Nitride phosphor/glass composite light conversion component for laser lighting and its preparation

A nitride phosphor, laser lighting technology, used in lighting and heating equipment, lighting devices, semiconductor devices of light-emitting elements, etc. problem, to achieve the effect of excellent luminescence performance, maintaining luminescence performance, and excellent thermal quenching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 0.5g La 3 Si 6 N 11 : Ce phosphor and 0.5g low melting point glass powder with a glass transition temperature of 620°C (D 90 = 10 μm) in a mortar and mix evenly, then add 1mL of organic binder, mix evenly to obtain phosphor slurry, and then apply it evenly on the transparent sapphire substrate with photonic crystal film on the surface by doctor blade method, the thickness is controlled to be 50 μm. After the phosphor slurry is leveled, place it on a hot table at 120°C for 10 minutes to solidify, then transfer it to a muffle furnace, raise the temperature to 650°C at 10°C / min and keep it warm for 10 minutes, then cool down with the furnace to obtain a laser lighting product. Nitride phosphor / glass composite light conversion components, such as Figure 4 shown. The thermal conductivity is 20W / (m·K), much higher than ordinary fluorescent glass ( Figure 5 for la 3 Si 6 N 11 : The XRD pattern of the Ce phosphor powder / glass composite coating is the physical superposi...

Embodiment 2

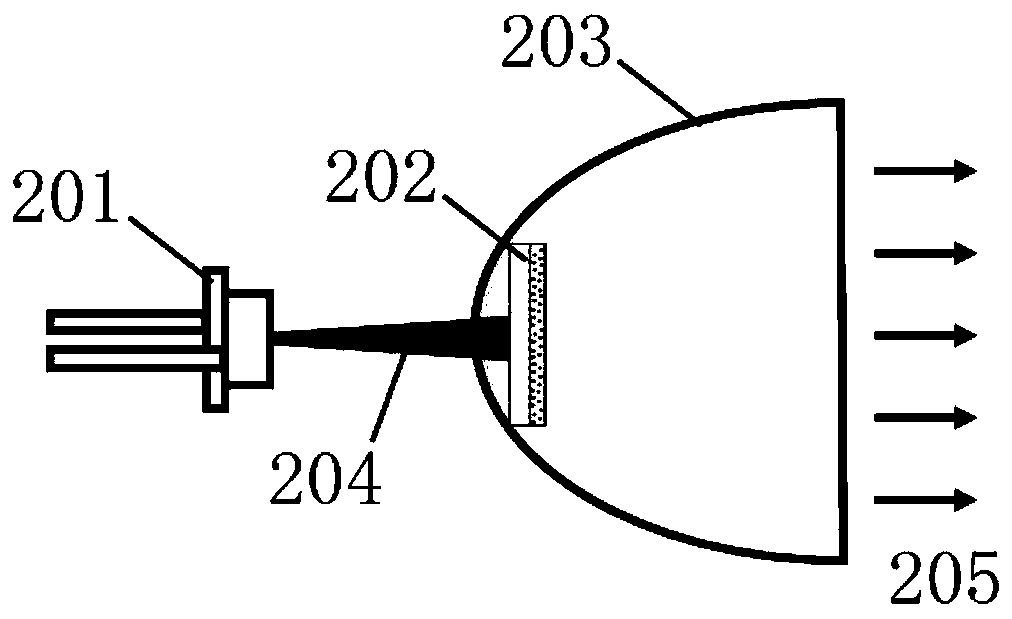

[0070] 0.7g La 3 Si 6 N 11 : Ce phosphor and 0.3g low melting point glass powder with a glass transition temperature of 550°C (D 90 = 20 μm) in a mortar and mix evenly, then add 1.5mL of organic binder, mix evenly to obtain phosphor powder slurry, and then apply it evenly on the white Al 2 o 3 On the ceramic substrate, the control thickness is 30 μm. After the phosphor slurry is leveled, place it on a hot table at 120°C for 10 minutes to solidify, then transfer it to a muffle furnace, raise the temperature to 570°C at 10°C / min and keep it warm for 10 minutes, then cool down with the furnace to obtain a laser lighting product. Nitride phosphor / glass composite light conversion component with a thermal conductivity of 13W / (m·K). The nitride phosphor / glass composite light conversion component for laser illumination and the blue laser diode with a wavelength of about 450nm (input current 0.5A) are pressed image 3 Coupled, a reflective laser lighting white light source can be...

Embodiment 3

[0072] 0.6g La 3 Si 6 N 11 : Ce phosphor and 0.4g low melting point glass powder with a glass transition temperature of 620°C (D 90 = 10 μm) in a mortar and mix evenly, then add 1mL of organic binder, mix evenly to obtain a phosphor slurry, and then apply it evenly on the gray AlN ceramic substrate with a doctor blade method, and control the thickness to 50 μm. After the phosphor slurry is leveled, place it on a hot table at 120°C for 10 minutes to solidify, then transfer it to a muffle furnace, raise the temperature to 650°C at 10°C / min and keep it warm for 10 minutes, then cool down with the furnace to obtain a laser lighting product. Nitride phosphor / glass composite light conversion component with a thermal conductivity of 70W / (m·K). The nitride phosphor / glass composite light conversion component for laser illumination and the blue laser diode with a wavelength of about 450nm (input current 0.5A) are pressed image 3 Coupled, a reflective laser lighting white light sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com