LED light source module with highlight power density

A technology of LED light source and power density, which is applied in the field of LED lighting, can solve problems such as being easily restricted, limited output light power, and large area of light-emitting panels, and achieves the goals of improving heat dissipation, reducing light absorption rate, and increasing light reflectance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

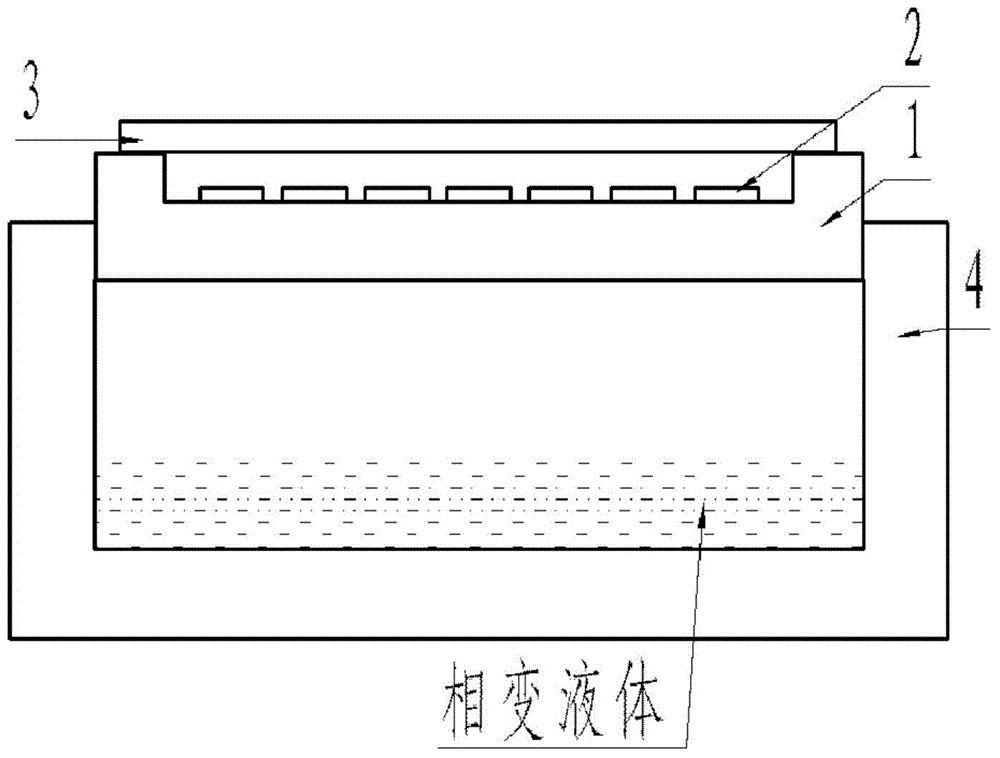

[0013] see figure 1 As shown, the present invention provides a high optical power density LED light source module, comprising:

[0014] A substrate 1, the substrate 1 is made of copper, aluminum or aluminum nitride ceramics. These materials are high thermal conductivity materials that are easy to realize circuit processing. There is a groove in the middle of the substrate 1; the depth of the groove is 2-5mm, which is lower than the thickness of the substrate, and a circuit layer is formed on the surface of the groove for circuit connection of chips.

[0015] A plurality of LED light-emitting chips 2, the plurality of LED light-emitting chips 2 are fabricated in grooves on the substrate 1 to form an array of LED light-emitting chips; the plurality of LED light-emitting chips 2 are composed of a plurality of large-size and high-power LED chips , parallel or series-parallel combination, the size of a single large-size high-power LED light-emitting chip 2 is greater than 2mm*2mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com