Method for preparing high-purity silicon by high temperature gas-solid reaction

A solid reaction, high-purity technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high energy consumption and long process, and achieve simple impurity removal process, low environmental pressure, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

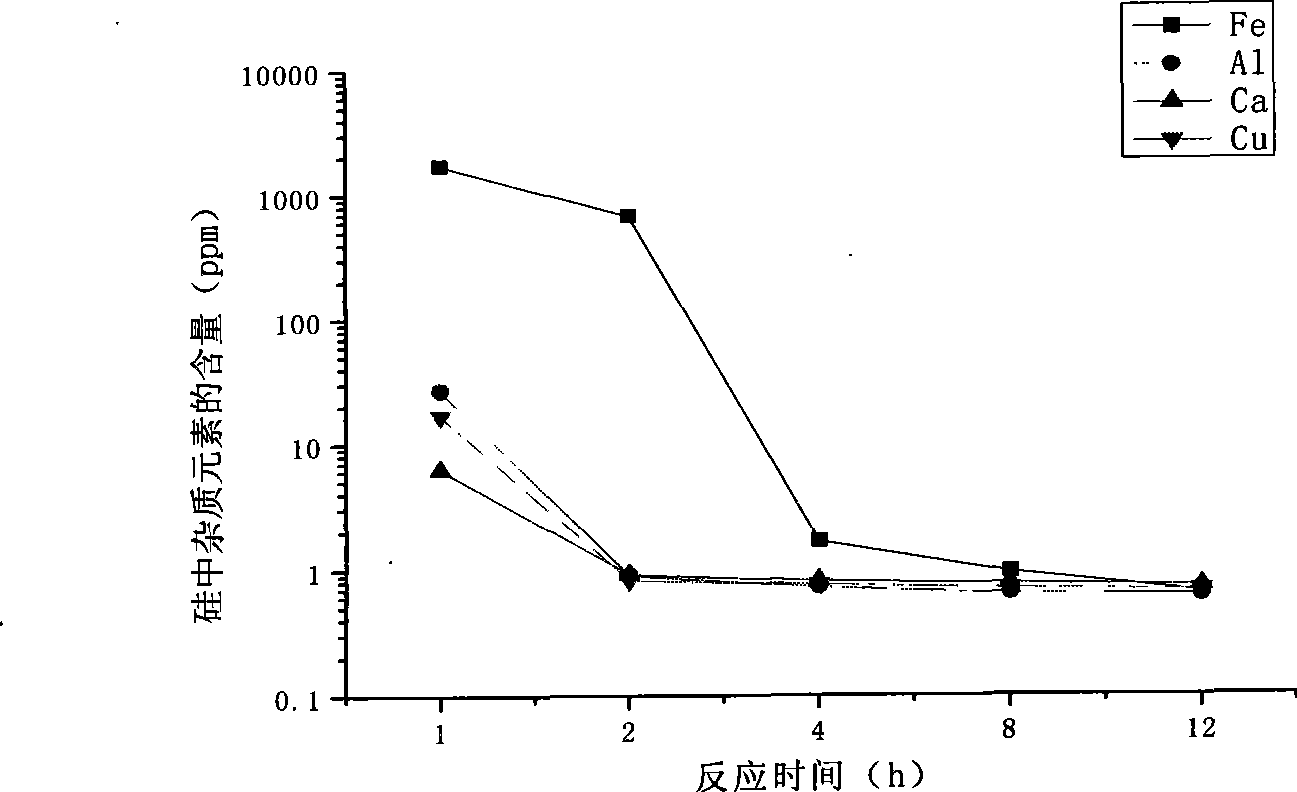

[0033] The industrial silicon with a purity of 95%-99.99% is used as the raw material, and the main impurity components include Fe content of 2731ppmw, Al content of 1472ppmw, Ca content of 191ppmw, and Cu content of 59ppmw.

[0034] Preliminarily crush and sieve the raw materials, take a sample with a particle size of 5±1mm, put it into the hearth of a high-temperature solid-phase reaction furnace with a mesh structure, and evacuate it to 1.0×10 -2 Pa to remove the air in the furnace, after inert gas replacement, the inert gas is any one or a mixture of helium, neon, argon, etc., the sample is heated to 1380 ° C, filled with hydrogen, chlorine, fluorine , hydrogen chloride, hydrogen fluoride, bromine or hydrogen bromide as the active gas, adjust the vacuum degree to 0.8×10 3 Pa performs gas-solid reaction treatment, the treatment time is 1h, 2h, 4h, 8h and 12h respectively, and the silicon material after the gas-solid reaction is cleaned with hydrochloric acid, hydrofluoric a...

Embodiment 2

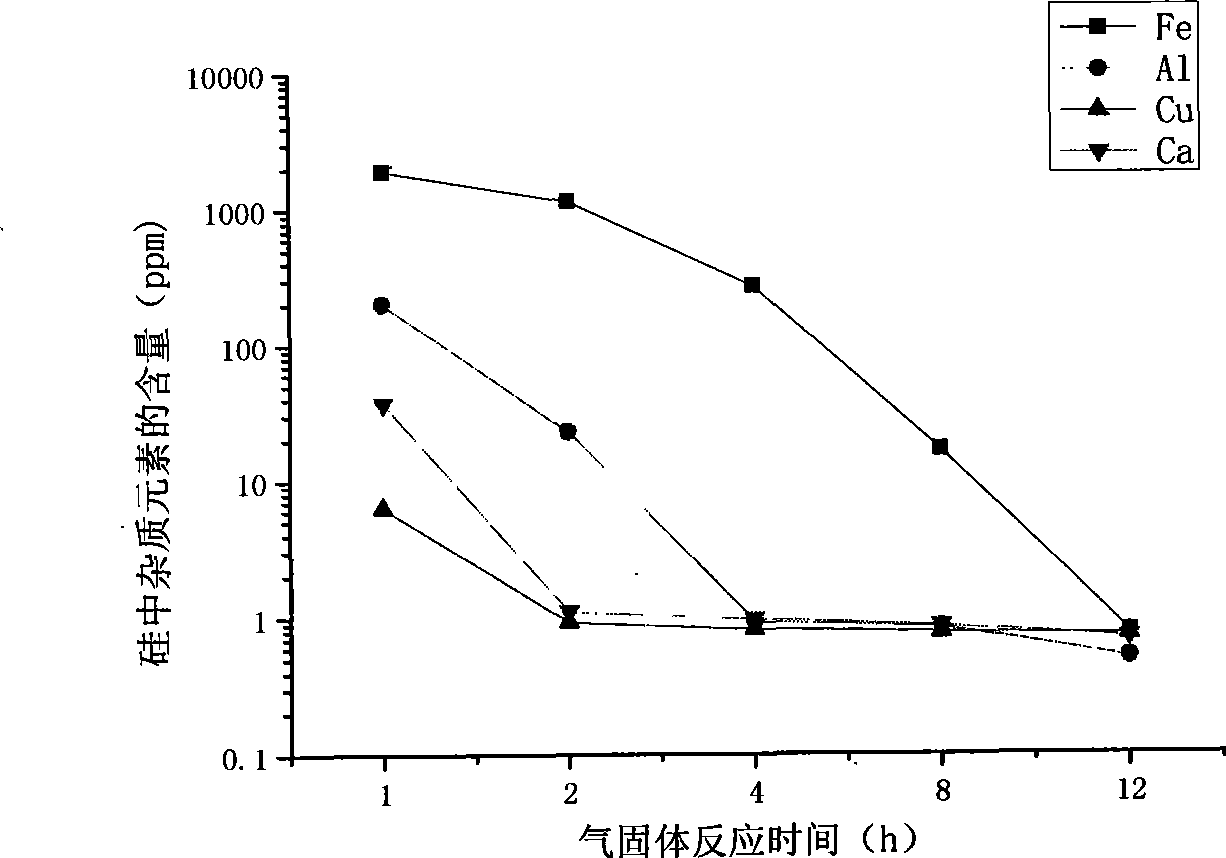

[0037] The industrial silicon with a purity of 95%-99.99% is used as the raw material, and the main impurity components include Fe content of 2731ppmw, Al content of 1472ppmw, Ca content of 191ppmw, and Cu content of 59ppmw.

[0038] The raw materials are preliminarily crushed and screened, and the samples with a particle size of 10±1mm are taken, put into the hearth of a high-temperature solid-phase reaction furnace with a porous structure, and vacuumed to 1.0×10 -3 Pa to remove the air in the furnace, after inert gas replacement, the inert gas is any one or a mixture of helium, neon, argon, etc., the sample is heated to 1380 ° C, filled with hydrogen, chlorine, fluorine , hydrogen chloride, hydrogen fluoride, bromine or hydrogen bromide as the active gas, adjust the vacuum to 0.8×10 4 Pa carries out gas-solid reaction treatment, and the treatment time is 1h, 2h, 4h, 8h and 12h respectively, and the silicon material after gas-solid reaction is treated with any two acids in hy...

Embodiment 3

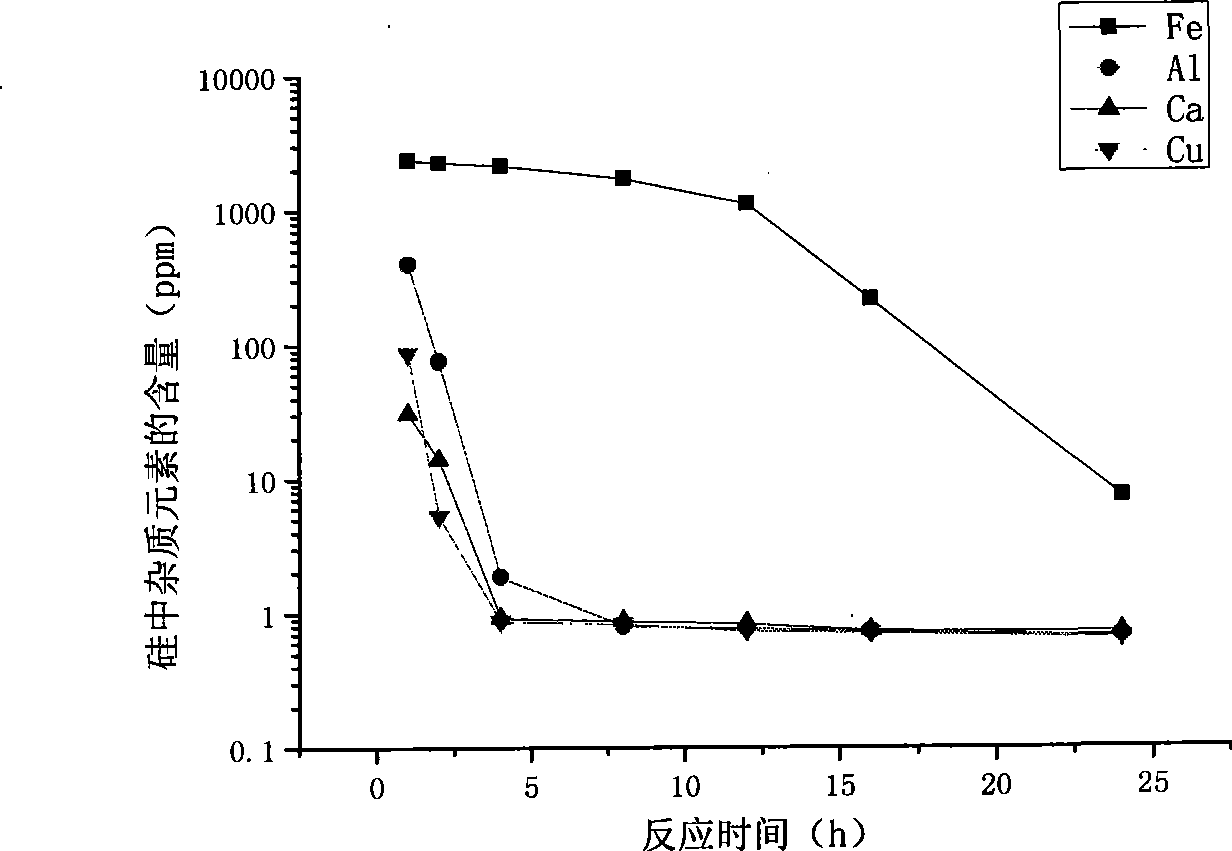

[0041]The industrial silicon with a purity of 95%-99.99% is used as the raw material, and the main impurity components include Fe content of 2731ppmw, Al content of 1472ppmw, Ca content of 191ppmw, and Cu content of 59ppmw.

[0042] Preliminarily crush and sieve the raw materials, take a sample with a particle size of 30±1mm, put it into the hearth of a high-temperature solid-phase reaction furnace with a mesh structure, and evacuate it to 1.0×10 -4 Pa to remove the air in the furnace, after inert gas replacement, the inert gas is any one or a mixture of helium, neon, argon, etc., the sample is heated to 1380 ° C, filled with hydrogen, chlorine, fluorine , hydrogen chloride, hydrogen fluoride, bromine or hydrogen bromide as active gas, adjust the vacuum degree to 1.3×10 5 Pa, for gas-solid reaction treatment, the treatment time is 1h, 2h, 4h, 8h, 12h and 24h and 36h (not shown in the figure), and the silicon material after the gas-solid reaction is treated with hydrochloric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com