Efficient-heat-dissipation integrated LED modulator tube structure and production process thereof

A technology of LED lamp tube and production process is applied in the field of integrated LED lamp tube structure with high efficiency and heat dissipation to achieve the effects of improving light output efficiency, improving heat dissipation coefficient and saving reactive power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

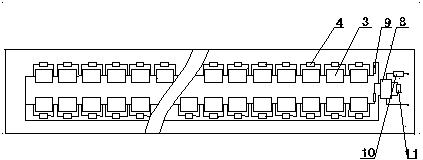

[0035] Such as Figure 1-2 As shown, the integrated LED tube with efficient heat dissipation according to the embodiment of the present invention includes an aluminum shell 1 and a PC cover 2. The PC cover 2 has a semi-circular structure and the horizontal end surface of the PC cover 2 and the aluminum shell 1 The horizontal end faces are fixed and spliced. The aluminum shell 1 is made of metal aluminum with high thermal conductivity (120~200 W / m·K) and has a semicircular cross-section, which is uniformly opened on the outer arc wall of the aluminum shell 1 Several grooves play the role of heat dissipation. The horizontal wall surface of the aluminum shell 1 is the packaging plane. Before packaging, the packaging plane of the aluminum tube is coated with an insulating layer composed of epoxy resin, oxide, and polymer materials. After baking and hardening, the circuit layer is printed with micro-wiring technology on the insulating layer, and then a white UV curing solder mask (S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com