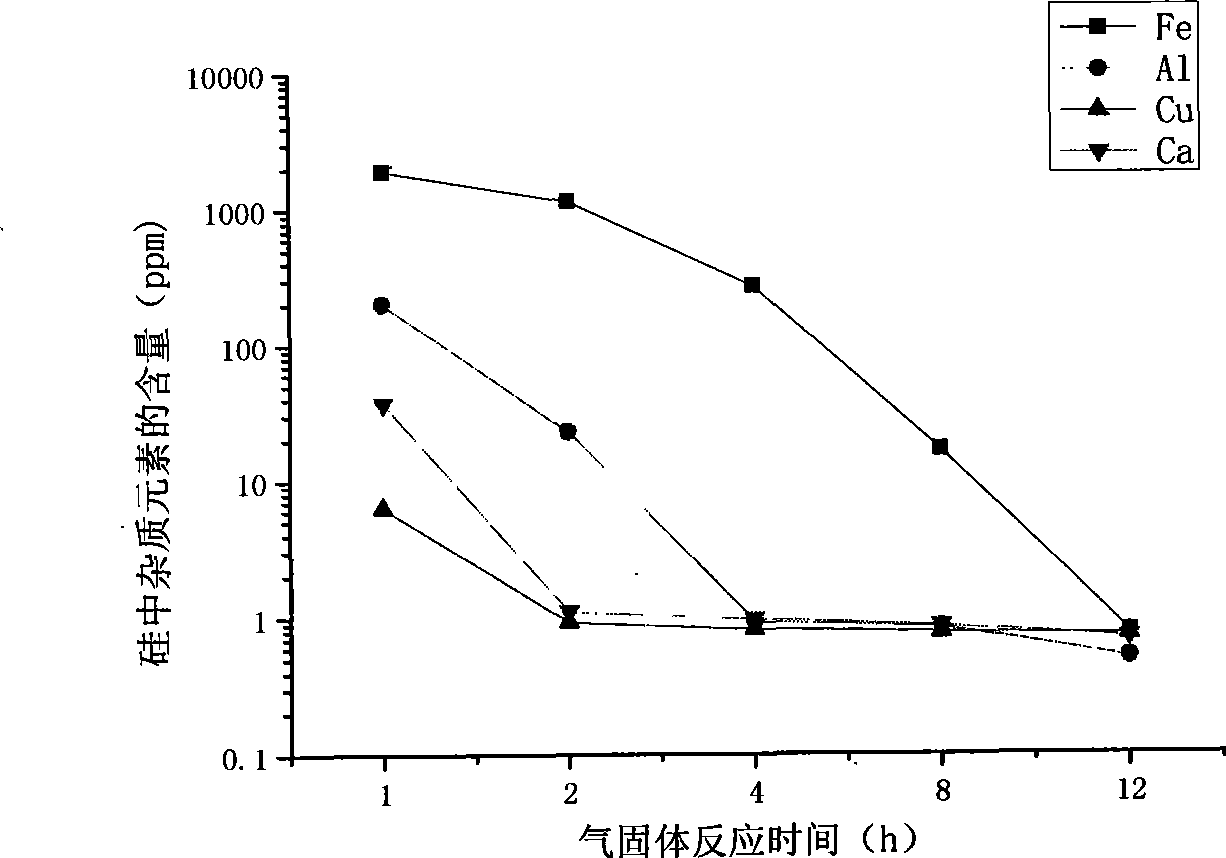

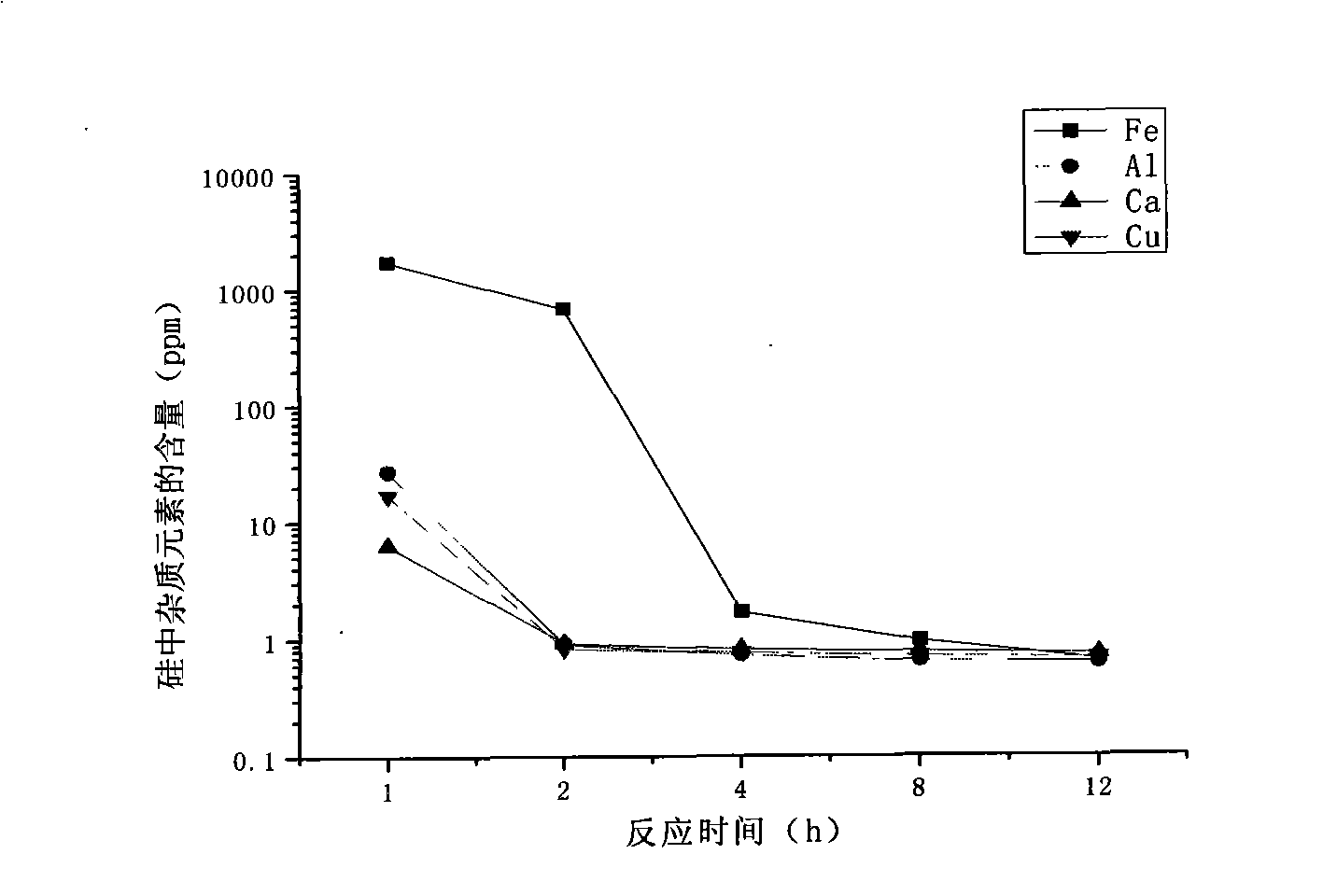

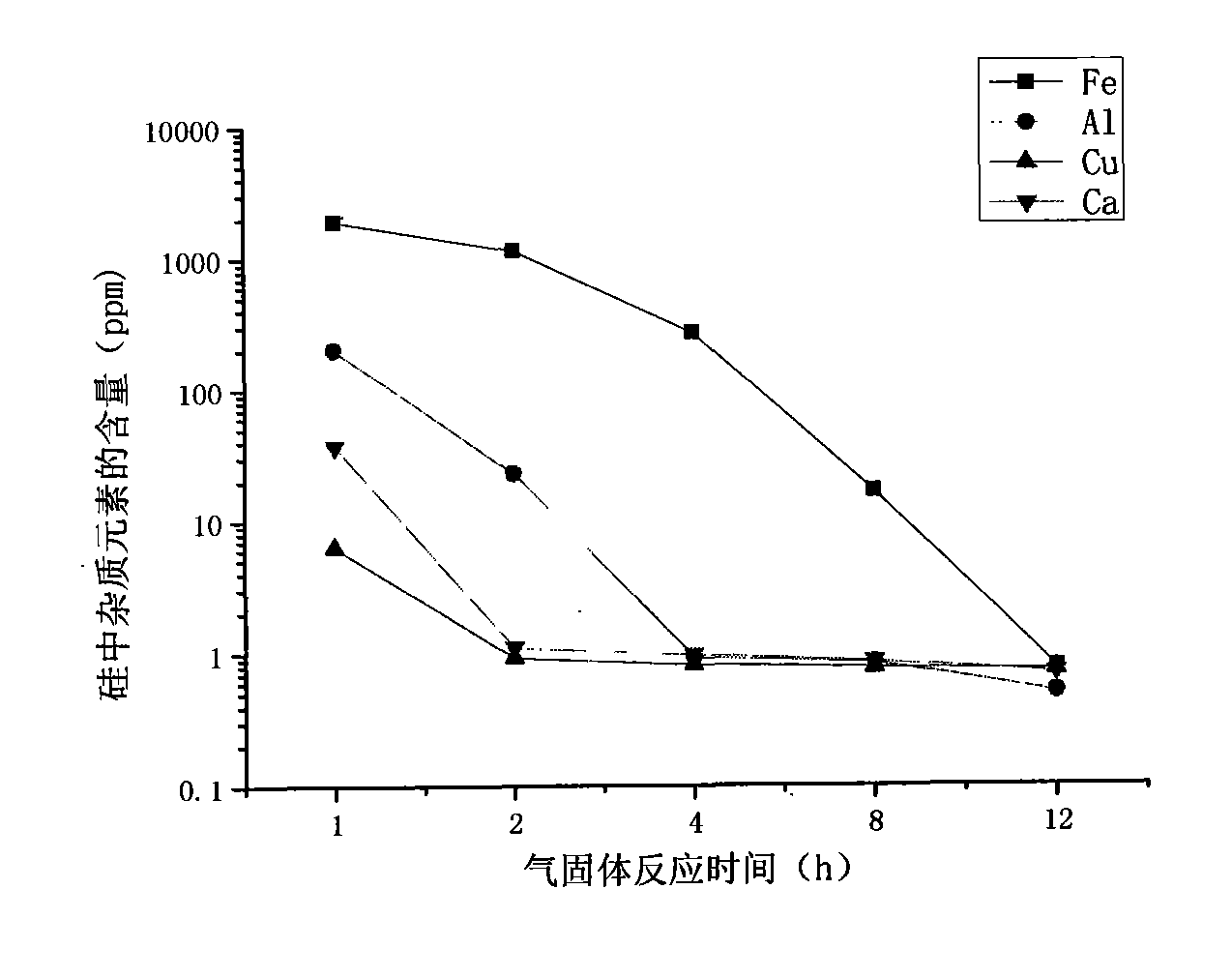

The invention discloses a method for preparing solar-grade silicon through purification of industrial silicon (2N). The method comprises that: the industrial silicon is subjected to primary pulverization pretreatment and is put into a high-temperature solid-phase reaction furnace; the industrial silicon and active gas are subjected to gas-solid reaction at high temperature to achieve the aim of removing metal impurities; then crystalline silicon is cleaned; the purity of the crystalline silicon reaches as high as 99.999 percent (5N), and is further subjected to vacuum melting of electron beams and oriented condensation treatment; finally, active atmosphere plasma is adopted to further purify the crystalline silicon, and volatile elements which have high activity and are easily oxidized to generate high saturated vapor pressure are removed; and polysilicon is cast in an integrated furnace for casting plasma polysilicon and is directly used for manufacturing a cell chip. The method combines high-temperature gas-solid reaction to remove the metal impurities, the electron beams to remove the volatile elements and a plasma purification and casting integrated furnace technology, improves the purity of the polysilicon to 99.99999 percent (7N) and, fully meets requirement of a solar cell industry on the solar-grade silicon.

Owner:晶海洋半导体材料(东海)有限公司 +1

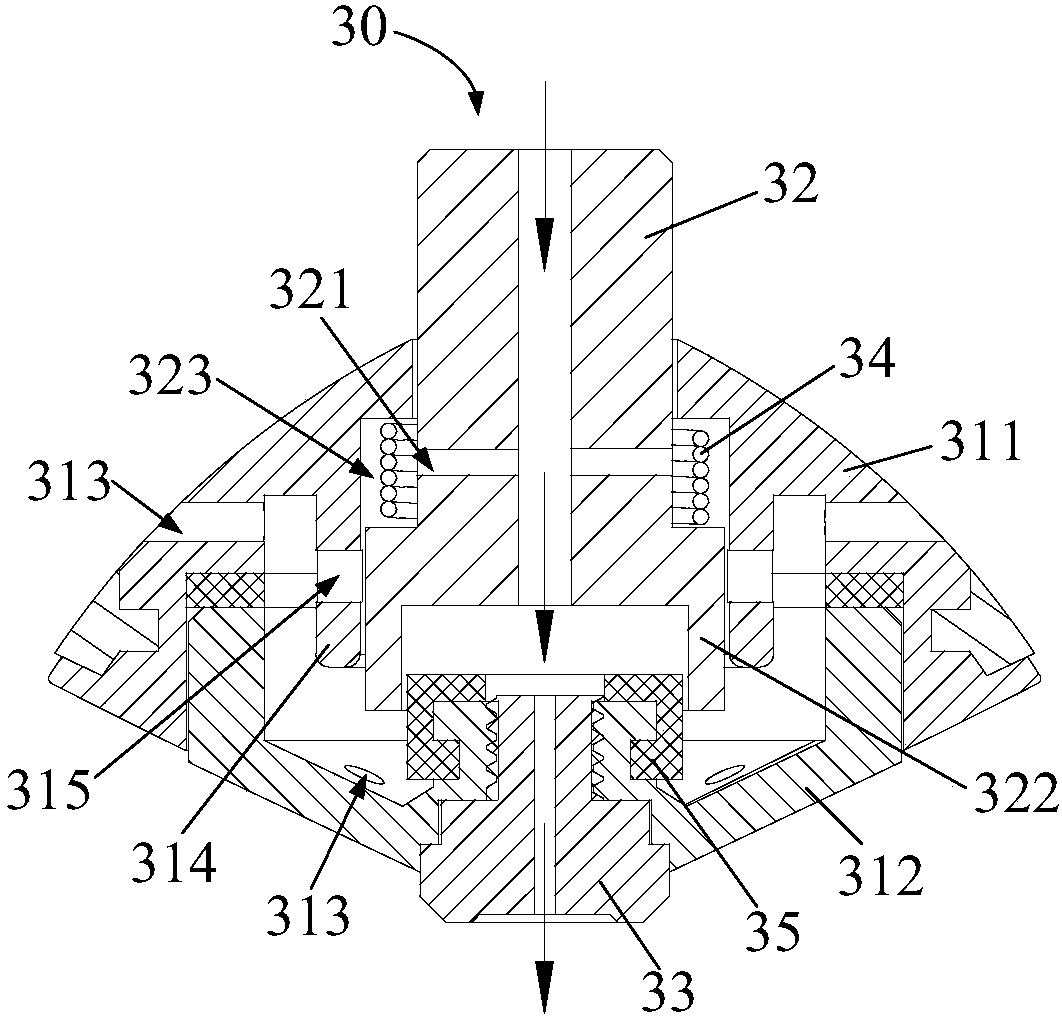

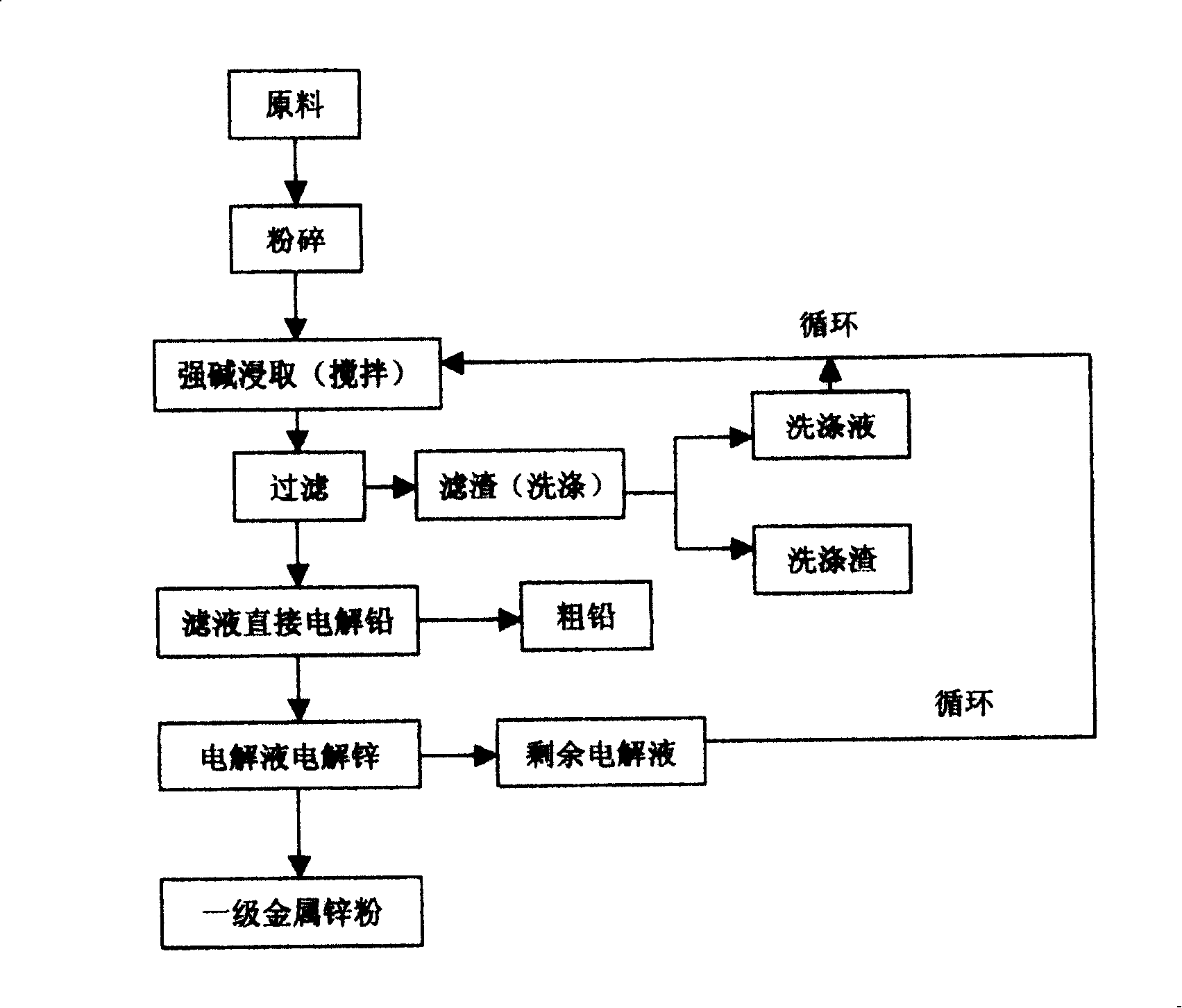

Method for producing metallic lead and zinc by using lead-zinc containing waste slag or lead-zinc monoxide mine

ActiveCN101012514ASimplify the cleaning processImprove current efficiencyPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

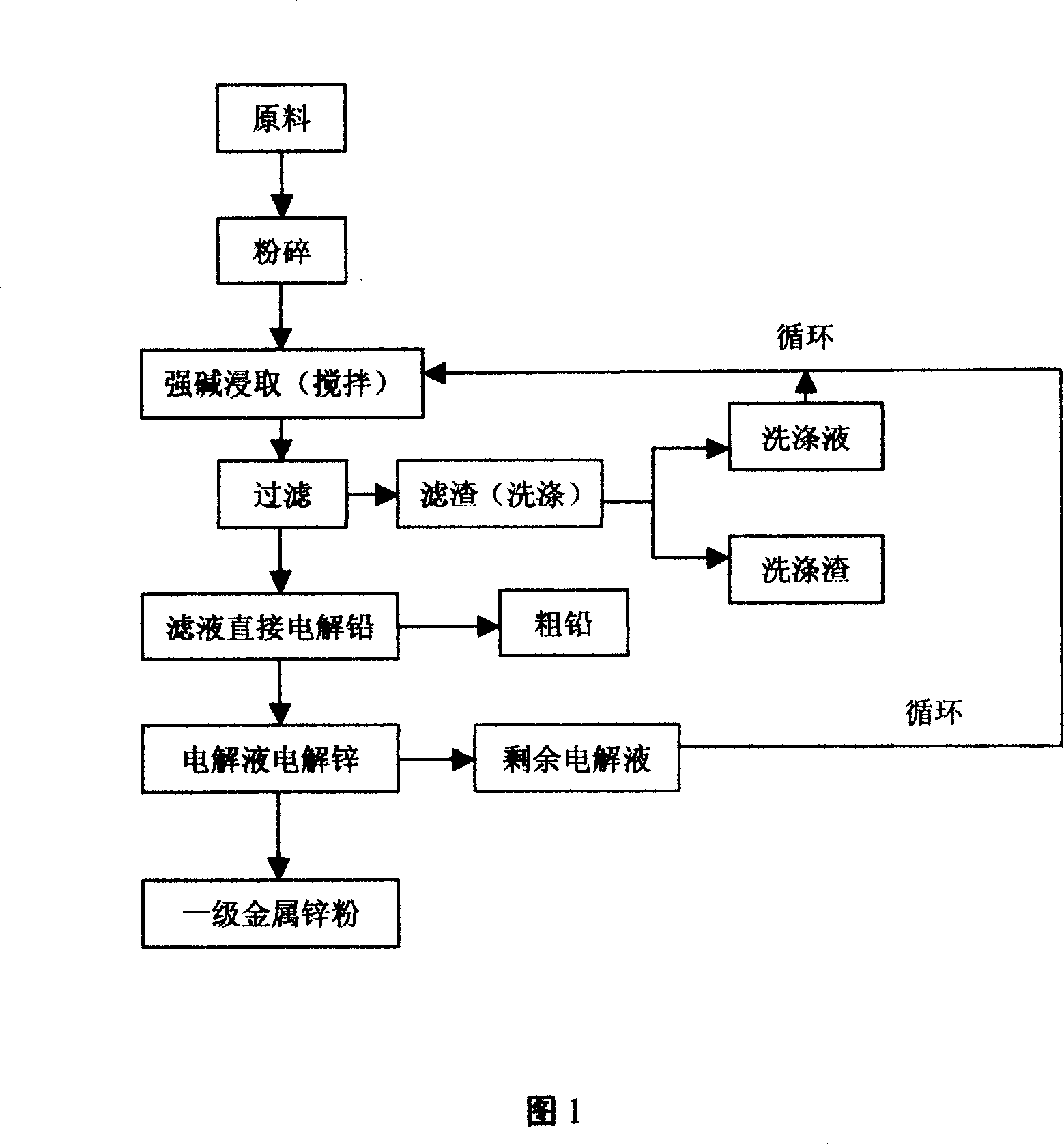

The invention discloses a manufacturing method of metal lead and zinc through waste slag with lead and zinc or low-grade lead or zinc oxide, which comprises the following steps: grinding lead zinc slag or lead zinc oxide into 0.1-1mm; stirring and leaching through strong base solution under 10-100 deg.c for 30-1000min; filtering; draining filtrate; electrolyzing filtrate directly to generate lead with current density at 100-1000A / m2 under 30-100 deg.c for 1-5h; stopping electrolyzing when tank voltage is improved to 1.8-2.5V; producing rough lead with 97-99.9% lead on the cathode; pressing; obtaining electrolytic refined lead; electrolyzing residual electrolytic liquid with zinc under 10-100 deg.c at 2.5-3.5V with current density at 500-1500A / m2 for 1-10h; drying zinc on the cathode protected by inert gas; obtaining one-grade metal zinc powder; circulating residual electrolytic solution in the alkaline leaching course directly.

Owner:昆明同越科技开发有限公司

Preparation method for high-purity melted quartz powder material

The invention discloses a preparation method for a high-purity melted quartz powder material. The method comprises the following steps of comprehensively removing impurities from crude vein quartz mine, namely performing rough crushing, manual selection, electrostatic impurity removal, fine crushing and screening, high-gradient magnetic separation, acid washing impurity removal, washing and air-drying to obtain clean quartz sand; placing the clean quartz sand in an active gas melting furnace for purification, namely introducing active gas in the high-temperature melting furnace to obtain a high-purity melted quartz block; crushing the melted quartz block into powder by using a centrifugal crusher, and performing high-gradient magnetic separation on the powder to obtain high-purity melted quartz powder. According to the method, quartz powder with purity of 99.99 percent can be obtained.

Owner:中材高新江苏硅材料有限公司

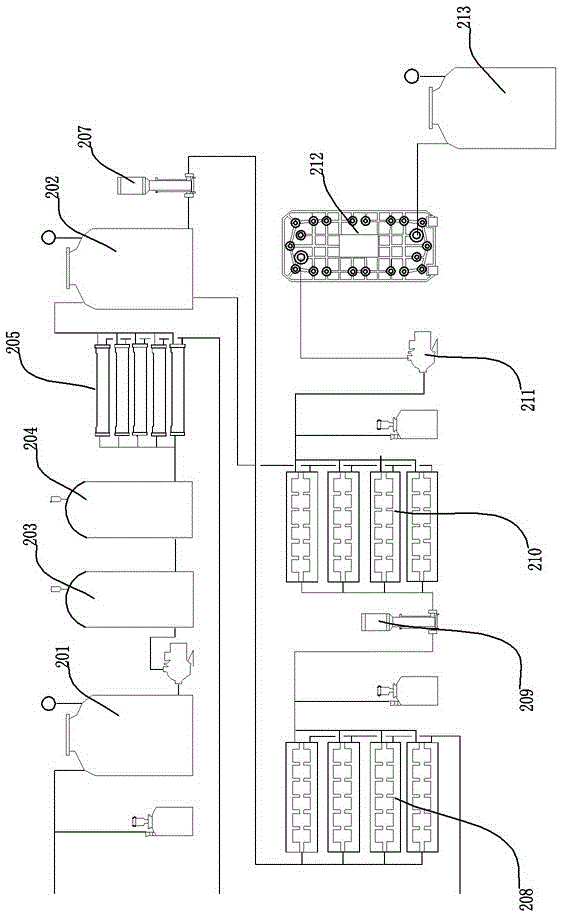

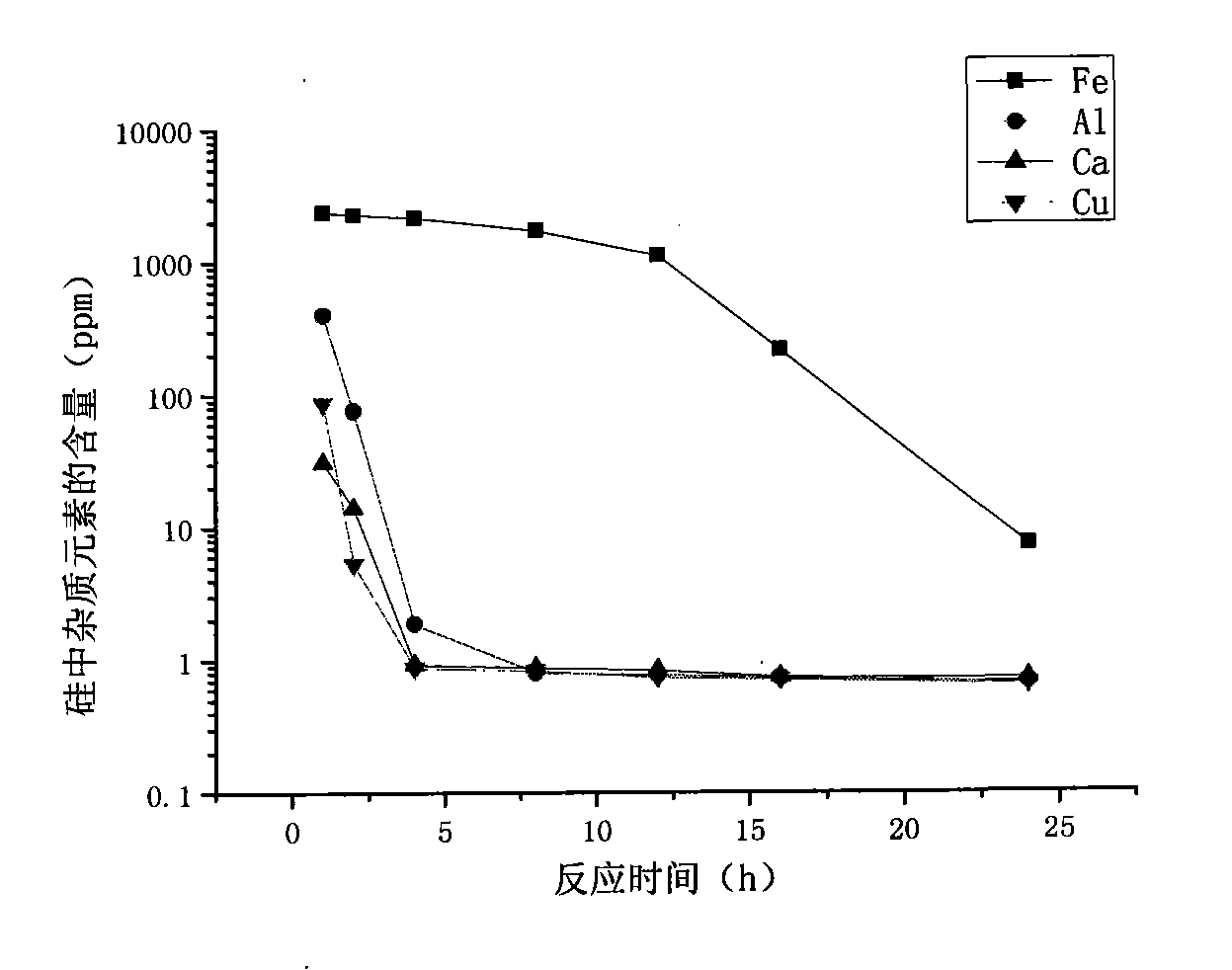

Method for preparing high-purity silicon by high temperature gas-solid reaction

The invention discloses a method for preparing high-purity silicon by using high temperature gas-solid reaction, which comprises the following steps: (1) taking low-purity silicon to be crushed, and then screening the low-purity silicon; (2) putting crushed silicon material into a high temperature solid phase reaction furnace, vacuumizing to be between 1.0*10 and 1.0*10Pa so as to remove most part of air inside the furnace, using inert gases to permute so as to remove air inside the furnace, increasing the temperature of the silicon material to be between 800 and 1412 DEG C, and charging active gases to perform the gas-solid reaction; and (3) cleaning the silicon material treated through the step (2) and obtaining the high-purity silicon product. The invention prepares the high-purity silicon by the gas-solid reaction, has high production efficiency, small investment on equipment, low energy consumption is low, great productivity, little influence on the environment, low cost, and high product purity, and can be further used for prepare the high-purity silicon used in the solar energy battery industry.

Owner:晶海洋半导体材料(东海)有限公司 +1

Zinc and cobalt separation method

ActiveCN106119560AHigh recovery rateAchieve primary separationProcess efficiency improvementSlagNinetieth percentile

The invention provides a zinc and cobalt separation method. The zinc and cobalt separation method specifically includes the steps that 1, most metal in slag with high content of zinc and cobalt enters leaching solutions in a leaching mode, the leaching rate reaches 95% of above, and the metal recovery rate is high; 2, iron, copper and cadmium are removed in a combined mode, the purification process is simplified, the content of the iron, the copper and the cadmium in the solutions can be lowered to 5 mg / L or below, and the purification efficiency is high; 3, preliminary separation of the zinc and the cobalt is realized, the technology is simple, and the operation is easy; and 4, residual zinc is further removed, and complete separation of the zinc and the cobalt is realized. According to the method, the technology is simple, separation of the zinc and the cobalt is complete, the consumption is small, the production cost is low, and the recovery rate of the zinc and the cobalt in materials containing the zinc and the cobalt can reach 90% or above.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Elevator button and its manufacture

ActiveCN101075503AImprove abilitiesBeautiful appearanceElectric switchesAblative recordingCopperMachining time

This invention is an elevator button and its production method. The button is a stainless steel part with at least one layer of electroplated coating and letter and / or figure on it. During production, first make a stainless steel part, then electroplated coating at least one time, then cutting the letter and / or figure on the button through a laser. The electroplated coating is chromic and / or copper and / or nickel multi layers or single layer.

Owner:XIZI OTIS ELEVATOR

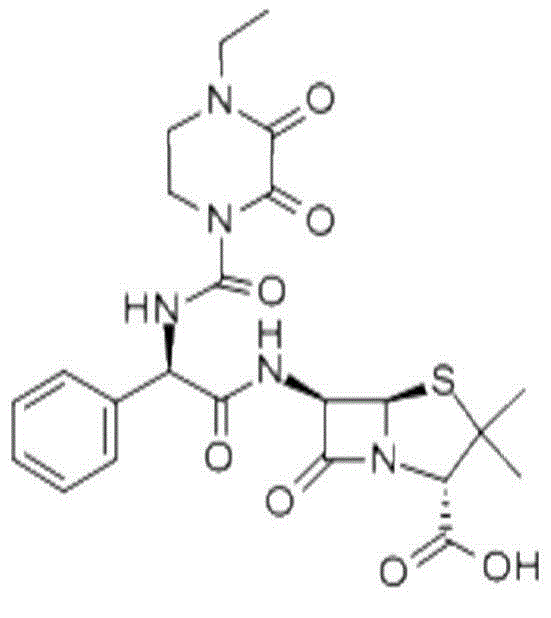

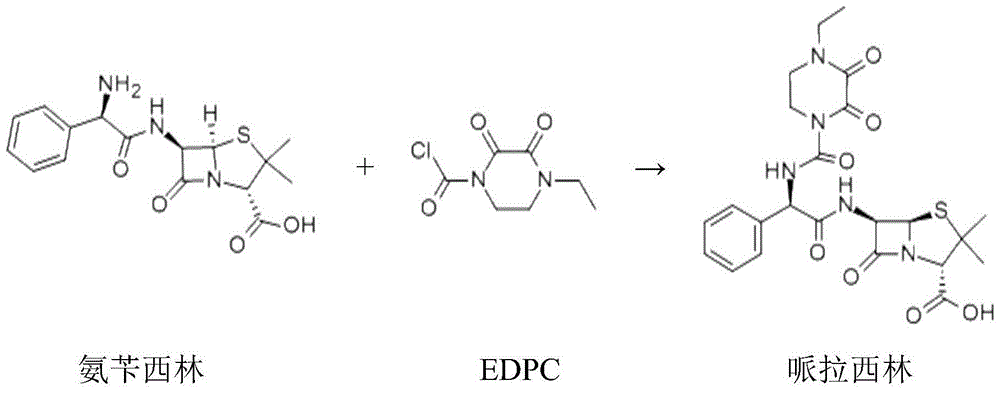

Method for preparing piperacillin acid

The invention discloses a method for preparing piperacillin acid. The method comprises the following steps: adding ampicillin, water and a buffer solution with the pH of 6.0-9.0 into a reactor; adding EDPC into the reactor, meanwhile, adding an alkaline regulator to control the pH to be 6.0-9.0, and reacting for 30-60 minutes in the temperature range of 0 to 10 DEG C while carrying out heat preservation; and adding a solvent to crystallize, controlling the crystallizing point to be 15+ / -2 DEG C, dropwise adding an acidic regulator to regulate the end pH to be 1.5-2.0, carrying out crystal growing for 1 hour in the temperature range of 0 to 10 DEG C, and then, filtrating, washing and drying crystals, thereby obtaining the piperacillin acid finished product. According to the method, during acylation, water is used as a solvent, and the buffer solution is added, so that synthetic reaction for piperacillin acid is inhibited from going towards a reverse reaction direction, the yield of piperacillin acid is increased, and the purity of the product is improved.

Owner:NORTH CHINA PHARM GRP SEMISYNTECH CO LTD

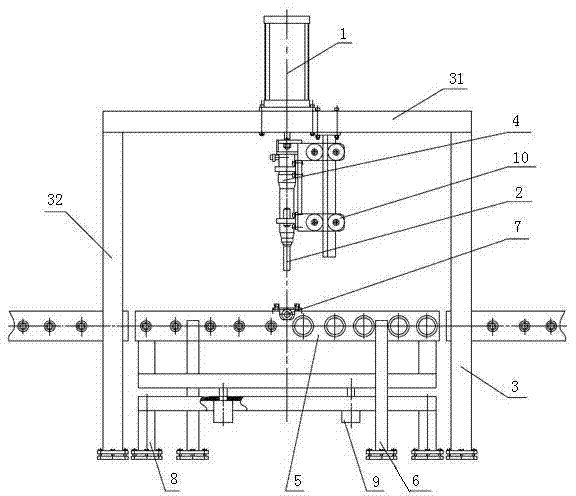

Device and method for separating iron shapes from castings in shells of wheel reducers

The invention relates to a device and a method for separating iron shapes from castings in shells of wheel reducers, and belongs to the field of sand-lined casting for iron shapes. The device comprises a framework, an ejection cylinder, a vibration device, an iron shape conveying roll table, iron shape carrying struts, roll table lifting cylinders and ejector rob guiding mechanisms. The iron shape carrying struts are connected with the iron shape conveying roll table, the roll table lifting cylinders are fixed onto roll table carrying seats, one end of each ejector rod guiding mechanism is connected with the framework, the other end of each ejector rod guiding mechanism is connected with the ejection cylinder, the ejector rod guiding mechanisms act along with vertical actions of the ejection cylinder, vibration force generated by the vibration device and ejection force generated by the ejection cylinder act on the same straight line, and the acting direction of the ejection force is consistent with that of the vibration force. The device and the method have the advantages that the castings in the shells of the wheel reducers can be conveniently separated from the iron shapes, the device is simple in structure and convenient to operate, and requirements of large-scale production can be met.

Owner:浙江省机电设计研究院有限公司

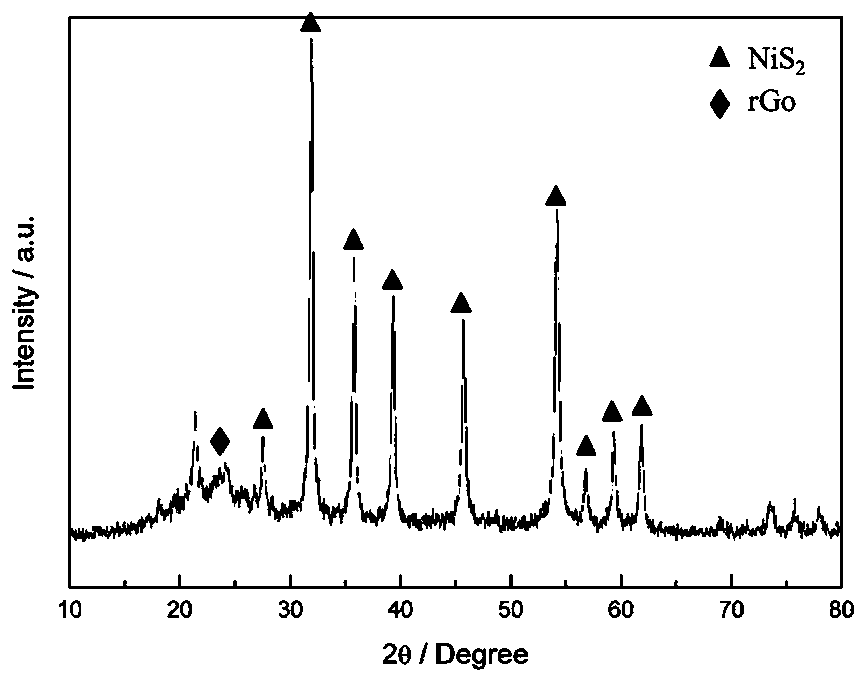

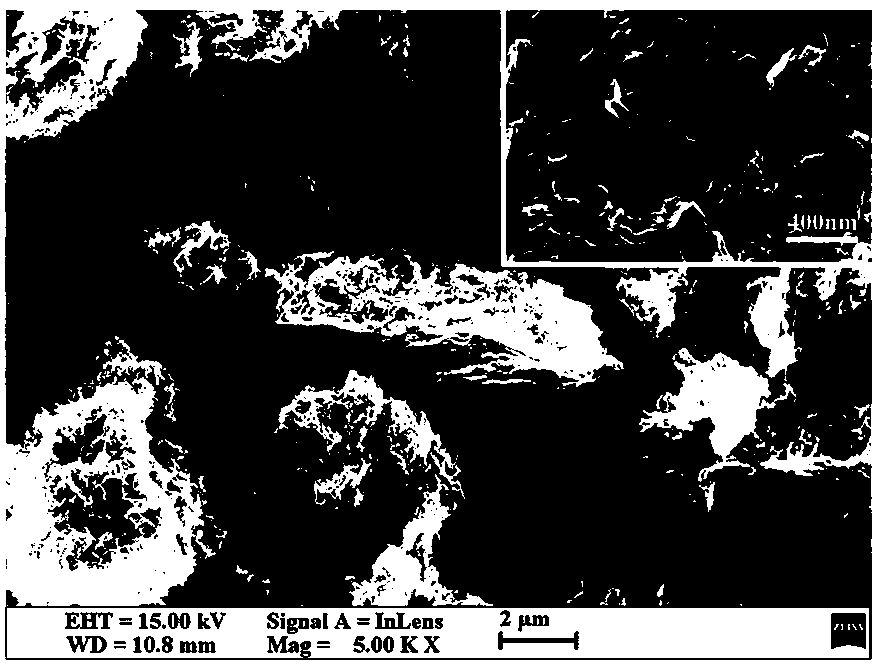

Preparation method and application of spongy graphene/nickel-cobalt sulfide composite material

ActiveCN109003827AWide pore size distributionLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureSulfideHigh pressure

The invention belongs to the field of nanometer materials and electrochemistry, in particular to a preparation method of a spongy graphene / nickel-cobalt sulfide composite material. Deionized water andn-octane are used as a solvent, sulfur, nickel nitrate and cobalt nitrate are used as a sulfur source, a nickel source and a cobalt source, sodium dodecyl benzene sulfonate is used as a surfactant, in a stainless steel autoclave, magnetic stirring is provided, reaction is performed at a certain temperature for a period of time to obtain a spongy graphene / nickel-cobalt sulfide composite material,and the composite material is coated on the surface of nickel foam, dried in vacuum and pressed into an electrode material. By regulating the morphology of the composite material, the prepared graphene / nickel-cobalt sulfide composite material has a larger specific surface area when serving as a composite electrode material, thereby fully contacting the composite material with an electrolyte, and greatly improving the electrochemical performance.

Owner:福建宸琦新材料科技有限公司

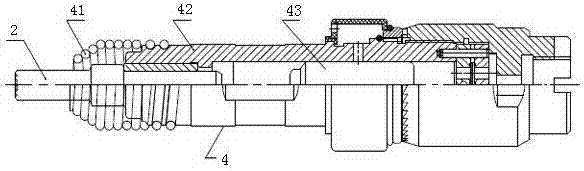

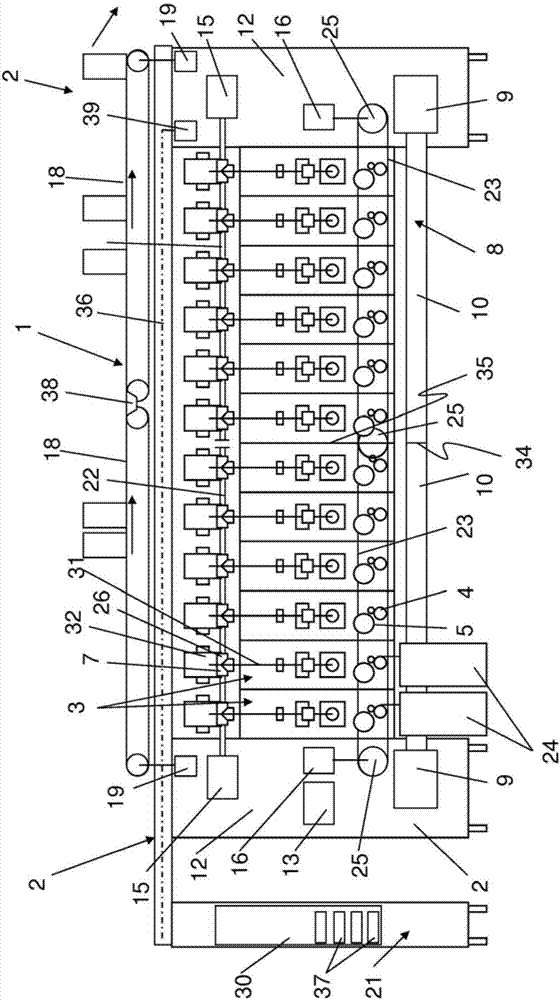

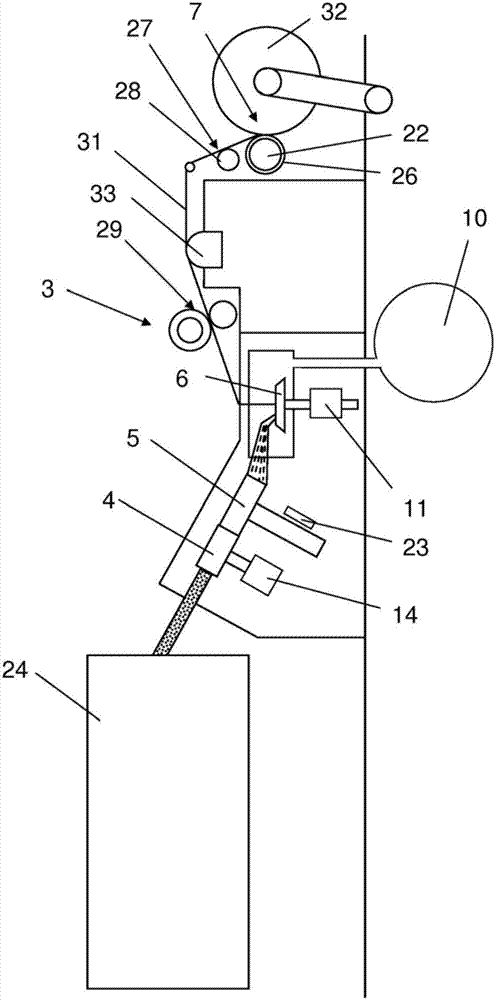

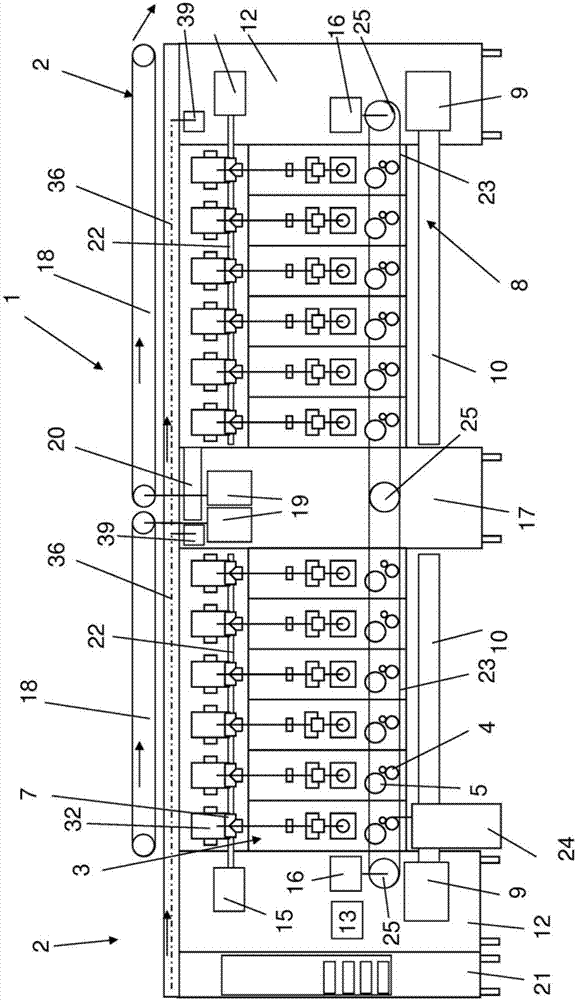

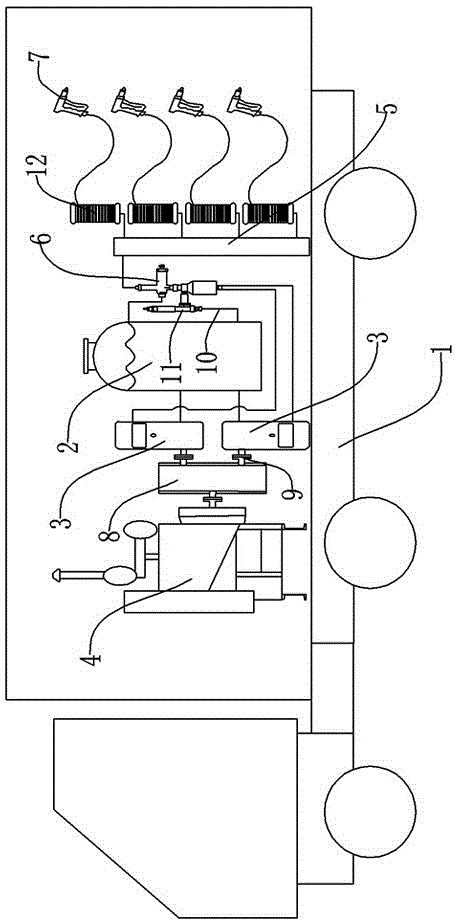

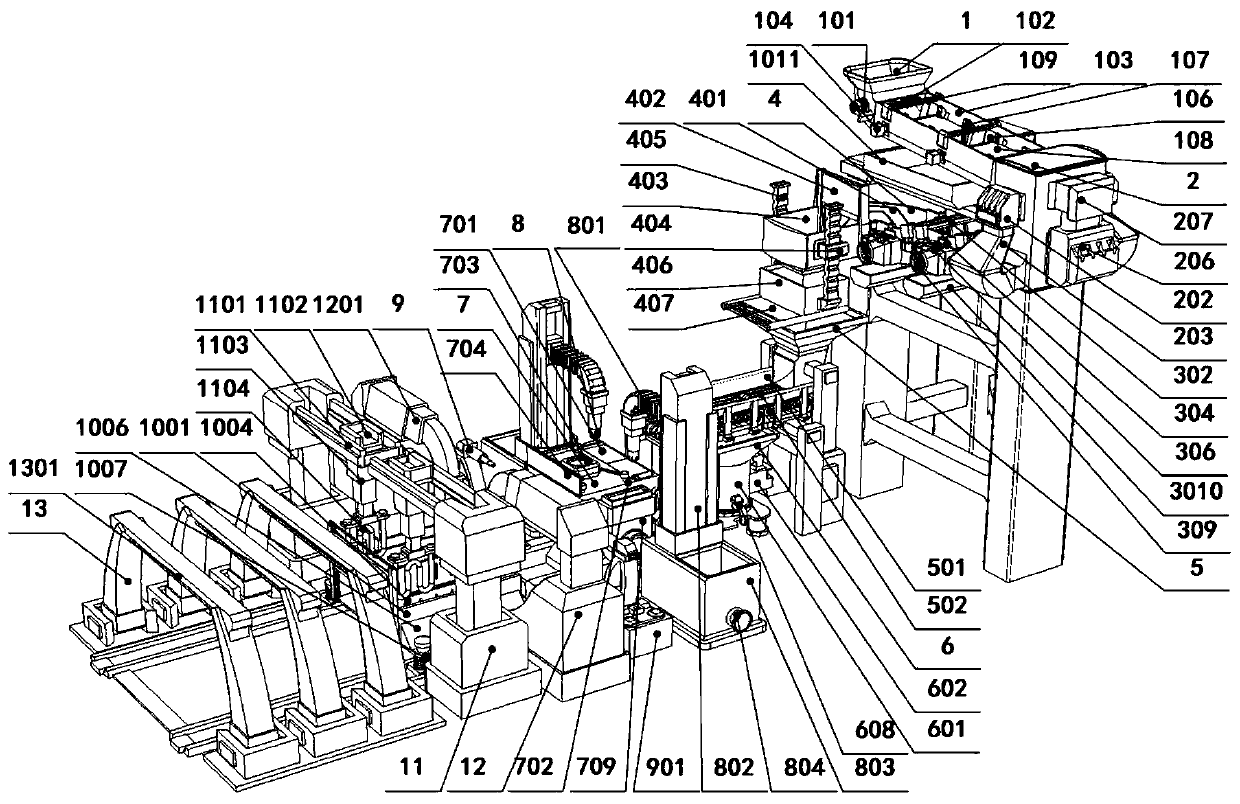

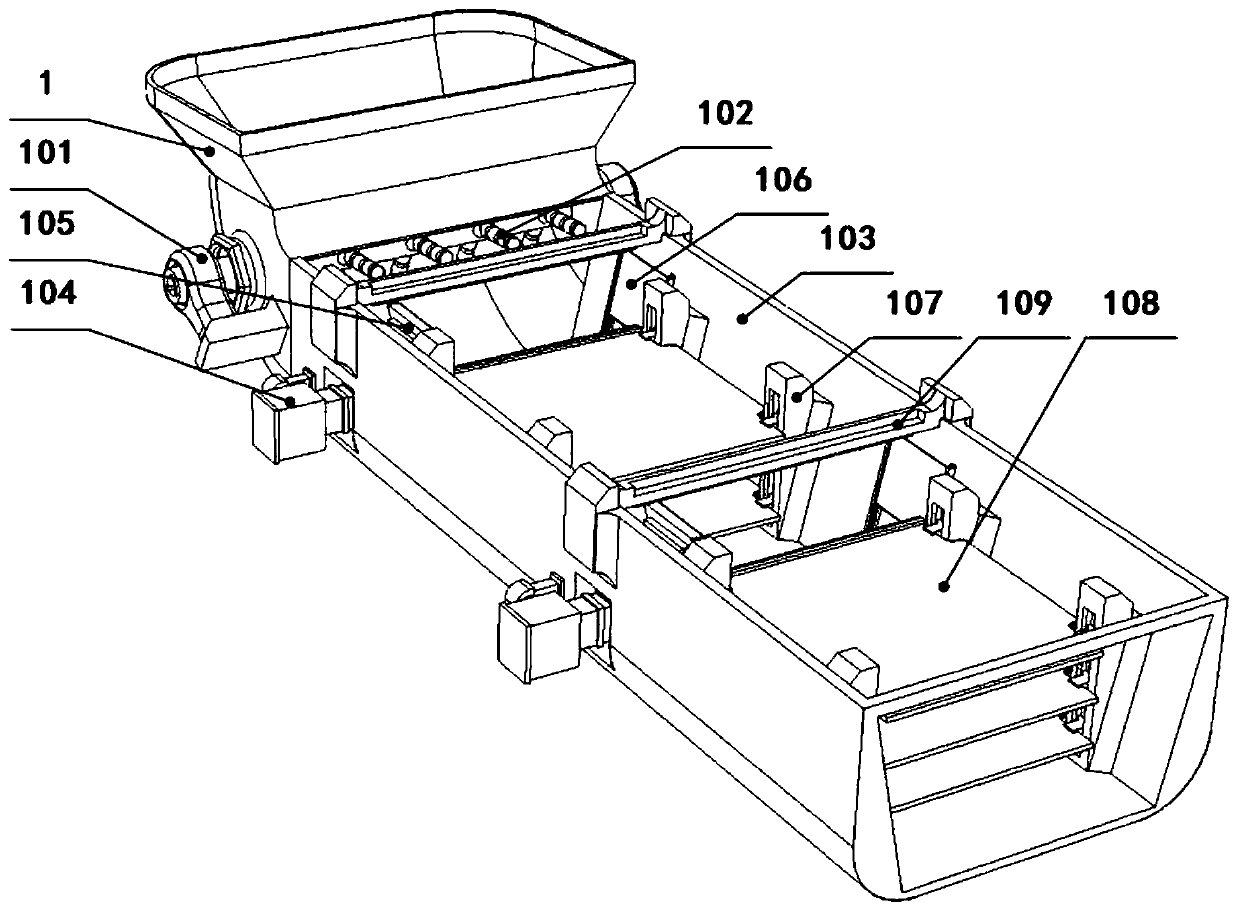

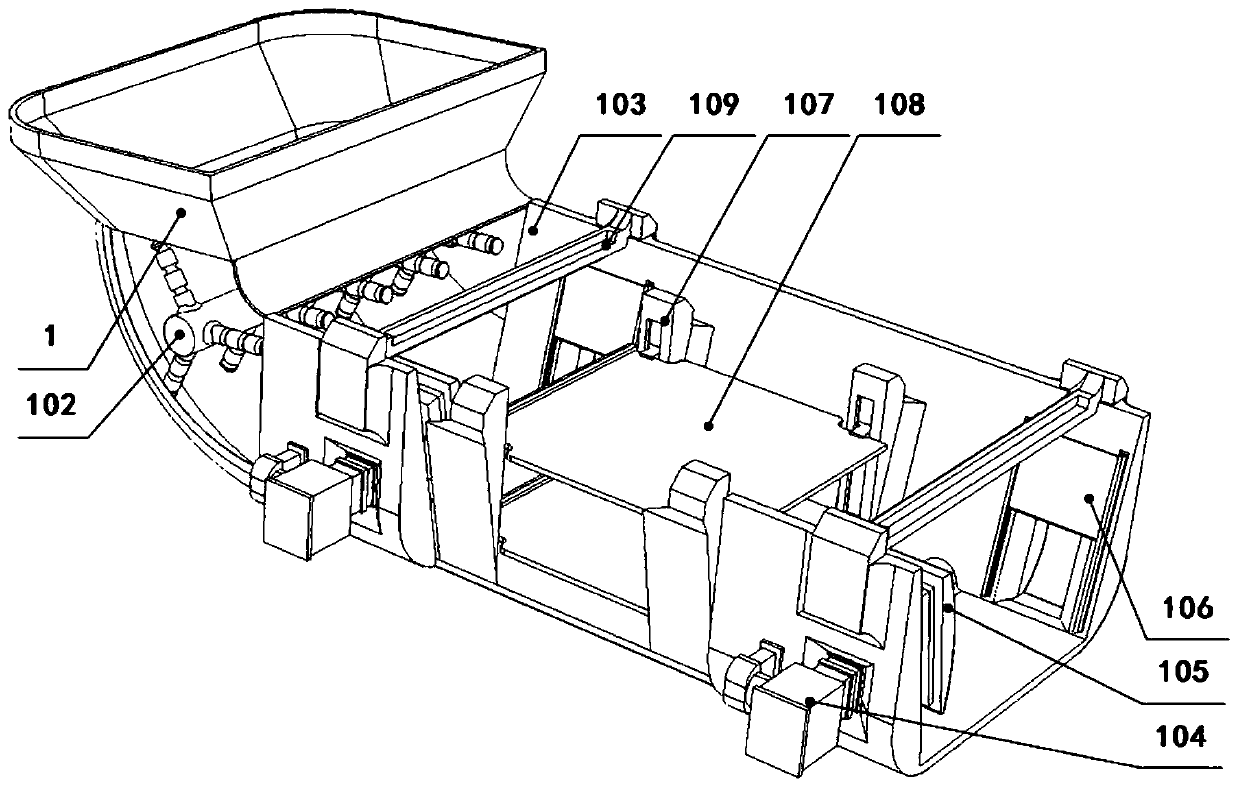

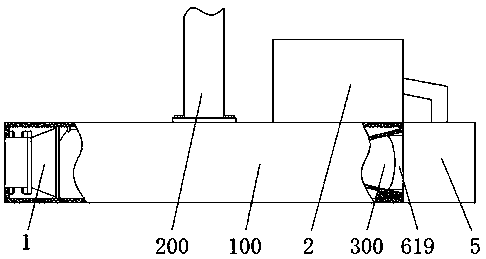

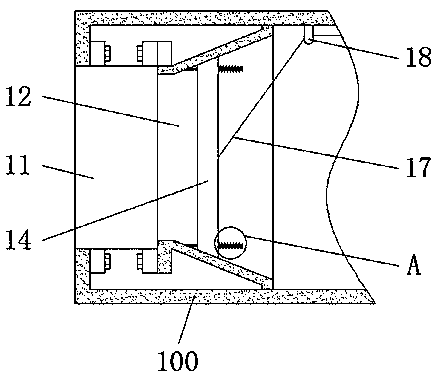

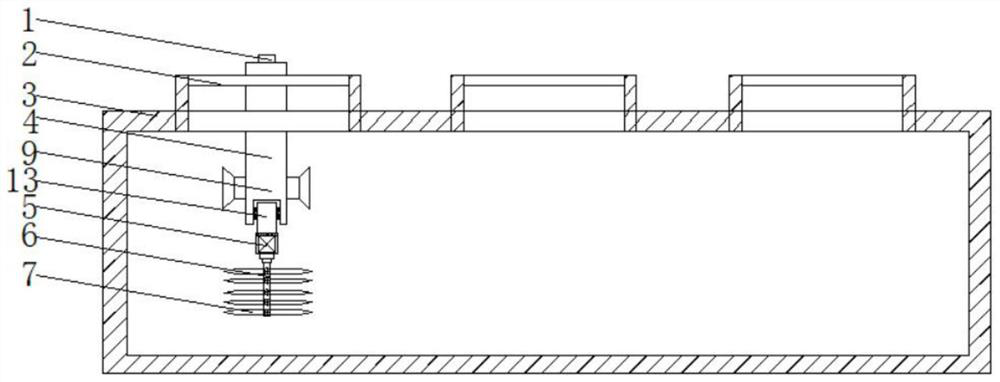

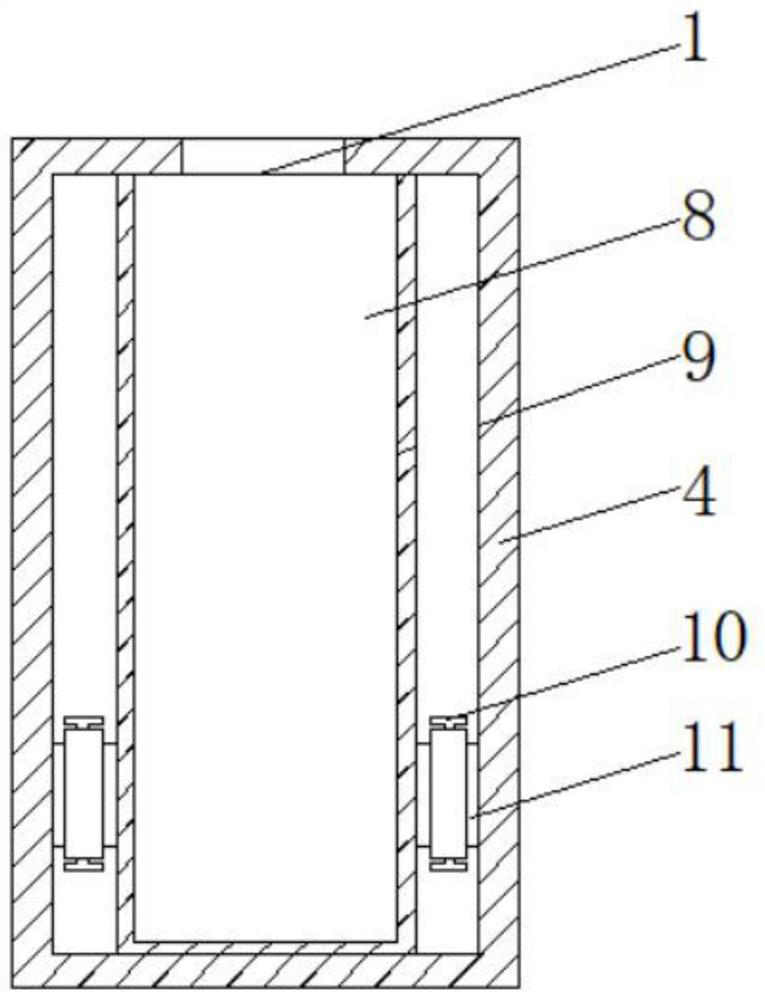

Rotor spinning machine comprising a plurality of working positions and a suction device

ActiveCN107109712ARun energy savingEnergy-saving operation modeContinuous wound-up machinesSliding contact bearingsYarnEngineering

The invention discloses a rotor spinning machine comprising a plurality of working positions and a suction device. The rotor spinning machine has a plurality of working positions (3) arranged next to each other in the longitudinal direction of the rotor spinning machine (1) between two front ends (2) of the rotor spinning machine, each working position having a plurality of working units for producing and winding up a yarn (31). The working units comprise at least one feed device (4), an opening device (5), a spinning rotor (6) and a winding device (7). The rotor spinning machine further comprises a suction device (8) for producing a negative spinning pressure at the working positions. The suction device comprises at least two separate negative pressure sources (9), a negative pressure source being arranged at each of the two front ends of the rotor spinning machine, and each negative pressure source being connected to a separate negative pressure channel (10) which extends only over a part of the working positions in the longitudinal direction of the rotor spinning machine. Every working position has an individual drive (11), in particular an electrical individual drive for the spinning rotor.

Owner:RIETER INGOLSTADT GMBH

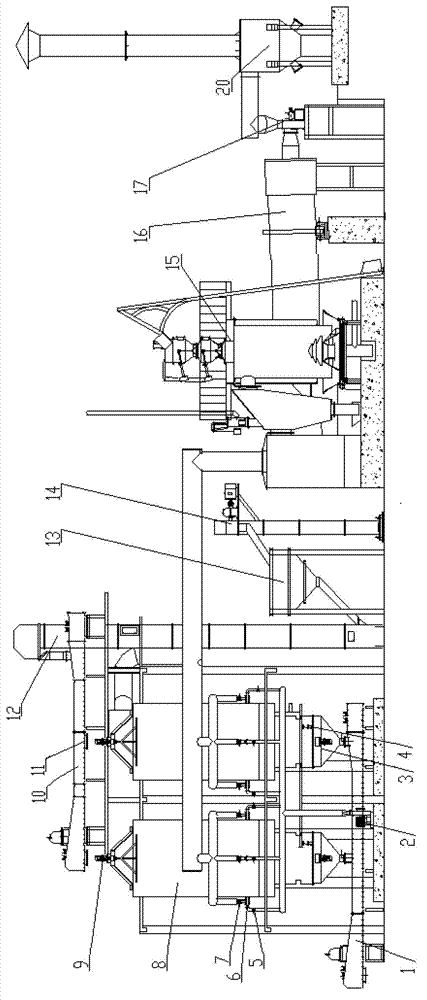

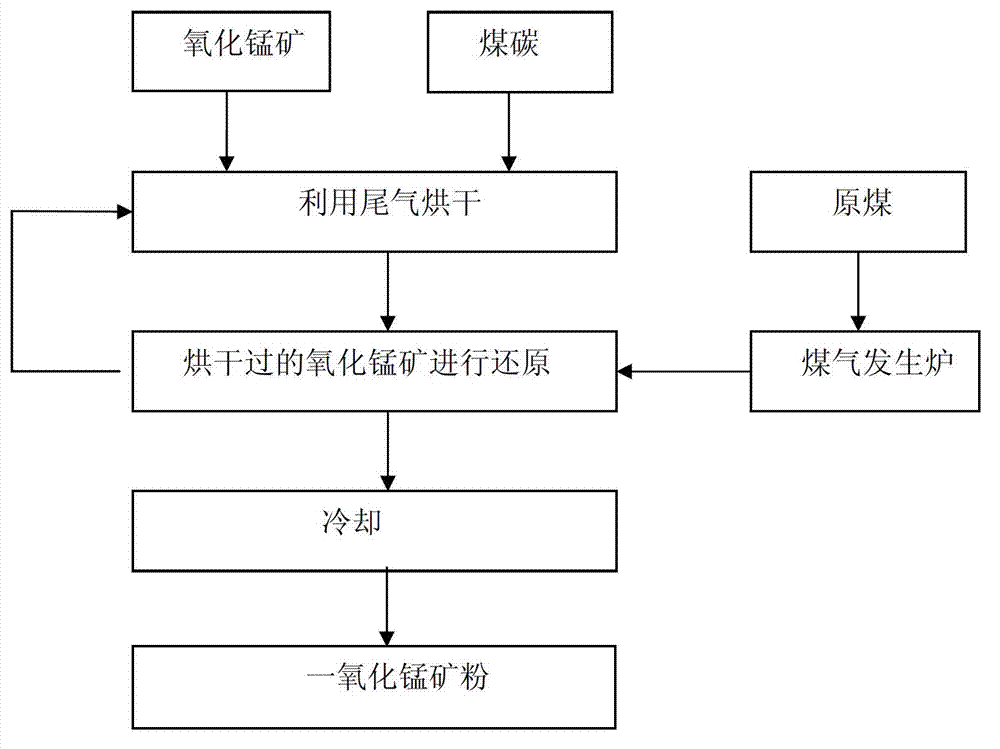

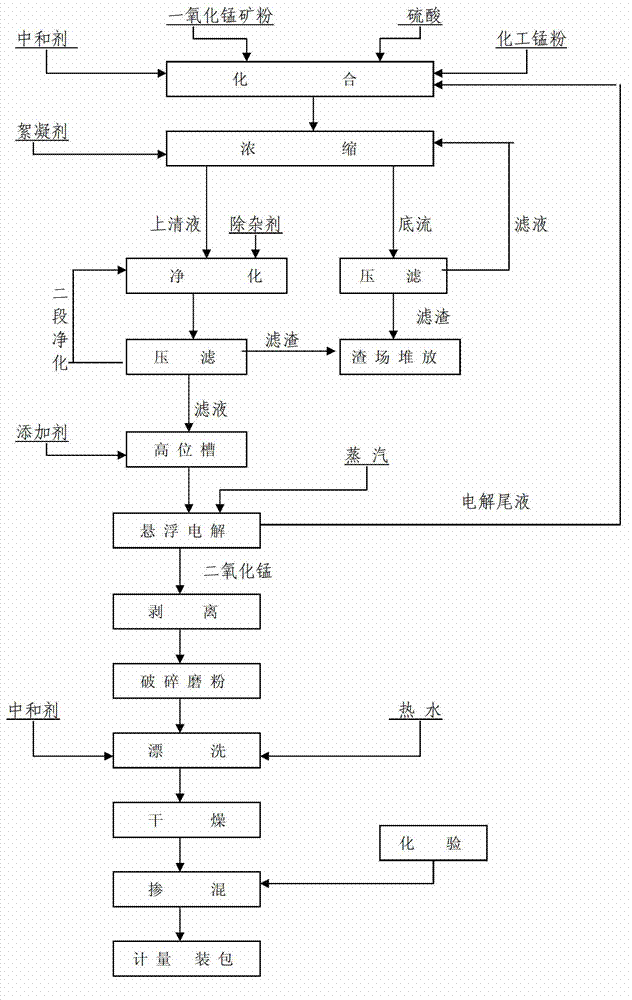

Method for producing electrolytic manganese dioxide

ActiveCN103205772ASolve raw material dependenceReduce procurement costsElectrolysis componentsElectrolysisManganese oxide

The invention discloses a method for producing electrolytic manganese dioxide. The method comprises the following steps of: a, drying and conveying uniformly mixed manganese oxide ore powder and coal to a feed port in the top of a reduction furnace which is vertically arranged to do motions from top to bottom; b, spraying gas through a hot gas nozzle below the reduction furnace to burn, and spirally raising high temperature smoke produced after combustion in a furnace chamber of the reduction furnace; c, discharging the cooled reduced high-temperature manganous oxide through a discharging device, and thus obtaining the manganous oxide ore powder; d, utilizing the manganous oxide ore powder and sulfuric acid to carry out leaching combination reaction, and obtaining a crude manganese sulfate solution after solid-liquid separation; and e, purifying the crude manganese sulfate solution to remove impurities, pouring the purified manganese sulfate solution into an electrolytic tank to electrolyze so as to obtain an electrolytic manganese dioxide product. The manganous oxide ore powder prepared by the method can be used as a substituted raw material for producing the electrolytic manganese dioxide, so that a manganese carbonate ore raw material depending problem of manganese industries is solved, and the acid consumption and cost are greatly lowered.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

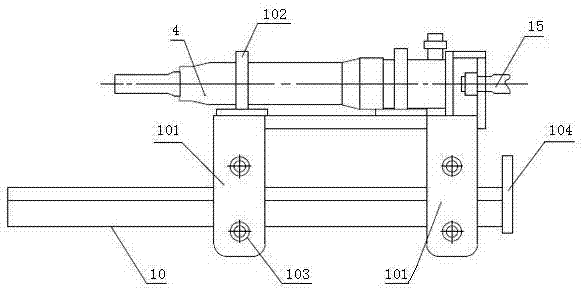

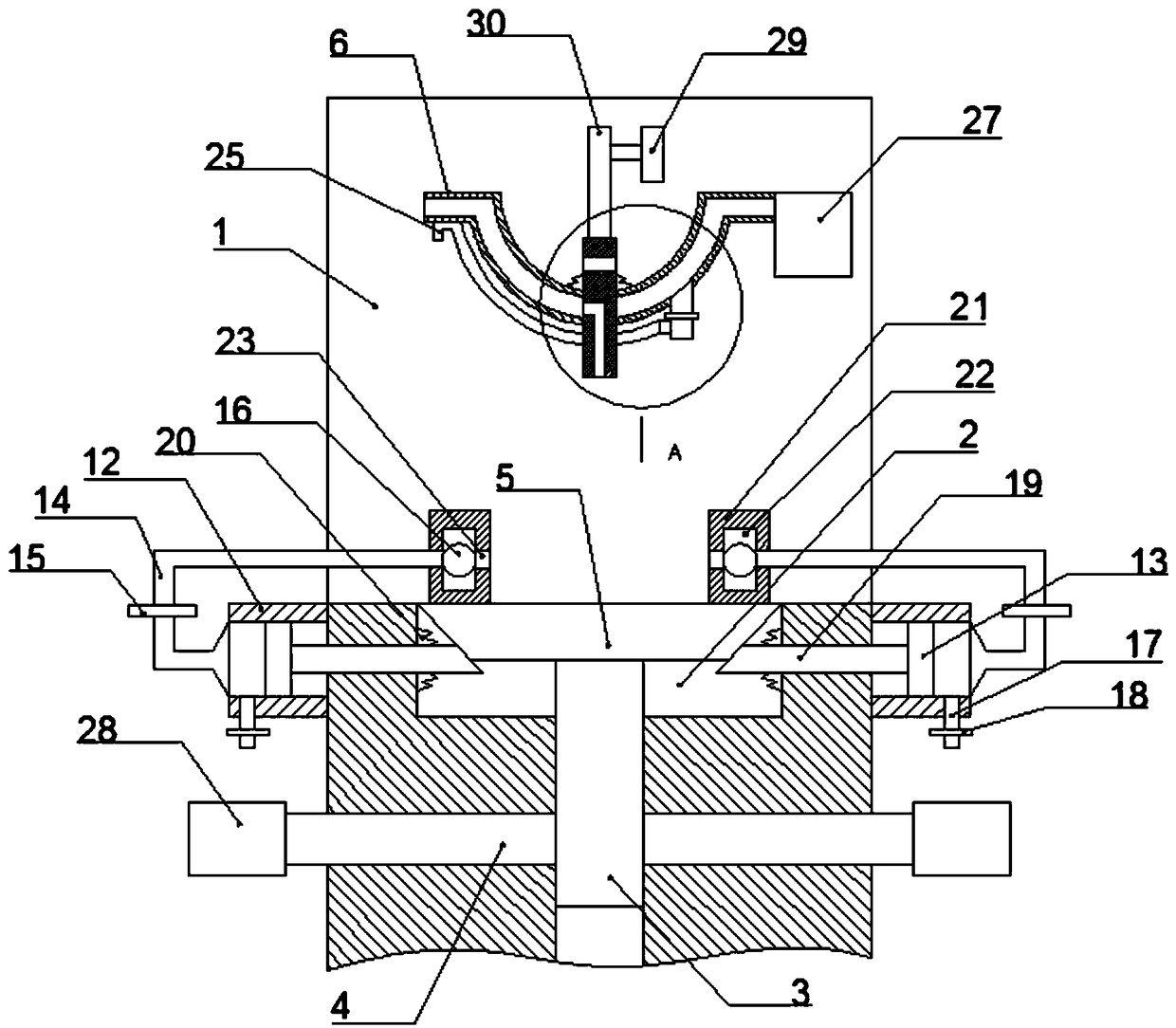

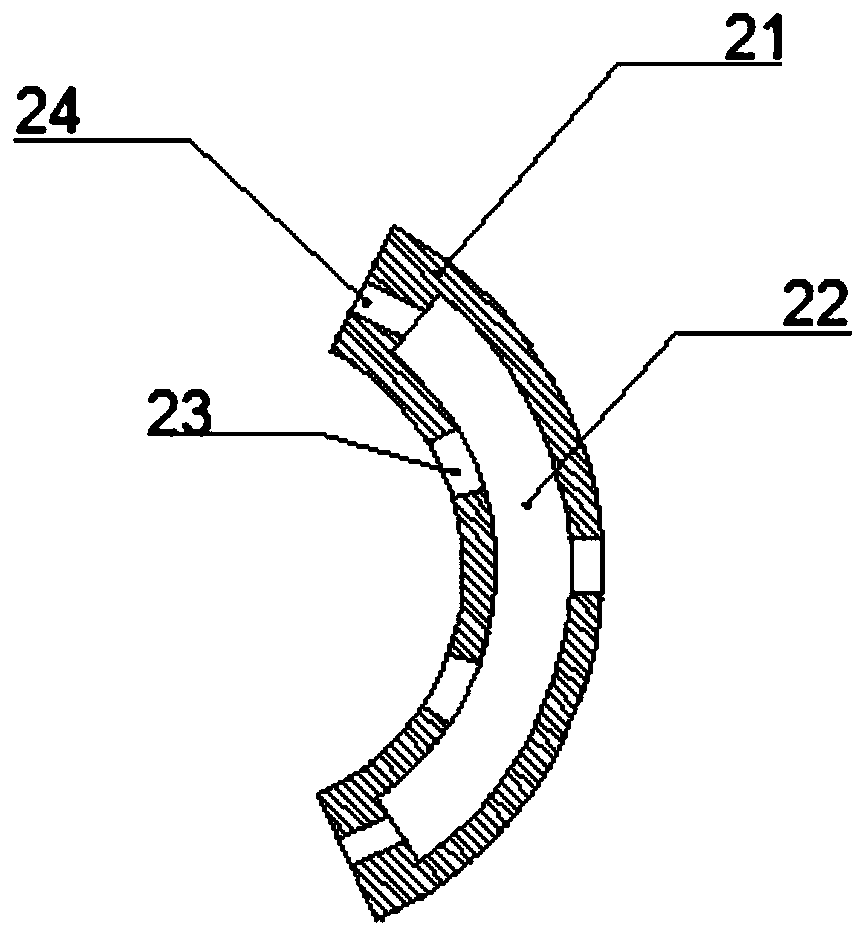

Rare earth extracting and impurity removing device

ActiveCN105886757AReduce backlogFlow synchronizationProcess efficiency improvementRare earthImpurity

The invention provides a rare earth extracting and impurity removing device. A hidden chamber A of an extracting and impurity removing chamber is communicated with a feed liquid guide-in pipe. A water phase chamber A of a feed liquid clarifying chamber is communicated with the feed liquid guide-out pipe. The hidden chamber A and multiple mixing chambers A are arranged in the extracting and impurity removing chamber. The mixing chambers are partitioned through overflowing plates A and flow blocking plates A. The overflowing plates A are fixed to the bottom of the extracting and impurity removing chamber, and the height of the overflowing plates A is smaller than the depth of the extracting and impurity removing chamber. The flow blocking plates A are fixed to the upper portion of the extracting and impurity removing chamber, and the lower ends of the flow blocking plates do not make contact with the bottom of the extracting and impurity removing chamber. After the device is adopted for removing impurities, continuous production process is achieved in the extracting and impurity removing processes, the impurity removing and extracting agent can be recycled automatically, and material overstock is reduced; no staff are needed for carrying out operation, and the impurity removing effect is efficient and stable; feed liquid automatically flows back to a separating and extracting groove after the impurities are removed, and the speed of the feed liquid is synchronous with the flowing speed of the separating and extracting groove.

Owner:CHALCO GUANGXI RARE EARTH DEV CO LTD

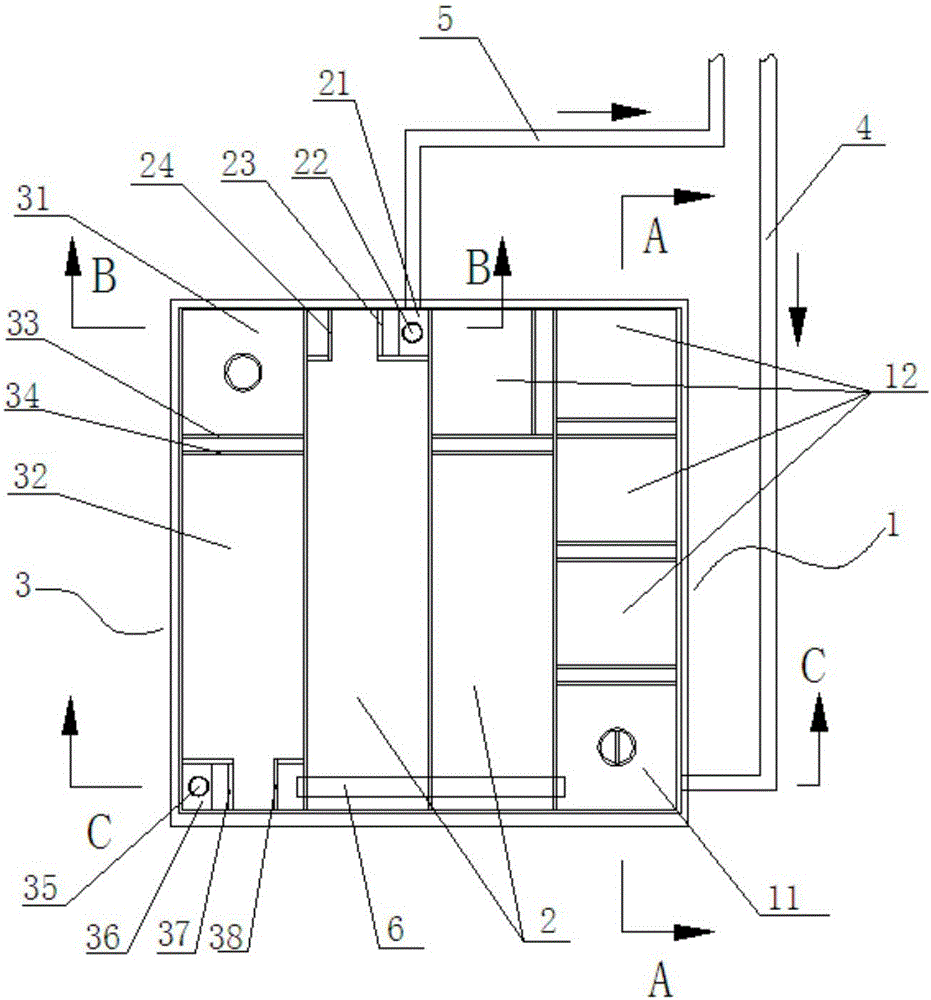

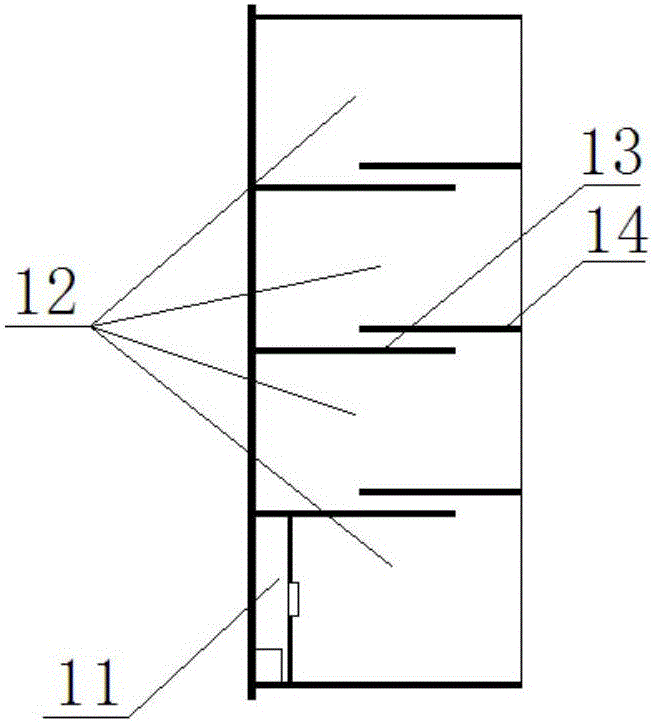

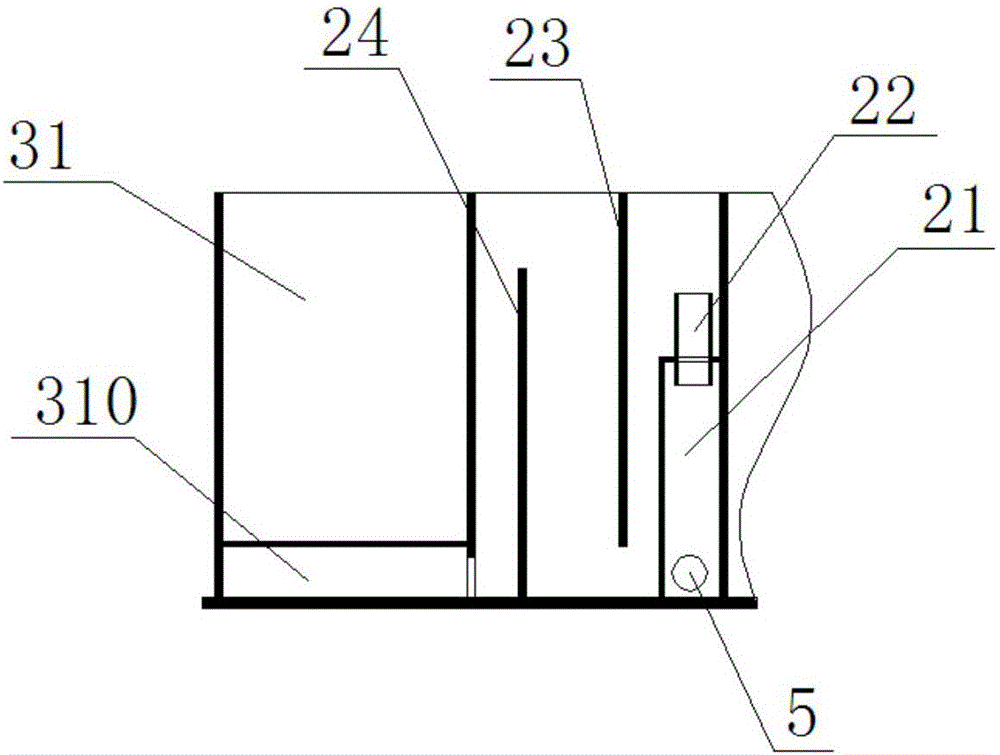

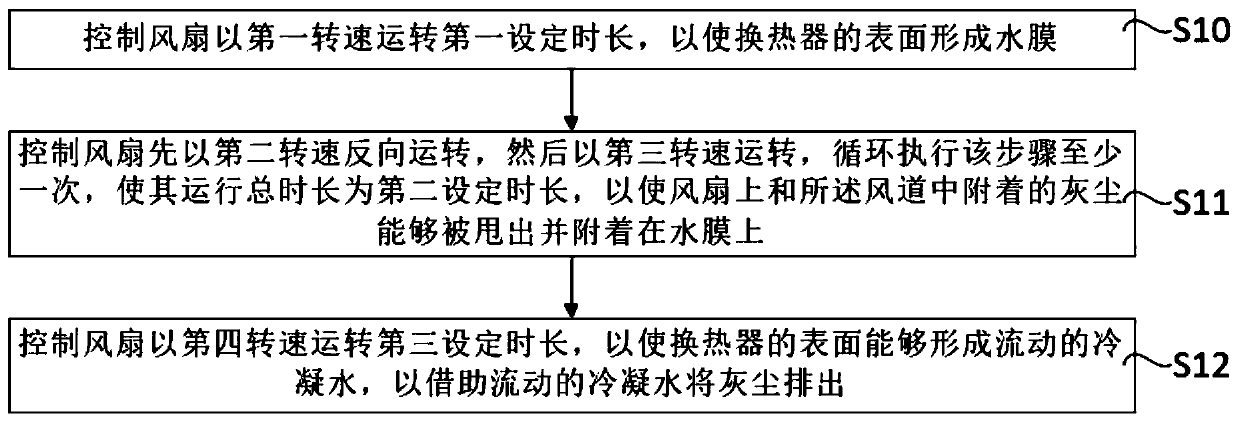

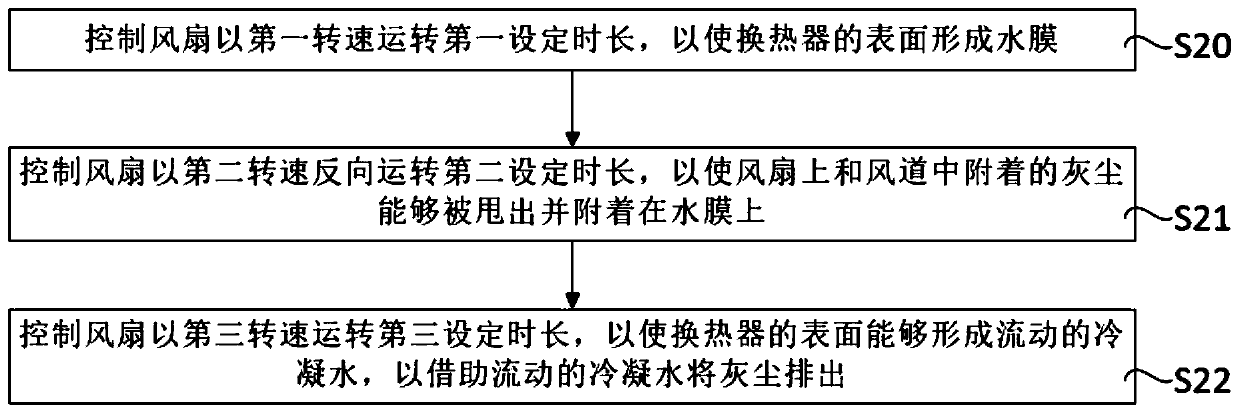

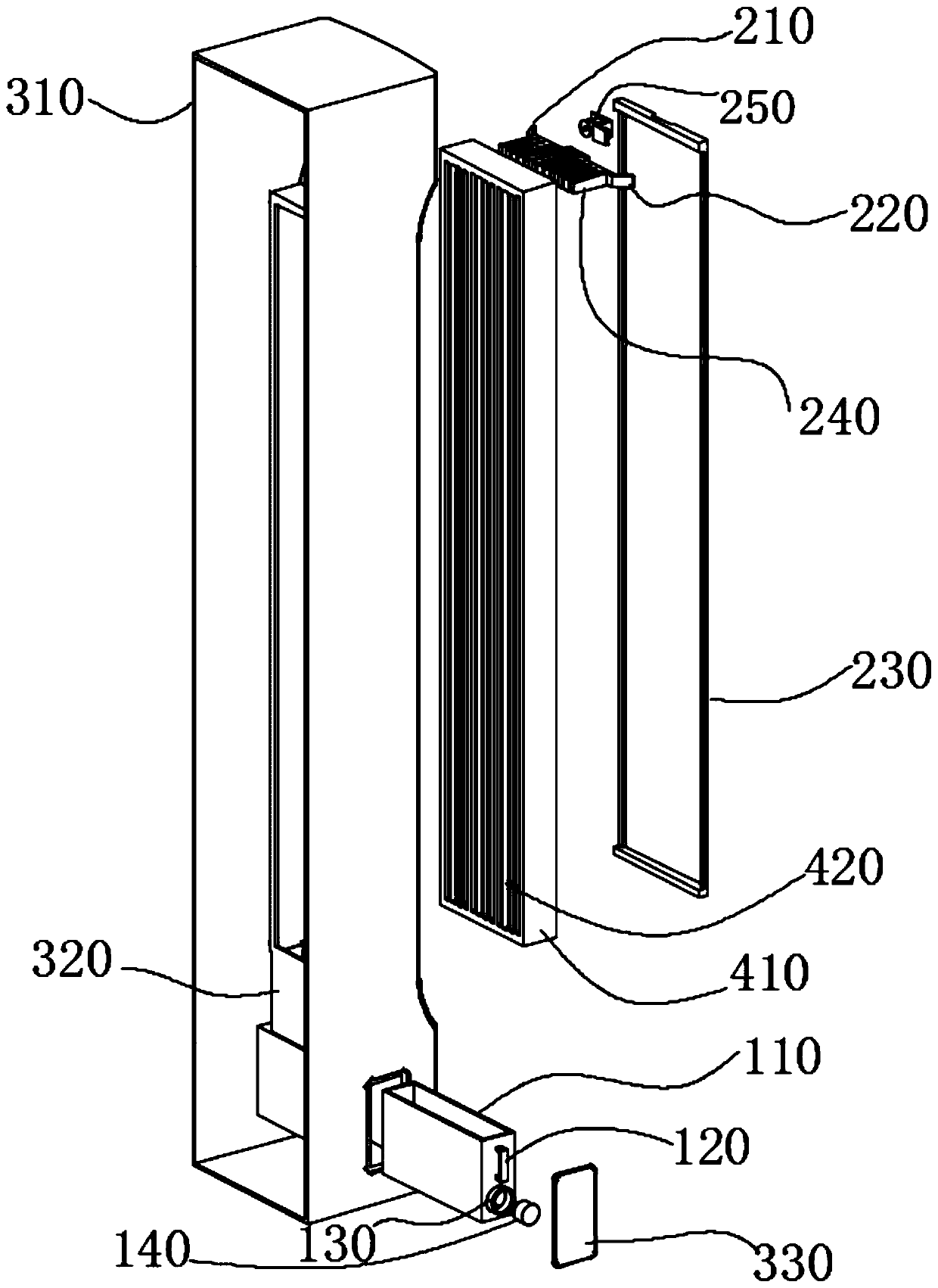

Air conditioner and self-cleaning control method for fan and air duct thereof

ActiveCN110986248AImprove adsorption capacityLow costMechanical apparatusCondensate preventionEngineeringProcess engineering

The invention relates to the technical field of air conditioners and provides an air conditioner and a self-cleaning control method for an fan and air duct thereof to solve the problems that the and air duct of an existing air conditioner are high in dust removal cost and inconvenient to us. The control method comprises the steps: controlling the fan to run at a first rotating speed for a first set duration to form a water film on the surface; controlling the fan to operate reversely at a second rotating speed and then operate at a third rotating speed, and circularly executing the step at least once, so that dust attached to the fan and the air flue can be thrown out and attached to the water film; and controlling the fan to operate for a third set duration at a fourth rotating speed, sothat flowing condensate water can be formed on the surface of the heat exchanger, and dust is discharged by means of the flowing condensate water. According to the control method provided by the invention, deep self-cleaning of dust in fans and air ducts of the indoor unit and the outdoor unit can be achieved, a disassembling and assembling machine is not needed, a special cleaning tool does not need to be arranged, and the dust removal cost can be greatly reduced.

Owner:CHONGQING HAIER AIR CONDITIONER CO LTD +2

Clean production technology and method for lithium sulfate

InactiveCN108383140AImprove conversion rateImprove leaching rateLithium sulfates/sulfitesLithium sulphatePregnant leach solution

The invention provides a clean production technology and method for lithium sulfate. A technique and a roasting additive are used. The production process comprises the steps of sieving, mixing, granulating, roasting, soaking, impurity deposition, crystalizing, drying and the like, and the roasting additive comprises components including Na2SO4, K2SO4, CaCO3, CaO and the like. By the clean production technology and method for lithium sulfate, the roasting conversion rate and leaching rate of lithium can be increased, moreover, acid is not used, types and contents of impurities in leaching liquid are less, a follow-up impurity removal process is simple, and acid and alkali consumption is low. The production process is simple, the lithium extracting rate is high, energy and materials are reused, and thus, the clean production technology and method are suitable for large-scale production.

Owner:天津二八科技股份有限公司

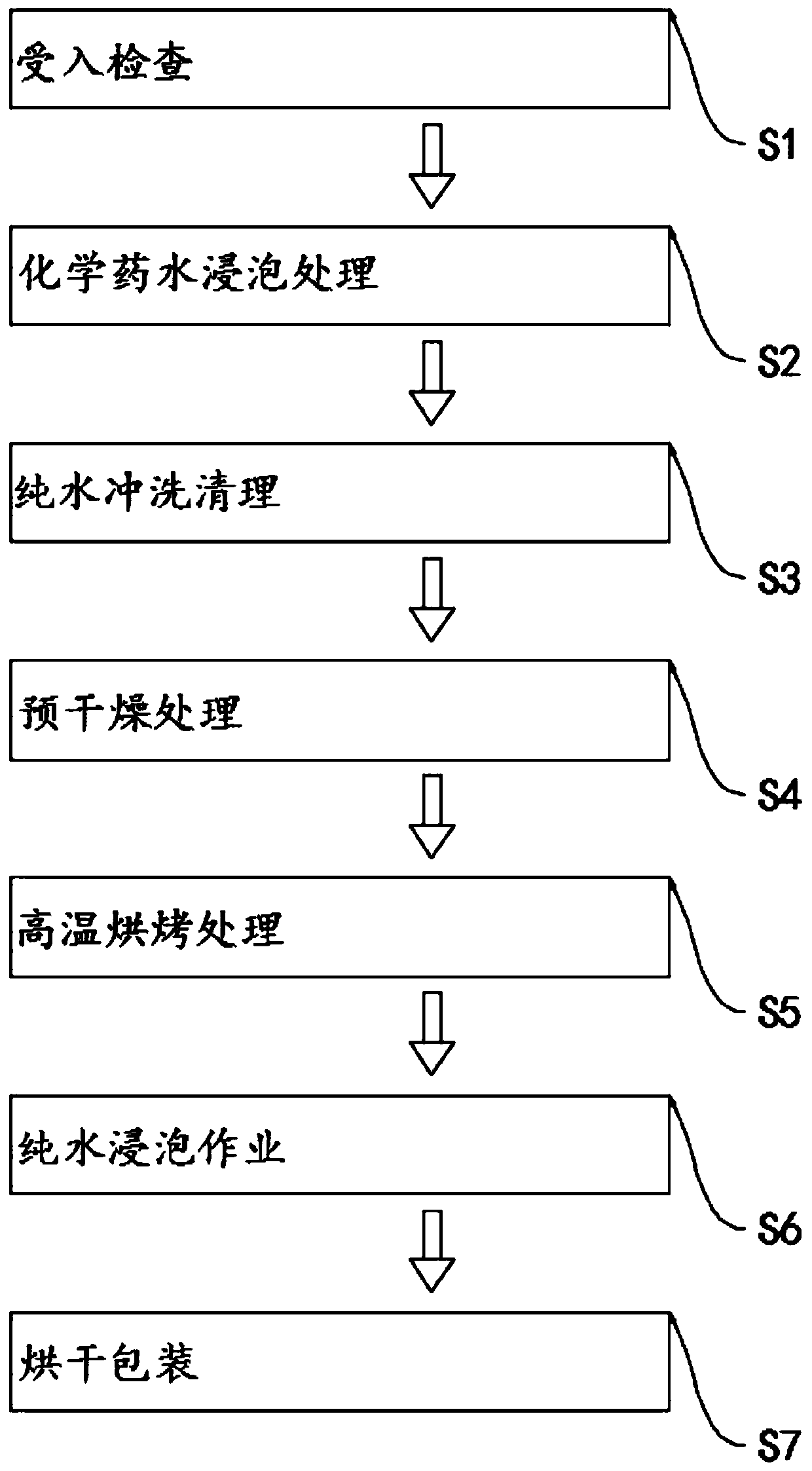

Cleaning and regenerating method of titanium crucible

InactiveCN111482423ASimplify the cleaning processReduce wash timeDrying solid materials without heatHollow article cleaningSurface moistureTitanium

The invention discloses a cleaning and regenerating method of a titanium crucible, and relates to the technical field of OLED panel production. The method comprises the following steps of receiving inspection, wherein integrity inspection is carried out on a titanium crucible body, and the residual amount of a film layer is determined; soaking treatment with chemical liquid; pure water flushing and cleaning, wherein the titanium crucible body soaked with the liquid is flushed with pure water, and floating ash and impurities on the surface of the crucible are removed; pre-drying treatment, wherein an air gun is used for blowing the surface of the titanium crucible body flushed with the pure water, surface moisture is removed, and the titanium crucible body is placed in a drying box to be dried; high-temperature baking treatment, wherein the titanium crucible body subjected to pre-drying treatment is subjected to high-temperature baking treatment; pure water soaking operation, wherein the titanium crucible body subjected to high-temperature baking treatment is placed in pure water to be soaked; and drying and packaging, wherein the titanium crucible body soaked with the pure water isdried and packaged for use. The method has the advantages that the crucible residual film is effectively cleaned, and meanwhile the crucible loss is reduced.

Owner:四川富乐德科技发展有限公司

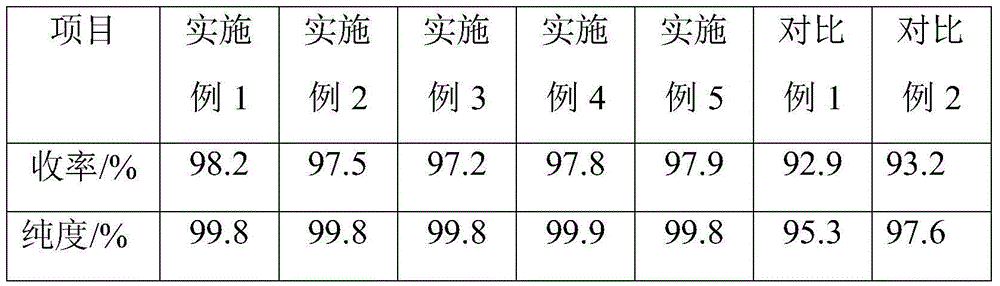

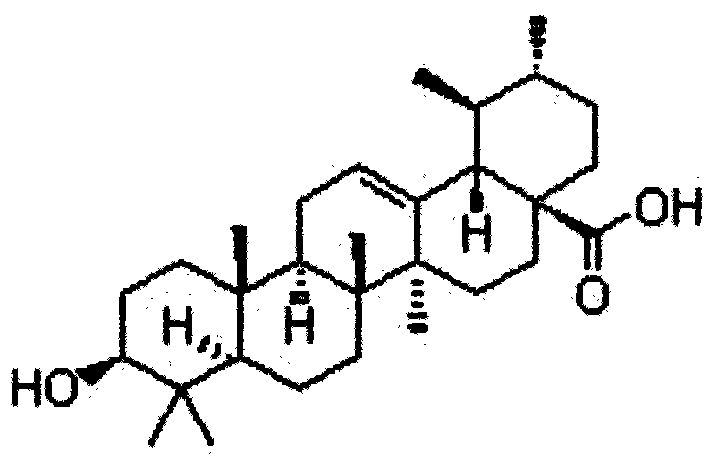

Method for extracting ursolic acid from loquat leaf

The invention relates to a method for separately extracting ursolic acid which is low in cost, high in output and short in period, and is easy to realize industrialization. The method comprises the technical steps of extracting, decoloring, condensing and recrystallizing. The method for producing ursolic acid has the advantages of less solvent kinds, simple process, high yield and extremely high purity.

Owner:NANJING ZELANG MEDICAL TECH

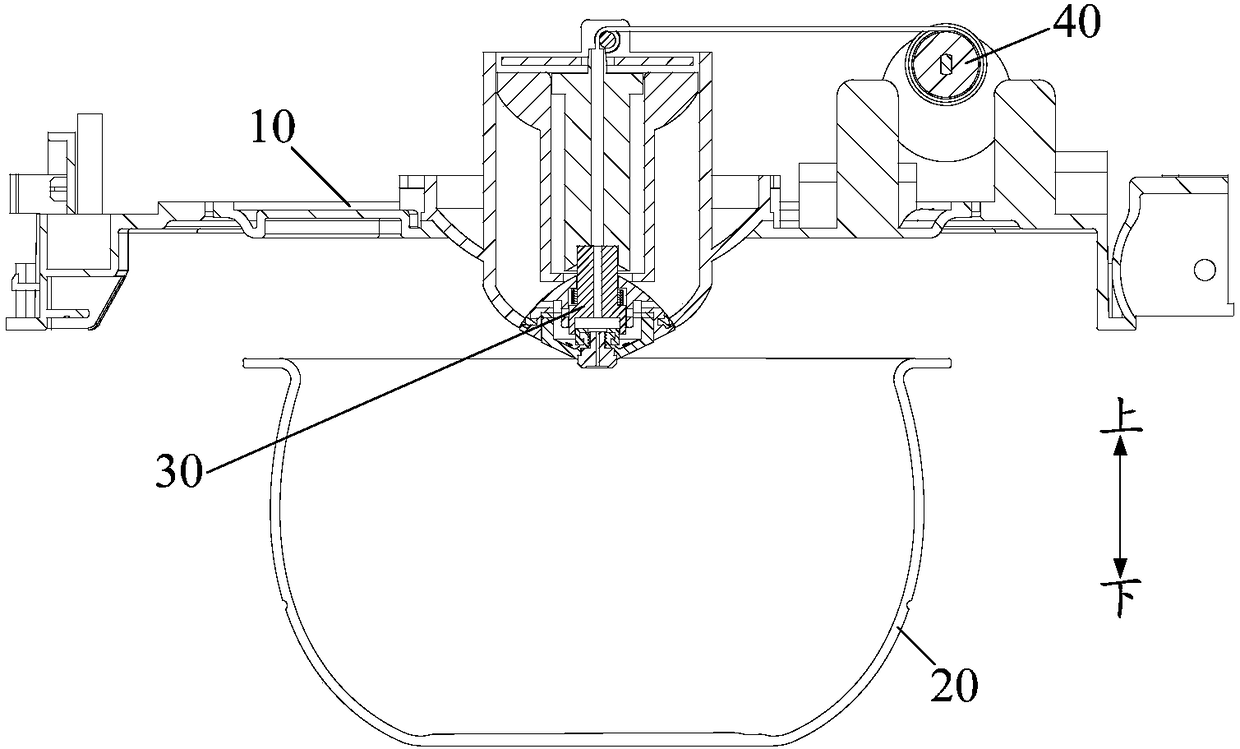

Cooking utensil

PendingCN109247842ASimplify the cleaning processShorten cleaning timeCooking-vessel lids/coversBeverage vesselsWire sourceAirflow

The invention provides a cooking utensil. The cooking utensil comprises an upper cover, an inner pot, an air inlet pipe and a spray head assembly, wherein the inlet end of the air inlet pipe can be connected to an air source; and the spray head assembly is movably mounted on the upper cover, and can move in a reciprocating manner between the upper cover and the inner pot, the spray head assembly communicates with the outlet end of the air inlet pipe for moving to the bottom of the inner pot for spraying air flow, so that materials and water generate relative movement under the effect of the air flow, and thus the materials are washed. For the cooking utensil, the materials including rice and water are placed in the inner pot, then the automatic washing is realized by utilizing pneumatic stirring, the materials including rice are directly washed in the inner pot, thus the washing process is simplified, and the washing time is saved; the process of conveying the materials into the innerpot after the washing process is saved, and thus the problem that the rice has difficulty in entering the pot and residue exists when washing is carried out in the upper cover in the prior art is solved; and meanwhile, the spraying range of the spraying head assembly is wide, and thus the stirring range is expanded and stirring efficiency is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Method for extracting stephanine from stephania

InactiveCN102020654AReduce energy consumptionNo pollution in the processOrganic chemistryBulk chemical productionStephaniaStephanine

The invention provides a method for extracting stephanine from stephania. In the invention, stephania medicinal materials are taken as raw materials. The method comprises the following steps of: smashing the raw material into 40 to 80 meshes, and adding the raw material to an extractor; extracting by adopting supercritical CO2; collecting stephanine extracts; dissolving the stephanine extracts by acid water, and filtering the stephanine extracts; adding cation exchange resin for absorption; washing ion columns by water until the ion columns are neutral, and eluting by utilizing 4 to 7 times of alkaline alcohol; decompressing and concentrating eluent, and adding alumina mixed samples to the concentrated solution for drying; ultrasonically extracting by utilizing methyl alcohol solution; decompressing and concentrating extracting solution; adjusting pH by utilizing ammonia water, and standing for crystallizing; and recrystallizing by utilizing ethanol solution and drying to obtain a product. The method for producing stephanine has the advantages of little energy consumption, little pollution and high product content and is suitable for industrial production.

Owner:NANJING ZELANG MEDICAL TECH

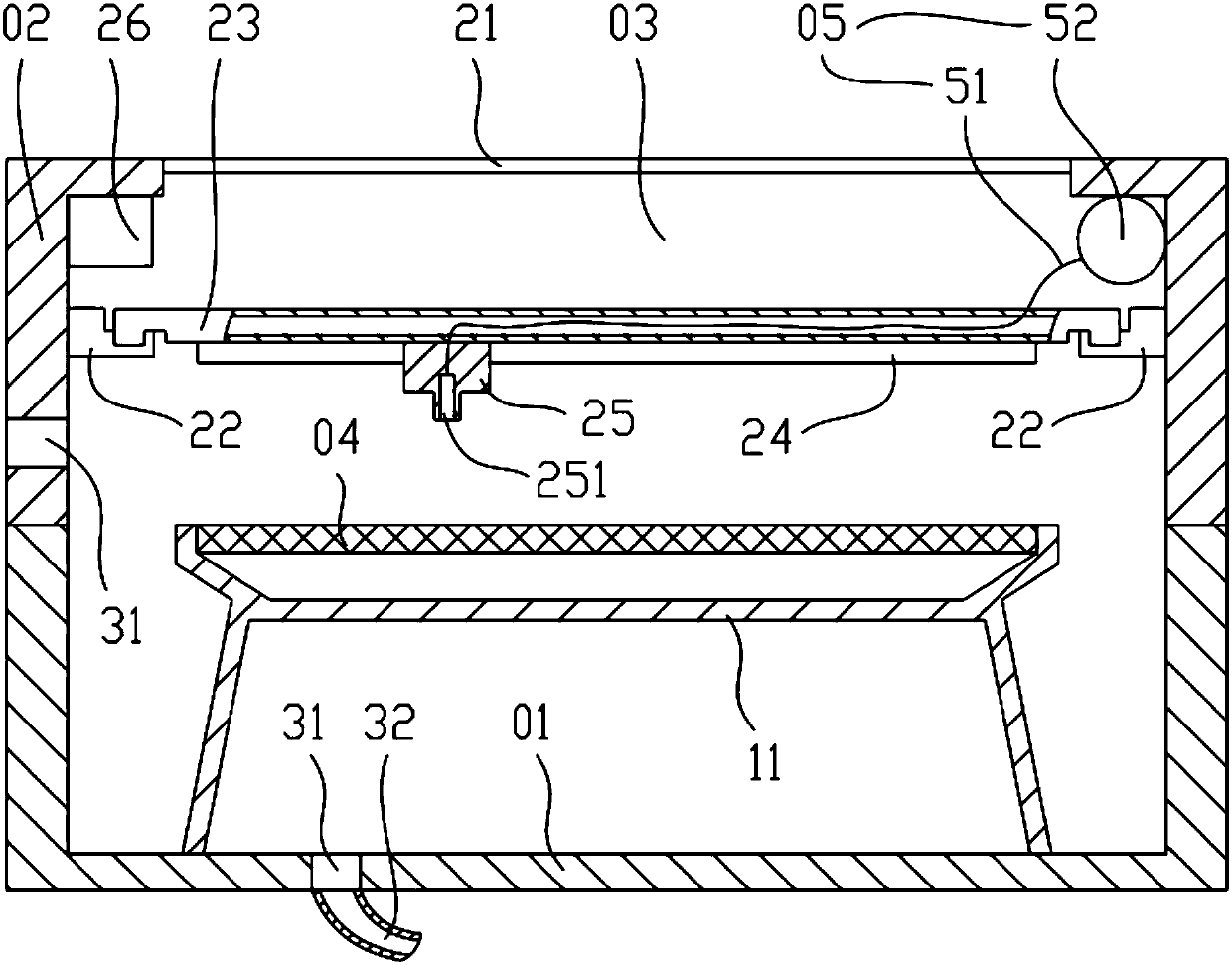

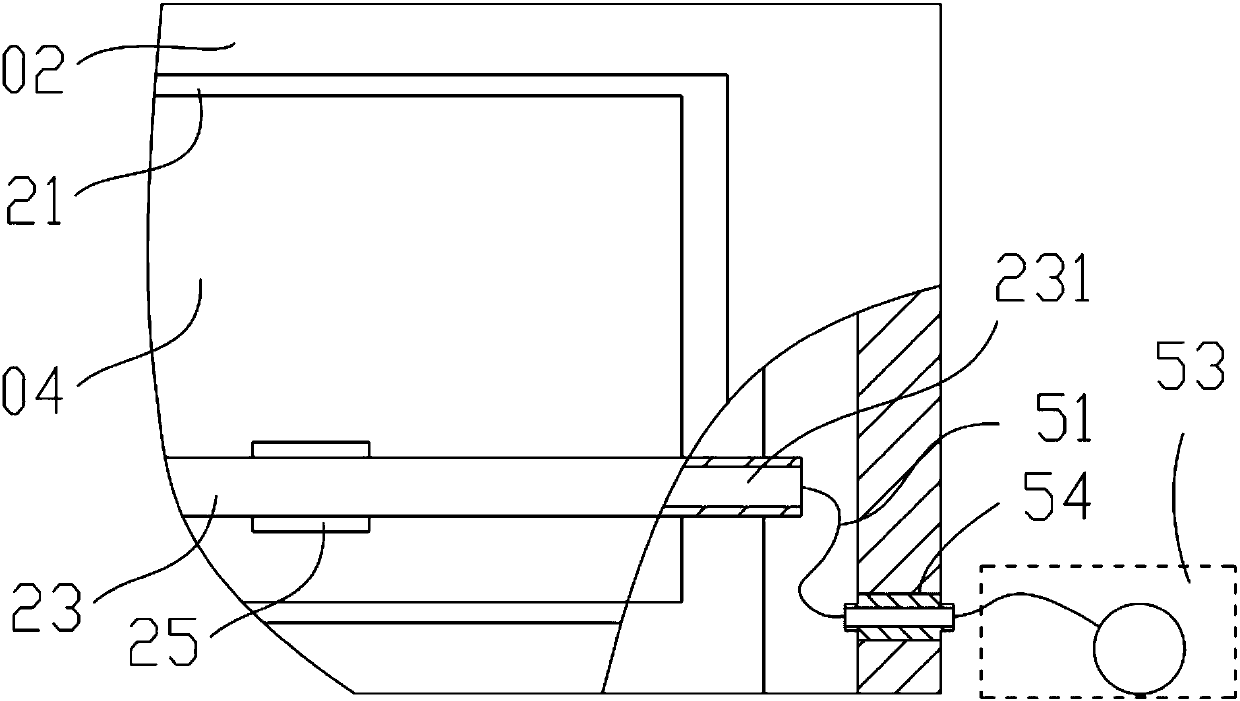

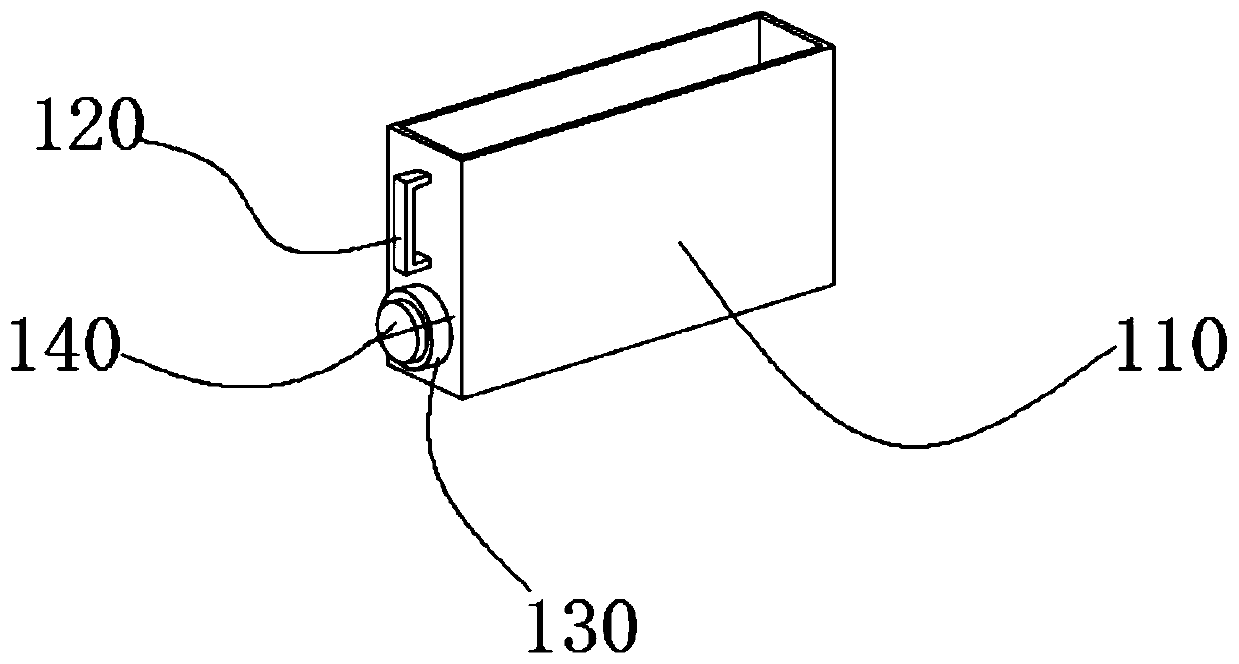

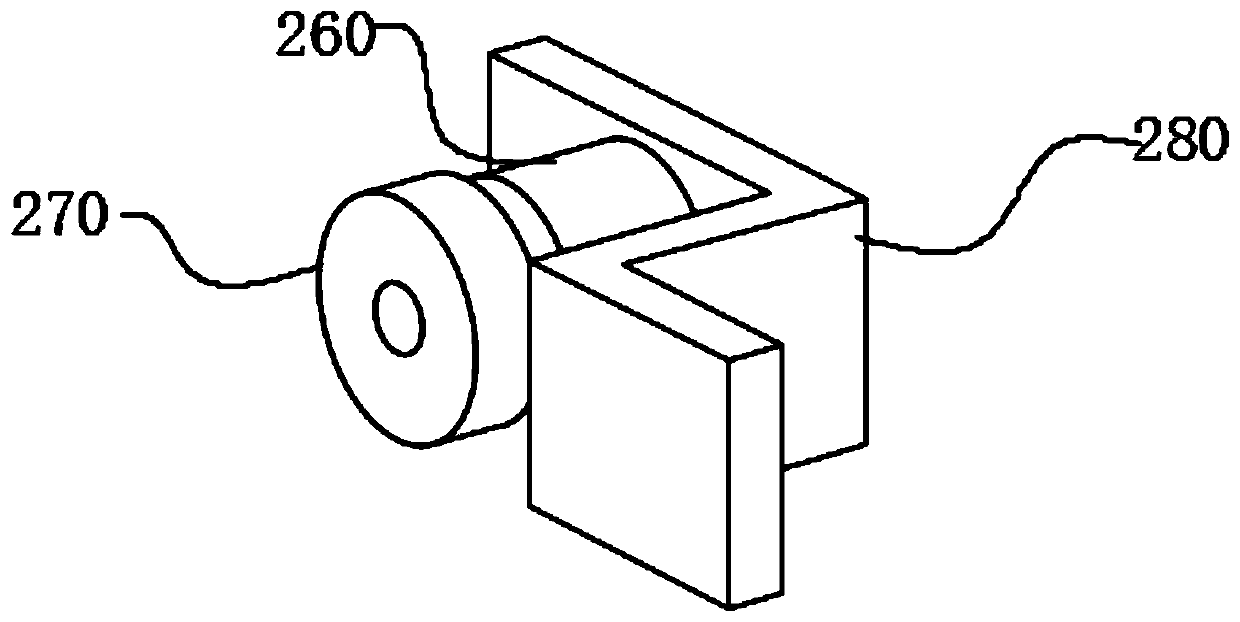

Self-cleaning mask box

InactiveCN107600687AShort timeSave equipmentClosure with auxillary devicesCleaning using gasesLiquid-crystal displaySprayer

The invention relates to the field of liquid crystal display manufacturing, and discloses a mask box capable of achieving the self-cleaning function. The mask box comprises a box body and a cover body. The cover body comprises a pair of sliding rails and a support stretching across the sliding rails. The support is provided with a sprayer and a guide rail matched with the sprayer. The sprayer is connected with an air channel and used for spraying air into a photomask in the box body, so that impurities on the photomask are cleaned up. The sprayer can move freely both in the first direction andin the second direction, and thus all the ranges of the photomask are covered. Cleaners can observe the photomask via an inspection window on the cover body, and the sprayer is moved to the positionswith the impurities for blowing air. The process of a series of motions of putting the photomask onto a special photomask cleaning machine and then carrying out grabbing, overturning and the like isomitted, time consumption of cleaning preparation work is reduced, the cleaning process is simplified, equipment of the special photomask cleaning machine on a production line can further be eliminated, and the space and cost are saved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for producing metallic lead and zinc by using lead-zinc containing waste slag or lead-zinc monoxide mine

ActiveCN100400683CSimplify the cleaning processImprove current efficiencyPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a manufacturing method of metal lead and zinc through waste slag with lead and zinc or low-grade lead or zinc oxide, which comprises the following steps: grinding lead zinc slag or lead zinc oxide into 0.1-1mm; stirring and leaching through strong base solution under 10-100 deg.c for 30-1000min; filtering; draining filtrate; electrolyzing filtrate directly to generate lead with current density at 100-1000A / m2 under 30-100 deg.c for 1-5h; stopping electrolyzing when tank voltage is improved to 1.8-2.5V; producing rough lead with 97-99.9% lead on the cathode; pressing; obtaining electrolytic refined lead; electrolyzing residual electrolytic liquid with zinc under 10-100 deg.c at 2.5-3.5V with current density at 500-1500A / m2 for 1-10h; drying zinc on the cathode protected by inert gas; obtaining one-grade metal zinc powder; circulating residual electrolytic solution in the alkaline leaching course directly.

Owner:昆明同越科技开发有限公司

Electrified water washing device and method

The invention discloses an electrified water washing device and method. The electrified water washing device comprises a traveling trolley, an ultrapure water tank, a water pump and an engine, wherein the ultrapure water tank and the water pump are arranged on the traveling trolley, and the engine drives the water pump to operate. An inlet pipeline of the water pump is communicated with the ultrapure water tank. An outlet pipeline of the water pump is communicated with an inlet of a manifold. A pressure adjusting device is arranged on the outlet pipeline of the water pump. The manifold is provided with a plurality of outlet branch pipes. Each outlet branch pipe is connected with a high-pressure spraying gun through a pipeline. According to the electrified water washing device, the pressure of the outlet pipeline of the water pump is adjusted, the spraying angle and direction of each high-pressure spraying gun is arranged, the high-pressure spraying guns are matched with one another, and thus multi-angle and multi-direction spray-washing can be carried out on insulation facilities at a proper pressure and speed; accordingly, the electrified water washing device and method are suitable for cleaning the insulation facilities under different conditions, can be used for rapidly and efficiently completing cleaning of the insulation facilities, and can guarantee the cleaning effect more easily.

Owner:GUANGDONG POWER ENG

Method for preparing high-purity silicon by high temperature gas-solid reaction

ActiveCN101481111BIncrease productivitySolve the problem of difficult removalSilicon compoundsGas solidHot Temperature

Owner:晶海洋半导体材料(东海)有限公司 +1

Filling equipment for liquor

PendingCN108862171AGuaranteed qualitySimplify the cleaning processSynchronising machinesArchitectural engineeringThreaded rod

The invention discloses a filling equipment for liquor. The filling equipment for the liquor comprises a stand; the stand is vertically provided with limiting groove and a threaded hole; a threaded rod is in threaded connection to the interior of the threaded hole; the side wall of the stand is provided with a side hole; the side wall of the threaded rod is provided with a side rod which penetrates through the side hole and is used for driving the threaded rod to rotate; the top of the threaded rod is provided with a disc; a first spring is arranged between the disc and the limiting groove; the positions on the stand and on the two sides of the threaded rod are provided with tensioning mechanism used for limiting a winebottle respectively; the stand is provided with a pipeline into which awinebottle mouth is put; a vertical plate is vertically connected to the middle part of the pipeline in a sliding manner and is provided with a transverse plate and an L-shaped bottom hole; the bottom hole is communicated with the pipeline; the bottom of the pipeline is provided with an auxiliary pipe; the auxiliary pipe is provided with a first one-way valve which enters the pipeline through theexternal; and the stand is provided with a reciprocating mechanism used for driving the vertical plate to perform reciprocating movement in a vertical direction. The technical scheme of the inventionmainly solves the problem that the winebottle is adhered with dusts, and the quality of the liquor is influenced after the liquor is filled at present.

Owner:重庆技嘉模具有限公司

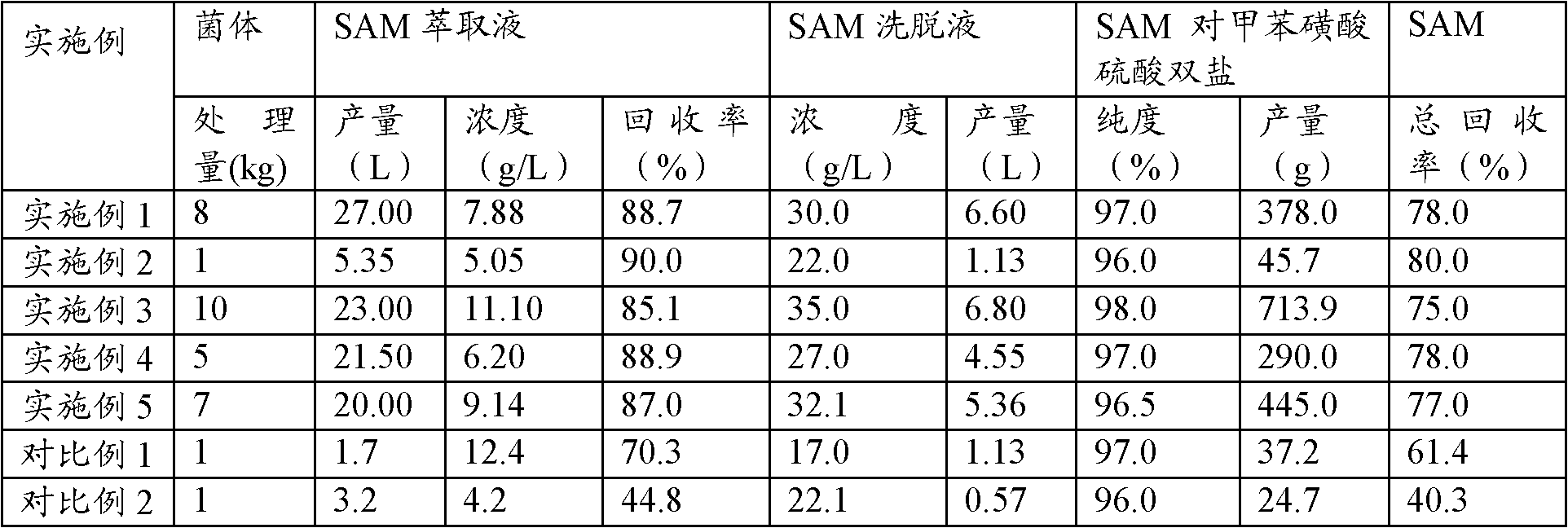

Preparation method for S-adenosine-L-methionine disulfate tosylate

ActiveCN102321136AReduce the amount of adsorptionSimplify the cleaning processSugar derivativesSugar derivatives preparationAdenosineBULK ACTIVE INGREDIENT

The invention discloses a preparation method for S-adenosine-L-methionine disulfate tosylate. The method comprises the following steps of: precipitating S-adenosine-L-methionine (SAM) which is prepared through thallus collection, cell disruption of an acid heat method, extraction, and separation and purification; adjusting and controlling proportion of sulfate radial to para-toluenesulfonic acid radical; and drying to prepare the high-purity SAM disulfate tosylate. The method has the advantages of simple technological line, high processing capacity, product recovery rate of up to 75-80 percent, proportion of active ingredients in a product of more than 90 percent, product purity of up to 96-98 percent, corresponding indexes meeting pharmacopoeial requirements, low production cost and capability of realizing industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Soybean processing device

InactiveCN109892406AWill not harmSimplify the cleaning processCheese manufactureMilk substitutesEngineeringPre treatment

The invention relates to a soybean processing device, which comprises an impurity removal system I, a dust removal system, an impurity removal system II, a weighing system, a screening system, a soybean milk processing system, a soaking system and a marinating system which are arranged sequentially, wherein the device can carry out integrated pretreatment and deep processing on soybeans; the device can carry out fine dust removal and impurity removal on the soybeans by arranging two impurity removal systems and one dust removal system; the impurity removal process is simple; the impurity removal efficiency is high; the device can not damage the soybeans in the impurity removal and dust removal process of the soybeans. According to the device, soybeans subjected to impurity removal are weighed by the weighing system, and subsequent processing is carried out in batches in a quantitative manner, so that the dosage in the marinating process of the soybeans is effectively controlled, and the marinating effect is greatly improved; the soaking system is used for carrying out high-temperature soaking on the soybeans, so that the soaking efficiency is accelerated, meanwhile, the soaking effect of the soybeans can be ensured to be uniform through aeration treatment, so that the soaking efficiency is further accelerated, and the processing efficiency is greatly improved.

Owner:储会春

Food nutrition catering teaching device

ActiveCN111243346AWill not affect normal workClear in timeProjectorsElectrical appliancesAnimal scienceNutrition

The present invention discloses a food nutrition catering teaching device. The food nutrition catering teaching device comprises a projector main body, a trigger device is arranged on the left side surface of an inner cavity of the projector main body, and a suspension rod is fixedly connected to the top surface of the projector main body. The triggering device, a dustproof device, a strain deviceand a release device are matched, the dustproof device can be automatically turned over when the projector main body works; the dustproof device is ensured not to influence the normal work of the projection lens; the dustproof device can be automatically closed when the projector main body stops working; normal operation of the dustproof function of the dustproof device is ensured; the cleaning device is matched with the driving device; the food nutrition catering teaching device can automatically wipe dust attached to the surface of the projection lens after work; and dust can be removed intime, the projection quality can be improved, the dust removal process is very simple, manual dust removal is not needed, the workload of maintenance personnel is reduced, and the practicability of the food nutrition catering teaching device is improved.

Owner:李则均

Dredging method for preventing blow-off pipe from being blocked

InactiveCN112049231AAchieve shredding and cleaningQuick clean upSewer cleaningGrain treatmentsClearing AgentStructural engineering

The invention discloses a dredging device for preventing a blow-off pipe from being blocked. The device comprises a pipe body, wherein clearing openings are formed in the surface of one side of the pipe body at equal intervals; a liquid storage flow guide assembly is arranged on the inner side of each clearing opening, an adjusting groove is formed in the bottom end of the liquid storage flow guide assembly, a rotating rod is fixedly installed on the inner side of the adjusting groove, a connecting block is rotatably installed on the outer side of the rotating rod, and a crushing assembly is arranged at the bottom end of the connecting block. According to the method, in the pipeline dredging process, the blockage position can be observed and positioned in real time first through an observation window, then the clearing opening at the corresponding blockage position is opened, a holding rod extends to the pipeline blockage position on the inner side of the clearing opening, and rapid clearing can be achieved by spraying a clearing agent; and a traditional mode that it is required to clear from the starting end of a pipeline to the tail end is replaced, a target to be cleared is clearer, the clearing procedure is simpler, the clearing workload is greatly reduced, and the overall clearing efficiency is improved.

Owner:GUANGXI AGRI VOCATIONAL COLLEGE

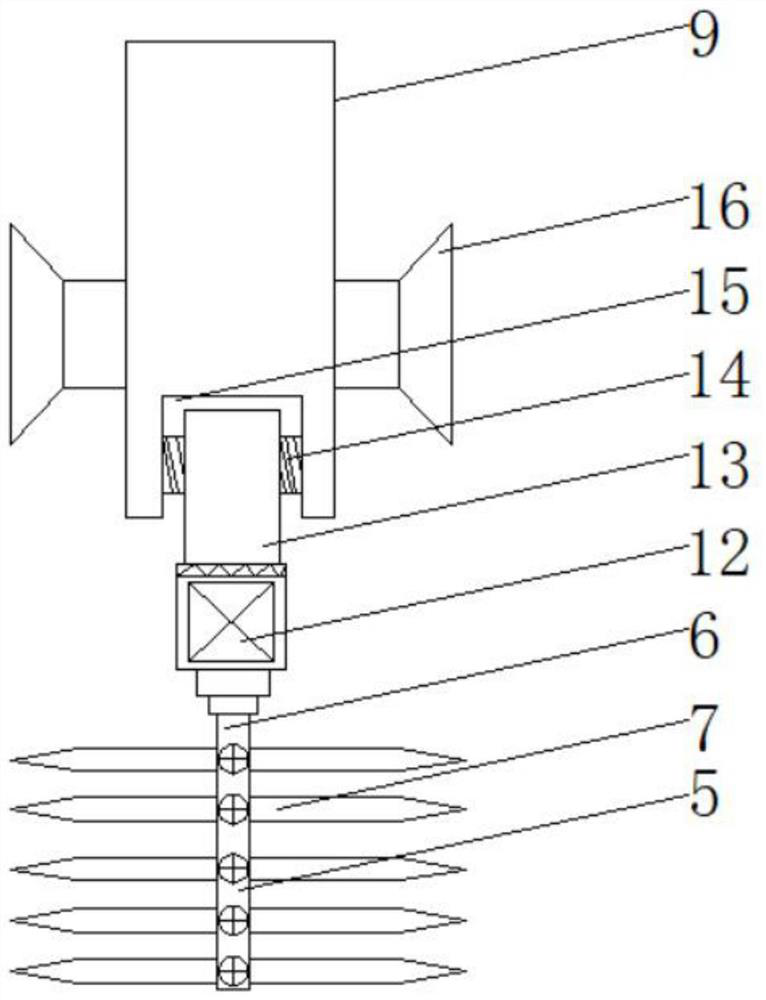

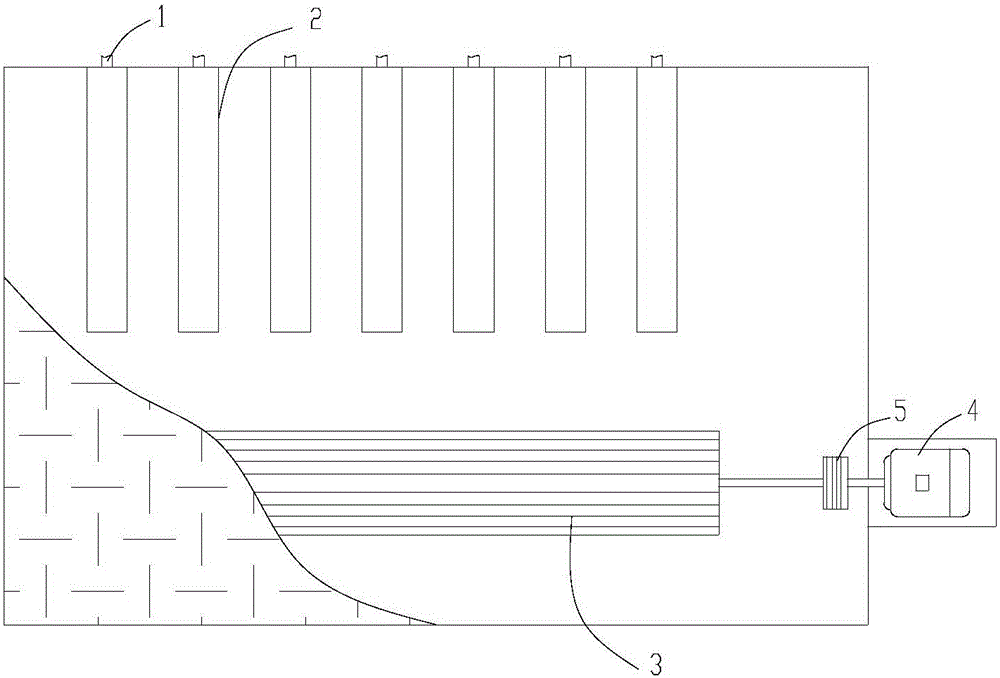

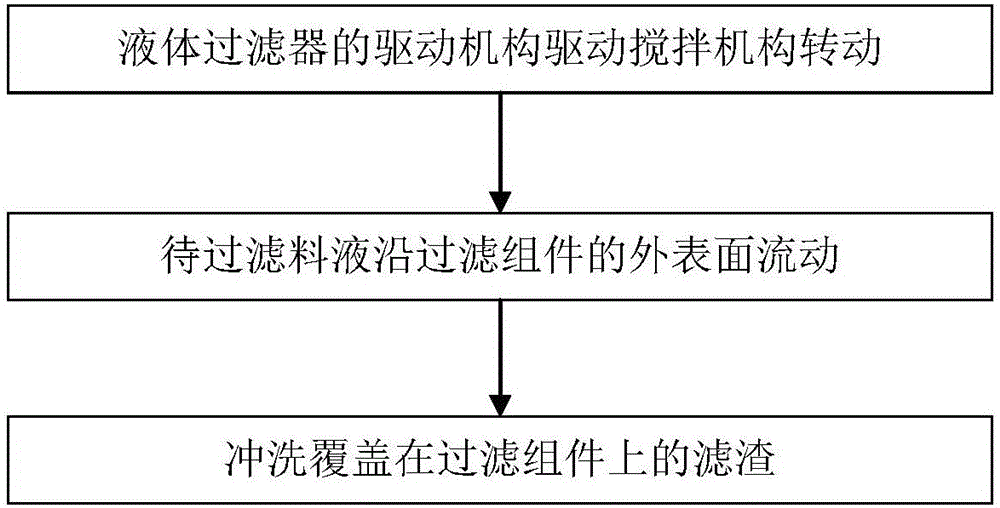

Liquid filter and cleaning and regeneration method thereof

ActiveCN105148592ASimple structureSimple and applicable cleaning and regeneration methodStationary filtering element filtersCleansing AgentsCost (economic)

The invention relates to a liquid filter and a cleaning and regeneration method thereof. The liquid filter comprises a liquid inlet and at least one filter assembly and is further provided with an agitating mechanism which corresponds to the filter assembly and is connected with a driving mechanism, wherein the filter assembly is a hollow filter element structure consisting of a flexible porous metallic film and provided with a liquid drain outlet. The liquid filter is simple in structure, can filter liquid to be filtered, can simultaneously use the liquid to be filtered to clean the filter assembly through the rotation of the agitating mechanism, thereby can realize self-cleaning while filtering, can prevent filter residues from being settled, and can guarantee the filter capacity to be stable and the filtering efficiency to be always higher. The cleaning and regeneration method of the liquid filter is simple, applicable, safe and reliable, the adjustment is facilitated, the cleaning efficiency is higher and the cleaning process is simpler by means of filter residue settlement prevention, and since the liquid to be filtered is directly used as cleaning solution and no additional cleaning agent is needed, the economic costs are greatly reduced.

Owner:CHENGDU INTERMENT TECH

Process for producing elemental boron with 99%-99.99% high purity

The invention provides a method for producing elemental boron with 99%-99.99% high purity, and belongs to the technical field of chemical substance preparation. Powdery hexagonal boron nitride is prepared from boride and nitride as raw materials by low-temperature dehydration and high-temperature synthesis, hexagonal boron nitride powder is purified and subjected to pyrolysis, and fine boron powder is obtained finally. The purity of elemental boron prepared with the method is as high as 99%-99.99%, particle size is smaller than or equal to 30 mu m, and the method is simple in process, environmentally friendly and nontoxic.

Owner:董克胜

Air inlet and dust removal device and air delivery device with air inlet and dust removal device

PendingCN110841805AAvoid spillingReduce the burden of useVapor flow controlElectrodes cleaningDust controlEnvironmental engineering

An air inlet and dust removal device and an air delivery device thereof are disclosed. The air inlet and dust removal device is provided with a shell, and an electrostatic dust removal mechanism, a cleaning mechanism and a dust collecting box which are located in the shell. The electrostatic dust removal mechanism is assembled in an air inlet channel in the shell; the cleaning mechanism is assembled in the electrostatic dust removal mechanism; and the dust collecting box is arranged below the electrostatic dust removal mechanism. As the air flow enters the air inlet channel, the electrostaticdust removal mechanism adsorbs dust in the air flow onto the electrostatic dust removal mechanism itself, and then the cleaning mechanism cleans the dust on the electrostatic dust removal mechanism into the dust collecting box. The dust collecting box can be directly taken out for cleaning, and a vacuum cleaner also can be connected to the dust collecting box to directly suck out the dust, so as to avoid dust spilling during the removal process. The air inlet and dust removal device can purify dust in the air flow, and solves the trouble that traditional dust removal requires disassembling ofequipment, so that the dust removal process is simpler.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com