Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Maximize heat exchange efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

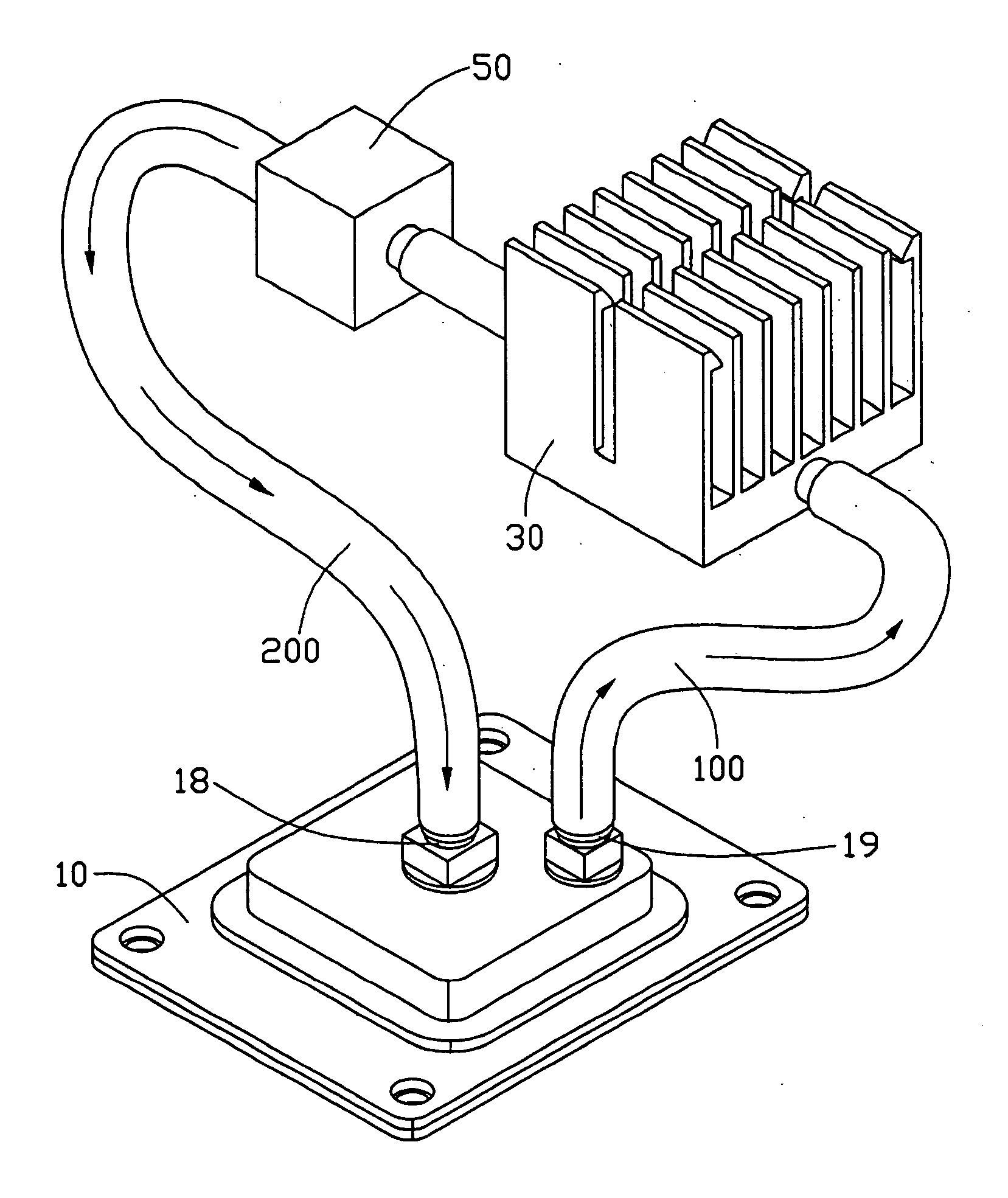

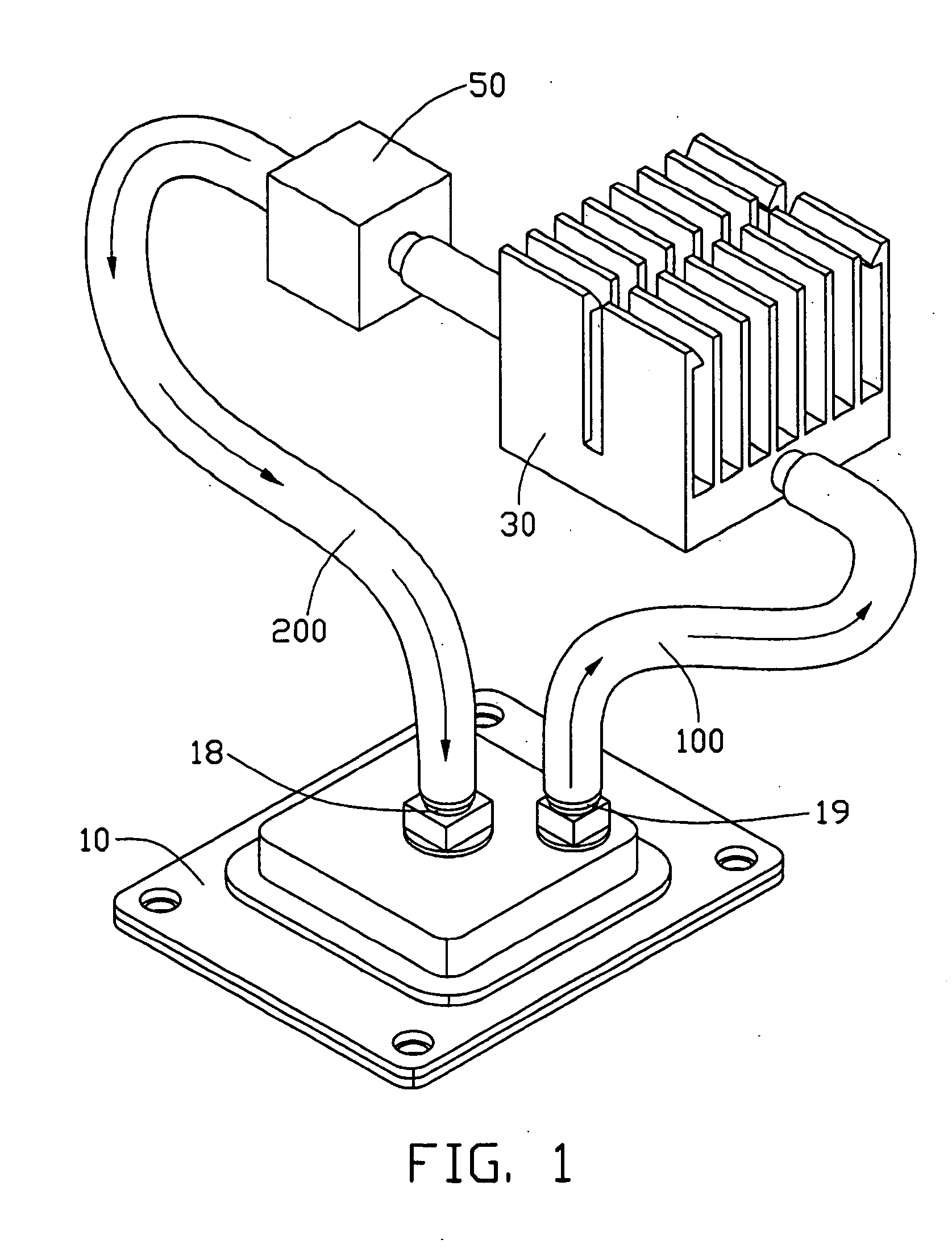

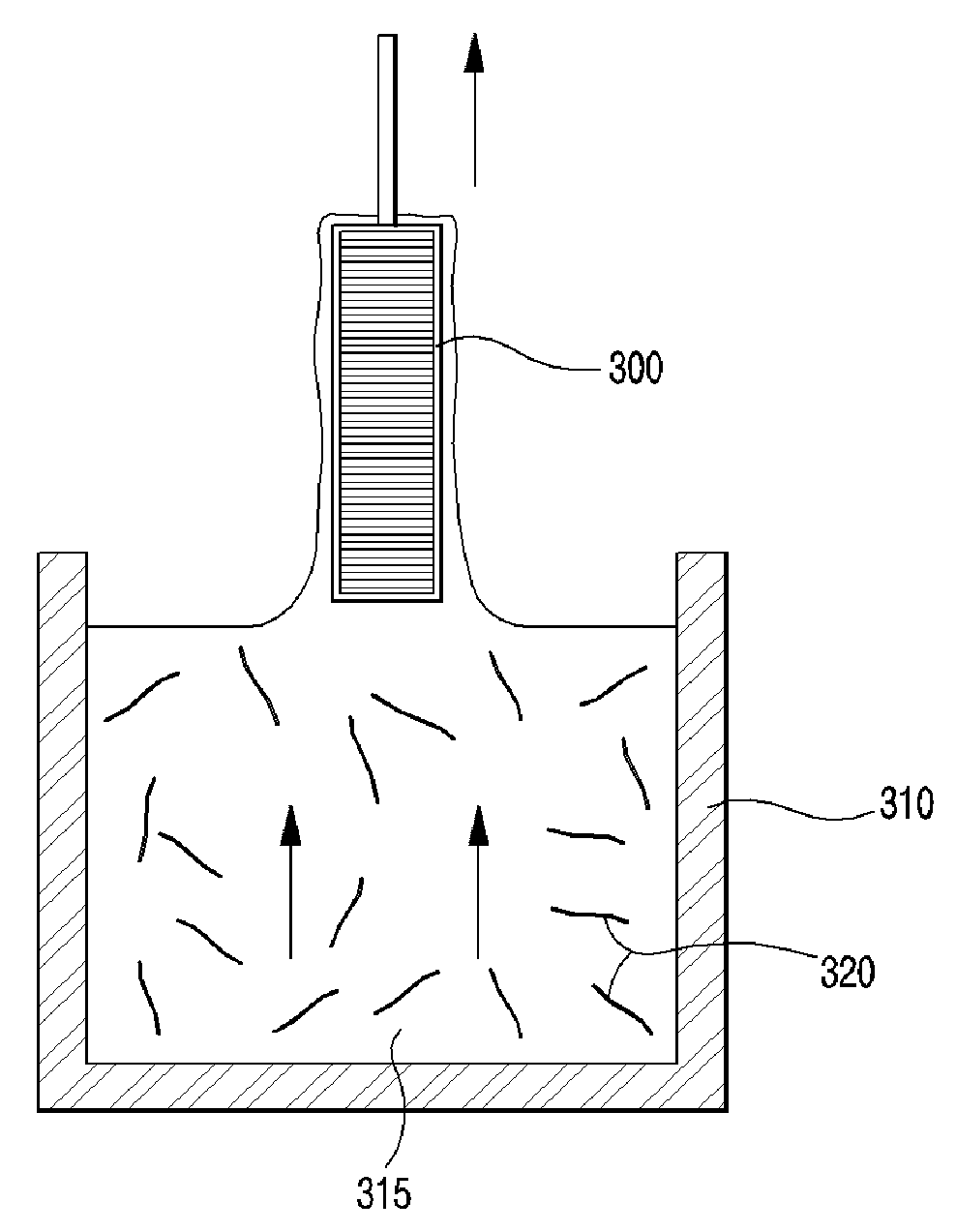

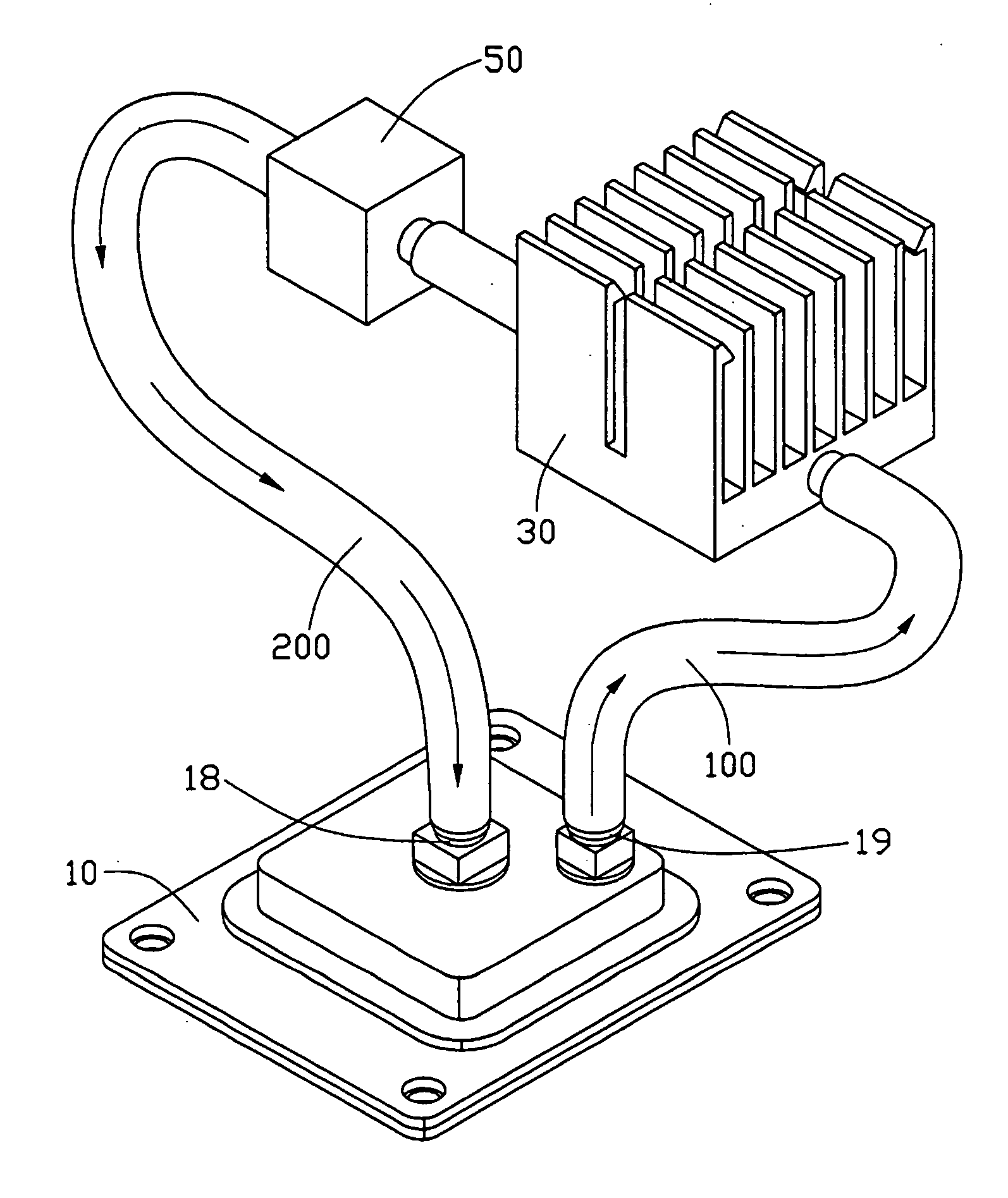

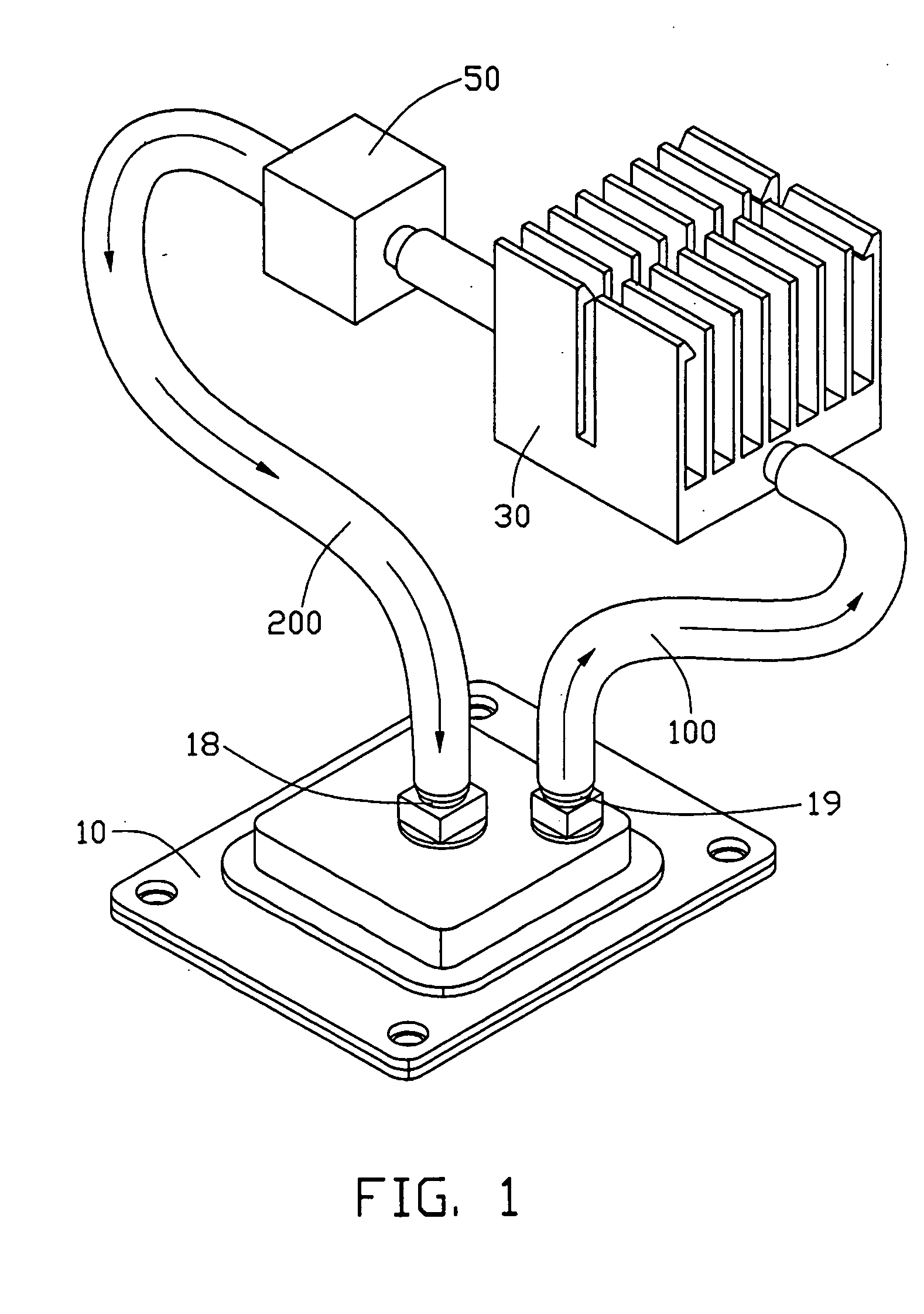

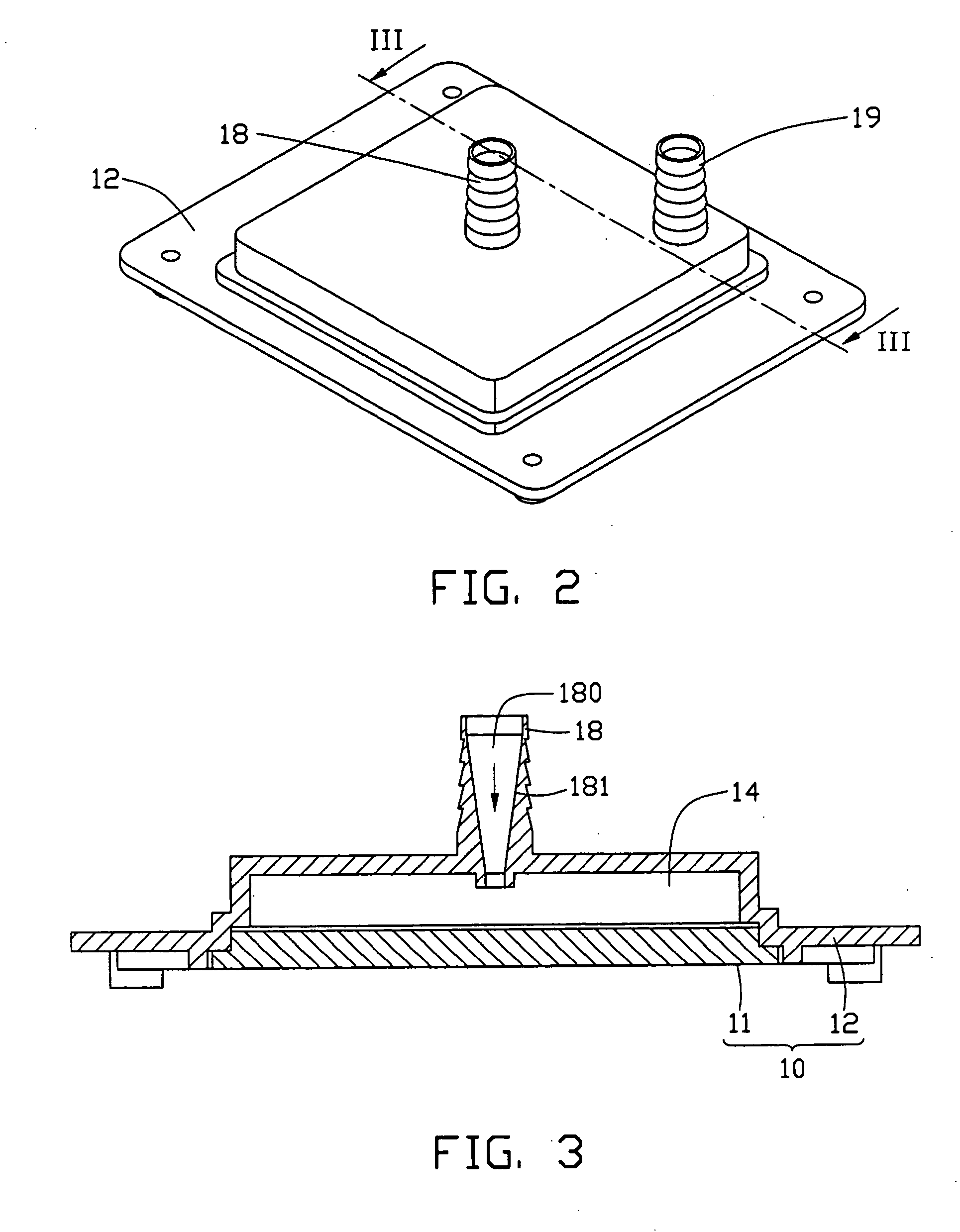

Liquid cooling device

InactiveUS20050082666A1Maximize heat exchange efficiencyAccelerate liquid flowSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringEngineering

Owner:HON HAI PRECISION IND CO LTD

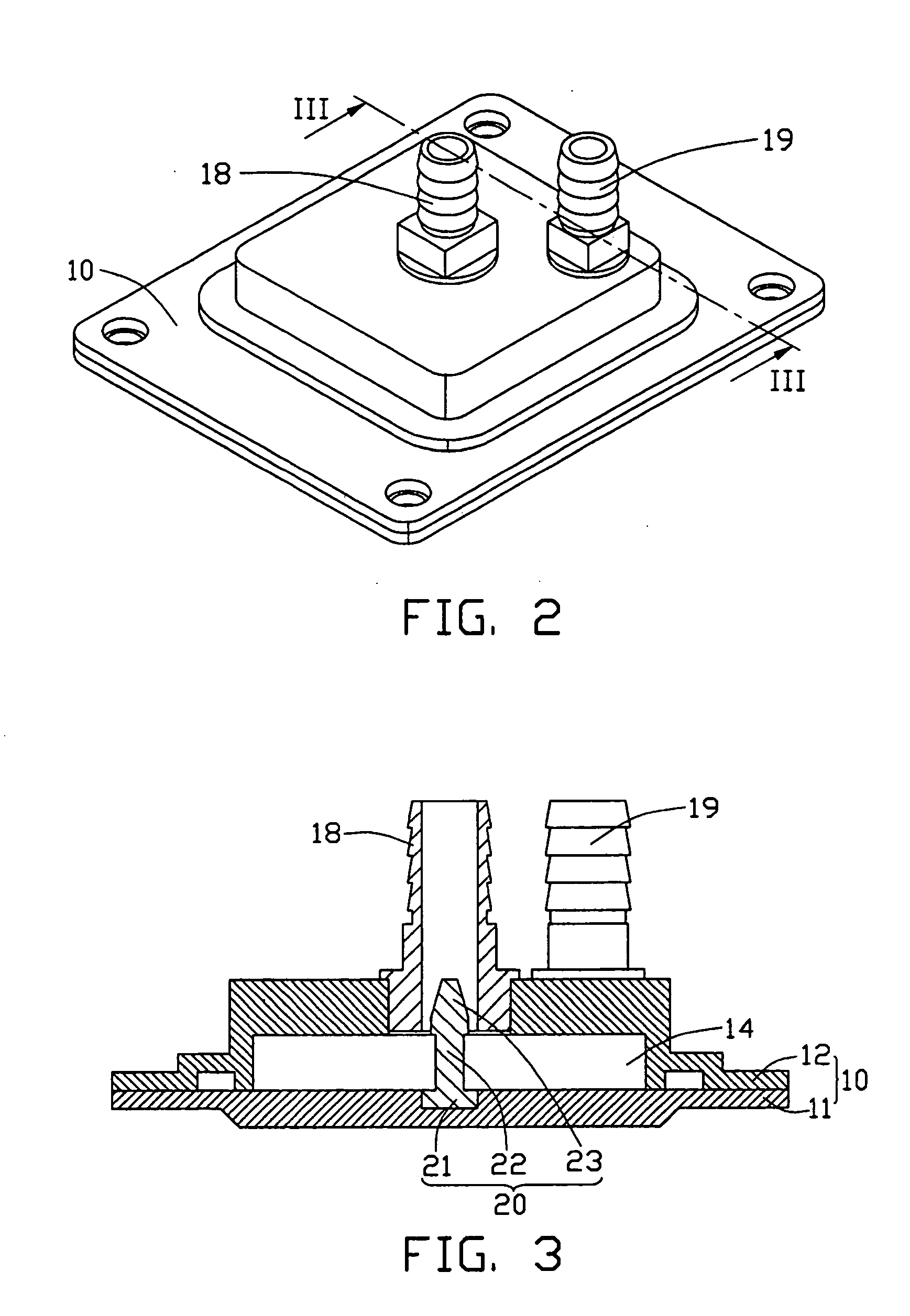

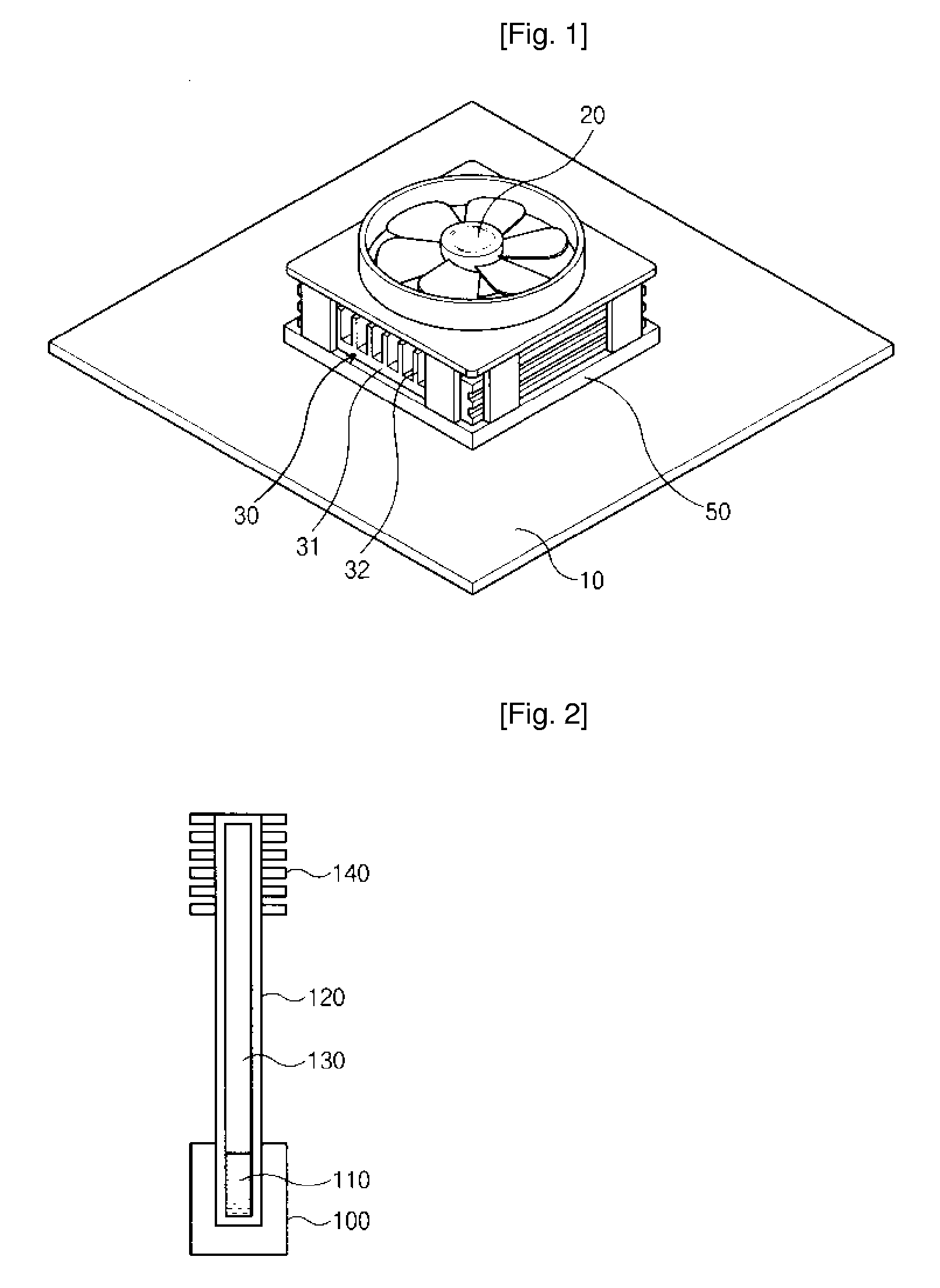

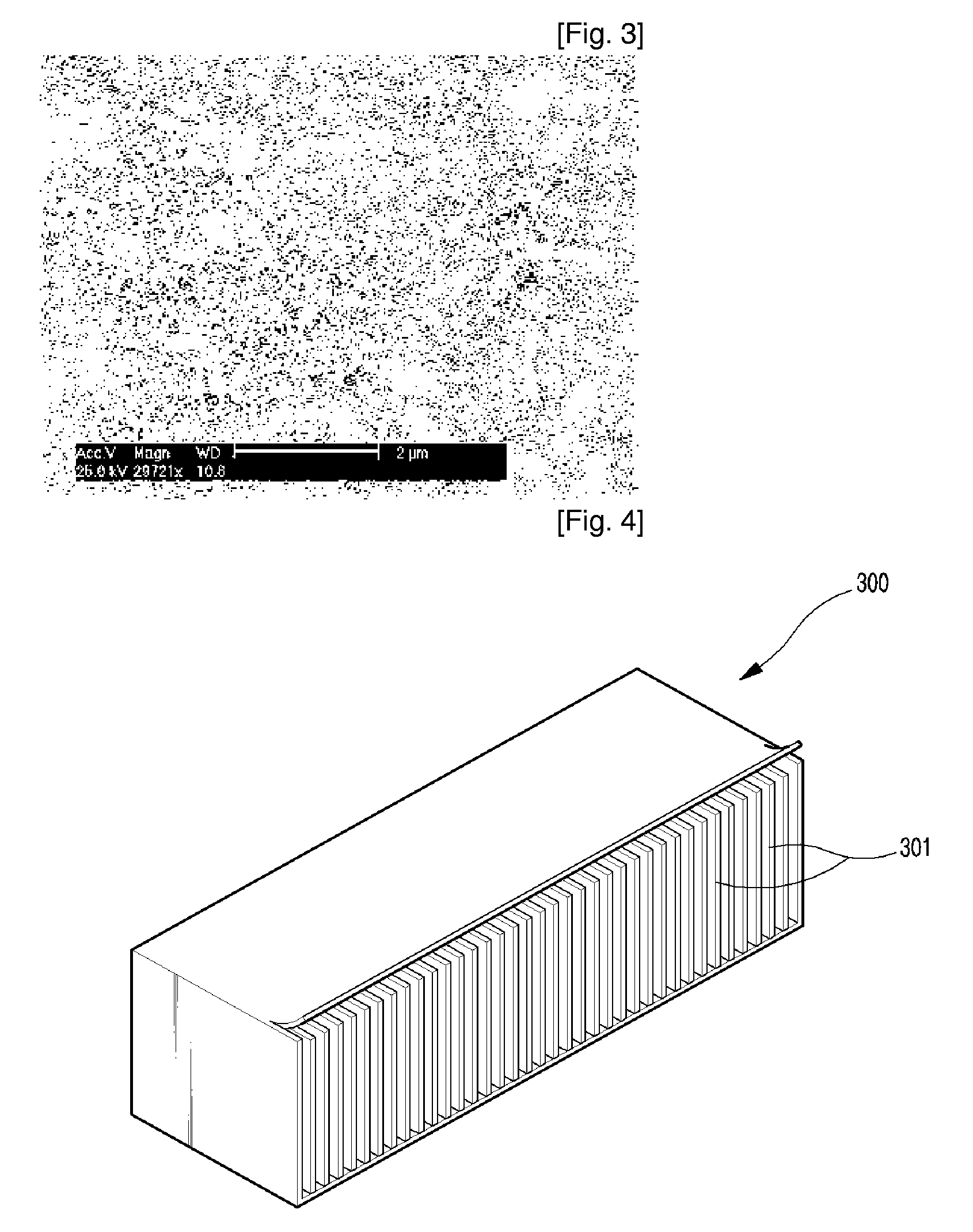

Cooling device coated with carbon nanotube and of manufacturing the same

InactiveUS20090059535A1Maximize heat exchange efficiencyEfficient heat generationMaterial nanotechnologyPretreated surfacesCarbon nanotubeOptoelectronics

Provided are a cooling device coated with carbon nanotubes and method of manufacturing the same. Carbon nanotubes are dispersively coated on a surface of the cooling device that radiates generated by a predetermined apparatus or component through thermal exchange. Thus, a carbon nanotube structure is formed so that the cooling device can improve in a thermal radiation characteristic and become small-sized. As a result, electronic devices can be downscaled and heat generated by a highly integrated electronic circuit chip can be effectively radiated, thus increasing lifetime and performance of an operating circuit.

Owner:KIM YONG HYUP +7

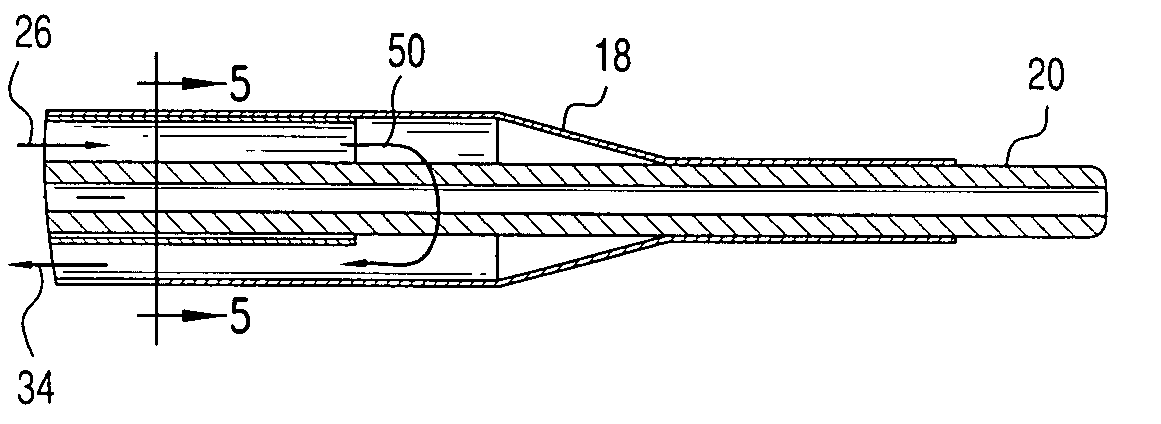

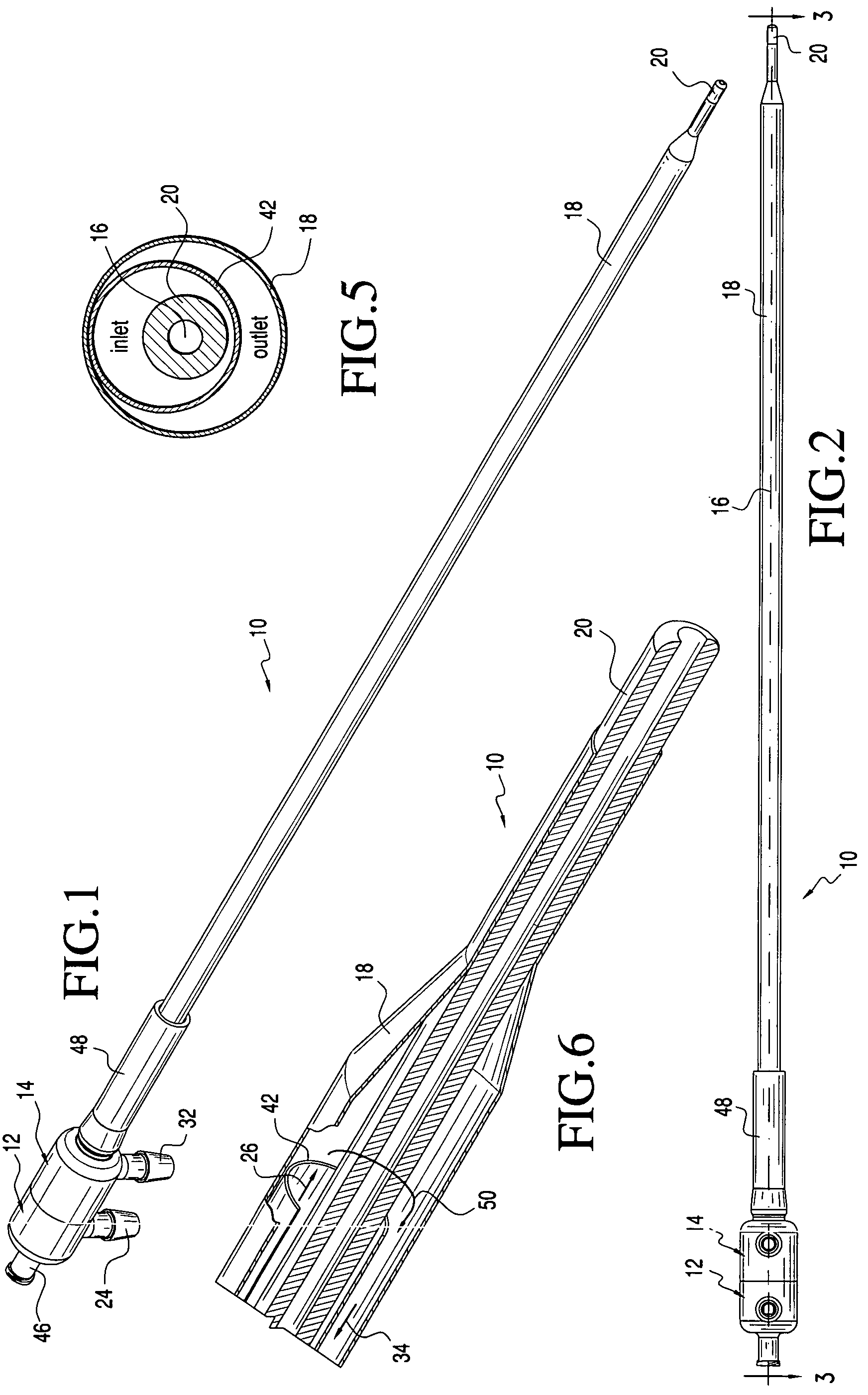

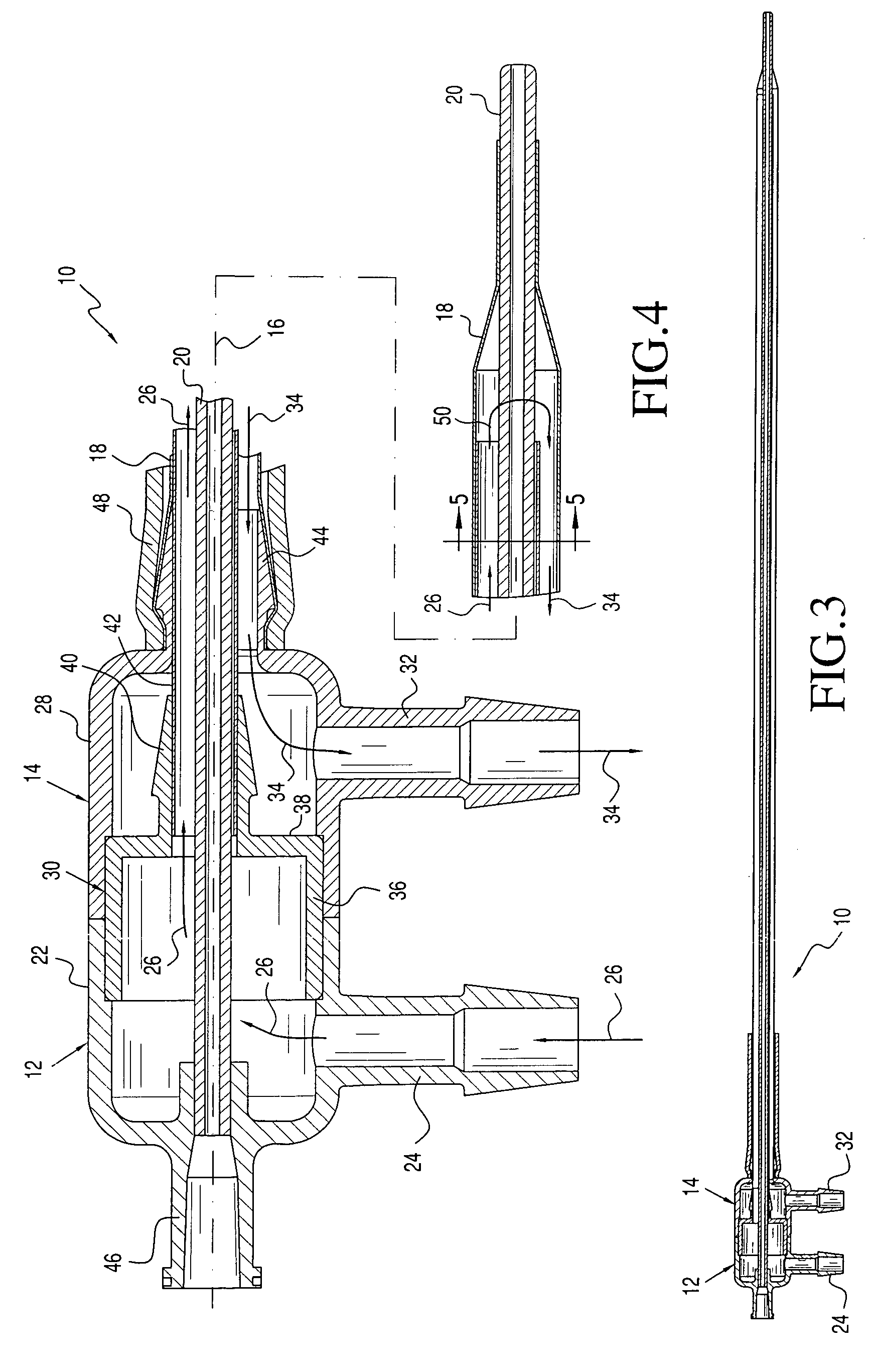

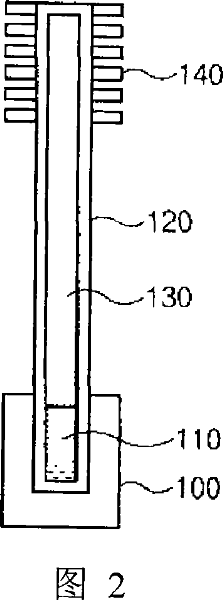

Heat exchange catheter and method of use

ActiveUS7621889B2Prevent urethral sloughingImproved hydrodynamic propertiesMedical devicesDilatorsEngineeringInlet flow

An inlet flow of heat exchange fluid flows from an inflow housing inlet section, and through an inflow housing main section. It then flows through an inlet fluid passageway formed between an inner balloon and a discharge tube. The flow continues around a distal end of the inner balloon, thus becoming an outlet flow of the heat exchange fluid which is directed through an outlet fluid passageway formed between the inner balloon and an outer balloon, then through an outflow housing main section and finally discharged through an outflow housing outlet section. The inner balloon is in a position offset from the central axis of the catheter. The offset relationship enhances the fluid dynamic properties of the catheter. It provides an increased turbulence, which, in turn, maximizes the heat exchange efficiency.

Owner:VARIAN MEDICAL SYSTEMS

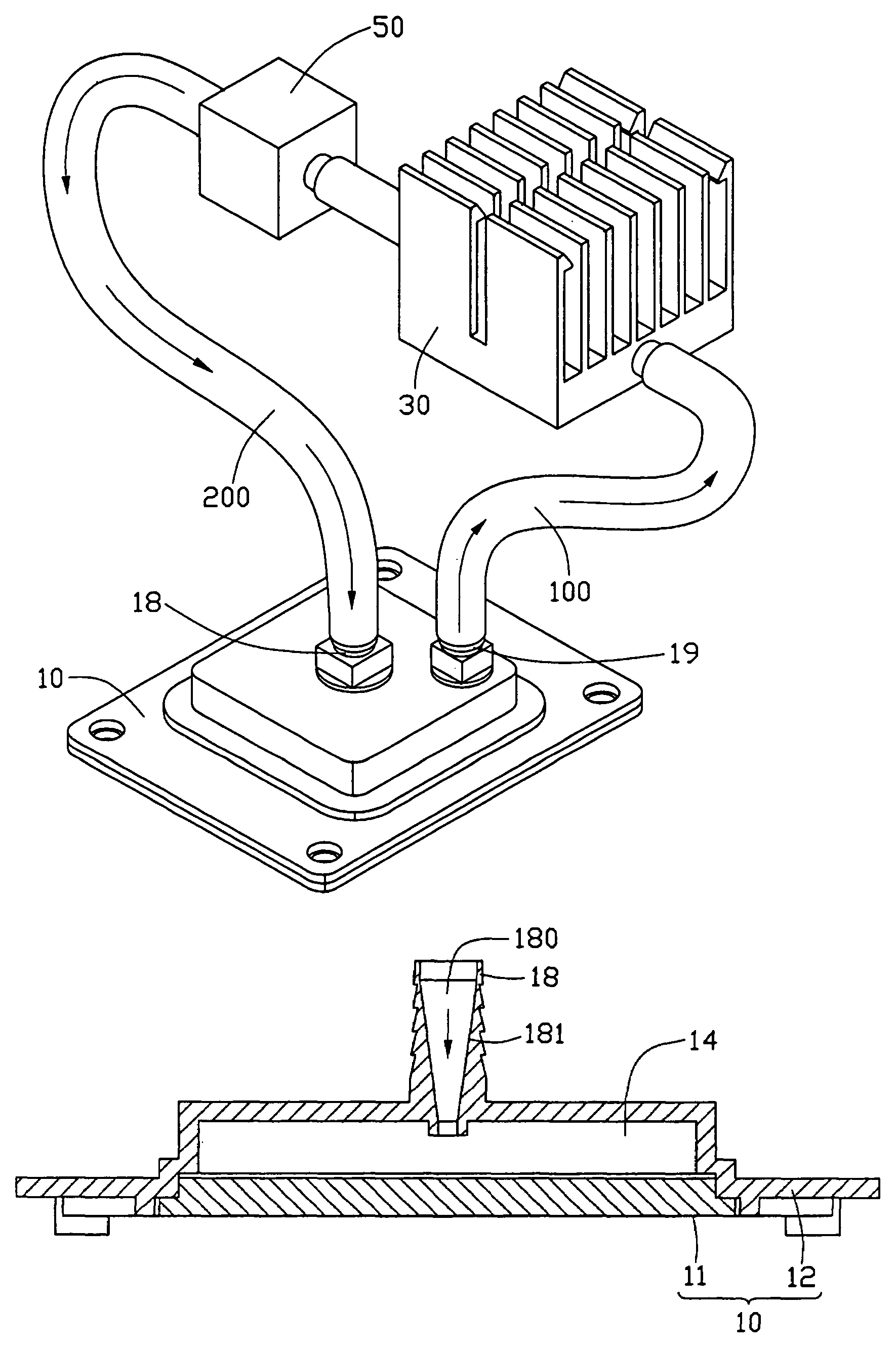

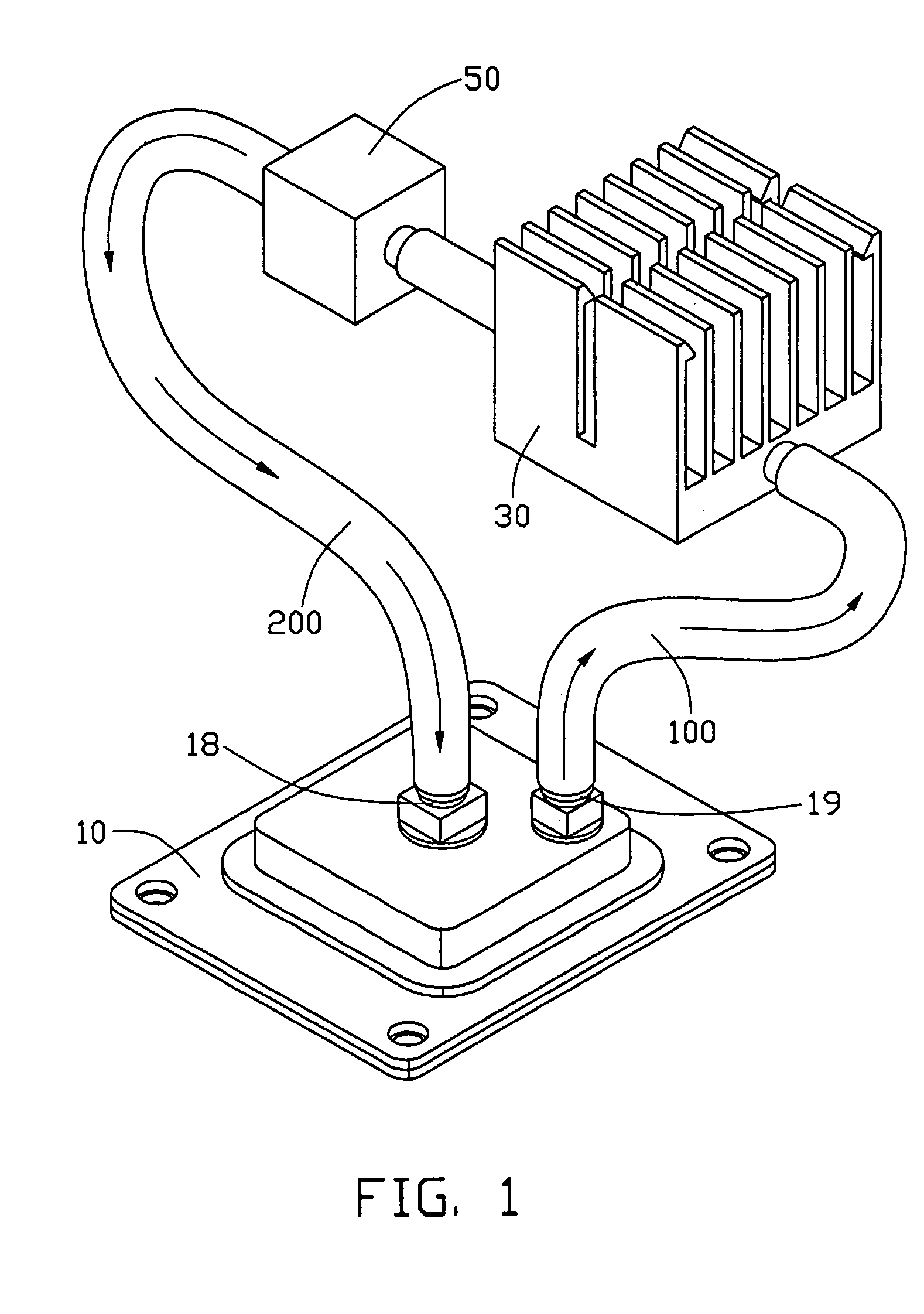

Liquid cooling device

InactiveUS7143815B2Maximize heat exchange efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringRADIUS

Owner:HON HAI PRECISION IND CO LTD

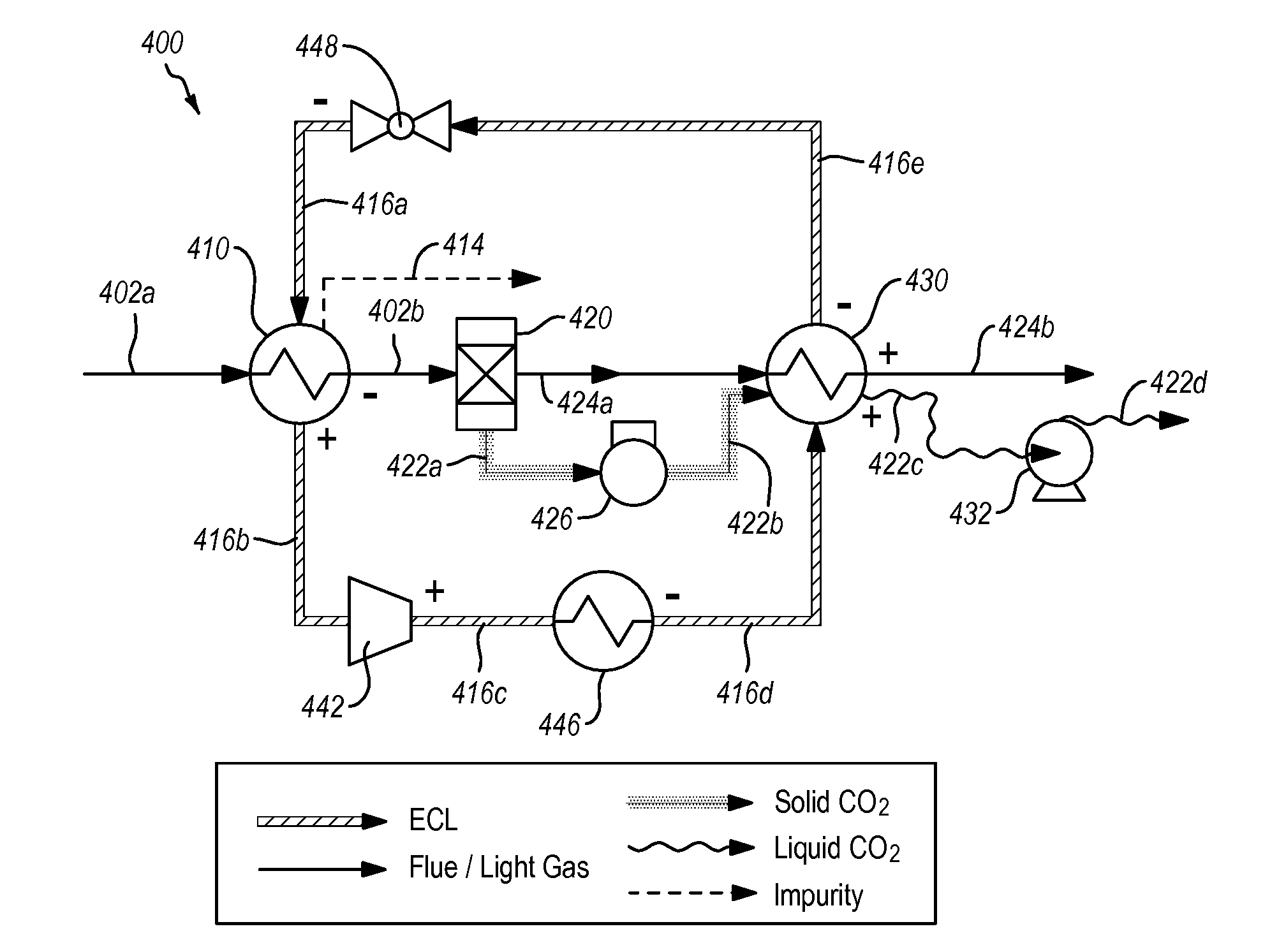

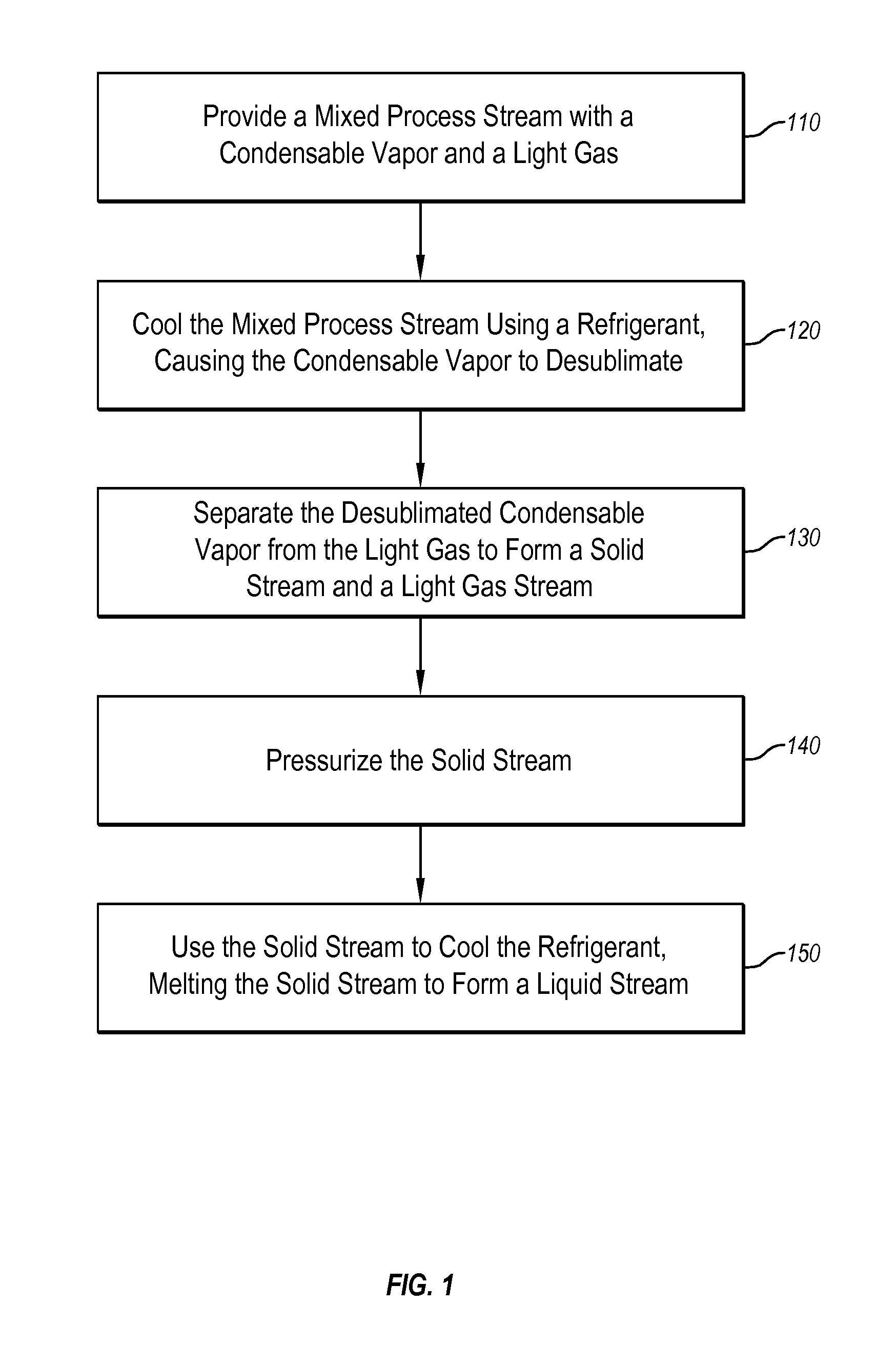

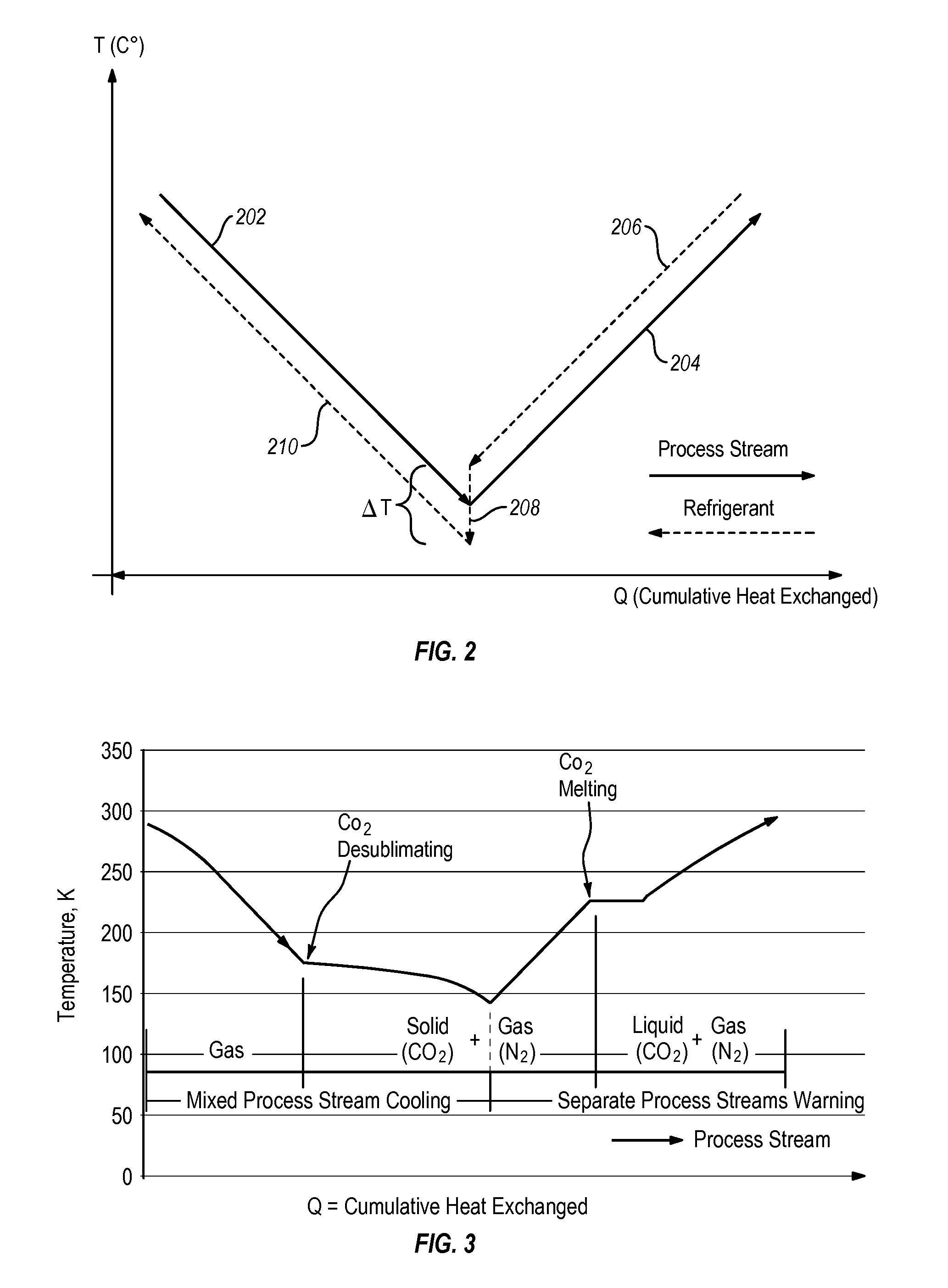

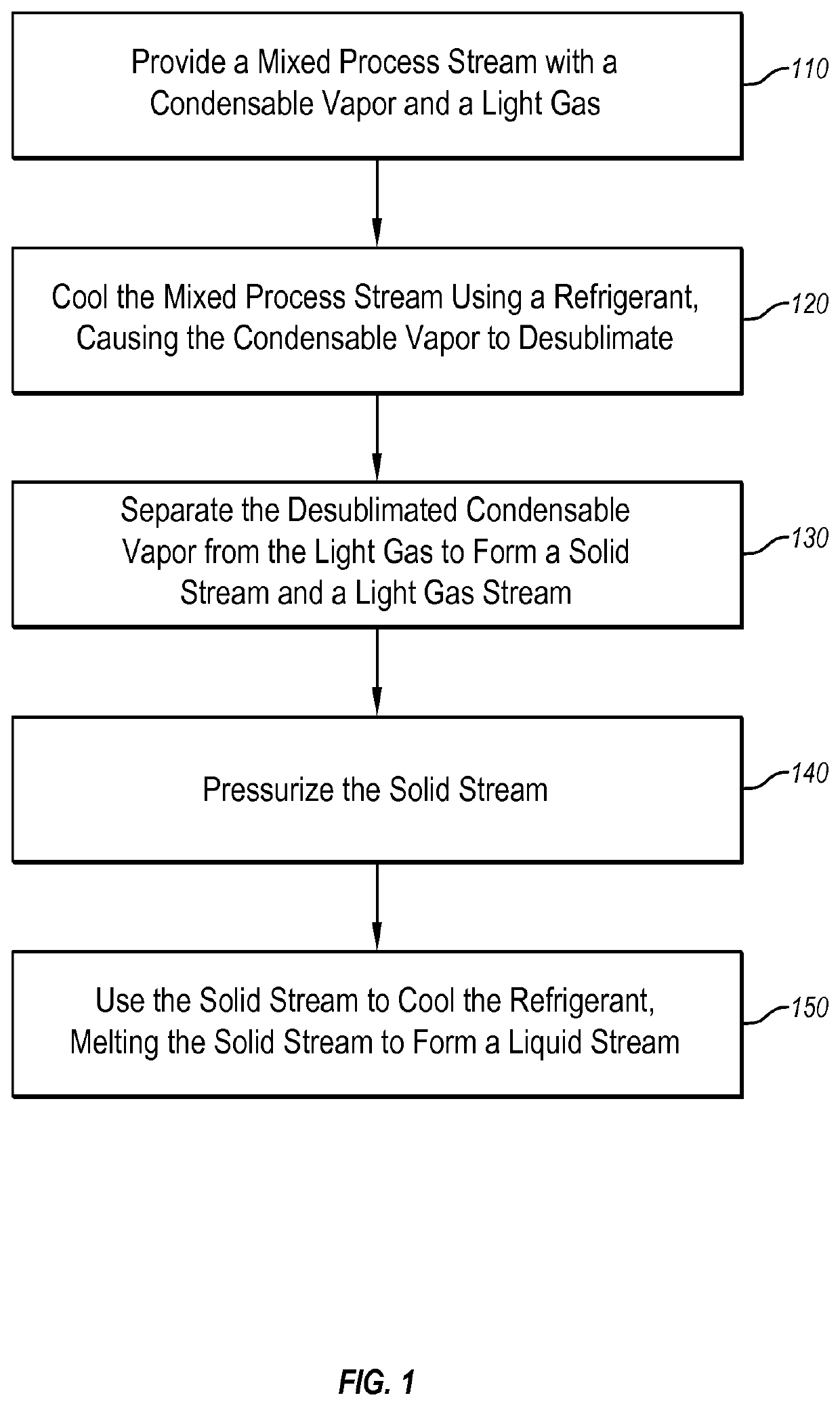

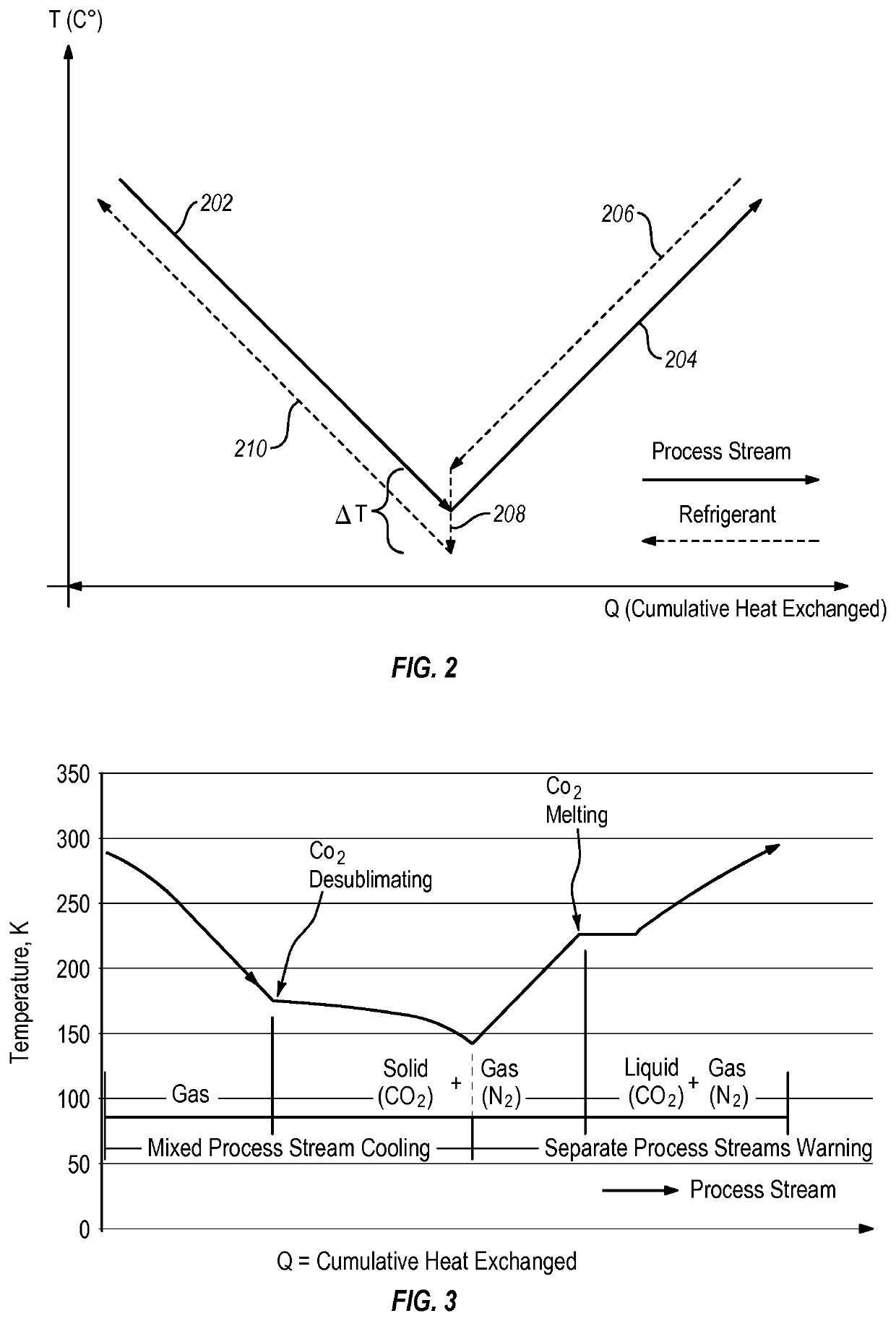

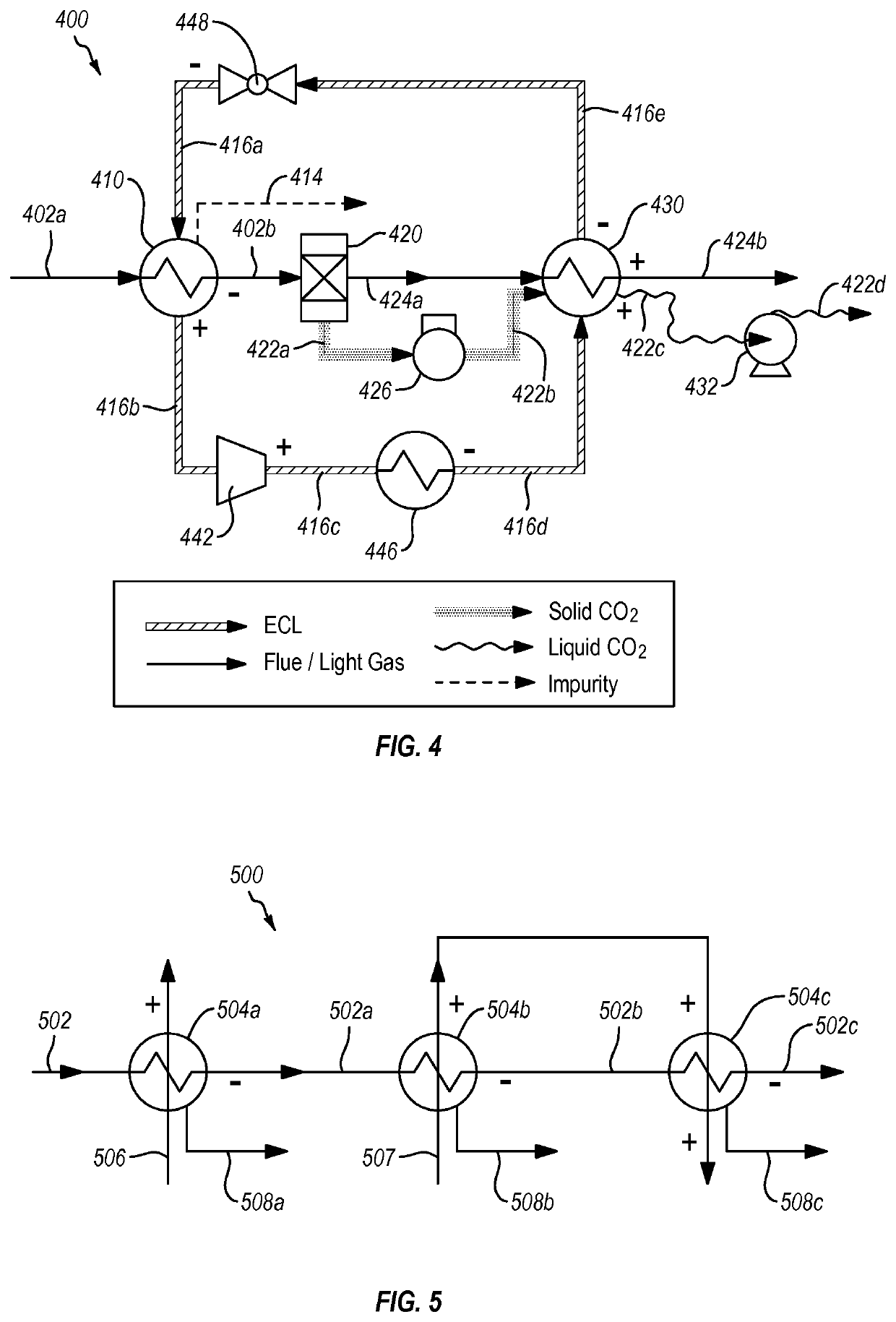

Systems and methods for separating condensable vapors from light gases or liquids by recruperative cryogenic processes

ActiveUS20120297821A1Effective recoveryEliminate the problemSolidificationLiquefactionCooling downRefrigerant

Methods and systems of the current invention separate condensable vapors such as carbon dioxide from light gases or liquids in a mixed process stream. The separation is carried out in a cryogenic process using one or more external cooling loops (ECLs) that first cool down a mixed process stream containing condensable vapors and light gases or liquids, causing the condensable vapors to desublimate and form solids. Next, the solids are separated from the light gases or liquids, forming a solid stream and a light gas or liquid stream. Then the refrigerants of the ECL are cooled by warming the separated solid stream and light gas or liquid stream, efficiently recovering energy used in cooling and desublimating the condensable vapors.

Owner:U S BANK TRUST CO NAT ASSOC

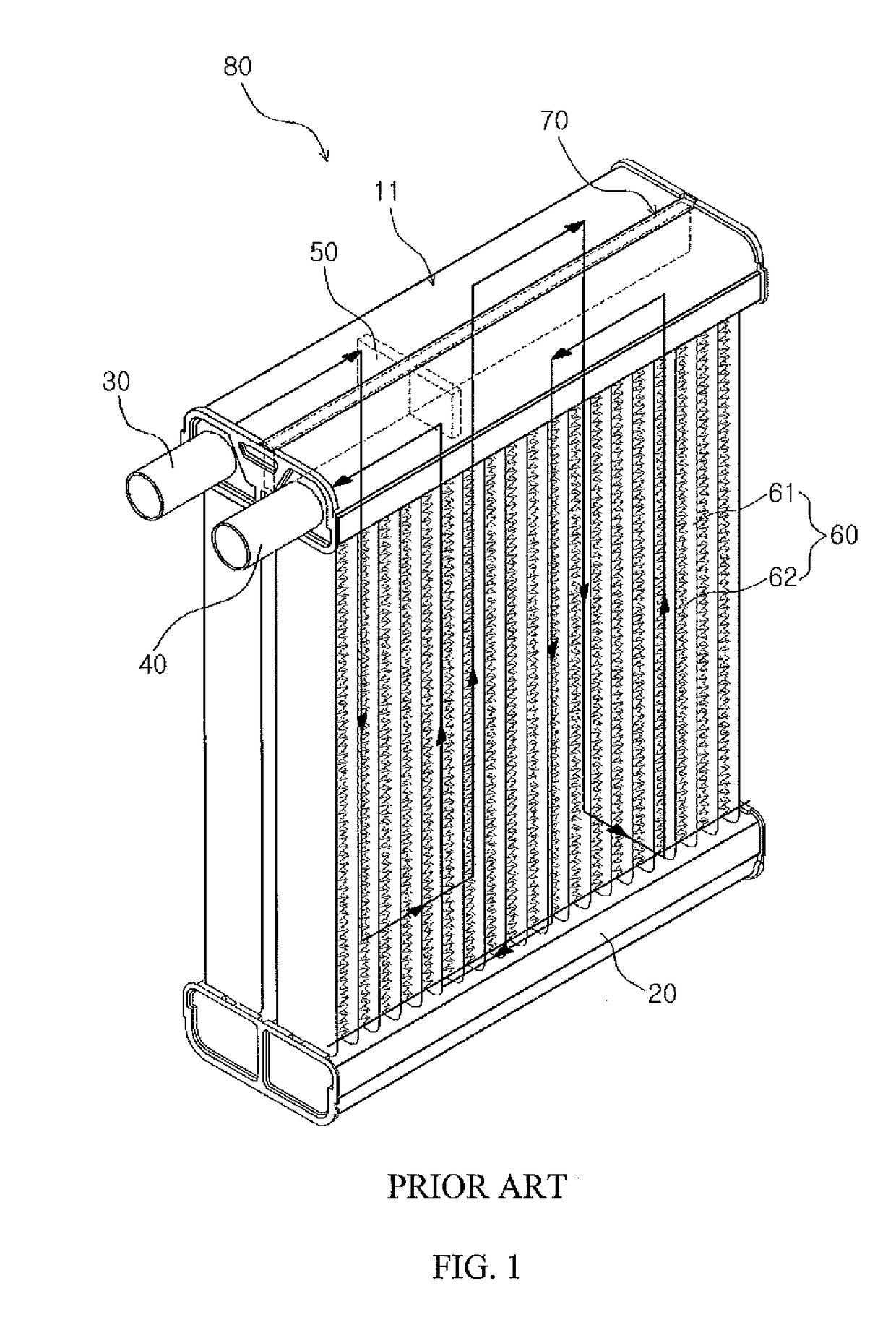

Evaporator

ActiveUS20100243223A1Maximizing heat radiation amountMaximum temperature deviationEvaporators/condensersVehicle heating/cooling devicesEngineeringRefrigerant

The present invention relates to an evaporator, and more particularly, to an evaporator which can restrict a surface area of a communication hole with respect to a cross sectional area of a compartment and a surface area of a tube with respect to a surface area of a fin, thereby providing a dimensional extent for maximizing the heat exchange efficiency. Therefore, by optimizing a relation between the surface area of the communication portion and the surface area of the compartment of the first header tank and dimensions for each surface area and the heights of the tube and fin, the present invention provides a dimensional extent for maximizing the heat radiation amount, reducing the maximum temperature deviation of the core portion and allowing the refrigerant and air to be smoothly flowed, thereby maximizing the heat exchange efficiency.

Owner:HANON SYST

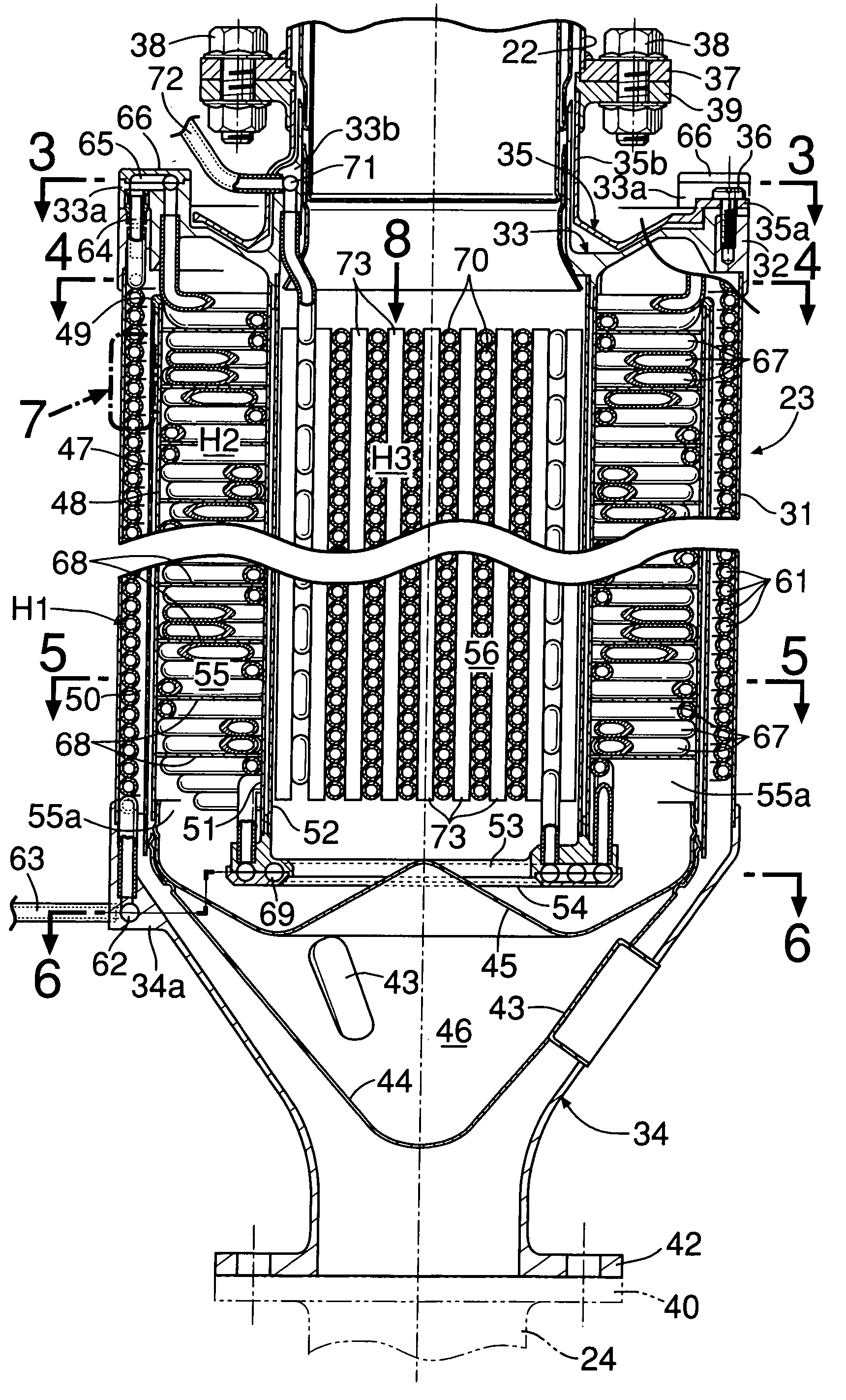

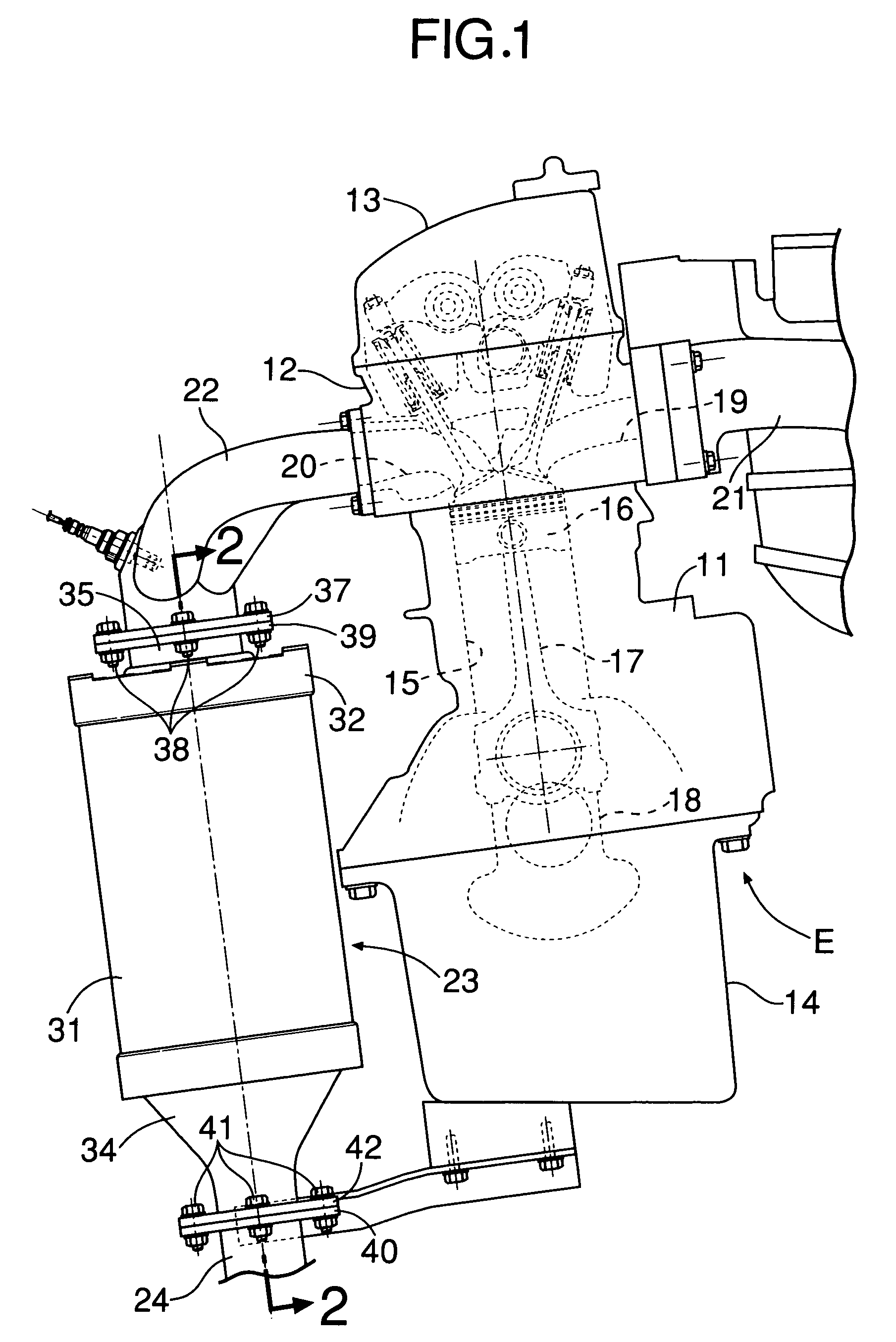

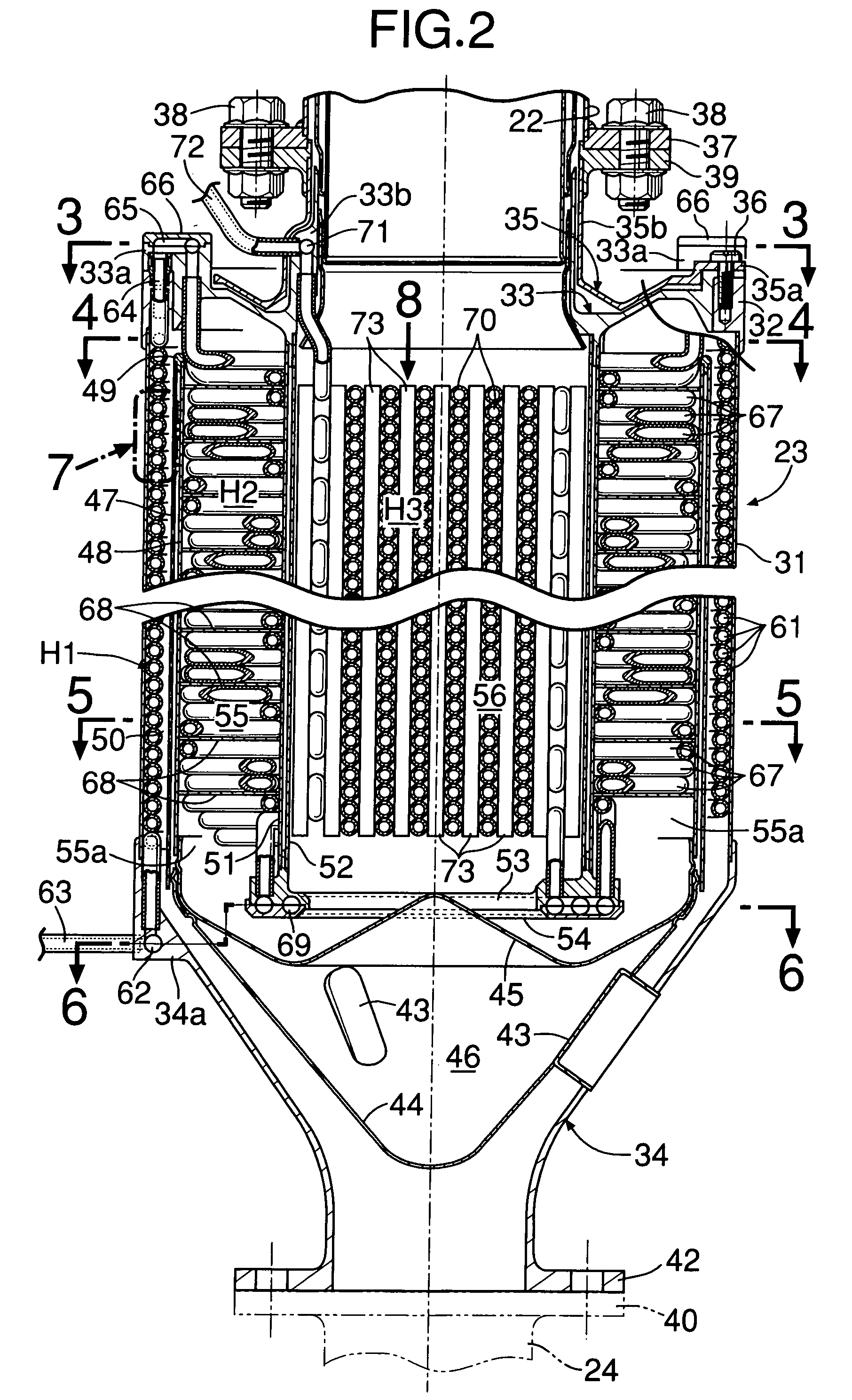

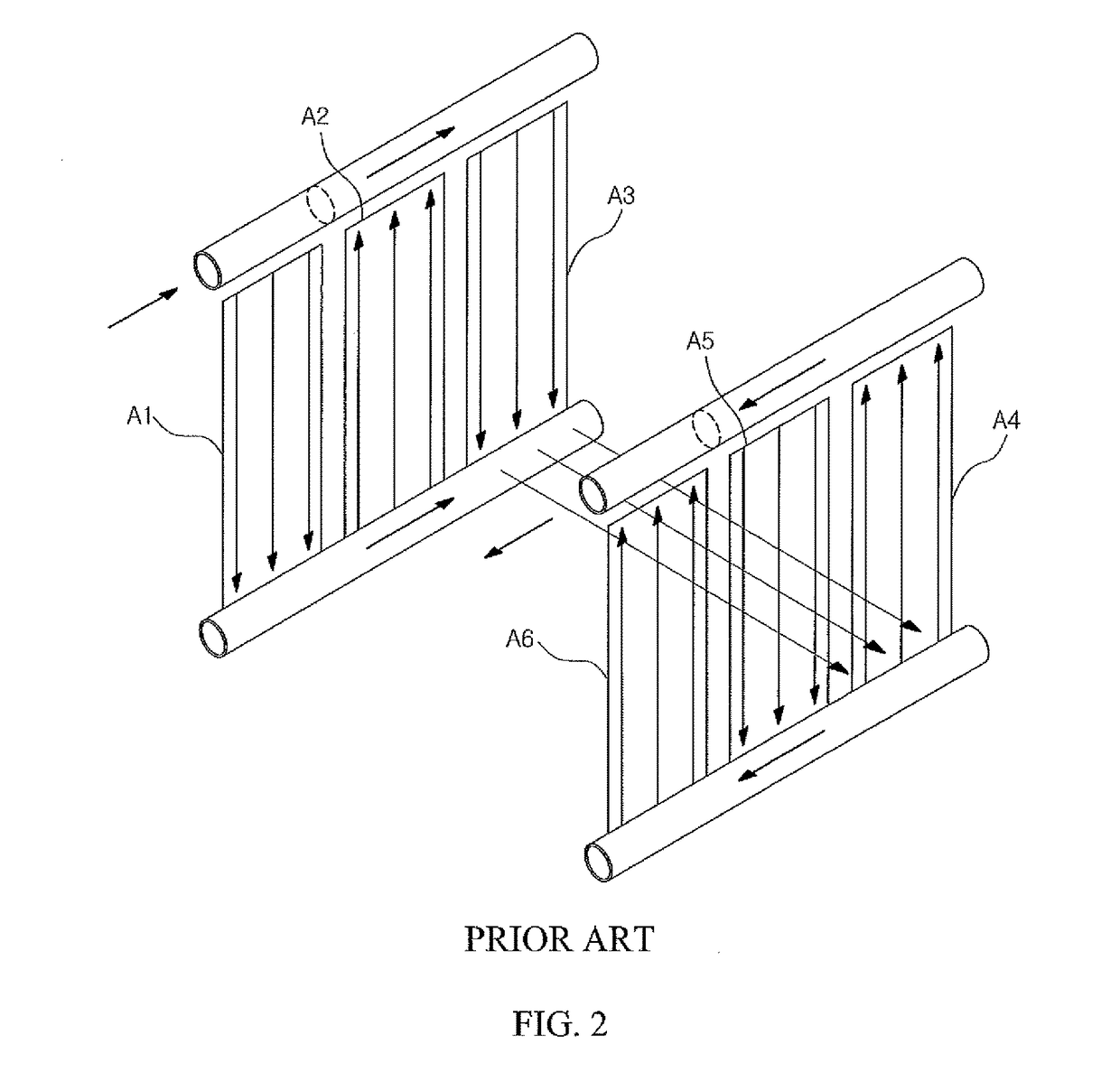

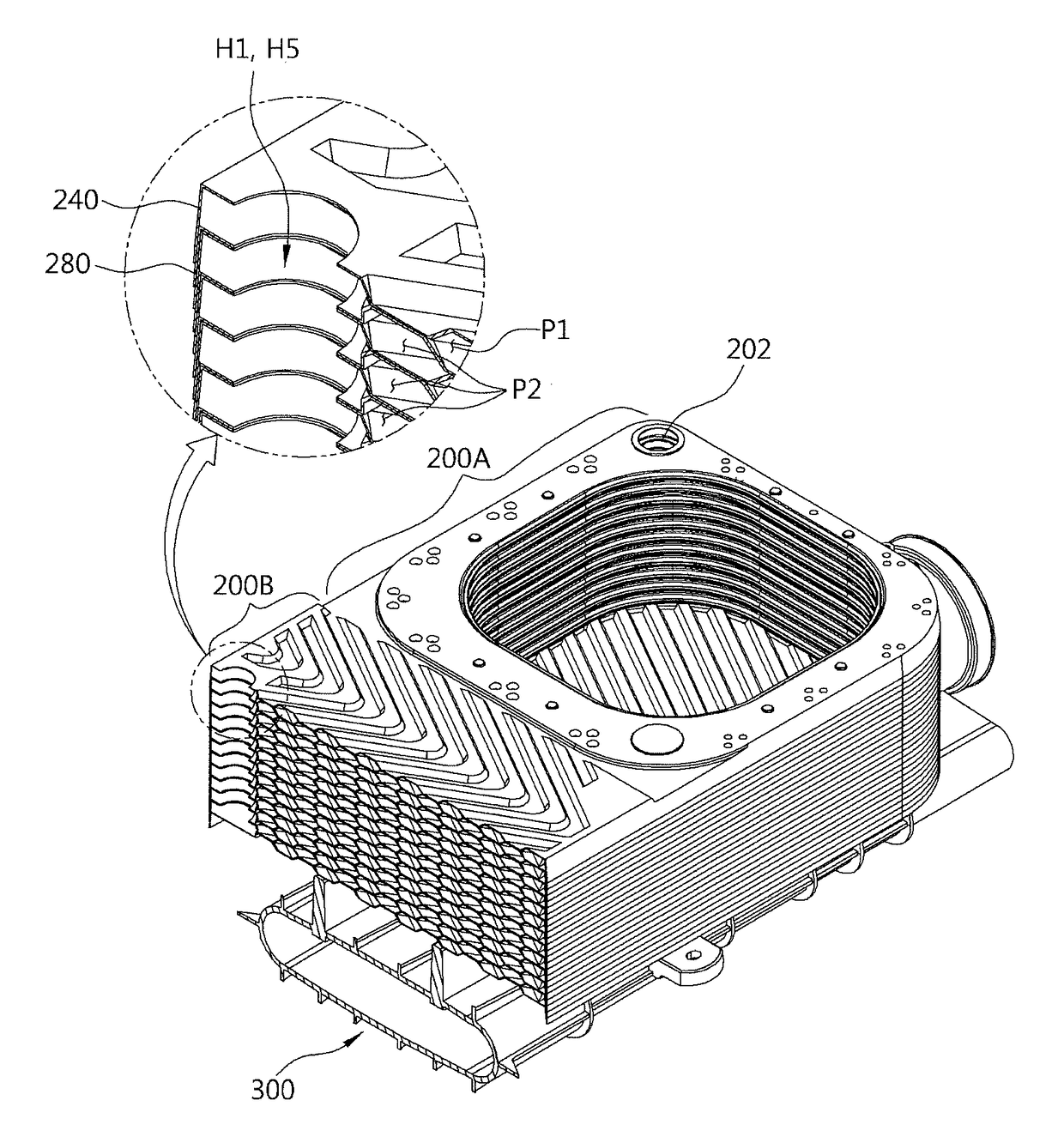

Heat exchanger

InactiveUS20050103484A1Maximize heat exchange efficiencyReduce weightInternal combustion piston enginesRecuperative heat exchangersEngineeringHeat transfer tube

There is provided an evaporator (23) disposed between an exhaust manifold (22) and an exhaust pipe (24), the evaporator (23) including, in sequence from the upstream side toward the downstream side, a first exhaust gas passage (56) having a third stage heat exchanger (H3), a second exhaust gas passage (55) having a second stage heat exchanger (H2), and a third exhaust gas passage (50) having a first stage heat exchanger (H1). Formed in the annular second exhaust gas passage (55) of the second stage heat exchanger (H2) is a spiral passage divided by a spiral heat transfer plate (68), and arranged in a spiral shape so as to follow the heat transfer plate (68) are a plurality of undulating heat transfer tubes (67) that are stacked out of phase. Increasing the exhaust gas passage length by the heat transfer plate (68) and agitating the flow of exhaust gas by the heat transfer tubes (67) enables the opportunity for contact of the exhaust gas with the heat transfer plate (68) and the heat transfer tubes (67) to be increased, thereby enhancing the heat exchange efficiency.

Owner:HONDA MOTOR CO LTD

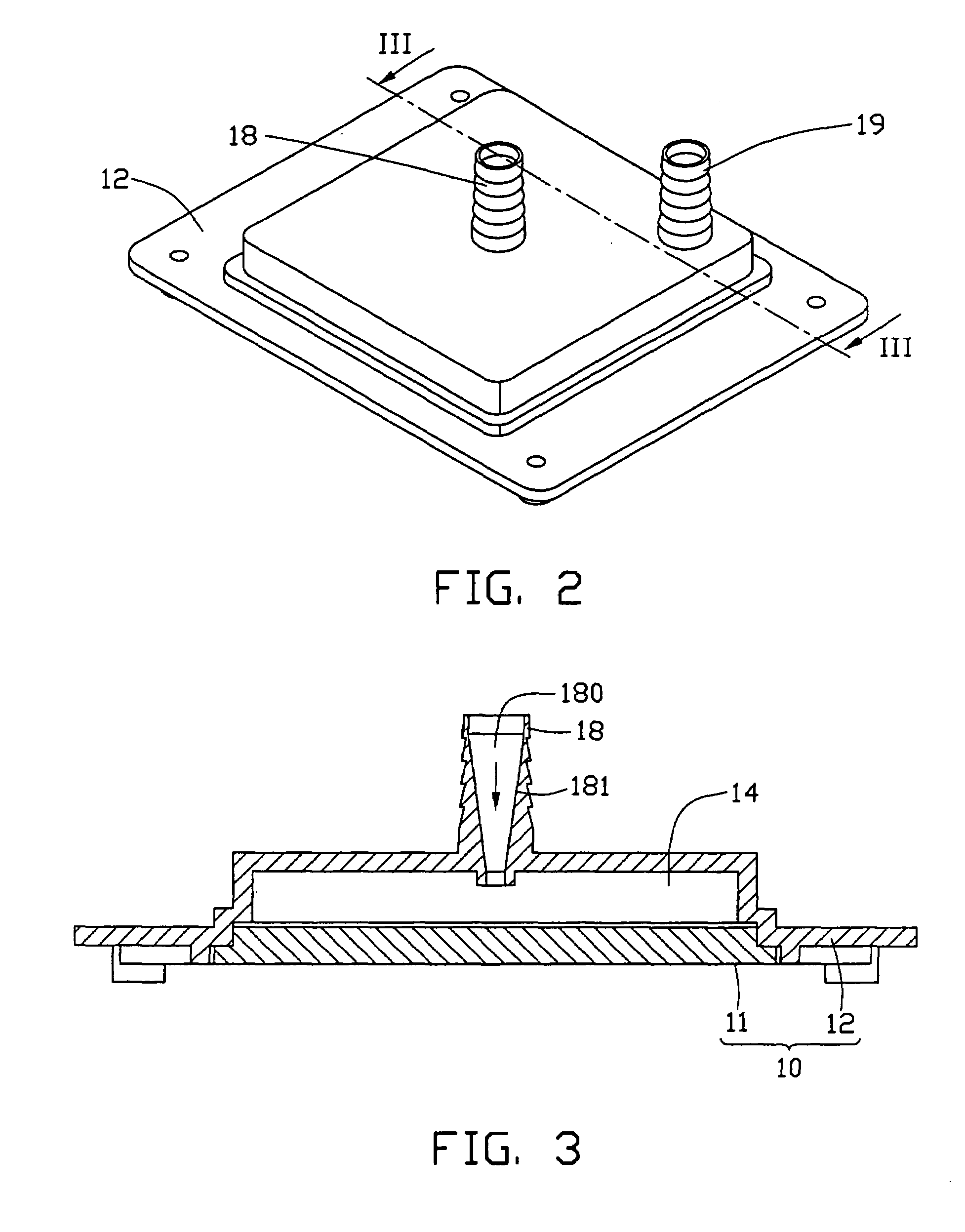

Liquid cooling device

InactiveUS20050241804A1Maximize heat exchange efficiencySemiconductor/solid-state device detailsSolid-state devicesRADIUSEngineering

Owner:HON HAI PRECISION IND CO LTD

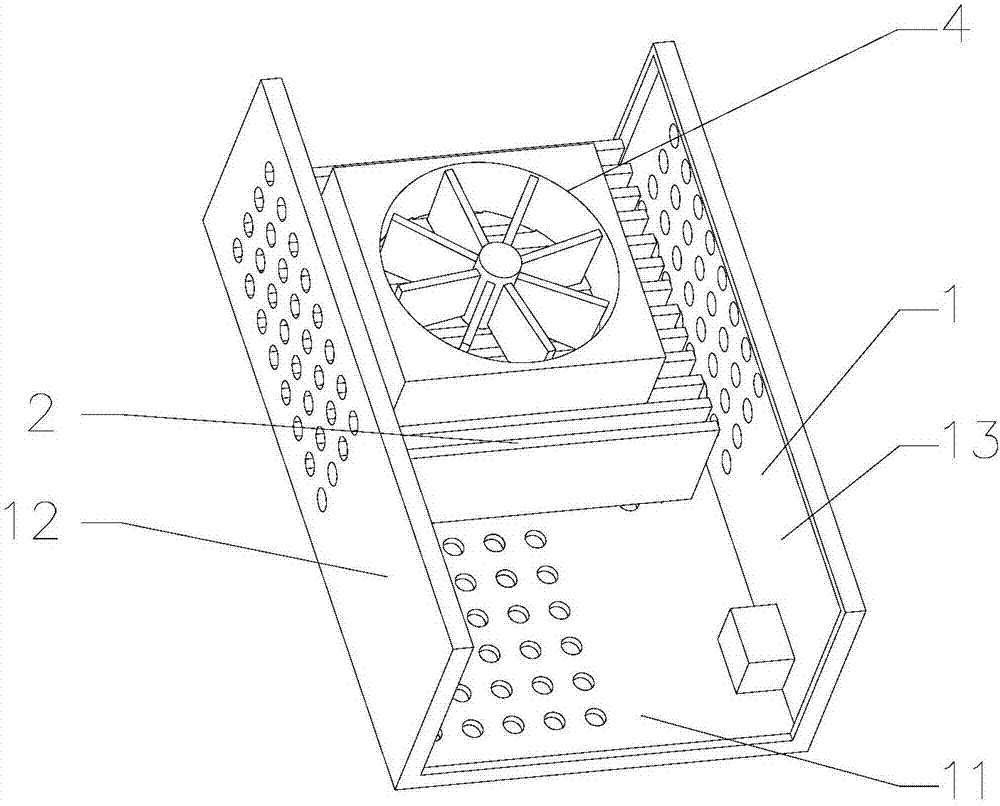

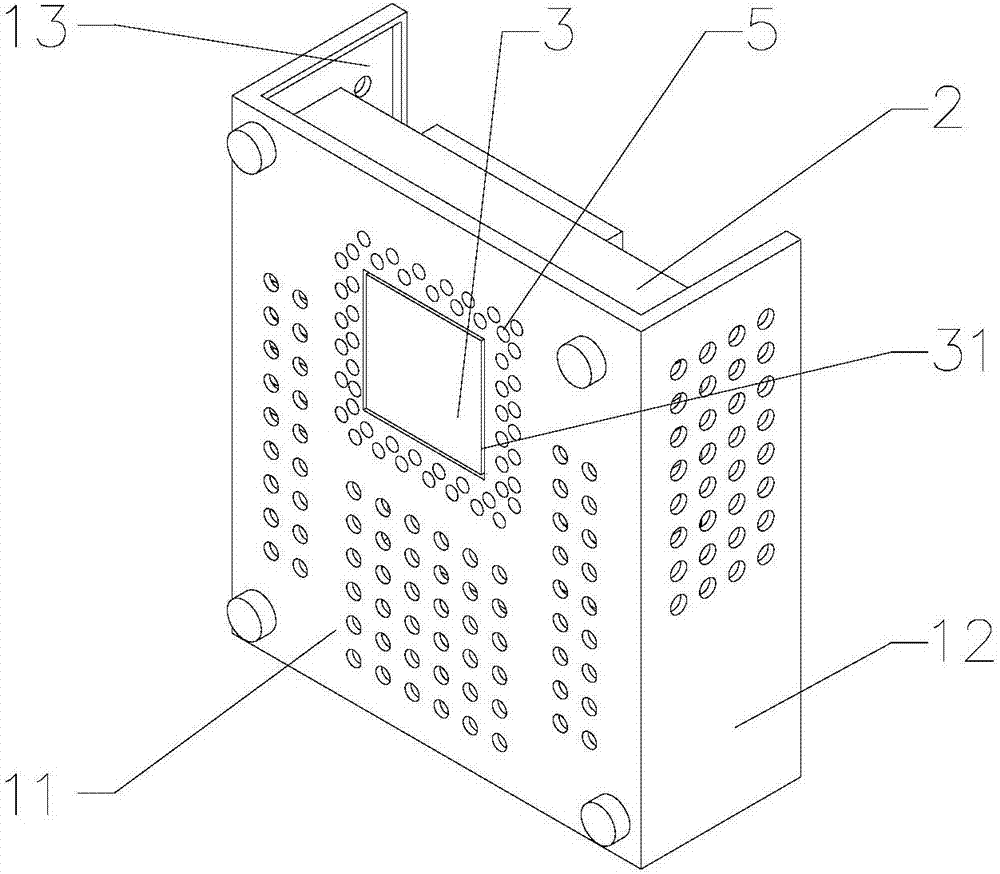

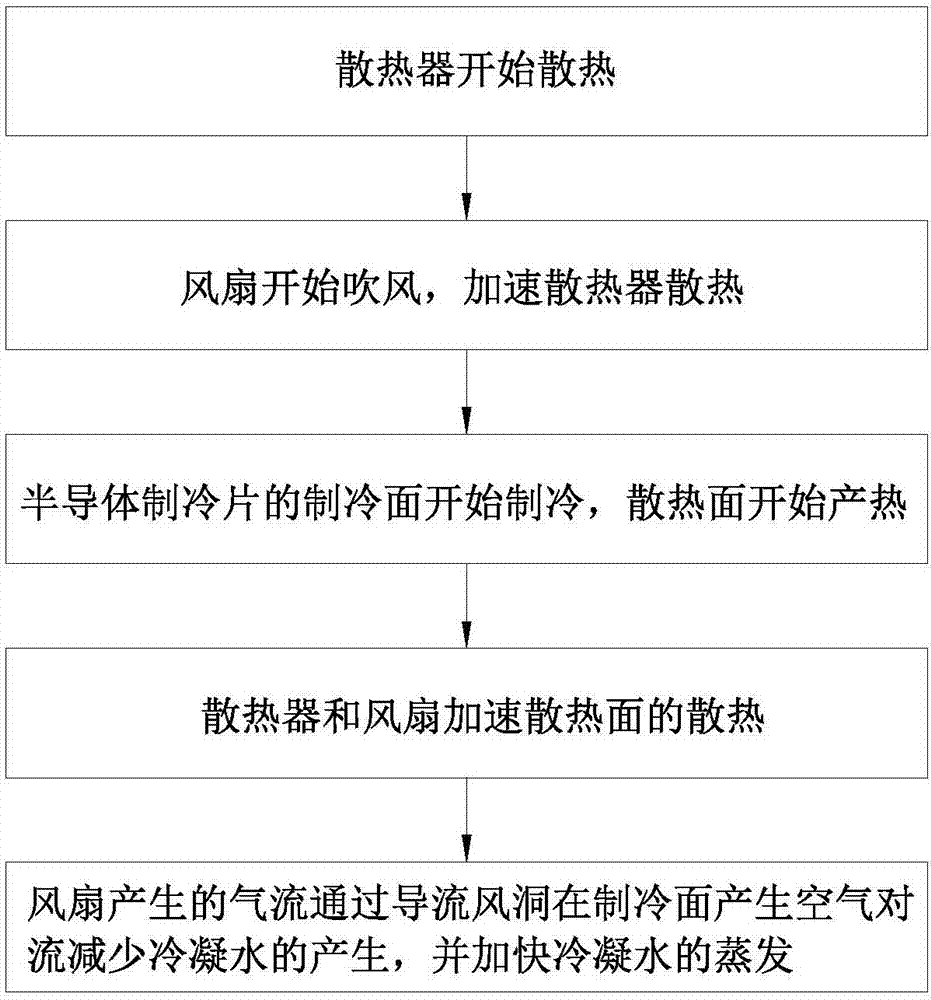

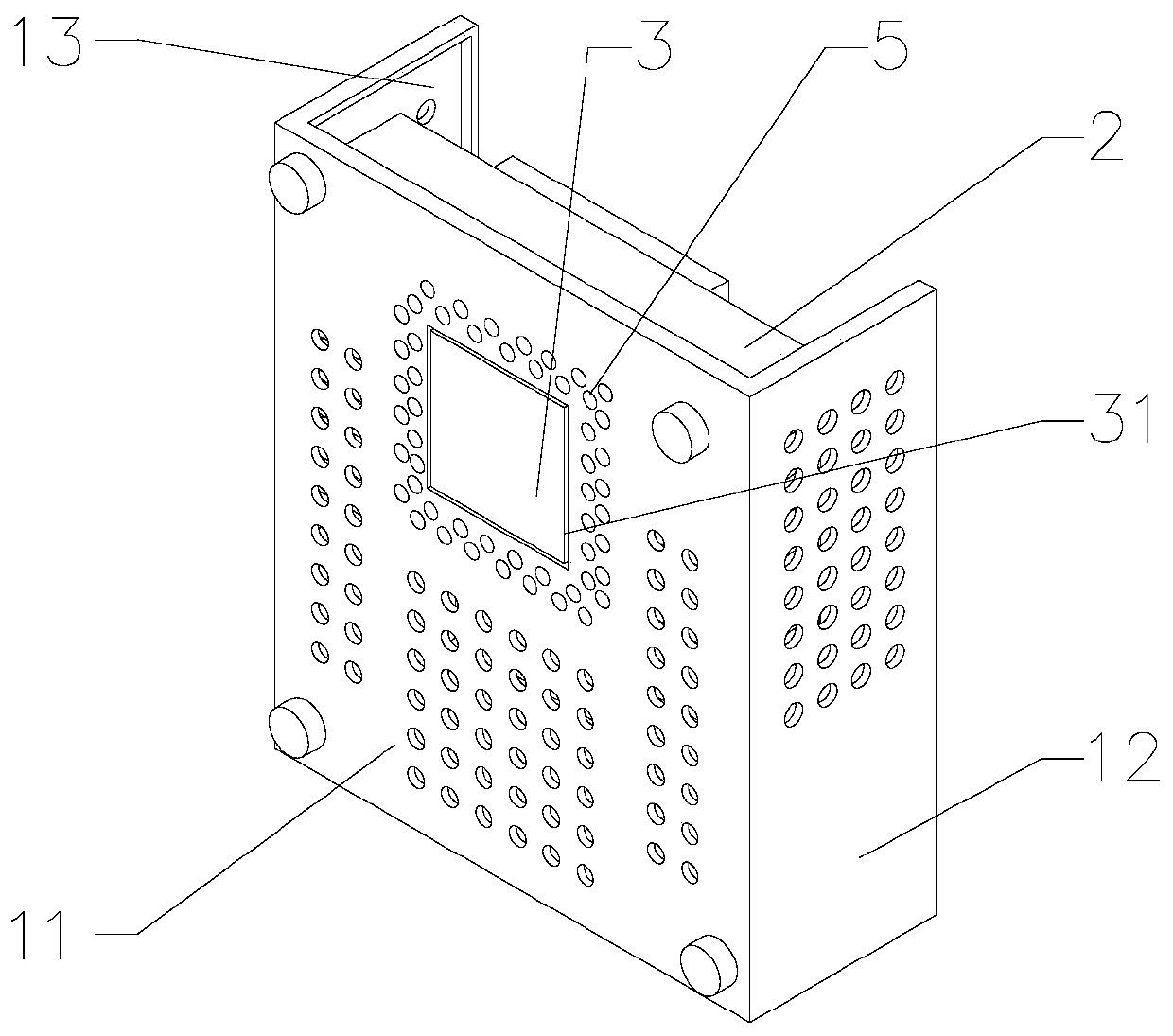

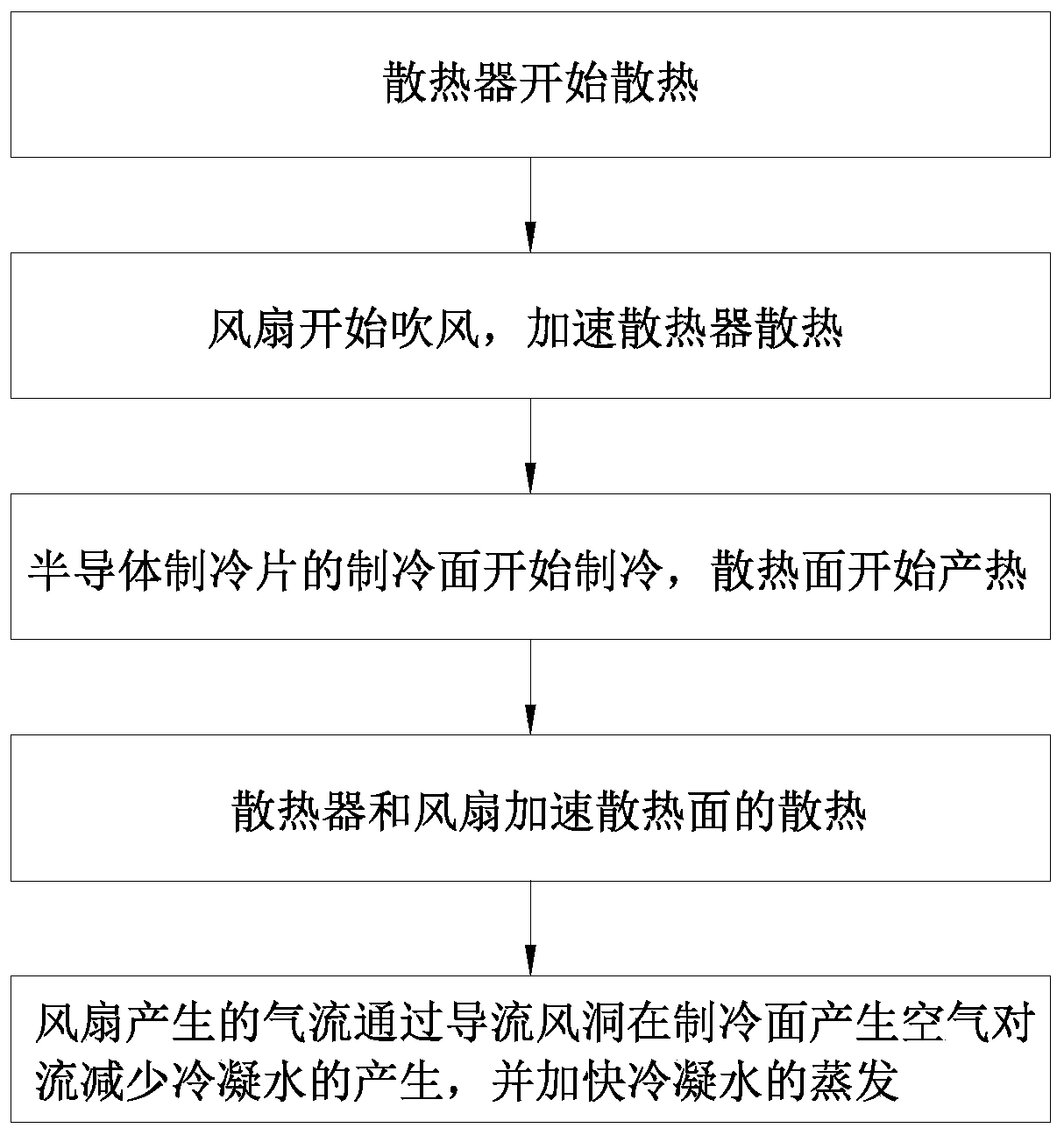

Heat radiating method of radiator for communication equipment

ActiveCN107517570AReliable coolingAchieve coolingThermometer detailsTemperature control using digital meansEvaporationEngineering

The invention provides a heat radiating method of a radiator for communication equipment. The heat radiating method at least includes an initial heat radiation step, a refrigerating step and a condensate water treatment step. In the initial radiation step, the radiator starts working and radiates heat transmitted by the communication equipment, a fan starts working and provides sufficient air flows to the radiator to form air convection around the radiator, and heat radiation of the radiator is accelerated. In the refrigerating step, a semi-conductor refrigerating piece works to reduce the temperature around the refrigerating surface thereof. In the condensate water treatment step, air-convection heat radiation of the refrigerating surface of the semi-conductor refrigerating piece is achieved by the air flows generated by the fan through flow guide wind tunnels so as to reduce condensate water generated by working of the semi-conductor refrigerating piece and accelerate evaporation of the condensate water. Through the initial heat radiation step, the refrigerating step and the condensate water treatment step, heat radiation efficiency of the radiator is improved, and the communication equipment is prevented from being influenced by the condensate water.

Owner:STATE GRID ZHEJIANG HANGZHOU YUHANG POWER SUPPLY +2

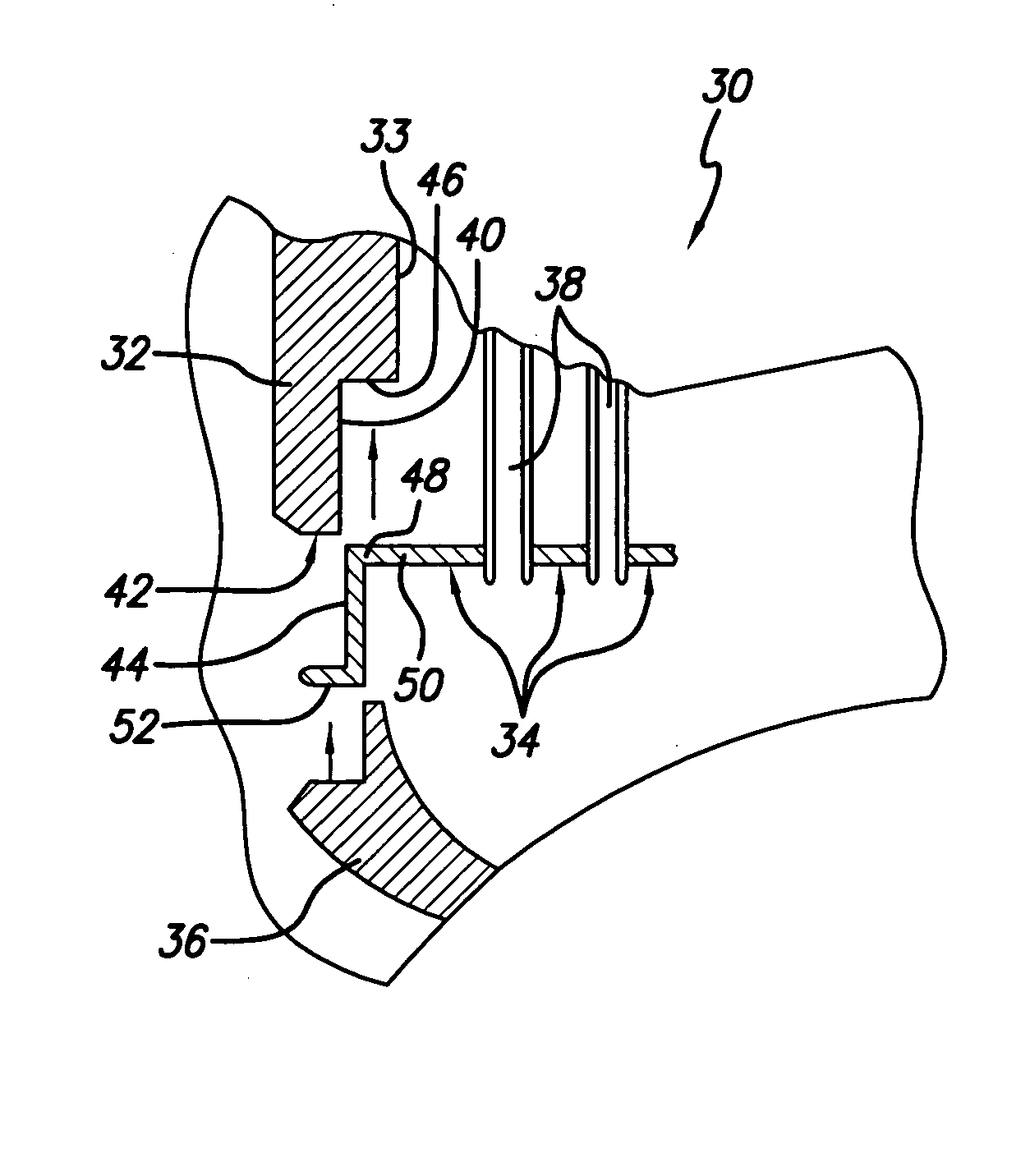

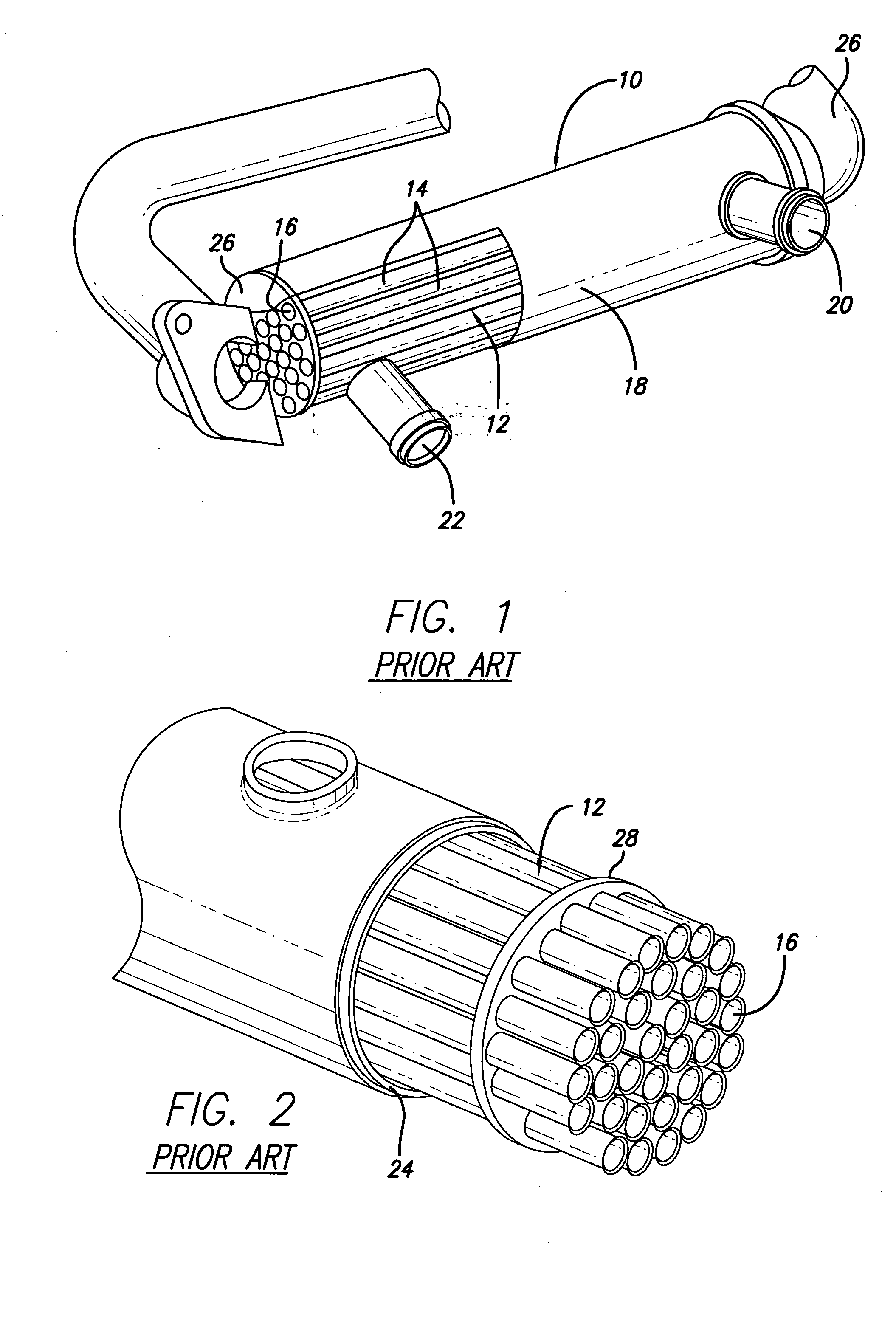

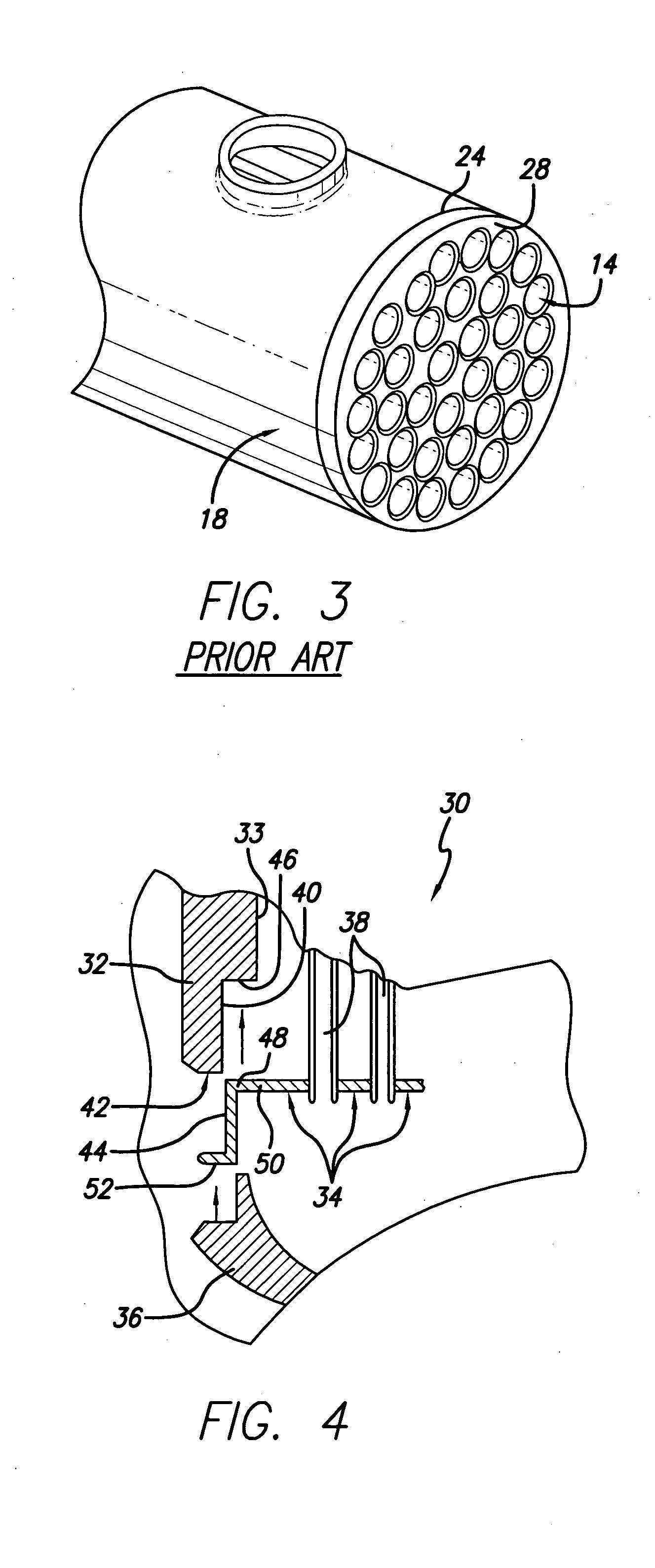

Nested attachment junction for heat exchanger

InactiveUS20050126768A1Minimize and eliminate possibility of leakageMaximize heat exchange efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringMechanical engineering

Heat exchangers of this invention include a shell having an inner chamber defined by an inside wall surface, and having at least one opening adjacent an end of the shell. A tube bundle comprising a plurality of assembled together tubes are disposed within the inner chamber. A header plate is attached to the tubes and is positioned adjacent an end of the tube bundle. The header plate includes an outside diameter that fits within the shell inside wall surface to provide a nested attachment junction therebetween. The header plate and shell are fixedly connected to one another by use of a braze joint formed by the placement of brazing material between the interfacing header plate and the shell surface sections. A tank is attached to the shell adjacent the shell end.

Owner:HONEYWELL INT INC

Cooling device with carbon nanaotube coating and method of forming the same

InactiveCN101044809AMaximize heat exchange efficiencyImprove overall lifespanMaterial nanotechnologyCarbon nanotubesCarbon nanotubeOptoelectronics

Provided are a cooling device coated with carbon nanotubes and method of manufacturing the same. Carbon nanotubes are dispersively coated on a surface of the cooling device that radiates generated by a predetermined apparatus or component through thermal exchange. Thus, a carbon nanotube structure is formed so that the cooling device can improve in a thermal radiation characteristic and become small-sized. As a result, electronic devices can be downscaled and heat generated by a highly integrated electronic circuit chip can be effectively radiated, thus increasing lifetime and performance of an operating circuit.

Owner:SEOUL NAT UNIV R&DB FOUND

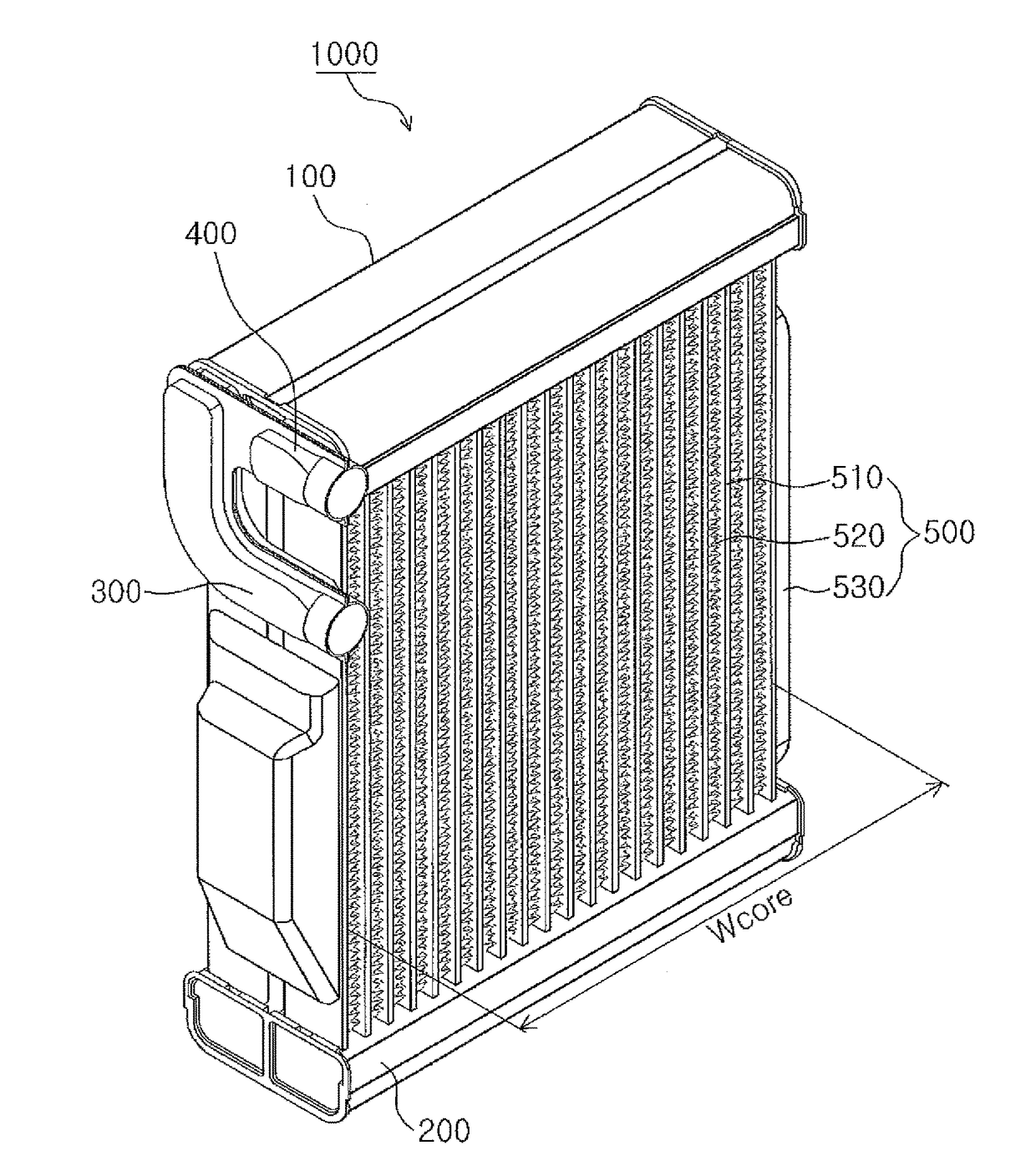

Evaporator

ActiveUS20170158027A1Reduce temperature changesMaximize heat exchange efficiencyAir-treating devicesEvaporators/condensersEngineeringRefrigerant

The present invention relates to an evaporator (1000) and, more specifically, to an evaporator (1000), in which refrigerant is uniformly distributed to each area through 8-pass flow from a first area (A1) to an eighth area (A8) so as to reduce temperature variation and maximize the heat exchange efficiency with respect to outdoor air, and air is discharged to the left and right sides in a vehicle room with uniform temperature distribution so as to maintain the comfort of passengers.

Owner:HANON SYST

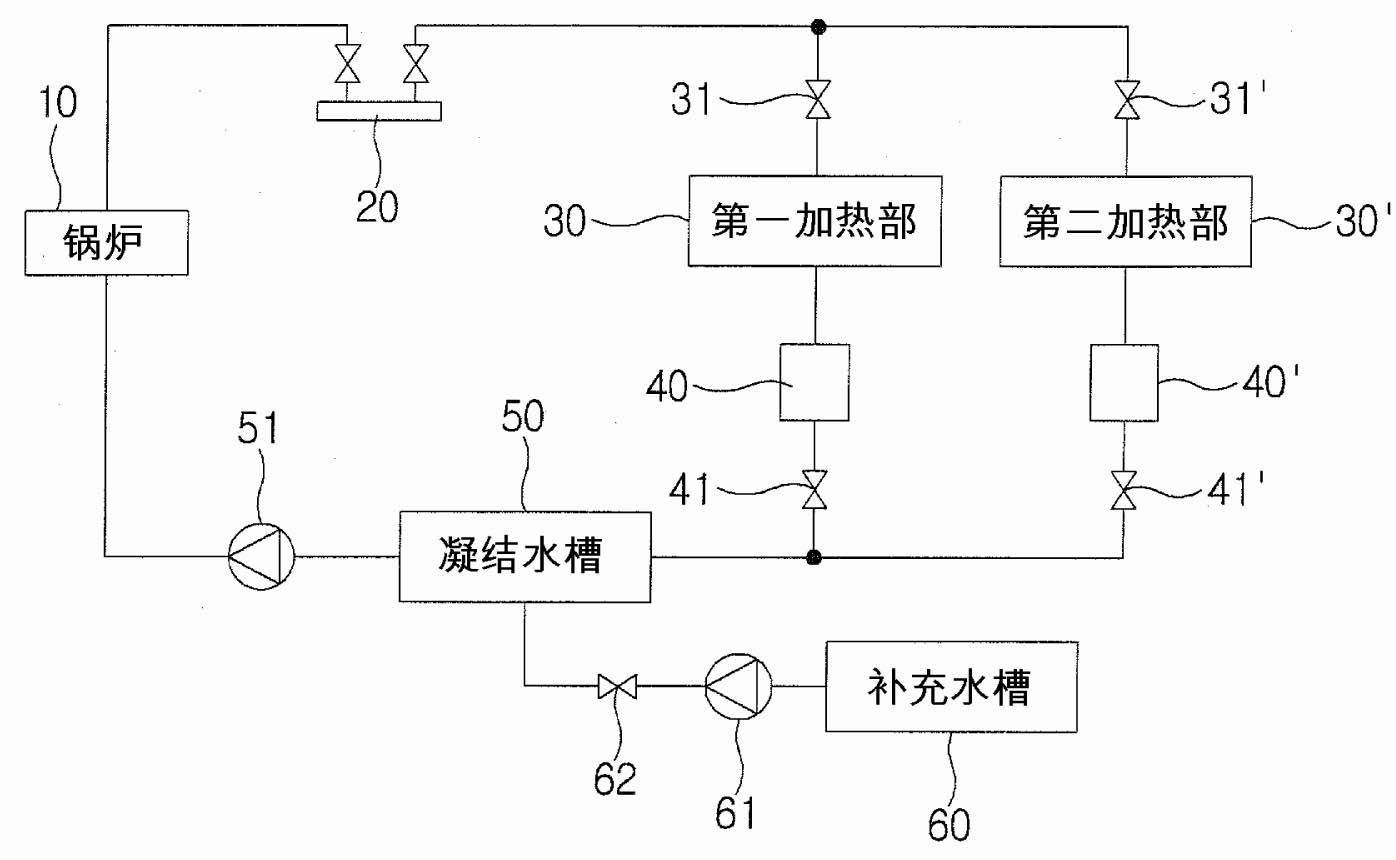

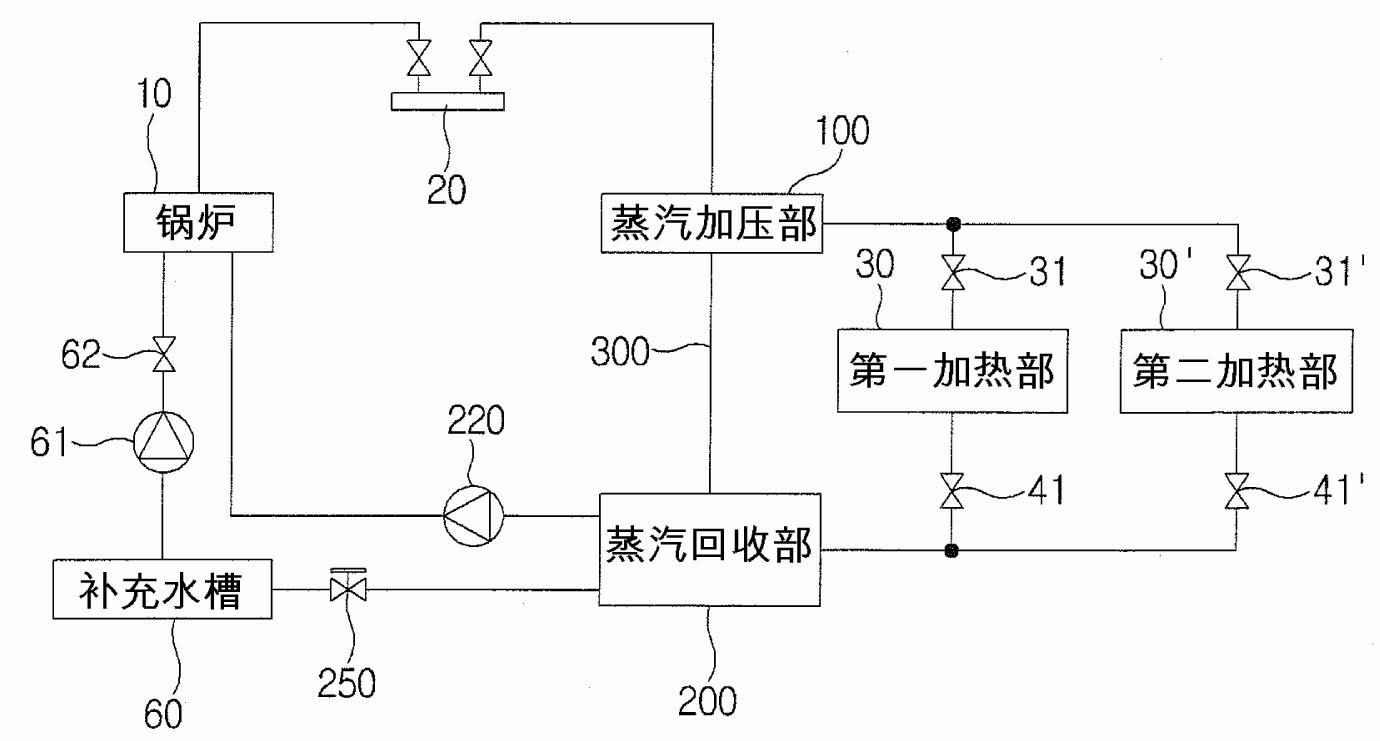

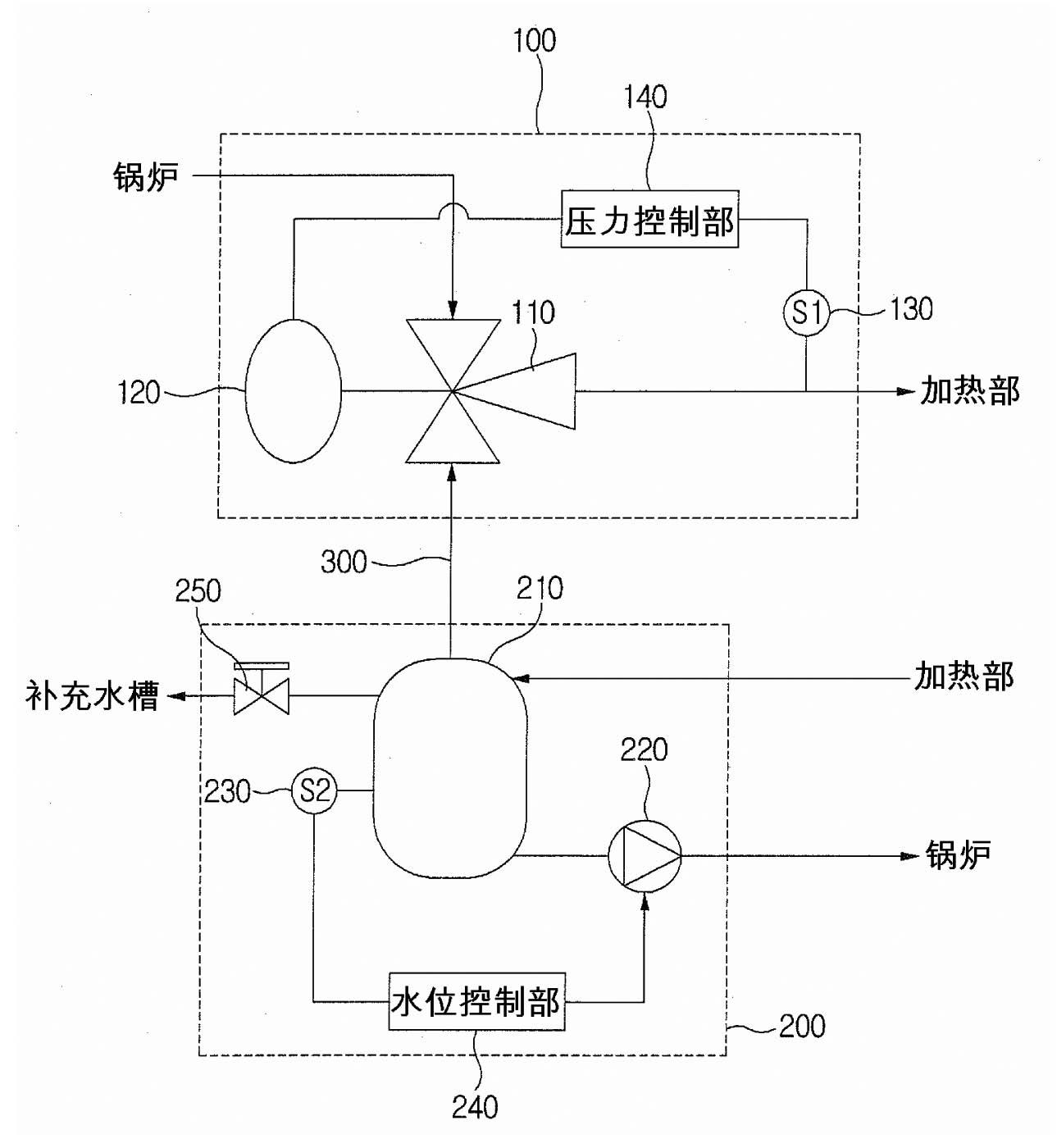

Apparatus for recovering vent steam and drain

ActiveCN102149985AImprove efficiencyReduce usageWater heatersSteam engine plantsAtmospheric airEngineering

Owner:YEONGIL PUMPTECH

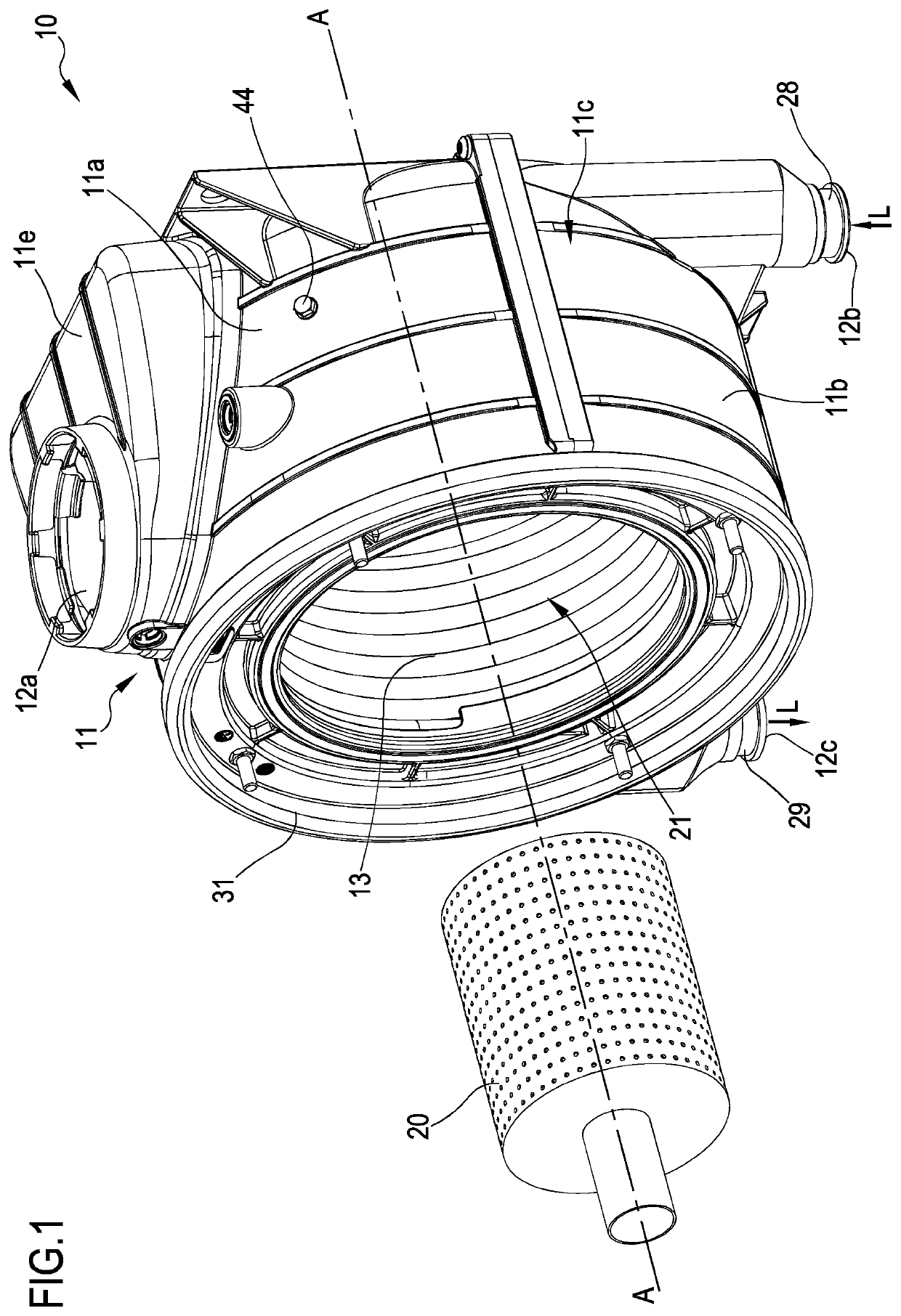

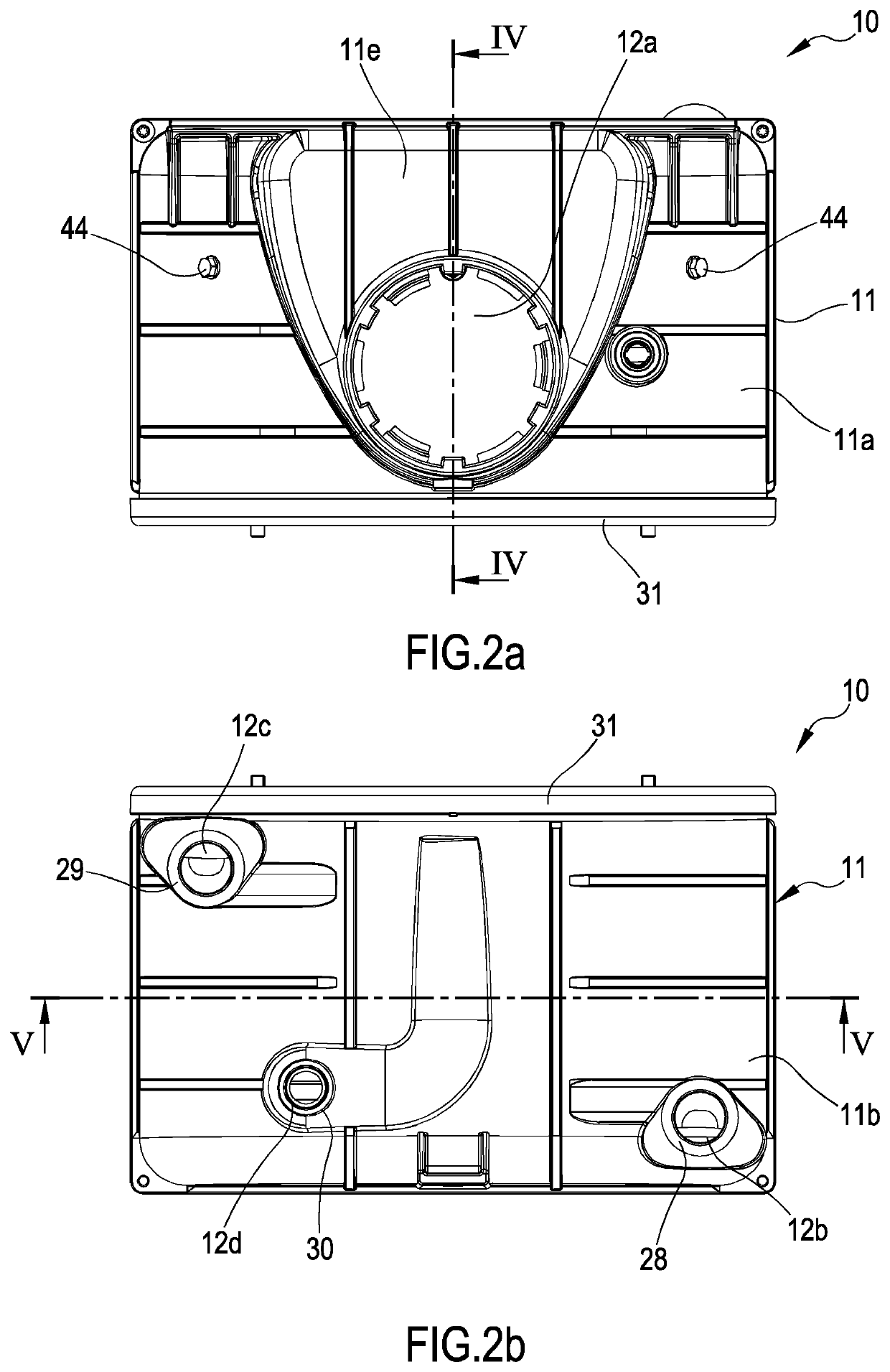

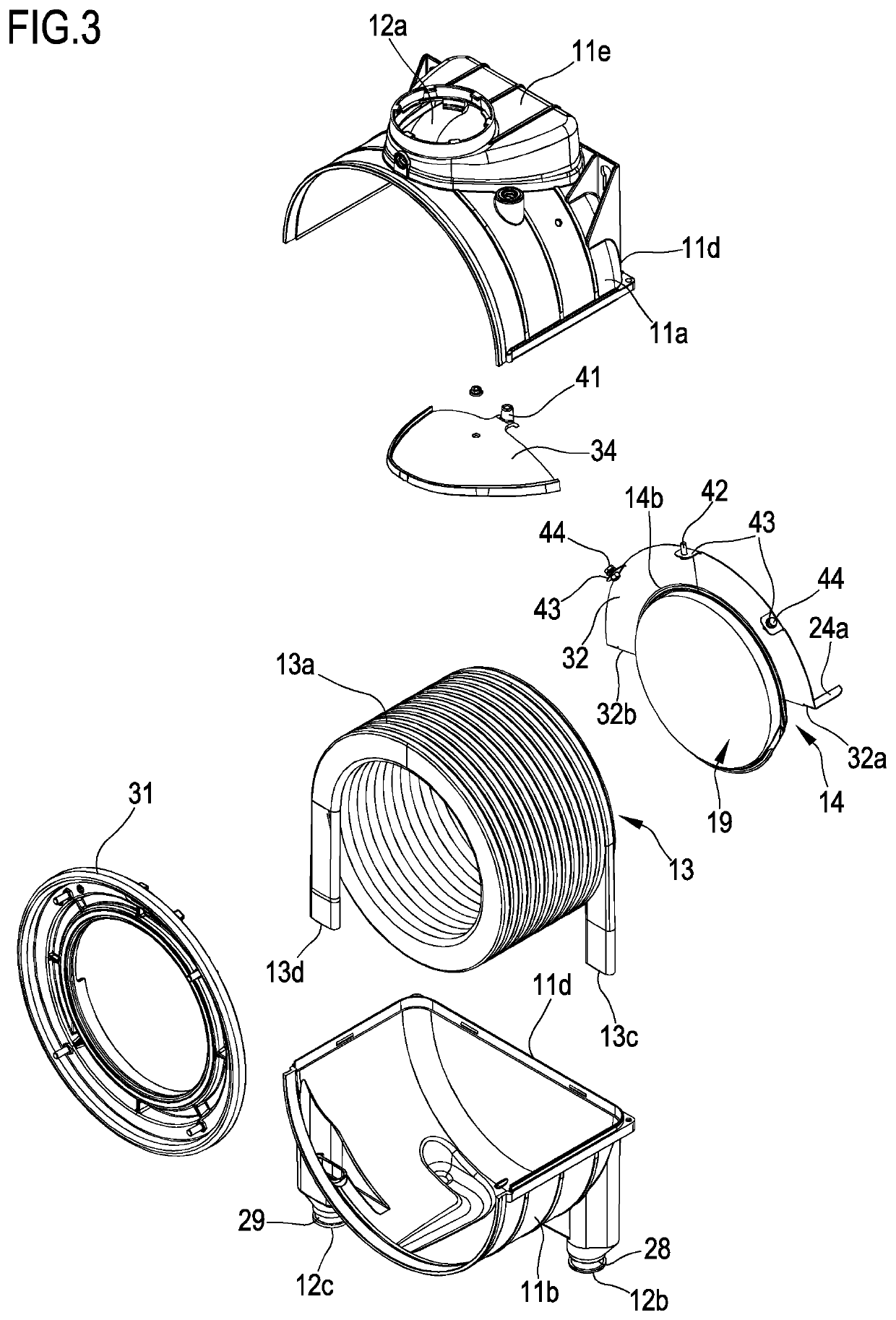

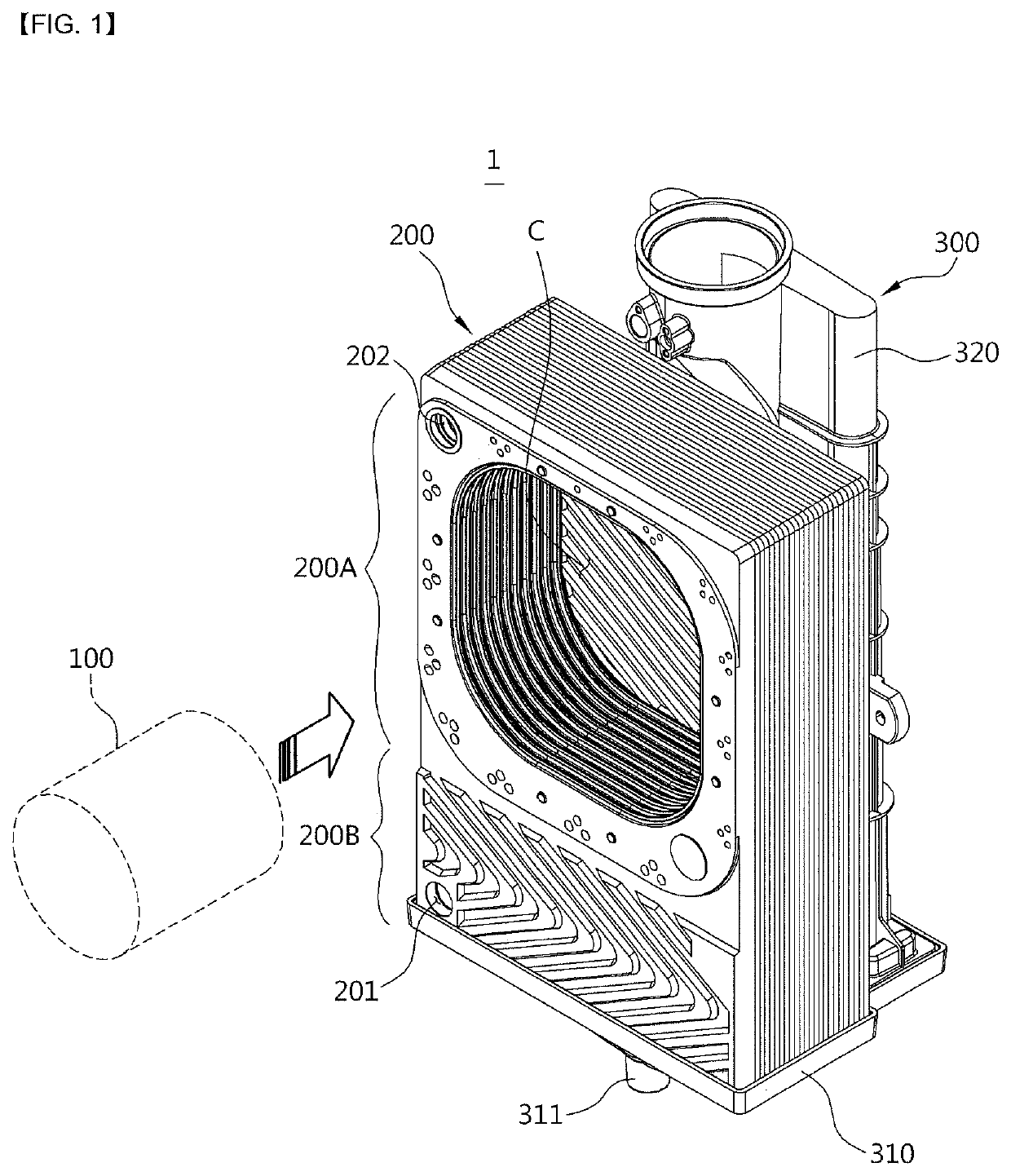

Heat exchange cell and method

ActiveUS20200386482A1Low costMinimization of of pressureHeat exchanger casingsStationary tubular conduit assembliesEngineeringHeat transfer fluid

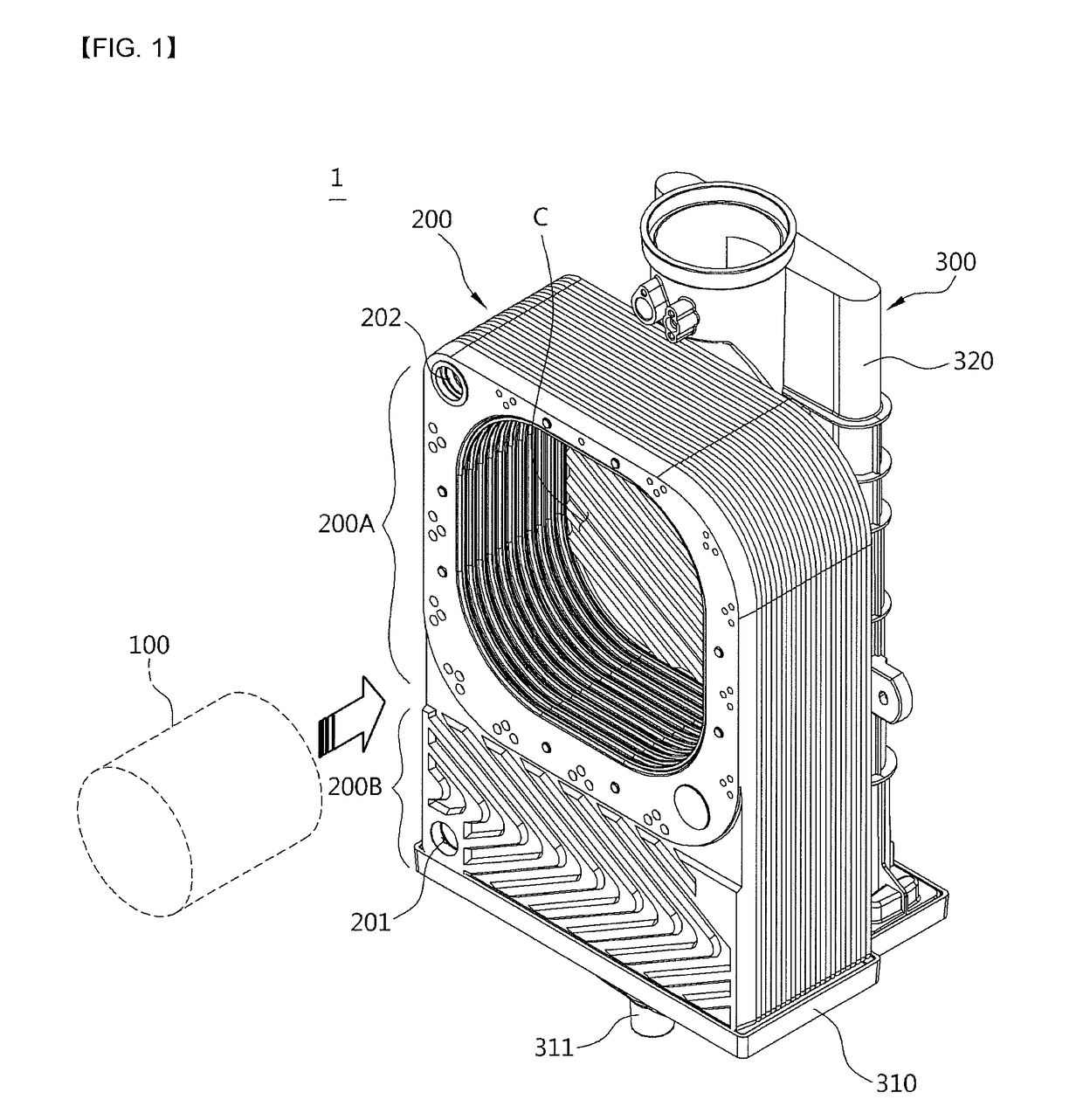

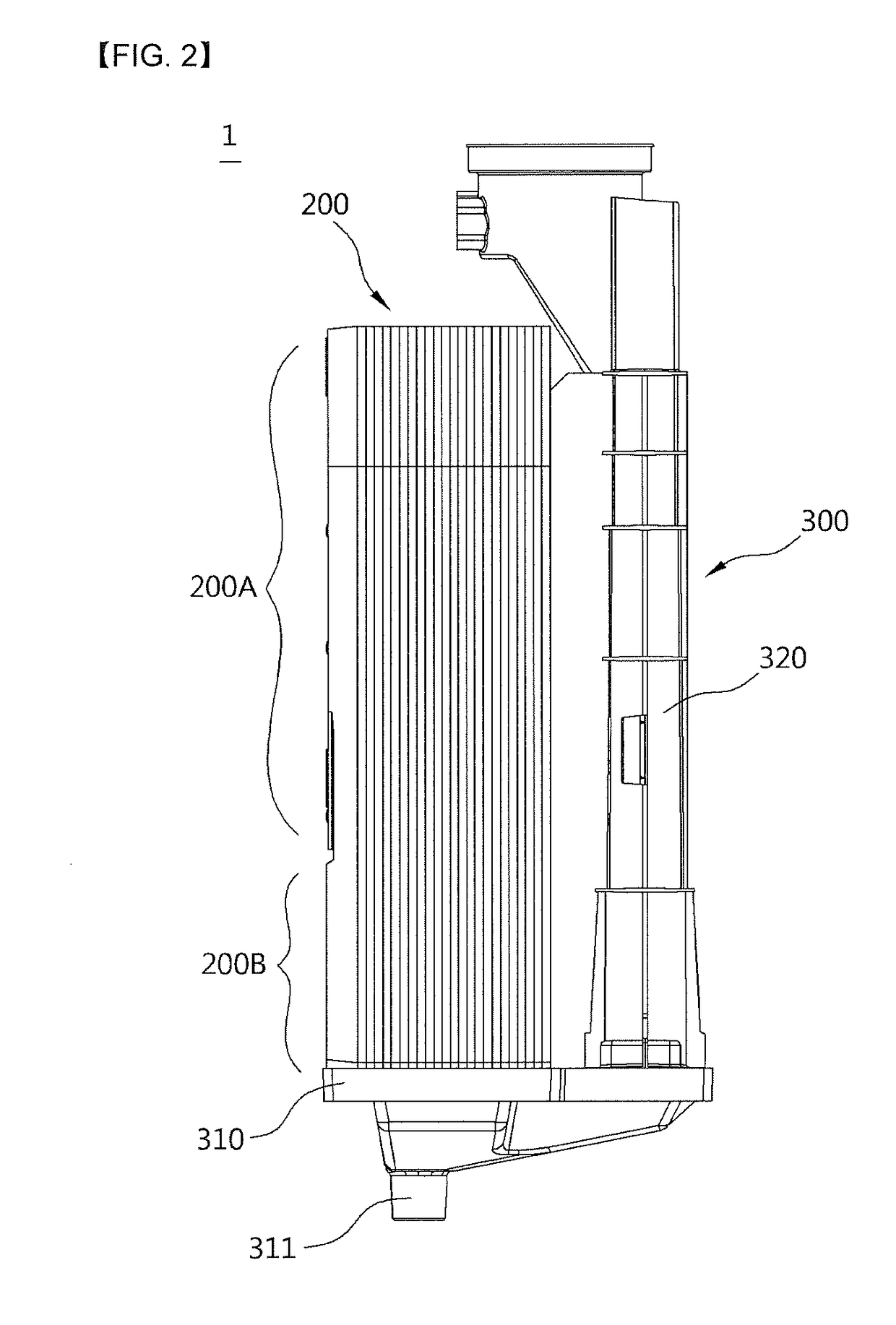

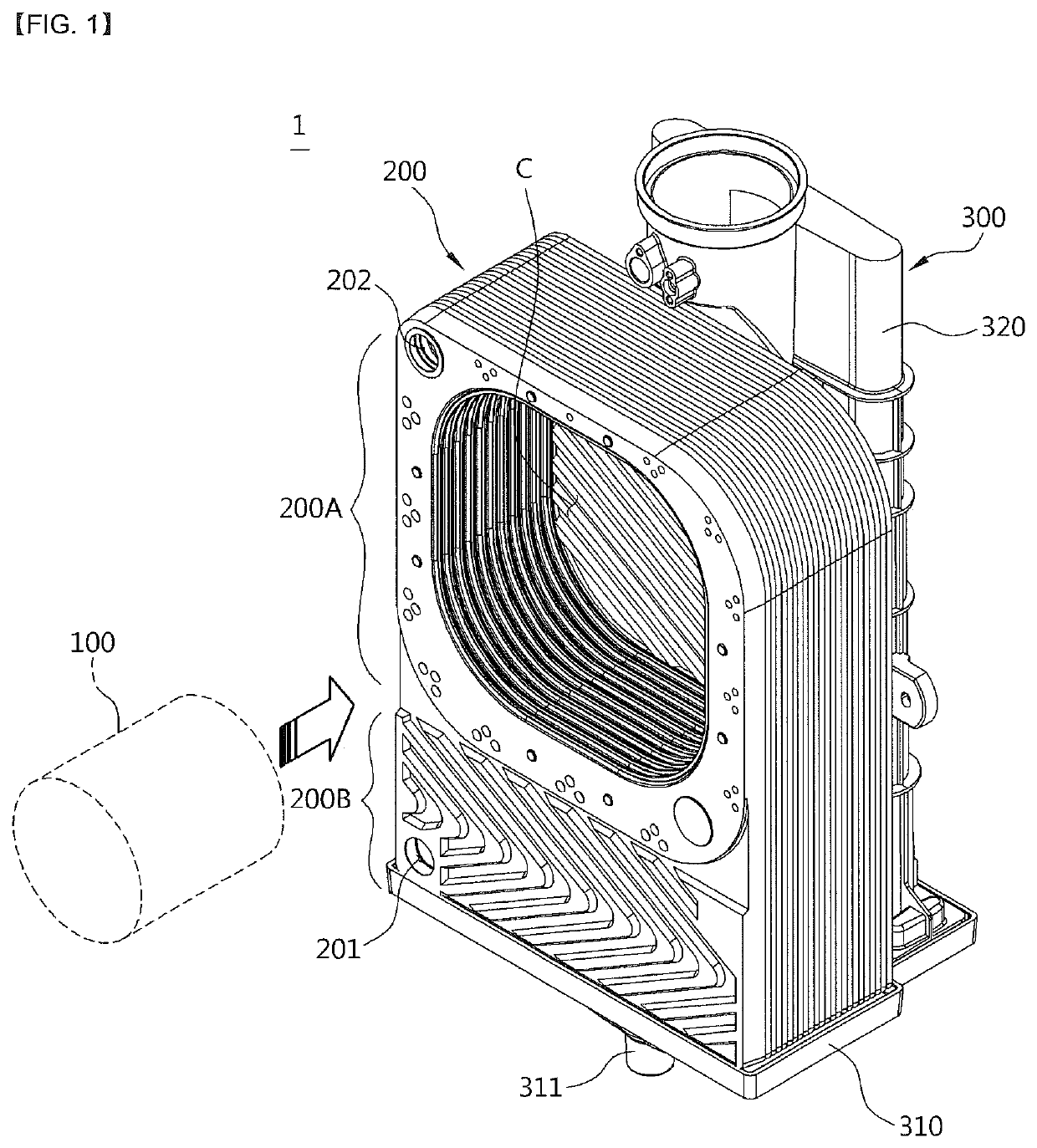

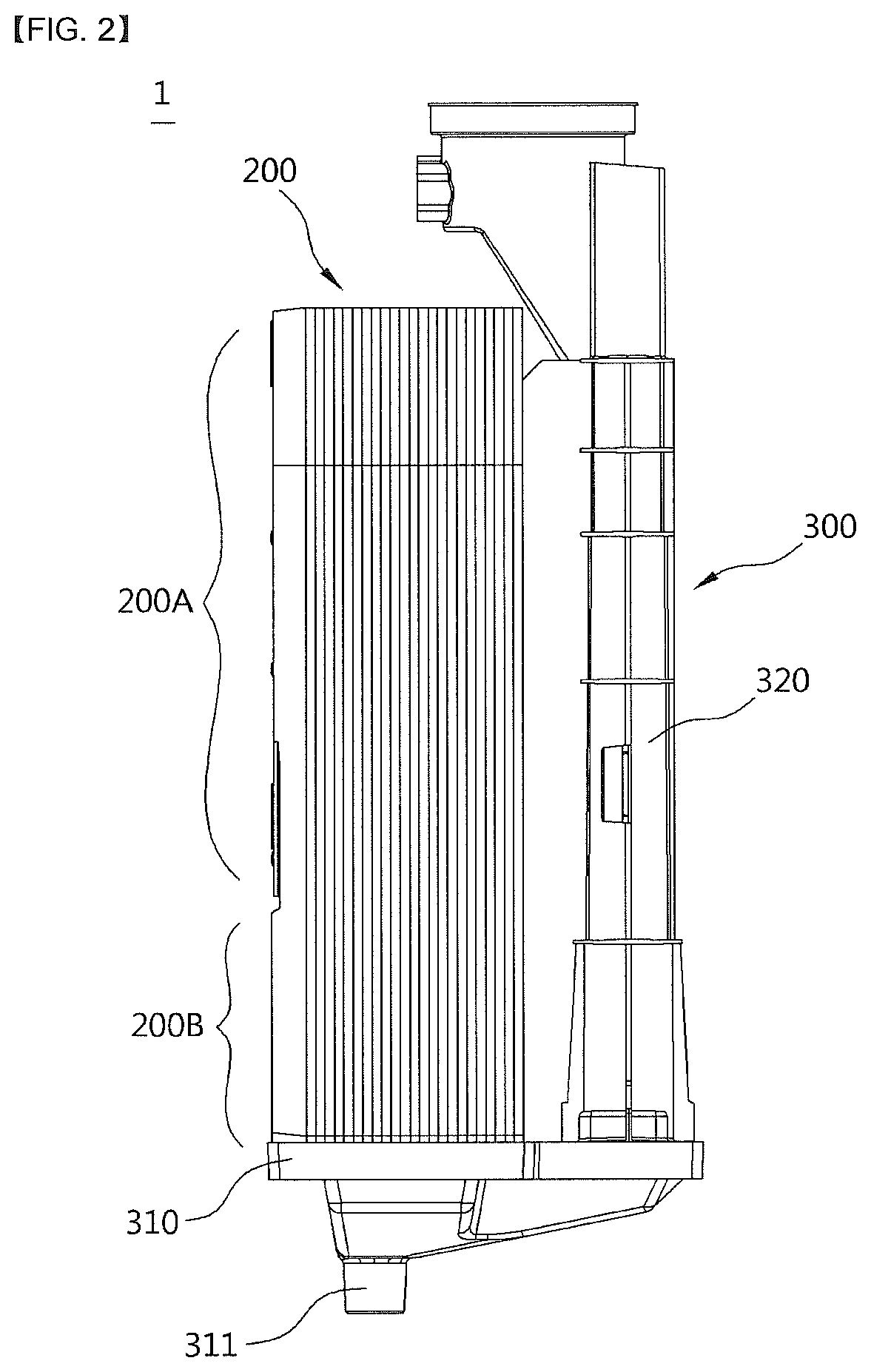

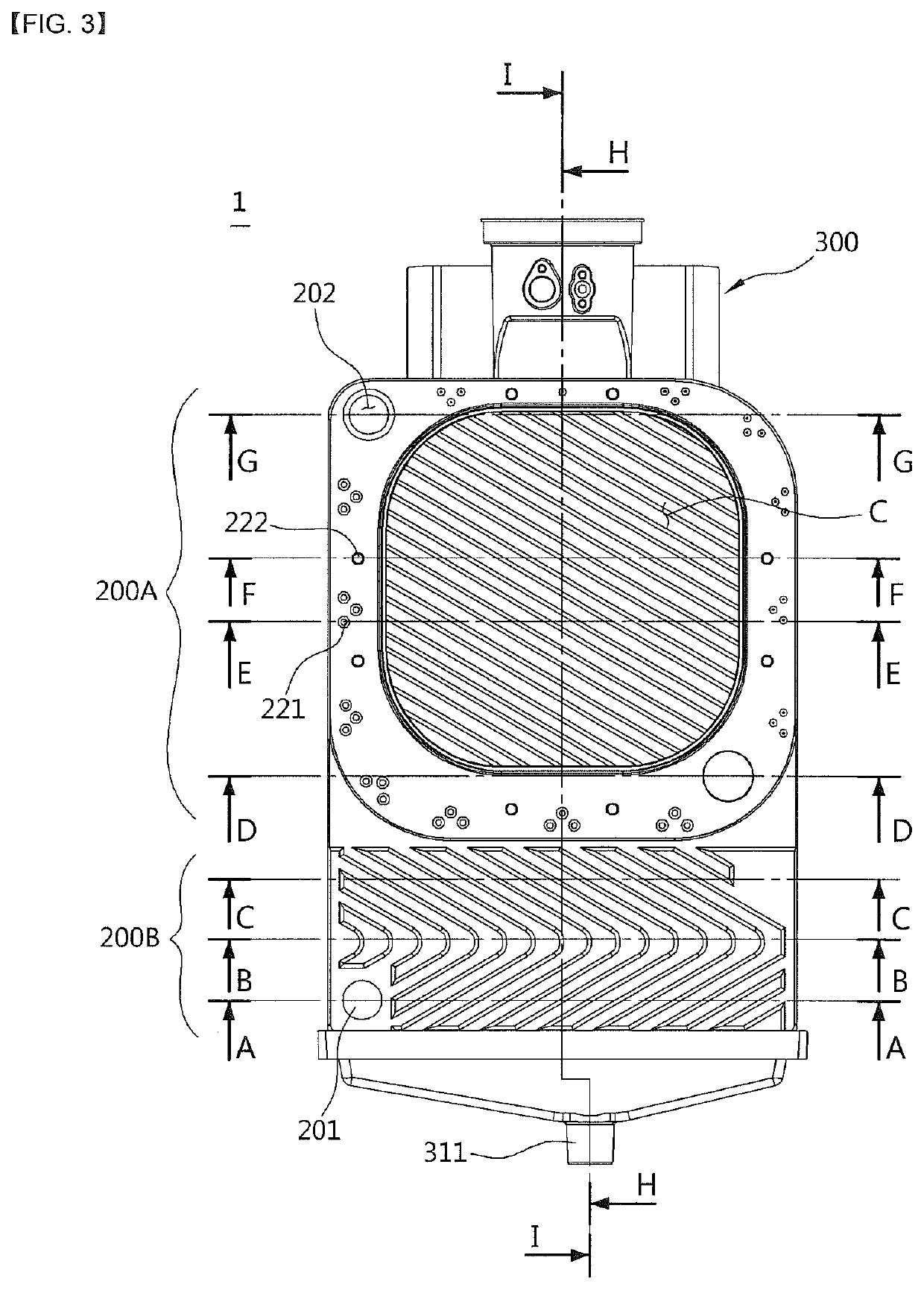

A heat exchange cell (10) is described comprising a helically-shaped heat exchanger (13), mounted in a containment casing (11), in which a first heat transfer fluid circulates; a first heat exchange chamber (22), defined in the casing (11), in which a first heat exchange portion of the heat exchanger (13) is housed and in which a first collection chamber (15) of the second heat transfer fluid is defined externally to the heat exchanger (13); a second heat exchange chamber (26) defined in the casing (11), in which a second heat exchange portion of the heat exchanger (13) is housed and in which—externally to the heat exchanger (13)—a second collection chamber (16) of the second heat transfer fluid is defined; and a fluid outlet passage (35) from the second heat exchange chamber (26) defined in a peripheral side wall (11c) of the containment casing (11) in proximity to a rear wall (11d) thereof. The first and second heat exchange chambers (22; 26) are separated internally to the heat exchanger (13) by a first separating element (14) comprising a substantially plate-shaped body and externally to the heat exchanger (13) by at least a second separating element (32) extending radially between a radially outer wall (13a) of the heat exchanger (13) and the peripheral side wall (11c) of the containment casing (11) so as to define at least one passage (17) of fluid between the first (15) and the second (16) collection chamber of the second heat transfer fluid. The heat exchange cell (10) further comprises a pair of axial separator baffles (24a; 24b), axially extending between the second separating element (32) and the rear wall (11d) of the containment casing (11), and configured to separate a first portion (16a) of the second collection chamber (16) of the second heat transfer fluid defined upstream of the axial separator baffles (24a; 24b) from a second portion (16b) of the second collection chamber (16) of the second heat transfer fluid defined downstream of the baffles (24a; 24b).

Owner:CONDEVO

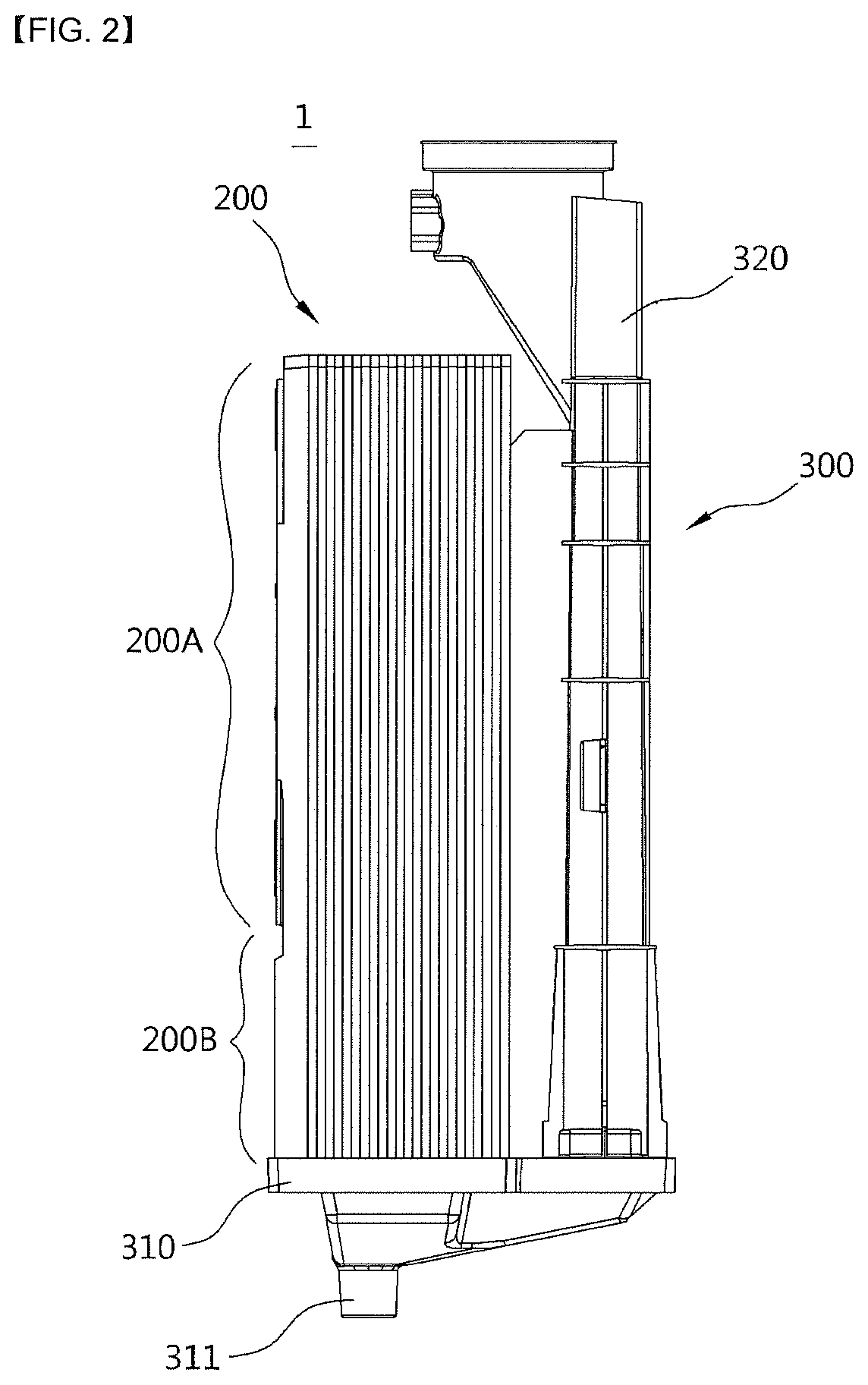

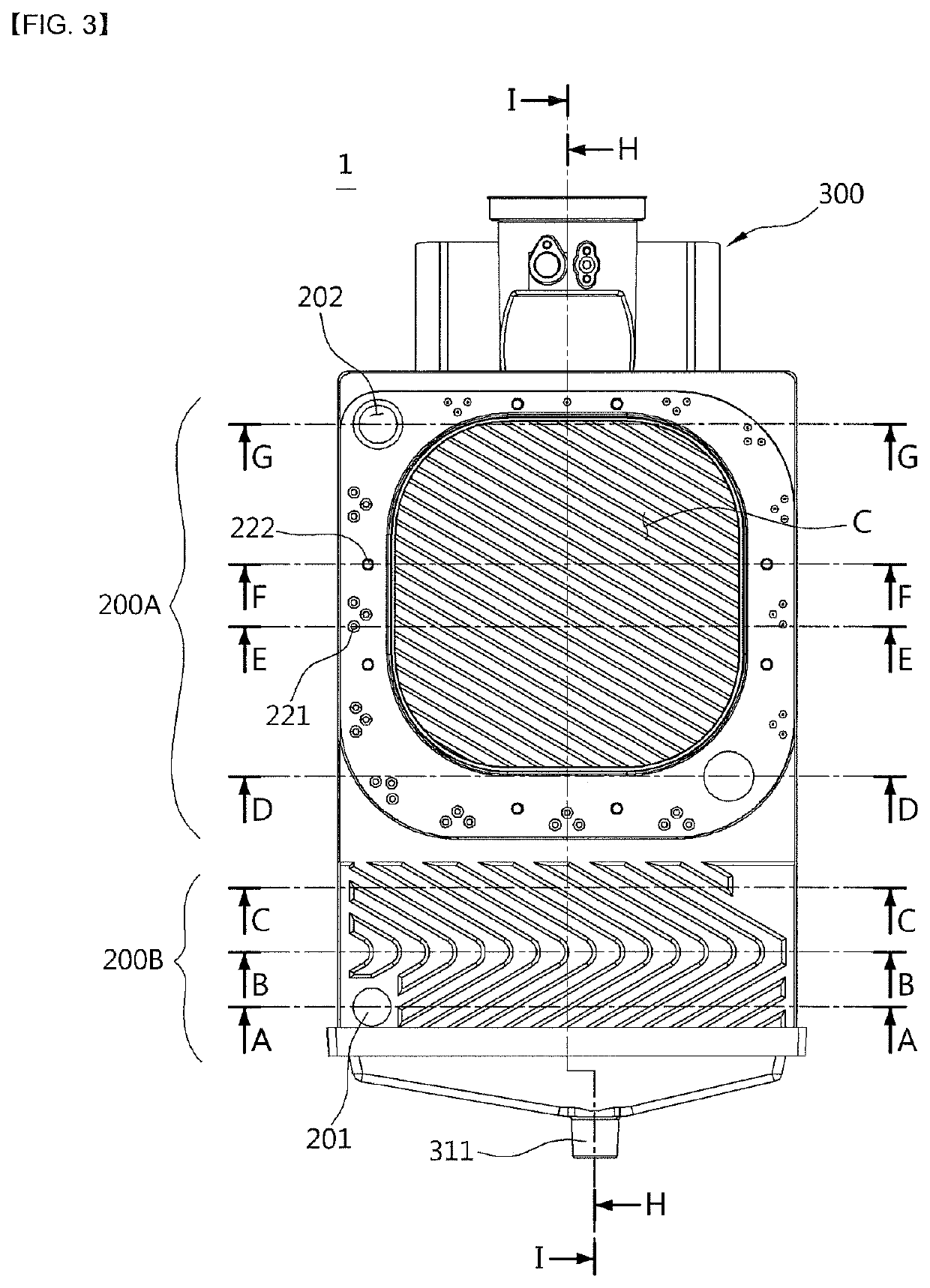

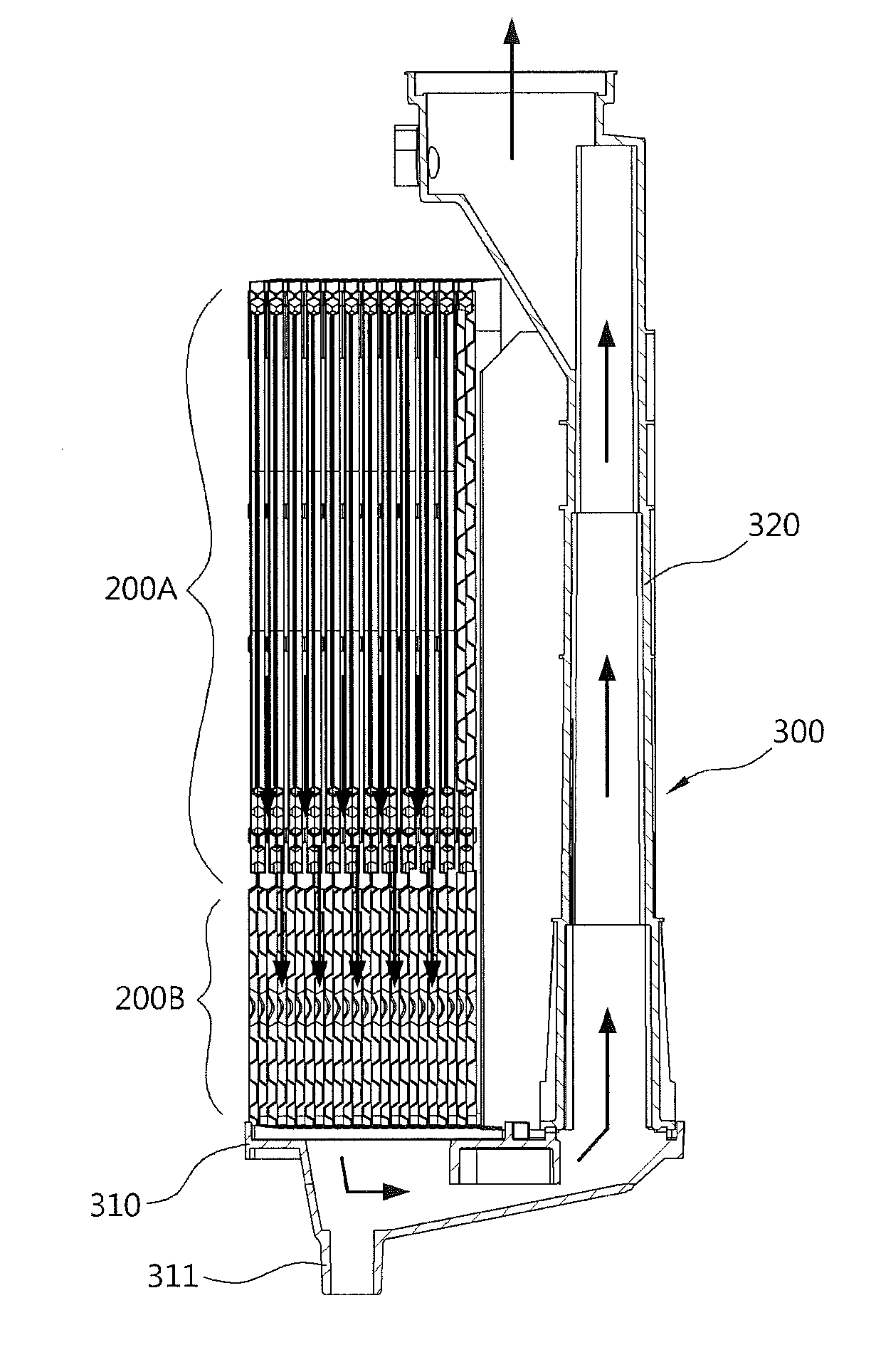

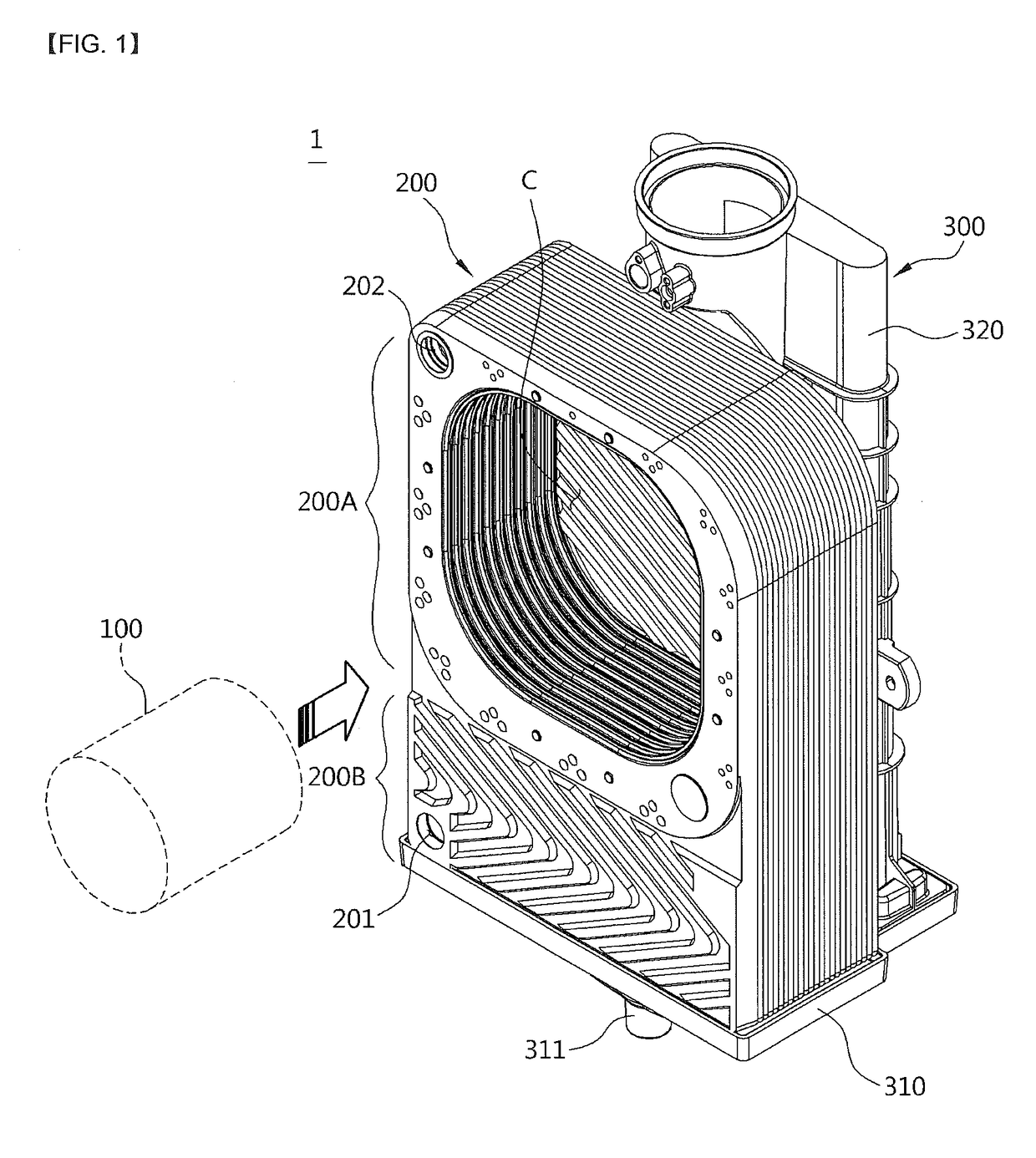

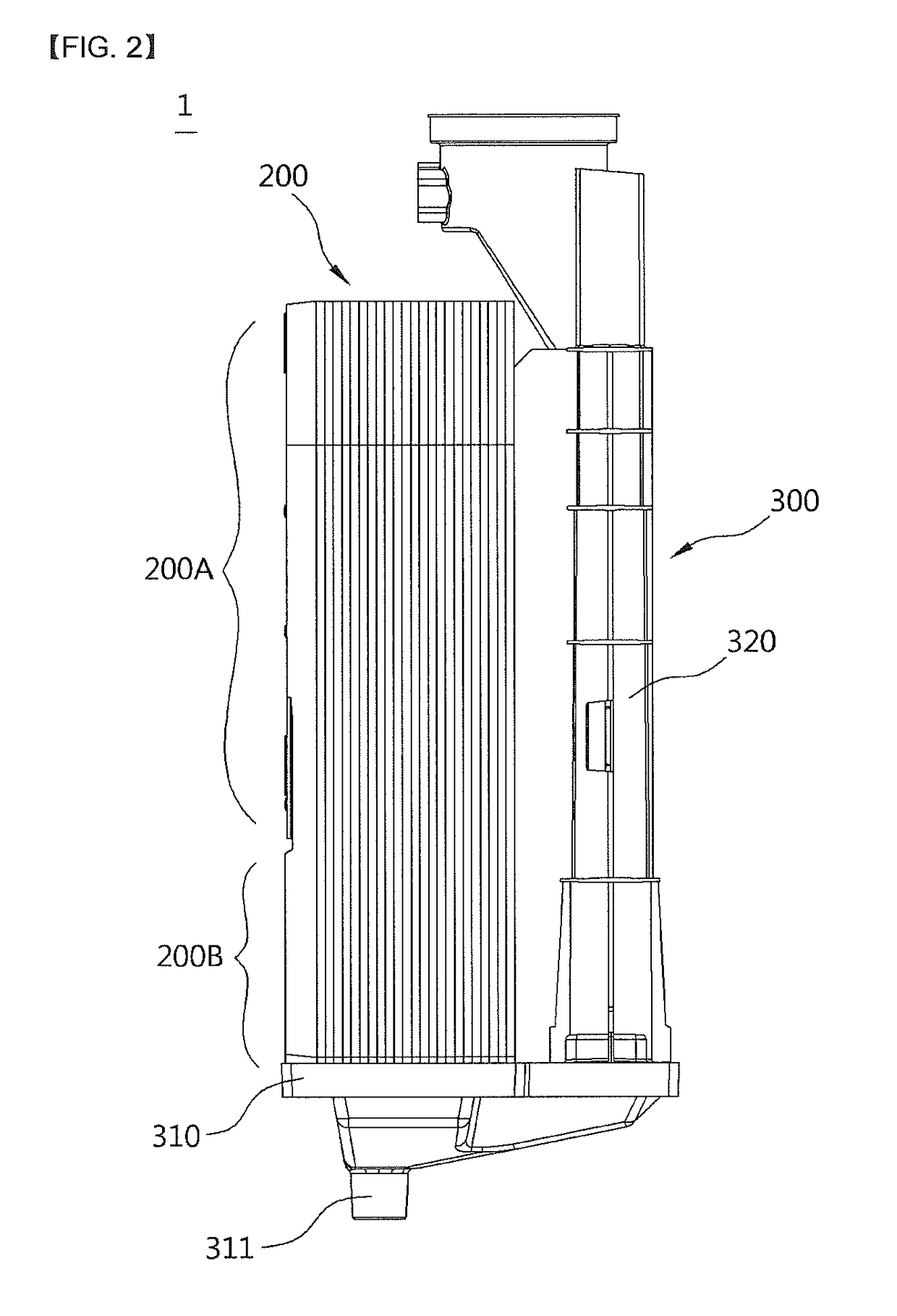

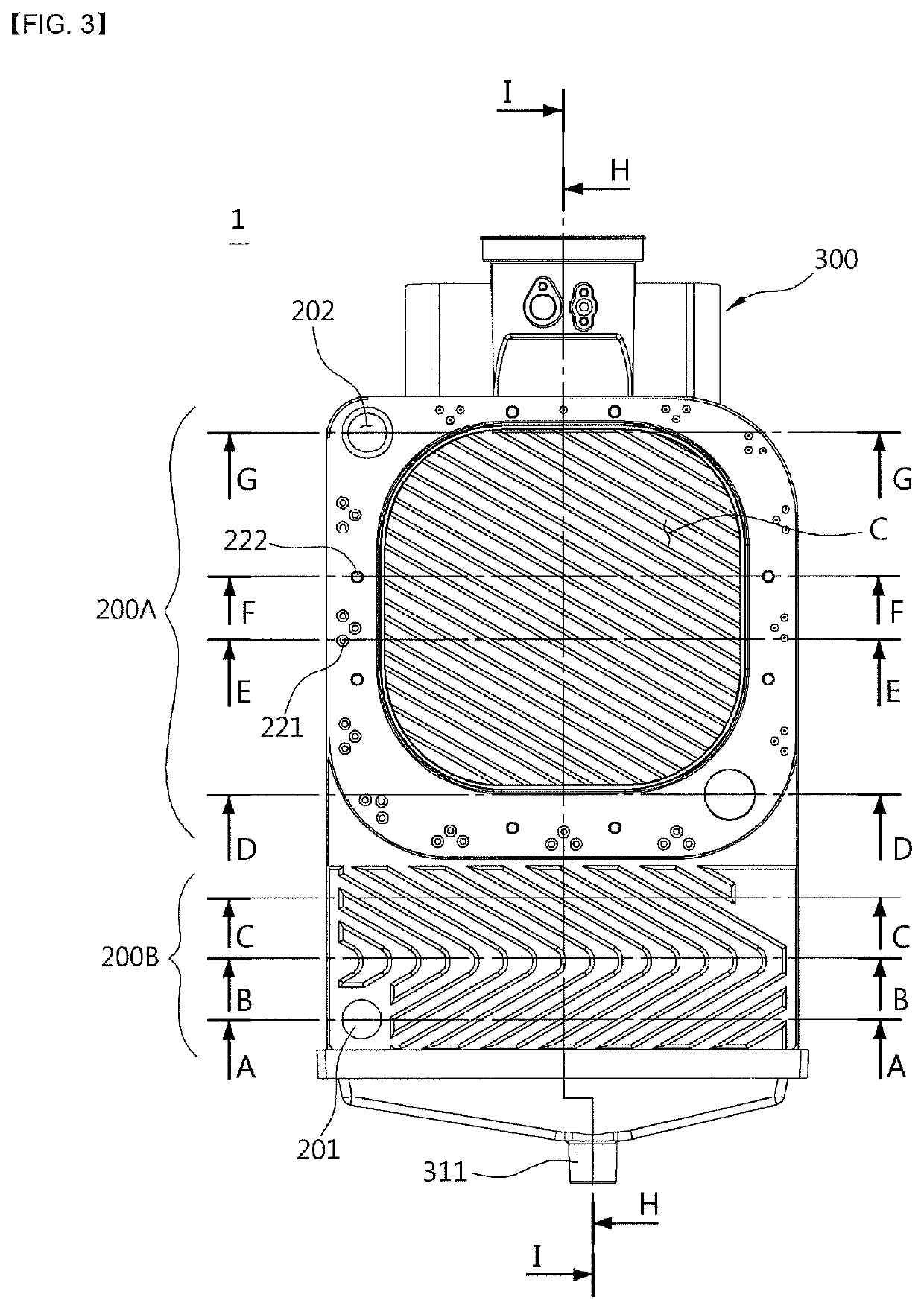

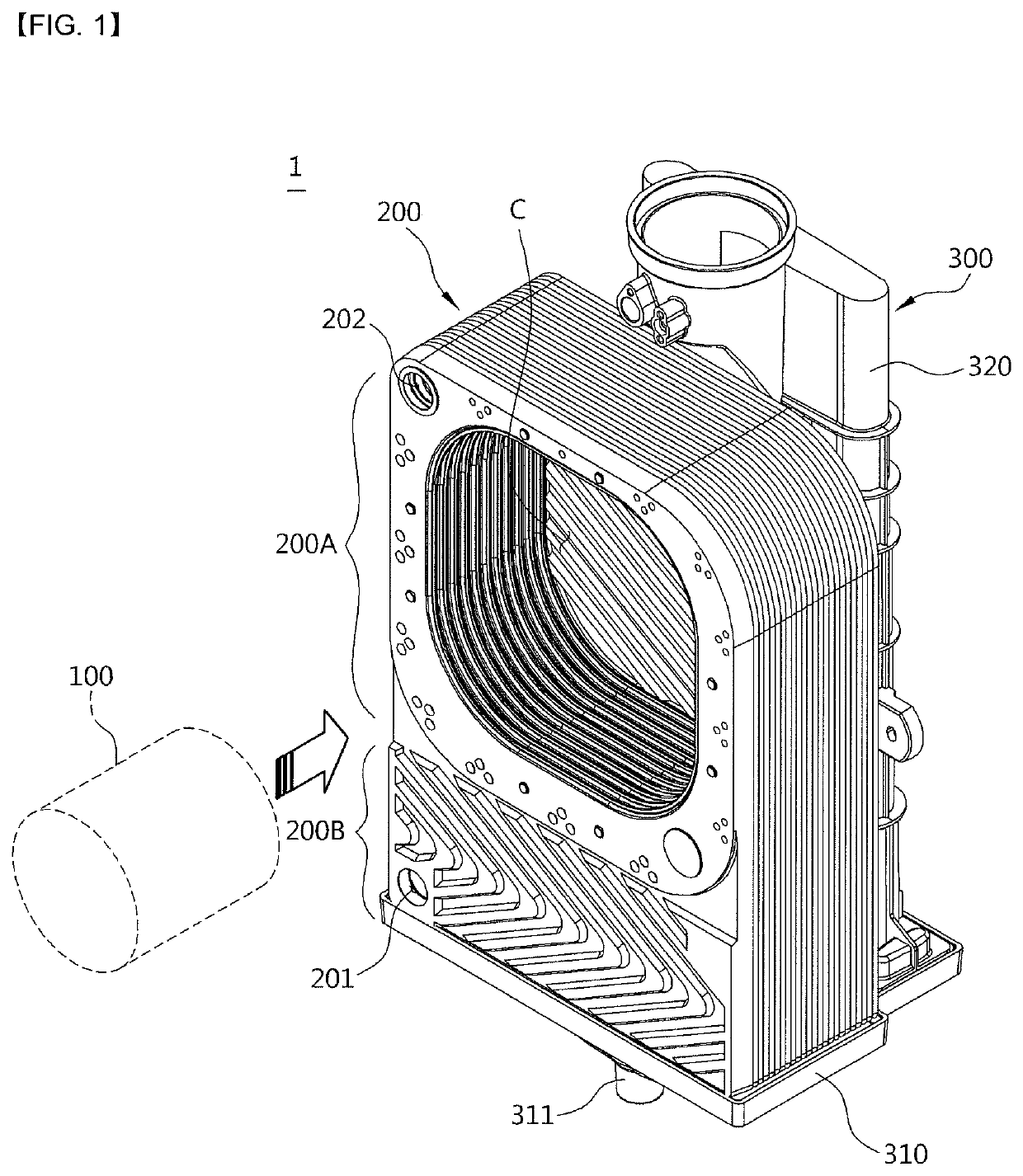

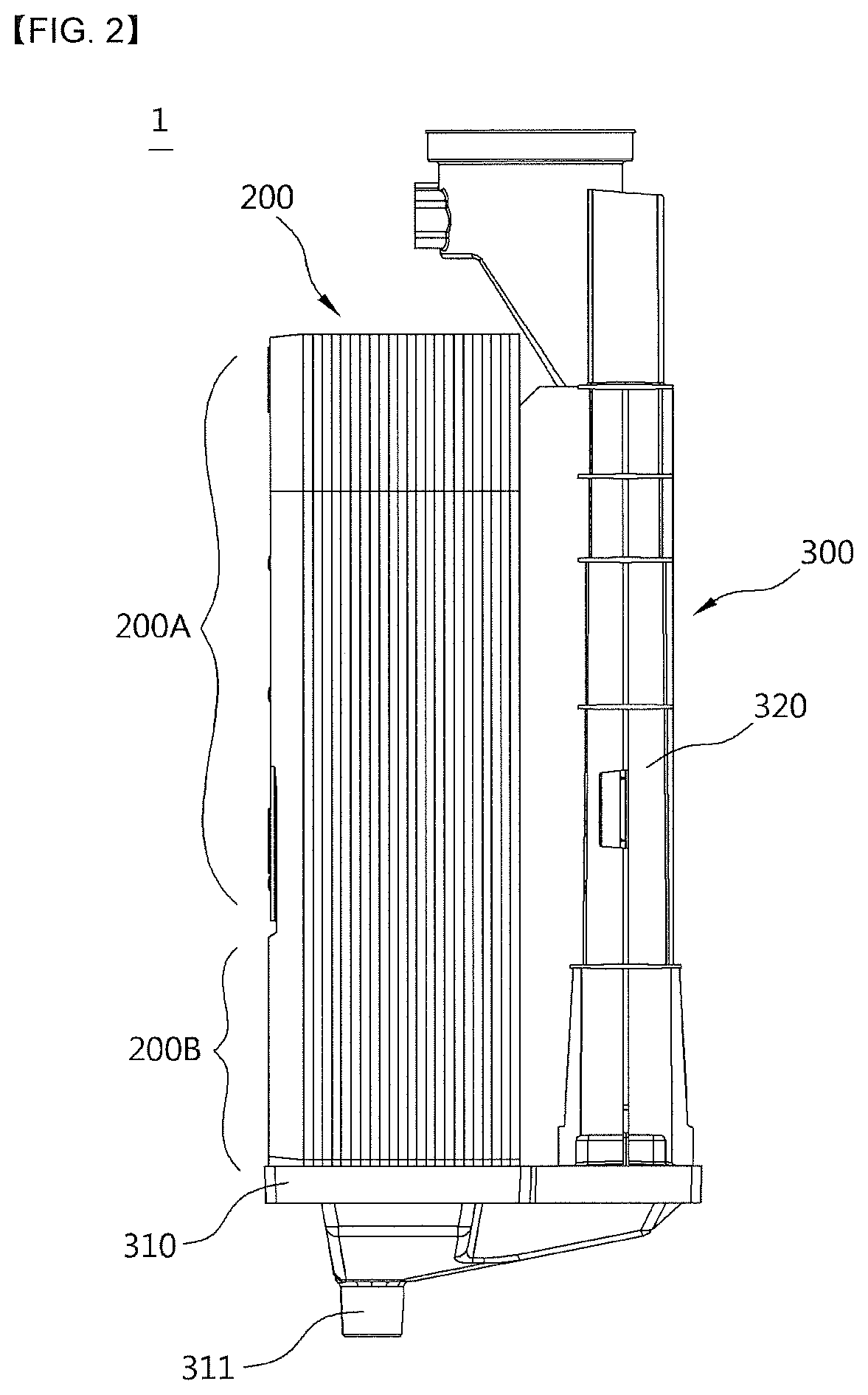

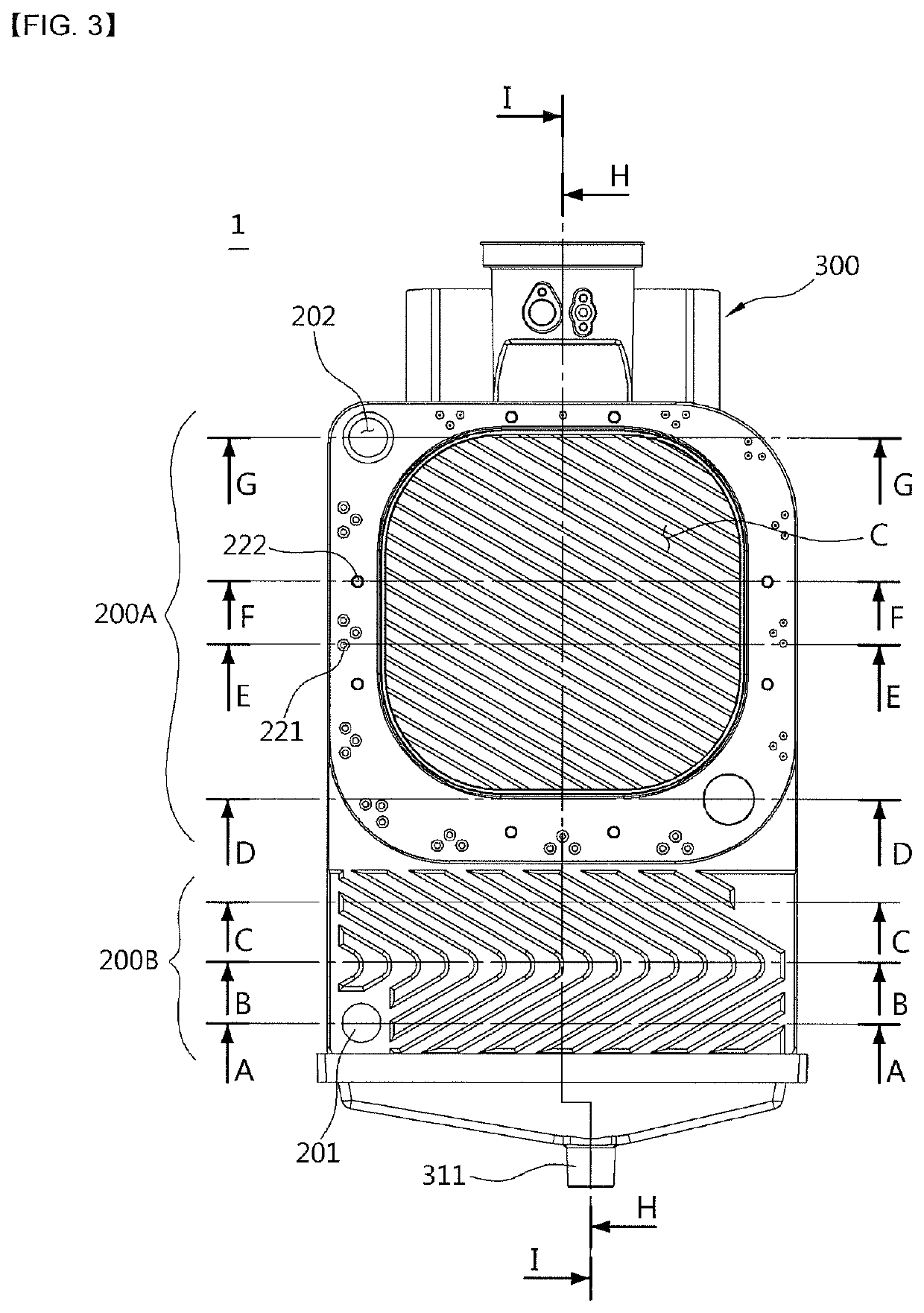

Heat exchanger

ActiveUS20180231274A1Easy to disassembleSolve the narrow working spaceHeat storage plantsAir heatersCombustion chamberCombustor

A heat exchanger according to the present invention comprises a heat exchange portion in which heating medium flow paths, where a heating medium flows through a space between a plurality of plates, and combustion gas flow paths through which a combustion gas combusted in a burner flows are adjacently and alternatingly formed, wherein the heat exchange portion comprises a sensible heat portion, which surrounds the outside of a combustion chamber and comprises an area on one side of the plates, for heating the heating medium using the sensible heat of the combustion gas generated by combustion of the burner, and a latent heat portion, which comprises an area on the other side of the plates, for heating the heating medium using the latent heat of water vapors in the combustion gas which has completed heat exchanging in the sensible heat portion, wherein a connection passage for the heating medium is formed between the sensible heat portion and the latent heat portion, the plates are formed in a vertical structure so that the sensible heat portion is positioned on the top part and the latent heat portion is positioned on the bottom part, and wherein the burner has a cylindrical shape and is assembled by being inserted laterally from the front surface of a space in the combustion chamber.

Owner:KYUNGDONG NAVIEN

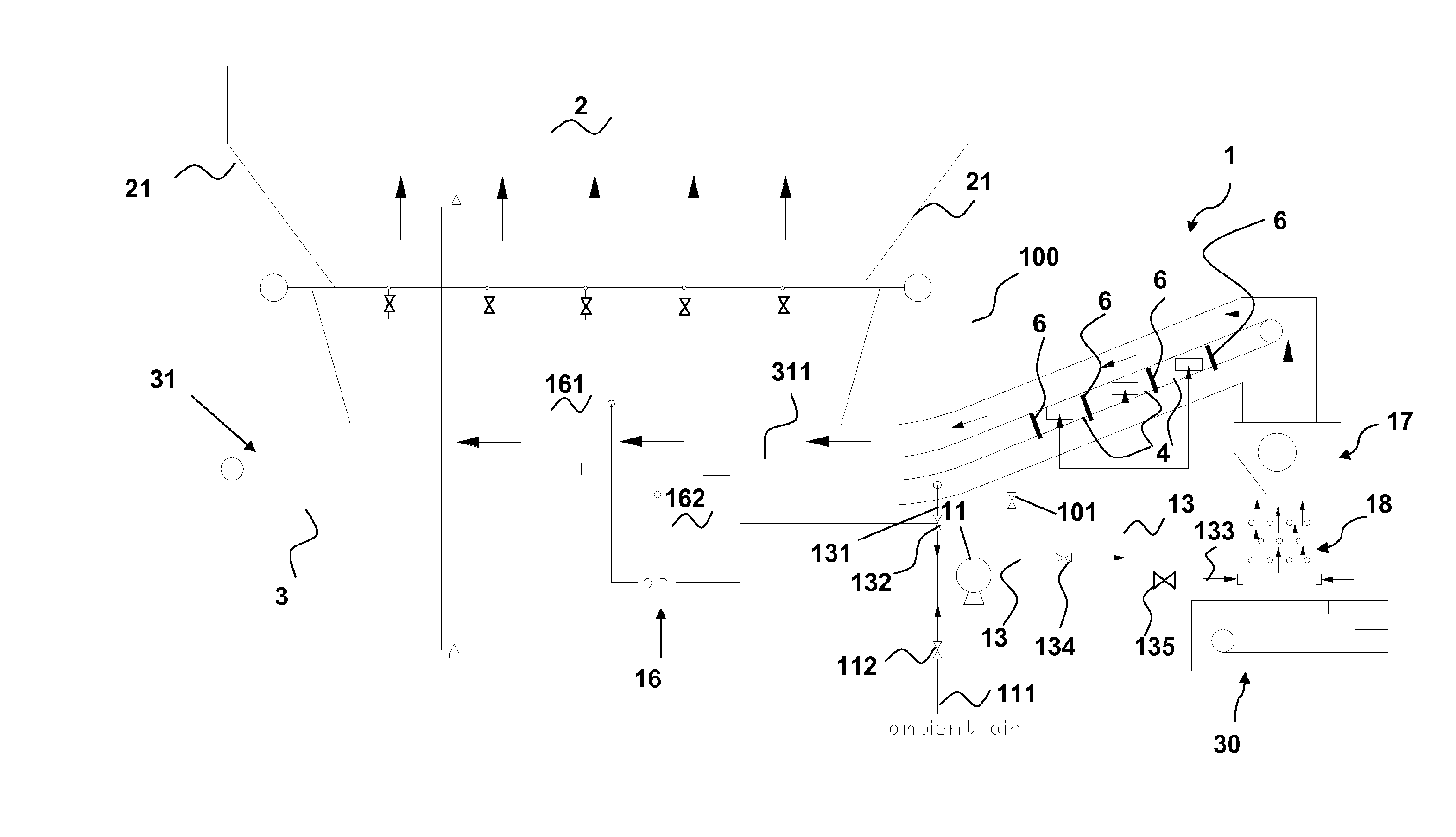

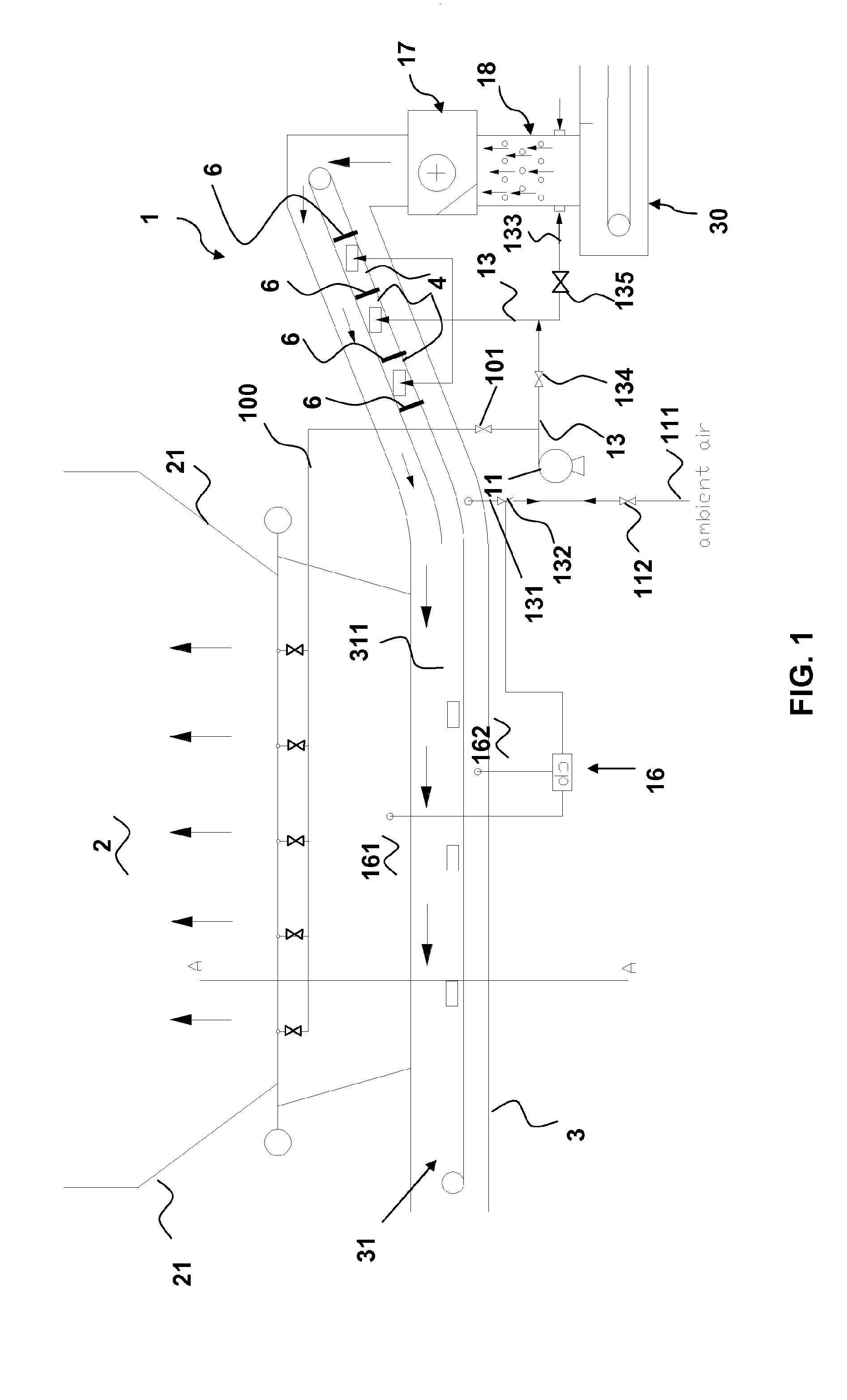

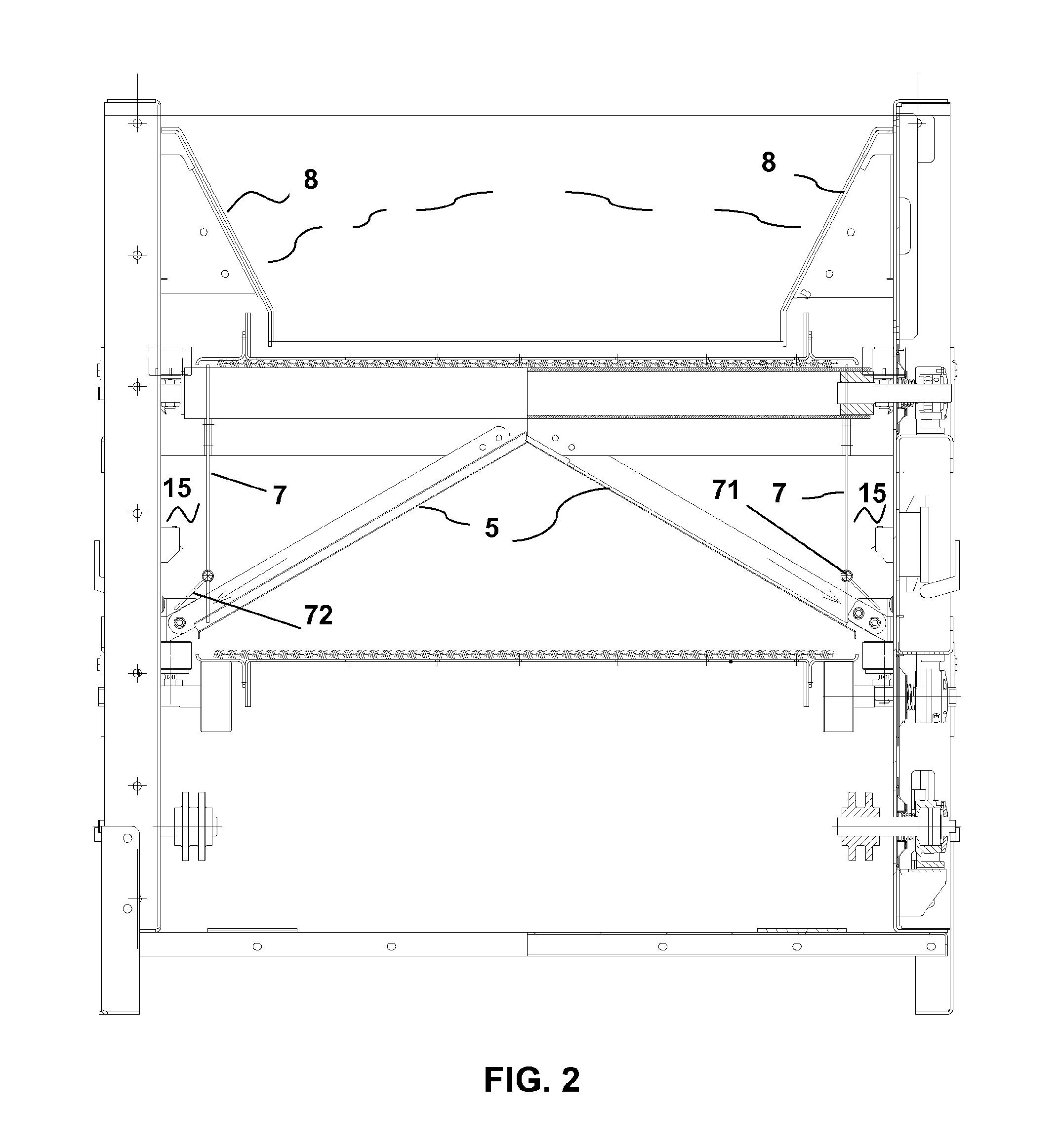

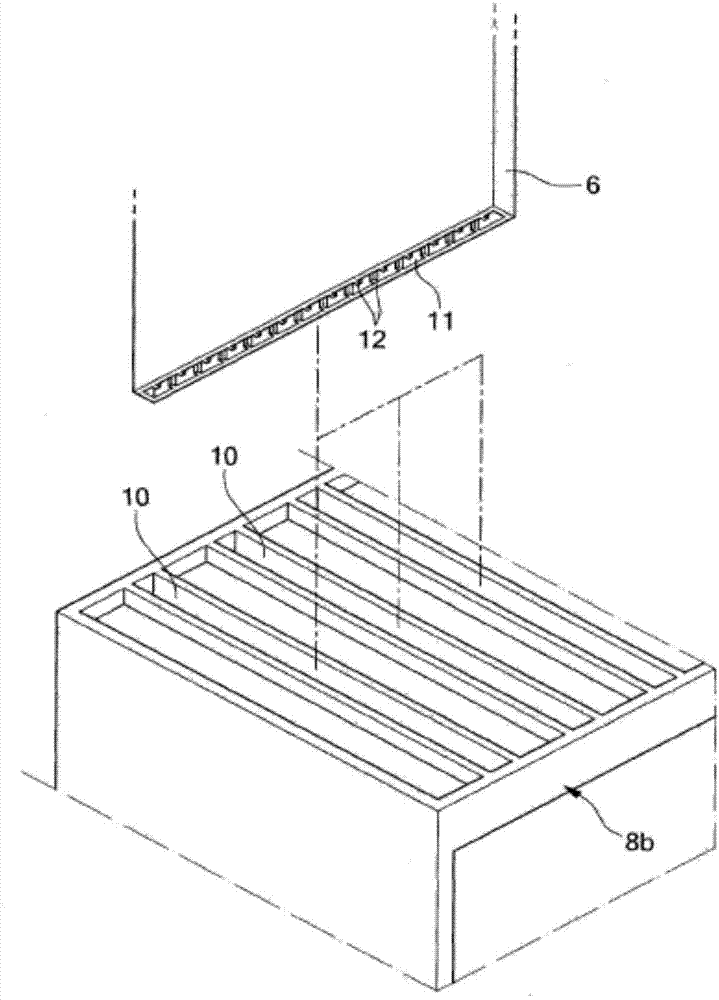

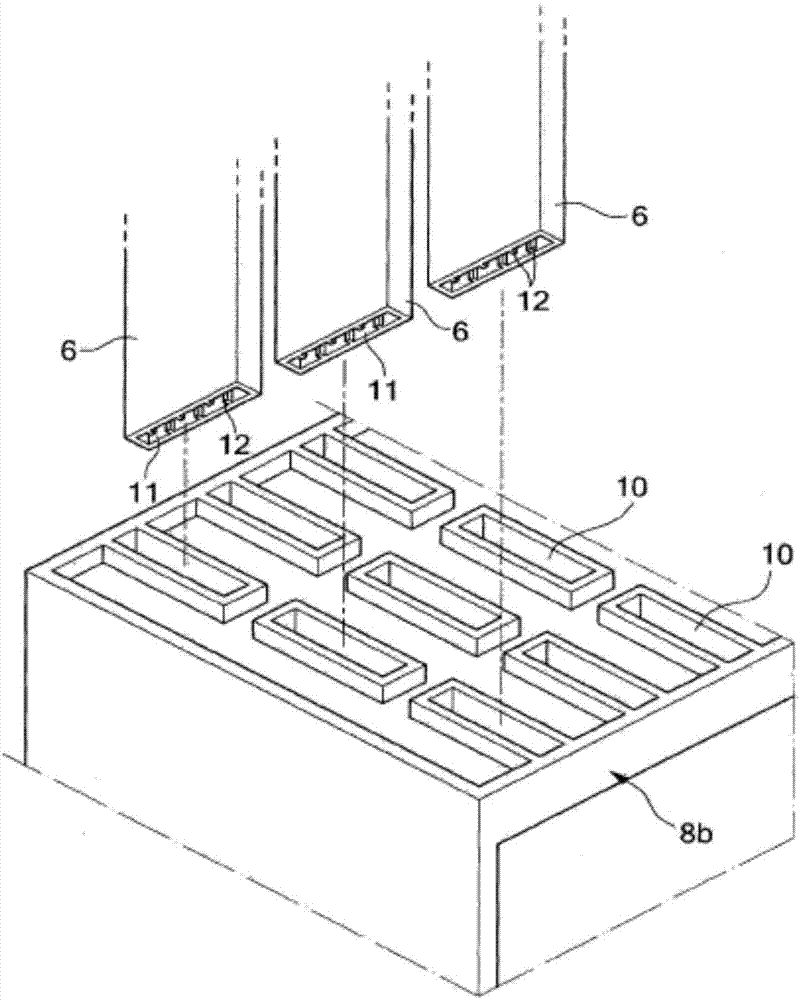

System and method for cooling and extraction of heavy ashes with increase in total boiler efficiency

InactiveUS20130284079A1Avoid disadvantagesMinimizing air outflowDomestic stoves or rangesGratesFossil fuelBoiler efficiency

A cooling system for heavy ashes of the type adapted to be used in association with a combustion chamber, in particular for large flow rates of heavy ashes deriving, for example from solid fossil fuel, in an energy-production unit is described. The cooling system has: a transport belt for transporting the heavy ashes, adapted to be arranged below the combustion chamber and having a containment casing and a transport surface equipped with openings for the transit of cooling air, and cooling means for cooling the heavy ashes received on the transport surface.

Owner:MAGALDI POWER SPA

Systems and methods for separating condensable vapors from light gases or liquids by recuperative cryogenic processes

ActiveUS10724793B2Effective recoveryEliminate the problemSolidificationLiquefactionThermodynamicsProcess engineering

Methods and systems of the current invention separate condensable vapors such as carbon dioxide from light gases or liquids in a mixed process stream. The separation is carried out in a cryogenic process using one or more external cooling loops (ECLs) that first cool down a mixed process stream containing condensable vapors and light gases or liquids, causing the condensable vapors to desublimate and form solids. Next, the solids are separated from the light gases or liquids, forming a solid stream and a light gas or liquid stream. Then the refrigerants of the ECL are cooled by warming the separated solid stream and light gas or liquid stream, efficiently recovering energy used in cooling and desublimating the condensable vapors.

Owner:U S BANK TRUST CO NAT ASSOC

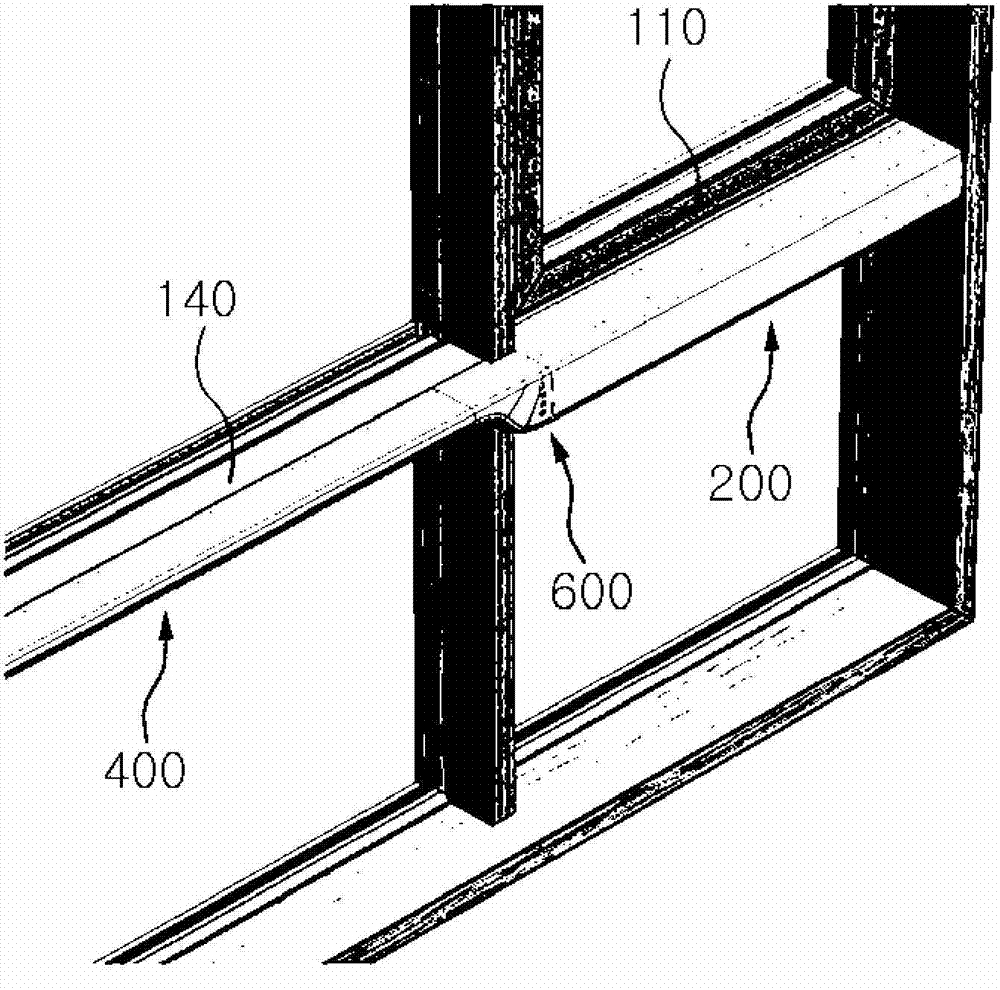

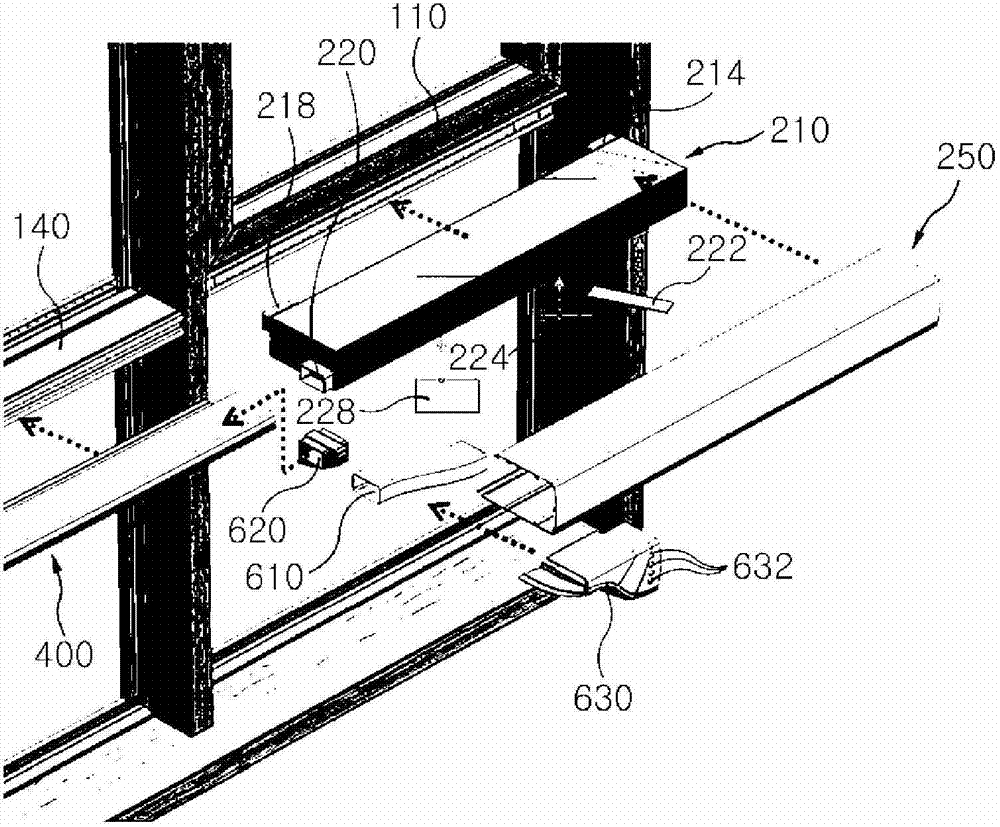

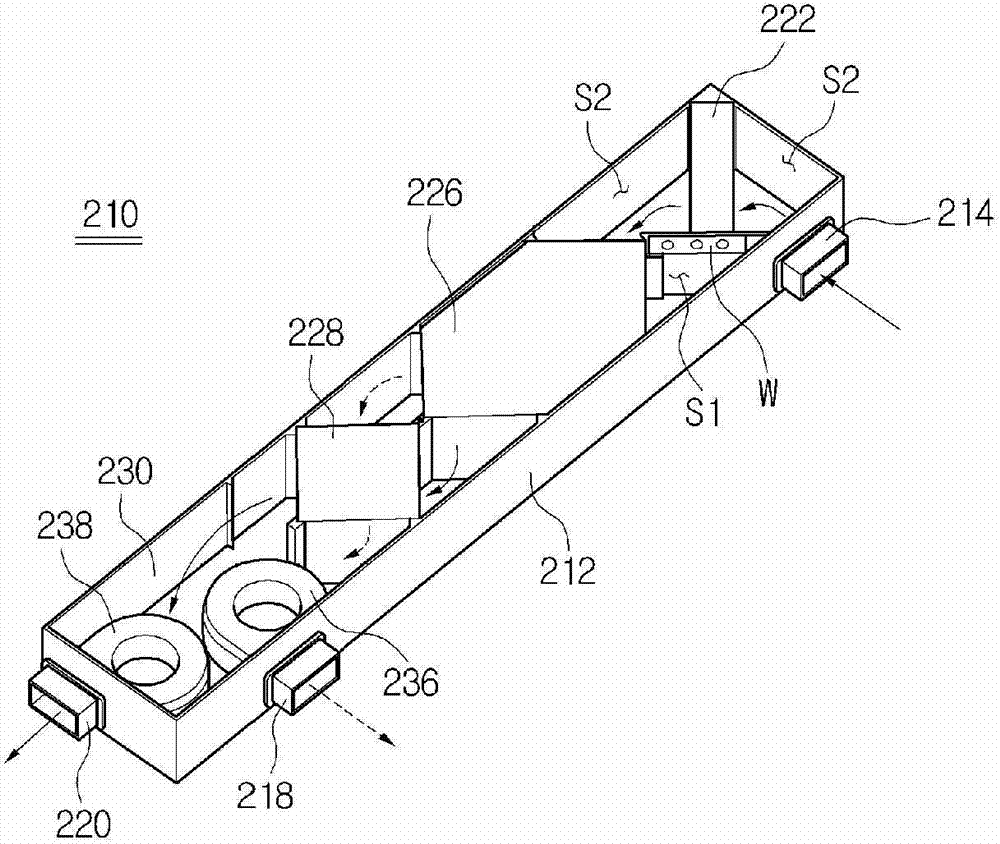

Ventilation device for windows with heat pipe

ActiveCN102906509ARealize heat exchangeAchieve maintenanceEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringHeat pipe

Disclosed is a ventilation device for windows, including a heat exchange module which is disposed at a window frame of a divided window so as to allow heat exchange between air introduced from an outdoor space and air introduced from an indoor air without mixture therebetween; and an exhaust module which is disposed at the window frame so as to be adjacent to the heat exchange module, wherein a heat pipe is provided at a partition wall which is disposed in the heat exchange module so as to separate indoor air and outdoor air from each other, thereby achieving the heat exchange between the indoor air and the outdoor air. Therefore, it is possible to smoothly replace the indoor air while the heat exchange between air introduced from an outdoor space and air introduced from an indoor air is performed.; In the heat exchange module, since the heat pipe is disposed at the partition wall so as to perform the heat exchange between the indoor air and the outdoor air, it is possible to maximize the whole heat exchange efficiency.

Owner:LG HAUSYS LTD

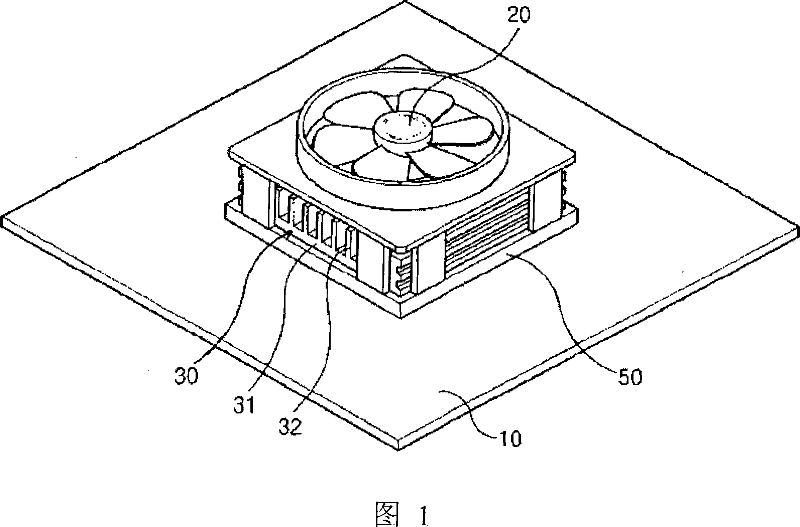

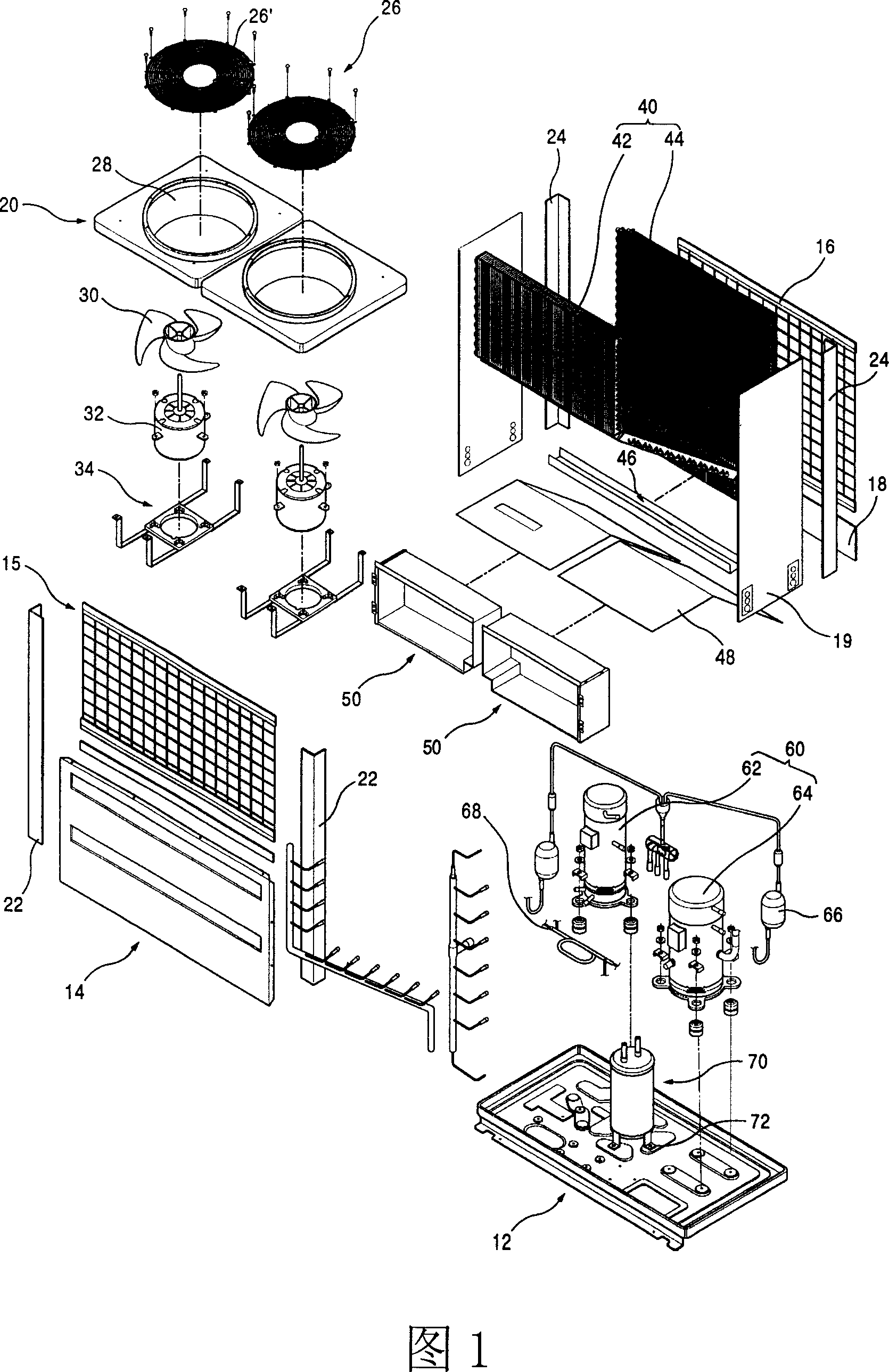

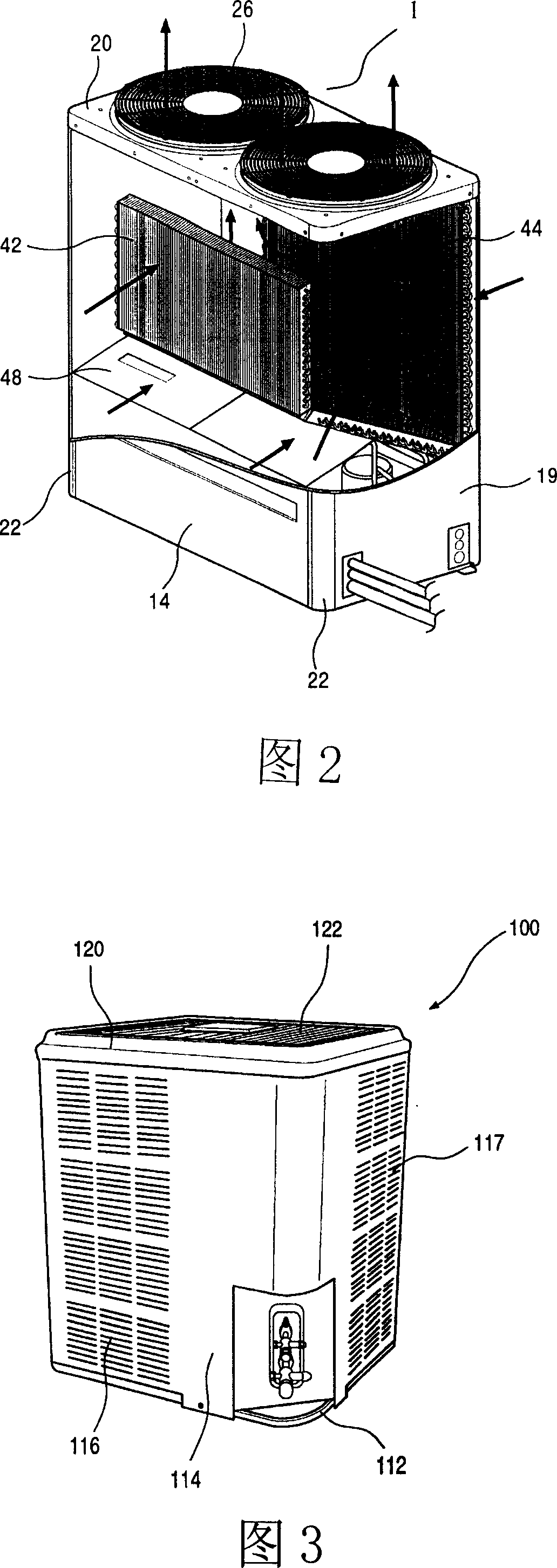

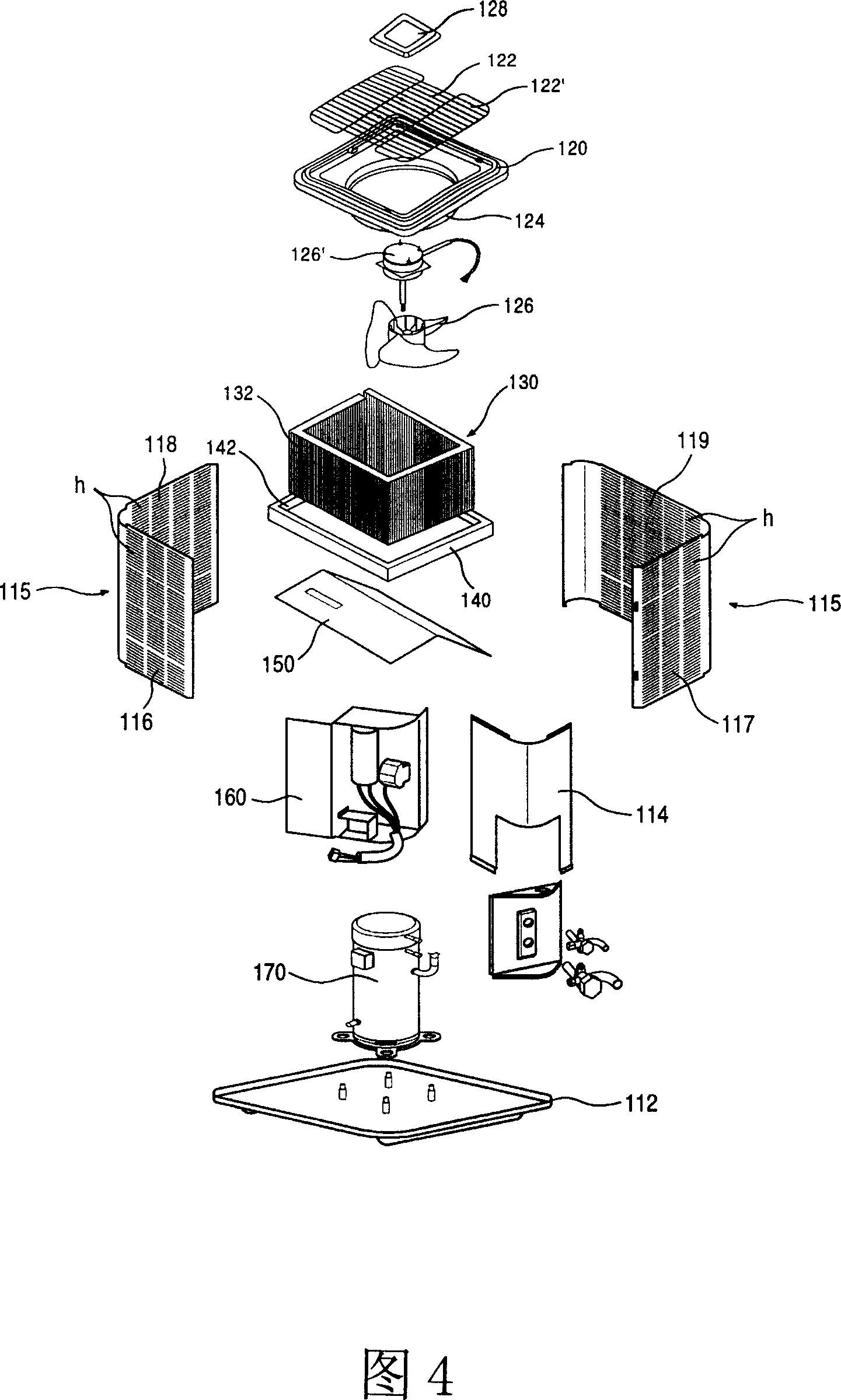

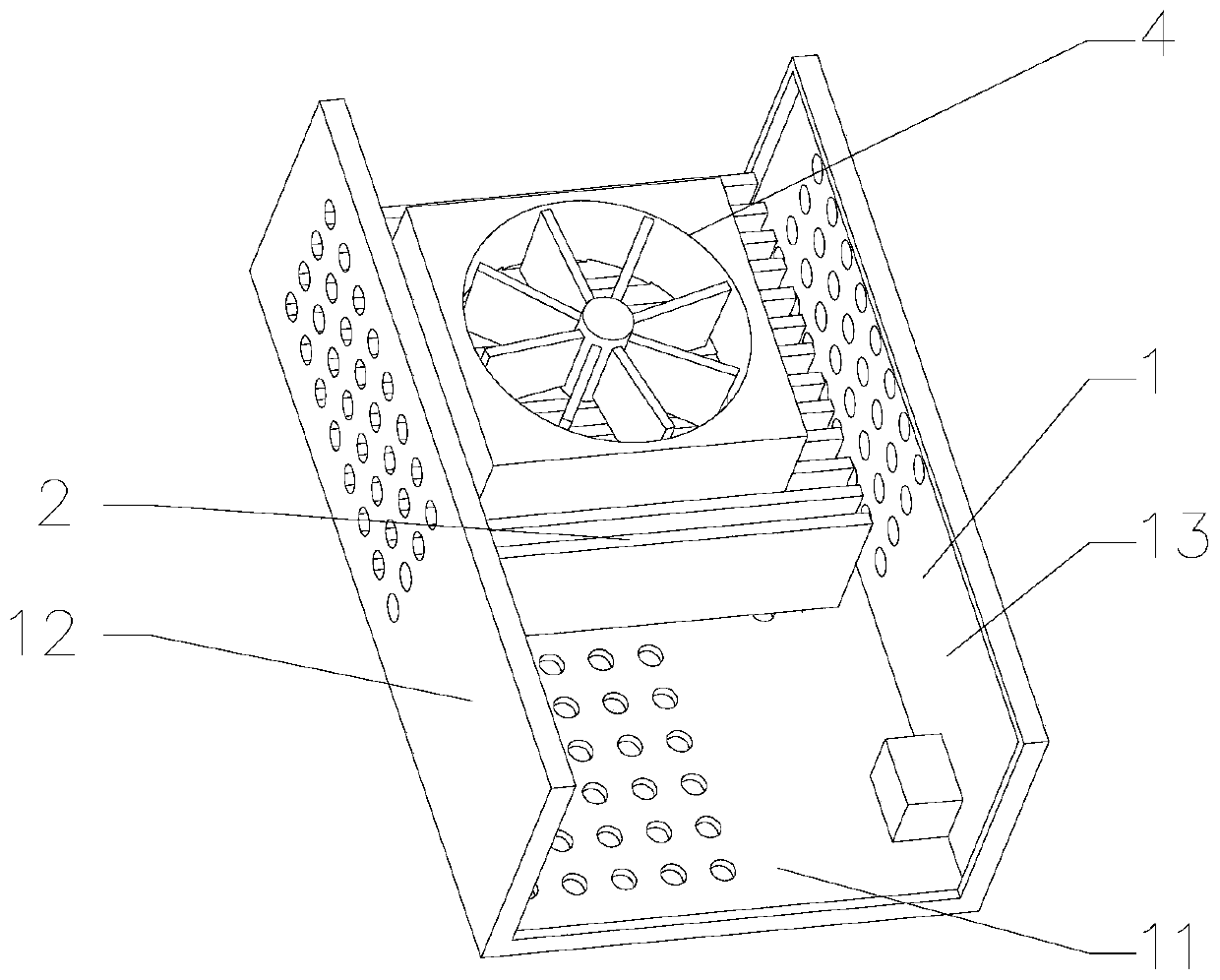

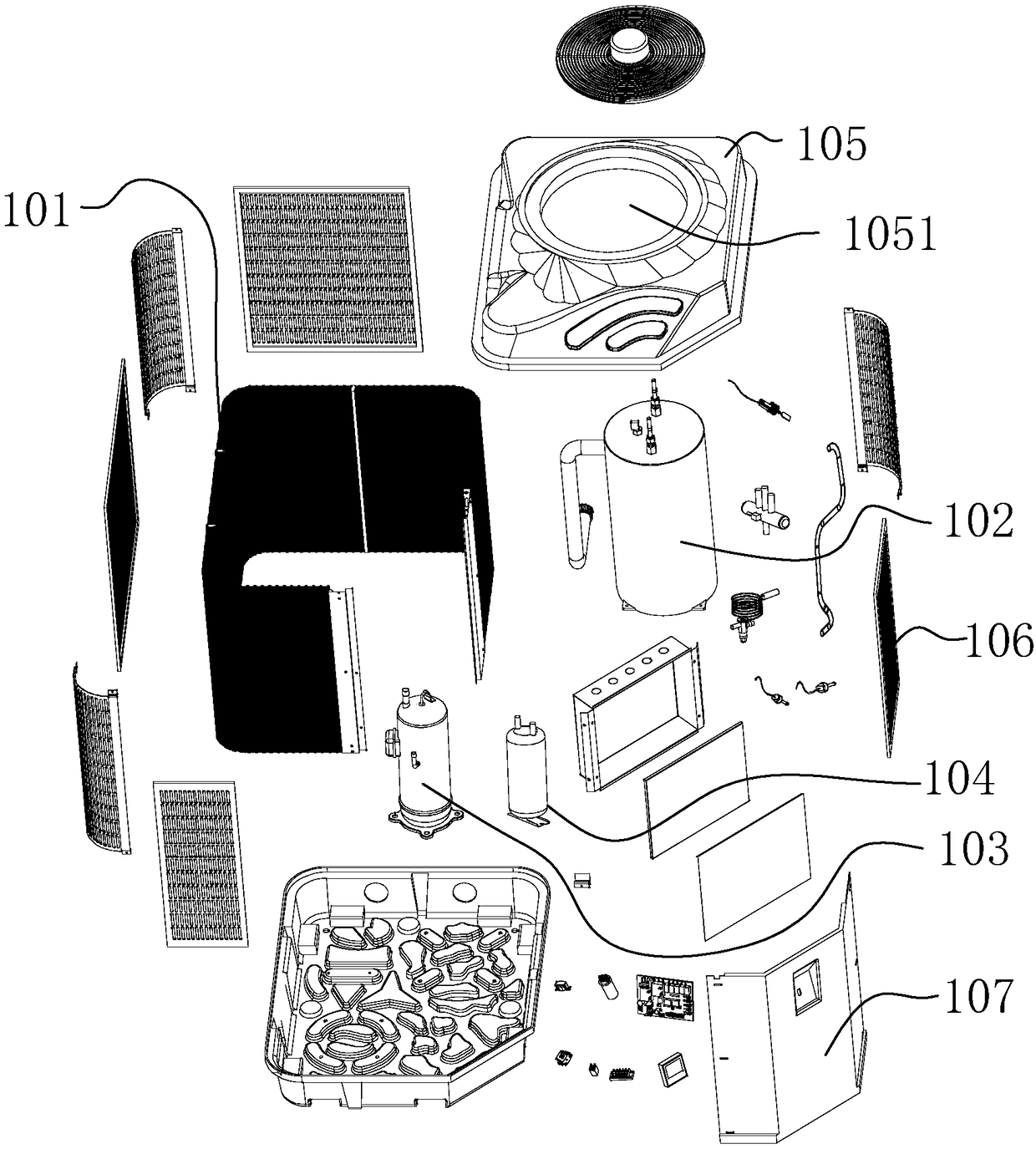

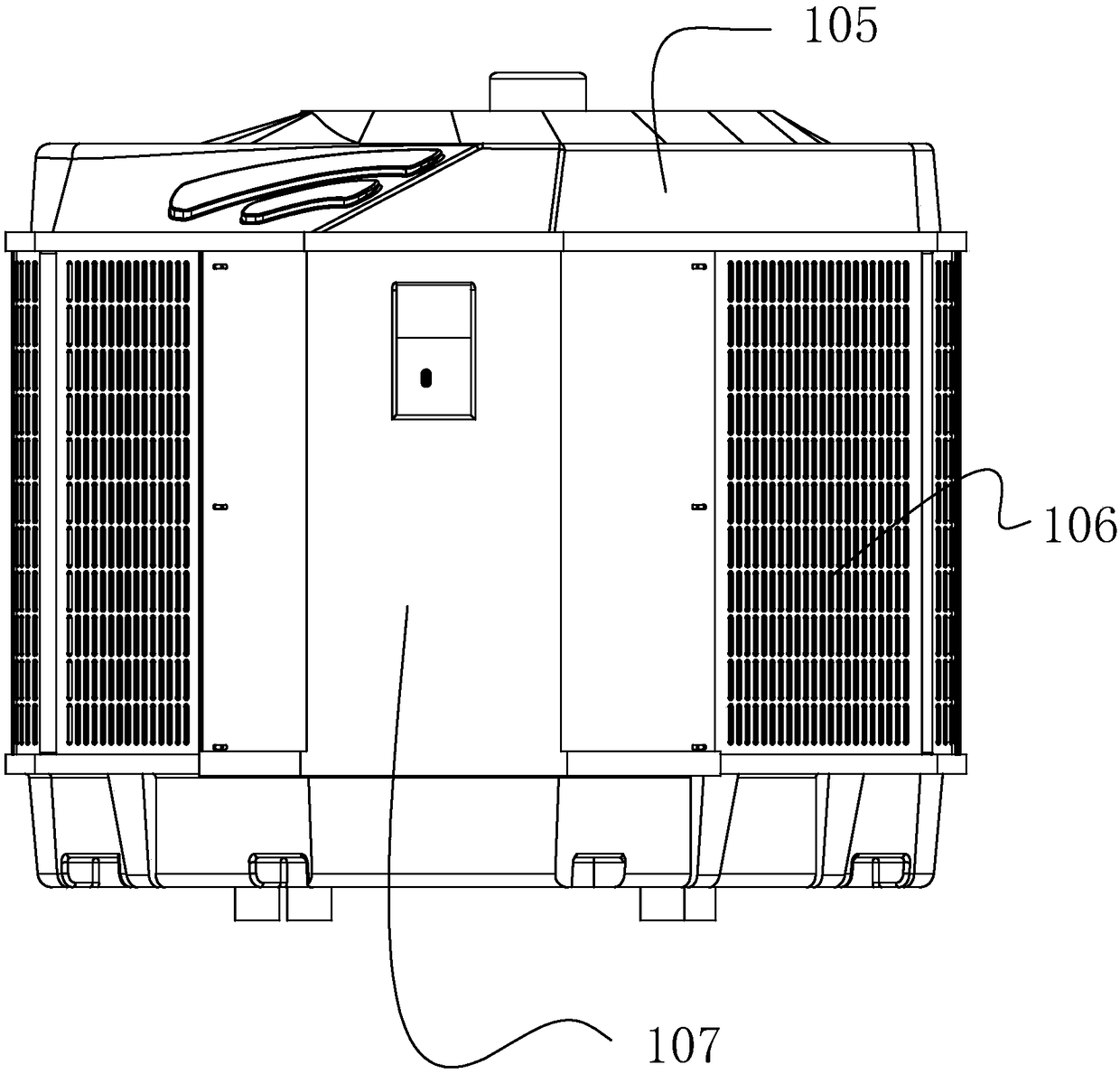

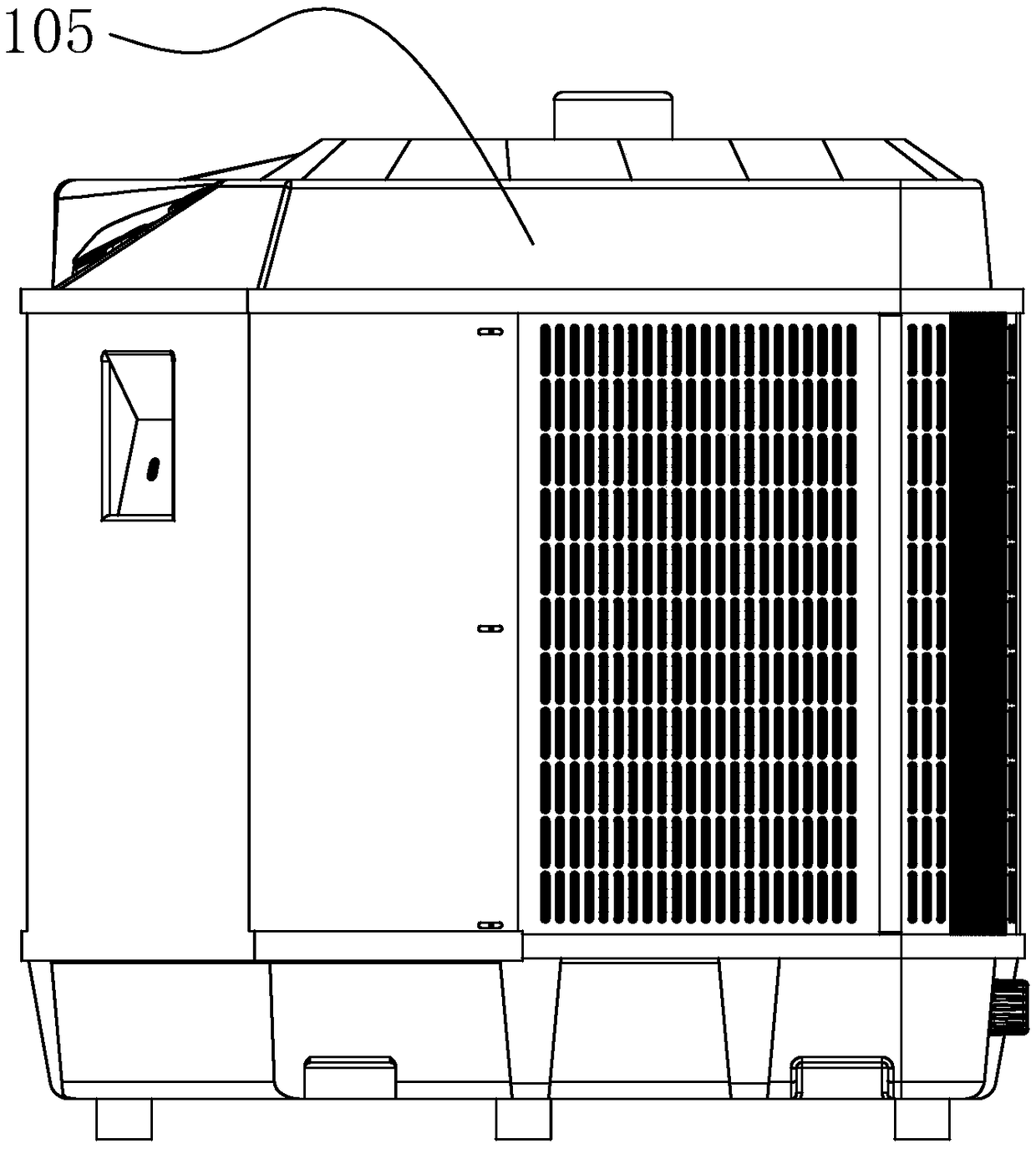

Outdoor machine for air conditioner

InactiveCN1987265AMaximize heat exchange efficiencyLighting and heating apparatusAir conditioning systemsEngineeringMicro heat exchanger

An outdoor set of air conditioner has an outdoor heat exchanger consisting of a tubular heat exchanger and a plate-shaped heat exchanger and with a hexagonal opening opposite to fan, and water draining bottom tray for collecting and draining the condensed water.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

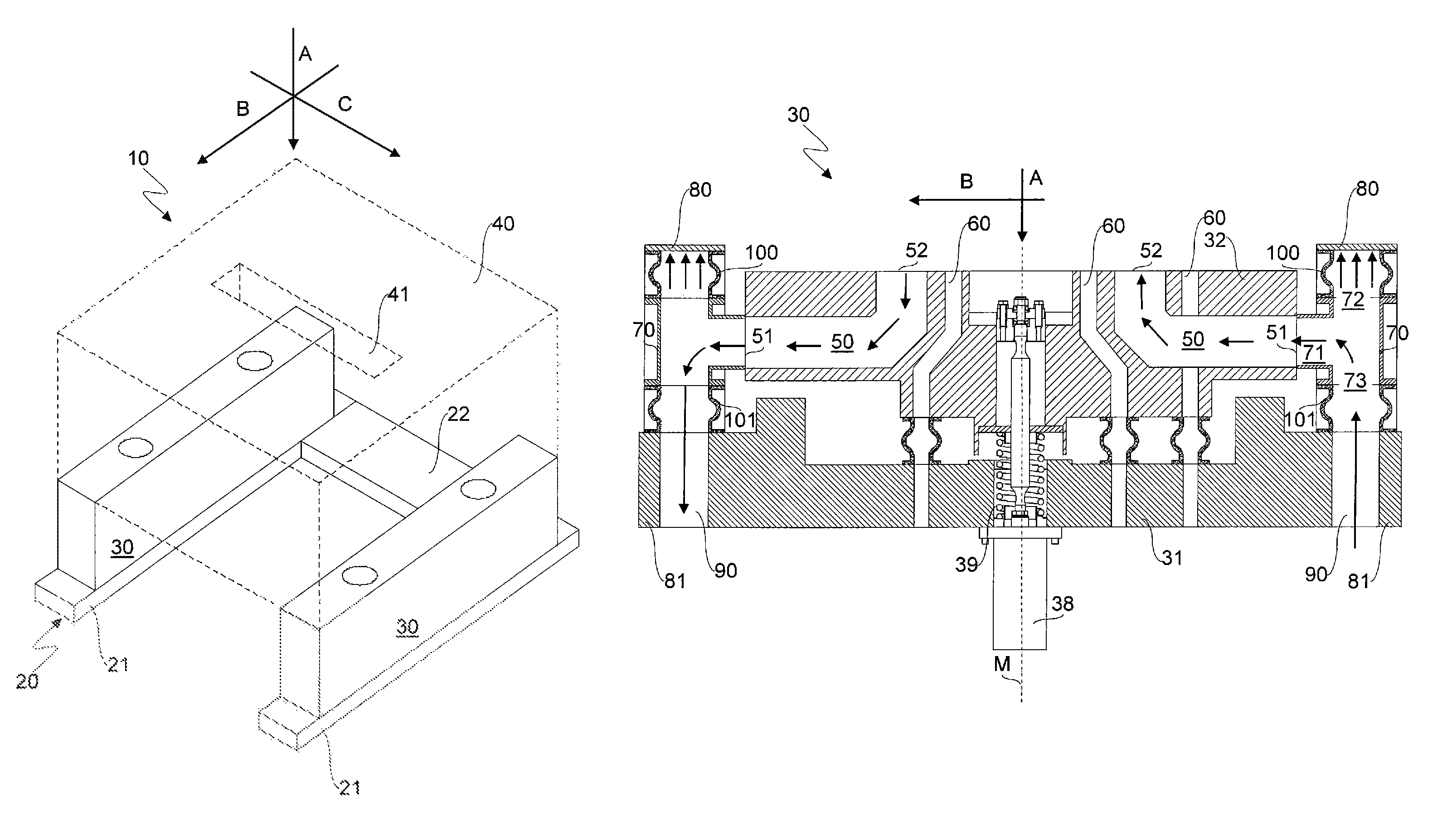

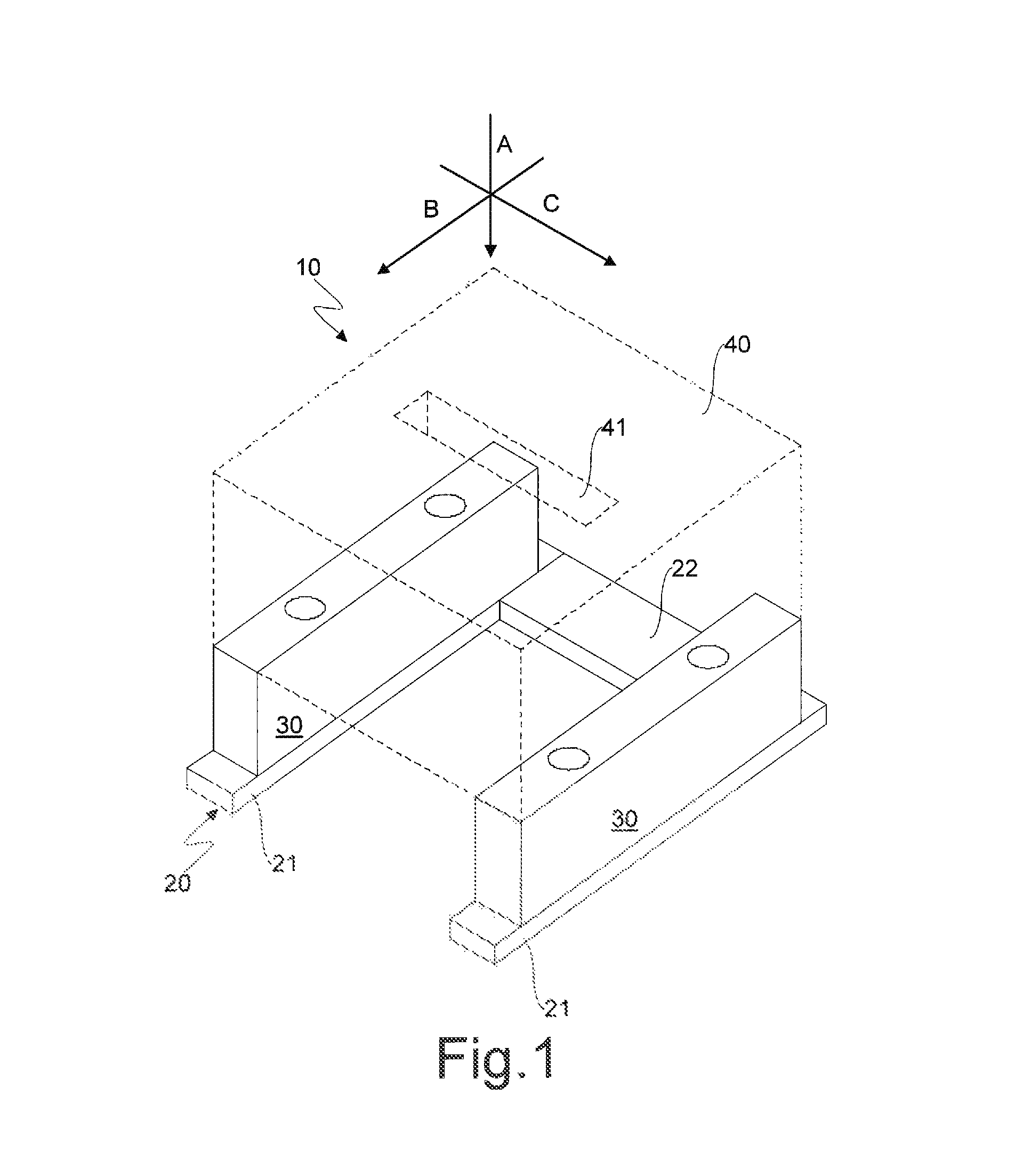

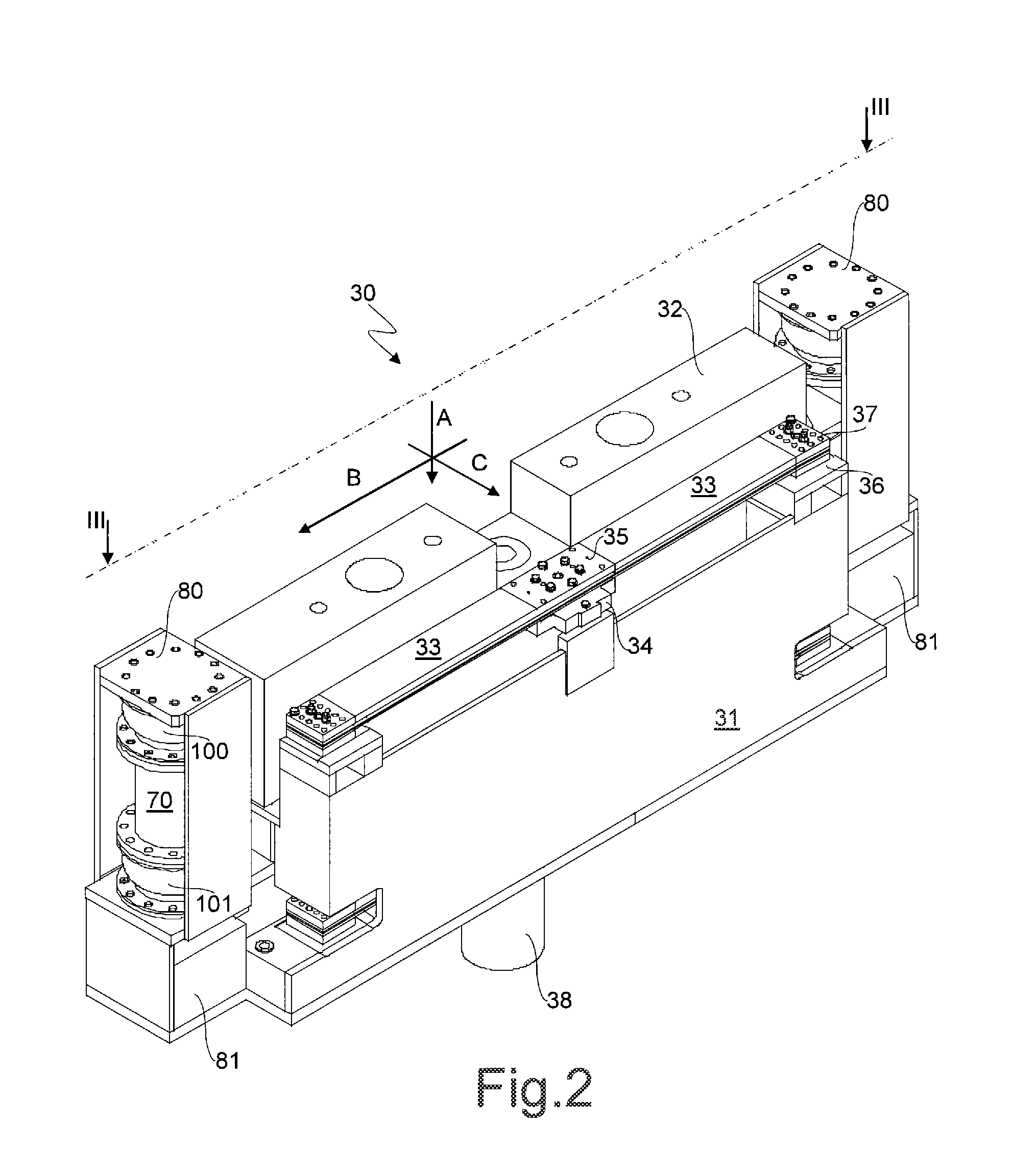

Device for supporting and oscillating continuous casting moulds in continuous casting plants

ActiveUS9186721B2Minimizes pressure fluctuationMaximize heat exchange efficiencyCooling fluidServomechanism

A device for supporting and oscillating continuous casting molds in continuous casting plants includes at least one support suitable to support a continuous casting mold, the support including a fixed assembly restrained to a frame of the device and a movable assembly that is slidably restrained to the fixed assembly in a vertical direction and connected to a servomechanism suitable to move it in a reciprocating manner relative to the fixed assembly along the axial direction, the movable assembly including a plurality of channels suitable to allow a flow of a cooling fluid to and from a cooling circuit of the mold, the channels being supplied by supply pipes arranged along the vertical direction. The device further includes at least one connecting pipe suitable to allow to connect a supply pipe, the connecting pipe having a T shape and including a first duct rigidly connected to the movable assembly in a horizontal direction, as well as a second and a third duct extending from the first duct in opposite ways along the vertical direction, the second and third ducts being respectively connected to first and second end portions of the fixed assembly through further axially deformable ducts and being respectively a blind duct and a flow-through duct suitable to allow the cooling fluid to flow towards the first and the second ducts. The second and third ducts, and preferably also the first duct, of the at least one connecting pipe have the same diameter of the supply pipes.

Owner:ARVEDI STEEL ENG

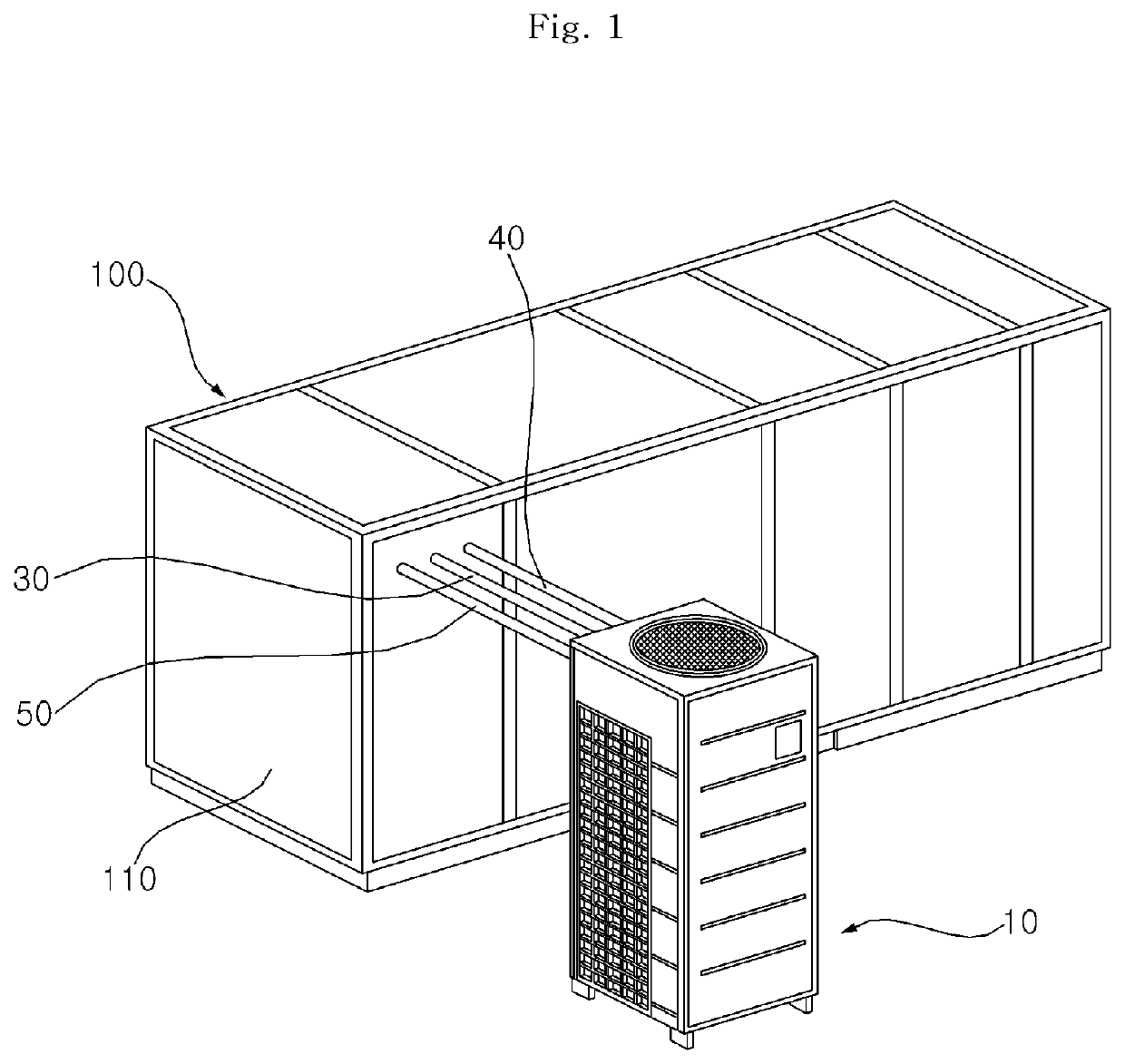

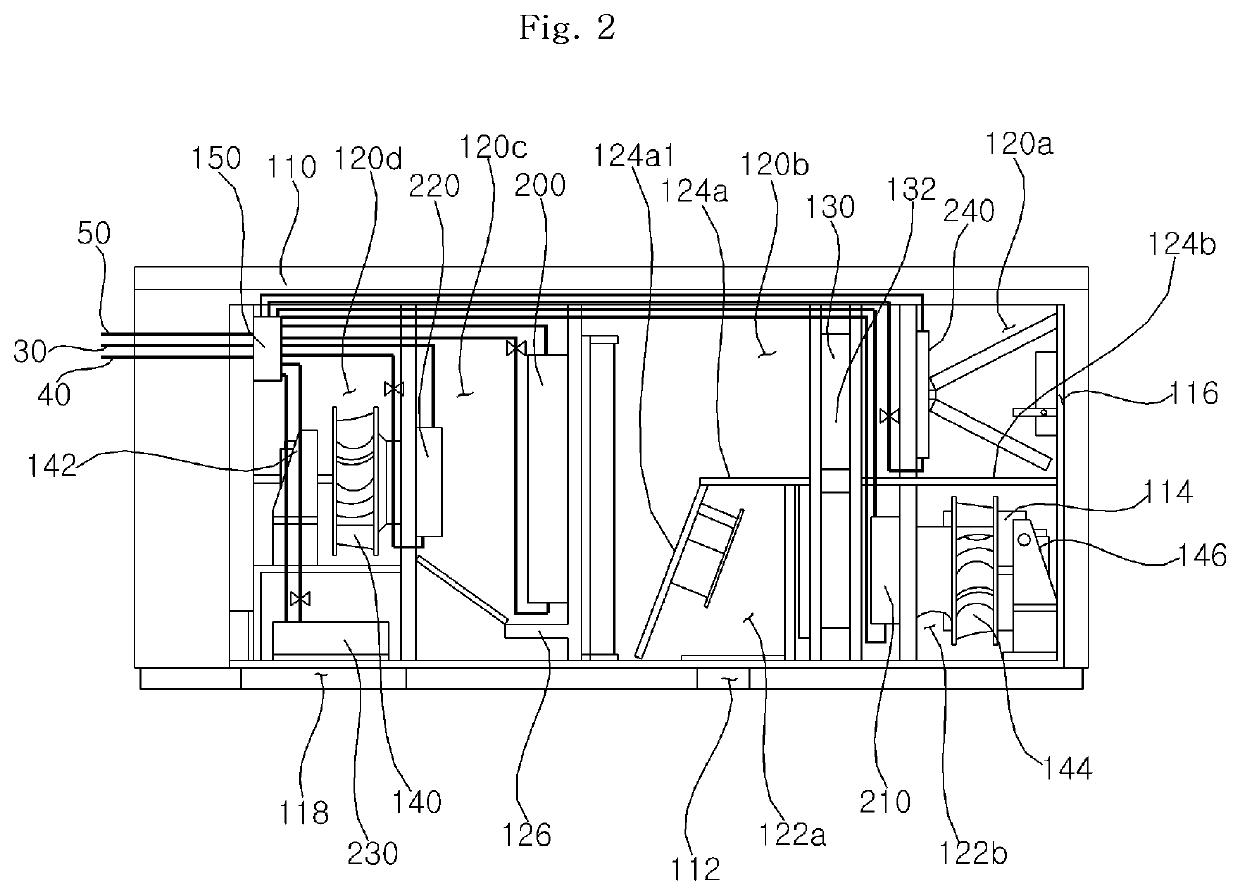

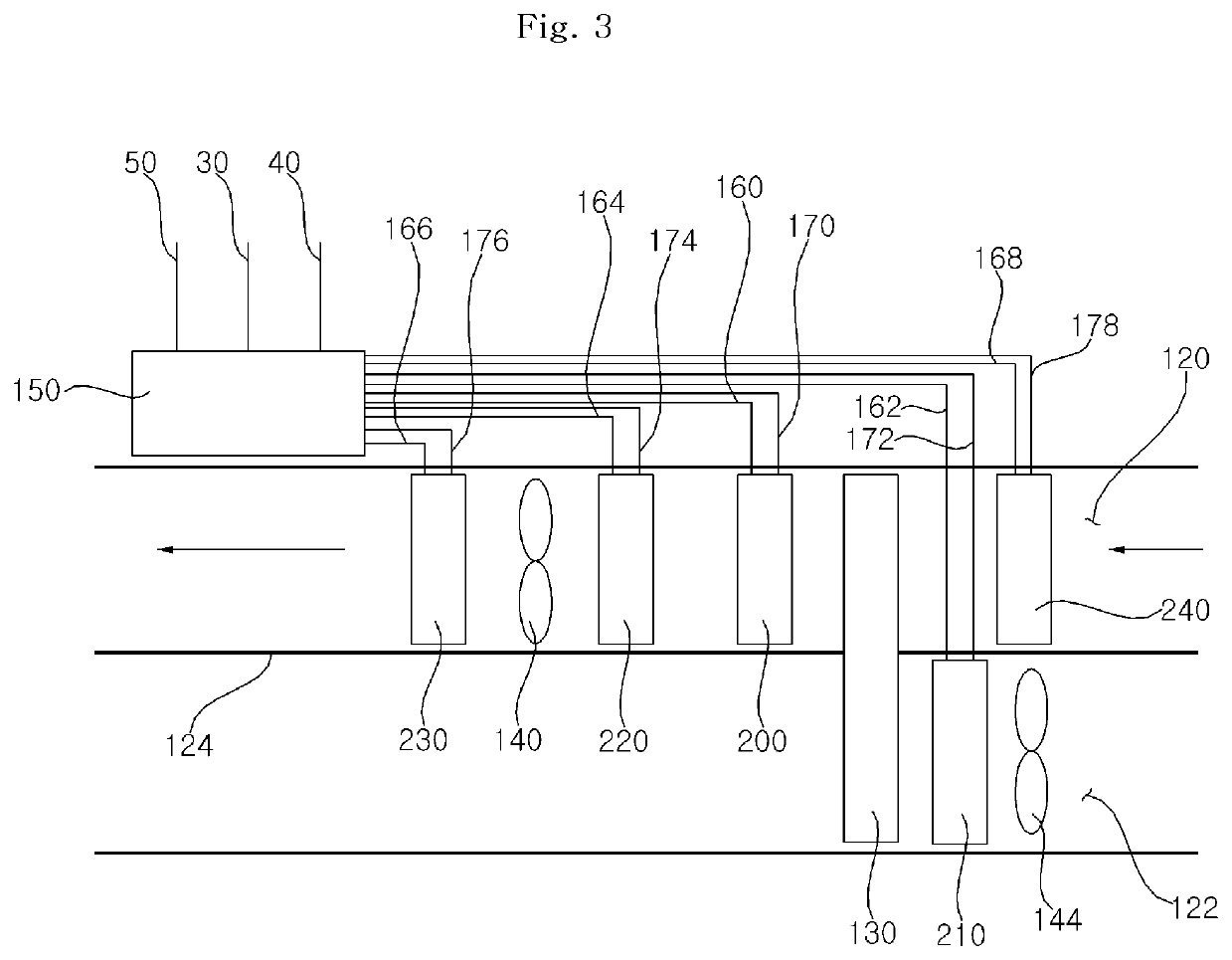

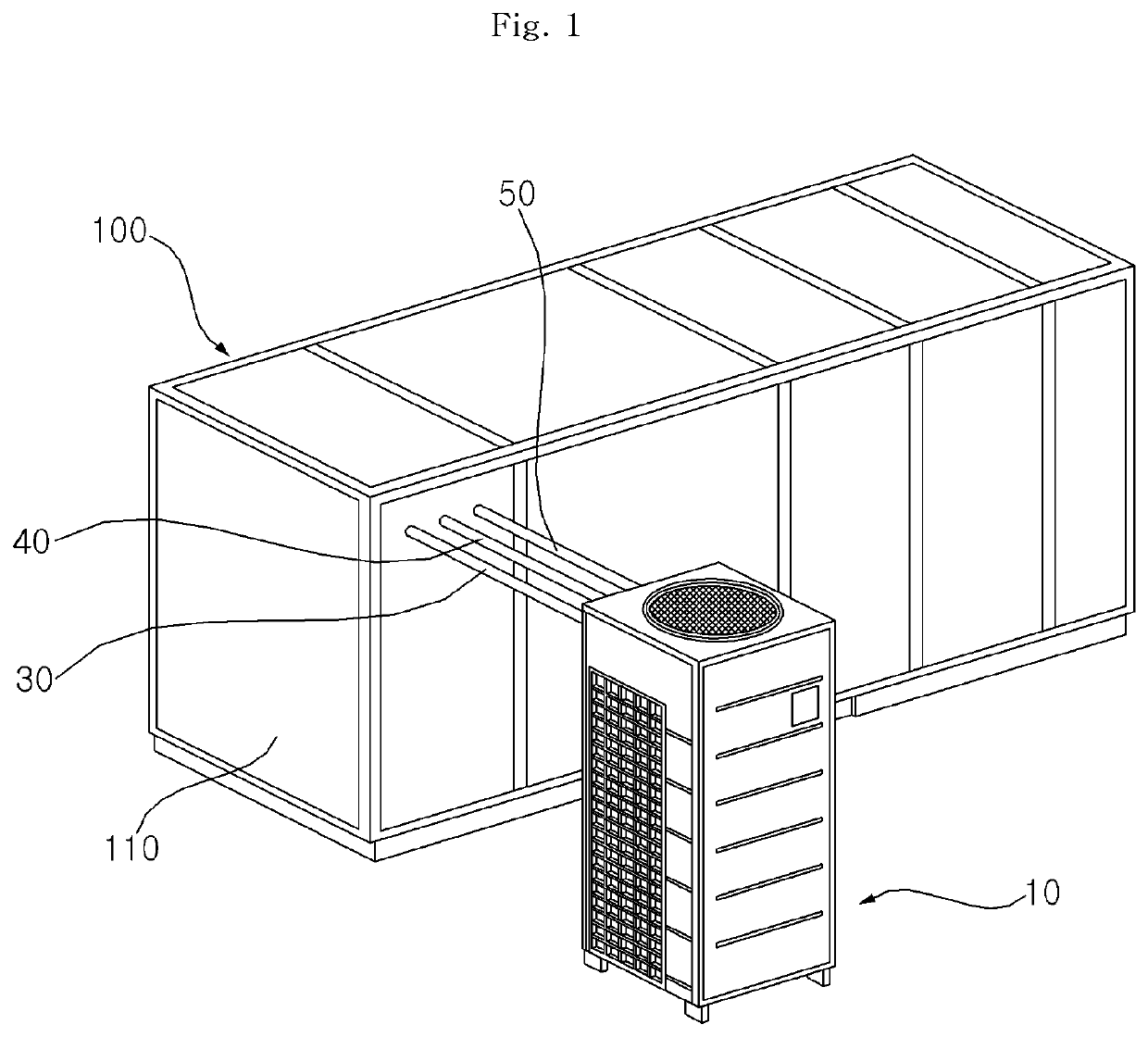

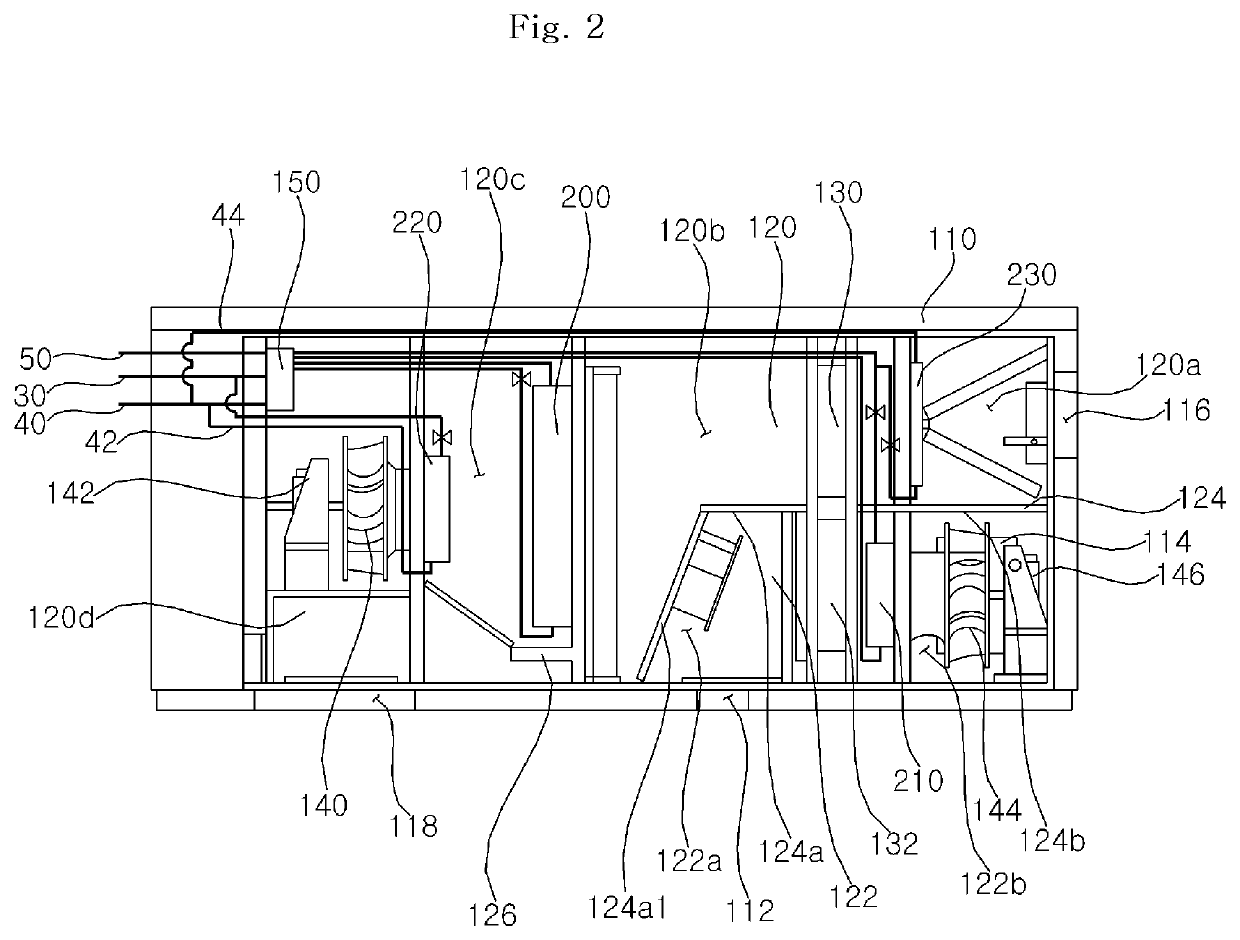

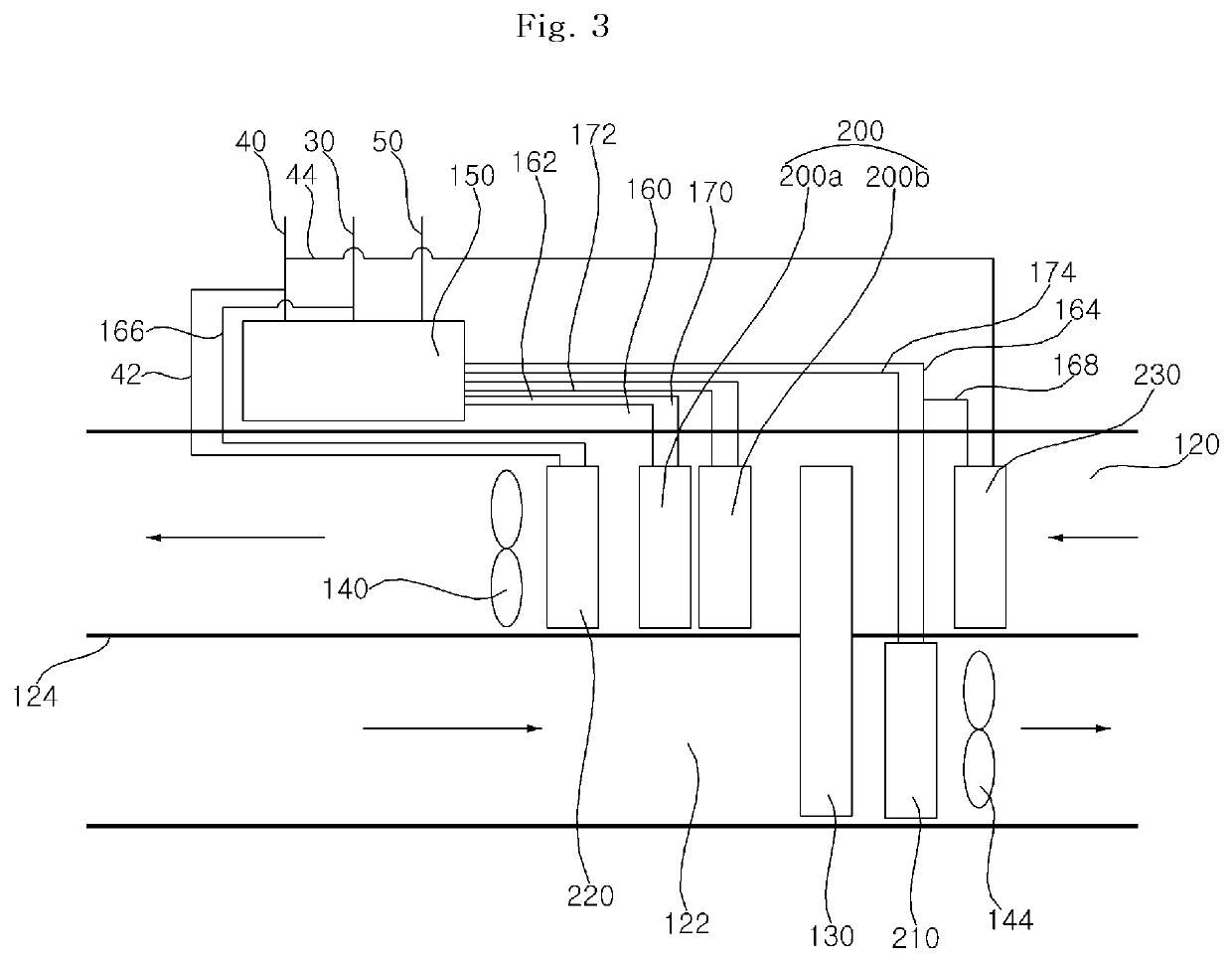

Air conditioner

PendingUS20210239377A1Minimize power consumptionMaximize heat exchange efficiencyEnergy recovery in ventilation and heatingMechanical apparatusRefrigerant distributionEngineering

An air conditioner includes an outdoor unit including a compressor for compressing a refrigerant and an outdoor heat exchanger for exchanging heat between the refrigerant and outside air. A ventilation device is connected to a plurality of refrigerant pipes, and configured to direct outside air into an indoor space, and indoor air to the outside. The ventilation device includes a case, a main heat exchanger, a recovery heat exchanger, and a refrigerant distributor. The refrigerant distributor is configured to direct the refrigerant between the main heat exchanger and the recovery heat exchanger.

Owner:LG ELECTRONICS INC

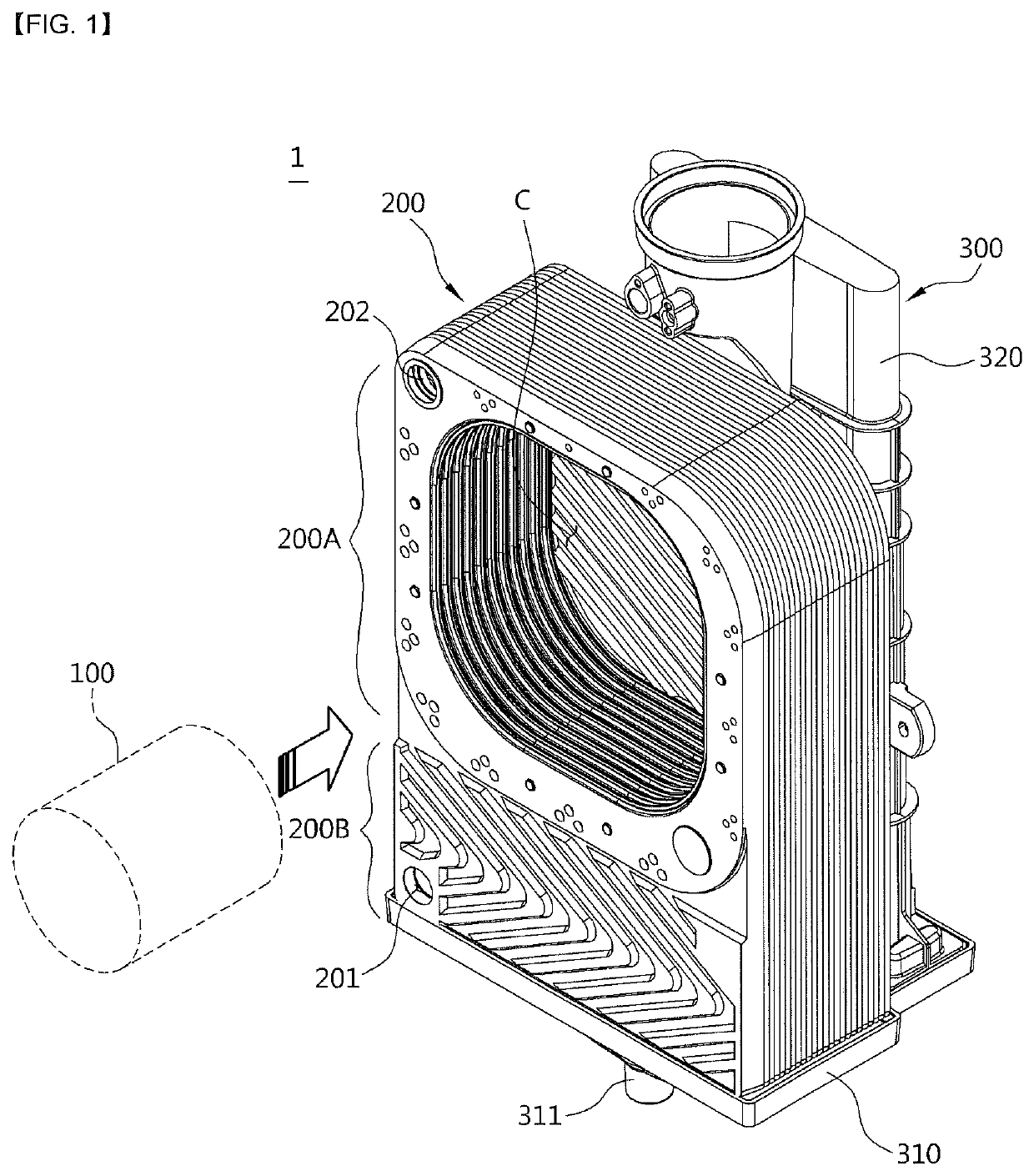

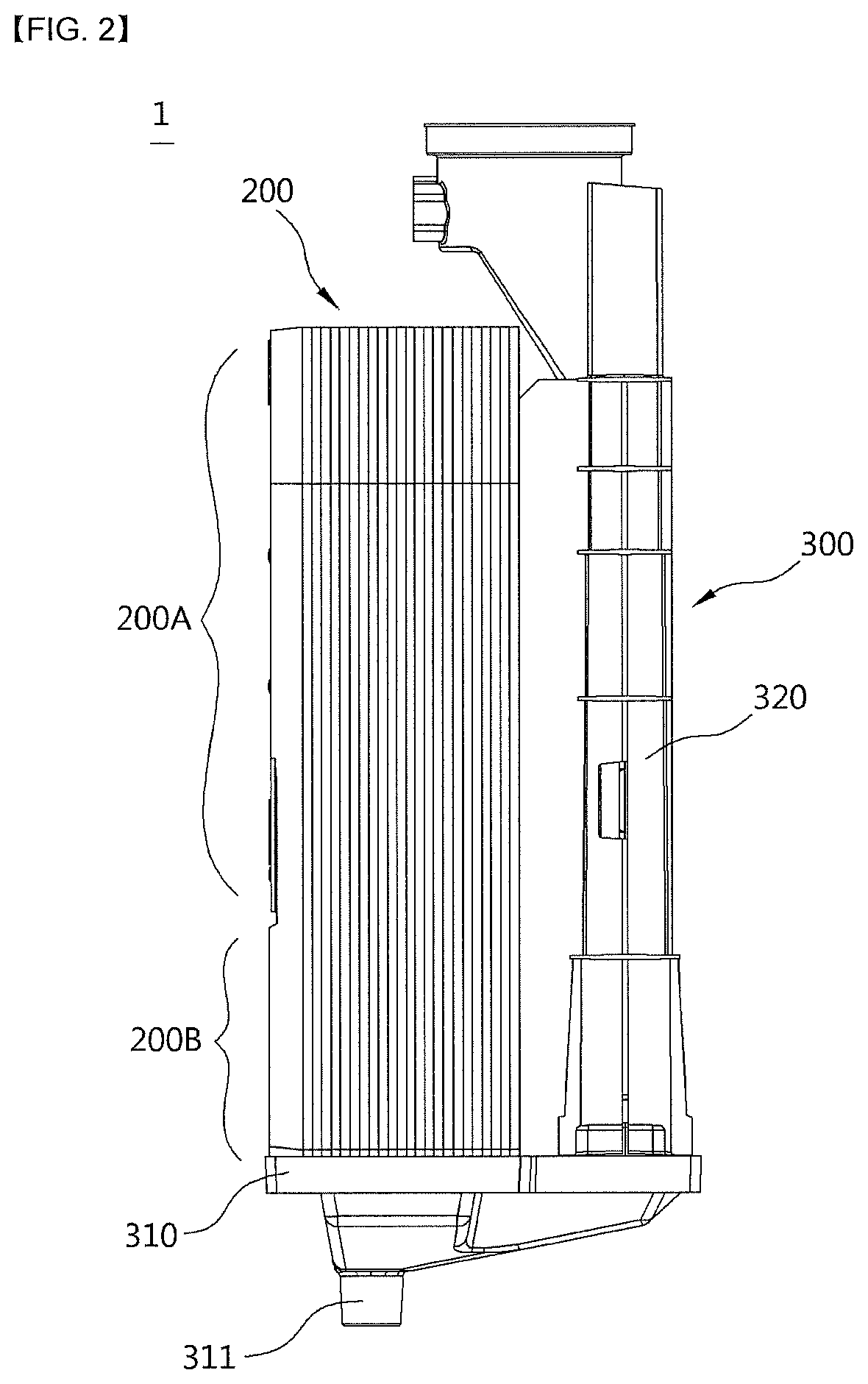

Heat exchanger

ActiveUS10598406B2Improve thermal efficiencyGuaranteed heat exchange effectHeat storage plantsEnergy efficient heating/coolingCombustorCombustion chamber

The present invention relates to a heat exchanger that can enhance thermal efficiency by enabling combustion heat of combustion gas generated by the combustion of a burner to be maximally returned to a heating medium, the heat exchanger being provided with a heat exchange unit having heating medium flow channels through which a heating medium flows and combustion gas flow channels through which combustion gas combusted in the burner flows to be alternately formed and adjacent to each other in spaces between a plurality of plates, wherein the heat exchange unit comprises: a sensible heat unit which surrounds the outer side of a combustion chamber, is formed of one side area of the plates, and heats the heating medium by using sensible heat of combustion gas generated by the combustion of the burner; and a latent heat unit which is formed of the other side area of the plates, and heats the heating medium by using latent heat of water vapor included in combustion gas that has finished undergoing heat exchange in the sensible heat unit, wherein a flow channel cap is coupled to the rear of the sensible heat unit so as to provide a flow channel for combustion gas in order to enable combustion gas that passed through the combustion gas flow channels formed on the upper part of the sensible heat unit to enter into the combustion gas flow channels of the latent heat unit.

Owner:KYUNGDONG NAVIEN

A kind of heat dissipation method for heat dissipation device of communication equipment

ActiveCN107517570BReliable coolingAchieve coolingThermometer detailsTemperature control using digital meansRefrigerationCommunication device

The present invention provides a heat dissipation method for a heat dissipation device of a communication device. The heat dissipation method includes at least the following steps: a preliminary heat dissipation step: the radiator starts to work, the radiator dissipates the heat transferred from the communication device, and the fan starts to work. The fan provides sufficient airflow to the radiator to form air convection around the radiator to speed up the heat dissipation of the radiator; cooling step: the semiconductor cooling sheet works to reduce the temperature near the cooling surface of the semiconductor cooling sheet; condensed water treatment step: the airflow generated by the fan passes through The diversion wind tunnel conducts air convection heat dissipation on the cooling surface of the semiconductor refrigeration sheet to reduce the condensed water generated by the operation of the semiconductor refrigeration sheet and accelerate the evaporation of the condensed water. Through the preliminary heat dissipation steps, cooling steps and condensed water treatment steps, the heat dissipation is improved. The heat dissipation efficiency of the device, and ensure that the communication equipment will not be affected by condensed water.

Owner:STATE GRID ZHEJIANG HANGZHOU YUHANG POWER SUPPLY +2

Air conditioner

PendingUS20210239376A1Minimize power consumptionMaximize heat exchange efficiencyEnergy recovery in ventilation and heatingMechanical apparatusEngineeringHigh pressure

An air conditioner includes an outdoor unit including a compressor for compressing a refrigerant and an outdoor heat exchanger for exchanging heat between the refrigerant and outside air. A ventilation device is connected to the outdoor unit through a liquid refrigerant pipe, a high-pressure refrigerant pipe, and a low-pressure refrigerant pipe. The ventilation device supplies the outside air to an indoor space, and discharges indoor air to the outside. The ventilation device includes a case, a main heat exchanger, a recovery heat exchanger, a refrigerant distributor, and a re-heat heat exchanger. A liquid refrigerant pipe valve is disposed in the liquid refrigerant pipe for controlling an amount of refrigerant.

Owner:LG ELECTRONICS INC

An integrated structural refrigerator

ActiveCN106247472BHigh strengthStable jobMechanical apparatusLighting and heating apparatusVapor–liquid separatorResonance

The invention discloses a refrigerating machine of an integrated structure. The refrigerating machine of the integrated structure comprises a base body which is in a disc shape and is integrally formed. The base body comprises a basin body and a basin bottom. A compressor installation area, a gas-liquid separator installation area and a heat exchanger installation area are arranged on the basin bottom. A plurality of convex reinforcing bags are arranged on the basin bottom. An evaporator installation part is arranged on the basin body. According to the refrigerating machine of the integrated structure, vibration of a compressor can be absorbed to the maximum extent, resonance caused when the compressor operates can also be reduced, and thus it can be guaranteed that the compressor can operate stably, and the service life of the compressor is prolonged; and certain heat exchangers can also vibrate in the same way, the strength of the basin bottom can be integrally improved through the reinforcing bags, and thus the overall rigidity of the refrigerating machine of the integrated structure is improved. Through a frame-shaped evaporator, the heat exchange efficiency can also be improved to the maximum extent, and the size of the refrigerating machine can be reduced to the maximum extent. The refrigerating machine of the integrated structure is applied to the field of heat exchangers and refrigerating machines.

Owner:FOSHAN ALTO REFRIGERATION MFG

Heat exchanger

ActiveUS20180209690A1Simple structureSimple installation structureRecuperative heat exchangersHeat storage plantsCombustion chamberCombustor

The present invention relates to a heat exchanger enabling the reduction of the number of components constituting the heat exchanger, the simplification of the coupling structure thereof, and also, the decrease of combustion gas flow resistance and the minimization of noise and vibration generation, the heat exchanger being provided with a heat exchange unit having heating medium flow channels through which a heating medium flows and combustion gas flow channels through which combustion gas combusted in the burner flows to be alternately formed and adjacent to each other in spaces between a plurality of plates, wherein the heat exchange unit comprises: a sensible heat unit which surrounds the outer side of a combustion chamber, is formed of one side area of the plates, and heats the heating medium by using sensible heat of combustion gas generated by the combustion of the burner; and a latent heat unit which is formed of the other side area of the plates, and heats the heating medium by using latent heat of water vapor included in combustion gas that has finished undergoing heat exchange in the sensible heat unit, wherein bent flange units are formed on the edges of the plurality of plates, and in a state where the flange units of neighboring plates overlap, certain areas among the edges of the plurality of plates have formed thereon combustion gas pass-through units having combustion gas flowing through the combustion gas flow channels pass therethrough.

Owner:KYUNGDONG NAVIEN

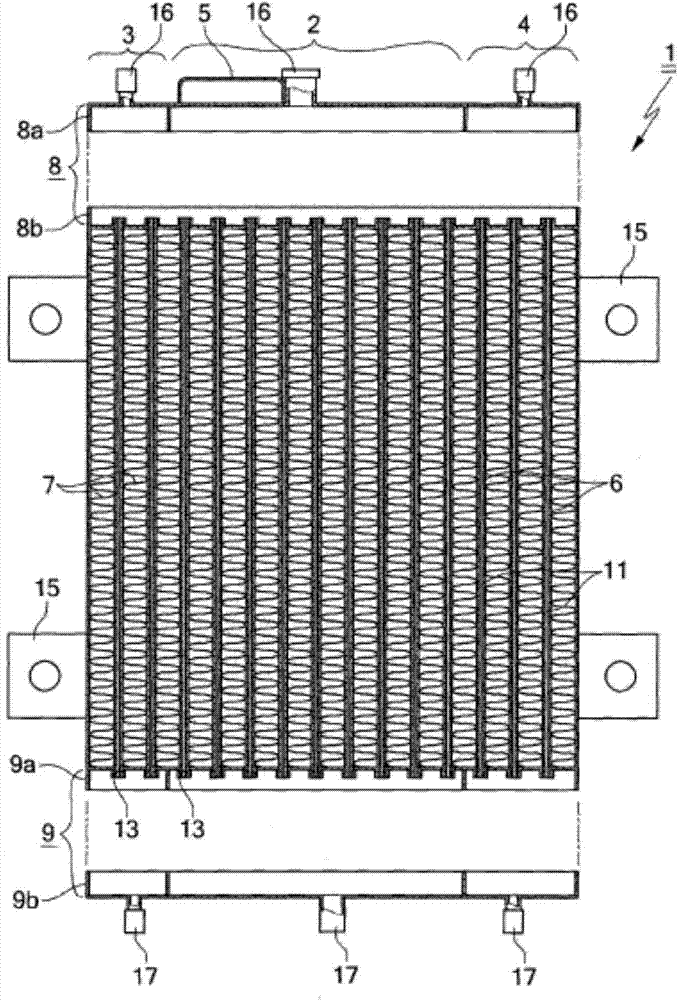

Heat exchanger

InactiveCN103597310AMaximized heat transfer surface areaMaximize heat exchange efficiencyHeat exchanger casingsCoatingsPlate heat exchangerEngineering

PURPOSE: A heat exchanger is provided to minimize an error rate by securely assembling radiation fins to radiation pin joints of a main body and to reduce water contamination because lead is not required. CONSTITUTION: A heat exchanger comprises a main body. The main body is vertically divided into upper and lower bodies(8,9) and is horizontally divided into a radiator(2), an oil cooler(3), and a condenser(4). Heat exchanger pipes(6) are assembled to coupling holes formed on the upper and lower bodies. Radiation fins(7) are assembled between the heat exchange pipes. The radiator, the oil cooler, and the condenser have upper inlets(16) connected to fluid paths(11) of the heat exchange pipes and lower outlets(17).

Owner:YOO HAN

Heat exchanger

ActiveUS10641522B2Improve the heating effectLow flow resistanceEnergy efficient heating/coolingAir heatersCombustion chamberCombustor

The present invention relates to a heat exchanger having a simplified assembly structure as well as a simplified structure for heat-insulating a combustion chamber, the heat exchanger being provided with a heat exchange unit having heating medium flow channels through which a heating medium flows and combustion gas flow channels through which combustion gas combusted in the burner flows to be alternately formed and adjacent to each other in spaces between a plurality of plates, wherein the heat exchange unit comprises: a sensible heat unit which surrounds the outer side of a combustion chamber, is formed of one side area of the plates, and heats the heating medium by using sensible heat of combustion gas generated by the combustion of the burner; and a latent heat unit which is formed of the other side area of the plates, and heats the heating medium by using latent heat of water vapor included in combustion gas that has finished undergoing heat exchange in the sensible heat unit, wherein the rear of the sensible heat unit has provided thereon connection flow channels of the heating medium so that the heating medium that passed through the heating medium flow channels of the latent heat unit can flow to the heating medium flow channels of the sensible heat unit, and the rear of the sensible heat unit also has a water housing cooling unit formed thereon for heat-insulating the combustion chamber.

Owner:KYUNGDONG NAVIEN

Heat exchanger

ActiveUS10690379B2Easy to disassembleSolve the narrow working spaceHeat storage plantsEnergy efficient heating/coolingCombustorCombustion chamber

A heat exchanger according to the present invention comprises a heat exchange portion in which heating medium flow paths, where a heating medium flows through a space between a plurality of plates, and combustion gas flow paths through which a combustion gas combusted in a burner flows are adjacently and alternatingly formed, wherein the heat exchange portion comprises a sensible heat portion, which surrounds the outside of a combustion chamber and comprises an area on one side of the plates, for heating the heating medium using the sensible heat of the combustion gas generated by combustion of the burner, and a latent heat portion, which comprises an area on the other side of the plates, for heating the heating medium using the latent heat of water vapors in the combustion gas which has completed heat exchanging in the sensible heat portion, wherein a connection passage for the heating medium is formed between the sensible heat portion and the latent heat portion, the plates are formed in a vertical structure so that the sensible heat portion is positioned on the top part and the latent heat portion is positioned on the bottom part, and wherein the burner has a cylindrical shape and is assembled by being inserted laterally from the front surface of a space in the combustion chamber.

Owner:KYUNGDONG NAVIEN

Heat exchanger

ActiveUS10816239B2Simple structureSimple installation structureRecuperative heat exchangersHeat storage plantsCombustorCombustion chamber

The present invention relates to a heat exchanger enabling the reduction of the number of components constituting the heat exchanger, the simplification of the coupling structure thereof, and also, the decrease of combustion gas flow resistance and the minimization of noise and vibration generation, the heat exchanger being provided with a heat exchange unit having heating medium flow channels through which a heating medium flows and combustion gas flow channels through which combustion gas combusted in the burner flows to be alternately formed and adjacent to each other in spaces between a plurality of plates, wherein the heat exchange unit comprises: a sensible heat unit which surrounds the outer side of a combustion chamber, is formed of one side area of the plates, and heats the heating medium by using sensible heat of combustion gas generated by the combustion of the burner; and a latent heat unit which is formed of the other side area of the plates, and heats the heating medium by using latent heat of water vapor included in combustion gas that has finished undergoing heat exchange in the sensible heat unit, wherein bent flange units are formed on the edges of the plurality of plates, and in a state where the flange units of neighboring plates overlap, certain areas among the edges of the plurality of plates have formed thereon combustion gas pass-through units having combustion gas flowing through the combustion gas flow channels pass therethrough.

Owner:KYUNGDONG NAVIEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com