Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Short heat transfer distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat exchanger and temperature control unit

ActiveUS20050269067A1Maximize heat exchange efficiencyLonger path lengthTemperatue controlStationary conduit assembliesTemperature controlUnit system

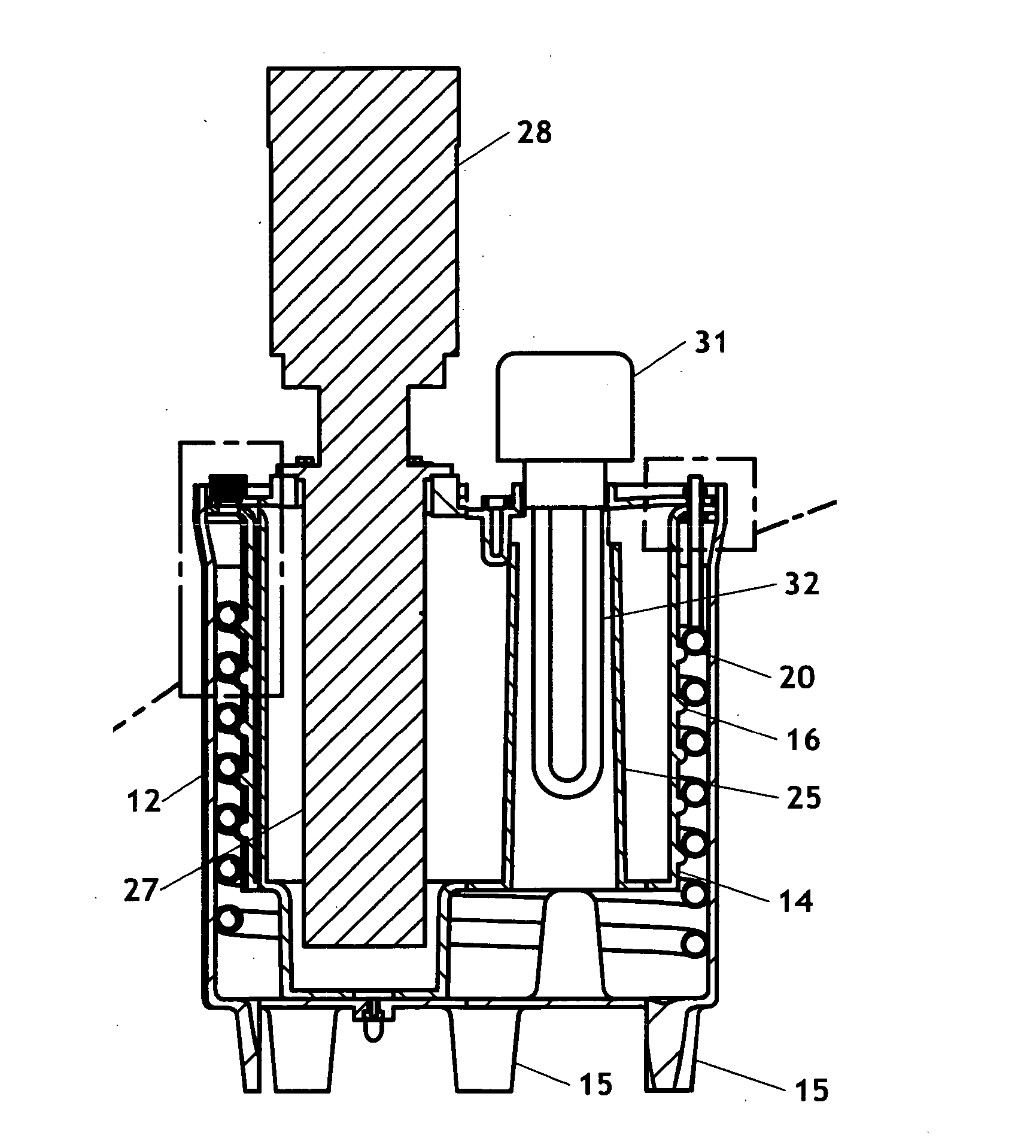

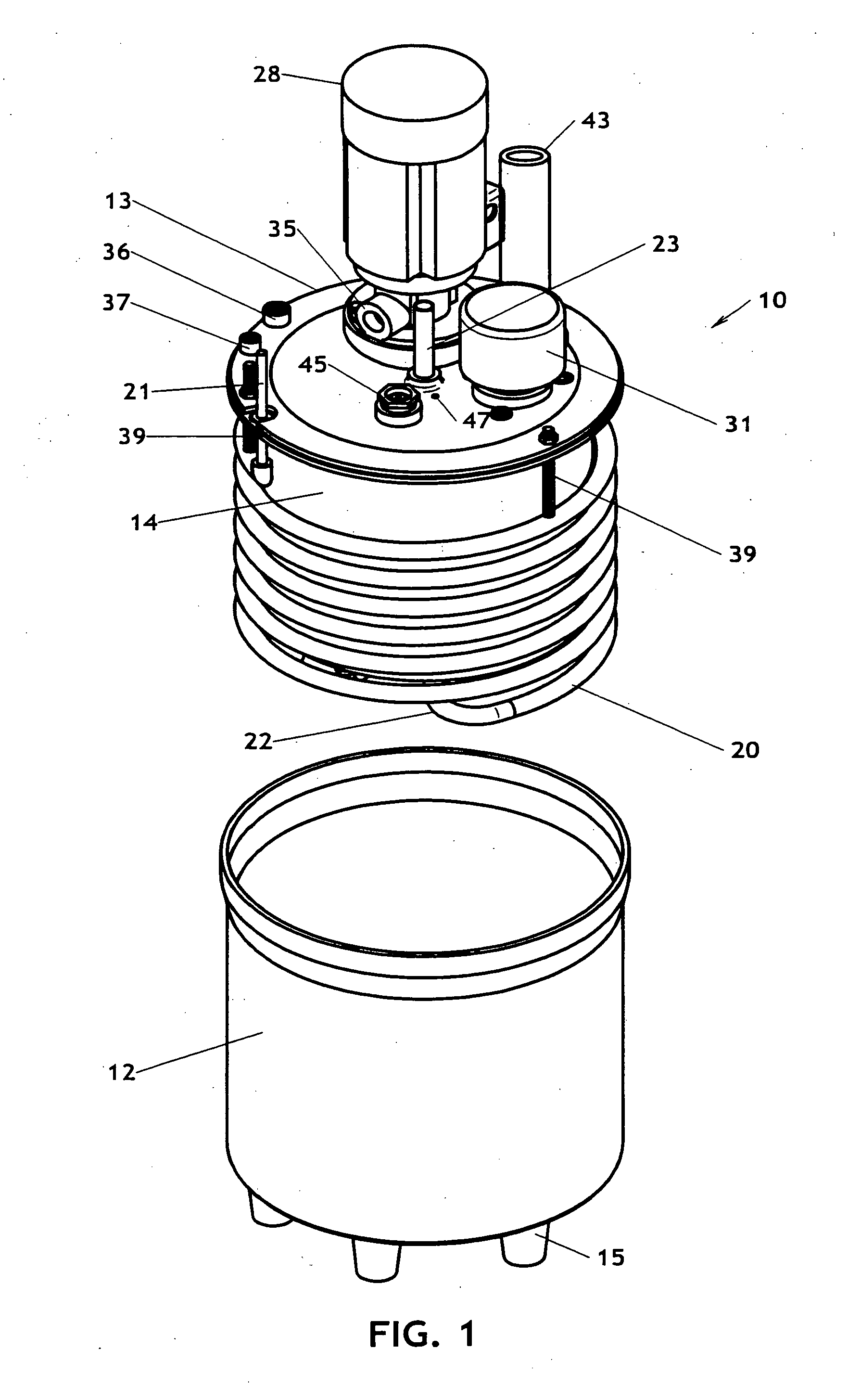

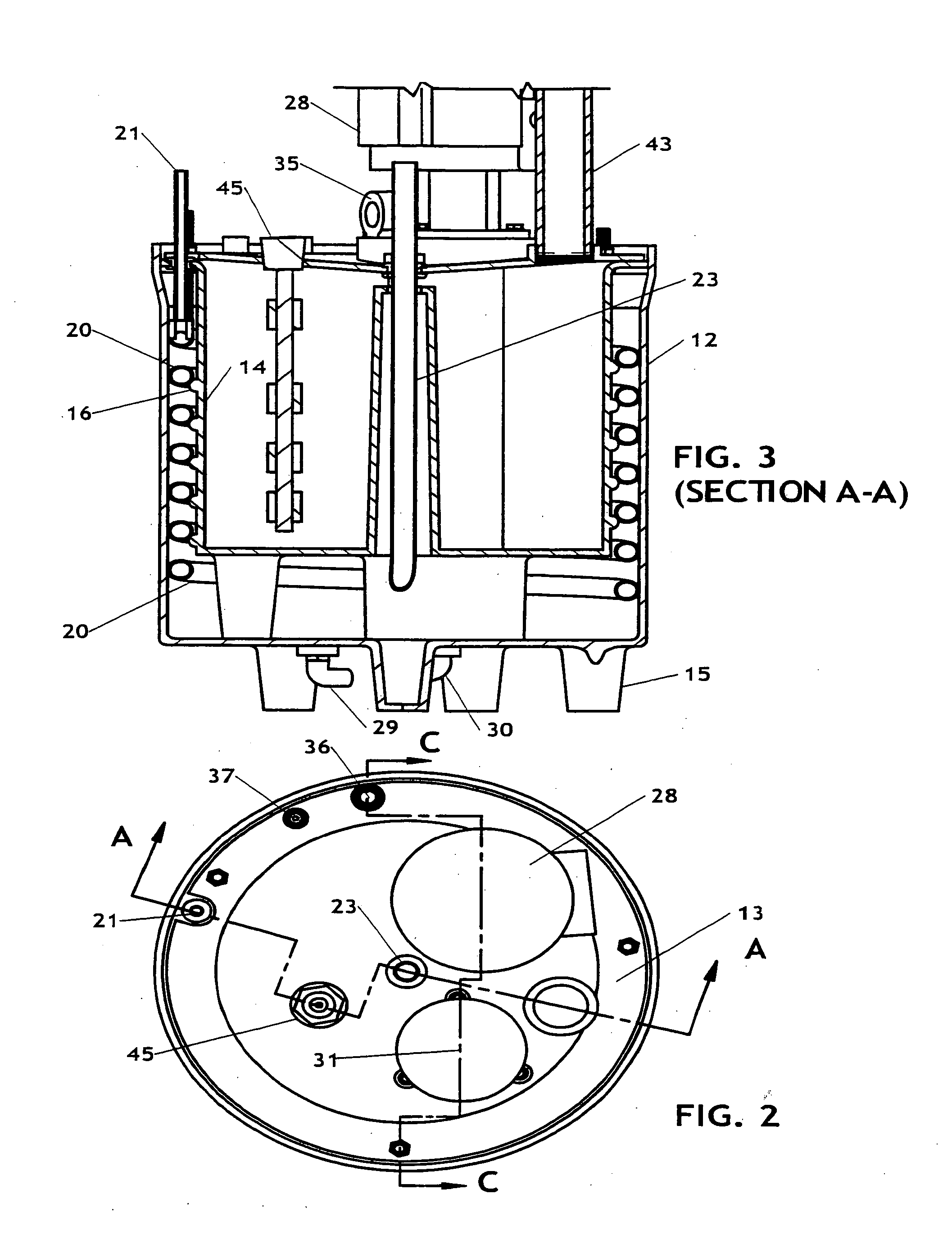

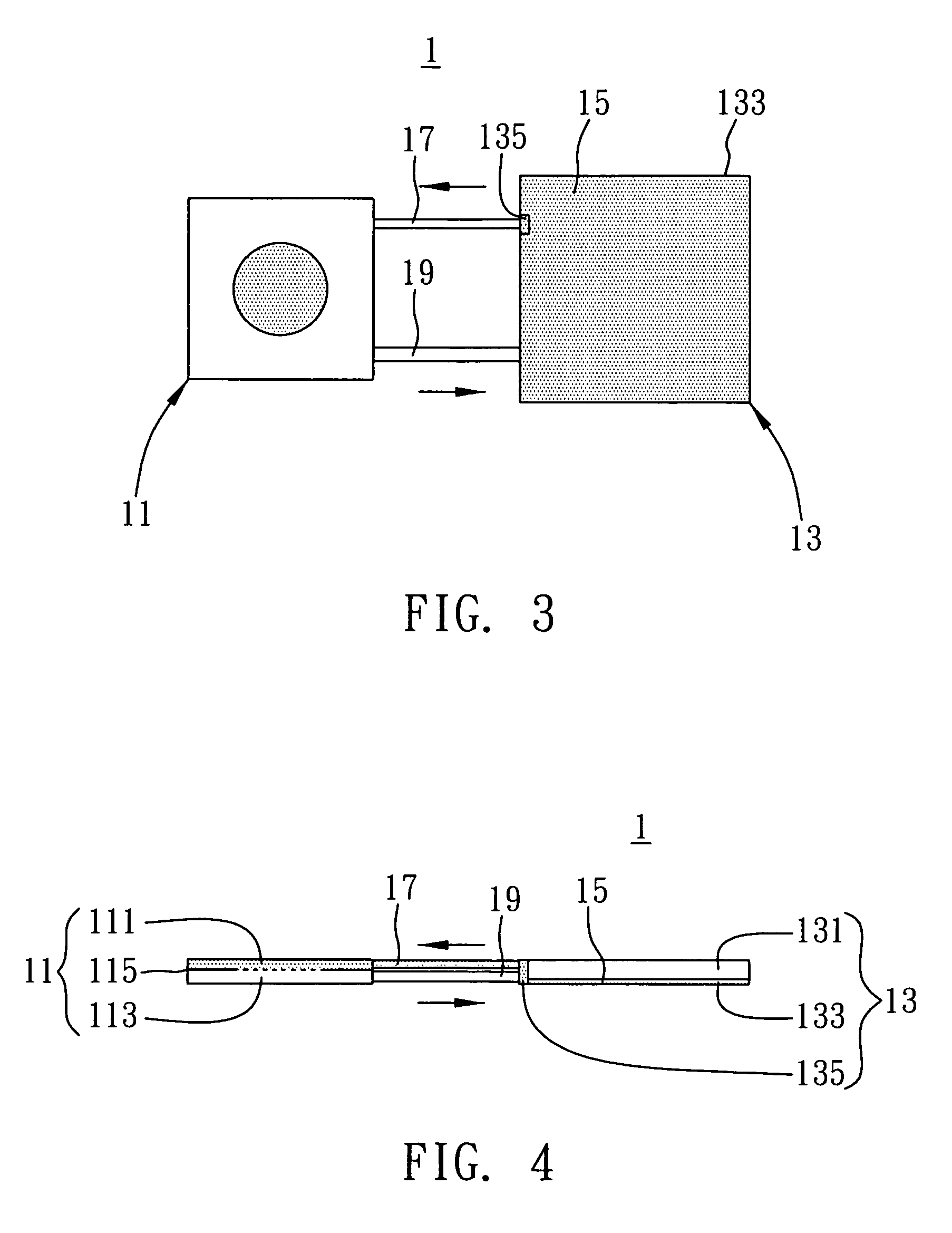

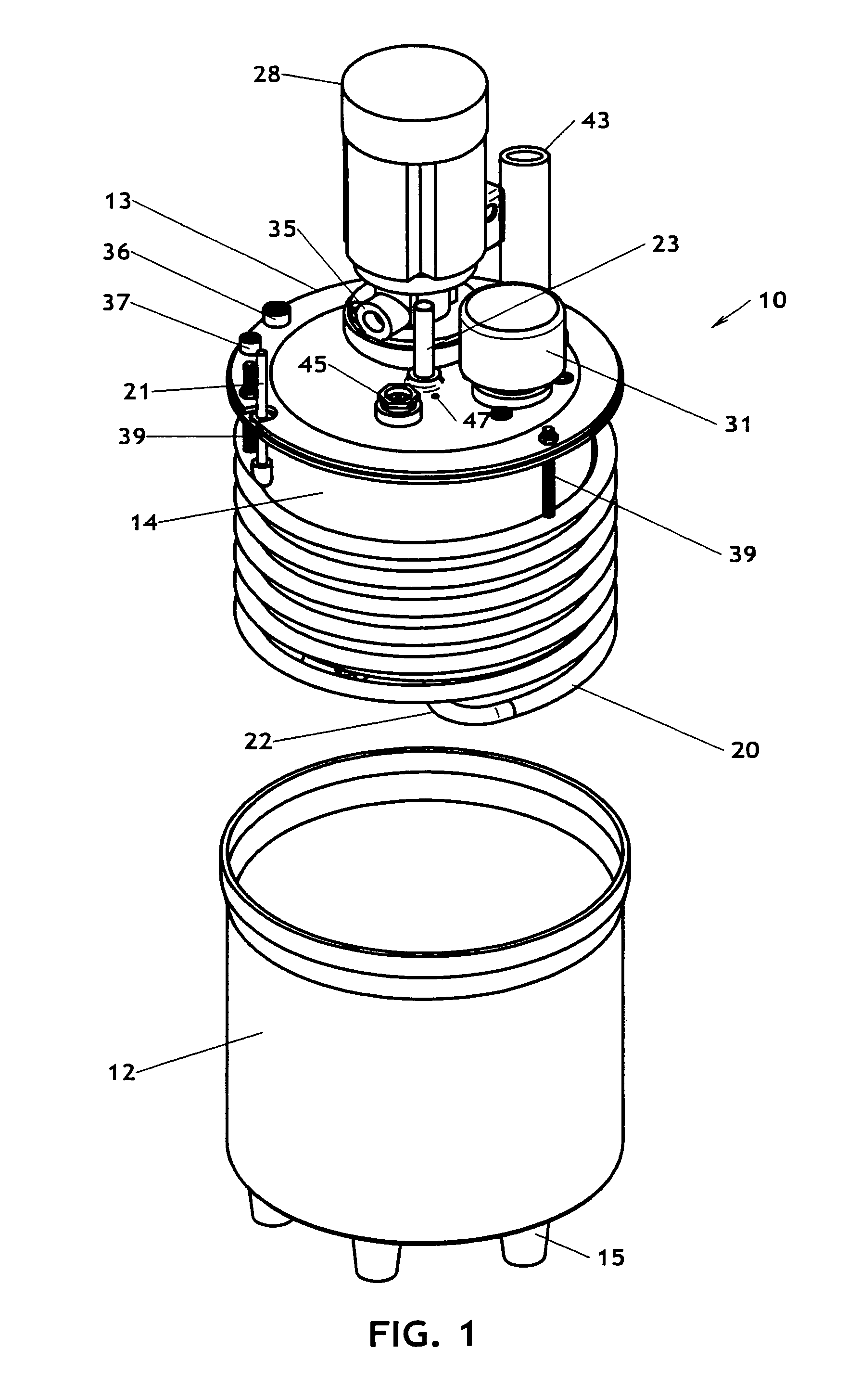

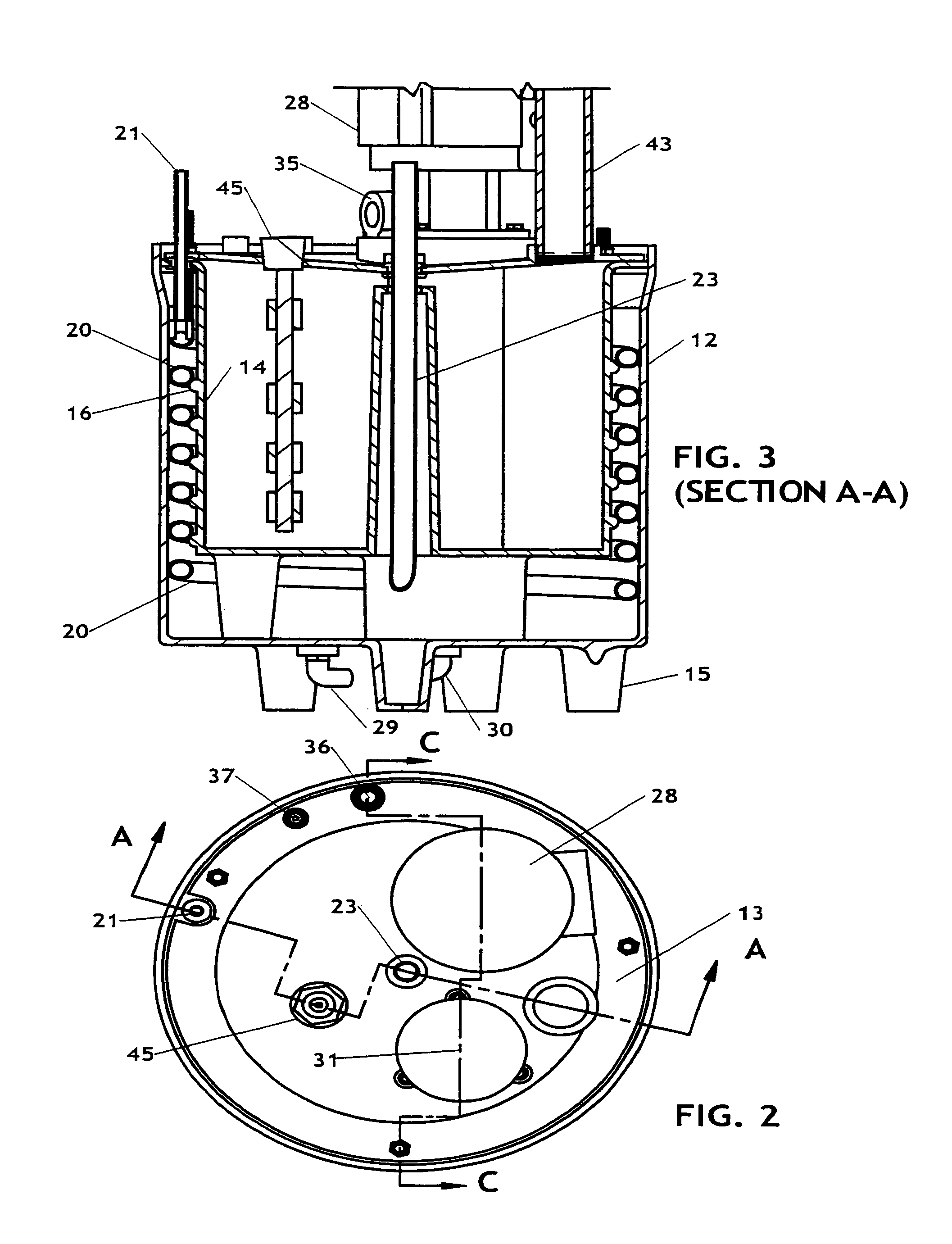

Systems and methods for heat exchange in accordance with the invention define adequately long-interchange distances for two fluids by wrapping a tube containing a first fluid about the wall of an inner cylindrical tank, within a gap formed with a second concentric tank. A second fluid is transmitted in the space defined between the turns of the tube and the two walls, providing effective short length thermal interchange through the tube walls. The tube is in the line contact with both tank walls and the fluids can flow rapidly over an adequately long length, so that high efficiency is provided in a low cost system.

Owner:BE AEROSPACE INCORPORATED

Preparation method of large-diameter aspheric lens

ActiveCN107298524AReduce structural differencesSmooth dischargeGlass pressing apparatusVacuum pumpingNitrate

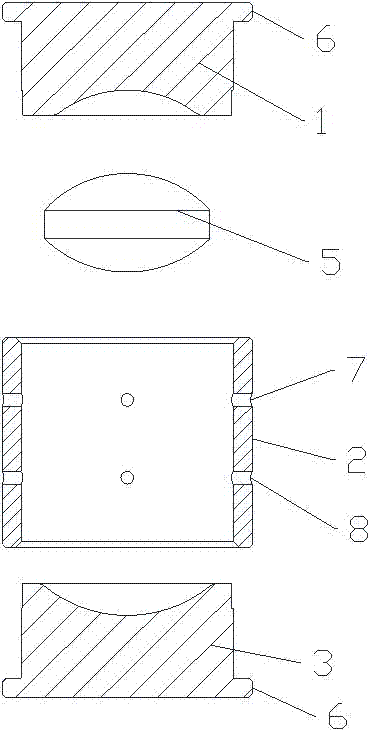

The invention discloses a preparation method of a large-diameter aspheric lens. The preparation method comprises the following steps: (1) making a die kernel and a glass nitrate material; (2) putting the glass nitrate material in the die kernel; (3) putting the die kernel on a die pressing station; (4) vacuum-pumping the station; (5) injecting nitrogen gas into the station; (6) increasing the temperature; (7) enabling the temperature to be uniform; (8) molding by die pressing; (9) annealing; (10) reducing the temperature; (11) discharging the nitrogen gas; (12) taking out the die kernel; (13) taking out a product. The preparation method disclosed by the invention has the benefits that the adjustment of an internal structure of the lens is finished through the relatively-slow temperature reducing process, so that a structural difference among all parts of glass is reduced; the residual stress inside the lens is released, so that an aspheric outline of a molding body is fixed on the status quo of the completed die-pressing stage; the residual stress inside the lens is reduced to a reasonable range so as to prevent the molded lens from cracking due to non-uniform temperature distribution in the subsequent quenching procedure.

Owner:深圳市天阳谷科技发展有限公司

Composite phase-change material bag and preparation method thereof

The invention provides a composite phase-change material bag and a preparation method thereof and relates to the field of phase-change materials. The composite phase-change material bag is obtained byvacuum seal of an aluminum-plastic film and comprises a foam metal layer and a graphene layer which are alternately arranged in a laminated structure form; the foam metal layer contains a phase-change material. By using the composite phase-change material bag, the technical problems of low heat conduction efficiency and easiness in liquid leakage after foam metal and the phase-change material arecompounded in the prior art can be alleviated, and the aims of improving the heat conduction efficiency and reducing liquid leakage are achieved.

Owner:BEIJING NAT BATTERY TECH

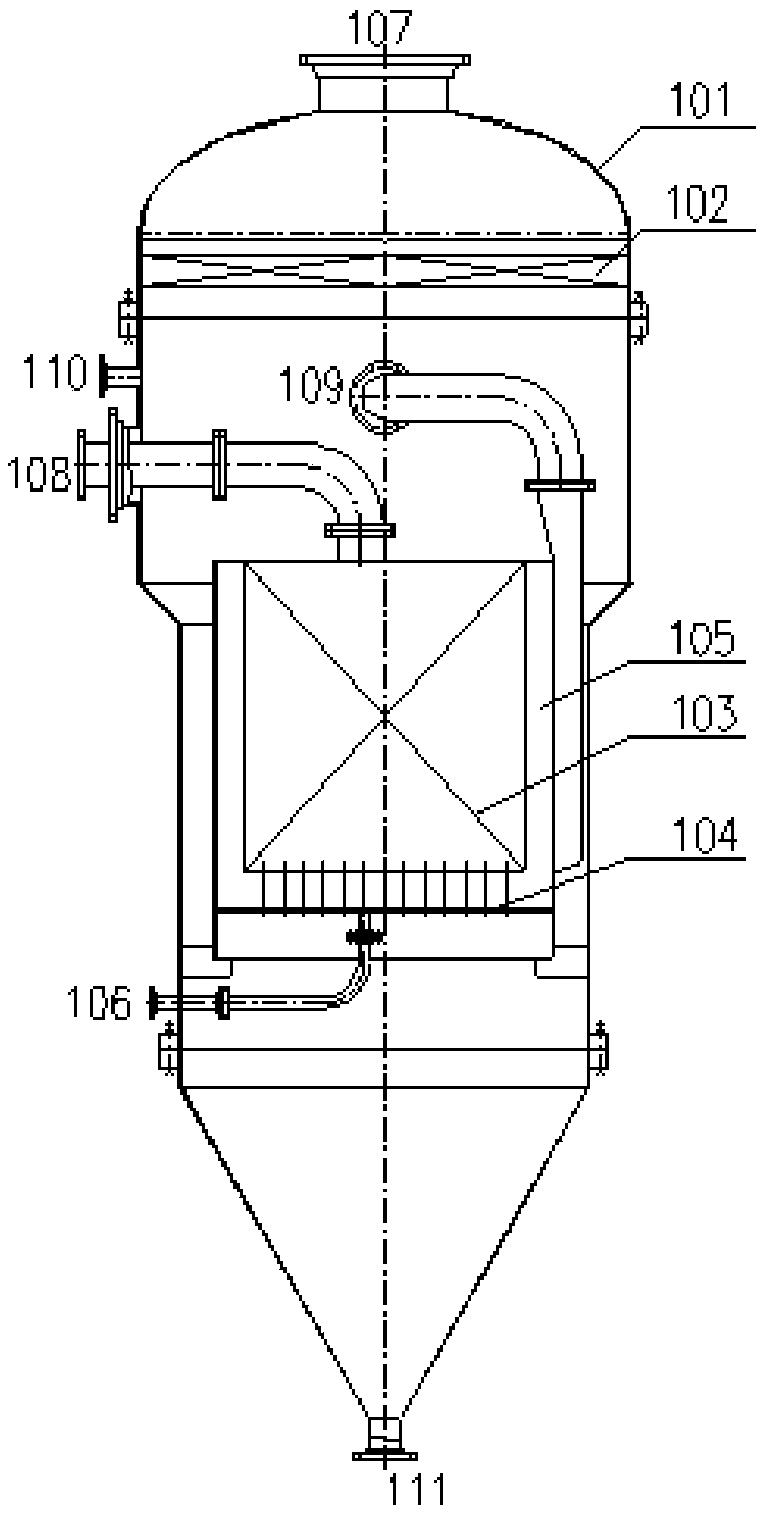

Closed circulating evaporation and condensation system for treating high-salt and high-COD wastewater

PendingCN110844955AAvoid cloggingAvoid sex changeWater/sewage treatment by heatingProcess engineeringThermal recovery

The invention provides a closed circulating evaporation and condensation system for treating high-salt and high-COD wastewater. The closed circulating evaporation and condensation system comprises: awastewater tank; a wastewater pump, one end of which is connected with the wastewater tank; an evaporation tower, which is arranged on one side of the wastewater tank; a condenser, which is arranged in the evaporation tower; a spraying pipe, which is installed in the evaporation tower, connected with the wastewater pump, and located above the condenser; and a primary heat recoverer, which is connected with the evaporation tower. The closed circulating evaporation and condensation system for treating the high-salt and high-COD wastewater has the advantages of low cost and capability of achieving normal-pressure evaporation, medium-low-temperature evaporation, efficient evaporation, energy-saving evaporation and stable evaporation.

Owner:安徽同速科技有限公司

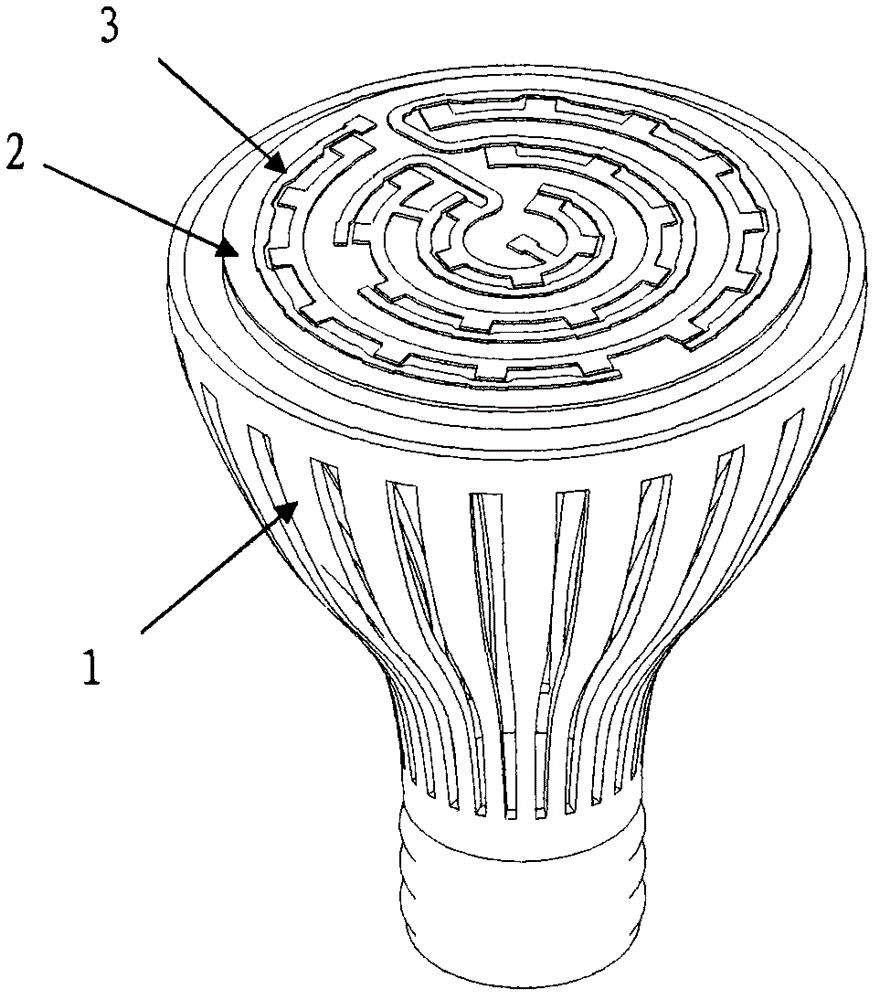

Light-emitting diode (LED) lamp module capable of packaging LED chip on radiating supporting carrier circuit and method

InactiveCN102748605ASimple and cheap to makeImprove efficiencyPoint-like light sourceLighting heating/cooling arrangementsSurface mountingEngineering

The invention relates to an LED lamp module capable of directly packaging an LED chip on a radiating supporting carrier circuit. The LED lamp module comprises a solid radiating supporting lamp carrier circuit and the LED chip, wherein the solid radiating supporting lamp carrier circuit comprises a solid radiating supporting lamp carrier and a circuit which is integrated with the solid radiating supporting lamp carrier, and the LED chip is directly packaged on the solid radiating supporting lamp carrier circuit. The invention also relates to a method for manufacturing the LED lamp module. Compared with traditional LED modules, the LED lamp module capable of directly packaging the LED chip on the solid radiating supporting lamp carrier circuit shortens the heat transfer distance greatly, the heat transfer effect is good, surface mounting technology (SMT) welding is not required to be performed on LEDs and components, the whole manufacturing process is shortened, simultaneously, materials are saved, the manufacturing time is shortened, the production efficiency is greatly improved, and the production cost is reduced.

Owner:王定锋

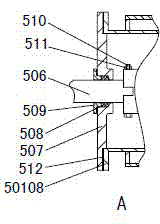

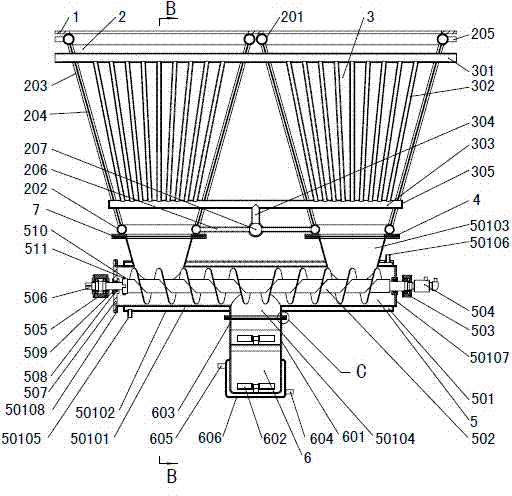

Semi-coke waste heat recovery system

ActiveCN104214754ASolve the problem of difficult cooling and heat exchangeImprove heat transfer effectSteam generation using hot heat carriersCokeCarbide

The invention discloses a semi-coke waste heat recovery system and belongs to the field of semi-coke processing equipment. The semi-coke waste heat recovery system comprises heat exchangers and water-cooled screw conveyers (5); two heat exchangers are fixed below one coke discharging port of a carbide furnace in parallel; one water-cooled screw conveyer (5) is fixed below the two heat exchangers; the upper side of each water-cooled screw conveyer (5) is provided with two feeding holes (50103) which are respectively communicated with discharge holes of the heat exchangers; the lower side of each water-cooled screw conveyer (5) is provided with a first discharge hole (50104); the heat exchangers comprise an outer heat exchanger (2) used for defining a material channel. The heat exchangers and the water-cooled screw conveyers are adopted to sequentially cool and exchange heat of semi-coke; meanwhile, the semi-coke can rotate and blend under the rotary push of water-cooled screw bodies in the water-cooled screw conveyers, the heat exchange effect is obviously enhanced, and the problem that the semi-coke is cooled and exchanges heat difficultly can be effectively solved, so that the semi-coke is subjected to dry quenching, energy and water resource are saved, and the pollution is small.

Owner:SHANDONG UNIV OF TECH +1

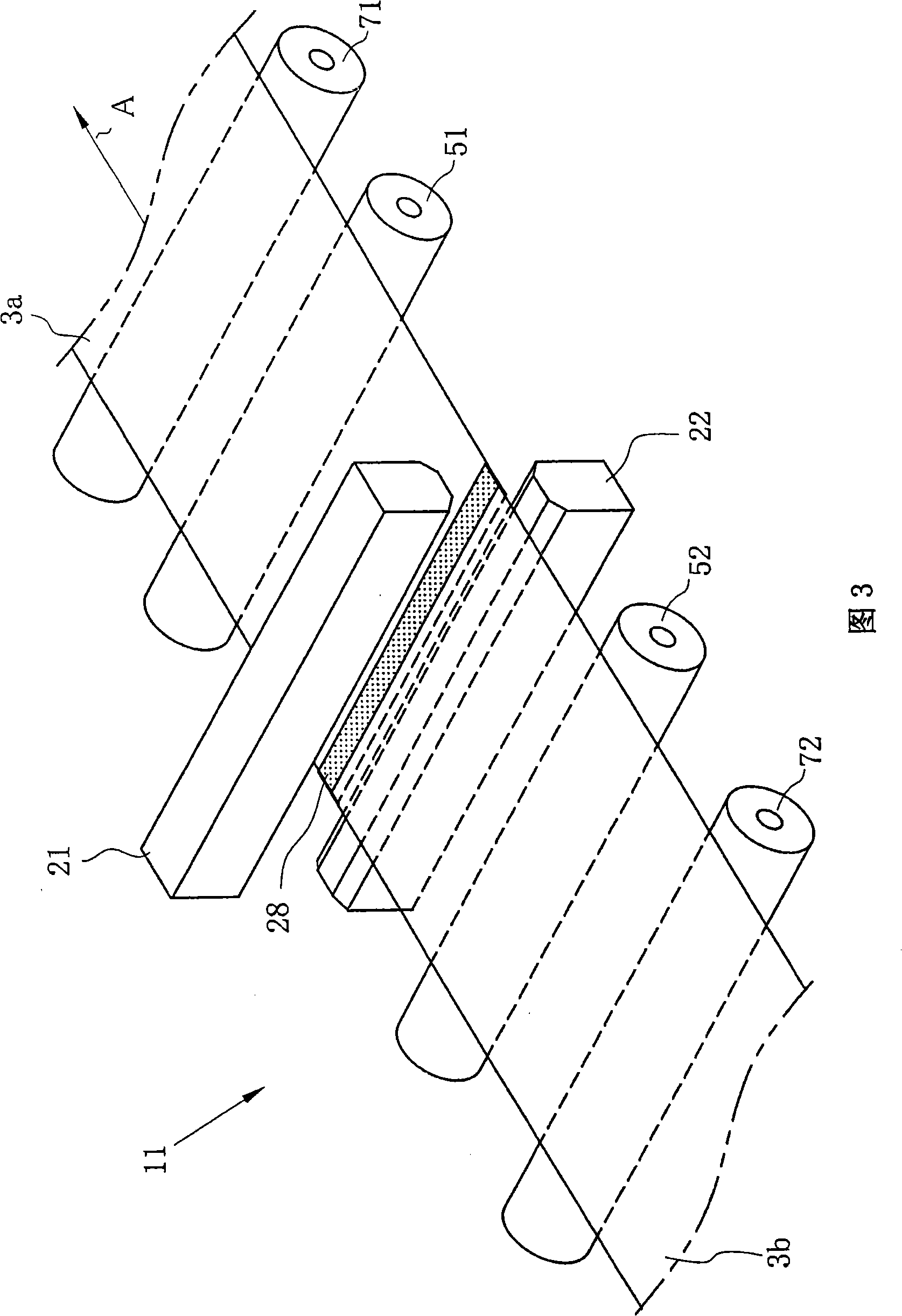

Polymer film splicing method and device, and stretching method

The invention relates to a polymer film joint method and a device and a polymer film stretching method. An off-line stretching device includes a film supply chamber, a tenter section, a relaxation chamber, a cooling chamber, and a winding chamber. The film supply chamber includes a splicing section, where a rear end of a preceding film and a front end of a trailing film are overlapped to be spliced to each other by thermal welding. The thermal welding is performed from above and below the film while a temperature of welding heads of a heat sealer, contacting with the film, is kept at a level equal to or less than a decomposition temperature of the preceding and trailing films. The spliced film is stretched in the tenter section and subjected to heat treatment for stress relaxation in the relaxation chamber, to shrink in a film width direction. Since the shrinkage amount of a spliced area and that of a peripheral area become equal to each other, the occurrence of wrinkles in the spliced area and tears of the film in the peripheral area can be prevented. Additionally, since a heat transfer distance between a film surface and a film splicing surface can be shortened, the heating from above and below the film enables high-speed welding.

Owner:FUJIFILM CORP

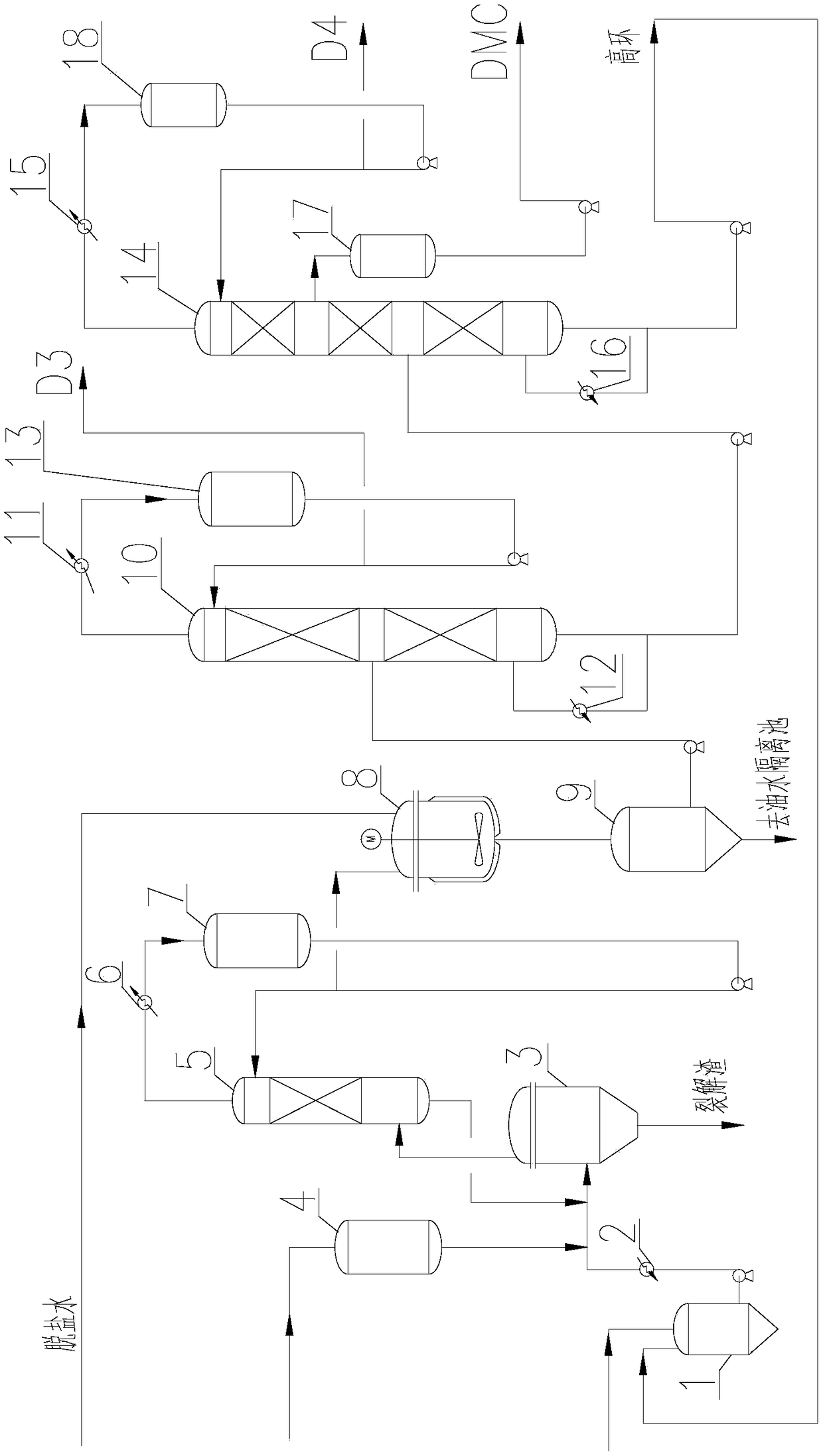

Organic silicon hydrolysate pyrolysis method and device of solvent oil thermal drive circulation

ActiveCN108409780AMixed mass transfer process is fastFully contactedSilicon organic compoundsChemical/physical/physico-chemical processesPlate heat exchangerHydrolysate

The invention relates to an organic silicon hydrolysate pyrolysis method and device of solvent oil thermal drive circulation. Double spiral channels in a form of spiral-like plate heat exchanger are coaxially arranged in the middle of a pyrolysis device; the upper and lower ends of one spiral channel of the double spiral channels are not sealed, so that the spiral channel can serve as a pyrolysischannel, and the upper and lower ends of the other spiral channel are sealed to form a heat exchange medium channel; solvent oil is distributed in an annular space between the column consisting of thepyrolysis channel and the double spiral channels and the pyrolysis device; a mixture of organic silicon hydrolysate and KOH solution is fed into the pyrolysis channel; the heat exchange medium of theheat exchange channel provides heat to the pyrolysis channel; the organic silicon hydrolysate is mixed with solvent oil in the pyrolysis channel, and experiences vaporization while reacting; bubblesrise to drive the liquid in the pyrolysis channel to go up to the top of the pyrolysis channel; after gas-liquid separation, the solvent oil, the unreacted organic silicon hydrolysate and the KOH solution go down to the bottom of the pyrolysis device through the annular space, forming natural circulation. Without a stirring device, the heat and mass transfer efficiency is high, and local overheating is avoided; the production cycle of the device is prolonged, and the alkali consumption is reduced; moreover, the annulus yield as well as the quality of D4 and DMC is improved, and the operation is stable, safe and reliable.

Owner:QINGDAO KEDA LONGTENG TECH DEV +1

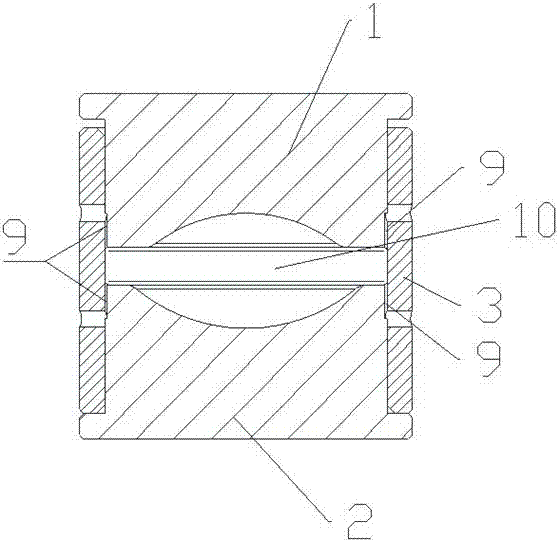

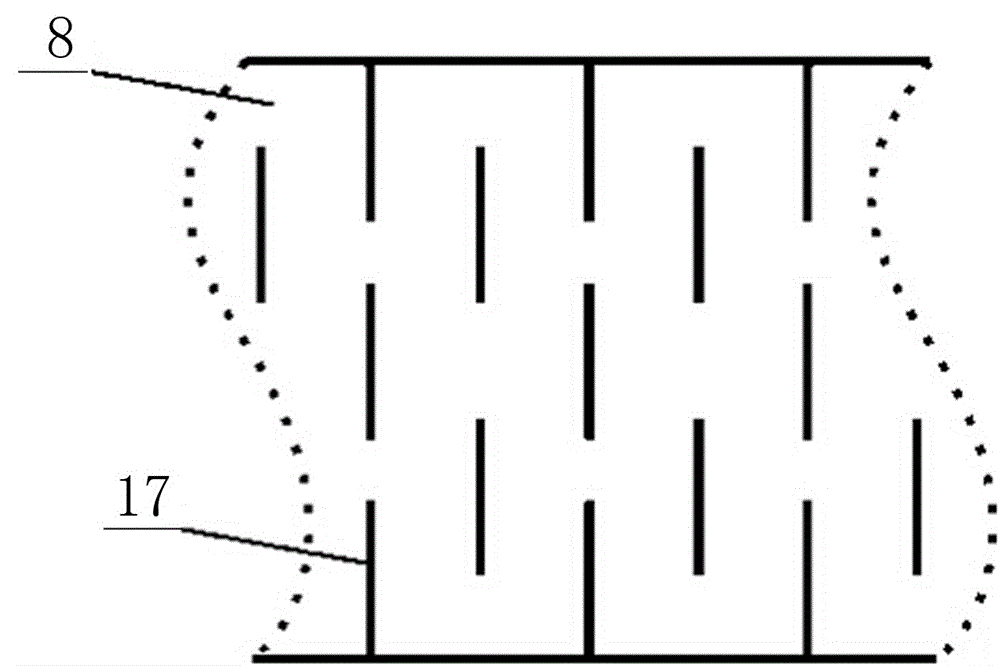

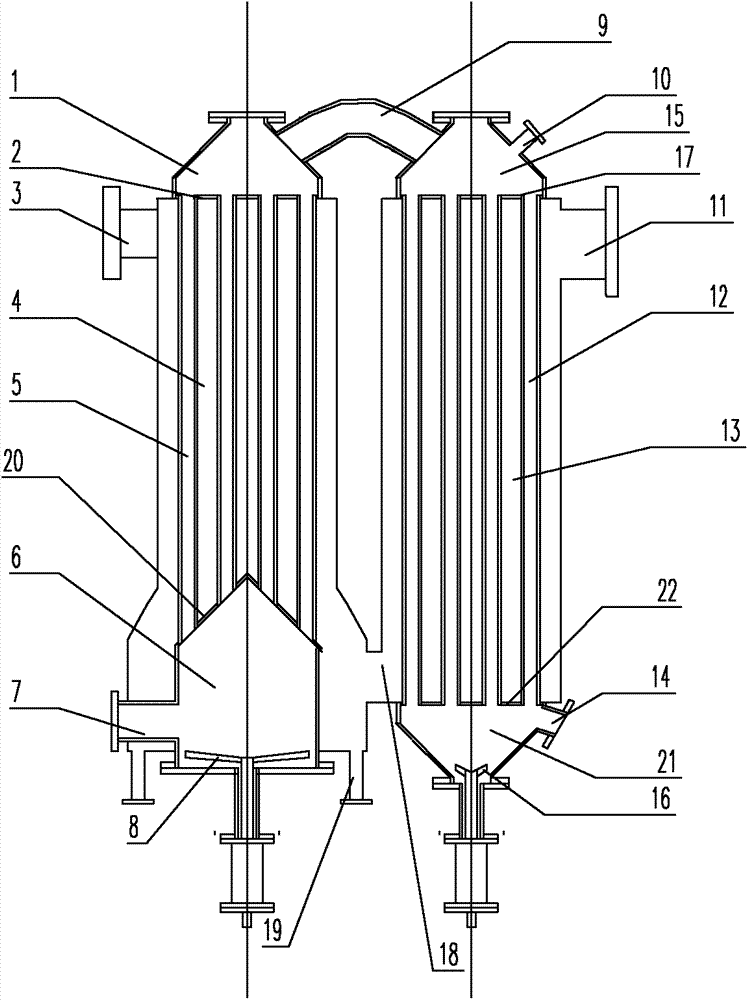

Heat exchanger for semicoke residual heat utilization

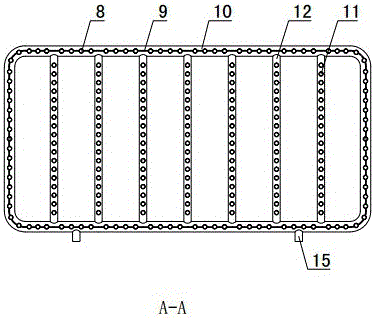

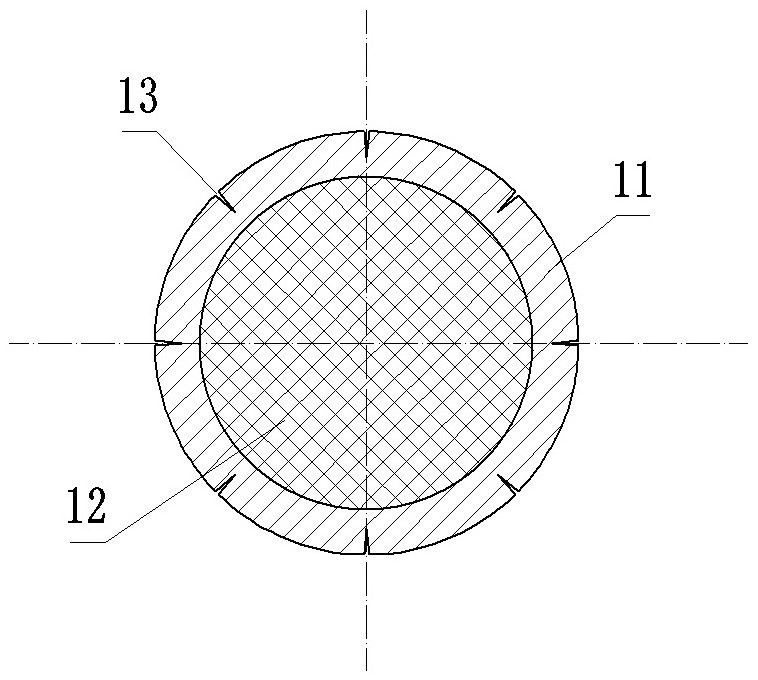

ActiveCN104236337AImprove heat transfer effectImprove cooling uniformityHeat exchanger casingsStationary tubular conduit assembliesHeat conductingEngineering

The invention relates to a heat exchanger for semicoke residual heat utilization and belongs to the field of semicoke processing equipment. The heat exchanger comprises an annular external upper header (10) and a plurality of annular external lower headers (2), wherein N connecting pipes (13) are uniformly arranged along the length direction of the external upper header (10), the two ends of each connecting pipe (13) are fixedly connected and communicated with the two long sides of the external upper header (10) respectively, and the external upper header (10) and the connecting pipes (13) jointly form N+1 rectangular rings; the external lower headers (2) are arranged just below the rectangular rings, the rectangular rings and the corresponding external lower headers (2) are fixedly connected and communicated through a plurality of external heat exchange pipes (11), a heat conducting baffle (8) is fixedly arranged between every two adjacent external heat exchange pipes (11), so as to enclose N+1 semicoke flow passages, and a material guiding device is arranged at an inlet of each semicoke flow passage. The heat exchanger has the advantages of semicoke dry-distillation, blowdown efficient-cooling, residual heat recovery, uniformity in semicoke blanking, uniformity in heat exchange and the like.

Owner:SHANDONG UNIV OF TECH +1

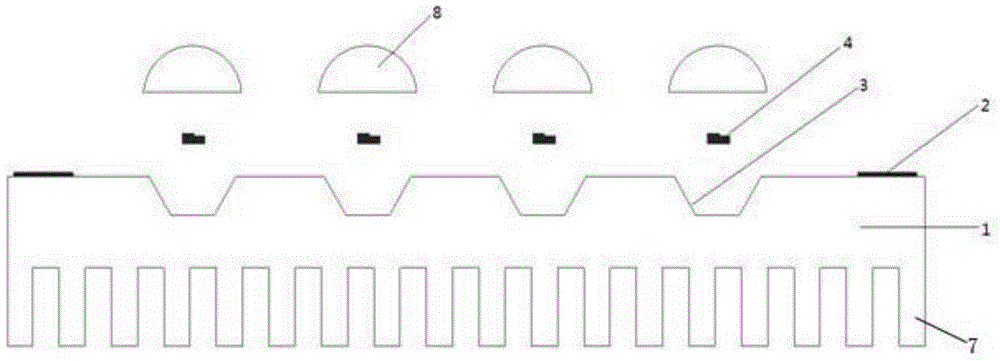

MCOB LED package structure

InactiveCN104157637ASpeed up heat transferShort heat transfer distanceSolid-state devicesSemiconductor devicesHeat transmissionMetallic materials

An MCOB LED package structure comprises a substrate and a plurality of LED chips. The substrate comprises a first surface and a second surface back onto the first surface, a plurality of cup-shaped bowls are formed in the first surface, and the second surface is provided with a plurality of cooling fins. The substrate is of a structure integrally formed by metal materials or ceramic materials or polymer composite materials. The cup-shaped bowls are manufactured through optical simulation. The LED chips are fixed into the cup-shaped bowls, the first surface is provided with an electronic circuit and a plurality of different power interfaces, the LED chips are connected with the electronic circuit, and the electronic circuit is connected with the power interfaces. According to the MCOB LED package structure, the substrate of the structure integrally formed by the metal materials or the ceramic materials or the polymer composite materials is adopted, so that thermal transmission capacity of the substrate is increased; the cup-shaped bowls are directly formed in the substrate, and the LED chips are installed in the cup-shaped bowls, so that the heat transmission distance is shortened; the cooling fins are arranged, the cooling rate is further increased, and therefore the cooling effect of the LED package structure is improved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV

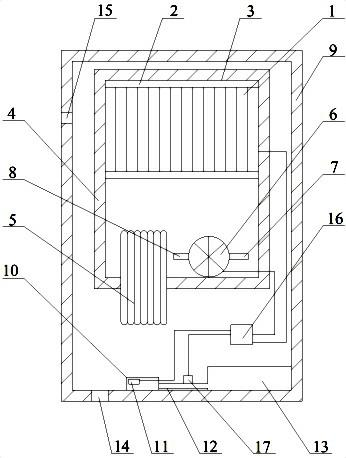

Battery system with heating function

InactiveCN102437395AIncrease surface areaIncrease the heating areaSecondary cellsCombustorHeat conducting

The invention discloses a battery system with a heating function. The battery system with the heating function comprises a battery module (3) and a heat-insulating shell (4). The heat-insulating shell is sealed, contains a heat-insulating material and covers the battery module, a heat-conducting tube (5) passing through the heat-insulating shell (4) is arranged at the bottom of the heat-insulating shell (4), a fan (6) is arranged at the bottom of the heat-insulating shell (4), an air outlet (8) of the fan (6) and the heat-conducting tube (5) are arranged face to face, at least a part of air blown out of the air outlet (8 ) is in contact with the heat-conducting tube (5) to generate heat exchange, the heat-conducting tube (5) is heated by a combustor (10), fuel of the combustor (10) is provided by a detachable fuel bottle (13), and the whole system is controlled by a controller (16). The battery system with the heating function disclosed by the invention is suitable to work at a low temperature, is convenient, safe and reliable to use, and has the advantages of low cost and high heating efficiency.

Owner:CHENGDU UNI LINK ENERGY

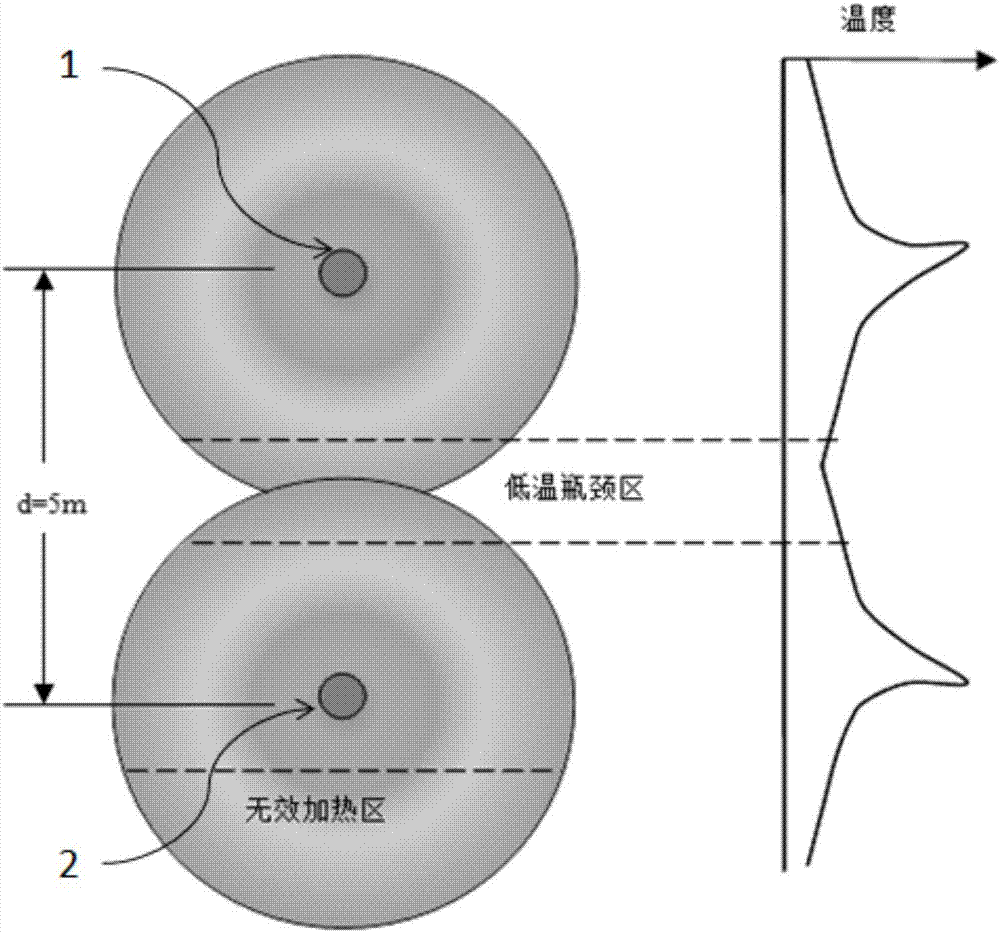

Electro-magnetic induction internal thermal type metallic magnesium vacuum reduction furnace

InactiveCN105018730AImprove structural strengthNot easy to damageIncreasing energy efficiencyElectric heating for furnacesLithiumStrontium

The invention relates to the technical field of vacuum metallurgical equipment, in particular to an electro-magnetic induction internal thermal type metallic magnesium vacuum reduction furnace which comprises a furnace body. A material basket (8) is arranged in the furnace body, and a central channel penetrating through the bottom face of the material basket (8) is formed in the center of the material basket (8). One or more heating cylinders (7) are concentrically arranged in the material basket (8). The material basket (8) and the heating cylinders (7) are filled with furnace burdens (9). A rectangular iron core is arranged in the furnace body. One long edge of the rectangular iron core penetrates through the central channel of the material basket (8), and a primary side coil (12) is wound around the other long edge of the rectangular iron core. The leading-out end of a copper winding of the primary side coil (12) is led out of the furnace through an insulated sealing device on the furnace body and is connected with a power source device. The electro-magnetic induction internal thermal type metallic magnesium vacuum reduction furnace is reasonable in design, distribution of a temperature field of the reduction furnace can be regulated, and heat transfer efficiency is high; the vacuum reduction furnace is used for high-vapor-pressure metallothermics production of magnesium, lithium, strontium, calcium and the like.

Owner:SHANXI UNIV

Loop type heat dissipating apparatus with sprayer

InactiveUS7882889B2Improve cooling efficiencyReduce thermal resistanceDomestic cooling apparatusSemiconductor/solid-state device detailsWorking fluidSprayer

Owner:IND TECH RES INST

Efficient anti-scaling condensation pipe

InactiveCN101520285ASolve easy foulingImprove heat transfer coefficientEvaporators/condensersHeat transfer modificationVapor liquidEconomic benefits

The invention relates to an efficient anti-scaling condensation pipe. A thin-wall circular pipe is made of stainless steel, straight pipes with equal diameter are at two ends, a corrugated pipe is on the middle part, and the outer surface of the corrugated pipe is evenly distributed with raised pyramid lug bosses. The condensation pipe has the following advantages that: because fluid in the corrugated pipe disturbs intensively at low flow rate to generate turbulent flow which has complete flushing function on the pipe wall, the easy-scaling problem of the condensation pipe is well solved; simultaneously, due to surface curvature change and axial extension change of the corrugated pipe caused by temperature and larger linear expansibility difference of the stainless steel pipe wall and the scale, the scale is easy to fall off, self cleaning of the pipe is achieved, and the scale removing problem of the condensation pipe is well solved; moreover, the pyramid lug bosses on the outer surface of the corrugated pipe increase the heat exchange area and puncture condensate membranes, so drops are easy to form and drop quickly along a wave crest, and the vapor-liquid conversion time is quickened. The pipe has light weight, high strength and quick heat transfer, and is superior to the prior structural copper pipe in economic benefit, service life and the like.

Owner:吕美琪

Heat exchanger and temperature control unit

ActiveUS7243500B2Easy to operateShort heat transfer distanceTemperatue controlStationary conduit assembliesTrombe wallTemperature control

Systems and methods for heat exchange in accordance with the invention define adequately long-interchange distances for two fluids by wrapping a tube containing a first fluid about the wall of an inner cylindrical tank, within a gap formed with a second concentric tank. A second fluid is transmitted in the space defined between the turns of the tube and the two walls, providing effective short length thermal interchange through the tube walls. The tube is in the line contact with both tank walls and the fluids can flow rapidly over an adequately long length, so that high efficiency is provided in a low cost system.

Owner:BE AEROSPACE INCORPORATED

Efficient cooling barrel body of reduced iron rotary barrel type cooling machine

ActiveCN104789760AIncrease the heat exchange areaShort heat transfer distanceMetallurgyWater channel

The invention relates to an efficient cooling barrel body of a reduced iron rotary barrel type cooling machine, and the efficient cooling barrel body is mainly used for cooling reduced iron pellets and sintered pellets in metallurgical mine industry. The efficient cooling barrel body comprises a barrel body (1), a plurality of half cooling pipes (3) and a plurality of round cooling pipes (4), wherein the half cooling pipes (3) are uniformly arranged on the inner wall of the barrel body (1) and fixedly connected with the inner wall of the barrel body (1) to form a plurality of water channels; the round cooling pipes (4) are arranged on the inner side of a circumferential rotary body defined by the half cooling pipes (3); the half cooling pipes (3) and the round cooling pipes (4) are connected with a water supply unit and a water return unit. The half cooling pipes (3) and the round cooling pipes (4) are arranged in the barrel body (1), so that the heat exchange area is effectively enlarged, blending and heat transfer of materials are enhanced, and the efficient cooling barrel body has the advantages of good material cooling effect and small deformation of the barrel body.

Owner:SHANDONG UNIV OF TECH

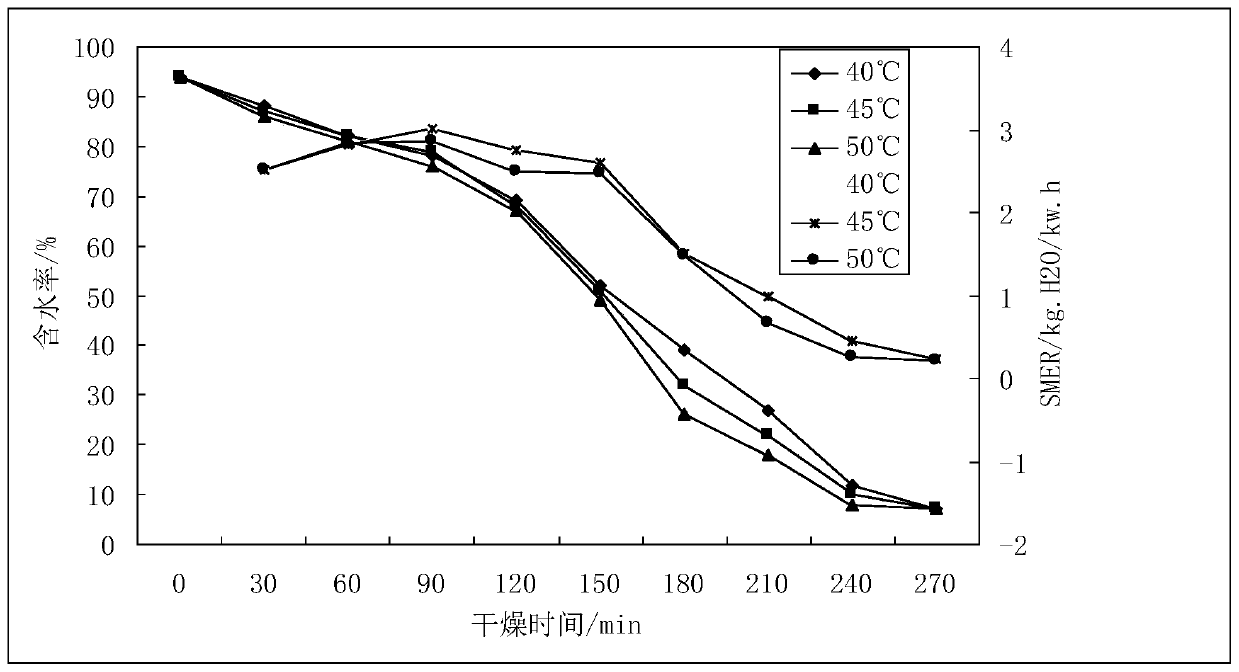

Day lily infrared heat pump combined drying technology

InactiveCN109770284AEasy to operateEasy to processFood processingFruits/vegetable preservation by dehydrationFixation - actionRoom temperature

The invention discloses a day lily infrared heat pump combined drying technology. The technology includes the following steps of S1, picking, cleaning and airing fresh day lily; S2, filling a processing bag with the day lily; S3, executing fixation action on the day lily in the processing bag; S5, stopping the fixation treatment, and filling a material plate with the day lily; S6, drying the day lily in the material plate through a heat pump; S6, conducting far infrared fixation treatment on the day lily in the drying treatment process of the heat pump; S7, stopping the radiation treatment ofa far infrared heat source and the drying treatment of the heat pump; S8, taking out the day lily, evenly spreading and airing the day lily, and conducting cooling until the room temperature is reached; S9, conducting vacuum bagging and storing on the aired day lily. The day lily drying efficiency is improved, the efficient low-consumption drying of the day lily is truly realized, coking and colorchanging caused by high-temperature drying of part of flower bodies are avoided, the loss of vitamins and other nutrients in flower buds is avoided, and the non-enzymatic browning of the day lily isreduced. The day lily processing effect is good, and the nutritional value is high.

Owner:QU COUNTY DANGQU DAY LILY TECH DEV CO LTD

Linking method for dual horizontal wells

ActiveCN107401397AShort heat transfer distanceShorten connection timeFluid removalHorizontal wellsWater flow

The invention discloses a linking method for dual horizontal wells and relates to the field of oil and gas exploitation. The linking method comprises steps of testing a steam injection horizontal well and a producing horizontal well, injecting a solvent to the steam injection horizontal well and the producing horizontal well, injecting water to the steam injection horizontal well via a shaft of the steam injection horizontal well, injecting water to the producing horizontal well via a shaft of the producing horizontal well, continuously injecting water to the steam injection horizontal well and the producing horizontal well respectively, improving water injection pressure of the steam injection horizontal well and the producing horizontal well, closing the steam injection horizontal well and the producing horizontal well and injecting gas to the steam injection horizontal well and the producing horizontal well respectively when a first preset condition is met to enable underwell water to flow back to the ground, and injecting equal-pressure steam to the steam injection horizontal well and the producing horizontal well to meet a second preset condition when the underwell water flows back to the ground. Link evenness of the dual horizontal wells can be effectively enhanced, linking time of the dual horizontal wells can be shortened and solvent consumption amount can be greatly reduced.

Owner:PETROCHINA CO LTD

Efficient-heat-dissipation integrated LED modulator tube structure and production process thereof

InactiveCN104019389ALight attenuation is smallShort heat transfer distancePoint-like light sourceElongate light sourcesComputer moduleEngineering

The invention relates to an efficient-heat-dissipation integrated LED modulator tube structure and a production process of the efficient-heat-dissipation integrated LED modulator tube structure. The horizontal wall of an aluminum shell is a packaging plane. A printed circuit layer is arranged on the packaging plane. Chips are welded to the printed circuit layer of the aluminum shell. A silica gel layer is arranged in the area defined by a surrounding glue layer of the aluminum shell. The upper surface of the silica gel layer is evenly coated with a fluorescent powder coating. An intelligent IC drive element is directly welded to the printed circuit layer of the aluminum shell. The two ends of each chip are connected with voltage regulator tubes respectively. The chip-support-aluminum substrate-tube body multistage thermal resistance obstacle is thoroughly omitted, the heat conduction way is improved, and the heat conduction distance is greatly shortened; a support and the aluminum substrate are omitted, and production cost is reduced; the problems that the luminous efficiency is low and the luminous decay becomes large are solved; no extra drive module is needed, and automatic attachment is completed; heat produced when the intelligent IC drive element and electronic elements work is directly transmitted outwards through aluminum pipes, and therefore the heat dissipation effect of a drive module is improved, and the service life of a power supply is prolonged.

Owner:GUANGDONG JINYUAN LIGHTING TECH

Multiple furnace core furnace for smelting silicon carbide and its mehtod for producing silicon carbide

InactiveCN1181306CEfficient use ofImprove insulation effectMuffle furnacesChemical industrySmelting processGraphite

The silicon carbide smelting furnace comprises heat insulating wall, heat maintaining material, reaction material, two or more plate furnace cores buried inside the reaction material and electrodes. The furnace cores are arranged parallelly or spatially and each of the furnace cores has ends connected to electrodes. The silicon carbide smelting process includes desiging furnace shape; compounding furnace core material with graphite, bitmute, silicon carbide and silicon dioxide; selecting electrode material and shape; and determining the ratio of the reaction material and heat insulating material. The present invention has obvious energy saving effect, high product yield and high product quality.

Owner:咸阳新能源材料产业技术研究院有限责任公司

Box type evaporator for waste heat utilization of high-temperature solid materials

ActiveCN105953199ACompact structureEfficient waste heatEnergy industrySteam superheatersIsolating mechanismsEngineering

The invention discloses a box type evaporator for waste heat utilization of high-temperature solid materials and belongs to the field of cooling equipment for the high-temperature solid materials. The box type evaporator is characterized in that an outer cylinderl (2) and an inner cylinder (1) are combined to form a sleeve type header; the lower end of a heat exchange box (7) is open; the sleeve type header seals the upper end of the heat exchange box (7); a feeding port (4) communicated with the inner cylinder (1) is arranged at the upper part of the sleeve type header; a water-cooled spiral distributor for conveying and cooling the materials is arranged inside the inner cylinder (1); a heat exchange cavity is arranged on the side wall of the heat exchange box (7) ad is communicated with an inner cavity of the outer cylinder (2); multiple isolating mechanisms are arranged inside the heat exchange box (7) in parallel and divide the heat exchange box (7) into multiple material channels; and the materials in the inner cylinder (1) fall into the material channels via discharge ports (6). Both the sleeve type header and the heat exchange box of the box type evaporator for waste heat utilization of the high-temperature solid materials can bear pressure, so that the evaporator can be directly applied to production of steam, and waste heat of the high-temperature materials is efficiently utilized.

Owner:SHANDONG LIANXING ENERGY SAVING SERVICE

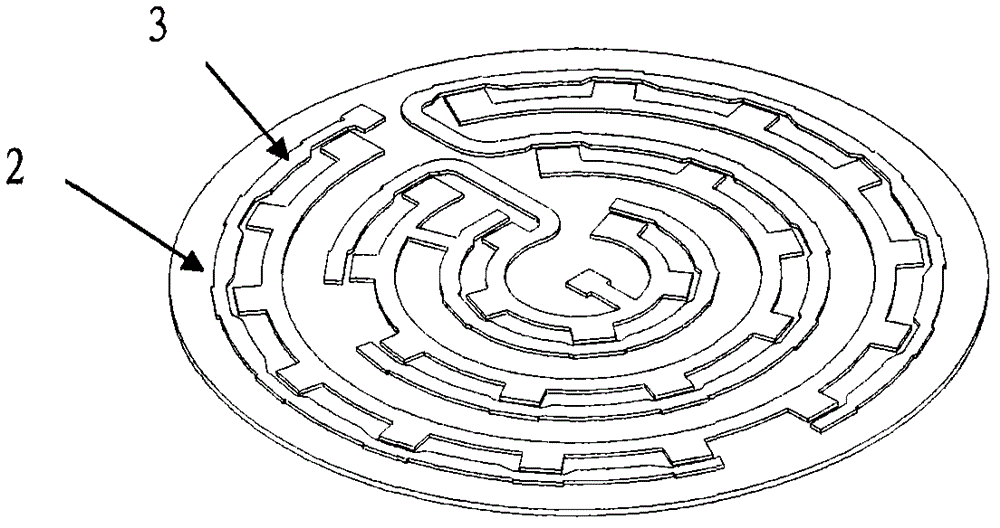

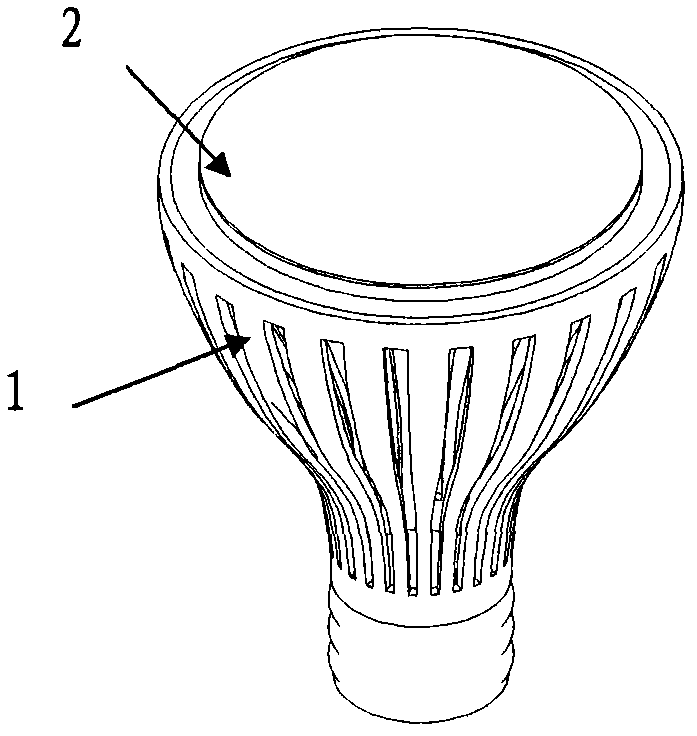

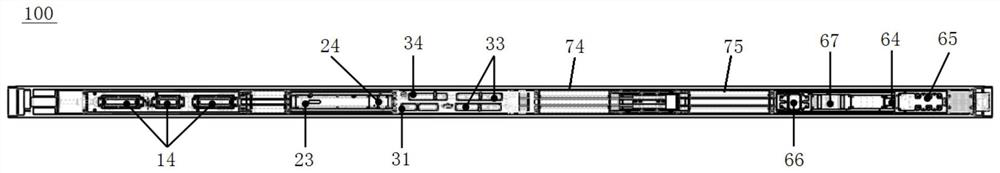

LED (Light Emitting Diode) lamp module and manufacturing method thereof

InactiveCN102734665AReduce pollutionShort heat transfer distancePoint-like light sourceElectric circuit arrangementsSurface mountingEngineering

The invention relates to an LED (Light Emitting Diode) lamp module and a manufacturing method thereof. Specifically, the LED lamp module provided by the invention comprises a stereoscopic radiating support lamp carrier, a sticky conductive medium and an LED, wherein the sticky conductive medium is distributed on the stereoscopic radiating support lamp carrier to form a circuit of the LED lamp module; and the LED is fixedly stuck to the circuit formed by the sticky conductive medium, and conducts with the circuit. The sticky conductive medium plays a role of a conductive circuit, as well as roles in sticking the LED and other electronic devices. The invention further provides an LED lamp module manufacturing method. According to the LED lamp module, etching is not needed to manufacture the circuit board, the whole manufacturing process flow is shortened as the LED and other devices are also not welded by SMT (Surface Mounting Technology), the materials are saved, the manufacturing time is shortened and the production efficiency is greatly improved, the environment pollution caused by etching in traditional circuit board manufacturing process is reduced, the production cost is greatly reduced, and the environment is protected.

Owner:王定锋

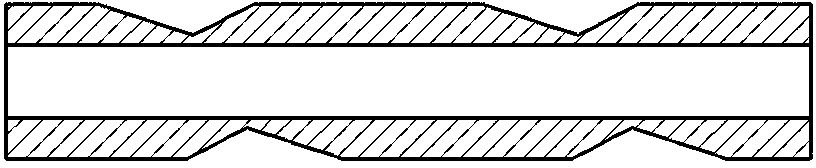

Internal combustion engine exhaust gas recirculation cooler

InactiveCN103742299AIncreased turbulenceShort heat transfer distanceNon-fuel substance addition to fuelExhaust gas recirculationEngineeringExhaust gas recirculation

The invention relates to an internal combustion engine exhaust gas recirculation cooler. The internal combustion engine exhaust gas recirculation cooler comprises a housing, heat exchange pipes, pipe plates and a fluid inlet-outlet and is characterized in that threads are processed outside the heat exchange pipes. The threads are processed outside the heat exchange pipes, so that turbulent flows formed by a cooling medium outside the pipes are intensified, a heat transfer distance between exhaust gas and the cooling medium at the thread bottom is shortened, the heat exchange efficiency is improved, and the internal combustion engine exhaust gas recirculation cooler is simple, convenient, easy to operate and obvious in effect.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

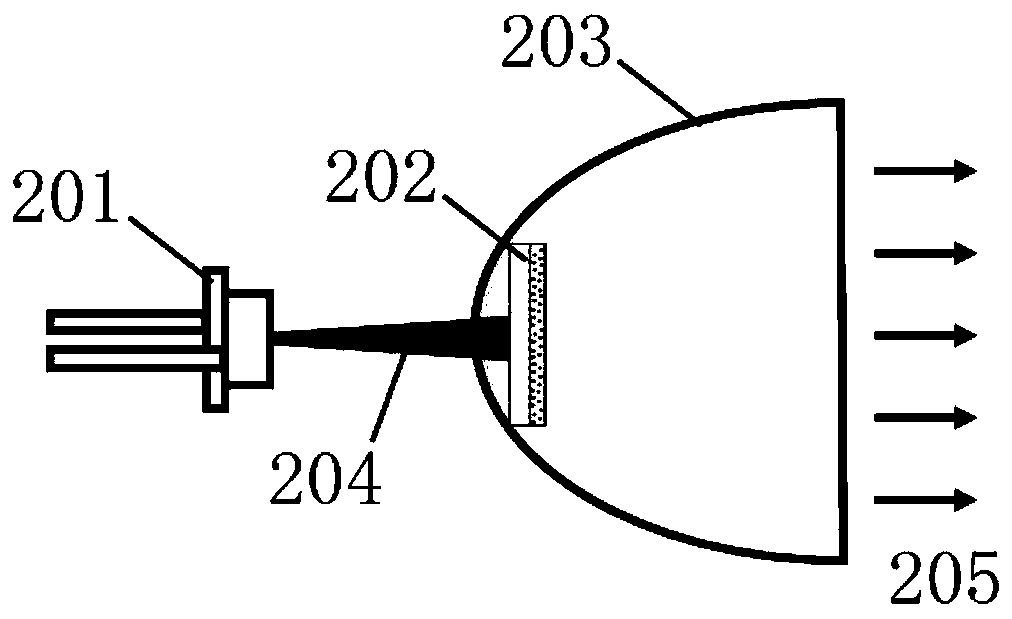

Nitride phosphor/glass composite light conversion component for laser lighting and its preparation

InactiveCN108895314BImprove quantum efficiencyExcellent thermal quenching performanceSemiconductor devices for light sourcesGlass compositesPhysical chemistry

The invention relates to a nitride phosphor / glass composite optical conversion kit for laser illumination and a preparation thereof, which relates to light conversion components. Nitride phosphor / glass composite optical conversion kit for laser illumination comprises a nitride phosphor / glass composite coating and a high thermal conductivity ceramic substrate, the nitride phosphor / glass composite coating is closely grown on the high thermal conductivity ceramic substrate. The preparation of phosphor slurry: the nitride phosphor / glass composite optical conversion kit is prepared for laser illumination. The nitride phosphor / glass composite optical conversion kit can be used in laser illumination. The luminous efficiency above 280 lm / W can be obtained by coupling the provided nitride phosphor / glass composite optical conversion kit for laser illumination with a laser source with emission wavelength about 450 nanometers.

Owner:XIAMEN UNIV

Refrigeration adsorber and its manufacturing method

InactiveCN1641296ACompact structureGuaranteed heat transfer areaClimate change adaptationEnergy efficient heating/coolingSorbentEngineering

The invention is a type of refrigerating absorber and its manufacturing method. It comprises inner and outer two round tubes suiting with each other. There is fixed with up and down cover boards, entrance and exit of carrier at each end of the outer round tube while passage of the carrier and passage of cryogen in the inner round tube. There is fixed pipe for cryogen in or out on the up cover board and up end cap while mouth for absorbent to be loaded. The absorbent is filled between the passage of cryogen and the passage of carrier. The manufacturing process is welding elements adopting the method of argon-arc welding with stainless steel. The invention makes advantages of jacket-style heat exchanger and heat exchanger with arranging pipes so it not only has high efficiency of diathermancy and mass transfer, fine pressure endure, but also has compact structure because of which it can reduce volume of the absorber to a large degree and increase charge of the absorbent.

Owner:SOUTH CHINA UNIV OF TECH

Liquid methanol heating furnace

ActiveCN109780582AUniform temperature distributionShort heat transfer distanceLiquid heating fuelLighting and heating apparatusLiquid stateLiquid fuel

The invention discloses a liquid methanol heating furnace which is a device integrating liquid methanol low-temperature start, methanol vaporization, methanol catalytic combustion and water preheating. The device is composed of a liquid methanol start cavity, a methanol and water preheating cavity, a methanol vaporization cavity, a methanol catalytic combustion cavity and a methanol exhaust gas secondary combustion cavity. In normal operation, liquid methanol is completely converted into carbon dioxide and water after being subjected to preheating, vaporization, catalytic combustion and secondary catalytic combustion; released heat is used for heating water, and hot water is used for civil heating or sanitary purposes. The device is compact in structure, sufficient in methanol combustion and high in thermal efficiency; no by-products such as CO are generated, hot and cold fluids are alternately distributed, local hot spots in a system can be effectively avoided, system operation is safe, the device can be widely applied to civil heating or sanitary facilities with methanol or other liquid fuel as fuel, and the device has the advantages of being clean, safe, hygienic, reliable and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Brazing welding wire, brazing welding wire forming method and brazing welding wire forming die

PendingCN113414517AShorten laying timeIncrease melting rateDrawing diesWelding/cutting media/materialsFiller metalBrazing

The invention relates to a brazing welding wire, a brazing welding wire forming method and a brazing welding wire forming die. The brazing welding wire comprises a brazing filler metal pipe with an inner cavity; and brazing flux filling the inner cavity of the brazing filler metal pipe, wherein a groove is formed in the peripheral face of the brazing filler metal pipe and extends along the axis of the brazing filler metal pipe or spirally extends around the axis of the brazing filler metal pipe. The brazing welding wire forming die comprises a die body, wherein a forming cavity is formed in the die body; a protrusion is arranged on the inner wall of the forming cavity, and when a brazing welding wire passes through the forming die, the protrusion is used for forming the groove in the peripheral face of the brazing filler metal pipe. The brazing welding wire forming method comprises the following steps: enabling a brazing filler metal pipe to pass through a forming mold; and forming a groove in the peripheral face of the brazing filler metal pipe through a protrusion arranged on the inner wall of a forming cavity of the forming die, wherein the groove extends along the axis of the brazing filler metal pipe or spirally extends around the axis of the brazing filler metal pipe. According to the scheme, the brazing flux melting rate of the brazing welding wire can be increased, the brazing flow laying time is shortened, and the welding quality is improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Method and device for air-floatation flow-state high-temperature heat-transfer gasification of biomass

ActiveCN102260538BNot dilutedGuaranteed LysisGranular/pulverulent flues gasificationCokeProcess engineering

The invention discloses a method and a device for air-floatation flow-state high-temperature heat-transfer gasification of biomass. The method comprises the following steps: (1) stirring a biomass gasifying raw material so as to form a mist state; (2) cracking under the heating of high temperature smoke at 800-1000 DEG C so as to obtain high temperature tar gas; (3) carrying out high temperature cracking and gasification on the high temperature tar gas and steam at the temperature of 1050-1150 DEG C; and (4) filtering, condensing and purifying solid residue and gas while stirring so as to obtain gas with a middle heat value. The device comprises a gas making furnace and at least one coke cracking furnace, wherein the gas making furnace comprises a gas collecting chamber and a stirring chamber; and the coke cracking furnace comprises an upper coke cracking furnace gas collecting chamber provided with a coke cracking furnace row tube, and a coke cracking furnace row tube shell layer is communicated with a gas making furnace row tube shell layer. According to the invention, a heat source in the whole cracking and gasification process is derived from high temperature smoke generated by combustion of a biomass micrometer fuel which is a renewable clean energy and is wide in source and low in cost. The method and device provided by the invention have the characteristics of high heatefficiency, high gas making efficiency and high gas heat value.

Owner:HUAZHONG UNIV OF SCI & TECH

Framework structure of nuclear magnetic resonance logging instrument

PendingCN114635683AReduce volumeReduce the temperatureElectric/magnetic detection for well-loggingSurveyNMR - Nuclear magnetic resonanceEngineering

The invention belongs to the technical field of logging instruments, and discloses a skeleton structure of a nuclear magnetic resonance logging instrument. The skeleton structure comprises a tail skeleton, a main control skeleton, a triangular skeleton, an antenna driving module, a front skeleton and a heat absorber module which are axially connected in sequence; the heat absorption body module comprises a main control heat absorption body fixed in the main control framework in an embedded mode, a triangular framework heat absorption body fixed in the triangular framework in an embedded mode, a front heat absorption body fixed in the front heat absorption framework in an embedded mode, and a tail heat absorption body fixedly connected between the tail framework and the main control framework. The antenna driving-triangular framework heat absorbing body is fixedly connected between the triangular framework and the antenna driving module, and the antenna driving-main discharging framework heat absorbing body is fixedly connected between the antenna driving module and the front discharging framework. According to the skeleton structure of the nuclear magnetic resonance logging instrument, the problems that electronic devices at different positions on the skeleton structure are insufficient in heat dissipation capacity and uneven in heat dissipation can be solved.

Owner:CHINA OILFIELD SERVICES

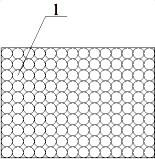

Composite phase change material based on foamed copper and its preparation method and heat storage package

ActiveCN108048046BImprove thermal conductivityShort heat transfer distanceHeat storage plantsChemical industryGraphiteGraphene

The invention provides a composite phase change material with foamy copper as a base body and a preparing method thereof and a heat storage bag, and relates to the field of phase change materials. Thecomposite phase change material with the foamy copper as the base body comprises a foamy copper metal layer and a graphene layer which are alternatively arranged in a stratified structure, and the foamy copper metal layer comprises the phase change material. Through the composite phase change material, the technical problems that in the prior art, after foam metal and the phase change material are compounded, the heat conduction efficiency is low, and liquid is easily leaked can be solved, and the aims of improving the heat conduction efficiency and reducing leakage are achieved.

Owner:BEIJING NAT BATTERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com