Method for preparing piperacillin acid

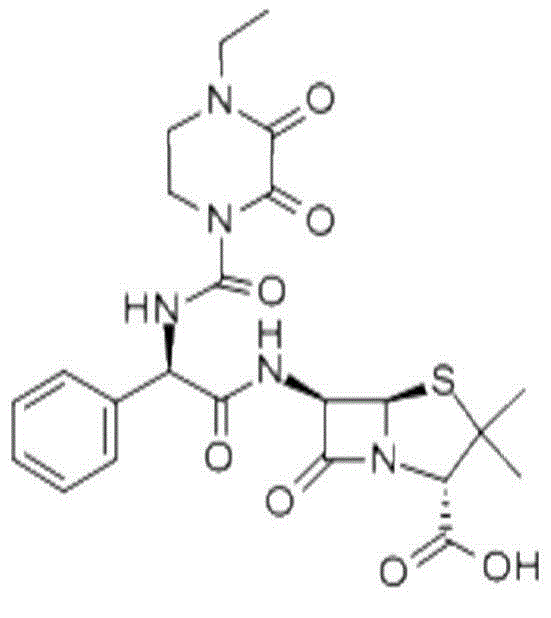

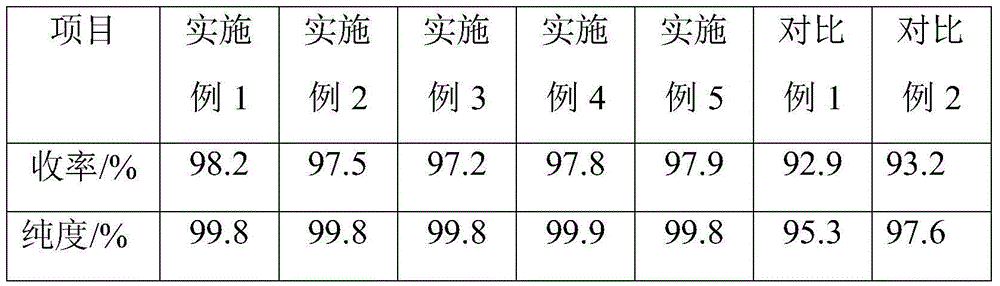

A technology of piperacillin acid and ampicillin, which is applied in the field of drug preparation, can solve the problems of ampicillin degradation and increase the difficulty of impurity removal, and achieve the effects of improved purity, wide market promotion value, and reduced side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

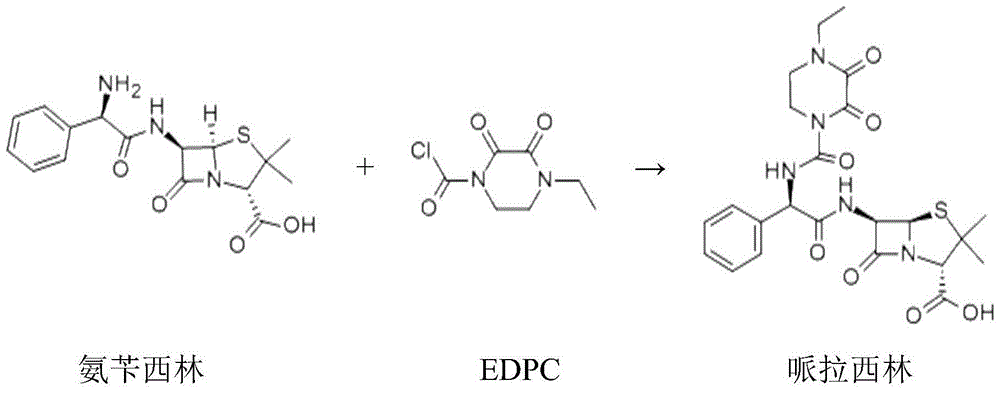

[0026] A kind of preparation method of piperacillin acid disclosed by the invention comprises the following steps:

[0027] a, add raw materials: add ampicillin, water, buffer solution of pH=6.0~9.0 in the reactor; Wherein the mass ratio of ampicillin and water added is 1:3~1:10, the added water and buffer solution The volume ratio is 4:1~10:1, and the buffer solution is boric acid-borax buffer solution, citric acid-disodium hydrogen phosphate buffer solution, glycine-sodium hydroxide buffer solution, sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution or One of the ammonia-ammonium chloride buffer solutions.

[0028] Wherein, the ampicillin adopted in the present invention is a commercially available product, and the quality of ampicillin should meet the Pharmacopoeia standard. The pH of the boric acid-borax buffer solution is 7.5-9.0, and its preparation method is referred to the preparation of common buffer solutions. The pH of the citric acid-disodium...

Embodiment 1

[0035] A preparation method of piperacillin acid, comprising the following steps:

[0036] a, add raw materials: add raw materials in the reactor according to the mass ratio of ampicillin and water as 1:5, and the volume ratio of water and buffer solution as 4:1, add 8g ampicillin, 40mL water, 10mL pH in this embodiment =7.5-9.0 boric acid-borax buffer solution;

[0037] B, acylation reaction: in the reaction vessel of step a, continue to add raw materials by the mass ratio of EDPC and ampicillin as 1:2, add 4g EDPC in the present embodiment, add sodium hydroxide solution simultaneously, control pH to be 7.0-8.5 , after adding EDPC, insulate and react for 30 minutes at a temperature of 8°C;

[0038]c. Crystallization and purification: continue to add 50 mL of water to the reaction vessel of step a according to the volume ratio of the solvent to the water added in step a as 1.25:1, and crystallize. Control the crystallization temperature to 15° C. The pH at the end point was ...

Embodiment 2

[0040] A preparation method of piperacillin acid, comprising the following steps:

[0041] a, add raw materials: in the reactor, the mass ratio of ampicillin and water is 1:6, and the volume ratio of water and buffer solution is 9.6:1. Add raw materials, add 16g ampicillin, 96mL water, 10mL pH in the present embodiment =6.0-8.0 citric acid-disodium hydrogen phosphate buffer solution;

[0042] B, acylation reaction: in the reaction vessel of step a, press EDPC and the mass ratio of ampicillin is 1:4 to continue to add raw material, add 4g EDPC in the present embodiment, add sodium carbonate solution simultaneously, control pH to be 6.0-8.0, After adding EDPC, insulate and react for 45 minutes at a temperature of 3°C;

[0043] c. Crystallization and purification: continue to add 96mL of ethyl acetate to the reaction vessel of step a according to the volume ratio of the solvent and the water added in step a as 1:1 for crystallization, control the crystallization temperature to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com